Photochemical effect driven fluid behavior control in microscale pores and channels

Shuli Wang, Ruimin Zhou, Yaqi Hou, Miao Wang, Xu Houa,b,,e

a Department of Physics, Research Institute for Biomimetics and Soft Matter, Fujian Provincial Key Laboratory for Soft Functional Materials Research, Jiujiang Research Institute, College of Physical Science and Technology, Xiamen University, Xiamen 361005, China

b Institute of Artificial Intelligence, Xiamen University, Xiamen 361005, China

c State Key Laboratory of Physical Chemistry of Solid Surfaces, College of Chemistry and Chemical Engineering, Xiamen University, Xiamen 361005, China

dCollege of Materials, Xiamen University, Xiamen 361005, China

e Tan Kah Kee Innovation Laboratory, Xiamen 361102, China

ABSTRACT Manipulating the fluid transport in the microscale pores and channels is playing a paramount role in the realization of the versatile functions of microfluidics.In recent years, using light to control the fluid behavior in the microchannels/pores has attracted many researchers’attention due to the advantages of light such as non-contact stimulation, tunable excitation, high spatial and temporal resolution.With efforts, great achievements and progresses have been achieved for photochemical effect driven microscale flow control, including fluid pumping, flow rate control, and fluid mixing, etc. In this review, we discuss the responsive mechanisms of photochemical effect driven fluid behavior control at the microscale.We also give a comprehensive review on the latest research progresses in photochemical effect controlled microfluid behaviors.Besides, prospective opportunities for the future development of light control of microscale flow are provided to attract scientific interest for the fast development and applications of various microchannel/pore systems.

Keywords:Photochemical effect Fluid behavior Microscale pore Microchannel Microfluidics

1.Introduction

Manipulating the transport behaviors of fluids in the microscale channels and pores plays an important role in realizing the specific functions of microfluidic systems [1–10].The ratio of surface area to volume increases dramatically with the decrease of channel dimension, and viscous force and interfacial force become dominant to the fluid transport in microscale channels and pores,which makes the fluid regulation possible through changing the surface properties of the channels/pores or the properties of the fluids [11,12].With the rapid development of chemical synthesis for functional materials, and micro-/nano fabrication technologies, researchers have developed a variety of microscale fluid control units, such as micropumps [13–16], microvalves [17–19], micromixers [20,21], microseparators [22,23].These micro units have significantly advanced the fundamental researches and practical applications of microchannels/pores-based microfluidic systems in chemistry, biology, physics, materials science,etc.However, traditional microscale flow control units are generally highly specified for given operations, and cannot be modified for new applications once fabricated [24].In order to meet the needs of more intelligent applications, a variety of responsive units have been developed in microchannels/pores for actuating microscale flow through smart regulation of the chemical/physical properties of the fluids or solid surfaces under external stimuli.These external stimuli can be temperature [25,26], light [27–29], electricity [30,31], magnetism [32],force [33], pH [34],etc.Each kind of stimulus-responsive unit has its specific advantages and application scenarios.Among these external stimuli, light can provide remote stimulation, tunable excitation (power and wavelength), high spatial resolution, and excellent temporal resolution [35,36].In addition, light is also biocompatible and can be utilized for regulating biological fluids in a highly precise and non-invasive manner.

In a light controlled microchannel/pore system, the properties of the transport fluids or the solid surfaces are dynamically controlled by light irradiation through photochemical or photophysical effect.Microscale flow control by photochemical effects was mainly realized by light induced wettability changes and light induced deformations of the microchannels/pores [37,38].In addition, light driven microfluid control can also be realized by utilizing the synergistic effect of photothermal effect and temperatureresponsive materials [39,40].In these situations, there always exist chemical property changes in the system, which makes the more flexible light driven microfluid control possible by rational design of the relevant chemical reactions.Optical tweezer and light induced Marangoni effect are the two common representatives that use the photophysical effect to regulate microfluid behaviors [41–43].Based on the above photosensitive effects, researchers have realized a variety of light responsive regulation of fluid behaviors such as fluid pumping, flow rate control, and mixing, which promotes the fundamental researches and practical applications of microchannel/pore systems and optofluidics.Some recent reviews have already discussed the optical tweezers and light induced Marangoni effect for microscale flow control [44–46].Therefore, we attempt to review the recent progresses of the light control of microfluid through photochemical effects, mainly including direct photochemical effects and synergistic effects of photothermal effects and thermal-responsive materials.

