Micro-mechanical damage diagnosis methodologies based on machine learning and deep learning models

Shahab SHAMSIRBAND ,Nabi MEHRI KHANSARI

1Future Technology Research Center,College of Future,Yunlin University of Science and Technology,Yunlin 64002,China

2Faculty of Mechanical Engineering,Sahand University of Technology,Tabriz 51335-1996,Iran

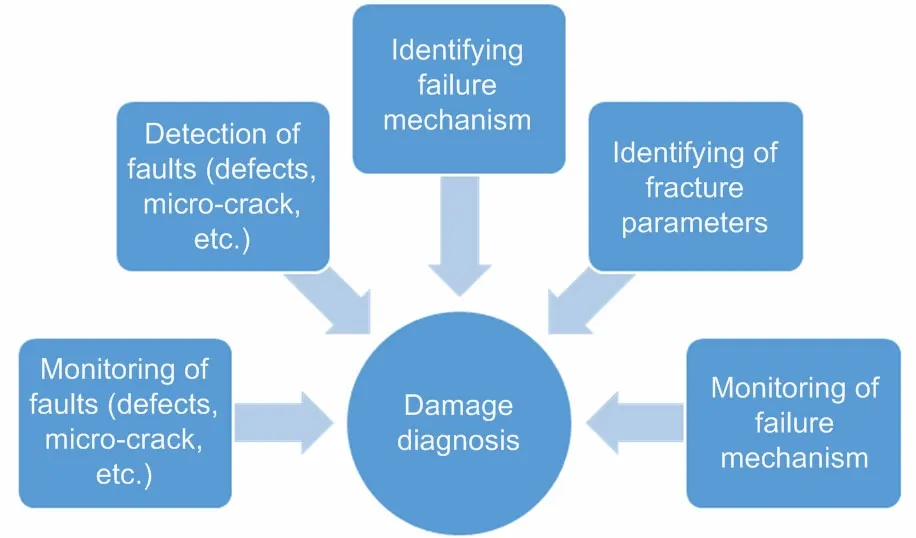

Abstract:A loss of integrity and the effects of damage on mechanical attributes result in macro/micro-mechanical failure,especially in composite structures.As a progressive degradation of material continuity,predictions for any aspects of the initiation and propagation of damage need to be identified by a trustworthy mechanism to guarantee the safety of structures.Besides material design,structural integrity and health need to be monitored carefully.Among the most powerful methods for the detection of damage are machine learning (ML) and deep learning (DL).In this paper,we review state-of-the-art ML methods and their applications in detecting and predicting material damage,concentrating on composite materials.The more influential ML methods are identified based on their performance,and research gaps and future trends are discussed.Based on our findings,DL followed by ensemble-based techniques has the highest application and robustness in the field of damage diagnosis.

Key words:Damage detection;Machine learning (ML);Composite structure;Micro-mechanics of damage;Deep learning (DL)

1 Introduction

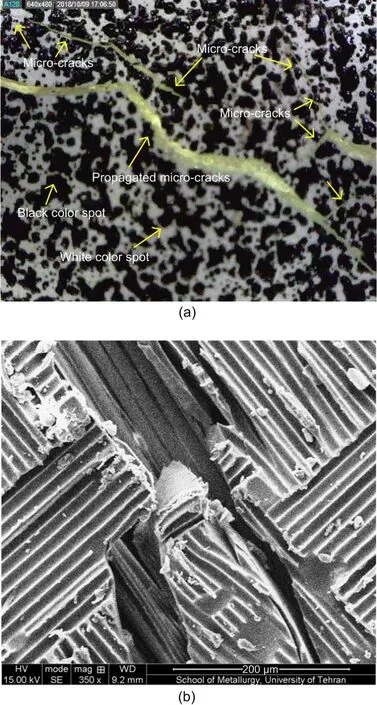

Depending on the application,defects in materials may be created for different reasons and in different forms.For instance,the initiation and propagation of defects in orthotropic solid materials (e.g.concrete,wood,and some composite structures) are decisive factors in failure analysis of these materials.Unlike deformable materials,in which failure is associated with the initiation of micro-voids,in brittle and quasi-brittle materials,failure is associated with the development of micro-cracks (Khansari et al.,2019).In this case,softening is caused by the growth of the damage zone in the material,causing changes in the distribution of ensemble stresses.Generally,two well-known analytical approaches,continuum damage mechanics (CDMs) and micro-mechanics of damage (MMD),are applied to investigate damage in isotropic and anisotropic structures (Khansari et al.,2019).MMD is divided into three main methods:shear lag,variation principals,and stress transfer mechanics.These methods represent analytical methods and cannot detect the position,size,or configuration of the damage.Fig.1 shows micro-crack initiation and detection of crack propagation in the vicinity of the crack tip in digital image correlation(DIC) and scanning electron microscope (SEM)glass/epoxy test specimens using an optical method(Khansari et al.,2019).

