A review on hollow fiber membrane module towards high separation efficiency: Process modeling in fouling perspective

Xianhui Li, Mohammad Younas, Mashallah Rzakazmi, Quang Vit Ly,Jianxin Li

a Key Laboratory for City Cluster Environmental Safety and Green Development of the Ministry of Education, Institute of Environmental and Ecological Engineering, Guangdong University of Technology, Guangzhou 510006, China

b Southern Marine Science and Engineering Guangdong Laboratory (Guangzhou), Guangzhou 511458, China

c State Key Laboratory of Separation Membranes and Membrane Processes, National Center for International Joint Research on Membrane Science and Technology, Tiangong University, Tianjin 300387, China

d Department of Chemical Engineering, University of Engineering and Technology, P.O.Box 814, Peshawar, Pakistan

e Faculty of Chemical and Materials Engineering, Shahrood University of Technology, P.O.Box 3619995161, Shahrood, Iran

f Institute of Research and Development, Duy Tan University, Da nang 550000, Vietnam

ABSTRACT Hollow fiber microfiltration (MF) and ultrafiltration (UF) membrane processes have been extensively used in water purification and biotechnology.However, complicated filtration hydrodynamics wield a negative influence on fouling mitigation and stability of hollow fiber MF/UF membrane processes.Thus, establishing a mathematical model to understand the membrane processes is essential to guide the optimization of module configurations and to alleviate membrane fouling.Here, we present a comprehensive overview of the hollow fiber MF/UF membrane filtration models developed from different theories.The existing models primarily focus on membrane fouling but rarely on the interactions between the membrane fouling and local filtration hydrodynamics.Therefore, more simplified conceptual models and integrated reduced models need to be built to represent the real filtration behaviors of hollow fiber membranes.Future analyses considering practical requirements including complicated local hydrodynamics and nonuniform membrane properties are suggested to meet the accurate prediction of membrane filtration performance in practical application.This review will inspire the development of high-efficiency hollow fiber membrane modules.

Keywords:Hollow fiber microfiltration and ultrafiltration process Mathematical modeling Filtration hydrodynamics Membrane fouling Optimization

1.Introduction

Membrane technology has been widely applied in various industries such as medical, chemical, energy, environmental and food industries around the world because it only requires less energy during operation and more importantly it is easier to scale up [1,2].Commonly, membrane filtration system is a preferred unit operation in industrial applications owing to its mild operating condition.As the core component of membrane system, the hollow fiber membrane (HFM) module is more preferable over other membrane configurations such as spiral wound and flat sheet,etc.The most attractive advantage is its self-supporting property, leading to a larger effective surface area and higher packing density [3,4].However, compared to the other membrane configurations, the decrease of local flux and trans-membrane pressure (TMP) along flow direction are more prominent in the hollow fiber configuration because of the serious internal pressure drop in the narrow fiber lumen [5,6].Unfortunately, this non-uniform local flux distribution will result in more complicated local hydrodynamics and severer membrane fouling [7,8].It should be noted that the instability of local filtration behavior will be intensified as increasing the membrane module size due to the enhanced non-distribution of local flux distribution.Therefore, much attention has been paid to the optimization of the HFM module in order to realize high efficiency in practical applications [9–11].

Optimizing operating conditions is a road to enhance the performance of the HFM system, however, this is a time-consuming and expensive job.Mathematical modeling has significant advantages over experimental measurements such as cost-effectiveness,safety, and flexibility [12].In addition, not fully understanding of the transport mechanism occurring inside the HFM system prob-ably overlooks the interaction of important parameters.Therefore,to facilitate a comprehensive consideration during the HFM module design, modeling the membrane separation characteristics is indispensable.However, membrane filtration modes (cross-flow,dead-end, and submerged filtrations) and membrane module configurations (vertical and horizontal configurations) significantly affect the solute transportation [13–15].For instance, in contrast to the dead-end and submerged filtrations in the absence of retentate, the cross-flow filtration enables retentate flowing continuously from the module outlet.This causes a strong shear force on the membrane surface, which benefits fouling mitigation [15].Compared to the horizontal configuration, the vertical configuration suffered from more severe fouling because of more nonuniform local flux distributions [13].The massive difference between these membrane filtration principles results in various theoretical models and numerical approaches.In the last decade, plenty of models have been proposed to predict filtration performance and elucidate fouling mechanisms based on different theories, including mass and momentum transfer, hydrodynamics,etc.[16–18].However, there are few comprehensive reviews regarding the relationship between membrane fouling and local filtration properties of HFM.

This work aims to synthesize previous studies and current state-of-the-art in modeling studies of hollow fiber microfiltration (MF)/ultrafiltration (UF) membrane processes, which are classified based on their applied theories (Table 1).The filtration phenomenon described by each model will be discussed in the following sections, aiming to guide the selection of the best model for a particular simulation case.Possible improvements of these membrane-based filtration models are discussed and future research scopes are suggested, so as to provide some guidelines concerning the development of appropriate HFM modules for practical applications.

