Effect of baffle injectors on the first-order tangential acoustic mode in a cylindrical combustor

Runze DUAN, Heng ZHANG, Ling TIAN, Enyu WANG,Linsheng LIU,*

a School of Energy and Environmental Engineering, Hebei University of Technology, Tianjin 300401, China

b Hebei Key Laboratory of Thermal Science and Energy Clean Utilization, Tianjin 300401, China

KEYWORDS Baffle injectors;Combustion instability;Cylindrical combustor;Gap between adjacent injectors;Tangential acoustic mode

Abstract Combustion instability is a very important issue in the development of the propulsion systems used in aerospace.It is very important to associate the high frequency combustion instabilities with the acoustic characteristics of the combustion chamber. In this paper, the effects of various baffle injectors which were installed on the injector faceplate on the first-order tangential acoustic mode were investigated theoretically and experimentally. The effects of the gap between adjacent injectors on the first-order tangential acoustic mode in a cylindrical chamber were considered. The acoustic admittance of the injectors was derived. The results showed that the amplitude and frequency of the first-order tangential acoustic mode increase with the increase in the gap between adjacent injectors, but decrease with the increase in the number and height of the baffles.The baffle injectors have a greater influence on the amplitude and frequency of the first-order tangential acoustic mode than the baffle blades.

1. Introduction

Performance and stability are two conflicting concerns for the development of a new rocket engine. Generally speaking, the combustion instabilities have many opportunities to encounter in the high performance of the rocket combustion chamber,especially the high frequency first-order tangential mode which is also the most destructive. The high frequency combustion instabilities are known as the acoustic pressure oscillation.1-4

The feedback loop between acoustic wave and unsteady heat release must be broken to eliminate the combustion instabilities occurring in rocket combustion chambers. The two techniques widely used to do this are active control and passive control strategies.5-9As an effective way to control unstable modes in combustion chambers,the active control is,however,difficult to implement in practice limited by cost and certification. Therefore, it is more interesting to build the combustion chambers that will be stable by passive control approaches.Radial baffle blades are usually mounted on the injector faceplate to modify the acoustic fields of the combustion chamber,as shown in Fig. 1.10The effect of the radial baffle blades on the acoustic pressure oscillations with inviscid flow was investigated by Quinlan et al.11They found that the radial baffle blades can effectively suppress the acoustic pressure oscillations in the combustion chamber. The phenomenon was analyzed by Baer and Mitchell12using the linear analysis method. The theoretical method was developed by Wicker et al.13through a nonlinear and linear analysis method. They studied the effect of the height and number of the baffle blades on the acoustic pressure oscillations in the combustion chamber. The results reported that the amplitude and frequency of the acoustic pressure oscillations decrease with the increase in the height and number of the baffle blades. However, the blade height has a much greater acoustic damping effect than the blade number.The effects of the radial and circumferential blades on the acoustic pressure oscillations in the combustion chamber were investigated by Miller.14The results reported that the radial and circumferential blades affect the tangential and radial acoustic modes.Sohn et al.15found that even number of the baffle blades has little influence on the second-order tangential mode.

All the literature mentioned above mainly focused on the radial and circumferential blades. However, due to the blades mounted on the injector faceplate, there are combustion discontinuities in some important combustion region, which is harmful for the combustion efficiency and thrust control of rocket engines. Moreover, the higher the baffle height, the greater the effect on the combustion efficiency.Therefore,considering the performance, heat loss, thrust control and manufacturing complexity, it is desired to reduce the number and height of the blades mounted in the combustion chamber.Structural baffle injectors have usually been used in combustion chambers to dissipate the combustion instability and solve the combustion discontinuity by placing them intermittently between injectors,as shown in Fig.216.The effect of the baffle injectors on the first-order tangential acoustic mode was numerically investigated by Zhu17and Lee18et al. The results reported that the acoustic admittance can be affected by changing the gap between blades, and then the energy of the first-order tangential acoustic mode was dissipated. This was because the gap between the blades increased the viscous and eddy dissipation, causing the increase in the acoustic admittance. Park and Sohn19investigated the effect of the gap between baffle injectors on the first-order tangential acoustic mode. The acoustic admittance was increased by changing the gap to dissipate acoustic energy and suppress combustion instability.

Previous researchers have numerically and experimentally investigated the effect of the baffle injectors mounted on the injector faceplate on the first-order tangential acoustic mode.16,17,19However, the effect of the baffle injectors on the acoustic admittance and the mechanism behind the firstorder tangential acoustic mode are still unclear. Therefore, it is necessary to investigate the effect of the baffle injectors on the first-order tangential acoustic mode through a theoretical analysis. In this paper, the acoustic admittance of the baffle injectors mounted on the injector faceplate is derived. The effects of the baffle injectors on the first-order tangential acoustic mode are investigated, theoretically and experimentally.

