Effect of Surface Energy of Electrospun Fibrous Mat on Dynamic Filtration Performance for Oil Particles

ZHOU ZhiyongZHOU MengjuanHUANG XiaoruiZHANG HongnanDUAN GaigaiQIN XiaohongLIU Li

1 College of Textiles, Donghua University, Shanghai 201620, China 2 Co-Innovation Center of Efficient Processing and Utilization of Forest Resources, College of Materials Science and Engineering, Nanjing Forestry University, Nanjing 210037, China

Abstract: Oil particle removal, different from the removal of general salt particular matter, has an unusual filtration process in which oil particles will be captured by forming a continuous film on the surface of the filter. Therefore, it is important to investigate the effect of surface property of the filter on the oil particle dynamic filtration process. In this study, three fibrous mats with different surface energies were fabricated from polyacrylonitrile(PAN), polyacrylonitrile/cellulose acetate(PAN/CA), and polyacrylonitrile/polyvinylidene fluoride(PAN/PVDF) solutions by needleless electrospinning. PAN/PVDF fibrous mat presented the lowest surface energy(19.99 mJ/m2), followed by PAN/CA fibrous mat(29.49 mJ/m2) and PAN fibrous mat(40.91 mJ/m2). As the oil particle filtration went on, the PAN/PVDF fibrous mat presented both the fastest filtration efficiency decline(4.72% in 10 min) and the fastest filtration resistance increase(543.41 Pa in 10 min).

Key words: fiber technology; interface; electrospinning; dynamic filtration; oil particle

Introduction

As the development of society, health has become the focus of attention worldwide[1]. According to the World Health Organization(WHO), air pollution, by which more than 5 million people are killed around the world every year, has become one of the most issues causing health problems[2]. In developing countries, 90% people are suffering from the constant threat of indoor smoke and mist/smog suspending in the air. And the air pollution largely contributes to the premature death and the increased fatality rate from acute respiratory infections, lung cancer, stroke,etc.[3]Particulate matter, always known as aerosol forming mist from factories, cars, home and other human activities, is the sum of all the liquid and solid microscopic/fine particles suspending in the air[4], which can contain hazardous components. Generally, filtration is a typical approach to remove them through filter[5]. Filter medium, considered as the first important line of defense against particulate pollutant, is predominately fabricated by fibrous structures[6-7]. Many works have been conducted to investigate effects of the pore size and the porosity on filtration properties. However, the research on surface properties of the filter is relatively less.

Solid particles have irregular shapes, but liquid ones are always keeping nearly spherical shape in the air[8]. Specially, oil particles, sometimes called oil droplets, can move like liquid on the surface of objects[9]. And many organic toxic chemicals tend to dissolve well in organic solvents[10-11]. Particularly, oil particle removal, different from the general salty solid particular matter, has an unusual filtration process, in which oil particles will be captured by forming a continuous clogging film on the surface of the filter during the filtration process[12]. Owing to this unique filtration process of oil particles that they still possess an ability to move during the filtration process, the filtration performance for oil particles, to some extent, varies depending on the process. Generally, the oil particle filtration mainly consists of three stages: an initial stage, a transitional stage, and a quasi-equilibrium stage[13-15]. In addition, Weietal.[16]validated the surface hydrophobicity effects on small oil mist filtration by coating a perfluoroalkyl acrylic copolymer. However, less research focuses on the relation between surface properties and dynamic filtration process. Therefore, this prompts us to investigate the effect of surface properties of the filter on the oil particle dynamic filtration process.

Herein, three fibrous mats were fabricated from polyacrylonitrile(PAN), polyacrylonitrile/cellulose acetate(PAN/CA), and polyacrylonitrile/polyvinylidene fluoride(PAN/PVDF) solutions by needleless electrospinning. The mass fraction among them was controlled to tune the surface energy to study the corresponding oil particle filtration performance. The fibrous diameter and the pore size of mats were diminished by controlling electrospun parameters. Then the effect of surface energy of fibrous mats on the dynamic filtration performance for oil particles was explored, which proved the importance of surface energy of fibrous mats on filtration.

