Poly(thioether)-b-polysiloxane-b-poly(thioether) triblock copolymer towards homogeneous dielectric elastomer with high dielectric performance

Zhnbin Feng, Jifng Guo, Suting Liu, Guofei Feng, Xing-Hong Zhng,∗

a MOE Key Laboratory of Macromolecular Synthesis and Functionalization, Department of Polymer Science and Engineering, Zhejiang University, Hangzhou 310027, China

b Center of Chemistry for Frontier Technologies, Zhejiang University, Hangzhou 310027, China

c Department of Chemical Engineering, Weifang Vocational College, Weifang 262737, China

ABSTRACT Dielectric elastomers (DEs) have drawn much attention owing to their application prospects in artificial muscles and soft robotics, it is still a big challenge to prepare DEs with high electromechanical performances.This work reports a highly stretchable poly(thioether)-b-polysiloxane-b-poly(thioether) triblock copolymer based homogenous DEs with high electromechanical properties.The triblock copolymer(PSiPGE) was synthesized through the ring-opening polymerization (ROP) of phenyl glycidyl ether (PGE)and carbonyl sulfide (COS) catalyzed by silicon alkoxides.The dipoles (benzene rings) on the side groups of PSiPGE improved the dipole polarizations and the phase separation structure of this triblock copolymer enhanced the interfacial polarizations between poly(thioether) and polysiloxane, and thus improving the dielectric constant (ε’, up to 5.8).In addition, the PSiPGE exhibited low elastic modulus (Y, 0.04 MPa),and thus possessed high electromechanical sensitivity (β, ∼145 MPa−1) which is much higher than that of most homogenous DEs.This work provides a new strategy to construct homogenous DEs with excellent electromechanical performances, leading to a greater application aspect in the actuated devices.

Keywords:Poly(thioether)-b-polysiloxane-bpoly(thioether) triblock copolymer Homogenous Dielectric elastomer Phase separation Electromechanical performance

Dielectric elastomers (DEs) [1], one of the soft electric-response materials [2], can possess the transformation of electricalmechanical energy under an applied electric field [3] with the advantages of large deformation, high energy density and electromechanical coupling efficiency, light weight and fast response speed[4,5].With these combined superiorities, the applications of DEs could range from artificial muscles [6], sensors [7] to optical lenses[8] and soft robotics [9].A disadvantage of DEs that limiting its commercial applications is the requirement of high actuated electric field (>100 kV/mm) [10,11] due to the low dielectric constant(ε’) and high dielectric loss (tanδ) [12].Thus, it is a great challenge to prepare DEs with highε’and large actuated strain at low electric field.

To enable DEs excellent electromechanical performance at low electric field, a high electromechanical sensitivity (β) is needed[13], which is defined as the ratio ofε’ to Young’s modulus(Y) [14].Thus, decreasing Y [15] and increasingε’ [16] are the main methods to prepare DEs with high actuated behaviors.In the past few years, massive efforts have been made to improveε’ of DEs to obtain higher actuated strain [17–24].One of the most commonly used approach is to add conductive fillers such as graphene or graphene oxide (GO) [17,18], CNTs [19,20], metal nanoparticles [21], or high-ε’ceramics (TiO2[22] and BaTiO3[23])or conjugated conductive polymers (polyaniline [24] and polyhexylthiophene [12]) to the elastomer matrix.After the introduction of nanofillers or stiff conductive polymers, theε’ of elastomers could be enhanced significantly [4,25] but the Y and dielectric loss also increase, resulting in the decrease in flexibility of the elastomer matrix [26].Another widely way to achieve excellent electro-mechanical performance is to synthesize homogeneous DEs with low Y and highε’through molecular design or chemical graft modification [10,27–29].These studies usually focus on grafting polar groups (such as -COOH, -COO-, -OH) [30] on the mainchains of elastomers to enhance the dipole polarizations, achieving highε’and actuated strain [5].Besides, homogeneous DEs could also be obtained through the copolymerization of acrylate monomers[27] or between acrylate and polyurethane [10].Although theε’was not high (up to about 6), the as prepared DE exhibited high actuated strain (about 52% @21.57 kV/mm) due to the low Y and highβ.Up to now, there are few monomers that could be used to prepare copolymerized homogeneous DEs, and it is urgent to find out more suitable polar monomers to realize large-scale preparation of copolymerized DEs.

