An Overview of Metal–Organic Frameworks for Green Chemical Engineering

Xiang-Jing Kong,Jian-Rong Li

Beijing Key Laboratory for Green Catalysis and Separation &Department of Environmental Chemical Engineering,Beijing University of Technology,Beijing 100124,China

ABSTRACT Given the current global energy and environmental issues resulting from the fast pace of industrialization,the discovery of new functional materials has become increasingly imperative in order to advance science and technology and address the associated challenges.The boom in metal–organic frameworks(MOFs)and MOF-derived materials in recent years has stimulated profound interest in exploring their structures and applications.The preparation,characterization,and processing of MOF materials are the basis of their full engagement in industrial implementation.With intensive research in these topics,it is time to promote the practical utilization of MOFs on an industrial scale,such as for green chemical engineering,by taking advantage of their superior functions.Many famous MOFs have already demonstrated superiority over traditional materials in solving real-world problems.This review starts with the basic concept of MOF chemistry and ends with a discussion of the industrial production and exploitation of MOFs in several fields.Its goal is to provide a general scope of application to inspire MOF researchers to convert their focus on academic research to one on practical applications.After the obstacles of cost,scale-up preparation,processability,and stability have been overcome,MOFs and MOF-based devices will gradually enter the factory,become a part of our daily lives,and help to create a future based on green production and green living.

Keywords:Metal-organic frameworks(MOFs)Application Green chemical engineering

1.Introduction

The beginning of the 21st century has been markedly characterized by immense pressure to implement energy conservation and emission reduction,and by a continual growth in demotic environmental awareness.Toward the alleviation of critical environmental concerns,a relatively new field of industry—namely,green chemical engineering—has gained tremendous impetus,as it promotes chemical products and processes that mitigate and/or eliminate the use and generation of hazardous substances[1,2].Such sought-after technological innovations require competitive targeted products in order to meet both market demand for remarkable nano-and micro-scale end-use properties,and environmental demand for sustainable meso- and macro-scale industrial processes.The ascendance of green chemical engineering underlines the necessity of discovering novel and versatile functionalized materials that can serve as platforms for multiple applications.

Metal–organic frameworks(MOFs),which are constructed from inorganic nodes(metal ions or clusters)and organic linkers,have aroused enormous attention due to their structural diversity,property uniqueness,and functional tailorability,particularly for the applications in green chemical engineering[3,4].The past decades have witnessed rapid growth in the design,synthesis,characterization,property,and application exploration of MOFs[5,6].Unlike traditional inorganic materials,MOFs permit close control of their composition,morphology,pore property,and function by the careful selection of building units and the incorporation of smart functionalities;this greatly widens the scope of their applications and improves their efficiency in given applications[7].

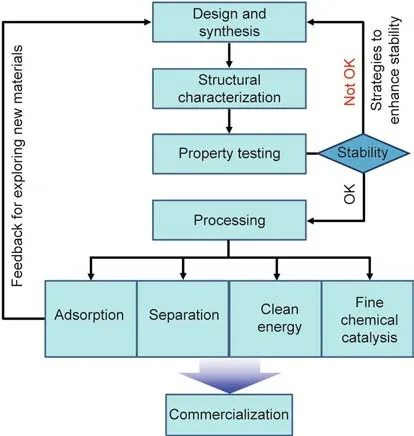

This review is not intended to be an exhaustive literature collection that minutely describes the basic compositions,structural features,and all inherent properties of MOFs.Several dedicated reviews have already been published for this purpose[2–13].Herein,we intend to provide a brief introduction to MOFs from the perspective of their synthesis and applications in green chemical engineering.This article is organized into the following sections:①methodologies of MOF synthesis and scale-up preparation;②general methods for MOF structural characterization and stability testing,strategies to enhance stability,and processing approaches;③several representative and cutting-edge domains in which many state-of-the-art MOFs would serve as good candidates for potential industrial applications,which would in turn instruct the exploration of new materials;④viability analysis of MOFs in commercialization and industrial implementation;and⑤outlooks for both academic research and practical applications,as illustrated in Fig.1.Overall,our aim is to show that MOFs can be much more than just intellectual exercises;they can make a difference in the course of changing the world.We hope that this review will catch the attention of both chemists and engineers,and will stimulate more research interest in the design and application exploration of MOF materials to push forward green chemical engineering.It should be pointed out that MOF composites and MOF derivatives also play a significant part in many research fields related to green chemical engineering,in which they may show improved performance in specific applications[14–16].Such materials always function through complex mechanisms,which totally differ from those of pristine MOFs,thus escaping discussion.

2.Synthesis

The synthesis of MOFs has been attracting close attention throughout their rapid development[5,8,17].The main objective in MOF synthesis is to establish appropriate synthesis conditions under which the desired compound is able to nucleate and grow.The concepts of miniaturization and parallelization for largescale screening conditions dramatically accelerate the discovery of new MOFs,and promote synthesis method optimization.For green and industrially sustainable MOF production,however,different criteria should be taken into consideration,namely:①choosing cheaper,safer,and/or biocompatible building units;②decreasing energy input;③using innocuous reaction media;④easy activation;and ⑤continuous manufacturing[18].

2.1.General synthesis

Fig.1.Flow diagram of MOF evaluation routes in green chemical engineering from foundation to application.

To date,numerous prominently varied synthetic methodologies have been developed for synthesizing MOFs[5,8,17].In general,appropriate MOF synthesis conditions should allow coordination bonds to be formed,broken,and reformed for error correction and extensive propagation during crystallization.Solvothermal synthesis is the most effective and widely adopted method;in this method,a metal species and a multi-topic organic ligand are mixed with a high-boiling-point solvent(e.g.,dimethylformamide(DMF),dimethylacetamide(DMA),or dimethyl sulfoxide(DMSO)),and then heated[8].Parameters including the reagent ratio,temperature,solvent,pH,reaction time,and so forth,can be systematically varied and optimized.These parameters are likely to influence not only the obtained structure,but also the crystal morphology,phase purity,and performance of the material.In some cases,particularly with strong coordination bonds such as those in zirconium(Zr)-MOFs,a modulator must be employed to help harvest crystalline products by preventing the rapid formation and precipitation of amorphous materials[19].High-throughput(HT)methods,which are a powerful tool to speed up the building of new MOFs and to modify synthesis conditions,are closely related to the concepts of miniaturization,parallelization,and automation[20,21].Alternative methods including electrochemical[22],mechanochemical[23],microwave-assisted[24],and sonochemical synthesis[25]have been established for specific purposes in MOF synthesis,such as morphology/size control,speeding up the reaction,and scale-up preparation[8].Various post-synthetic methods have also been developed to create new MOFs and,particularly,to functionalize given MOFs;these methods include solventassisted linker incorporation,post-synthetic modification,and transmetalation[26,27].

In the process of MOF synthesis,guest molecules(i.e.,solvents and residual starting materials,in a few cases)are inevitably trapped in the voids of the host network.In order to determine the porosity and surface area,the trapped guest molecules must be removed through an activation process.Heating the assynthesized MOF samples directly under vacuum is sometimes satisfactory,but is only suitable for certain stable MOFs synthesized in low-boiling-point solvents[28,29].In most cases,MOF activation through straightforward heating and degassing results in incomplete guest-molecule removal or even framework collapse.The most convenient approach to solve this issue is to replace highboiling-point or high-surface-tension solvents with lower species(e.g.,ethanol or acetone)before heating the MOF samples in a vacuum[5].Activation with supercritical carbon dioxide(scCO2)is an extension of traditional MOF activation methods.Milder scCO2activation,which eliminates strong capillary forces and surface tension through a supercritical phase,avoids phase changes in the removal of guest molecules[30].

2.2.Green synthesis

The principal aspect of researching MOFs for green chemical engineering is to find a method for greening MOF synthesis.In general,harmless reactants,an innocent solvent,mild conditions,and fewer byproducts are key factors in the green synthesis of MOFs.At least some of these considerations have been fulfilled in the synthesis of popularly explored MOFs such as Hong Kong University of Science and Technology(HKUST)-1,zeolitic imidazolate framework(ZIF)-8,and MOF-74[31,32].

To avoid possible byproducts,such as corrosive acids(mainly HCl and HNO3)generated by the reaction of metal salts and protonated ligands in an aqueous solution,metal salts containing benign anions or linker salts with innocuous metal cations are preferred.Thus,metal hydroxides and oxides are usually chosen,not only to ensure that water is the only byproduct,but also to achieve high atomic efficiency.In this regard,mechanochemical synthesis methods are always favored due to the insolubility of metal hydroxides/oxides.Other common approaches employ metal ions with carefully selected counter anions,such as acetates[32].

On the other hand,the choice of organic ligands has a strong impact on the design and utilization of MOFs,as it affects not only the final topology,but also specific functions.This selection criterion will be advantageous for the large-scale production of materials,based on simple,commercially available ligands or on those that can be readily obtained while producing less toxic byproducts.The Matériaux de l’Institut Lavoisier(MIL)-53(Al)series and MOF-74 were successfully synthesized with organic salts as the linker sources,thereby avoiding the generation of corrosive acids and environmental hazards[33,34].

The use of an innocuous solvent is also important for green synthesis.MOF materials are popularly synthesized using solvothermal methods,in which solvents are needed to dissolve the organic ligand and metal salt.DMF is a commonly used solvent with good solubility,albeit with toxicity,as it can decompose into harmful dimethylamine upon heating to high temperature.For green MOF synthesis,DMF should be omitted or replaced by an innocuous solvent[32].

From the standpoint of sustainability and environmental impact,solvent-free conditions are the best choice for the difficult MOF synthesis,as they involve safer and cleaner,albeit less soluble,sulfates or oxides salts.At present,three principal routes for the solvent-free synthesis of MOFs have been explored:mechanochemical,thermochemical,and diffusion-controlled‘‘accelerated aging” reactions.As reported by Cliffe et al.[35],ZIFs can be synthesized by the ‘‘accelerated aging” method.