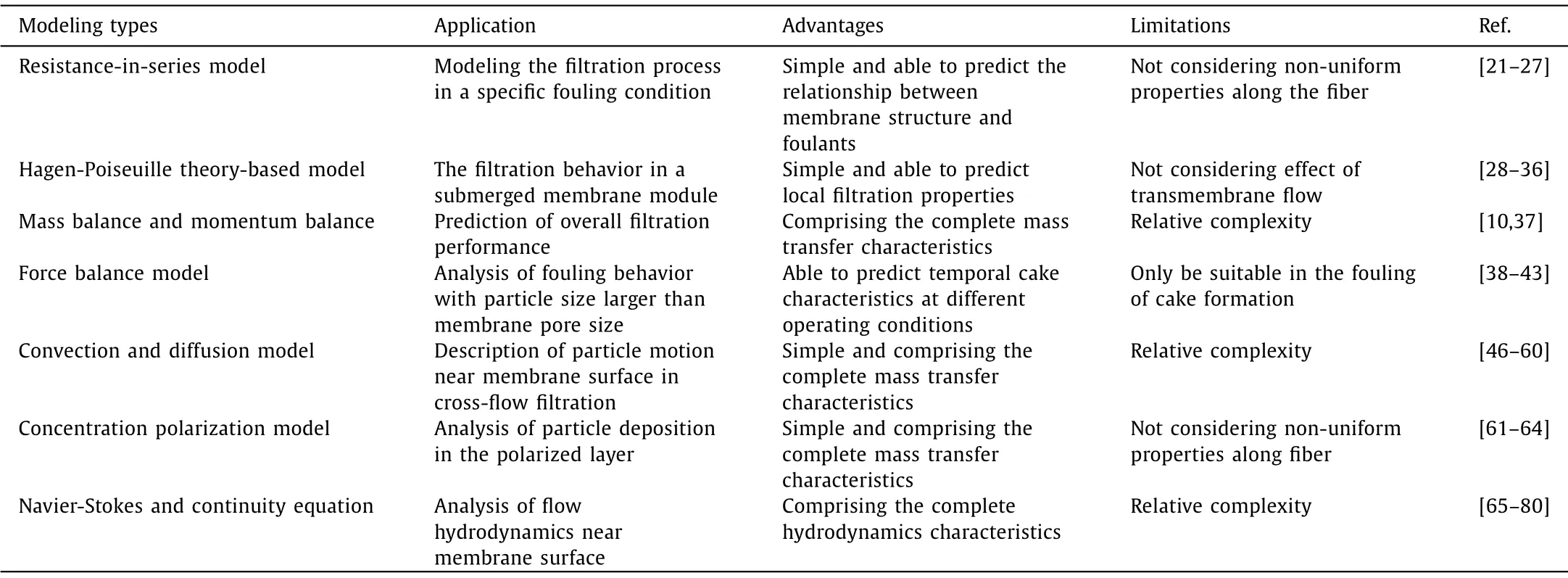

Table 1 Summary of different models reported in the literature.

2.Modeling the filtration process

Fouling is a major and inevitable problem in membrane modules and applications, including HFMs.It reduces permeate flux over time, so as to play its role in reducing cost efficiency [19].Fouling can be defined as the blockage on the pores and surface of the membrane by soluble or suspended matters, such as colloids,biological, inorganic, and organic components [20].Fouling can be solved through chemical, physical, and hydrodynamic cleanings.To fully understand the solute transport mechanisms and interactions between foulants and filtration characteristics, different calculating approaches are proposed to predict the membrane filtration performance.In addition, to accurately extrapolate the filtration of behavior of hollow fiber membranes, the significant parameters of module geometry (e.g.,fiber diameter, fiber length, and number of fibers) have been incorporated into these models.The limitations and improvements of each model are also discussed at the end of each section.

2.1.Resistance-in-series model

During filtration of suspension, hydraulic resistance rises significantly owing to the deposition of foulants and the concentration polarization.Darcy’s Law is the basic model that describes the hydraulic permeability,k, for the hollow fiber stating asv=−kP/μ,where μ is the viscosity of the fluid,Pis pressure, andvis the velocity [21].According to the Darcy’s Law, the flux is considered to be controlled by several hydraulic resistances in series (Eq.1)[22,23]:

whereΔPis the pressure (Pa),Rmis the resistance due to membrane thickness (m−1),Rcis the resistance of the deposited foulants (m−1),Rbis the boundary layer resistance (m−1).

Generally, four models are used for the description of fouling behaviors depending on the effective particle sizes as well as the membrane pore size as follows:

(1) The standard blocking model premises an accumulation on the pore walls of the membrane.The membrane permeability is significantly reduced as the pores become constricted.In this case, the decrease of membrane permeability is related to a reduction in the total pore volume.

(2) The intermediate blocking model premises that a portion of particles block some pores while the rest accumulate on the top of deposited particles.

(3) The complete blocking model is based on the assumption that the particles have a similar size with the membrane pores,and each particle arriving to the membrane easily blocks pores without superposition of particles.The effective membrane filtration area is thus decreased resulting from the particles deposited on the membrane.

(4) Cake filtration model premises that particle accumulation results in a permeable cake with increasing thickness.

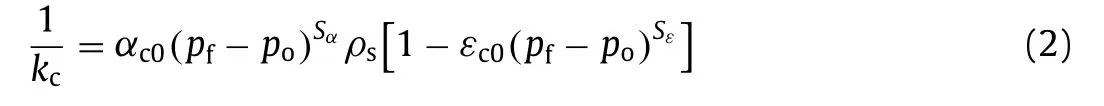

These mechanisms have been used separately or integrally to explain experimental results.For instance, Leeet al.proposed a model to describe TMP increase during the filtration of starch solution on the basis of a complete blocking theory in a submerged hollow fiber membrane filtration process [24].It pointed out that fouling easily occurred around the potted area of the membrane close to the outlet of the module, which should be cleaned more frequently than the other parts of the membrane.Another modified model was derived to account for the relationship between the filtration characteristics (feed water characteristics and membrane properties) and fouling mechanisms [25].The simulated results showed that the major fouling mechanism of hydrophobic and hydrophilic membranes for the filtration of raw water was standard blocking and cake formation, respectively.In particular,by separately examining the pressure drop across the cake and membrane, Kinlet al.established a model for prediction of the local filtration behavior along the HFM attached with a compressible cake layer [26].The cake permeability (kc) was expressed as Eq.2.

whereαcis the specific cake resistance (m−1),pfis the pressure on the feed side (Pa),pois the pressure on the fiber outer wall(Pa),SαandSεare the compressibility index towards the specific cake resistance and porosity, respectively,ρsis the density of suspended particles (kg/m3) andεcis the filtration cake porosity.It demonstrated that the maximum local flux appeared at the place with the highly compressible cake layer.If the resistance is offered by pressure and radial flow in hollow fiber, the total resistance can be calculated by the inverse of hydraulic permeability using the following equation (Eq.3):

whereLis the fiber length,ΔPis pressure,ro2andri2are the fiber outer and inner radii, respectively, andKis the fiber conductivity[27].