Poly(thioether)s [31], a new type of sulfur-containing polymers, could be synthesizedviathe coupling reaction of carbonyl sulfide (COS) with epoxides and consequent decarboxylative ring-opening polymerization (ROP) of the cyclic thiocarbonates [32].They are very promising in the application of ion-exchange membranes, electrolytes and some optical materials [33].A series of epoxides with different side groups [34–36] could be used to synthesize poly(thioether)s with tunable structure polarities andTgin our previous study.The introduction of polar side groups is beneficial for the increase ofε’ of poly(thioether)s.Compared with commercial VHB based DEs [37],the poly(thioether)s we synthesized before were not crosslinked and exhibited high viscidity, limiting its application in the fields of DEs.If the poly(thioether)s could be chemically (adding extra crosslinker) or physically crosslinked (constructing micro-phase separation structure) [38], it will be an alternative material for the construction of DEs.

Silicon alkoxides, the oligomer with strong base, are derived from the ring opening polymerization (ROP) of octamethyl cyclotetrasiloxane (D4) catalyzed by inorganic alkali such as KOH,NaOH, have been used to catalyze the anionic ROP of cyclic siloxane [39,40].More importantly, the silicon alkoxides own dual active sites and can be used to synthesize poly(thioether)-bpolysiloxane-b-poly(thioether) block copolymer.Due to the incompatibility of polysiloxane domains and poly(thioether) domains,the microphase separation structure can be constructed to achieve physical crosslinking [41].

Herein, we reported a new approach to synthesize poly(thioether)-b-polysiloxane-b-poly(thioether) triblock copolymer from COS and epoxides catalyzed by silicon alkoxides,constructing homogeneous DE.The silicon alkoxides can catalyze the coupling reaction of COS and epoxides, and then decarboxylative of the cyclothiocarbonates can be achieved at high temperature to form poly(thioether) chain segments (hard segments, plastic phase); besides, the double active sites of silicon alkoxides can be double-terminated to form triblock copolymers with polysiloxane as soft segments (rubber phase).The poly(thioether)-b-polysiloxane-b-poly(thioether) block copolymer possesses microphase separation structure, and the morphology could be tuned by its composition.More importantly, the block copolymer possesses highε’(about 5.8), low Y (0.04 MPa)and exhibits highβ(up to 145 MPa−1) and actuated strain(13.4%@14.2 V/μm) due to the combination of dipole polarizations and interfacial polarizations.These results indicate that this new poly(thioether)-based homogenous DE could be very promising for developing electromechanical actuators with high performance.

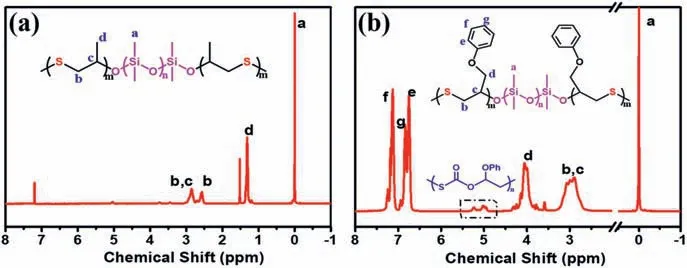

Fig.1.1H NMR spectra of (a) PSiPO and (b) PSiPGE from PO/PGE, COS and silicon alkoxides.