1 Materials and Methods

1.1 Materials

PAN powder(75 000 g/mol) was supplied by Shanghai Jinshan Petrochemical Co., Ltd., China. PVDF(530 000 g/mol) was supplied by Sigma Aldrich(Shanghai) Trading Co., Ltd., China. CA(mass fraction of acetyl was 39.8%) was supplied by Shanghai Aladdin Biochemical Technology Co., Ltd., China.N-Ndimethylformamide(DMF, analytical reagent) was purchased from Sinopharm Chemical Reagent Co., Ltd., China. All chemicals were used without further treatment.

1.2 Preparation of spinning solution

A certain amount of PAN and CA or PVDF was dissolved in DMF solution to prepare fibrous membranes with different surface energies. For PAN/CA solution, the mass fraction of PAN to CA was 8: 2, and the total mass fraction was 8%. For PAN/CA solution, the mass fraction of PAN to CA was 7: 3, and the total mass fraction was 12%. To obtain homogeneous spinning solutions, the mixed solutions should be stirred magnetically(350 r/min) at 60 ℃ for 5 h, and stood for about 2 h before electrospinning.

1.3 Fabrication of fibrous mat

Electrospinning fibrous mats with different surface energies were fabricated by a needleless electrospinning setup, as illustrated in Fig. 1. It consisted of five main parts: a DC high voltage power supply, a rotating drum collector, a solution pump, a moving platform, and a metal curved edge bowl-like spinneret, as shown in Fig. 1(a). The polymer solution was poured into the spinneret firstly until the liquid level was saturated. The solution flow rate could be adjusted with a peristaltic pump. It could be observed that multiple jets formed on the edge of the metal spinneret when a high voltage was applied, as shown in Fig. 1(b). In this study, PAN, PVDF and CA were selected as the components to adjust surface energy by controlling the mass fraction. While being subjected to a voltage of 55-60 kV, the distance between the spinneret and the collector, the temperature, and relative humidity were kept to be 18 cm, 21 ℃ and 40%, respectively, during the electrospinning process. The fibrous diameter was controlled by adjusting the total concentration of spinning solutions and the mass fraction of PAN to CA or PVDF. Generally, the pore size was influenced significantly by the thickness of fibrous mats, so the spinning time was controlled to change the thickness of fibrous mats to obtain mats with similar pore sizes.

Fig. 1 Schematic and image of electrospinning:(a) needleless electrospinning setup; (b) electrospinning process

1.4 Characterization

The morphology of fibrous mats was characterized by scanning electron microscopy(SEM6000, KYKY Technology Co., Ltd., China). The values of the average fibrous diameter were calculated from a minimum of 100 fibers measured by the Nano-measurer 1.2 software and the pore size distributions were determined by the Porometer type aperture tester(POROLUXTM100FM, Porometer NV Co., Ltd., China). The contact angle of fibrous mats was measured by a drop method with a contact angle tester(OCA15EC, Data Physics Instruments Co., Ltd., China). The surface groups of fibers were measured and characterized by a Fourier transform infrared spectroscopy(FT-IR) (Antaris 2, Thermo Fisher Instruments Inc., American). Surface energy of fibrous mats was calculated by the Owens two-liquid method[17]. An automatic filter material tester(TSI 8130, TSI Incorporated Co., Ltd., American) was employed to evaluate the filtration performance. The concentration of dioctyl phthalate particles(DOPs) was in a range of 50-200 mg/m3, the mass median diameter was about 0.3 μm, and the flow rate was 32 L/min. The quality factorQFwas calculated according to whereQFis the quality factor,ηis the filtration efficiency, and ΔPis the pressure drop.