Fig.1 Micro-crack initiation (a) and detection of crack propagation (b) in the vicinity of a crack tip in glass/epoxy DIC and SEM test specimens

The micro-mechanics of inhomogeneity-induced solid-like materials comprising micro-cracks has been classified by several authors.For instance,ellipsoidal defects in elastic solids were described by Eshelby(1957).In a similar study,Walpole (1967) proposed a general solution of anisotropic elasticity for a spherical inclusion in a medium of cubic anisotropy.A mathematical formulation was derived for solving Boussinesq’s equation to describe the stress field in anisotropic materials under various loadings (Willis,1968).Mura and Lin (1974) derived theoretical concepts to describe the eigen strain of anisotropic materials.These concepts concentrated on various kinds of inclusions and cracks.Thus,the micro-mechanics of anisotropic materials has been described with significant precision.Mathematical methods devised for transversely isotropic materials with dispersion of 2D elliptical cracks in the vicinity of a field of discontinuity with arbitrary shape show that local stresses and displacements are valid (Kassir and Sih,1968).Asaro(1975) obtained a general integral theory for internal stress problems in anisotropic elastic media.The main focus of the study was dislocations and their internal stresses.Later,a theoretical method was derived for stress and displacement of a flat elliptical crack field(Irwin,1962),as well as expressions describing the energy of a crack in an isotropic medium (Budiansky and Rice,1973).Taking into account the importance of residual strength,an analytical approach was proposed for the effective elastic modulus of both circular and elliptical defects (Budiansky and O'connell,1976).The research concentrated on the selfconsistent method (SCM),in which the elastic moduli can be obtained for solids with random 2D defects.Budiansky and O'connell (1976) outlined general concepts for arbitrary defects and proposed theoretical results for elliptic 2D cracks.However,the characteristics of defect-induced anisotropic plates,especially at the crack tip domain,require a representation of nonlinearity in stress and displacement fields.Asymptotic (Hoenig,1982) and computational(Hoenig,1978) approaches have been proposed to identify the complexity of the stress and displacement of the elastic field of defects induced in anisotropic plates subjected to homogenized far stress fields.Also,stress and displacement fields around ellipsoidal discontinuities can be evaluated based on numerical (Ghahremani,1977) and analytical (Laws,1975)methods for uniform loading.