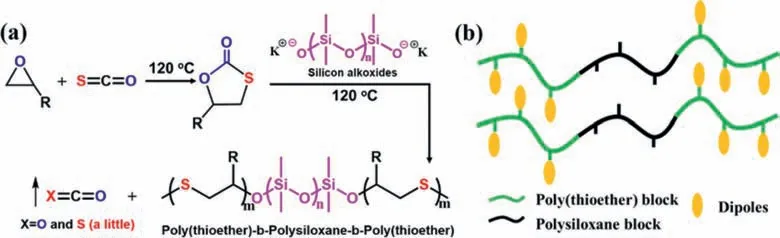

The triblock copolymers were synthesizedviaa two-step procedure (Scheme 1a): The ROP reaction of D4, forming the silicon alkoxides; then the copolymerization between epoxides (such as PO and PGE) and COS was carried out catalyzed by the silicon alkoxides at about 120 °C for about 12 h.During this process, the coupling reaction of COS with epoxides firstly occurred, followed by decarboxylative ROP of the cyclic thiocarbonates with releasing of CO2and a little bit of COS [32], finally, the triblock copolymers were synthesized and the detailed mechanism for this process is shown in the Scheme S1 (Supporting information).

Scheme 1.(a) Synthetic route to poly(thioether)-b-polysiloxane-b-poly(thioether) triblock copolymer from carbonyl sulfide (COS) and epoxides catalyzed by silicon alkoxides.(b) Schematic representation of the structure of this triblock copolymer.

The copolymerization of epoxides and COS catalyzed by silicon alkoxides was evidenced by1H NMR, the results were shown in Fig.1.Taking PSiPO (Fig.1a) for example, peak a (0 ppm), peak b(2.57 ppm), peak c (2.85 ppm) and peak d (1.31 ppm) represent the proton of silicon methyl, methylene (-CH2-) and methine, respectively, indicating the successful synthesis of PSiPO.In Fig.1b,all the characteristic peaks could be found in the1H NMR spectra for the PSiPGE except for a new peak at about 5 ppm, indicating the successful synthesis of PSiPGE.The new peak at about 5 ppm corresponds to the proton of poly(monothiocarbonate) according to our previous study [34].As the peak corresponding to the poly(monothiocarbonate) is very weak, the main product synthesized from PGE, COS and silicon alkoxides is the poly(thioether)-bpolysiloxane-b-poly(thioether) copolymer and the schematic representation of the structure is shown in Scheme 1b.The structures of PSiPO and PSiPGE were also verified by13C NMR (Fig.S1 in Supporting information), suggesting the successful copolymerization of PO/PGE, COS and silicon alkoxides.

The molecular weight of PSiPO and PSiPGE were characterized by GPC, and the results were shown in Fig.S2 (Supporting information).As the refractive index of polysiloxane is close to that of THF which is the mobile phase in GPC, the molecular weight of silicon alkoxides could not be detected by using GPC, so it was verified by MALDI-TOF MS, and the result was shown in Fig.S3 (Supporting information).It was found that the molecular weight of silicon alkoxides is about 2.48 kg/mol, the detailed Mn, Mw, PDI and the phase compositions are summarized in Table S2 (Supporting information).Compared with the triblock copolymer based DEs in the previous study [2,14], the PDI for the PSiPO or PSiPGE is much narrower, which agrees well with the poly(thioether)s catalyzed by organic bases in our previous report [42].Furthermore, the diffusion-ordered (DOSY) NMR spectrum exhibits a single diffusion coefficient (Fig.S2b), indicating that the triblock copolymer consists only one component.All these results evidenced that the poly(thioether)-b-polysiloxane-bpoly(thioether) copolymer could be synthesized under the catalysis of silicon alkoxides.

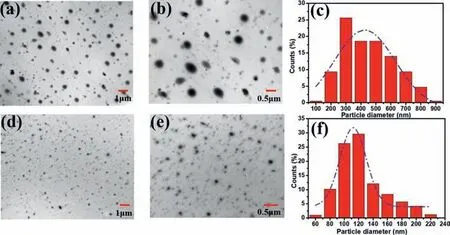

Fig.2.(a, b) TEM images of PSiPGE with silicon alkoxides concentration of 0.1 g/mL.(c) The size distribution of the particle in (a, b).(d, e) TEM images of PSiPGE with silicon alkoxides concentration of 0.15 g/mL.(f) The size distribution of the particle in (d, e).