This minireview is organized as follows.Firstly, we discuss the responsive mechanisms of photochemical effect driven fluid behaviors control at the microscale.Secondly, we focused on the latest research progresses in photochemical effect driven fluid behaviors in microscale pore and channel systems, including pumping, flow rate control, and mixing of microfluid.Finally, we make a brief prospect of the future development and application of the field.

2.Responsive mechanisms of photochemical effect driven microfluid control

2.1.Light induced wettability change

Light can change the surface energy of the solid surface or the interfacial tension between the fluid and solid surface to induce the change of wettability of a liquid on a surface.Surface wettability refers to the degree of a liquid can wet a given surface [47–49].The contact angle is the most direct and common parameter to characterize the wettability of a liquid on a solid surface.For an ideal flat solid surface, the contact angle (θ) is determined by the interfacial tension of the solid-gas interface (γSG), solid-liquid interface (γSL), and liquid-gas interface (γLG) through the Young equation [50]:

For a liquid in a microscale channel or pore, the Laplace pressure (P) that exist at the curved interface is determined by the contact angle of the liquid on the channel surface (θ), the surface tension of the liquid (γ), and the dimension of the channel/pore(d).For a round channel/pore, the Laplace pressurePequals to 4γ/d.If the contact angle is smaller than 90°, the Laplace pressure has a positive effect on the microfluid transport, and promotes the fluid transport in the channel/pore.But Laplace pressure becomes a barrier for microfluid transport if the contact angle surpasses 90°.In most practical situations, the contact angle of a static droplet varies between the receding contact angle and advancing contact angle.Generally, a microfluid can be transported in a microchannel/pore when the applied pressure (ΔP) is larger than the Laplace pressure calculated from the advancing contact angle.

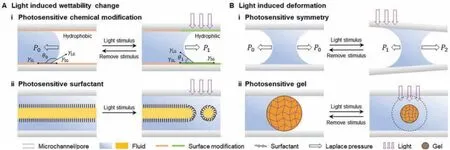

Through photosensitive chemical modifications on the solid surfaces, the wetting property of the surfaces can be controlled by the light stimulus to regulate the microscale fluid behaviors.As shown in the schematic in Fig.1A-i, surface wettability can be changed from hydrophobic to hydrophilic after light stimulus, which totally changes the effect of Laplace pressure from pinning the liquid to promoting the liquid.The light induced wettability change usually occurs in channel/pores with titanium dioxide (TiO2) modifications[38], and responsive polymer brushes such as poly(N-isopropyl acrylamide) (PNIPAM) [40].TiO2is one of the most traditional yet promising photocatalysis, with a band gap of 3.2 eV for the anatase phase, and surface of TiO2becomes hydrophilic under photogenerated hydroxyl groups under UV illumination.When the system temperature is lower than the lower critical solution temperature(LCST) of PNIPAM, the isopropyl groups on the PNIPAM polymer chains form intermolecular hydrogen bonds with water molecules,making the PNIPAM brushes hydrophilic.When the temperature is higher than LCST of PNIPAM, the intermolecular hydrogen bonds breaks and the intramolecular hydrogen bonds are formed, and the PNIPAM brushes become hydrophobic.Therefore, through changing the system temperature by photothermal effects under light irradiation, we can dynamically change the surface wettability by light.

In addition, light induced wettability change can also be realized through photoisomerization of photosensitive surfactants between the fluids and the solid substrates [51].Surfactant is an essential part of multi-phase flow in microfluidic systems [52].Surfactant is a substance that can self-assemble on the interface between a solution and a different phase (gas or solid).Surfactant has a chemical structure with two distinct functional groups with different affinity within a single molecule.Photosensitive surfactant is a kind of specific surfactants that their chemical structure also contained photosensitive components, such as azobenzene (Azo)group.Azo group undergoes an isomerization from atranstocisform under UV irradiation [53].Azo has a strongπ–π∗band in the UV region, and a weak n–π∗band in the visible region.The Azo isomerizes fromcistotransform under visible light irradiation.The reversible photoisomerization changes the geometry of Azo from planar to nonplanar upon irradiation, decreasing the distance between theparacarbon atoms from 9.9to 5.5, increasing in the dipole moment from 0.5 D to 3.1 D.Therefore, the polarity of the photosensitive surfactant molecule can be regulated by light irradiation induced isomerization [54], which makes the flow control of multiphase flow in a microchannel possible by the light stimulus.As shown in the schematic in Fig.1A-ii, the fluids show laminar flow in the channel under appropriate conditions(including channel dimension, flow rate, concentration of surfactant,etc.).After being irradiated by light, the surfactants undergo a configuration change and lead to the increase of surface tension between the fluid (yellow) and the microchannel surfaces, leading to a larger contact angle of the fluid on the surface of the channel/pore.The resulting weakened wettability destabilizes the jet regime and induces the formation of a stable droplet regime under constant conditions, providing an active regulation of microfluid control.