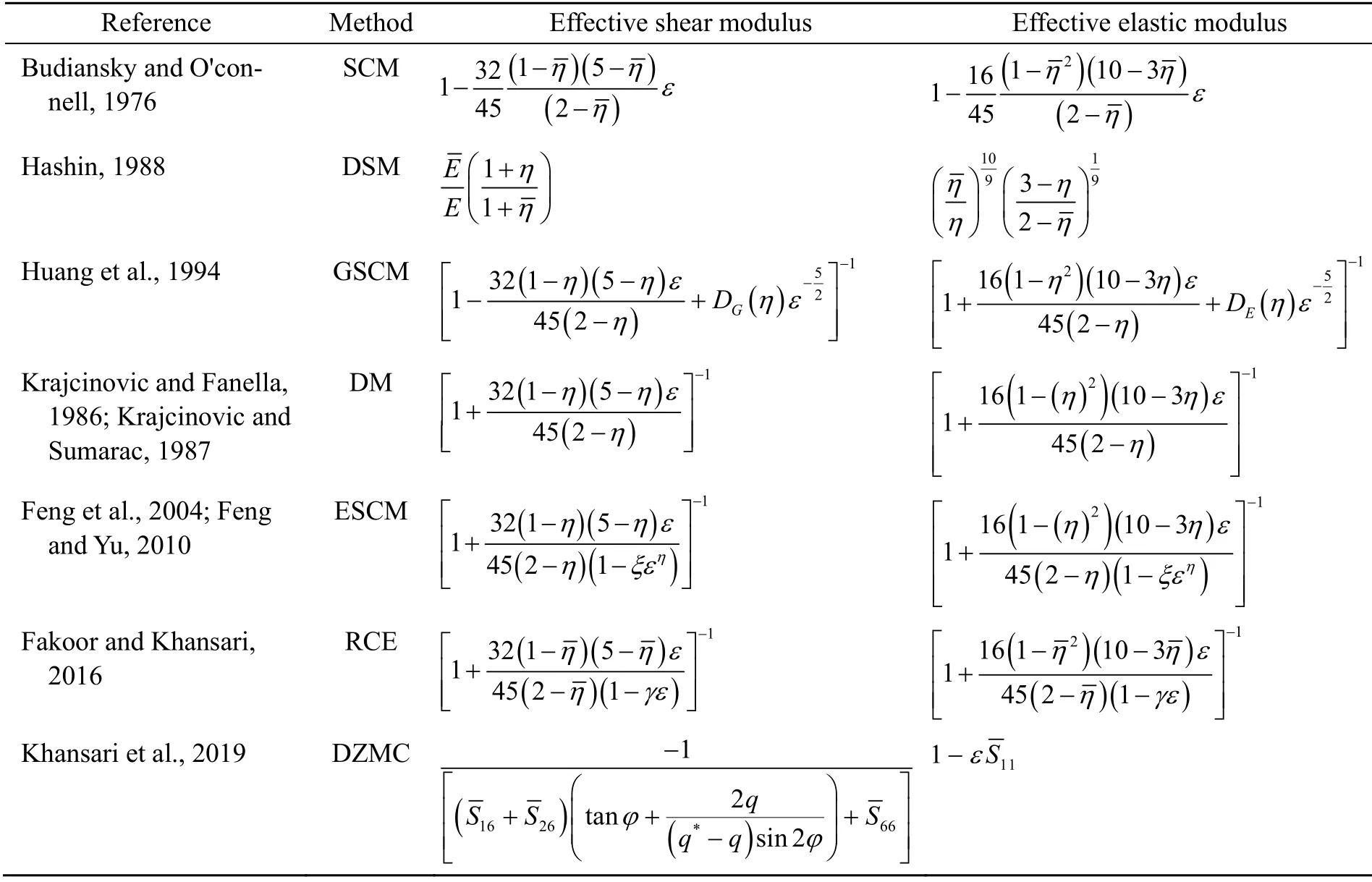

Other significant parameters required for the analytical representation of materials with induced defects are their closed or open shapes and densities.Nguyen et al.(2017) extended the proposed solution of porous media effective constants based on the theories of Walsh and Budiansky-O'Connell,in which the density of closed and open micro-cracks depends on the stress configuration (Hoenig,1978).The interaction between micro-defects like micro-cracks can be another significant parameter for classifying theoretical methods.There are theories with assumptions of non-interaction (Sneddon,1946,1951;Willis,1968;Krajcinovic,1989;Ju,1991;Nemat-Nasser and Hori,1993;Fakoor and Khansari,2016) like deep collocation method (DCM),and more accurate methods with assumptions of interaction (Kachanov,1993) like SCM (Budiansky and O'connell,1976),generalized self-consistent method (GSCM) (Christensen and Lo,1979;Huang and Liu,1998),effective self-consistent method (ESCM) (Feng and Yu,2000),Mori-Tanaka method (Mori and Tanaka,1973),and differential method (Hashin,1988).However,methods which take account of the uncertainty of microcrack interaction,like the stochastic methods (Hoenig,1978,1982;Kunin,1982;Fakoor and Khansari,2016,2018a;Khansari et al.,2019),may be convenient for representing defect-induced solids.Some of the effective methods,including interaction theories,are presented in Table 1.

Table 1 Effective methods for defect representation,including interaction theories

In Table 1,DSM,RCE,DZMC,and DM represent differential scheme method,representative circular element,damage zone micro-mechanical criterion,and dilute concentration method,respectively.