The thermal analysis of PSiPO and PSiPGE were also carried out and shown in Fig.S4 (Supporting information).Two distinct transition temperature could be observed for both samples in DSC curves (Fig.S4a), which represent different domains.The transition temperature at about −120 °C belongs to the glass transition of polysiloxane and the other is attributed to the poly(thioether)s.In the TGA curves (Fig.S4b), two different decomposition temperature could also be found for both samples.All these evidences indicated the successful synthesis of the triblock copolymer.

Fig.2 and Fig.S5 (Supporting information) illustrate the nanomorphology of the triblock copolymer by TEM and AFM, as the sample of PSiPO could not be freezing sectioned due to its poor film-forming, only the sample of PSiPGE catalyzed by different concentration of silicon alkoxides were characterized.As expected,the microphase separation could be observed with clear phase boundaries in all the samples.The nanodomains of polysiloxane(dark domains) are well dispersed in the matrix of poly(thioether)(bright domains) due to the low content of polysiloxane segments.Unlike the worm-like form of polystyrene in the SBS [43],sphere-like form (Figs.2a, b, d and e) could be observed for the polysiloxane segments as the thermodynamic incompatibility with poly(thioether).For the PSiPGE sample catalyzed by 0.1 g/mL of silicon alkoxides (named as PSiPGE-0.1), the well-defined soft segments with the mean particle size of 400 nm (Fig.2c) could be observed; however, for the PSiPGE sample catalyzed by 0.15 g/mL of silicon alkoxides (named as PSiPGE-0.15), the mean particle size decreases to about 120 nm.The size decrease of soft segments illustrates that the content increase of hard segments [44,45].The AFM-phase images were also carried out to verify the structure of microphase separation (Fig.S5), which is consistent with the TEM results.

Generally, the island-sea nano-morphology of triblock copolymer could enable it excellent mechanical properties [46].In this study, the soft segments (polysiloxane) are acted as dispersed phase whereas the hard segments (poly(thioether)) are acted as the continuous phase, resulting in the increase of the toughness and the decrease of mechanical strength.As shown in Fig.S6 (Supporting information), the PSiPGE exhibit highly stretchable performance with the elongation at break of over 1000%, whereas the ultimate tensile strength is about 0.06 MPa with the Young’s modulus of about 0.04 MPa.

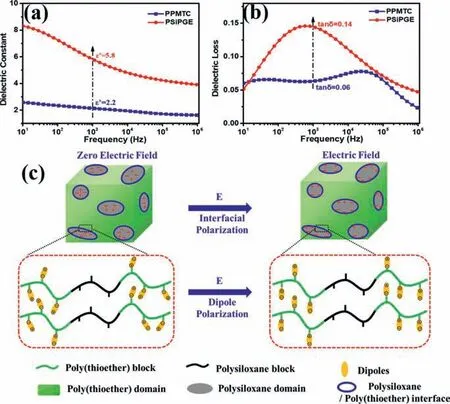

Fig.3.(a) The dielectric constant (ε’) and (b) the dielectric loss (tanδ) of the pure PPMTC and PSiPGE.(c) The mechanism of the improvement of the dielectric performances.

Fig.3 illustrates the dielectric properties of pure poly(propylene-monothiocarbonate) (PPMTC) and PSiPGE as a function of frequency at room temperature, the detailed values are summarized in Table 1.It is found that theε’decreases as the frequency increases (Fig.3a) for both PPMTC and PSiPGE samples,indicating the frequency dependence ofε’.Compared with PPMTC,theε’of PSiPGE with significant micro-phase separation structure is much higher at the range of 10–106Hz.Taking theε’at 103Hz for example, theε’of PPMTC is about 2.2, whereas it is about 5.8 for PSiPGE which is more than 2.5 times that of PPMTC.Interestingly, the backbone of PPMTC is rich in thiocarbonate groups(dipoles), it still exhibits lowε’.The reason for this phenomenon is that the polar groups of PPMTC are located in the mainchains,the dipoles are difficult to move and difficult to be polarized under the electric fields [47].On the contrary, the dipoles (benzene ring)for the PSiPGE are located in the side groups, which are tended to be polarized much easier, leading to the increase ofε’(Fig.3c).