Of course,water is the best alternative solvent because sufficient reserves are available and it is environmentally friendly,which facilitates subsequent purification and recycling.A large number of MOFs have been prepared in water,including HKUST-1[36],the MIL series[37],and the Universitetet i Oslo(UiO)series[38].Cyrene(dihydrolevoglucosenone),a green solvent with almost no eco-toxicity of mutagenicity,has been investigated in the preparation of several representative MOFs[39].Ionothermal synthesis,which uses ionic liquid as both a solvent and a template,has also been considered as a green method to prepare MOFs[40,41].

In addition to solvent-free and green-solvent-based strategies,microwave-assisted synthesis is an eco-friendly approach for the preparation of MOFs in aqueous conditions,and can significantly accelerate the self-assembly of inorganic and organic components[42].

2.3.Scale-up preparation

MOFs are generally prepared in milligram scales in the lab by heating in expensive organic solvents for several hours to days.The evaluative criteria for industrial MOF synthesis are commonly set to resolve the safety,toxicity,availability,and cost of all reagents,as well as the operability and productivity in amplified production[18,43–46].The huge disparity between the conditions required for laboratory preparation and those for commercialization has created a strong demand for the development of highefficiency and low-cost methods for the large-scale production of MOFs.

The majority of promising scale-up approaches present one or more of the following challenges:

(1)Use of organic solvents.In a scale-up approach,the corrosivity,toxicity,cost,recyclability,and flammability of organic solvents present intractable problems in some cases.

(2)Anion accumulation.Nitrates present an explosion hazard,and chlorides can give rise to corrosive byproducts.Oxides and hydroxide metal species are thus favored.

(3)Ligand availability.Customized and complicated organic ligands are needed for many MOFs.

(4)Particle-size control.Thin film applications require nanosized particles,while for storage applications,larger particles are needed in order to preserve their stationary state.

(5)Activation.Non-volatile solvents and unreacted raw materials in MOF pores must be removed before utilization.

(6)Shaping.For practical industrial applications,the shaping of a MOF into different forms is necessary[45].

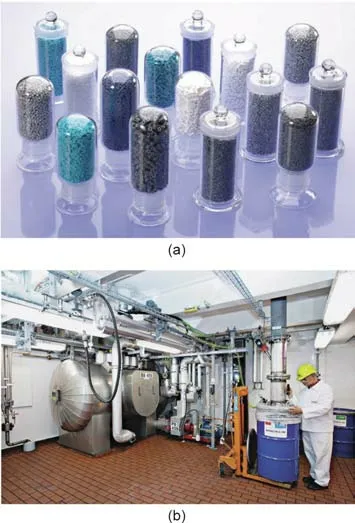

Each MOF presents its own specific challenges due to its unique composition,structure,and properties,making the synthesis of these materials more complicated than that of zeolites.Various strategies have recently been evaluated to cope with these challenges,including electrochemical,mechanochemical,and microwave-assisted synthesis,as well as continuous-flow production.BASF was the first to demonstrate the scale-up synthesis of MOFs via an electrochemical process for the industrial preparation of HKUST-1,by using metal electrodes directly as a metal source in order to exclude metal anions[46].Microwave-assisted synthesis,spray drying,and flow chemistry permit crystallization to occur at a faster rate and result in the production of MOF crystals with a smaller size.Mechanochemical synthesis,in which extra solvent or heating is not required,avoids post-synthetic washing and activation,and thus exhibits great potential for the scale-up production of MOFs.For the time being,plenty of archetypal MOFs are being produced using scale-up approaches,and are then shaped into different bodies,including ZIF,MIL,the UiO series,HKUST-1,MOF-5,MOF-74,and so forth(Fig.2)[43–46].

3.Structural characterization and stability

3.1.Structural and morphologic characterization

Fig.2.(a)Differently shaped bodies of MOF materials;(b)large-scale production facilities of MOFs at BASF in Germany.(a)Reproduced from Ref.[43]with permission of the Royal Society of Chemistry,©2009;(b)reproduced from Ref.[46]with permission of the Royal Society of Chemistry,©2015.

Single crystal X-ray diffraction(SXRD)or Rietveld refinement of powder X-ray diffraction(PXRD)data give absolute structural information on MOFs.Basic MOF characterization data contain a PXRD pattern to determine the crystallinity and phase purity of the material,and a Brunauer–Emmett–Teller(BET)measurement to confirm the porosity.Additional characterization protocols and techniques include:chemical stability testing of MOFs in aqueous solutions at varied pH;thermogravimetric analysis(TGA)to indicate the framework thermal stability;scanning electron microscopy(SEM)for particle size and morphology,in combination with energy-dispersive X-ray spectroscopy(EDS)for elemental composition and content;nuclear magnetic resonance(NMR)spectroscopy to quantify the linker ratios in mixed linker-based structures;inductively coupled plasma optical emission spectroscopy(ICP-OES)for elemental ratios;and diffuse reflectance infrared Fourier-transform spectroscopy(DRIFTS),as well as Fourier-transform infrared(FT-IR)spectroscopy,to confirm the existence or non-existence of infrared(IR)-responsive functional groups in the target MOF material.All characterization methods should be used for the correct purpose in order to identify the precise composition,structure,and morphology traits of target MOF materials,thus laying a foundation for subsequent property prediction and application exploration[5].

3.2.Stability

Good stability of MOFs,including their mechanical,thermal,and/or chemical stability,is the prerequisite for their application in an expansive scope.The stability of a MOF is influenced by various factors,including the species of metal ions,size and configuration of organic ligands,coordination geometry between metals and ligands,operating environment,and hydrophobicity of pore surfaces.Coordination bond strength between inorganic nodes and organic ligands—as such bonds have a weaker linkage than covalent bonds—always plays a crucial role in determining MOF stabilities[47].Here,we overview the specific influencing factors in MOF stability in different forms,along with associated enhancing strategies.

3.2.1.Mechanical/framework stability

MOFs are well known for their high porosity,which inescapably reduces their mechanical strength in resisting pressure or a vacuum.Under mechanical stress or a vacuum,this instability contributes to phase transitions,partial collapse,or even amorphization of the framework structure.To fully activate MOFs while avoiding structural collapse,solvent-exchange methods are commonly adopted before evacuation[5].Compared with MOFs built with low-valent metal ions,Zr-MOFs typically have better mechanical stability due to their high connectivity of Zr-based clusters and strong Zr–O coordination bonds in the framework[47].Framework geometry,structural defects,and network interpenetration are also relevant to the mechanical stability of MOFs[48].Furthermore,an interesting subset of MOFs have been rationally designed with reversibly flexible structures,and exhibit superior mechanical compliance[49].

3.2.2.Thermal stability

In most cases,the thermal decomposition of MOF materials is a consequence of the cleavage of coordination bonds,which is accompanied or followed by the dehydration of the metal nodes,the dehydrogenation,carbonization,or even burning of the linker,and the amorphization or melting of the MOF.The thermal stability of MOFs is normally determined by the strength and connectivity of the coordination bond.

Coordination bond strength can be increased by replacing lowvalent metal ions connected to the carboxylate linkers with highvalent species(Al3+,Zr4+,and Ti4+),thus increasing the thermal stability of MOFs[50].Another way to increase the coordination bond strength in order to increase the framework thermal stability is to vary the functional groups attached on the organic ligand.The interpenetration or interweaving of networks can enhance the stability through favorable framework–framework interaction[47].In addition,intentional mechanical stress during preparation sometimes prompts the MOF phase to transform from a metastable state to a more stable one[51].

3.2.3.Chemical stability

Chemical stability refers to the ability of MOFs to retain their framework structural integrity under specific chemical conditions[47].Two main factors that determine the chemical stability of MOFs are the MOF structure(i.e.,internal factors)and the operating environment(i.e.,external factors).

Water stability is a significant quality for industrial applications of MOFs due to the presence of a large amount of water in processes such as preparation,storage,and application.The decomposition of MOFs in liquid water or water vapor can be considered as a series of substitution reactions in which the coordinated linkers with metal nodes are replaced by OH-or H2O entities.Hence,a direct way to withstand such substitution is to increase the robustness of the coordinate bonds between the metal nodes and organic linkers,or to introduce hydrophobic functional groups to prohibit water molecules from attacking[52,53].

Compared with neutral H2O molecules,the OH-and H+in basic and acidic aqueous solutions are much more destructive to MOFs.As the chemical environments in alkaline and acidic solutions are different,MOF stability would be affected in different ways by bases and acids.Various MOFs composed of carboxylate-based ligands and high-valent metal cations show great stability in acidic solutions,but are more vulnerable in basic conditions.On the other hand,MOFs composed of azolate-based ligands and low-valent metal ions generally exhibit better stability in basic conditions,whereas their robustness in acidic solutions is much weaker[54].

Besides OH-and H+,other coordinating anions(e.g.,F-,CO32-,and PO43-,to name a few)can also destroy the framework structure of MOFs.Carboxylate ligands are easily displaced when such coordinating anions are present as competitors in the solution,especially for MOFs built with high-valent cations,such as Zr4+,Fe3+,and Al3+[55].The high binding constants between the highvalent metal ions and these competitive anions indicate a strong interaction.An effective strategy to prevent the destruction of frameworks by these anions is to construct MOFs with azolatebased linkers and low-valent metal cations[56].