The concept of resistances-in-series is a convenient way to provide an overview of the fouling contributions in the membrane filtration process.Nevertheless, no details of fouling layers can be given behind the models, since there is a lot of varieties in this calculating approach.For example, current resistances-in-series approaches cannot accurately predict protein filtration behavior because the protein undergoes complicated transformations such as polymerization, aggregation, or coagulation.Therefore, linking fouling to the concentration polarization phenomenon, local hydrodynamics, and force balance of foulants is the significance of accurately predicting real filtration performance and finding the fouling control strategies.

2.2.Hagen-Poiseuille theory-based model

The Hagen-Poiseuille equation as a basic hydrodynamic equation is particularly applied to calculate a pressure drop of laminar flow through a rigid pipe [28,29].It can be expressed as Eq.4.

wherevis the flow velocity (m/s),diis the inner diameter (m),μis the fluid viscosity (Pa.s).

Therefore, it has been extensively employed to predict the filtration behavior of HFM modules.For example, Carrollet al.simulated the local TMP gradients along the fiber in the double-end and dead-end modules based on Hagen-Poiseuille theory [30,31].They found that the non-uniform distribution of the local flux led to the non-uniform deposition of foulants, but the local flux profile got more uniform with the cake growth.Further, Changet al.developed a mathematical model incorporating the local flux concept into the Hagen-Poiseuille equation to investigate the effect of fiber features (radius, length, and membrane resistance) on filtration resistance and axial pressure drop along the fiber [9].The critical flux is regarded as the flux at which the drag forces of foulants towards the membrane are equal to the shear forces of foulants that transported away from the membrane.It was assumed that as the maximum initial flux at the fiber outlet (Jimax) was lower than the critical flux (Jcr), no deposition occurred and the filtration resistance kept constant throughout the filtration.The local flux distribution was expressed as follows (Eqs.5 and 6) based on Hagen-Poiseuille equation.

where

whereLis the fiber length (m),Jmiis the average flux (m/s),Rtotis the overall resistance (m−1).

