Fretting wear behaviour of machined layer of nickel-based superalloy produced by creep-feed profile grinding

Weijie KUANG, Qing MIAO, Wenfeng DING,*, Ynjun ZHAO,Bio ZHAO, Xueing WEN, Shopeng LI

a National Key Laboratory of Science and Technology on Helicopter Transmission, Nanjing University of Aeronautics and Astronautics, Nanjing 210016, China

b College of Mechanical Engineering, Suzhou University of Science and Technology, Suzhou 215009, China c State Key Laboratory of Superabrasives,Zhengzhou Research Institute for Abrasive&Grinding Co.Ltd,Zhengzhou 450001,China

d AECC Xi’An Aero-Engine LTD, Xi’an 710021, China

KEYWORDS Creep-feed profile grinding;Fretting wear;Nickel-based superalloy;Tribolayer;Wear debris

Abstract Fretting wear has an adverse impact on the fatigue life of turbine blade roots.The current work is to comparatively investigate the fretting wear behaviour of the nickel-based superalloy surfaces produced by polishing and creep-feed profile grinding,respectively,in terms of surface/subsurface fretting damage,the friction coefficient,wear volume and wear rate.Experimental results show that the granulated tribolayer aggravates the workpiece wear, while the flat compacted tribolayer enhances the wear resistance ability of workpiece,irrespective of whether the workpiece is processed by polishing or grinding.However,the wear behaviors of tribolayers are different.For the polished surface, when the normal load exceeds 100 N, the main defects are crack, rupture, delamination and peeling of workpiece materials;the wear mechanism changes from severe oxidative wear to fatigue wear and abrasive wear when the loads increase from 50 to 180 N.As for the ground surface,the main wear mechanism is abrasive wear.Particularly,the ground surface possesses better wear-resistant ability than the polished surface because the former has the lower values in coefficient friction(0.23),wear volume(0.06×106 μm3)and wear rate(0.25×10-16 Pa-1).Finally,an illustration is given to characterize the evolution of wear debris on such nickel-based superalloy on the ground surface.

1. Introduction

Nickel-based superalloys are widely used in the aviation industry due to the excellent performance, such as high resistance to creep, fatigue and oxidation at elevated temperatures.1-4The nickel-based superalloy blade is the core hotend component of an aeroengine. To connect the blade and disc of an aeroengine, the blade root is usually designed with complex shape and mainly manufactured by creep-feed profile grinding.5-9Normally, in high speed and high load running environment, the fretting wear will inevitably occur between the root and disc joints due to the small oscillatory frictional displacement and the sizeable centrifugal force.10-12Under such conditions, if the fretting wear resistance of blade roots is weak, the performance and the service life will significantly deteriorate. There are two main parts for direct adverse results caused by fretting wear13: ①The cracks will be triggered and further propagated to reduce the blade root fatigue life. ②The clearance between the assembly parts will be enlarged, which leads to the running vibration. It can be stated that fretting wear is one of the main reasons responsible for the failure of such key components.14-18

Therefore, in the past decades, many researchers have studied the nickel-based superalloy about the fretting wear characteristics. For instance, Soria et al.16investigated the impact of cycle numbers on the fretting wear evolution of Inconel 690 alloy at room temperature. Results indicated slight variations in the coefficient of friction (COF) for tests under different cycle numbers (e.g., 1.38 × 106cycles,1.31 × 105cycles and 1.25 × 106cycles respectively). Meanwhile, some investigations focused on the influence of surface modification on fretting wear behaviour of nickel-based superalloy. For example, Lavella and Botto19compared the fretting wear behaviour of CMSX 4 superalloy with and without plasma-sprayed T-800 coating. For coated surface,the COF and tangential contact stiffness were found to have little change with cycle numbers. In other words, the coated surface showed better wear-resistant ability. Amanov14investigated the fretting wear behaviour of Inconel 718 superalloy with and without ultrasonic nanocrystal surface modification(UNSM). Compared with untreated specimen, the COF of the treated specimen was reduced from 0.68 to 0.65 at room temperature, and thus the treated specimens had better wear resistance.