3.2.4.Strategy for enhancing stability

As discussed above,the crucial issue in enhancing MOF stability is improving the strength of the coordinate bond between the inorganic nodes and organic linkers.Based on Pearson’s hard/soft acid/base theory,the affinity between soft Lewis bases and acids(or hard Lewis bases and acids)is much stronger than that between soft bases and hard acids(or hard bases and soft acids).Therefore,researchers choose to build networks with carboxylate-based ligands(hard Lewis bases)and high-valent metal ions(hard Lewis acids),or with azolate-based ligands(soft Lewis bases)and lowvalent transition metal ions(soft Lewis acids)for robust MOFs.The viability of this strategy has been demonstrated by many examples of stable MOFs[54].Selecting a suitable operating environment,creating framework catenation,and incorporating hydrophobic functional groups into pores are also valid means of strengthening MOF stability[47,54].

4.Processing

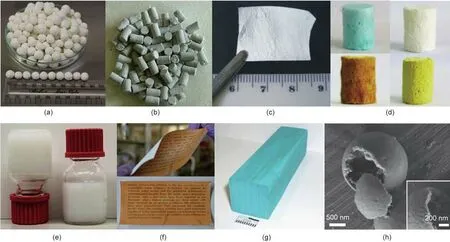

With the inherent properties retained or improved,processing MOFs into different forms provides obvious advantages in allowing them to be readily stored,transported,and used.Systematic control over shape and size is favorable for advancing MOF materials for industrial application,achieving their great potential in practice,and eventually placing them on the market[57].MOFs can usually be shaped into different forms with either anin situ(direct method)or post-synthesis(indirect method)procedure.In the former method,crystalline powders are directly arranged into desired forms such as membranes or hollow superstructures during the formation of MOFs.In the latter method,processing is a secondary process executed on preformed crystalline powders.Among the most common shapes that MOF crystallites can be fabricated into are granules,pellets,membranes,foams,gels,paper sheets,and hollow structures(Fig.3)[58–66].However,the specific shape of a MOF is usually determined by the requirements of real-life applications,given the processing feasibility and performance availability.In this section,we highlight popular processing methods that have been adopted to engineer MOF powders into various shapes.

4.1.Granules

Granulation is the process of agglomerating powder materials into granules without altering their chemical composition and architecture.This can be executed using wet or dry approaches according to the processing technique.In the wet approach,in order to adhere the powder particles into granule forms,a volatile solvent is generally needed,which is removed by drying afterwards.The properties of the formative granules rely strongly on those of the original MOF powder and the viscosity of the binder,as well as on the interactions between them;thus,binder selection is critical.Poly(vinyl alcohol),graphite,and cellulose ester are widely chosen as binders in the shaping of MOFs.When a material is vulnerable to solvents or heating,a dry granulation approach is applied,which uses high stress(compression).Practical granulation processes for MOFs often involve a centrifugal granulator,a high shear mixer,or an extruder[58].

Ren et al.[59]shaped UiO-66 powder into granules(with diameters ranging from 0.5 to 15 mm)(Fig.3(a))using a granulator,with 10% mass fraction sucrose as the binder.This approach produced UiO-66 granules in a kilogram batch.The results of the drop test and simulated tumbler drum test showed zero breakage of the granules after 70 consecutive drops at a height of 0.5 m,and 5%breakage after one hour of tumbling time at a speed of 25 r·min-1;thus,these granules demonstrated better mechanical strength in resisting abrasion in a real hydrogen storage environment than those made using a mechanical pressing method.

4.2.Pellets

As the most conventional and effective method of shaping MOFs,pellet formation follows similar rules to granulation.Particle agglomerates are formed by imposing pressure on the powder materials,with or without the addition of a binder(i.e.,according to a wet or dry method).The shapes of the resulting agglomerates differ,with granulation resulting in spherical agglomerates and pellet formation resulting in cylindrical agglomerates.Such a difference in the shapes of MOF materials can affect their performance in certain industrial applications.The addition of binders can also influence the MOF properties.For example,an organic polymer binder can improve the mechanical stability of the MOF pellets,while a graphite binder can enhance their thermal conductivity.On the other hand,the binder molecules may block the pores of the source MOFs,causing a decrease in the surface area.Mechanochemistry is another extensively employed method to shape MOF powders into pellets.Several classical MOFs,such as ZIF-8,Al(fumarate)(OH)(AlFu),HKUST-1,and UiO-66,have been shaped into pellets(Fig.3(b))with an extrusion approach that involves imposing pressure on precursor powders[60,67].

Fig.3.MOFs shaped in the forms of(a)granules,(b)pellets,(c)a thin film,(d)foams,(e)gels,(f)a paper sheet,(g)a monolith,and(h)a hollow structure.(a)Reproduced from Ref.[59]with permission of Hydrogen Energy Publications,©2015;(b)reproduced from Ref.[60]with permission of the American Chemical Society,©2012;(c)reproduced from Ref.[61]with permission of the Royal Society of Chemistry,©2012;(d)reproduced from Ref.[62]with permission of the American Chemical Society,©2016;(e)reproduced from Ref.[63]with permission of the Royal Society of Chemistry,©2017;(f)reproduced from Ref.[64]with permission of the Royal Society of Chemistry,©2016;(g)reproduced from Ref.[65]with permission of the John Wiley and Sons,©2010;(h)reproduced from Ref.[66]with permission of Nature,©2013.

In industry,adsorption beds such as fluidized and fixed beds are optimal choices for the separation of liquid and gas mixtures.Granules and pellets are ideal stationary phases for separation in these beds,due to the close packing and high density of MOFs in a small volume[58].In a study by Kim et al.[68],MIL-100(Fe)granules(1.18–1.70 mm in size)were fabricated and then packed into an adsorption column for the separation of SF6from a nitrogen(N2)stream.With a higher working capacity(1.45 mmol·g-1)than Zeolite 13X(0.97 mmol·g-1)at 1 bar(1 bar=105Pa),as well as easier regeneration,the MIL-100(Fe)granule has great potential for SF6/N2separation.

4.3.Membranes

Processing MOF powders into membranes is critical for many industrial applications such as toxic gas filters and water purification.Pure MOF membranes(including most MOF thin films)are prepared by continuous growth methods,and their chemical properties merely depend on those of the MOF materials themselves.A bottom-up approach is adopted to form MOF thin films on different substrates,employing methods such as crystal growth,layer-bylayer(LBL),liquid-phase epitaxy(LPE),seeding,electrochemical deposition,and Langmuir–Blodgett deposition.The fabrication of a series of free-standing MOF membranes well-integrated on electrospun nanofibrous supports has been realized via a seeded secondary growth approach(Fig.3(c))[61].The design principles of MOF-based thin films for high-efficiency applications emphasize‘‘design for purpose”;that is,suitable MOF materials and synthesis methods are chosen according to the targeted component or process.Numerous MOF thin films have been prepared based on different MOF materials for gas or liquid separation,which will be discussed in detail in Section 6.3.However,due to the inherent fragility of MOF thin films and the intricate methods that are used to make them,much research on MOF thin films is still necessary to achieve further technical breakthrough in their actual separating application[58].

4.4.Foams and gels

Unlike efforts to shape MOFs into granules,pellets,and thin films,the formation of a standalone MOF foam has rarely been reported.The majority of relevant investigations in this area concentrate on growing MOF crystals on foam-like structures[69].For this purpose,Chen et al.[62]proposed a continuous-phase transformation processing strategy.Several MOFs were fabricated and shaped into processable fluids,shaped bodies,and even MOF foams,which could realize a reversible conversion among these forms(Fig.3(d)).To be specific,HKUST-1@Fe3O4nanoparticles were dispersed into a carboxymethylcellulose solution to form a magnetic fluid,which could be patterned into different shapes and transformed into a foam or a gel form using different methods.In addition,the robust and hierarchically porous HKUST-1@Fe3O4foam showed excellent catalytic C–H oxidation performance.

Xerogels and aerogels are technically regarded as foams.A xerogel can be obtained by removing the liquid in a gel,and an aerogel is obtained by replacing the liquid with a gas,while the structure of the gel has tiny or no changes[70].Many solid materials can be readily molded into different shapes by using porous gels.MOF foams and sponges are extraordinary candidates for energy carrier storage and transportation due to their features of light density and high porosity.Nevertheless,MOF-based gel materials(Fig.3(e))have scarcely been reported as yet,primarily because of their high fragility[63].

4.5.Paper sheets,hollow structures,and other shapes

Previous studies have reported on MOFs in forms such as paper sheets(Fig.3(f))[64],monoliths(Fig.3(g))[65],and hollow structures(Fig.3(h))[66].MOFs shaped as filter papers and sheets can easily be prepared by means of crystal growth,pulp processing,coating,and inkjet printing onto polymer,pulp,and cotton fibers.Another way to process MOFs is to grow MOF crystals into hollow structures using methods such as templating,Ostwald ripening,etching,and spray drying.Interfacial synthesis and spray drying are prospective methods for shaping MOF powders in scale-up processing for their fast,facile,and continuous operation procedures.

To achieve better performance in industrial applications,MOFs need to be produced on a large scale,be industrially tested,and be shaped into different forms.By carefully controlling the MOF chemistry,various methodologies have been established for processing MOFs.However,strategies for shaping MOFs require further optimization.For example,an appropriate pressure is requisite to prevent the MOF framework from structurally collapsing during compression,and a suitable binder is necessary to avoid pore blocking and ensure optimum void fractions between primary powders in order to relieve the diffusion limitations of shaped bodies.Although the network fragility and complex fabrication procedures introduce significant difficulties,there is an excellent chance of developing applicable device-processing methods with greater feasibility and efficiency,in order to access the outstanding potential of MOFs,as promised by their elaborate structures and prominent properties in practical implementation.

5.Adsorption applicatio n

The growing scarcity of fossil fuels—accompanied by increasingly severe environmental problems and climate change,attributed to rapid civilization and industrialization—has driven an initiative to develop alternative green fuels and pollutantmanagement methods.Adsorption-based technology has demonstrated some particular advantages for these purposes,including low energy input,high storage capacity and selectivity,ease of operation,and good regeneration of adsorbents.Thanks to their tunable pore size and structure,high porosity,rich active open metal sites(OMSs),and wide range of modifiable functional groups on the framework,MOFs are an attractive category of materials for adsorption applications.The use of MOF adsorbents for industrial processes aligns with the demands of green chemical engineering,to some extent.It can be forecasted that,in the near future,the discovery of advanced porous MOF materials for efficient fuel storage,pollutant removal,water harvesting,and other adsorption-based technologies will significantly contribute to clean energy exploitation and environmental protection.