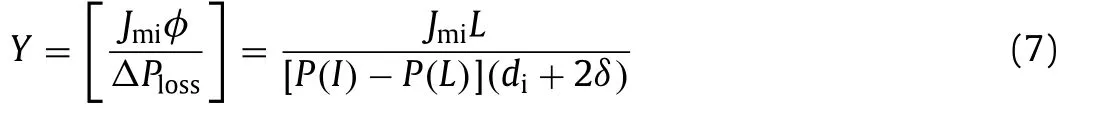

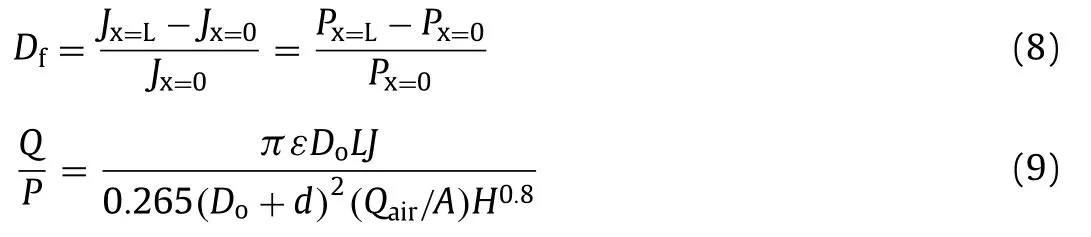

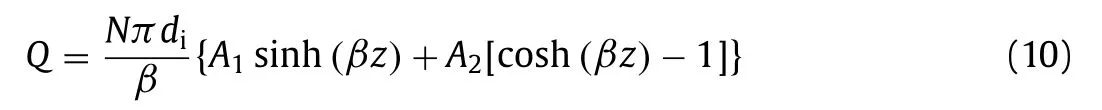

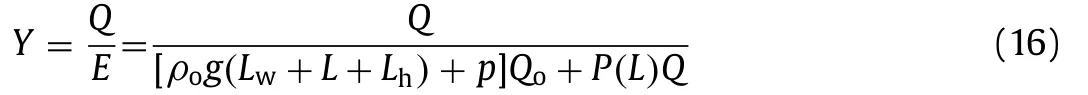

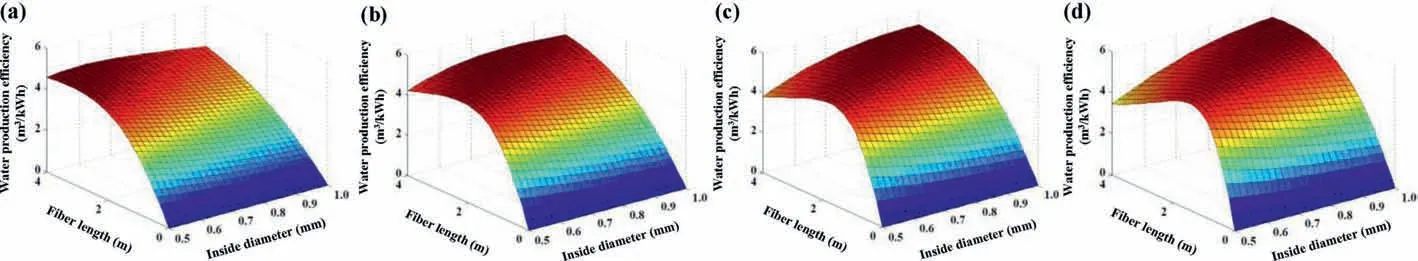

Under the condition ofJimax>JcrandJmi whereYis the specific productivity of the permeate flow(m3/kWh),φis the fiber packing density,P(I) is the pressure at fiber dead-end (Pa),P(L) is the pressure at fiber outlet (Pa),diis the fiber inner diameter (mm) andδis the fiber thickness (mm).The simulation suggests that the optimal fiber inner radius is 0.20–0.35 mm as the fiber length is 0.5–3.0 m. To obtain maximum energy efficiency of submerged hollow fiber membrane module, Yoonet al.developed a model containing the module configuration and packing density as well as the optimum range of the fiber length and diameter for both one- and two-side suctions based on the Hagen-Poiseuille theory [32].In this model, the optimization objective functions were the pressure difference between both ends of the fiber (Df) and the power effi-ciency (Q/P) (Eqs.8 and 9), respectively. whereDois the fiber outer diameter (m),εis the area ratio of fiber bundle,dis the distance among fibers (m),Qairis the airflow rate(m3/min),Ais the total footprint (m2) andHis the pressure head(m). Results showed that for dead-end filtration mode, the optimum ranges of the fiber length and outer diameter were estimated to be 1.0–1.9 m and 2.2–3.2 mm, respectively, as the operating flux was 20–50 L m−2h−1and the ratio of outer to inner diameters was 2:1[32].For double-end filtration mode, the optimum fiber length and diameter were 1.0–1.9 m and 1.3–2.0 mm under the same operating conditions, respectively. Furthermore, a general modeling to predict the flux profile,pressure, and flow rate in a hollow fiber membrane module containing adsorbent beads was developed by Daiet al.[33].The permeate flow rate at any length of the module (Q) was calculated as follows (Eq.10) [33]: where the parameters ofA1andA2are the membrane permeation constants, which are related with the local fluxes at the beginning and dead-end of the module, respectively. In addition, to reveal the uniformity of TMP profile along the fiber, a parameter called the uniformity factor,β, was incorporated into the model defined as follows (Eq.11): where TMP0and TMPLare the TMP at the beginning and end of the membrane module, respectively.Theβrequired is calculated as the maximum value between TMP0and TMPL.A lowerβcorresponds to a more uniform TMP profile.Results showed that this model could successfully predict the TMP and solvent flux profiles[33]. To investigate the effect of membrane fouling on the local flux,Changet al.further proposed an improved model based on a cake filtration theory [5].The cake filtration theory correlated the cake structure to the electrostatic interaction with a concept of force balance between the inter-particle interactions and the hydraulic forces.The resistance of cake layers (Rcr) formed on the membrane surface was calculated by Eq.12. whereϕis the Happel function,rois the cake solid volume fraction andais the particle radius (m). It was found that the foulants deposited on the membrane surface could influence the local flux distribution, which tended to be uniform once the particles were deposited on the membrane[5].In addition, the non-uniform distribution of the cake resistance would intensify as the increase in the operating flux and the decrease in the fiber inner diameter, particle size, and particle zeta potential.Specifically, Wang and Waite paid particular attention to the cake layer growth rate and the local flux distribution on the HFMs using a model developed by combining Darcy law and Hagen-Poiseuille equation [34].It showed that the local flux profile was non-uniform and not constant, and thus resulting in a non-uniform growth rate of foulants, cake layer, and average porosity during HFM filtration.In addition, they also found that the non-uniformity was most significant at the initial filtration but was gradually diminished resulting from cake layer build-up as filtration progressed [34]. To further investigate the aeration affecting fouling control, Liuet al.[35] simulated the time-dependent filtration performance by introducing an empirical parameter named gas bubbling cleaning efficiency (E) based on the basic method provided by Changet al.[5].Herein,Erepresented the influence of the back-transport force on the foulants away from the membrane surface induced by bubbling, and is related to the nozzle size and the gas flow rate.The cake resistance can be calculated byin the absence of gas bubbling but should be reduced to(1 −E)under the condition of gas bubbling.The local flux distribution was found to become more uniform with an increasedE[35].AlthoughEpartly reveals the effect of gas bubbling on the local filtration behavior,it is only an empirical parameter.Furthermore, a model for the biological system was created, which incorporated the geometry(e.g., the module layout structure) and hydrodynamics of the system (e.g., the two-phase plug flow in the feed side and hydrodynamics within the fiber) [36].This model showed that high concentration of extracellular polymeric substances strongly increased biofouling, while high concentration of solids enhanced pore blocking and cake layer formation.In addition, although an increase of the aeration rate led to decreasing the thickness of cake layer, it also resulted in an increase of the specific resistance of the cake layer. In summary, these models established based on the Hagen-Poiseuille theory provide an important guidance for the module optimization and process control of membrane systems.However,it should be noted that the Hagen-Poiseuille equation is only valid for a horizontal impermeable pipe, which is not the case for membranes that are permeable to water.Hence, the models based on the mass and momentum balances have been developed to solve this issue, elucidating the effect of the transmembrane flow on the TMP and local flux distribution along the permeable HFM[10,16,37]. To take into account the transmembrane flow to more precisely predict the filtration behavior, a mathematical model was developed by Liet al.based on the momentum balance and complete mass balance [10].A slip parameter (α) was introduced to address the influence of the transmembrane flow on the internal flow resistance (Eqs.13–15), where Here,fis Fanning frictional factor,RerandReare radial and axial Reynolds number, respectively.αis the dimensionless slip parameter,Kis the membrane permeability (m s−1Pa−1),andvare the axial and radical flow velocity (m/s) inside the fiber, respectively. Liet al.reported that by introducingαto address the transmembrane flow, the simulations fit better with the experimental results than the traditional model on the basis of the Hagen-Poiseuille theory [10,37].For instance, the deviation between the experimental and simulated suction pressure calculated by the developed model (1.1%) was less than that (12.8%) obtained by the Hagen-Poiseuille theory as the operating flux was 22.8 L m−2h−1.The non-uniformity of the local flux distribution was found to be positively correlated with the fiber length and operating flux, but negatively correlated with the fiber inner diameter.Particularly, to optimize the fiber diameter and length, the water production effi-ciency (Y) of module as an objective function was calculated (Eq.16) [10]: wheregis the gravity constant,Lis the fiber length (m),Lwis the height difference between fiber and air nozzle (m),ρois the feed density (kg/m3),Lhis the distance from the liquid level to the fiber outlet (m),Qis the flow rate (m/s),Qois the aeration rate(m/s),pis the standard atmospheric pressure (Pa),Eis the energy consumption of membrane system (W). Fig.1.The influence of fiber diameter and length on the water production efficiency at the different operating flux of (a) 10, (b) 15, (c) 20 and (d) 25 L m−2 h−1, respectively.Copied with permission [10].Copyright 2015, American Institute of Chemical Engineers. Fig.2.