The effective module of elasticity of multiphase materials (e.g.quasi-isotropic and homogeneous) can be modeled based on the definition of linear elasticity principles when the ratios of the different phase moduli are not too large.The variation of effective moduli can be derived by considering variation-based elasticity principles such as the Hashin-Shtrikman variational principle (Hashin and Shtrikman,1963).According to the variational principles that can underpin an applicable theory of multiphase material analysis,mathematical derivations are enhanced for nonlinearity,such as inhomogeneity,by considering clustering methods.Schneider (2019) proposed a self-consistent analysis for non-linear materials according to the derivation of a cluster-based Lippmann-Schwinger equation that was broadly based on the Hashin-Shtrikman variational principle at small strains.

Therefore,not only heterogeneous detection of materials,but also multistate modeling and calculation of heterogeneous media should be computed,especially for localization of the microstructure,macro-structural instability,and accurate computational procedure.Liu ZL et al.(2018) proposed a non-local macroscopic damage model for instability representative volume elements (RVEs) in which the macroscopic response of the damage zone can be analyzed as well as micro-scale stress and strain fields.The model ascertained that the macro-scale strain was sensitive to the micro-scale constitutes.

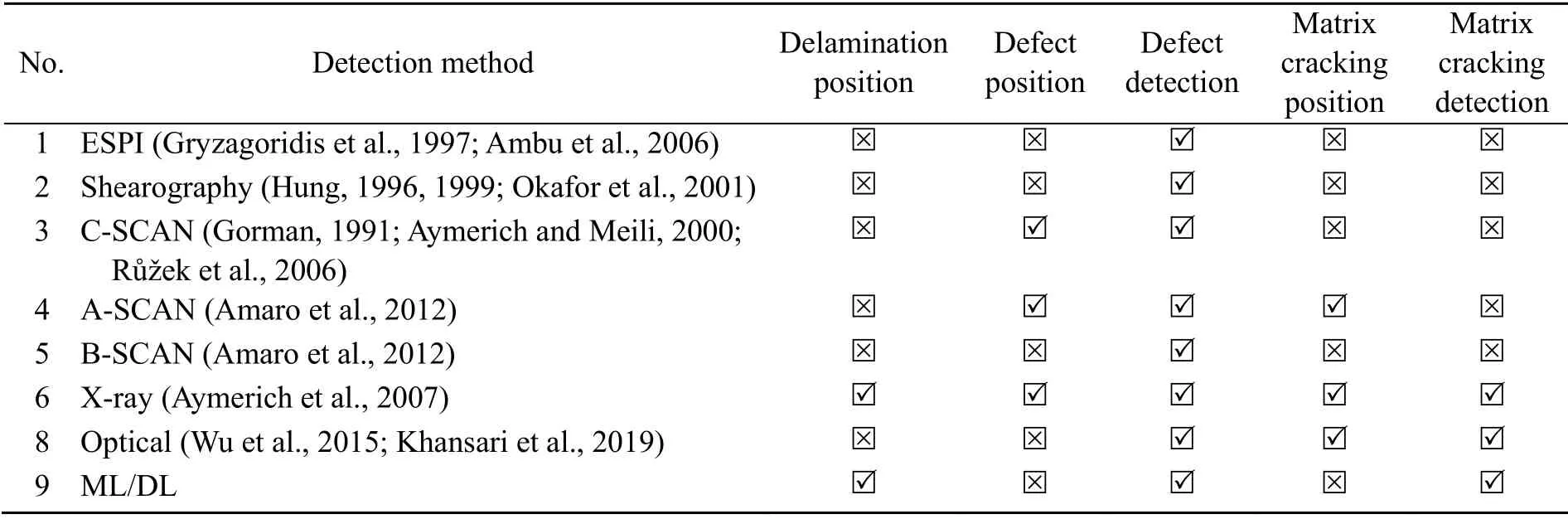

Although the analytical and numerical investigation of damage has a significant role in material behavior,the detection of the damage zone is a prerequisite step that can be evaluated by machine learning(ML) and deep learning (DL) methods.ML as a smart method (Cheng et al.,2020;Godoy et al.,2020;Zhang et al.,2020),uses reliable procedures for identifying discontinuities in material structures.In addition to the main review,here we present some ML/DL detection methods which have been used to detect micro-defects(micro-cracks in micro-scale),and which can be used instead of some costly experimental methods.Table 2 presents a comparison of defect detection in a glass/epoxy composite using the ML/DL and the non-destructive testing (NDT) methods.