5.1.Gas storage

Among diverse possible fuels,hydrogen(H2)and methane(CH4)are considered to be predominant candidates for clean energy source carriers.However,their volumetric energy densities under ambient pressure are relatively low,which seriously impedes their widespread utilization,especially in mobile/transportation applications.As an alternative to compression and liquefaction,adsorption technology based on MOF adsorbents offers a prospective solution to the continual challenges of safely storing and efficiently using H2and CH4[71,72].A desired MOF adsorbent—as a fuel storage material for vehicular application—should have not only a high fuel uptake capacity,but also(and even more importantly)a high deliverable capacity.Various strategies for improving the fuel storage capacity of MOFs have been investigated,including tuning pore chemistry,embedding OMSs,and linker or node functionalization[73].

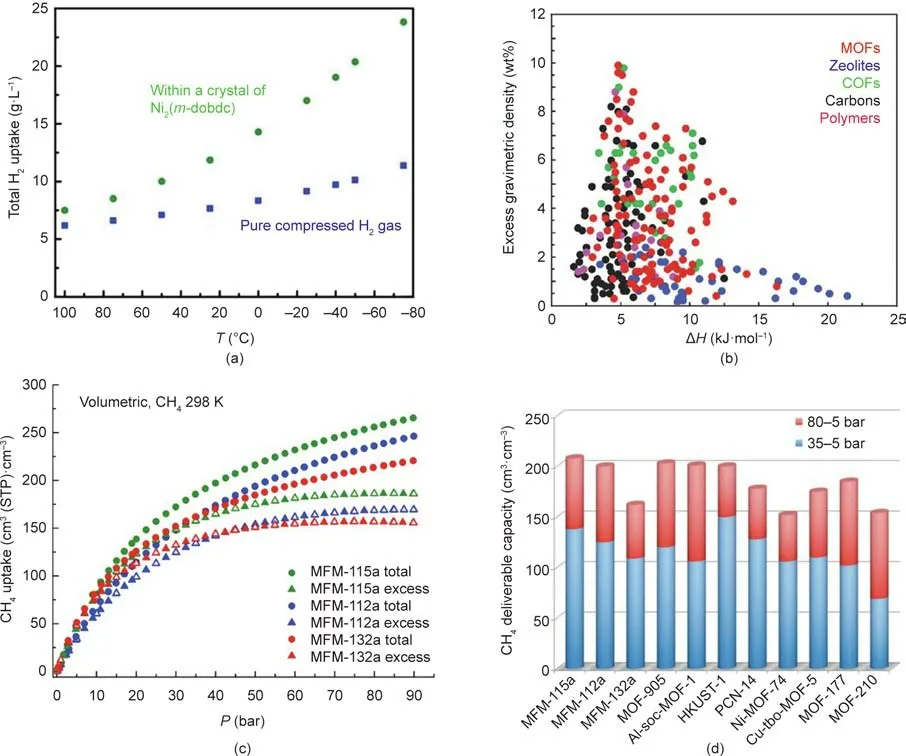

H2is the most ideal green energy carrier for sustainable development because of its high thermal efficiency and pollution-free combustion.To achieve a target driving range of 483 km for fuel-cell-based lightweight vehicles,the US Department of Energy(DOE)has confirmed specific targets for H2storage systems:a gravimetric capacity of 5.5%mass fraction and a volumetric capacity of 40 g·L-1based on the mass and volume of the entire system,respectively.These targets must be available in the temperature range of 40–60°C with a maximal pressure of 100 bar.In 2018,Kapelewski et al.[74]revealed that the modified MOF-74 type M2(m-dobdc)(M=Co,Ni;dobdc4-=2,5-dioxido-1,4-benzenedicarboxylate)was corroborated to be the best-performing physisorptive storage material,with a working volumetric capacity of 11.0 g·L-1at 25°C between 5 and 100 bar,and of 23.0 g·L-1with a temperature swing between -75 and 25°C at 100 bar(Fig.4(a)).Fig.4(b)[71]shows the correlation between excess gravimetric H2uptake and enthalpy of H2adsorption for various porous materials,which can instruct the better designing and screening of MOF sorbents for H2storage.

CH4,as the major constituent of natural gas,is also regarded as a preferable clean fuel.For onboard CH4storage systems,the gravimetric capacities of adsorbents should reach 0.5 g·g-1(700 cm3·g-1)at 298 K,while the volumetric capacities should be 263 cm3methane per cubic centimeter sorbent,which is equivalent to the density of compressed natural gas at 298 K and 250 bar[75].Yan et al.[76]reported the CH4storage properties of a series of isostructural MOFs—that is,Manchester framework material(MFM)-112a,MFM-115a,and MFM-132a—among which MFM-115a showed an astonishingly high deliverable CH4capacity of 208 volume fraction at room temperature between 5 and 80 bar,rendering it among the top-performing MOFs for CH4storage(Figs.4(c)and(d)).

Acetylene(C2H2)is an indispensable gaseous chemical in modern industry that is commonly used as a gas fuel for oxy-acetylene welding and metal cutting,and as a crucial starting material to produce multiple fine chemicals and electronic materials.The secure storage and transport of C2H2is greatly impeded by its explosiveness when compressed under a pressure over 2 bar at ambient temperature,even in the absence of oxygen[72].Matsuda et al.[77]have reported that a MOF,Cu2(pzdc)2(pyz)(pzdc=pyrazine-2,3-dicarboxylate;pyz=pyrazine),can accommodate C2H2with an adsorbed density of about 0.434 g·cm-3,which is 200 times higher than the compression limit for the safe usage of C2H2at room temperature.

5.2.Pollutant removal

Fig.4.(a)Comparison of the total volumetric capacities of Ni2(m-dobdc)and pure compressed H2 at 100 bar;(b)excess gravimetric H2 uptake versus enthalpy of H2 adsorption for various classes of hydrogen storage materials(COF:covalent organic frameworks);(c)total and excess volumetric CH4 adsorption isotherms for MFM-115a,MFM-112a,and MFM-132a in the pressure range 0–90 bar at 298 K(STP:standard temperature and pressure);(d)comparison of the deliverable CH4 capacities in some MOFs at 298 K(soc:square–octahedral;tbo:twisted boracite).(a)Reproduced from Ref.[74]with permission of the American Chemical Society,©2018;(b)reproduced from Ref.[71]with permission of the Royal Society of Chemistry,©2018;(c,d)reproduced from Ref.[76]with permission of the American Chemical Society,©2017.

In recent years,the excessive burning of fossil fuels worldwide has had a permanent effect on habitats due to the discharge or emission of massive amounts of hazardous compounds into the air or water.The removal of such chemicals has conventionally posed a challenge due to their extensive utilization,fine water solubility,and poor biodegradability.Therefore,adsorption technology has experienced rapid growth as an effective decontamination tool for applications such as air treatment,water purification,and fuel upgrading,as it avoids the need for intensive energy consumption and offers good adsorbing capacity[2,78–81].Many MOFs are potential sorbent materials due to their inherent merits in terms of structure and property,which can be tailored to achieve stronger or more selective binding affinity toward targeted adsorbates.

5.2.1.Air treatment

Various airborne pollutants,including toxic industrial chemicals(TICs),volatile organic compounds(VOCs),and fine particulate matter(PM),have caused severe air contamination and deteriorated human living conditions.To mitigate these detriments,abundant MOFs have been found to be promising adsorbents for the adsorptive capture of harmful gases in the atmosphere[2,78,79].

The TICs(e.g.,NH3,H2S,SOx,NOx,and CO)are a notorious family of air pollutants.Ammonia(NH3)is widely employed in the production of fertilizers,detergents,and pharmaceuticals,and has an odor threshold for humans as low as 5 ppm.Through hydrogen bonding,NH3can strongly interact with the inorganic nodes or organic linkers of MOFs.Certain functional groups,such as–OH and–NH2,typically show strong affinities to the NH3molecule in hydrogen bonds,in addition to–COOM(M=Cu,Ag,Na,or K)groups in chemisorption mechanisms.NH3can connect to OMSs through coordinate bonds,as observed in MOF-74 and HKUST-1.Furthermore,it is a critical ability of MOFs to bind the adsorbate with priority over water,because most ambient airstreams include moisture.Hydrophobic MOFs have been suggested to interact with NH3preferentially over water[78].

Hydrogen sulfide(H2S)is a hypertoxic gas that is generally viewed as an impurity in the natural gas and petroleum industry,and is a byproduct of anaerobic decomposition.Humans are extremely sensitive to the pungent rotten-egg odor of H2S,which can be perceivable at levels as low as 4.7 ppb.Bhatt et al.[82]built three isoreticular rare earth(RE)-fcu-MOFs(fcu=face-centred cubic)displaying remarkable performance in the removal of H2S from CO2-containing gases and CH4-containing gases such as biogas,natural gas,and landfill gas.Their high H2S/CO2selectivity even outperformed those of the benchmark materials activated carbon and zeolites.

Sulfur and nitrogen oxides(SOxand NOx)are atmospheric pollutants that are byproducts of fossil fuel combustion and are known to cause acid rain.Tan et al.[83]minutely investigated the interaction between the acid gases SO2and NO2and M-MOF-74(M=Zn,Co,Ni,Mg)with abundant OMSs,and found that SO2can be molecularly adsorbed into Zn-MOF-74 and Mg-MOF-74 with high binding energy.In contrast,for NO2,a strong Zn–NO2binding significantly weakens the N–O bond,accelerating the divergent degradation of NO2molecules into NO and NO3-.These results indicate that denitrification and desulfurization processes using MOF-74 as the adsorbing material in flue gas decontamination are viable.