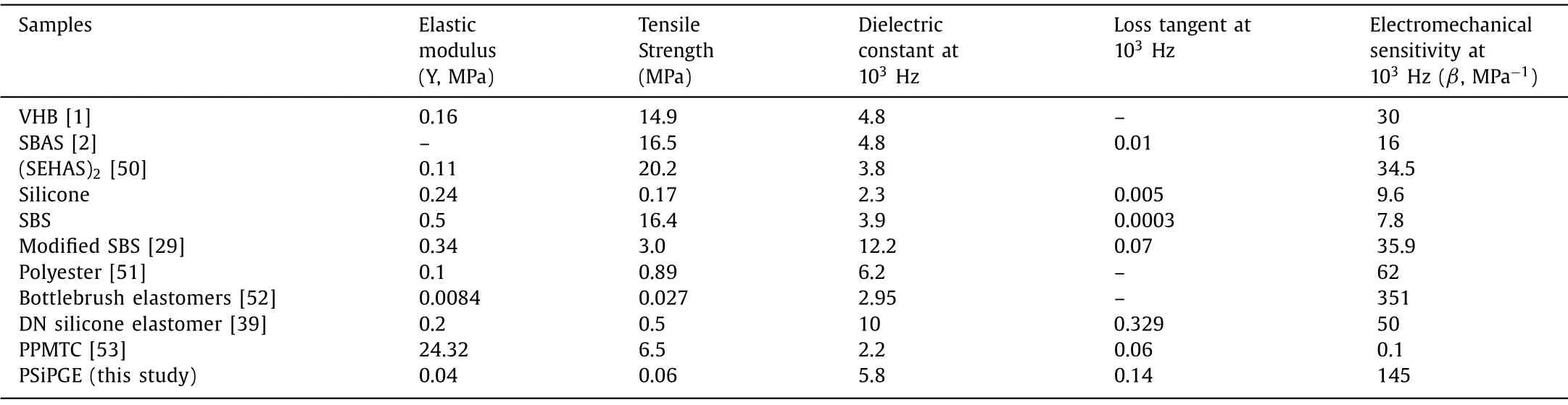

Table 1 Physical and electromechanical properties of various homogenous DEs without pre-strain and the addition of plasticizer.

In addition, the phase separation structure could also affect theε’(Fig.3c).For the homogenous DEs with continual phase structure, the interfacial polarizations are commonly not generated as there are no obvious phase interfaces; for the PSiPGE with separation structures, clearly phase interfaces could be observed (Fig.2),large amounts of free charges accumulate at the interfaces [48,49]between polysiloxane and poly(thioether) under the external electric field and finally, the interfacial polarizations occur, which is beneficial to the improvement ofε’.

The dielectric loss tangents (tanδ)versusfrequency of the PPMTC and PSiPGE are shown in Fig.3b.The tanδof PPMTC is quilt low and almost exhibit frequency independent at the range of 10–105Hz, and it will decrease in 105Hz to 106Hz.For the PSiPGE sample, the tanδincreases sharply from 10 to 103Hz and then decreases at the range of 103Hz to 106Hz, and a significant relaxation peak could be observed at about 103Hz.The relaxation peak shifts from 105Hz (high frequency) for the PPMTC to about 103Hz (low frequency) for PSiPGE, illustrating that the polarization ability of PSiPGE is much stronger than that of PPMTC [16].Specif-ically, the tanδat 103Hz of the PSiPGE increases slightly from 0.06 to about 0.14 compared with PPMTC.

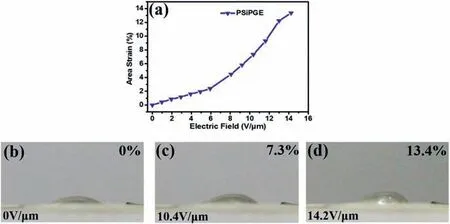

Fig.4.(a) Area strain-applied electric field curve of PSiPGE without prestrain; actuating images of PSiPGE under the electric field of (b) 0 V/μm, (c) 10.4 V/μm and(d) 14.2 V/μm.