2.2.Light induced deformation

Light induced deformation includes the deformation of the profile of channels/pores and the volume change of responsive bulk materials in the channels/pores.Considering a droplet in a channel with symmetric shape and homogeneous surface chemical compositions, the Laplace pressure at the two sides of the droplet have the same value but opposite directions.Therefore, the two Laplace pressures offset each other and the droplet is static.But in a conical shaped channel or pore, the different curvature radius of the droplet at the two sides induces different Laplace pressure in the opposite directions, which makes the droplet self-propel towards one direction when the Laplace pressure difference conquers the resistance force [55].As shown in Fig.1B-i, if the surface is lyophilic, the droplet will move towards the narrower end.However, the droplet moves towards the wider end when the surface is lyophobic.Therefore, responsive change in the shape of a channel/pore under light stimulus endows the microchannel/pore system with smart regulation capability for actuating microfluids.Light induced deformation could be realized by fabricating microchannels/pores with materials capable of photodeformation,such as linear liquid crystal polymers with an alkyl backbone containing double bonds and photoresponsive Azo moieties in side chains [56].The photoisomerization of Azo under light stimuli can reversibility change the orientation of liquid crystal molecules, and further deforms the profile of the channel.

Fig.1.Typical examples of light driven microfluid control.(A) (i) Light induced wettability change of the surfaces from hydrophobic to hydrophilic leads to the effect of Laplace pressure on the fluid change from negative to positive.(ii) Light irradiation changes the surface tension through the configuration of surfactant, resulting in the wettability change of the fluid on the solid surface, which further changes the profile of the fluids.(B) (i) Light induced asymmetric deformation of the channel leads to the different Laplace pressure on the two sides of the droplet and drives the static droplet towards a specific direction.(ii) Light induced volume decrease opens the pathway for fluid transport in the channel/pore.

The volume of responsive bulk materials inside the microchannel can be regulated by the light stimulus.As shown in Fig.1Bii, the swollen state of the bulk material hinders the microscale flow through the channel.Phase transition under a light stimulus induce the collapsed state of the bulk material, and the resulting volume change opens a pathway for the fluid transport.Such kind of photoresponsive bulk material usually contains photosensitive groups such as Azo, spiropyran (Sp).Sp is a photo-chromic group that undergoes a heterocyclic ring cleavage at the C–O spiro bond to form a highly conjugated chromophore, the merocyanine(Mc) isomer, which absorbs strongly in the visible region [53].The open-ring Mc isomer can return to the initial close-ring Sp through a photo-chemical process.Incorporation of Azo or Sp group in the polymer matrices endow them with direct light responsiveness.In addition, temperature responsive gels such as PNIPAM hydrogels combined with components with excellent photothermal effect are also integrated into microchannel/pores to make the system responses to light stimulus.Gold nanoparticles, carbon nanotubes,MXenes are usually used to convert light to thermal energy for inducing the phase change of thermoresponsive materials.