Table 2 A comparison of NDT and ML/DL methods for defect detection

General damage detection methods for various materials and loading conditions can be investigated using ML and DL methodologies (Kan et al.,2017;Huang and Wang,2018;Jang et al.,2018;Krummenacher et al.,2018;Wang et al.,2018;Hong et al.,2019;Zhang et al.,2019).Based on their suitability and importance (Lin et al.,2017;Li HY et al.,2019;Ni et al.,2019;Patala,2019;Pu et al.,2019;Quaranta et al.,2019),ML and DL methods have a significant role in damage identification (Cha et al.,2018;Chen et al.,2019;Finotti et al.,2019).Although ML methods can provide convenient methods of detection,they are no longer used for the detection of defect positions.ML techniques can be divided into two categories based on the general structure of the method.Single techniques use one ML technique according to the main purpose.A single method contains a simple architecture suitable for simple and limited datasets,but cannot cope with complex tasks and huge datasets.Therefore,there is a need for other techniques.Recently,researchers have developed hybrid techniques.These techniques use two or more ML techniques to increase the accuracy of the system and exploit their capabilities.The only advantage of a single technique is a low processing time in simple systems.However,single techniques have disadvantages like low accuracy with large and complex datasets and low reliability for instilling confidence and ensuring system functionality (Dineva et al.,2019;Ardabili et al.,2020b).Hybrid techniques can overcome the disadvantages of single techniques.The most important advantage of hybrid techniques is their high processing potential for increasing the accuracy and functionality of the system (Mosavi et al.,2019;Ardabili et al.,2020a).Because of their greater efficiency,ML methods have been widely applied in fields such as soft computing and data mining,and combined with optimization methods(Gordan et al.,2017,2018).In addition to uncertaintybased methods,ML methods have been applied to the detection of the location of defects and the corresponding damage zone in composite structures(Fakoor and Khansari,2018b;Khansari et al.,2019).

Cha et al.(2018) proposed a detection method based on quasi-simultaneous real-time for various types of damage in which a developed region-based convolutional neural network (CNN) was used.Hong et al.(2019) proposed a multimillion-atom reactive molecular dynamics (RMD) method for the investigation of the defect healing process.Huang and Wang(2018) validated the accuracy of the bending-shearing critical crack method (BSCCM) and reduced the equivalent transformation formulas for a nonstandard specimen.Jang et al.(2018) applied ML and dual-sensing methods to the prediction of failure in an asymmetric structure.Zhang et al.(2019) used different ML algorithms to predict mechanical properties of single-layer graphene under different impact parameters.Krummenacher et al.(2018) proposed two ML methods for detecting wheel defects using sensors installed on a railway.Li HY et al.(2019)applied three clustering methods including selfconsistent,virtual,and finite element method (FEM)-clustering analysis in ML to investigate material behavior.However,the loading conditions and other parameters comprising material shortcomings and flaws can play a significant role in the detection of structural failure.For example,an ML framework has been used to identify damage loading conditions based on residual plastic deformation or damage status (Ren et al.,2018).Also,Chen et al.(2019) improved a new DL technique to characterize the impact load status for solid shell structures,in which the final case of inelastic deformation or damage was considered.The approach included a practical solution for solving some of the failure analysis inverse problems concerning permanent plastic deformation.Artificial intelligence (AI)-based ML has been used as a novel approach to identify the damage loading conditions of structures,including permanent plastic deformation.Permanent plastic deformation as a structural response was considered as DL-fed input and the loading conditions as output (Chen et al.,2019).Therefore,the static loading condition was identified by the proposed DL approach as well as the impact dynamic loading condition,considering permanent plastic deformation.

Recently,a DCM based on feedforward deep neural network (DNN) has been proposed to evaluate the continuous transversal deflection in thin Kirchhoff plate bending problems (Guo et al.,2019).This method provides both distributed collocation points inside the domain and boundaries,and minimization of the boundary and initial conditions by using the corresponding loss function.Another method based on artificial neural networks (ANNs) and an adaptive collocation method (ACM) was proposed to identify the partial differential equations (PDEs) (Anitescu et al.,2019).In this method,training points were used to present both the initial training steps as well as training points for later steps,considering a larger set of evaluation points.To distinguish the relationship between the effective macro-scale and overall properties of heterogeneous materials is a complicated process.DL method can be used to represent these relationships by considering a significant amount of data.A recent study used DL and image processing techniques to establish an accurate representation of the complexity of heterogeneous composite properties (Li X et al.,2019).Similarly,a multi-scale geological porous medium (e.g.mudstone,limestone,and rock) with pores of various sizes has been modeled using a DL-based hybrid data-driven method in which porous material is modeled by sub-scale simulations (Wang and Sun,2018).This method is more flexible and efficient than classical FEMs.A multiscale heterogeneous material assessment was also established by a deep material network based on an ML method and RVE localization (Liu et al.,2019).In this method,complexities of the overall material due to voids or discontinuities were described according to a neural network and homogenization solutions.