2 Results and Discussion

2.1 FT-IR analysis of fibrous mat

Fig. 2 FTIR spectra of PAN, PAN/CA and PAN/PVDF fibrous mats

2.2 Morphologies and structure of PAN, PAN/PVDF and PAN/CA fibrous mats

Generally, pore sizes of fibrous mats and fibrous diameters are key points to affect the filtration performance of the filter medium. Therefore, it is important to fabricate fibrous mats with similar fibrous diameters and pore sizes to further research the role of surface of filter medium. As SEM images shown in Figs. 3(a)-3(c), smooth fibers with mean diameters around 226, 200 and 220 nm were obtained by needleless electrospinning from PAN/DMF, PAN/CA/DMF, and PAN/PVDF/DMF solutions, respectively, with the modification of contents in the solution. Correspondingly, as illustrated in Fig. 3(d), the resulting pore sizes of these three fibrous mats were all chiefly distributed around 1.3 μm. The result of the contact angle measured by the device of OCA15EC was shown in Fig. 4. It clearly revealed that the contact angles all of PAN, PAN/PVDF, and PAN/CA fibrous mats were over 90o, indicating their hydrophobicity. As the addition of CA and PVDF, the contact angle changed, it increased from 109° to 135° when CA or PVDF were added into PAN spinning solutions. Generally, the contact angle experiment was considered as one of the most common ways to evaluate the surface energy due to its simplicity. According to the Owens two-liquid method[17], there is negative correlations between the contact angle and the surface energy. Fibrous mats with a larger contact angle depict lower surface energy. Consistently, with the addition of CA or PVDF, the surface energy of PAN fibrous mats changed, as shown in Fig. 5. PAN/PVDF fibrous mats had the lowest surface energy(19.99 mJ/m2), smaller than the surface energy of PAN/CA fibrous mats(29.49 mJ/m2) and PAN fibrous mats(40.91 mJ/m2).

Fig. 3 Morphology and structure of fibrous mats: (a) SEM of PAN fibrous mat; (b) SEM of PAN/CA fibrous mat; (c) SEM of PAN/PVDF fibrous mat; (d) profiles of corresponding diameter distribution; (e) pore size distribution

Fig. 4 Contact angle: (a) PAN fibrous mat; (b) PAN/CA fibrous mat; (c) PAN/PVDF fibrous mat

Fig. 5 Surface energy of PAN, PAN/CA, and PAN/PVDF fibrous mats

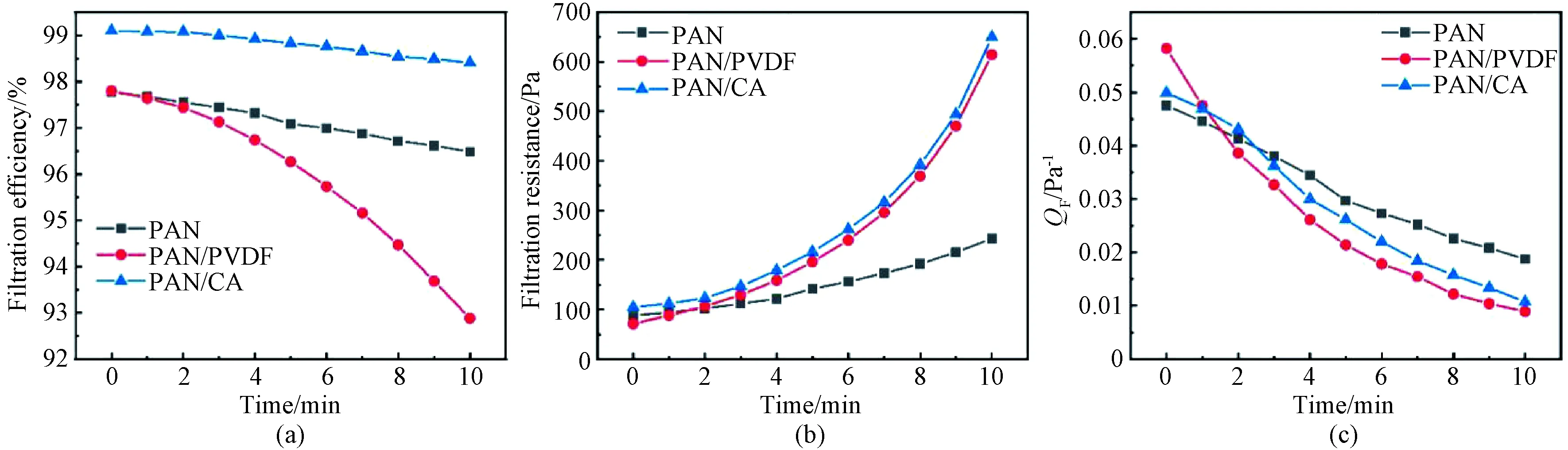

Fig. 6 Dynamic filtration performance of fibrous mats: (a) filtration efficiency; (b) filtration resistance; (c) QF