3.Photochemical effect controlled microfluid flow behaviors

3.1.Fluid pumping

Fluid pumping is the premise and necessary condition for realizing various functions of microchannel/pore systems [57].Syringe pump and pneumatic pump are commonly used to transport fluids in the channels/pores.In addition, inner surface designs of microchannel/pores also provide alternatives for fluid pumping.Optical tweezers and light induced Marangoni effects have been utilized for light responsive fluid pumping in microchannels.Recently, light induced deformation of the channels provides a new approach for fluid pumping.Yuet al.reported a light induced asymmetric deformation of microchannel for controllable photo driven microfluid pumping [37].The photodeformable microchannel is fabricated by a photosensitive linear liquid crystal polymer(LLCP) with an alkyl backbone containing double bond and photoresponsive Azo moiety in the side chain.Asymmetric geometry occurs under irradiation of attenuated 470 nm light along the microchannel.The azobenzene mesogens are photoisomerized fromtranstocisisomerization under a blue light irradiation, and realign along the direction that is perpendicular to the polarized direction.Their experimental results show that photoinduced reorientation results in the increase of cross-sectional area of the round microchannel through decreasing the thickness of the microchannel and the elongation of the perimeter of the channel.A higher light intensity induces a more significant deformation of the microchannel.Asymmetric cone-like geometry of the deformed channel generates a capillary force to drive liquids in the direction along the light attenuation, and the moving direction can be changed by reversing the direction of attenuation.Long distance pumping and uphill pumping are also achieved by the photodeformation.Very importantly, their photoresponsive microchannels can pump not only simple polar or nonpolar liquids (such as water, ethanol, acetone, ethyl acetate, hexane, silicone oil) but also complex fluids(such as emulsion, liquid–solid fluid mixtures, petrol), demonstrating the wide applicable range of the light induced fluid pumping through the photodeformation of microchannels.

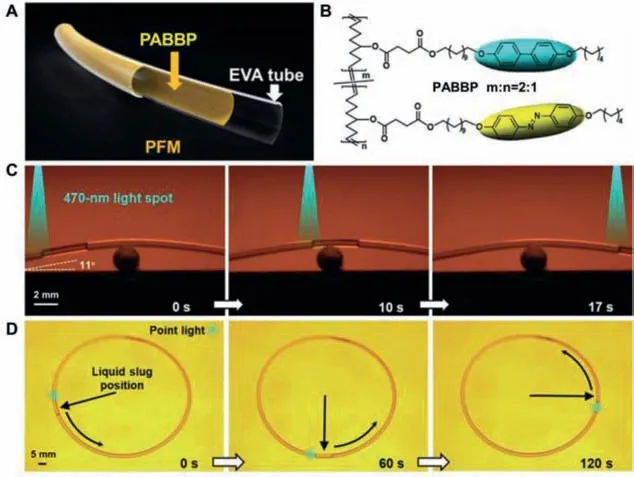

Afterwards, Yuet al.reported light controlled fluid pumping in a photocontrollable flexible microtube (PFM) that possesses a twolayered structure, with a photodeformable LLCP layer inside and a flexible supporting layer outside (Fig.2A) [58].To make the LLCP with excellent deformability and robust mechanical properties,they synthesized a new Azo containing LLCP, polycyclooctene with azobenzene and biphenyl side chains at 1:2 ratio (PABBP), by ringopening metathesis polymerization (Fig.2B).PFM was prepared by self-assembly of PABBP on an ethylene-vinyl acetate (EVA) copolymer microtube.As shown in Fig.2C, an isopropanol slug can be driven in the curved microchannel by 470 nm light because of the light induced asymmetric deformation of the microchannel and even climb over a slope of 11° incline at the speed of 0.4 mm/s.Due to the good flexibility of the PFM, it was programmed into various shapes.Fig.2D shows the light driven propelling of an isopropanol slug in a closed-loop microchannel, which cannot be realized by conventional syringe pumps.

3.2.Flow rate control

In the microchannel/pore systems, valves are essential to regulate the flow rate at the microscale.Up to now, various electric,magnetic, thermal, piezoelectric, light responsive microvalves have been developed.Light responsive microvalves are usually designed based on the light induced wettability change of solid surfaces or light induced volume change of bulk materials.

Fig.2.Light induced asymmetric deformation of microchannels for liquid pumping.(A) Schematic representation of the two-layered structure of the PFM.(B) Chemical structure of the PABBP.(C) Photographs show the light directed transport of an isopropanol slug in a curved PFM.(D) Photographs show the pumping of an isopropanol slug in a closed-loop microchannel.Reproduced/copied with permission[58].Copyright 2019, Wiley-VCH.