As mentioned above, although some literatures have been published about the effects of cycle number and surface modification on the fretting wear behaviour of nickel-based superalloy,20-24influences of grinding on fretting wear behaviour of nickel-based superalloy are still unclear. Furthermore, as the final process of machining turbine blade roots,creep-feed profile grinding will have significant impacts on the surface integrity, which determines the service performance of blade root.Hence, the primary aim of this study is to investigate the effects of grinding on fretting wear behaviour of DD6 nickelbased superalloy at room temperature. Different aspects,including the wear pattern, COF, wear volume and wear rate of polished and ground surface,are illuminated comparatively,and the evolution of fretting wear behaviour of ground surface is revealed.Finally,an illustration is given to clarify the evolution process of wear debris on the ground surface and analyse the wear-resistant ability of ground surface.

2. Experiments

2.1. Sample preparation

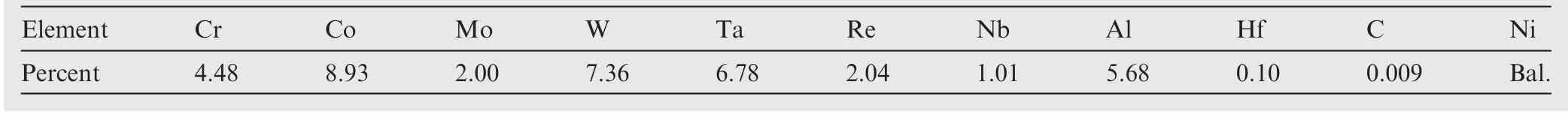

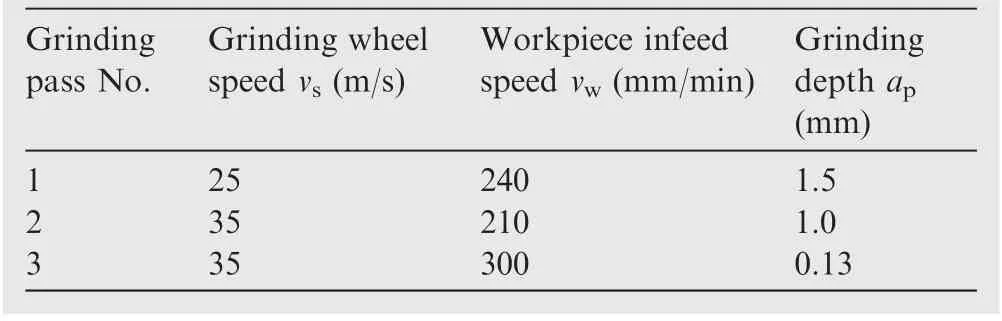

DD6 nickel-based superalloy with the chemical composition shown in Table 1 was chosen as the nether specimen,25and the hard steel YG6 ball (∅10 mm) was the upper specimen.On the one hand, DD6 bars used as the polished specimens would be cut into rectangular workpieces with the dimensions of 4 mm × 6 mm × 12 mm. The surface roughness of the mechanically polished surfaces is Ra 0.04 μm. On the other hand, the DD6 bars used as the ground specimens would be firstly cut into rectangular specimens. Then, the rectangular specimens were machined by creep-feed profile grinding to obtain turbine blade root specimen, and the grinding parameters were listed in Table 2. The total material removal stock was designed as 2.63 mm, which means the final shape of the blade root can be obtained when the grinding pass No. 3 was finished.24To get the flat surface from the blade root, the slender strip sample for fretting tests was extracted by using the diamond wire saw.The creep-feed profile grinding, and the extract of the turbine blade root surface are depicted schematically in Fig. 1 and Fig. 2, respectively. Before tests, all specimens would be ultrasonically cleaned using propyl alcohol for 10 min.