2.3 Dynamic filtration performance

During the filtration process against particulate matter, the particles suspended in the air will be captured or trapped among fibrous mats, or adsorbed on the surface of fibrous mats by the mechanism of diffusion, interception, inertial impaction, sieving, and electrostatic attraction[21]. Unlike the solid state, oil particles are easy to aggregate to form oil droplets, and the fluid nature allows oil particles to move/flow on the surface of mats, and tends to create oil film as oil particles flow and collect. Therefore, the surface property of fibrous mats will significantly influence the oil particle filtration process. The oil droplet is easier to move on the surface of fibrous mats when the surface energy is lower. And this will have a great impact on the dynamic oil particle filtration process.

To test the assumption above, the filtration efficiency and filtration resistance of the fabricated fibrous mats as described above were performed to validate the effect of surface energy. As presented in Fig. 6(a), during the process of filtration, the filtration efficiency of all fibrous mats decreased over time. And the efficiency of PAN/PVDF fibrous mats, possessing the lowest surface energy of 19.99 mJ/m2, was reduced by 4.72% in 10 min, and dropped dramatically compared with PAN/CA and PAN fibrous mats with higher surface energy as the filtration test went on. However, the filtration efficiency of PAN/CA fibrous mats(0.69%) was higher than that of PAN fibrous mats(1.29%), because the pore size distribution of PAN fibrous mats was broader than that of PAN/CA fibrous mats which was helpful to capture more oil particles. So this result was still in reasonable agreement with the previous description that particles were harder to be captured by fibrous mats with lower surface energy[18], which caused the particles to escape easily resulting in a faster filtration efficiency decline.

In sharp contrast to the efficiency, the filtration resistance showed a completely different trend with time, as shown in Fig. 6(b), and the fibrous mats with low surface energy exhibited a sharp increase. The filtration resistance of PAN/PVDF fibrous mats increased by 543.41 Pa in 10 min, the PAN/CA fibrous mats showed the same filtration resistance behavior as PAN/PVDF fibrous mats, and their filtration resistance increased by 540.74 Pa in 10 min, which was much larger than that of PAN fibrous mats(155.04 Pa) with the highest surface energy. As the surface energy of fibrous mats decreased, some oil particles intercepted on the surface of the fibrous mats in the filtration were easy to move on the surface of fibrous mats, thus leading to a faster gather resulting in clogging. The filtration resistance of PAN/PVDF and PAN/CA fibrous mats with low surface energy increased rapidly. Commonly, higher surface energy generates lower quality factor decline for the dynamic oil particle filtration, as illustrated in Fig. 6(c).

3 Conclusions

In conclusion, to validate the surface energy effect on the dynamic oil particle filtration, three fibrous mats with different surface energies were fabricated by needleless electrospinning technology. The result shows that the surface energy has a great impact on the oil particle filtration process. As the filtration process going on, the filtration efficiency of PAN/PVDF fibrous mats with the lowest surface energy drops most rapidly due to the escape of particles, and it decreases by 4.72% in 10 min. The filter medium with low surface energy causes a sharp increase in filtration resistance as a result of a fast oil particles gather. The filtration resistance of PAN/CA and PAN/PVDF fibrous mats increases by 543.41 Pa and 540.74 Pa respectively in 10 min, much faster than that of PAN fibrous mats(155.04 Pa). All in all, higher surface energy causes better dynamic oil particle filtration.

Journal of Donghua University(English Edition)2021年6期

Journal of Donghua University(English Edition)2021年6期

- Journal of Donghua University(English Edition)的其它文章

- Strain Pseudomonas putida PAO-1 Isolate with Polyphosphate Accumulating and Elongation Ability

- Theoretical Model on Transformation Factors of Scientific and Technological Achievements under the Belt and Road Initiative

- Exploitation of Waste Heat from a Solid Oxide Fuel Cell via an Alkali Metal Thermoelectric Converter and Electrochemical Cycles

- Gait Recognition System in Thermal Infrared Night Imaging by Using Deep Convolutional Neural Networks

- Feature Fusion Multi_XMNet Convolution Neural Network for Clothing Image Classification

- Data Augmentation Based Event Detection