(a) Schematic of forces excreted on a deposited particle and (b) comparison of the mass and average specific resistance of the cake between the experimental and calculated results.Copied with permission [40].Copyright 2010, WILEY-VCH Verlag GmbH and Co.KGaA, Weinheim. As shown in Fig.1a, under the operating flux of 10 L m−2h−1,Yincreased firstly and then reached a plateau with increasing the fiber length and decreasing the fiber inside diameter [10].As the operating flux increased to 15 L m−2h−1(Fig.1b),Yfirstly increased and then reduced with the increase of the fiber length.This trend was more obvious at the operating fluxes of 20 and 25 L m−2h−1(Figs.1c and d).Consequently, selecting a large fiber diameter and a reasonably long fiber length would benefitYat a certain averaged operating flux. In addition, to consider the effect of the fluid motion and convention on the permeate flux, Yeh used a complete momentum balance model integrated with the exponential model to simulate the permeate flux [16].The simulated results demonstrated that the operating pressure had a more significant effect than the feed concentration on the permeate flux.The completed mass and momentum balances-based models are lack of foulants properties influencing on filtration performance.The force balance models as other powerful tools have been used to analyze the behaviors of foulant deposition on membrane surface [38–43]. A force-balance model on the basis of the hydrodynamics theories was proposed to study the effects of operating flux, bubble size, and aeration rate on the specific filtration resistance and cake mass in the membrane filtration process [38–40].This model includes the inertial lift force (Fl), the drag forces generated by the permeate flow (Fp), the bubble flow (Fb), the suspension flow (Ft),the net gravitational force (Fg), and the net interparticle force (Fi)(Fig.2a).For example, the increased trend of cake mass (wc) and specific resistance (aav) were predicted by the model, with the theoretical curves very close to the experimental trends (Fig.2b).A narrower particle size distribution in the cake layer with a higher specific resistance was found at an increased aeration rate and a decreased bubble size.These predicted phenomena in accordance with the observations in experiments suggested the accuracy of the model to describe the cake properties. To investigate the effect of the particle with a wide size distribution on cake properties and filtration behavior, Lu and Hwang[41] proposed a force balance model for the cross-flow microfiltration (MF).The probabilities of particle deposition and the particle size distribution could be predicted from the theoretical critical frictional angle on the basis of the force analysis.It was assumed that when the frictional angle between particles was larger than the critical angle, the particle would be easily swept away.Otherwise, the particle would deposit stably.The predicted values of the specific resistance and cake porosity agreed very well with the experimental results during filtration of CaCO3solution.Hwanget al.[42] further investigated the effect of particle sizes from submicron to micron on the cross-flow filtration performance.They showed that the size distribution of particle in the cake layer became relatively uniform with increasing the cross-flow velocity, but became non-uniform when increasing the filtration pressure.Meanwhile, a higher filtration pressure resulted in a reduction in the cake porosity but an increase in the cake resistance.An opposite trend of cake properties was observed with the increasing cross-flow velocity.Moreover, to predict the filtration behavior under the aeration condition, a more common case for the submerged HFM system in practical applications, another complete filtration model was developed by combining the force balance model with the gas-liquid two-phase hydrodynamic model [43].It demonstrated that the aeration could aggravate the non-uniform profile of the local flux at the initial stage.However, since a larger local flux would result in more severe fouling, the local flux distribution would be selfadjusted by fouling as the filtration processed to become more uniform. Although these models provide deep insights into the filtration characteristics of the HFM, some challenges should be faced to simulate the real filtration process because of the complicated local hydrodynamics especially in the submerged HFM filtration process[44].Since the aeration not only disturbs the local gas-liquid-solid three-phase flow but also induces the movement of the flexible fibers, which intensifies the complication of local hydrodynamics[45], development of a simplified model incorporating the movement of fiber is the significant importance of prediction of real HFM filtration behavior.The local hydrodynamic around fiber not only determines the foulants removal but also affects local flux distribution along fiber [37].Establishment of a reliable hydrodynamics model helps us to comprehensively understand the local hydrodynamic environment around hollow fiber, and would be discussed in following section. The convection and diffusion equation is an attractive tool to describe the transport phenomenon occurring during the separation of solutes particularly in the convention-enhanced filtration process [46,47].For instance, Wüpperet al.[48] developed the convection and diffusion models to simulate the local filtration performance of hollow fiber dialyzers.It demonstrated that the transport of low and high molar mass solutes across the high-flux HFM was influenced by diffusion mechanism and diffusion-convection mechanism, respectively.Similarly, Curcioet al.[49] developed a semi-empirical model to differentiate the contributions of diffusion and convection to the transport of different solutes (i.e., the bovine serum albumin, glucose, apo-transferrin, and ammonia).The results showed that for the polysulfone (PSf) HFM, the convection only contributed significantly to the transport of low molecule weight solutes.However, for the polyethersulphone (PES) HFM, the convective contribution increased with the increase of the solute molecule weight. To overcome the limitations of classic models, including the concentration polarization model and the resistance-in-series model, a two-dimensional (2D) model on the basis of the convection-diffusion equation was developed to investigate the transport phenomena in UF [50].The predicted permeate fluxes were in excellent agreement with experimental data.The simulated results indicated that the fiber length had a significant influence on the profiles of the local concentration and permeate flux.Meanwhile, the convection-diffusion equations based 2D transport model could help in-deep analysis of the effect of module geometry and membrane transport properties on the efficiency of solute transport [51].The simulations indicated that the enhancement of convective and diffusive solute transport is beneficial for the removal of small-sized molecules by designing module geometry. In addition, Mortiet al.[52] provided a quantitative comparison of the convective and diffusive transport properties of homogeneous and asymmetric hemodialysis membranes using transport models.The local solute flux (Ji) of the HFM owning to both convection and diffusion could be expressed as follows (Eq.17): whereεbis local porosity,D∞is the Brownian diffusion coeffi-cient (m2/s),Cis the solute concentration (kg/m3), andKDandKCare the hindrance factors for diffusion and convection, respectively,representing the hydrodynamic interaction between the pore wall and solute. Fig.3.Variation of pressure along the fiber at the permeate side and at the retentate side for outside-in filtration mode.Copied with permission [18].Copyright 2009, Elsevier. The results presented that the clearance of the asymmetric membrane was more dependent on the molecular weight of solute in comparison with a homogeneous membrane [52].The sieving coefficient of the asymmetric membrane was less than those obtained from the homogeneous membrane.Similarly, Bakhshayeshiet al.