2.2. Fretting tests

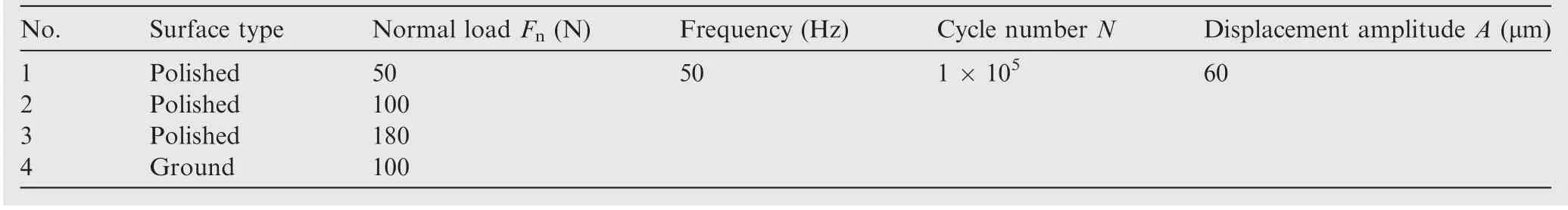

Fig. 3 shows the experimental setup of the fretting wear test.The tests were carried out under an oscillating friction tester(Optimal, SRV-IV, Germany) at room temperature of 20 °C and relative humidity of 50%in air.Hard alloy steel YG6 ball and nickel-based superalloy DD6 rectangular specimens formed a friction pair. The upper sample YG6 ball would reciprocate tangentially under the normal load FN. The fretting wear test parameters are shown in Table 3. A HXS-1000AK hardness tester with a Vickers indenter was used to measure the microhardness in the cross section of samples at a load of 50 g applied for 15 s.On cross sections,the test points are about 15 μm from the surface.26

Table 1 Chemical composition (wt%) of nickel-based superalloy.25

Table 2 Creep-feed profile grinding parameters.

2.3. Characterization

After fretting wear tests, the wear scars and cross section of samples were examined with a Scanning Electron Microscope(SEM) (COXEM, EM-30 PLUS, South Korea). An Energy Dispersive Spectrometer (EDS) attached was used to analyze compositions of tribolayers. The COF could be recorded by tribotester directly.A three-dimensional white-light interfering profilometer(Sensofar S-NEOX)was used to observe the morphology of wear scars,and the wear volume V could be calculated accordingly. Furthermore, to evaluate the fretting wear intensity, the Archard-based coefficient K was calculated27,28:

where S is the total displacement distance of one fretting wear test.

3. Results and discussion

3.1. Fretting damage on surface of polished samples

Fig.4 shows the SEM images of wear scars at the normal load of 50 N.The wear scars are classified into three parts(i.e.,Part I, Part Ⅱand Part III, shown in Fig. 4(b)): Part Ⅰ, the central part,where the tribolayer is full of granulated wear debris with submicron size(Fig.4(c));Part Ⅱ,the annular part,where submicron wear debris are pushed aside from central area and then are compacted on the edge, some peelings and ploughed grooves can also be seen in Fig. 4(d) and 4(e); Part III, the original part, even if this part cannot involve in the friction process directly, the original surface of the material can also generate uniform bugles under the effects of fretting,as shown in Fig.4(f).Furthermore,these bulges locate in different places are parallel to each other, forming a diamond-shaped pattern.These uniform bulges are due to the extrusion of material during fretting.It is worth noting that these bulges are regular and distributed with an angle to the fretting direction.On the same side,this phenomenon indicates that the fretting wear not only influences the contact zone but also the perimeter zone.

Fig. 5 shows the wear scar at the normal load of 100 N.Similarly, this wear scar can also be classified into three parts.In Part Ⅰ, when the detached debris is retained and accumulated in the contact surface to some degree,a compacted layer composed of wear debris can be formed,as shown in Fig.5(b).In Part Ⅱ,due to the increase of the normal load,the material will be compressed to generate many parallel strips with peaks and valleys,as shown in Fig.5(c).The direction of these strips is similar to that of the uniform bulges (Fig. 4(f)). Meanwhile,with the progression of fretting, the cracks between wear scar and bulk material occur (Fig. 5(d)). In Part III, with the increasing load, the parallel strips induce parallel cracks, as shown in Fig. 5(e) and 5(f). Compared with the severe wear behaviour in Fig. 4(a), the wear in Fig. 5(a) is relatively mild since the compacted layer might be beneficial to reduce friction between the workpiece and steel ball.