2. Computation scheme

2.1. Governing equation

Fig. 3 shows the baffle injectors uniformly mounted along the circumferential direction of the injector faceplate in a cylinder combustor.The main combustor radius and the radius of center baffle compartment are Rcand Rb, respectively. The main combustor length and baffle injector height are L and LB,respectively. Neglecting the air flow and viscous dissipation,the linear continuity equation, momentum equation, energy equation can be rearranged as12:

where U is mean velocity;p′is pressure disturbance in combustion chamber;γ is ratio of specific heat;p-is mean pressure;ρ-is mean density; ρ′is density disturbance; u is axial velocity disturbance; v is circumferential velocity disturbance; w is radial velocity disturbance.

Eqs. (1)-(5) can be combined and expressed as:

where Ma is Mach number;ω is frequency;c0is acoustic velocity; m is circumferential mode number; n is radial mode number; kmndenotes the characteristic value.

The chamber wall and the baffle injectors are assumed to be rigid plates. The characteristic value kmnsatisfies the follow relations20:

The superscript ‘‘μ” represents the μth baffle injector compartment.The subscripts p and q represent the circumferential and radial spatial variables, respectively.

The acoustic pressure and velocity can be written as20:

where the acoustic admittance boundary condition for the baffle injectors is unknown.

2.2. Acoustic admittance of baffle injectors

2.2.1. Acoustic admittance of acoustic wave passing through a single rigid cylinder Fig. 4 shows the scattered wave when an acoustic wave passes through a single rigid cylinder.

The continuity equation, motion equation, state equation can be written as.

where p denotes the pressure; U, V and W denote the velocity along three coordinate axes; ρ0denotes the density of the gas.Assuming that the incident wave can be written as:

pi=p0ei(ωt-kx)(48)

where k is wave number; p0denotes the pressure of the gas.

The incident wave in cylindrical coordinates is obtained as:

2.2.3. Acoustic admittance of acoustic wave passing through many rigid cylinders

Fig. 6 shows the scattered wave when an acoustic wave passes through many rigid cylinders.

where φgjis the angle between the given vector rgjand the positive x-axis. Substituting Eq. (85) into Eq. (84) yields.

The acoustic admittance for a row of columns can be obtained as:

By substituting Eq. (90) into Eq. (42), the characteristic value of the acoustic pressure in combustion chamber can be obtained.

3. Experimental model

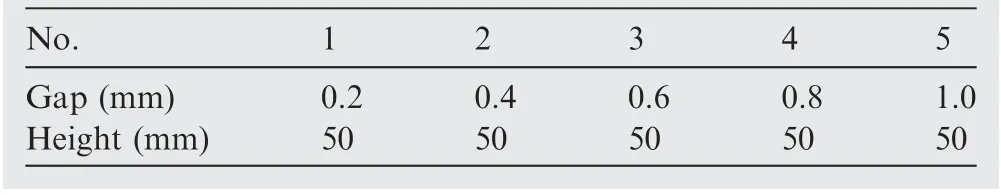

Table 1 Parameters of baffle injectors.

As shown in Fig. 7, an acoustic experimental model was built to investigate the effect of the baffle injectors on the first-order tangential acoustic mode in the cylindrical combustion chamber. The baffle injectors are mounted on injector faceplate,as shown in Figs. 8 and 9. Both the length and diameter of the combustion chamber are 250 mm and other parameters are shown in Table 1. The loudspeakers and microphones are mounted on the periphery of the cylindrical combustion chamber. The first-order tangential acoustic mode is obtained by Zhou21et al.’s and Duan22et al.’s method.The acoustic signals are produced by loudspeakers and received by microphones. In order to avoid the interference of other acoustic signals, the pure sinusoidal acoustic signal is induced by four loudspeakers, which have been installed in the periphery of the faceplate.The phase difference of the acoustic signal made by the loudspeakers was 90 ° to obtain first-order tangential acoustic mode. The acoustic signal of the chamber was received by the microphone sensors,21as shown in Fig. 10.

4. Results and discussion

4.1. Effect of gap between adjacent baffle injectors

Baffle number,N,is adjusted over the range of 3-6.The length of the baffle injectors is 50 mm.The gap between adjacent baffle injectors is adjusted over the range of 0(unbaffled injector)-1.0 mm.Fig.11 shows the effect of the gap between adjacent baffle injectors on the amplitude of the first-order tangential acoustic mode. When the baffle injectors are mounted on the injector faceplates, the amplitude of the first-order tangential acoustic mode is obviously suppressed.In the terms of physics,the acoustic admittance can be affected by mounting the baffle blades. The energy of the first-order tangential acoustic mode was dissipated.However,the amplitude increases with the gap between adjacent baffle injectors increased from 0.2 mm to 1.0 mm, and decreases with the increase in baffle number.Therefore, an appropriate gap between adjacent baffle injectors can effectively enhance the damping effect and improve the dissipation of acoustic energy.