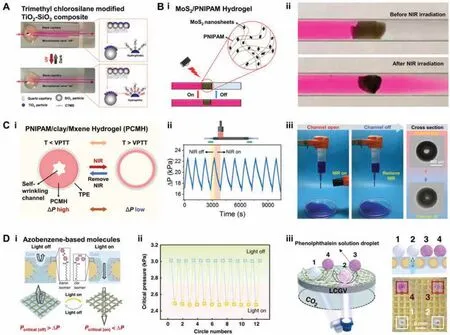

In a microchannel/pore, the hydrophobic area act as a burst valve, and the on/off switch is controlled by the driving pressure of the fluid.With light responsive chemical modifications,the wettability switches between hydrophobic and hydrophilic under the light stimulus, which enables exploiting both negative and positive pressure differences for microfluid control.Based on this,various photoresponsive microvalves have been developed.Demiret al.prepared micrometer scale pores in a titanium foil through laser microdrilling, and modified a TiO2layer on the surfaces of both the inner pores and outer membrane surfaces through anodic oxidation of titanium [59].After being stored in dark, the surfaces showed hydrophobic wettability, and the water did not pass through the micropores.After irradiation with UV light, the wettability of the surfaces became hydrophilic and water was transported through the pores at the same driving pressure, demonstrating a successful light controlled microvalve operation.Menget al.developed a UV-driven microvalve by photoresponsive wettability change of the microchannel with trimethyl chlorosilane modified TiO2/SiO2composite [38].In this microchannel, the surface wettability changed from hydrophobic to hydrophilic due to the photogenerated hydroxyl groups under UV illumination, resulting in the state of microvalve changed from the “off” to “on” (Fig.3A).The on/off switch of the microvalve can be recycled after repeatable UV irradiation and dark storage.Zhanget al.reported infrared light driven microvalve operation by thermoresponsive anisotropic wettability of Janus silicon pillars [40].

Light induced responsive volume change of bulk materials provides another way for microvalve design.Sumaruet al.developed a photoresponsive polymer gel microvalve through the local light irradiation [60].The microvalves were prepared byin-situpolymerization of photoresponsive gel composed of PNIPAM functionalized with spirobenzopyran chromophore in the microchannel, and the microvalves are opened by shrinkage of the gels under blue light irradiation.Diamondet al.reported light actuated iongelbased microvalves byin-situpolymerization of the iongels with benzospiropyran units and phosphonium-based ionic liquids, and the response time of the microvalves varied with the composition of the iongels [61].Fanet al.realized a near-infrared (NIR) light responsive microvalve by polymerizing PNIPAM hydrogel with MoS2nanosheets in the microchannel (Fig.3B-i) [62].The MoS2/PNIPAM hydrogel presents a reversible volumetric change in response to NIR irradiation, leading to the light responsive on/off switch of microfluids (Fig.3B-ii).

Wagneret al.reported a light regulation of the flow rate of microfluids byin-situpolymerization of PNIPAM hydrogel with graphene oxide nanoparticles [63].Recently, Wuet al.developed a blood-vessel like microchannel with a capability of responsive flow regulation of fluids [64].As shown in Fig.3C-i, the microchannel was composed of PNIPAM/clay/MXene hydrogel (PCMH)in the inner layer and a soft and highly stretchable styreneisoprene-styrene block copolymer based thermoplastic elastomer(TPE) in the outer layer.The inner PCMH layer swells and shrinks by switching the temperature below and above volume phase transition temperature (VPTT), resulting in reversible channel size changes.The inner PCMH can respond to either thermal or photothermal stimulus.NIR illumination induces the reduction of flow pressure because of the shrinkage of the inner PCMH layer and channel expansion, while the flow pressure increases due to the swelling of the PCMH layer after removing the NIR (Fig.3C-ii).In addition, non-contact NIR-induced flow transport and blocking can also be realized to regulate the fluid flow (Fig.3C-iii).Zhaoet al.reported a light responsive graphene-doped PNIPAM hydrogel microchannel with inverse opal structures [65].The flow rate of fluid in the microchannel could be regulated by shrinking of the hydrogel under NIR irradiation, and the deformation of the microchannel was reflected by the structural color change of the inverse opal structures.