Li and Zhang (2016) presented an adaptive stochastic resonance (SR) method integrated by ensemble empirical mode decomposition (EEMD) for the detection of structural defects (SDs).Because of the importance of the detection of vortex-induced vibration (VIV) for fluid-pass structures like airplanes,Lin(2018) proposed a new vision-based method for detecting the wake patterns of VIV.Their method employs multi-methods of edge feature description(EFD) with a multi-classifier of support vector machines (SVMs).Lin et al.(2017) proposed a new detection method considering deep CNN on noisy and noise-free datasets to realize damage locations.A data-driven hierarchical Bayesian degradation model was proposed by Liu et al.(2017) for the prediction of damage growth using the data-driven Bayesian model(DDMB) and finite element (FE),simultaneously.Pu et al.(2019) presented a detailed review of the prediction of rockburst potential by various applications of ML methods.Quaranta et al.(2019) presented an approach considering the integration of datamining and dimensionality reduction approaches for detection of structural health monitoring (SHM).Using this approach,the existing location and size of damage can be estimated.Two reviews (Gordan et al.,2017,2018) reported the general application of AI methods using hybrid algorithms of ANN and imperialist competitive algorithm (ICA) to identify the damage at a single-point in I-beam structures.Salehi et al.(2019) proposed an SHM method combining intelligent data mining methodology and noisy and delayed signals.Liu RN et al.(2018) presented a review of AI algorithms for identifying defects in rotating machinery using ML and DL methods.Although,the paper presented a full-field method of fault recognition,the type of experimental fault (e.g.discontinuity,micro crack,or other defects) was not mentioned.Razavi-Far et al.(2019a,2019c) proposed a hybrid method of fault detection in which a hybrid framework was applied to the diagnosis of bearing defects.Fault detection was limited to bearing defects and the type of defect was not clarified.This limitation also applies to other studies (Razavi-Far et al.,2009,2017,2019b),in which the detection method concerned defects in a gearbox,U-tube steam generator (UTSG),and bearing,respectively.In previous studies,not only was the type of defect not clarified mechanically but also the detection was restricted to special implementation.All of the proposed studies were focused on the computer aspects and special implementation,whereas the main basis of the research is derived from knowledge of micromechanical damage and computer science.There is a gap in the research that motivated us to conduct a comprehensive review of ML and DL models (Ren et al.,2018;Salehi et al.,2019).A comprehensive review of ML-and DL-based models is needed which considers prediction of failure onset in various industrial materials.Therefore,in the present study,the main concept was to introduce an efficient review of micro-defects and micro-mechanical damage diagnosis,especially for isotropic and composite materials not considered in previous studies.Our main contribution is to present some well-defined micromechanical detection methods using ML and DL,which have been used to detect micro-defects (microcracks in micro-scale) in isotropic and orthotropic materials (e.g.composites).In the previous studies,not only were the types of defect not clarified,but also detection was limited to either isotropic or orthotropic materials.

The manuscript is organized as follows:Section 2 presents a brief explanation of the methodology of the research.Section 3 explains the most important and frequently used single and hybrid ML techniques,including ANN,SVM,decision tree (DT)-based,fuzzy-based,linear regression (LR),and ensemblebased techniques used for handling damage diagnosis.Section 4 explains DL techniques and describes studies of damage diagnosis.Section 5 presents the discussion and Section 6 the conclusions.

2 Survey methodologies

The first aim of this survey was to develop a platform as the state of the art of ML techniques in the application of material damage diagnosis.Accordingly,we set out to identify and classify selected articles related to the design and implementation of sustainable techniques in the subject areas.There are many problems associated with identifying failures experimentally.However,using smart methods of ML and DL can improve the accuracy of procedures.Here,we attempt to present and compare several ML and DL methods (Fig.2).