The electromechanical sensitivities (β) for the PPMTC and PSiPGE were also measured and listed in Table 1.Compared with PPMTC, the simultaneous increase in theε’and decrease in the Y of PSiPGE result in a much higherβ.For example,βat 103Hz increases sharply from about 0.1 MPa−1for PPMTC to about 145 MPa−1for the PSiPGE.The large increase inβwill enable PSiPGE larger actuation strain the improvement at low electric fields, and further research will be carried out to focus on the actuated performance of the PSiPGE.

The comparisons of physical and electromechanical properties of various homogenous DEs reported in the previous studies and PPMTC, PSiPGE in this study are listed in Table 1.Although theε’of PSiPGE is not the highest, theβis much higher than that of most previous reported homogenous DEs.It is the simultaneous increase in theε’and decrease in the Y that enabling PSiPGE excellent electromechanical performances.

The actuating behavior of PSiPGE (Fig.4) was measured according to standards for dielectric elastomer transducers in previous reports [50,54].As the SWCNT electrodes could not be coated at the surface of pure PPMTC perfectly, only the sample of PSiPGE was tested for the electro-actuated behavior.Here, a small and constant pneumatic pressure was applied to guide the direction of deformation and the applied voltage was slowly increased until the electric breakdown (Figs.4b–d).As expected, the actuation area strain of PSiPGE significantly increases with increasing the applied voltage (Fig.4a), the maximum actuation area strain of the sample was about 13.4%(@14.2 V/μm) due to its low modulus and highβ,demonstrating excellent electro-mechanical properties.It will provide an alternative method to the fabrication of homogenous DEs with wider application in the fields of artificial muscles and wearable devices.

In summary, we synthesized poly(thioether)-b-polysiloxane-bpoly(thioether) triblock copolymer based homogenous DEs with highly stretchable and excellent electromechanical performancesviathe ROP of PGE and COS catalyzed by silicon alkoxides.With the presence of dipoles on the side groups and the phase separation structure of this triblock copolymer, the dipole polarizations and interfacial polarizations of PSiPGE were enhanced simultaneously, leading to the improvement ofε’(∼5.8).In addition, the PSiPGE exhibited low modulus (0.04 MPa) with highly stretchable property (above 1100%) and thus, it possessed highβ(up to 145 MPa−1) which is higher than most previous reported homogenous DEs.Most importantly, the maximum actuation area strain could reach about 13.4% (@14.2 V/μm), which will enable this poly(thioether)-b-polysiloxane-b-poly(thioether)based homogenous DEs wider application in the fields of various biomimetic actuators.

It is believed that many new triblock copolymer-based DEs with excellent electromechanical performances could also be constructed through the ROP of some other epoxides and COS catalyzed by silicon alkoxides.The work provides a novel strategy to prepare DEs with well-defined structure and improved actuated behaviors.

Declaration of competing interest

The authors declare no conflict of interest.

Acknowledgments

We would like to express our sincere thanks to National Natural Science Foundation of China (Nos.51973190 and 21774108) and Zhejiang Provincial Department of Science and Technology (No.2020R52006) for financial supports.

Supplementary materials

Supplementary material associated with this article can be found, in the online version, at doi:10.1016/j.cclet.2021.11.091.

Chinese Chemical Letters2022年8期

Chinese Chemical Letters2022年8期

- Chinese Chemical Letters的其它文章

- Adsorptive removal of PPCPs from aqueous solution using carbon-based composites: A review

- A review on hollow fiber membrane module towards high separation efficiency: Process modeling in fouling perspective

- Recent advances in DNA glycosylase assays

- Chiral pillar[n]arenes: Conformation inversion, material preparation and applications

- Recent progress in carbon-based materials boosting electrochemical water splitting

- Working principle and application of photocatalytic optical fibers for the degradation and conversion of gaseous pollutants