Liquid gating membranes utilize a capillary stabilized functional liquid as a pressure-driven, reversible, and reconfigurable gate to fill and seal the pores/channels on demand [66–69].In recent years, various liquid gating pores and channels have been developed by the designs of the solid-liquid interface, liquid-liquid interface, and liquid-gas interface in the system to smartly control the fluids through the pores and channels [32,70-72].Through rational interfacial designs, the liquid-filling microscale pores can be closed by the liquid sealing and opened with a liquid-lined pathway under pressure, and the liquid gating pores can dynamically switch the flow behaviors of transport fluids.Most recently, Houet al.proposed a light-responsive liquid gating pores system for positional flow control [73].The light responsive liquid gating pores are prepared by infusing a functional liquid in the porous membrane with Azo-based chemical modifications (Fig.3D-i).The reversible photoisomerization of Azo-based molecular modifications under UV illumination changed the solid–liquid interaction between the solid surface and the gating liquid, which further induces the variation of the critical pressures of the system (Fig.3D-ii).Before UV illumination, the chemical modification shows atransform and the affinity between the solid surface and the nonpolar gating liquid is strong, resulting in a large critical pressure for fluid transport.When irradiated by UV light, the Azo-based molecular modification undergoes atranstocisphotoisomerization, which leads to the increase of polarity of the solid, decreases the affinity between the gating liquid and the solid surface, and further decreases the critical pressure.Therefore, when the driving pressure of the fluid is fixed between the critical pressures with and without UV illumination, the on/off state of the liquid gating pores can be realized by UV irradiation.In addition, due to the high spatial resolution of light, the positional opening of liquid gating pores can be realized(Fig.3D-iii).

Fig.3.Light responsive microvalves design for flow rate control in the microchannel or micropores.(A) On/off switch of the microvalve test results and schematic of UV/dark actuated wettability change of the trimethyl chlorosilane modified TiO2/SiO2 composite on the microchannel surface.Reproduced/copied with permission [38].Copyright 2014, American Chemical Society.(B) (i) Schematic illustration for the MoS2/PNIPAM hydrogel-based light-controlled microvalve.(ii) On/off switch of the microvalve by NIR irradiation.Reproduced/copied with permission [62].Copyright 2016, American Chemical Society.(C) (i) Schematic illustration of the layered structure of PCMH@TPE microchannel and the working principle under responsiveness.(ii) Real-time monitoring of the pressure changes of PCMH@TPE microchannel with and without NIR illumination.(iii) Open and close of PCMH@TPE microchannel by NIR stimulus.Reproduced/copied with permission [64].Copyright 2020, Royal Society of Chemistry.(D)(i) Schematic of the light induced molecular photoisomerization and reconfiguration of gating liquid for light controlled fluid transport through light responsive liquid gating pores.(ii) Critical pressure of the light responsive liquid gating pores with and without UV irradiation.(iii) Positional controlled fluid transport of the light-responsive liquid gating pores system.Reproduced/copied with permission [73].Copyright 2021, Springer Nature.

3.3.Fluid mixing

Mixing of different fluids in the microchannels is essential for microfluidic devices, which is critical for realizing the concept of lab-on-a-chip.However, the Reynold number of fluids in the microchannel is low and the fluids show laminar flow, and the mixing of fluids is predominantly determined by diffusion.Various microchannel surface structure, such as micropillars and staggered herringbone structure, have been designed in the microchannel to promote the mixing efficiency.The abovementioned structures are typically static and do not allow the users to vary their structure configurations on their demand.To overcome the limitations, active micromixers have been developed by incorporating responsive materials into microchannel, enabling the users to determine the degree of mixing.Among these active mixers, light responsive mixing possesses the advantage of remote controllability, flexible design, and high time and spatial resolution.Light controllable mixing can be realized by light induced wettability change and light induced deformation.

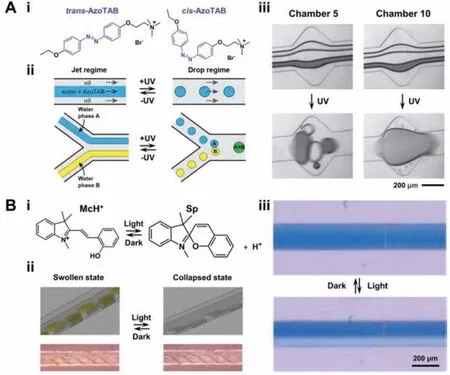

The wettability of the fluids on the solid substrate is important for droplet generation and mixing in microfluidics.Baiglet al.reported the light responsive switching of flow regime from tube phase to droplet phase [51].The configuration of the cationic photosensitive Azo trimethylammonium bromide surfactant (AzoTAB)has a transition fromtranstociswhen illuminated with UV light,which results in the increase of surface tension of the aqueous solution of AzoTAB and the contact angle of the solution on the surface, leading to the transition of “tube” regime to “droplet”regime.In a later work, the light induced water microdroplets were utilized as stirrers to conduct a photoresponsive mixing of the two continuous oil phase flows [54].Later, they reported a highefficient mixing of fluids under light stimulus by using a dual flow focusing microchannel [74].As shown in the schematic in Fig.4A,dual droplets generation can be realized under UV light irradiation,and can be mixed in the chambers in the downstream.However,the two water phases were never mixed in the microchannels due to the laminar flow regime without UV irradiation.