Fig.2 Flowchart of the important keyword subjects used to select relevant studies for review

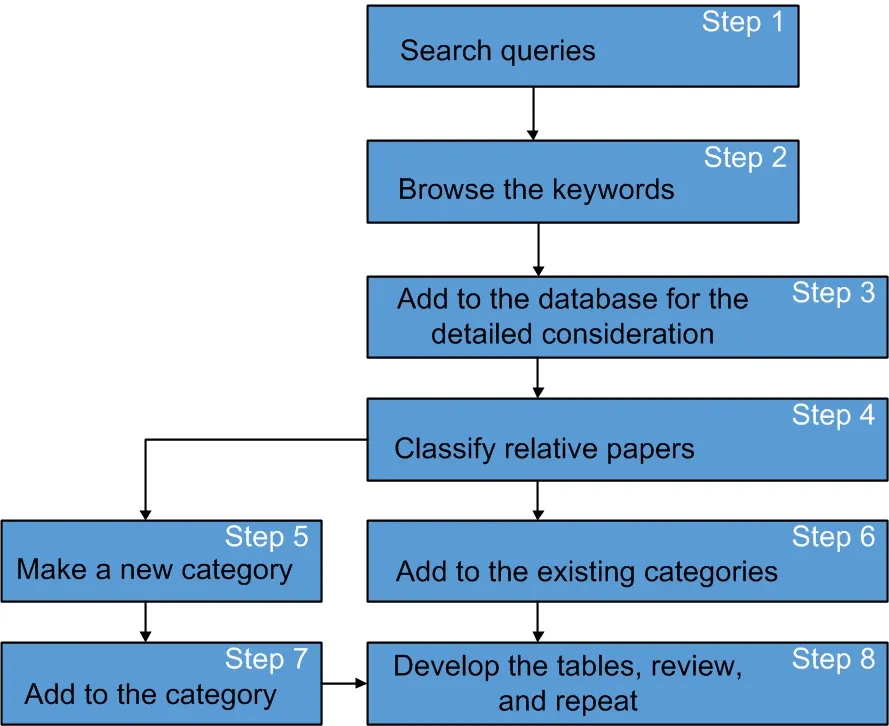

This approach provided a basic and structural framework based on a systematic database.Fig.3 presents a flowchart of the research methodology.The final approach was a modified version of a survey study.The first step involved the exploration of search queries in the field of damage detection.In the second step we explored articles to identify related literature and discard irrelevant publications.In the third step we created a database of relevant articles.In the fourth step we considered each article and identified the category of its applications.For an article that did not suit the existing categories,the fifth step allowed the creation of a new category,and the structure of the article was included in a new table of the application domain.In the sixth step,the details of the article were compiled in a table.If an article was deemed to relate to a new category,it was assigned to that category in step 7.In the final step,the content of the main database relating to the different categorieswas saved,the content of tables was updated,and the articles were reviewed.This workflow process was repeated until all the articles were categorized.

Fig.3 Flowchart of the methodology of research

3 Machine learning methods

The survey methodology classified the ML methods into seven groups:ANN-based,SVM-based,tree-based models,ensembles,Bayesians,LRs,and neuro-fuzzy.The last group was DL,which was considered separately.The notable papers were reviewed in each class.

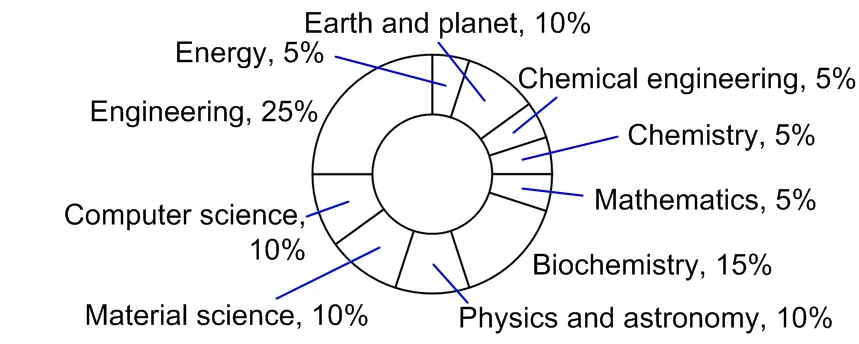

Fig.4 shows a sample generated by the Scopus Statistical Center which reports the application of ML techniques to different fields of science.Engineering had the highest percentage usage of ML in damage detection among the fields considered.