[53] proposed a theoretical model based on the convection and diffusion models to illustrate the axial variations in TMP and bulk mass transfer coefficient.It confirmed that the TMP profiles and the bulk mass transfer coefficients were related to the flowrate through the fiber lumens and the growth in the concentration polarization boundary layer, respectively.On the basis of this work,a theoretical framework was further developed to investigate the influences of operating conditions (feed and permeate flowrates)and the module geometry (fiber length and number of fibers) on the dextran retention profile in HFM module [54].It demonstrated that the use of a module with a shorter fiber and higher packing density could obtain the best trade-off between backfiltration and concentration polarization.In addition, the profile of dextran retention was insensitive to variations in the flow rates of feed and permeate at the optimal conditions. Several studies have used the computational fluid dynamics(CFD) tools to study the influences of operating parameters on the performance for different applications using different geometries of HFM modules [55,56].Usually, finite element approach and finite volume approach are used in CFD simulations.Borsi and Lorain [57] presented a quasi-3D hydrodynamic model coupled with transport, adsorption and attachment equations.The parameters in this model depended directly upon the module characteristics (the number of fibers, membrane thickness,etc.).In addition, this simple model can be used for long-term simulations and allows quick testing and comparison of the filtration behaviors under different filtration parameters.For example, it can easily predict whether the plant could work at a higher operating flux with an improved or at least unchanged hydraulic efficiency.Similarly, the hydrodynamic behavior of the submerged HFM bioreactor at different flow directions and viscosities was explored by Leslieet al.using a porous media model and MBR CFD model [58,59]. Specifically, Güntheret al.[18] investigated the influence of the packing density on the permeate flow velocity along the fiber using a CFD based model.The results showed that increasing the packing density would result in a non-uniform permeate flux distribution.Especially, when the packing density was very high, filtration flux would decrease dramatically.In contrast, when the packing density was low, the permeate flux was higher at the upper part of the fiber (Fig.3).The influence of the packing density on the spatial deposition of particles along the fiber was further predicted by a numerical model [60], which was in accordance with the trends with respect to the permeate flux.With the highest packing density, particles deposited more easily at the bottom of the fiber for both the inside/out and outside/in filtration modes.This trend was inversed for the case of the lowest packing density.Consequently, a moderate packing density could result in a higher permeate flux and a more homogeneous flux profile along the fiber. In addition to the convection-diffusion equation, the concentration polarization model is a powerful and simplified tool to describe the transportation characterization inside the membrane filtration process. To predict the filtration performance of macromolecules such as protein and dextran in the cross-flow HFM modules, Bakhshayeshiet al.established a mathematical model to simulate the permeate flux on the basis of the concentration polarization model [61].The permeate flux (J) can be calculated by the following expression (Eq.18): whereCbis the bulk concentration (mol),Csis the solute concentration on the membrane surface (mol),kmis the mass transfer coefficient,Sois the solute sieving coefficient. The fouling layer was assumed as a constant viscosity with a linear fluid velocity profile.This model could successfully predict the permeate fluxes at different particulate suspensions [61].To take into account the effect of the finite cake layer thickness, a modification of the concentration polarization model with shearinduced diffusion was proposed to describe the cake thickness and local permeate flux [62].This model confirmed that a stagnant gel layer in the UF significantly affected the steady permeate flux.A similar model was developed to predict the profile of the cake thickness and filtration flux along the fiber in the cross-flow module by considering the convective flow and the hydrodynamic diffusion of the particle layer [63].It was found that the cake volume fraction and the local TMP varied from the inlet to the outlet of the module.However, the application of these developed models is limited to cases where the permeate flux is independent of TMP. To improve the accuracy of prediction, Mondalet al.further combined the concentration polarization model and serial resistance to investigate filtration behaviors in the steady-state laminarflow regime [64].This model was used to determine the transition from the mass- to pressure-transfer-controlled regimes along the fiber.The predicted fluxes were in accordance with the measured values.In addition, by considering the solute diffusivity near the membrane surface, Yehl and Zydney proposed a modified concentration polarization model to predict the permeate flux, which was much closer to the experimental data [65].Coupling the concentration polarization model with local hydrodynamic behavior, such as Navier-Stokes and continuity equation, could provide insight into the relationship between the local fouling and filtration features[66–68]. Flow hydrodynamics through porous media and inside the porous tube can be simulated by the well-known Navier-Stokes and continuity equations, which also inspire researchers to develop models for membrane systems [69,70].For example, a model describing the radial and axial TMP in a cylindrical cross-flow filtration module was proposed on the basis of the continuity and momentum equations [66].In addition to the TMP drop, this model coupled with the concept of shear-induced diffusion and the resistance model could simulate the average permeate fluxwhich can be calculated by using following equation (Eq.19): Fig.4.Comparison of the constant flux and pressure modes in terms of the crossflow velocity ratio RU and permeate velocity ratio RV.Copied with permission [71].Copyright 2011, American Institute of Chemical Engineers. whereLis the filter length (m),ais the particle radius (m),τwois the shear force (Pa),φois the volume fraction of bulk suspension particle,ηis the relative viscosity (μ(φ)/μo) andis the dimensionless excess particle flux. Mondor and Moresoli [66] found that the radial TMP drop decreased from the inlet to the outlet.The difference of TMP drop between the fiber outlet and inlet is related to the fraction of the fluid flowing across the membrane.Further, they provided an extension of the model to the case as a stagnant layer was formed on the hollow fiber membrane surface [67].This model was in consideration of the axial TMP variation.The effect of the stagnant particle layer on the pressure drop across both the fouling layer and the membrane was investigated using this model.It demonstrated that the thickness of stagnant layer increased from the inlet of the fiber, and gradually reached a maximum and then decreased at the outlet of the fiber.In addition, the effect of the fiber radius and particle size on the average permeate flux was further investigated using the developed model [68].The predicted results indicated that the position where a cake began to form gradually moved to the outlet as a result of a reduction of shear-induced diffusion back-transport.In addition, the average permeate flux increased with an increase of lumen radius.These predicted results indicated that both hydrodynamic and back-transport mechanisms simultaneously play a vital role in the cross-flow MF operations[68]. Furthermore, Kimet al.[71] proposed a perturbation approach of the continuity and Navier-Stokes equations to study the influence of the hydraulic resistance and membrane length on filtration behavior inside the fiber.It was found that the flow velocity inside the fiber exhibited an exponential variation along the fiber.As demonstrated in Fig.4, the constant flux and pressure modes presented a similar velocity profile for the short membrane with the dimensionless transport parameter (βξ)<1.Whereas, the crossflow velocity ratioRUwas always larger than the permeate velocity ratioRVasβξexceeded 1. In order to compare the filtration performances of different module configurations, a porous medium model was developed to describe the hydrodynamics of the HFM module operated in a variety of flow configurations, including the dead-end, the closed-shell,and the cross-flow modes as well as the co-current and countercurrent contacting modes [17,72].The fluid continuity and Darcy law were combined to present a set of 2D differential equations.Specifically, the effect of fiber expansion under wet conditions was also combined into the model.Simulations showed that the filtration performance in a cell-free extracapillary space (ECS) was primarily controlled by the membrane resistance.Compared to the cell-packed conditions, the effect of ECS hydraulic permeability on the permeate flux was significant.This mode was a feasible alternative to the counter-current operation.Moreover, Polyakov and Kazenin [73] derived analytical expressions to investigate the effects of flow rate, TMP, and the fiber geometry on the reversible membrane fouling.It was found that both the rectangular and radial depth membrane filtration modules were much more efficient than the existing cross-flow and dead-end devices.Kostoglou and Karabelas [74] focused on the filtration flow in a single fiber and the unidirectional flow in the multi-fiber module.To solve a series of simpler sub-problems, the geometrical and physical simplifications were introduced.The simplification of geometry was usually developed on the basis of the unit cell concept with stochastic parameters.It was found that the decrease of pressure and the increase of flux led to a non-uniform flux distribution.The increase in the ratio of outer/inner diameter would result in an increase of pressure drop in the fiber lumen [74].Another Reynolds averaged Navier-Stokes turbulence modeling approach was incorporated into CFD modeling to simulate the wall shear stresses in two different membrane module configurations [75].It is proven that a modified module configuration with tangential inlet and outlet has better shear stress distribution than the normal module configuration. Further, Zhuanget al.