Fig. 6 shows the wear scar at the normal load of 180 N. It can be seen that the wear debris has a strong tendency to form the compacted tribolayer resulting from plastic deformation of the material, as shown in Fig. 6(a). Similar to the wear scar under 100 N, there are also many ruptures, cracks and strips,as shown in Fig. 6(b) and 6(c). Differently, when the load increases further from 100 to 180 N, the peelings and delamination are generated gradually,as shown in Fig.6(d)and 6(f).Furthermore,the parallel cracks are also observed in Fig.6(e),which might be caused by the compressed material during fretting.Induced by these cracks,some ruptures would be formed,under which the degree of damage on material caused by fretting wear is increased. Compared with cracks, these ruptures will cause the larger gap between material itself.This indicates that the compacted tribolayer can be divided into several fragments if the rupture further propagates in the contact surface.Thus, when the fretting process continues, these fragments could be delaminated and peeled off. The significant peeling and delamination are found in the central area of wear scar,as shown in Fig. 6(f). In general, the increasing normal load induces the formation of compacted tribolayers and substantially leads to cracks,delamination,rupture and peeling.These are the typical patterns of fatigue wear. The appearances of wear scars under loads of 100 and 180 N are similar due to the formation of the compacted tribolayers.

Table 3 Fretting wear tests parameters.

According to Figs.5 and 6,the formation process of bulges is shown in Fig. 7. Under the effect of fretting wear, the original material around the margin of wear scar is indirectly pushed by the hard alloy steel ball(Fig.7(a)).Therefore,some bulges are generated due to the severe deformation of the material. The bulges are uniformly distributed, and the direction is with an angle to the moving direction of hard alloy steel ball. The bulges in the upper and down regions are parallel,forming a diamond shape in the front regions, as shown in Fig. 7(b). In the further fretting process, these bulges will be changed to crack,strip and rupture,Fig.7(c).Such defects will induce and further accelerate the failure of components.

3.2. EDS analysis on polished samples

The EDS analysis was performed to detect the oxidation behaviour of wear scars,as shown in Fig.8.The scanning paths are marked with the white dotted line, as shown in Fig. 4(a), 5(a)and 6(a). On the wear scar obtained under 50 N, both O and Ni contents surge and plunge from the original surface to the wear scar. In other words, the whole wear scar is oxidized under such conditions, which agrees with the topographical feature of the wear scar (Fig. 4(a)). Moreover, the central detached debris is granulated and oxidized during the reciprocating friction process, generating many hard particles. However, when the normal loads are increased to 100 and 180 N respectively, the O content nearly just increases in the annular area at the edge.These phenomena are mainly because that the annular area fully contacts with oxygen in the air while the central area is in contact with the hard alloy ball. Consequently, the severe oxidative wear happens in the whole wear scar when fretting under 50 N,while the oxidative wear occurs mainly in the annular area at the edge of wear scars when fretting under 100 or 180 N.

Fig. 9 shows SEM images of the cross-section of the wear scar on the polished surface. As shown in Fig. 9(a), there are many asperities composed of submicron wear debris on the wear scar under 50 N normal load. Due to the shear stress on the contact surface, the fatigue delamination and rupture of the wear scar also exist.29Due to the plastic deformation of materials, the refined grids consisting of γ phases and γ’phases are also generated. This is caused by the shear stress formed from the interlayer slip in the severe fretting wear process. Furthermore, the refined grids might be the sign of the generation of nanocrystals or recrystallization phenomenon.They are dominated by the plastic deformation in subsurface.30,31Unlike the wear scar under the normal load of 50 N,the cross section of the wear scar under the normal load of 180 N is smooth and has no apparent defects.Furthermore,along with the depth from the surface, the wear scar can be classified into three layers (Fig. 9(b)): (1) The first layer is the severe deformation layer. The extensive plastic deformation happens in this layer due to the large normal loads and interactional wear debris between contact surfaces. The rapid deformation of the first layer also indicates that the wear debris has a strong tendency to form compacted tribolayer under such situations. (2) Under the first layer, there exists a mild deformation layer with slight plastic deformation.(3)The third layer is the original grain layer without fretting damage. This unique composite structure is helpful to protect the surface from being further damaged.

3.3. Fretting damage on surface and cross-section of ground samples

Fig. 10 shows SEM images and EDS scanning mapping patterns of wear scars on the profile ground surface under conditions of 100 N normal load, 50 Hz frequency, 60 μm displacement and 1 × 105cycle numbers. The dominant wear mechanism on the ground surface is abrasive wear which can be proved by the plough grooves oriented along the sliding direction, as shown in Fig. 10(a). The area D-2 shows a deep grinding scratch that collects many wear debris.Therefore,the wear debris generated between contact surface during friction process mainly has three types as follows: The first one is free to contact surface and further affect the wear scar;The second one consists of the compacted tribolayer under the influence of the friction;The third one expels from the contact area into the adjacent hollows and valleys.