Fig. 12 shows the effect of the gap between adjacent baffle injectors on the frequency of the first-order tangential acoustic mode. When the baffle injectors are mounted on the injector faceplate, the frequency of the first-order tangential acoustic mode is also suppressed. The frequency increases with the increase in the gap between adjacent baffle injectors, and decreases with the increase in baffle number. The theoretical results show a good correlation with the experimental results.The error between experiment value and theoretical value is less than 1.2%.

4.2. Effect of numbers of baffle injectors

Baffle number,N,is adjusted over the range of 0-6.The length of the baffle injectors is 50 mm. The diameter of the baffle injectors is 250 mm. The gap between adjacent baffle injectors is adjusted over the range of 0.2-0.8 mm. Fig. 13 shows the effect of baffle number on the amplitude of the first-order tangential acoustic mode.The amplitude of the first-order tangential acoustic mode decreases with the increase in baffle number.The physical mechanisms are explained as follows:the acoustic admittance can be affected by changing the baffle number,and then the energy of the first-order tangential acoustic mode was dissipated. Fig. 13 compares the experimental and theoretical results.

The gap between adjacent baffle injectors is adjusted over the range of 0-1.0 mm.Fig.14 shows the effect of baffle number on the frequency of the first-order tangential acoustic mode. The frequency of the first-order tangential acoustic mode decreases with the increase in baffle number. The theoretical results show a good correlation with the experimental results. The difference between the theoretical and experimental results is due to the simplification of Becker function (the third kind Bessel function) and the neglect of gas viscosity.

4.3. Effect of baffle injectors and baffle blades

Baffle number, N, is 6. The gap between adjacent baffle injectors is 0.2 mm. Fig. 15 shows the effects of the baffle injectors and baffle blades on the first-order tangential acoustic mode.For both the baffle injectors and the baffle blades, the amplitude of the first-order tangential acoustic mode decreases with the increase in baffle height.However,the baffle injectors have a more intense effect on the amplitude of the first-order tangential acoustic mode than the baffle blades. In other words,the baffle injectors have a greater damping effect on the firstorder tangential acoustic mode than the baffle blades. The results are similar to those from Lee et al.17

4.4. Effect of baffle injector height

Baffle number, N = 3. The gap between adjacent baffle injectors is 0.2 mm. The height (LB) of the baffle injectors is adjusted over the range of 20-80 mm.Fig. 16 shows the effect of baffle injector height on the first-order tangential acoustic mode. The amplitude of the first-order tangential acoustic mode decreases with the increase in the height of the baffle injectors. In other words, the increase in baffle height has a greater damping effect on the first-order tangential acoustic mode. The frequency of the first-order tangential acoustic mode also decreases with the increase in the height of the height of the baffle injectors.The physical mechanisms behind them are explained as follows:the first-order tangential acoustic mode is intensively converted into the longitudinal acoustic mode with the increase in the height of the baffle injectors.However, the height of the baffle injectors has little influence on the longitudinal acoustic mode.

5. Conclusions

The effect of the baffle injectors on the first-order tangential acoustic mode is investigated,experimentally and theoretically.The acoustic model for the combustor with the baffle injectors mounted on the injector faceplate is established.The main conclusions are obtained as follows:

(1) The baffle injectors which were mounted on the injector faceplate have an obvious damping effect on the amplitude and frequency of the first-order tangential acoustic mode.

(2) The amplitude and frequency of the first-order tangential acoustic mode increase with the increase in the gap between adjacent baffle injectors. The optimum gap is 0.2 mm.

(3) The amplitude and frequency of the first-order tangential acoustic mode decrease with the increase in the number and height of the baffle injectors.

(4) The baffle injectors have a greater damping effect on the first-order tangential acoustic mode than the baffle blades.

Declaration of Competing Interest

This manuscript has not been published or presented else

where in part or in entirety and is not under consideration by another journal. We have read and understood your journal’s policies, and we believe that neither the manuscript nor the study violates any of these. We declare that we have no financial and personal relationships with other people or organizations that can inappropriately influence our work. There are no conflicts of interest to declare.

Acknowledgements

This study was co-supported by the National Natural Science Foundation of China (Nos. 51806057, 52005152 and 12042211), the Natural Science Foundation of Hebei, China(Nos. E2019202460 and E2019202451), Tianjin Science and Technology Project, China (No. 19YFZCSF00850), the Key Research Program Projects of Hebei Province, China (No.19274502D)and the Industrial Technology Research of Hebei University of Technology, China (No. ZBYJY201902).

CHINESE JOURNAL OF AERONAUTICS2022年10期

CHINESE JOURNAL OF AERONAUTICS2022年10期

- CHINESE JOURNAL OF AERONAUTICS的其它文章

- Full mode flight dynamics modelling and control of stopped-rotor UAV

- Experimental study of hysteresis and catastrophe in a cavity-based scramjet combustor

- Flow control of double bypass variable cycle engine in modal transition

- Effects of chemical energy accommodation on nonequilibrium flow and heat transfer to a catalytic wall

- A reduced order model for coupled mode cascade flutter analysis

- Nonlinear system identification framework of folding fins with freeplay using backbone curves