[76] systematically studied the flux profile in an outside-in dead-end HFM module using CFD simulation.Three dimensionless numbers were defined to determine the position with the maximum local flux and to quantify the energy utilization and flux distribution.The simulated results indicated that the better uniformity of the local flux profile but higher energy consumption could be obtained by using wide, short, low permeable, and sparsely packed fibers [77].The impact of the membranemodule shell manifold on the initial flow distribution and fouling deposition in an industrial-scale dead-end HFM module was further investigated by Zhuanget al.[78,79] using the CFD model.The flow impingement and wall flow result in the flux mal-distribution,which intensifies the energy consumption.To realize efficient filtration performance, even distributed and large-area inlet holes are suggested to achieve uniform local flow distribution and decrease energy consumption.In addition, the effect of fiber arrangement on the distributions of velocity field was investigated by Wuet al.[80].The staggered arrangement exhibited greater shear stress than the aligned arrangement at the same operating conditions.Meanwhile, the number and arrangement of membrane modules in a turbulence intensified unit can be optimized to achieve a stronger turbulence kinetic energy by using CFD simulations [81]. Although Navier-Stokes equation based modeling studies provide an accurate prediction of the hydrodynamics and the mass transfer in the membrane filtration process, accurate prediction of local filtration flux may be achieved with the help of the incorporation of different fouling mechanisms.To properly characterize the real hydrodynamic conditions, it is encouraged to integrate multiple models rather than establish a complicated and time-consuming model. Numerous models including empirical and rational calculations have been developed to predict the effect of membrane type, module configurations and operating conditions on the fouling behavior.However, there is still a lack of knowledge on the feasibility of different fouling models and on the fouling mechanisms behind the fouling dynamic.In particular, for some complicated filtration processes (e.g., MBR includes both biological and physical processes), individual model is difficult to simulate their real filtration performance.For instance, classical resistance-in-series theory has shown its potential for fouling modeling, but this work does not consider the mechanisms such as development of fouling layer, activity and deformation of biofilm.Therefore, the integrated models by taking into account the interaction among different parts of the system are highly encouraged.The resistancein-series model could be integrated with biological kinetic models to describe the filtration performance of submerged hollow fiber membrane in MBR [82].The CFD modeling coupled with Hagen-Poiseuille equation provides a quantitative tool to investigate the influences of backwash intensity and duration, and fiber length on effectiveness of backwashing in MBR system [83,84].However, establishment of reliable models to predict the practical large-scale membrane process is still a significant challenge.Further works are therefore recommended to fully understand the behavior of the major components responsible for membrane fouling, which can upgrade the accuracy of filtration modeling predictions. Even if satisfactory results have been obtained in short-term operation, the use of long-term running data for validation of those models should be made, which can improve their accuracy in practical application.The modeling task would become more complex when producing a complicated integrated model, which consumes high computational cost.The complexity of integrated model significantly depends on the structure of the selected single models.More efforts should be devoted to the balance of the selected simple models, and the collection of sufficient and appropriate data for model calibration and validation. On the one hand, it is the lack of experimental data appropriate for validating the developed fouling model, because the physical phenomena they predict are beyond the scope of the existing monitoring techniques.Meanwhile, some complex hydrodynamic conditions in the real applications are usually simplified in models,e.g., the non-uniformly distributed air bubbles between fibers[85,86], the axial and transversal liquid turbulent flow [87] as well as fiber movement caused by the injected air [88].The validation of these models is therefore needed by means of novelin-situmonitoring techniques (such as nuclear magnetic resonance, ultrasonic time-domain reflectometry) to be developed [89]. Another study worthwhile considering is the development of cost model based on the basic filtration models discussed in this study.It would help optimize the configuration of membrane system to satisfy the sustainable operation.Like all models, cost model should be operated at dynamic conditions and need to be validated as well.To enhance the applicability, the simulated cost results are suggested to be compared with full-scale running data.Meanwhile, a rigorous calibration procedure is necessary for the application of cost model. This work presented an overview and commentary of published modeling studies on MF/UF HFM processes.These studies give us a comprehensive understanding of the relationship between the local filtration performance and membrane fouling in HFM modules, which offer a strategy to improve the membrane module design with enhanced hydrodynamics.However, challenges still exist in practical applications.In general, the empirical model requires a large amount of data for model establishment and has limited predictive capability.Although rational models provide more realistic analysis, they often fail to include all relevant variables under inexact premises.These unavailable data thus make model application difficult or even impractical.Meanwhile, the local filtration behavior in the dynamic membrane filtration process is both complicated and numerous.Therefore, it may not be practical to incorporate all the complexities into a single model.To ensure the accuracy of prediction, future research may be invested in developing a reduced model for data interpretation and process design.Novel designs that enhance filtration uniformity are crucial for sustainable membrane filtration, especially for emerging highlypermeable membranes, as they suffer from more severe membrane fouling and concentration polymerization.In conclusion, for the development of fouling control strategies and appropriate module design, a deep understanding of local filtration behavior is a crucial issue. Declaration of competing interest The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper. Acknowledgments The study is supported by Program for Guangdong Introducing Innovative and Entrepreneurial Teams (No.2019ZT08L213),National Key Research and Development Program of China (No.2020YFA0211003), Key Special Project for Introduced Talents Team of Southern Marine Science and Engineering Guangdong Laboratory (Guangzhou) (No.GML2019ZD0403), and National Natural Science Foundation of China (No.21878230).