Comparing the results of Fig. 5 with those in Fig. 10, the wear degree of the ground surface is milder than the polished surface under identical conditions. Comparing with the polished surface, this indicates that the ground surface can enhance fretting wear resistance because it allows to store more wear debris generated during the friction process. A similar conclusion was also reported in Refs.32,33.When the number of wear debris in the fretting wear decreases, the third-body abrasion between the mated surface will also be reduced.34,35Meanwhile, the EDS mapping images of the wear scar are shown in Fig. 10(b). It is found that because the element contents of Ni,Co and O remain unchanged,and the scar shows a shiny appearance (Fig. 10(a)),oxidative wear does not exist in such a situation. The SEM image of the wear scar on the ground surface is shown in Fig. 11. Slight plastic deformation can be observed near the flat surface of the wear scar.Besides,there are no affected features on the worn surface, which shows a mild wear degree.This phenomenon is also coincident with the topographical features of the wear scar on the polished surface, as shown in Fig. 10.

3.4. Friction coefficient, wear volume and wear rate

Variations of friction coefficient with cycle numbers during fretting tests are shown in Fig.12.It can be found that the evolution of friction coefficient in all tests shows a sharp rise at the initial state followed by a steady state. For polished samples,the cycle numbers to reach steady state decrease from 52,000 to 8000 when the normal loads increase from 50 to 180 N. It indicates that the larger normal load is helpful for the friction process to reach the steady state. Besides, the steady friction coefficients are also decreased with the increase of the normal loads. For example, under the normal loads of 50, 100 and 180 N, the steady friction coefficients are 1.00, 0.50 and 0.40,respectively. This phenomenon is coincident with the SEM observations in Figs. 4-6 since the compacted tribolayer is beneficial for wear resistance. Meanwhile, for the ground surface,it can be found that the cycle numbers to reach the steady state is 1800,and the steady friction coefficient is 0.23,both of which are lower than those obtained for polished samples.These results agree with the mildest fretting wear on the ground surface and can be attributed to the rough surface induced by grinding.

To figure out the evolution of friction coefficient, Fig. 13 shows the variation of friction coefficient of the polished surface under 180 N at 15,000 cycle numbers. As seen from Fig. 13, the fretting process can be divided into three stages:Stage I, at the beginning, the friction coefficient surges at about 1500 cycle numbers.In this stage,two matched surfaces begin to contact and interact,and a lot of wear debris are generated. Stage Ⅱ, the plunge occurs, implying that partial wear debris is expelled from the contact area. The remained wear debris reduces the COF because the shear stress between wear debris and contact surfaces is lower than the shear stress of workpiece material.36In these two stages, the coefficient friction increases from 0 to 0.8 and then decreases to 0.3. This can be classified as a running period. Stage III, the curve reaches a moderate increase as the COF increases from 0.3 to 0.4 gradually.The mild increase symbolizes that the friction process reaches the steady stage and the tribolayer is generating.The different forms of tribolayers can account for the difference in COF under steady states. For instance, the tribolayer with many granulated asperities (Fig. 4(a)) has a higher friction coefficient than the one with a flat surface(Fig. 6(a)). This phenomenon was due to that the asperities affected the friction coefficient significantly in contact.37

Figs. 14 and 15 show the wear volume and wear rate,respectively,as a function of the normal loads.They both have a similar tendency, i.e., the wear volume and wear rate decrease when the normal load is increasing. On the polished surface, from 50 to 100 N, the wear volume is reduced by 92% (from 1.12 × 106to 0.08 × 106μm3), and the wear rate is reduced by 96%(from 9.33×106to 0.33×10-16Pa-1)dramatically. The similar tendency is observed, i.e., both of the wear volume and wear rate are decreasing when the normal load is increasing. As explained above, under the normal load of 100 N, the compacted layer can be formed, while it cannot be observed under 50 N. Derived from these experiment results, the friction between two contacts is reduced due to the formation of the compacted layer, which could protect the bulk material from further worn. Thus, the wear volume can be reduced significantly with the increase of normal force(e.g.,from 50 to 100 N).When the normal load increases from 100 to 180 N, the wear volume increases slightly from 0.08×106to 0.13×106μm3,and the wear rate decreases from

0.33 × 106to 0.30 × 10-16Pa-1. It indicates that the wear intensity is decreased even if the wear volume is increased.For the ground surface, the wear volume and the wear rate both show the minimum value compared to the value from other experiments, which are 0.08 × 106μm3and 0.25 × 10-16Pa-1respectively in all tests. When the normal load increases from 50 to 180 N for the polished surface, the dramatic decrease in the volume and rate suggests that the most severe wear happens when the normal load is 50 N.While the ground surface in the fretting wear test with 100 N has the smallest wear intensity.