Yang et al.[84]recently reported that MIL-100(Cr)has the supreme N2O-capture capacities of 8.25 mmol·g-1at 273 K and 5.78 mmol·g-1at 298 K,and thus exhibits an extremely high N2O/N2simulated gas separation selectivity of up to 1000.

Statistics from the Centers for Disease Control and Prevention reveal that roughly 500 people die from carbon monoxide(CO)-incurred asphyxia in the United States annually.MOFs bearing rich OMSs,such as HKUST-1 and MOF-74,have been studied for CO capture due to the electrostatic interaction and coordinative bonding between OMSs and CO molecules.In addition,CO removal can be realized through catalytic oxidation to CO2,in some cases[78].

VOCs(e.g.,benzene(Bz)and xylenes)are widely used as reagents in industrial processes;they also exist in the urban atmosphere due to vehicle emissions,which is gravely deleterious to our environment and to human health.Furthermore,because of their high reactivity with other gassy contaminants that exist in the outdoor atmosphere(e.g.,NOx),VOCs energetically participate in the generation of secondary pollutants(e.g.,ozone).As demonstrated by Xie et al.[85],[Zr6(μ3-O)4(μ3-OH)4(BDB)6](Beijing University of Technology(BUT)-66),which shows high hydrolytic stability and possesses small hydrophobic pores,demonstrates high volumetric Bz adsorption capacity even at high temperature and low pressure,outperforming the commercial benchmark adsorbents Carboxen 1000 and Mobil Composition of Matter No.41(MCM-41).BUT-66 can adsorb parts per million levels of Bz in air even with moisture,which implies great prospects for practical application.

Among the frequently encountered solid pollutants in daily life(e.g.,dust,PM,pollen),fine PM is the most detrimental species,as it creates serious and long-term damage to air quality and regional climates.Levels of particulates with an aerodynamic diameter below 2.5μm(PM2.5)and 10μm(PM10)have been increasing worldwide in recent years,reducing local air visibility and impairing human respiratory systems.In the research of Zhang et al.[86],nanocrystals of four MOFs(ZIF-8,Mg-MOF-74,MOF-199,and UiO-66-NH2)were fabricated into nanofibrous filters(known as‘‘MOFilters”)with high MOF loadings(up to a mass fraction of 60%).When tested in a hazy environment,high PM-removal efficiencies of up to 88.33%±1.52% and 89.67%±1.33% for PM2.5and PM10,respectively,were achieved by the MOFilters,which also demonstrated good durability.

5.2.2.Wastewater treatment

A broad scope of contaminants are relatively soluble in water,including heavy metal ions,dyes,pesticides,detergents,pharmaceuticals,phenols,and others;water pollution with such contaminants can severely impair the health of all life forms along related food chains and,ultimately,endanger human life.Pollutants in wastewater can be classified into inorganic and organic species according to their chemical composition.From the perspective of energy conservation and cost reduction,adsorption[53,80]or photocatalytic degradation induced by solar energy[87](see Section 7.2.1 for details)are promising routes for eliminating wastewater contaminants.MOFs with hydrolytic stability and specific functionality are good sorbent candidates for grafting these substances from water,through interactions such as ion exchange,hydrogen bonding,acid-base interaction,and electrostatic interaction.To this end,the incorporated OMSs,functionalized linkers,and loaded active species could be optimized to enhance the adsorption capacity and selectivity of MOF materials in wastewater treatment.

Inorganic contaminants in sewage principally include heavy metal ions,excessive fluoride ions,and radioactive substances.Massive efforts have been devoted to eliminating these pollutants from wastewater with MOFs.

The casual disposal of residual heavy metals from labs and factories causes extensive water pollution.Common heavy metal ions in wastewater are arsenic,cadmium,lead,mercury,chromium,copper,nickel,cobalt,and zinc ions.Based on the strong Zr–O bond,which has good chemical stability,Li et al.[88]inspected MOF-808 for the removal of arsenic(As5+)from water.They discovered that the adsorption capability for As5+of monodispersed MOF-808 octahedral nanoparticles was about 24.8 mg·g-1,with an original As5+level of 5 ppm.

Wang et al.[89]demonstrated that HKUST-1 functionalized with sulfonic acid is capable of removing cadmium ions(Cd2+)from aqueous solution,with a high Cd2+uptake of 88.7 mg·g-1that exceeds that of the benchmark adsorbents.Furthermore,this method has fast kinetics,high selectivity,and easy regeneration toward cadmium ion adsorption.

According to Pearson’s hard/soft acid/base theory,soft bases generally show a strong affinity to soft acids[54].Based on this premise,many intriguing examples have been reported for the capture of mercury(Hg2+)using MOFs based on sulfur-containing ligands[90].Liang et al.[91]have established a new methodology of employing NCS–-functionalized MOF FJI-H12 to remove Hg2+from wastewater.FJI-H12 can remove Hg2+from water completely and selectively with a high saturation(439.8 mg·g-1)and distribution coefficient(1.85×106mL·g-1)relative to other MOFs.Remarkably,rapid and continuous removal of Hg2+from water was also achievable using a column loaded with FJI-H12 microcrystals,indicating that this method holds promise for realistic pollutant control and sewage treatment application.

Luo et al.[92]proposed the so-called MOF+technique for toxic chromate(in the form of Cr2O72–)removal from aqueous solutions,which is based on a significant synergic effect between UTSA-74 and Fe2SO4.The findings suggest that relative to pristine MOFs(i.e.,those without obvious chromate adsorption),the MOF+approach presents a superior performance,with a chromate adsorption capacity of 796 mg·g-1—the highest value among all known porous adsorbents in this regard.

For the adsorptive removal of excessive fluoride ions(F–),material robustness in fluoride solution is a prerequisite for MOF performance.Preliminary studies revealed that a relatively inactive metal center with high connectivity and pores with suitable hydrophobicity contributed to good stability of MOFs in fluoride solution.Stable AlFu MOF demonstrates an ultrahigh fluoride uptake capacity of 600 mg·g-1at 293 K,as reported by Karmakar et al.[93].

Nowadays,investigations on the use of MOFs as adsorbents for the removal of radioactive matter in wastewater are primarily centered on133Ba,99Tc,129I,232Th,235U,and238U.Zheng et al.[94]recently synthesized two crystalline zirconium phosphonate frameworks,SZ-2 and SZ-3.Strikingly,these two complexes have ultrahigh stability and exhibit a high uranium uptake over a wide pH range of 3–7.This process also proceeds in a very fast adsorption rate by the ion-exchange mechanism.

Organic contaminants in wastewater involve a wider range of classifications than inorganic contaminants,and comprise dyes,detergents,pesticides,pharmaceuticals and personal care products(PPCPs),phenolics,and more.Adsorption removal by MOF materials has been demonstrated to be an efficient and economical means of treating organic pollutants in water[80].

Dyes are a category of ubiquitous organic contaminants in water.Their intense color weakens or prevents incident sunlight from entering water bodies,thereby interfering with the balance of aquatic ecosystems.Furthermore,most dyes are poisonous and can induce disorders,including cancer.Haque et al.[95]demonstrated that MOF-235 is capable of the adsorptive removal of hazardous dyes(i.e.,anionic methyl orange(MO)and cationic methylene blue(MB))with good efficiency from water.The adsorption capacities of MOF-235 toward MO and MB were found to be as high as 477 and 187 mg·g-1,respectively,under appropriate pH values,greatly outperforming activated carbon for the same use.

Studies with MOFs as the sorbent in the removal of toxic pesticides from water have been relatively scarce,and the target objects have been limited to 2,4-dichlorophenoxyacetic acid(2,4-D),methylchlorophenoxypropionic acid(MCPP),and diquat(DQ)to date[80].

As a new class of organic pollutant,PPCPs have appeared in diversified water systems,including surface water,groundwater,and even drinking water.Due to their undegradability,the accumulation of PPCPs in wastewater poses a terrible environmental threat.A series of MOFs have been exploited for the adsorptive removal of PPCPs from water,including the MIL family,UiO-66,and ZIF-67.Wang et al.[96]constructed two stable isostructural Zr-MOFs—BUT-12 and BUT-13—for sensing and adsorbing a wide range of antibiotics and organic explosives in aqueous solution.BUT-12 and BUT-13 are responsive to nitrofurazone(NZF)and 2,4,6-trinitrophenol(TNP)at parts per billion levels,and are thus among the top-performing MOF-based luminescent sensors.Both MOFs also show high adsorption abilities,and therefore serve as effective tools for pollutant removal.

Van de Voorde et al.[97]attempted to segregate phenolics from aqueous mixtures by means of liquid-phase adsorption over a family of MOFs(MIL-140(B/C/D)),which were found to outperform other kinds of porous solids.A breakthrough experiment with an MIL-140C column in aqueous solution confirmed its potential for the capture of pure hydroquinone.

5.2.3.Fuel upgrading

The major species of impurities in fossil fuels are sulfurcontaining and nitrogen-containing compounds(SCCs and NCCs,respectively),which naturally exist as byproducts in fossil fuels.Upon burning,these compounds give off toxic SOxand NOxgases,in addition to CO2,resulting in numerous environmental problems.Hence,the capture and isolation of hazardous materials—especially SCCs and NCCs—are extremely important prior to the use of fossil fuels.Although some strategies for the removal of these contaminants have been developed in the last few decades,the latest progress in adsorptive desulfurization(ADS)and denitrogenation(ADN)with MOF-based materials promises a more facile approach[81].