2.3.Mass and momentum balances-based model

2.4.Force balance model

2.5.Convection and diffusion model

2.6.Concentration polarization model

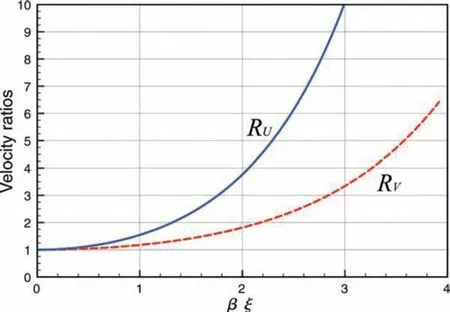

2.7.Navier-Stokes and continuity equation

3.Perspectives and challenges

4.Conclusions

Chinese Chemical Letters2022年8期

Chinese Chemical Letters2022年8期

- Chinese Chemical Letters的其它文章

- Adsorptive removal of PPCPs from aqueous solution using carbon-based composites: A review

- Recent advances in DNA glycosylase assays

- Chiral pillar[n]arenes: Conformation inversion, material preparation and applications

- Recent progress in carbon-based materials boosting electrochemical water splitting

- Working principle and application of photocatalytic optical fibers for the degradation and conversion of gaseous pollutants

- Crystal facet-dependent electrocatalytic performance of metallic Cu in CO2 reduction reactions