3.5. Evolution of fretting wear on ground surface

From the above analysis, the ground surface shows the best wear-resistant ability in all fretting tests.If the evolution mechanism of the wear debris on the ground surface during the fretting wear test can be figured out, the better wear resistance ability can be obtained. Therefore, this section gives an illustration to describe the evolution of wear debris. According to Fig.16,the evolution process of wear debris can be divided into three stages:

· Stage Ⅰ,the match surfaces begin to contact,and severe friction occurs. A mass of wear debris is generated during this process, as shown in Fig. 17. Some free wear debris will be expelled out of the wear area without being further affected.

· Stage Ⅱ, some remained wear debris is compressed in the contact area, which causes the plough grooves, as shown in Fig. 16. The other remained wear debris is put into the grinding scratches induced by the abrasive grains during grinding.

· Stage III,because the deep scratches can keep the wear debris away from the fretting process.The wear debris,which is pushed into the deep scratches, accumulates without being further affected during friction. Meanwhile, because the overflowing wear debris is compressed to form the compacted tribolayer, the surface wear resistance can be improved. In addition, the wear debris which moves into the shallow scratches,continues to participate in the fretting process.

On the other hand, experimental results show that the ground surface has the microhardness of about 452 HV0.05,which is 13% higher than that of polished one (about 400 HV0.05).This is due to the fact that the ground layer has more severe plastic deformation than the polished one.38And the plastic deformation usually contributes to improving the material hardness and therefore enhances the wear-resistant ability of ground surface.

4. Conclusions

This work mainly investigates the fretting wear behaviour of nickel-based superalloy DD6 on the polished and ground surfaces. The main conclusions are drawn as follows:

1) For the polished surface, the main wear mechanism is the severe oxidative wear at the load of 50 N due to the formation of granulated tribolayer, while the main wear mechanisms are changed to the fatigue wear and abrasive wear at the loads of both 100 and 180 N due to formation of compacted tribolayer. While for the ground surface, the main wear mechanism is abrasive wear. It is also found that the tribolayer composed of submicron granulated wear debris aggravates the surface wear while it can provide a protection on the surface when compacted to be a flat tribolayer.

2) When the normal loads increase,the friction coefficient,the wear volume and the wear rate decrease in the stable stage for both polished and ground surfaces. Meanwhile,compared to the polished surface,the ground surface possesses the better wear-resistant ability,which has the lower friction coefficient (0.23), wear volume(0.06 × 106μm3) and wear rate (0.25 × 10-16Pa-1).

3) The evolution of wear debris on ground surface during fretting was illustrated and discussed, including three stages mainly:Stage I,wear debris generated due to friction; Stage Ⅱ, the wear debris collected by the scratches produced by grinding; and Stage III, compacted tribolayer formed by the wear debris which is collected by the shallow scratches.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (Nos. 51921003 and 51775275),National Major Science and Technology Projects of China(No. 2017-VII-0002-0095), Six Talents Summit Project in Jiangsu Province (No. JXQC-002).

CHINESE JOURNAL OF AERONAUTICS2022年10期

CHINESE JOURNAL OF AERONAUTICS2022年10期

- CHINESE JOURNAL OF AERONAUTICS的其它文章

- Full mode flight dynamics modelling and control of stopped-rotor UAV

- Effect of baffle injectors on the first-order tangential acoustic mode in a cylindrical combustor

- Experimental study of hysteresis and catastrophe in a cavity-based scramjet combustor

- Flow control of double bypass variable cycle engine in modal transition

- Effects of chemical energy accommodation on nonequilibrium flow and heat transfer to a catalytic wall

- A reduced order model for coupled mode cascade flutter analysis