Studies show that specific functionalities such as active metal sites or pendent groups on ligands are much more important than porosity for ADS with MOFs.Yoon et al.[98]reported on the ADS capacity of diverse MOFs,and demonstrated that MOFs with OMSs are the most efficient adsorbents.MOF-74(Ni)and HKUST-1,which have sufficient OMSs in their structures,showed the maximum uptake of SCCs among the investigated MOFs.The polarity of the incorporated functional groups in a MOF is also responsible for its selective adsorptive performance toward these compounds.

In fact,the use of MOFs in ADN is more notable than their use in ADS,because of their preferred adsorption of NCCs over SCCs in most cases.The general trend in MOF adsorption selectivity is as follows:NCCs >SCCs >aromatics >aliphatics[99].Possible reasons for this trend are that the coordinative interactions between NCCs and the OMSs in MOFs are comparatively more exothermic than the interactions with SCCs,and the affinity of aromatics to MOF materials is greater than that of aliphatics.The adsorption behavior can also be explained using Pearson’s hard/soft acid/base theory.Van de Voorde et al.[100]applied a series of MIL-100 MOFs for the adsorption of contaminants in various model fuels,including indole(IND),thiophene(THP),and 1,2-dimethylindole(1,2-DMI).The results suggest that MIL-100(V)is an outstanding adsorbent with both high adsorption capacity and selectivity toward ADN.

5.3.Water adsorption

Water adsorption technologies have been extensively adopted in commercial applications,and are playing a significant part in our daily life.Ideal adsorbents should possess ①excellent chemical stability in water,②adjustable hydrophilicity,and ③a tailorable aperture for fine-tuning the adsorption profile and regulating the sorption kinetics.To improve the energy efficiency,water adsorbents should be developed to allow facile regeneration at or below 80°C;they should also utilize low-grade energy sources for further energy savings.Tuning the structure and function of MOFs makes it possible to modulate the strength of interactions with adsorbates accurately,thus facilitating the exploitation of solar energy or waste heat for sorption cycles.MOFs with high porosity and good hydrolytic stability are prominent candidates for industrial water sorbents in various fields,including fresh water production,adsorption-driven heat-reallocation systems,industrial or indoor dehumidification,humidity control,and more[52,53].

Atmospheric humidity is roughly estimated to equal 10%of the gross liquid freshwater reserves on earth.In many areas prone to drought around the world,atmospheric moisture is the most copious water resource.Therefore,the technology of adsorption-based water harvesting from the air is an energy-saving approach that is expected to relieve local water shortages[101].

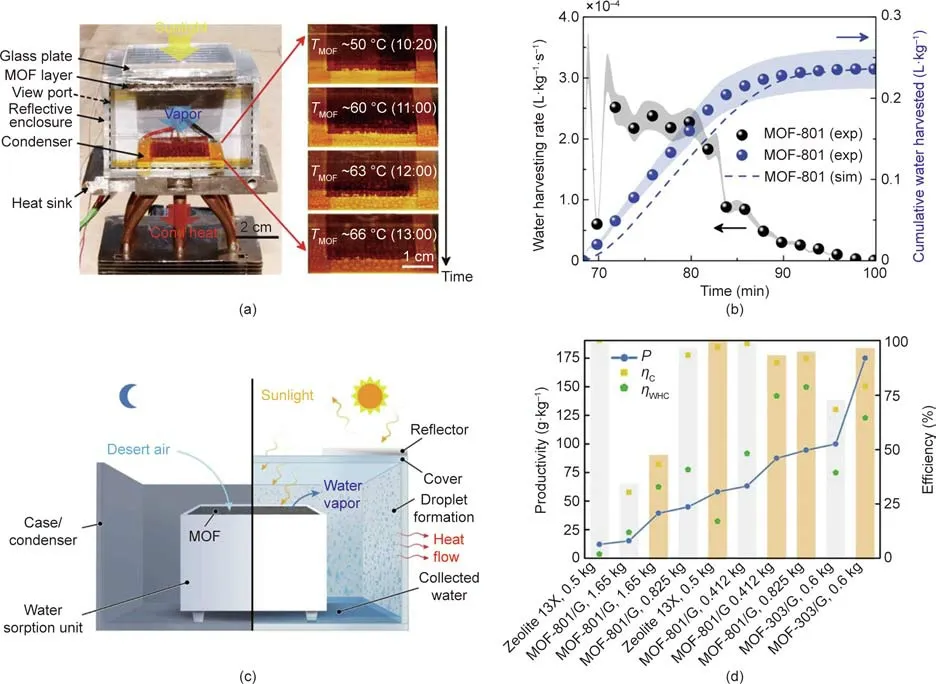

Kim et al.[102]reported the assembly of a device based on porous Zr-based MOF-801 that can harvest water vapor from the air at ambient conditions and is simply driven by natural sunlight at a flux of less than 1 kW·m-2.This device is able to capture 2.8 L of water per kilogram of MOF each day at relative humidity(RH)levels as low as 20%,and requires only low-grade heat from sunlight with no additional energy input(Figs.5(a)and(b)).

In the following year,Fathieh et al.[103]reported a lab-todesert demonstration in which a prototype device using up to 1.2 kg of MOF-801 adsorbents was tested in the lab,and then tested later in the desert of Arizona,USA.Using only natural cooling and ambient sunlight as an energy source,this device can harvest 100 g of water per kilogram of MOF-801 in each dayand-night cycle.These researchers also reported an aluminum(Al)-based MOF-303,which can deliver more than twice the amount of water.The desert experiment revealed crucial parameters relating to the material,energy,and atmosphere requirements for the efficient capture of moisture from desert air,even at a subzero dew point.These efforts bring water production in desert climates one step closer to practical application(Figs.5(c)and(d)).

Efficient MOF water adsorbents that can be recycled at low temperatures are particularly desired for the development of green adsorption-driven heat pumps and chillers for refrigeration;however,the design of such MOFs presents significant difficulties to date.Wang et al.[104]provided the water sorption profiles of a porous Zr-MOF,MIP-200(MIP stands for the materials of the Institute of Porous Materials from Paris),which is characterized by a high water uptake of 0.39 g·g-1belowP/P0=0.25(whereP0is saturation vapor pressure)on S-shaped sorption isotherms,facile regeneration,and—strikingly—a remarkably high coefficient of performance of 0.78 for refrigeration at a low driving temperature(below 70°C).Given its outstanding water adsorption performance,MIP-200 may be a promising substitute for currently available adsorbents for the purposes of commercial refrigeration.

Seo et al.[105]reported that two hierarchically porous MOFs with good hydrothermal stability—MIL-100 and MIL-101—show high adsorption capacities even at 40°C in combination with fast desorption below 80°C.The enhanced performance of MIL-100 and MIL-101 indicates their feasibility for commercial applications such as freshwater production and energy-efficient desiccant dehumidification.

Fig.5.(a)A water-harvesting device based on MOF-801(left);formation and growth of water droplets as a function of temperature and local time(right)(Cond:condensed).(b)Experimentally characterized water-harvesting rate and cumulative water harvested during desorption(exp:experiment;sim:simulation).(c)Schematic of a water harvester prototype for producing water from desert air.(d)Comparison of parameters pertaining to the efficiency and productivity of the water harvester in the desert.Measurements under low and high fluxes are shown as gray and orange bars,respectively(P:productivity;ηC:collecting efficiency;ηWHC:harvesting efficiency of a water harvesting cycle).(a,b)Reproduced from Ref.[102]with permission of American Association for the Advancement of Science,©2017;(c,d)reproduced from Ref.[103]with permission from the authors,©2018.

Indoor RH levels for comfortable and healthy surroundings within residential structures range from 45% to 65%.Towsif Abtab et al.[106]recently reported that a highly stable MOF,Cr-soc-MOF-1(soc=square–octahedral),exhibits an exceptional water vapor uptake of 1.95 g·g-1at 70%RH,and that the adsorbed water can be fully desorbed by means of easy reduction.Cr-soc-MOF-1 showed a record performance in terms of gross and deliverable capacity,reversibility,and recyclability,and thus has great potential for use in indoor moisture control and dehumidification.

The use of MOFs for diversified adsorption-based applications—ranging from fuel storage to pollutant removal and water sorption—has been demonstrated in efforts to address energy and environmental issues.The performances of MOFs surpass those of many conventional materials used for adsorption and require far less energy supply.However,several problems must be resolved before the practical implementation of MOFs as superior materials.Much more intensive research is needed on starting material availability,fabrication and regeneration cost,and framework stability in processing and working,in order to sharpen the competitive edge of MOF materials and make them realistic options to advance green chemical engineering.

6.Separation application

Separation is a critical process in production-and living-related applications including the petrochemical industry,mining,fine chemical engineering,pharmaceuticals,environmental management,and more.A broad range of separation approaches have been established to satisfy widely varying separation requirements.Although much progress has been made,significant challenges still remain in separation science and technology,such as intensive energy consumption,complex equipment,and safety hazards under harsh conditions.Hence,there is a pressing need to develop alternative methods for separation with higher efficiency,fewer adverse impacts,and lower cost.In adsorptive processes,separation relies on differences in the adsorption and desorption behavior of the constituents of a mixture,which are closely connected to their absorbency in terms of adsorptive equilibria and kinetics.Therefore,advancements in high-performing separation materials can facilitate the sustainability of separation processes.The intrinsic properties of MOFs—especially their highly tailorable pore and surface chemistry,which permits high selectivity toward guest species—makes this library of materials particularly appropriate for this challenging task.Research on MOF separations spans a wide range of fields,including gas or vapor separation,liquidphase separation,chiral separation,and MOF membrane-based separation,which are categorized according to the properties of the analytes[107,108].