Light induced reversible deformations of gels in the microchannels also provide a mixing strategy in microfluidic systems.Schenninget al.designed a light induced micromixer by filling a photoresponsive hydrogel in grooved structures of the microchannel[75].The photoresponsive hydrogel is based on PNIPAM containing a crosslinker, acrylic acid as internal proton donor, and Sp as light responsive moiety.Under the exposure of blue or white light emitting diode light, the polar Mc isomerizes to the apolar Sp (Fig.4B-i), resulting in shrinkage of the light-responsive hydrogel.As shown in Fig.4B-ii, there is an apparent height difference of the groove filled hydrogel structures before and after irradiation.When the hydrogel is in a swollen state without irradiation, apparent mixing of fluids was observed in the microchannel (Fig.4B-iii).After illumination, the hydrogel shrunk, resulting in an almost flat channel surface structures and the fluids showed laminar flow.

4.Conclusion and perspective

Light actuation provides a flexible regulation manner for the active fluid transport behavior control in microchannels/pores, with advantages of non-contact stimulation, tunable excitation, high spatial and temporal resolution.In this review, we discussed the responsive mechanisms of photochemical effect driven fluid behaviors control in the microchannels and pores, and discussed the latest research progresses in light regulated microflow control by photochemical effect.With rational photoresponsive chemical modifications of the solid surfaces, responsive bulk materials in the channels, and photoresponsive surfactant design at the interfaces,we can establish dynamic and responsive light control of fluid behaviors in the microchannels/pores, such as pumping of fluids, flow rate control of fluids, and mixing of fluids.

Fig.4.(A) (i) trans and cis isomerization of the AzoTAB surfactant.(ii) Schematic illustration of the light responsive droplet generation in a single microchannel and two populations of droplets formation in dual flow focusing microchannel to be mixed downstream.(iii) Representative microscopy images of the flow behavior in the chambers before and under UV illumination.Reproduced/copied with permission [74].Copyright 2016, Elsevier Ltd.(B) (i) Photoisomerization of protonated Mc to Sp in an acidic environment and the corresponding thermal back reaction.(ii) Schematic representation and photographs of the height difference of the groove filled hydrogel mixer before and after illumination.(iii) Micrographs show in the mixing state and the nonmixing state before and after illumination.Reproduced/copied with permission [75].Copyright 2018, Wiley-VCH.

Albeit great progress, there are still many challenges for this research field.Nowadays, the response time of some photochemical effect driven systems is relatively long such as several minutes, which hinders the real applications of the microdevices.Therefore, the design and synthesis of the novel surface modifications, bulk materials, and photoresponsive surfactants with quickresponsiveness are urgently required.In addition, a simple combination of light sources and microchannel/pores leads to a large volume of the devices, which may not meet the requirements of practical applications.Thus, highly-integrated and reliable design of light sources and microchannel/pores system is required to improve the portability of the microfluidic system.With the rapid development of chemical synthesis for responsive materials, we expect the proposing of new light responsive mechanism for microscale flow control to the fundamental researches and future applications of the microdevices.We also anticipate the future indepth applications of light actuation of microfluids in chemistry,biology, materials, energy-related areas, and the future development and commercialization of optofluidics.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Nos.52025132, 21975209 and 22005255), the National Key R&D Program of China (No.2018YFA0209500), the Overseas Expertise Introduction Project for Discipline Innovation (111 Project, No.B16029), the Fundamental Research Funds for the Central Universities (No.20720190037).

Chinese Chemical Letters2022年8期

Chinese Chemical Letters2022年8期

- Chinese Chemical Letters的其它文章

- Adsorptive removal of PPCPs from aqueous solution using carbon-based composites: A review

- A review on hollow fiber membrane module towards high separation efficiency: Process modeling in fouling perspective

- Recent advances in DNA glycosylase assays

- Chiral pillar[n]arenes: Conformation inversion, material preparation and applications

- Recent progress in carbon-based materials boosting electrochemical water splitting

- Working principle and application of photocatalytic optical fibers for the degradation and conversion of gaseous pollutants