6.1.Adsorptive gas separation

6.1.1.Air separation

One of the most attractive separation applications of research in porous materials is the efficient separation of light gases(i.e.,H2,N2,CH4,O2,CO,and CO2)to address energy and environmental issues.MOF materials have recently demonstrated great promise in the sequestration of CO2from other gases,among which selective CO2sorption from gas mixtures(especially from CO2/N2and CO2/CH4)has gained the most attention.Several comprehensive reviews have already summarized research advances in this area,including basic concepts,simulative and experimental results,insights into interaction mechanisms,and strategies for target designs[73,109,110].Most of the reported selective adsorption performances can be explained as being due to molecular sieving and/or specific interactions between guest species and the host frameworks.

Although some MOFs have been researched for CO adsorption,most cannot adsorb CO molecules strongly enough to capture trace amounts or to selectively bind CO over various other gases.Other frameworks afford such strong CO binding that the adsorption process becomes irreversible,making regeneration difficult,which hinders their utilization in practical applications.As a result,the design of smart frameworks with appropriate interaction with CO molecules is of great importance in CO separation.Reed et al.[111]demonstrated the selective adsorption of CO in a family of MOFs—Fe2Cl2(bbta)(H2bbta=1H,5H-benzo(1,2-d:4,5-d′)bistriazole)and Fe2Cl2(btdd)(H2btdd=bis(1H-1,2,3-triazolo[4,5-b],[4′,5′-i])dibenzo[1,4]dioxin)—through the cooperative binding effect.These compounds present high CO separation capacities with tiny temperature variations and facile regeneration,and thus may enable more efficient extraction of CO from industrial waste feeds.

Due to similarities between the shape of the O2and N2molecules and their size with that of argon(Ar),it is not easy to discover a porous material that is suitable for efficiently separating O2from air.Some MOFs have exhibited selective adsorption of O2over N2and other gases via size exclusion.In contrast,the presence of active OMSs in MOFs always results in a stronger preference for chemisorbing O2relative to N2through charge transfer.Bloch et al.[112]discovered the ability of Fe2(dobdc)to selectively uptake O2over N2via an electron transfer interaction.This O2adsorption is completely reversible,and the capacity is as high as 18.2%in mass fraction at 211 K,which is estimated to be equivalent to one O2molecule being adsorbed per iron(Fe)center.These findings,together with ideal adsorbed solution theory(IAST)calculations,indicate that Fe2(dobdc)is a competent candidate for the separation of O2from air at temperatures much higher than those currently set in industry.

6.1.2.Light hydrocarbons separation

Although adsorptive separation is considered to be a more energy-efficient alternative to traditional separations,its use in light hydrocarbon separation remains challenging due to the similar physicochemical properties of gaseous olefin,paraffin,and their olefin and alkyne counterparts with the same number of carbon atoms.MOFs,which permit precise tuning of composition and structure,have recently been demonstrated to have an exceptional ability to discriminate between the minor variations among these molecules in light hydrocarbon separation.

(1)Separation of gaseous olefins and paraffins.In the preparation of pure C2H4and C3H6for the production of polymers and high-value fine chemicals,the key processing step is the separation of ethylene/ethane(C2H4/C2H6)and propylene/propane(C3H6/C3H8)mixtures.Although various separations with MOFs were reported based on the π-complexation interaction and kinetic separation,these methods have not yet been demonstrated to be fairly effective.

Most MOF adsorbents preferably trap C2H4over C2H6and can thus be used for the removal of C2H6byproducts from C2H4.Bao et al.[113]reported a series of MOFs—namely,the M-gallate series(M=Ni,Mg,Co)—whose aperture sizes(3.47–3.69 Å,1 Å=10-10m)are perfectly adaptable to the molecular sieving of C2H4(3.28 Å×4.18 Å×4.84 Å)and C2H6(3.81 Å×4.08 Å×4.82 Å)via molecular cross-section size variations.In particular,Co-gallate shows a record IAST selectivity of 52 for C2H4adsorption over C2H6,as well as a C2H4uptake of 3.37 mmol·g-1at 298 K and 1 bar.Breakthrough experiments with 50:50(volume ratio)C2H4/C2H6mixtures also evidenced M-gallate’s high selectivity toward ethylene.

In the separation of C2H4/C2H6mixtures,if C2H6is preferentially adsorbed,the desired C2H4product stream can be directly obtained from the adsorption cycle through a simpler process,with higher efficiency,selectivity,and productivity.Compared with C2H4-selective adsorbents,a preference for C2H6would result in a decrease in the energy input of approximately 40% for C2H4/C2H6separation.Li et al.[114]recently reported a microporous MOF—Fe2(O2)(dobdc),which has Fe-peroxo sites—that prefers C2H6over C2H4and thus shows highly selective separation of C2H6/C2H4.With the use of a fixed-bed column packed with this MOF,polymer-grade pure C2H4(99.99%)can be directly recovered from C2H6/C2H4mixtures during the first adsorption cycle.The potential of Fe2(O2)(dobdc)for C2H6/C2H4separation is thus confirmed,with low energy consumption under ambient conditions.

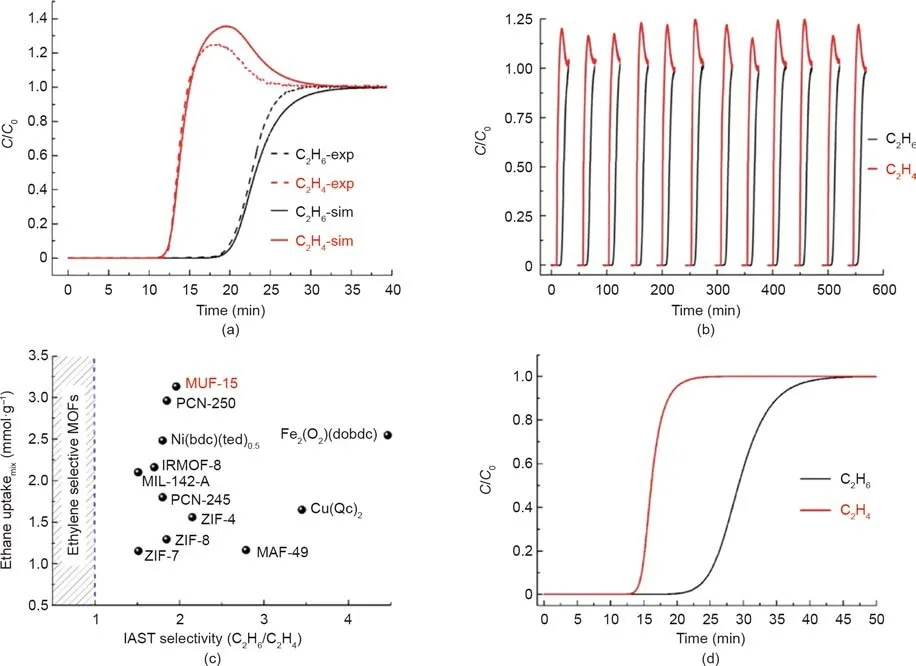

More recently,Qazvini et al.[115]reported that a MOF,Massey University framework(MUF)-15,can sequester C2H6from C2H6/C2H4mixtures.Its productivity in this separation is unprecedented:1 kg of MOF yields 14 L of polymer-grade C2H4gas in a single adsorption step from a 50:50 C2H6/C2H4feedstock.Multicomponent breakthrough curves suggest that this separation performance can be maintained over a wide range of feed compositions and operating pressures.Its attributes of framework robustness,synthesis from inexpensive precursors,constant performance in the presence of acetylene,and easy regeneration provide a MOFbased solution for challenging separations in chemical engineering(Fig.6).

The purity of C3H6mainly relies on the removal of C3H8,similar to the case of C2H4/C2H6.Cadiau et al.[116]used chemically stable fluorinated MOF King Abdullah University of Science and Technology(KAUST)-7 to separate C3H6from C3H8by fine-tuning the aperture size on a 0.2–1 Å scale.The restricted MOF window that was resulted from the incorporation of(NbOF5)2–leads to the selective molecular exclusion of C3H8from C3H6at ambient pressure.

(2)Separation of gaseous olefins and alkynes.The removal of a trace amount of alkyne impurity(i.e.,acetylene and propyne(C3H4))from an olefin stream is essential for the production of polymer-grade olefin feed gas.Adsorptive alkyne-selective capture using MOFs is more energy efficient and environmentally friendly than traditional methods,and the adsorbed alkynes can be further utilized in other applications;thus,this method has enormous appeal for researchers.

Cui et al.[117]developed control over pore chemistry and size in the hexafluorosilicate(SiF62-,SIFSIX)MOFs(SIFSIX-1-Cu,SIFSIX-2-Cu,SIFSIX-2-Cu-i,SIFSIX-3-Cu,SIFSIX-3-Zn,and SIFSIX-3-Ni)for the preferred capture of C2H2molecules over C2H4.Among these materials,SIFSIX-2-Cu-i exhibits a high adsorption capacity toward C2H2(2.1 mmol·g-1at 0.025 bar)and the highest C2H2/C2H4separation selectivity(39.7–44.8)under ambient conditions,as evidenced by the experimental breakthrough curves(0.73 mmol·g-1from 1:99 mixture).The absorbed C2H2molecules are assembled in an orderly manner within the MOF pores,by means of cooperative host–guest and guest–guest interactions.

Compared with C2H2/C2H4separation,C3H4/C3H6separation is notoriously more difficult due to the closer kinetic diameters of C3H4and C3H6.Li et al.[118]carried out a comprehensive screening of a series of MOFs with diverse structures,pore sizes,and functionalities,and identified UTSA-200 as the optimal separating material for the segregation of trace C3H4from C3H4/C3H6mixtures.This material has a record purification capacity for the removal of C3H4impurities from a 1:99(or 0.1:99.9)C3H4/C3H6mixture,and yields 99.9999%pure C3H6with a productivity of 62.0(or 142.8)mmol·g-1.

Fig.6.(a)Simulative and experimental breakthrough curves for an equimolar C2H6/C2H4 mixture with MUF-15.(b)Several C2H6/C2H4 separation cycles for a 25:75 C2H6/C2H4 mixture.(c)Ethane uptake in an equimolar C2H6/C2H4 mixture as a function of IAST selectivity among top-performing MOFs(IRMOF:isoreticular metal–organic framework;bdc:benzenedicarboxylate;ted:triethylenediamine;Qc:quinoline-5-carboxylate).(d)Simulative breakthrough curves for a 0.1:99.9 C2H6/C2H4 mixture.C/C0 represents the relative concentration.Reproduced from Ref.[115]with permission of the American Chemical Society,©2019.

A major barrier to the production of high-purity C2H2is the removal of coexisting CO2impurity,as C2H2and CO2are extremely close in size(3.32 Å×3.34 Å×5.70 Å vs 3.18 Å×3.33 Å×5.36 Å),shape,and boiling point(189.3 K vs 194.7 K).The separation of these compounds is indispensable but arduous.To address this issue,Peng et al.[119]employed two ultra-microporous MOFs with high hydrolytic stability,Nankai metal–organic framework(NKMOF)-1-M(M=Cu or Ni),to selectively adsorb acetylene versus several gases at ambient temperature.NKMOF-1-M shows better low-pressure uptake than current physisorbents and provides the highest selectivity reported to date for C2H2/CO2separation.

1,3-Butadiene(C4H6),which is a necessary raw material in rubber manufacturing,is usually the desired component in C4 hydrocarbon mixtures comprising butanes,butylenes,and butadiene from the steam cracker.The separation of C4 hydrocarbons is more challenging than the separation of C2 and C3 hydrocarbon mixtures,due to the coexistence of various structural and cis/trans isomers.Liao et al.[120]showed that a hydrophilic MOF,[Zn2(btm)2](H2btm=bis(5-methyl-1H-1,2,4-triazol-3-yl)methane),weakens 1,3-butadiene adsorption in a C4 hydrocarbon mixture.In a breakthrough measurement under ambient conditions,this adsorbent eluted the target 1,3-butadiene first,followed successively by butane,butene,and isobutene.Through this facile separation,the 1,3-butadiene purity was considerably improved(≥99.5%);meanwhile,side reactions under high temperature such as polymerization were avoided.

6.1.3.Isotopes separation

Although molecular sieving principles are widely applicable,they are not relevant for isotope separation,because isotopic molecules have almost identical adsorption properties.To separate isotopes,a quantum molecular sieving process may suffice,in which heavier isotopes are preferably adsorbed over lighter ones,based on the difference in the quantum energy levels of the atoms or molecules.The activity of several MOFs in H2/D2separation via quantum sieving was recently studied,including ZIF-7,ZIF-8,metal–organic framework Ulm-University(MFU)-4,and MOF-74(M).In this work,Cao et al.[121]selected an ultra-microporous MOF,[Fe(OH)(H2bta)]·H2O(H2bta=bis(tetrazolyl)amine),for experimental investigations of the ultralow-temperature separation of H2/D2through quantum sieving.They achieved a superior separation factor as high as 41.4±0.4 at 20 K.

6.1.4.Noble gases separation

Noble gases,including helium(He),neon(Ne),Ar,krypton(Kr),xenon(Xe),and radon(Rn),have very similar physical properties and occur naturally as mixtures with other gases.Thus,their separation is both important and troublesome.Of particular interest is the enrichment and separation of Xe and Kr from the off-gas stream from nuclear plants.The pore size of the adsorbents is crucial in determining Xe/Kr selectivity.In recent years,researchers from BASF have confirmed that with HKUST-1 as an adsorbent,a simple pressure-swing adsorption process is practicable in the preferable adsorption of Xe from Kr.The calculated adsorption capacity of HKUST-1 for Xe is greater than 60% in mass fraction—nearly twice the amount captured by commercial active carbon[122].

6.2.Liquid mixtures separation

As with gas-phase separations,porous materials have emerged as hopeful next-generation adsorbents for liquid-phase separations.Regrettably,fewer efforts have been devoted to MOFs for liquid-phase separations compared with gas-phase separations thus far.However,an increasing number of scientists have recently focused on the judicious design and selection of functional MOFs to separate target liquid mixtures[123,124].

6.2.1.Separation of linear/branched alkane hydrocarbons(C5–C6–C7)

The petroleum industry highly values the laborious separation of linear,monobranched,and dibranched isomers of alkanes,and particularly dibranched C5–C7 paraffins,which are the main components of gasoline with high research octane number(RON)values.Some MOFs can selectively accommodate linear alkanes while excluding their branched analogues in order to achieve effective separation.

In 2013,Herm et al.[125]published a report on Fe2(BDP)3(BDP2-=1,4-benzenedipyrazolate),a highly stable framework with triangular channels,which showed diverging behaviors toward different hexane isomers based on the degree of branching.A breakthrough experiment confirmed an adsorption selectivity trend ofn-hexane(nC6)>2-methylpentane(2MP)>3-methylpen tane(3MP)>2,3-dimethylbutane(23DMB)≈2,2-dimethylbutane(22DMB).Computational simulations indicate that Fe2(BDP)3can be similarly applied to separate pentane and heptane isomers based on the degree of branching.For pentane isomers,the adsorption strengths of Fe2(BDP)3show a decreasing order:n-pentane(nC5)>2-methylbutane(2MB)>neopentane(neo-P).For heptanes,they show the following order:n-heptane(nC7)>2-methylhexane(2MH)≈3-methylhexane(3MH)>2,2-dimethylpentane(22DMP)≈2,3-dimethylpentane(23DMP).

6.2.2.Separation of cyclic C6 isomers(benzene/cyclohexane)

The major difficulty in C6 hydrocarbon stream separation is segregating Bz from its azeotropic congener cyclohexane(Cy).Enabling the underlying Lewis acid/base interactions between the OMSs of an appropriate MOF and the target Bz molecules is expected to be a facile approach to manipulate the purification of Cy flow.Mukherjee et al.[126]exploited seven isostructural MOFs—M2(dobdc)(M=Ni,Mn,Zn,Mg,Cu,Co,Fe)—with abundant OMSs in structures for Bz adsorption in preference to Cy.IAST calculations and breakthrough simulations indicate that remarkably efficient separations of equimolar Bz/Cy mixtures are feasible over Mn2(dobdc).

Introducing favorable π–π stacking interactions between the πelectron-deficient MOF inner surface and π-electron-sufficient guest species(i.e.,Bz)can also accomplish Bz/Cy separation,as confirmed by Manna et al.[127].Following this concept,they then reported another MOF,diaminotriazine(DAT)-MOF-1,which is capable of sharp separations in a fixed bed,as evidenced by IAST calculations and breakthrough simulations.

6.2.3.Separation of cyclic C8 isomers(styrene/ethyl benzene and xylene isomers)

In the alkylation of a Bz reactor,the styrene(St)product stream usually contains 20%–40%unreacted ethyl benzene(Eb).Bulk production of polystyrene for commercialization demands large amounts of pure St as a primary monomer feedstock.A comparative performance assessment among HKUST-1,MIL-53(Al),and MIL-47(V)adsorbent beds indicated excellent St/Eb selectivity by MIL-47(V).Nevertheless,the more robust sorbent MIL-53(Al)is seemingly more appropriate for application in St/Eb separation on the required industrial scale,because during the exclusion of the undesirable Eb,higher St selectivity for other impurities(mainly toluene)in the crude St stream can also be achieved[128,129].

For the scale-up synthesis of polyethylene terephthalate(PET)in industry,p-xylene(pX),which is the well-known precursor,should have high purity.Nevertheless,discovering ap-selective sorbent is not an easy task,given the negligible differences between all of the critical physical parameters of xylene isomers,particularly from a pore and surface chemistry design standpoint.A series of MOFs have been developed as stationary phases forpX separation.In addition to the high performances provided by rigid MOF sorbents,such as the well-known MIL family,some MOFs with flexible pore windows(e.g.,ZIFs)exhibit a sorptionmediated ‘‘breathing” behavior that achieves the phenomenon of sorption-based separation of xylene isomers.As a significant benchmark,IAST calculations assessed the separation selectivity for breathable DynaMOF-100 and found them to be remarkably higher than those for BaX and metal–azolate framework(MAF)-X8,the best-performingpX-selective sorbents that have been evaluated for xylene isomer separation in the industrially recognized simulated moving-bed process[130].

6.2.4.Biofuel purification

Ethanol is the most common constituent of biofuel,and is also known as the popular concept ‘‘bioethanol.” The production of ethanol through the fermentation of molasses inevitably generates traces of methanol and water.Consequently,bioethanol purification is a current global focus in order to increase the deliverable capacity of this fuel.Zhang et al.[131]performed EtOH and water sorption experiments followed by molecular simulations involving six ZIFs(ZIF-8,ZIF-25,ZIF-71,ZIF-90,ZIF-96,and ZIF-97).Their study identified ZIF-8 as the most interesting candidate for practical use in ulterior biofuel purification.

6.2.5.Oil/water separation

The broad utilization of petroleum and diesel products as a major global energy source carries the perpetual risk of spillages and explosion during storage,transportation,and exploitation.Scavenging such spillages is urgent and costly,since the longer they were present,the more severe the destruction they wreak on aquatic biota would be,and the larger the amount of pollutants they would discharge.In this regard,MOFs have been verified as being suitable to contribute to some advances.

A family of highly hydrophobic MOFs,represented by fluorinated ultrahydrophobic metal–organic framework(UHMOF)-100,have been constructed on demand.Mukherjee et al.[132]further fabricated UHMOF-100 into a recyclable and low-cost membrane form namedUHMOF-100/polydimethylsiloxane(PDMS)/polypropylene(PP).This MOF composite shows high absorption capacity in an oil/water(1:1)mixture separation,which indicates that this composite is a potential solution to marine oil spillage and related environmental pollution.

6.2.6.Isomers separation