Fig.4 Application of ML to damage detection in various subject areas based on Scopus

3.1 Artificial neural network

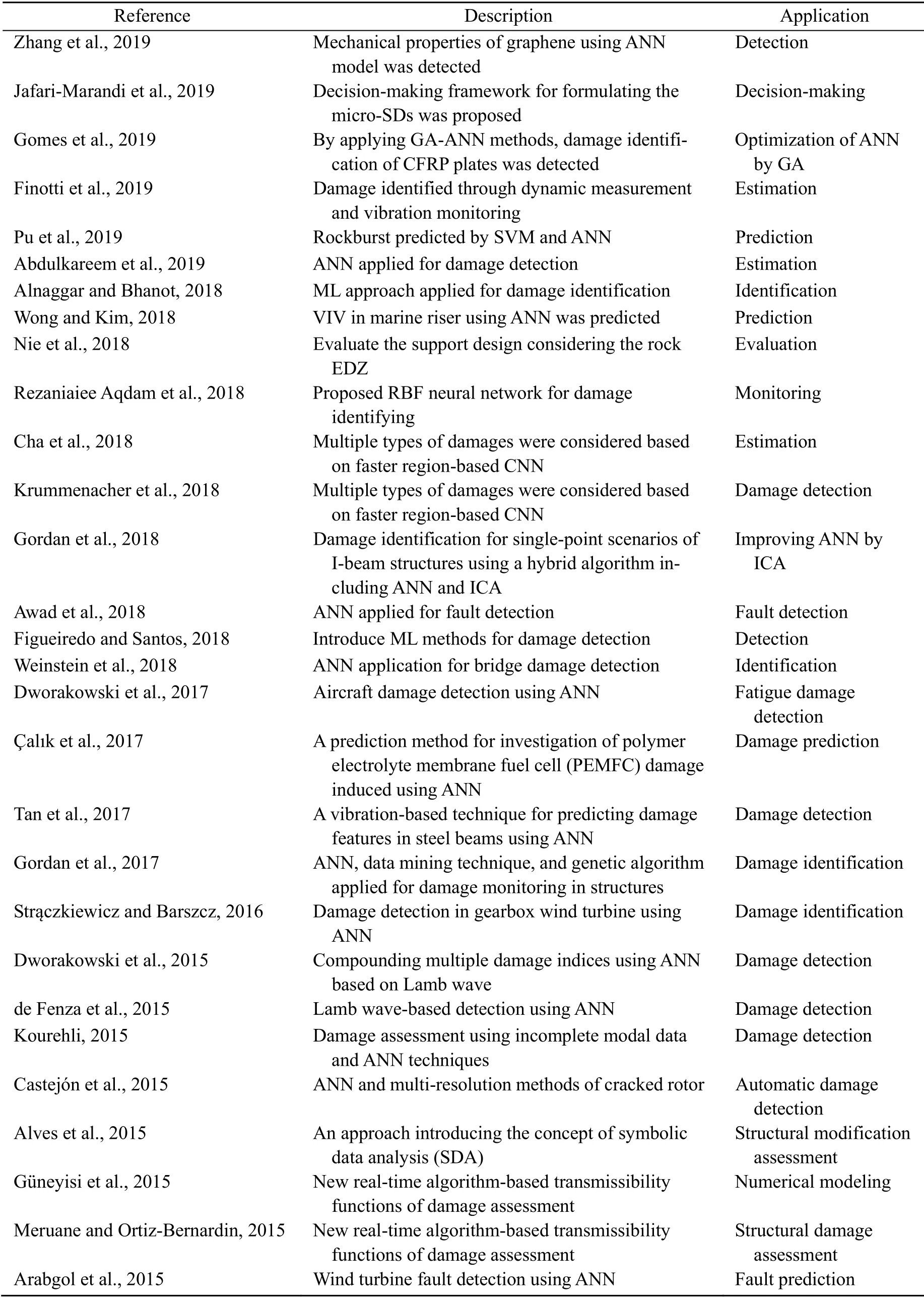

ANN can prepare general frameworks for analyzing damage induced in materials.Because ANN has various applications such as the accurate prediction of complex material behavior,it can be applied to damage detection and structural integrity in multivariable problems.Notable ANN-based models for damage diagnosis and prediction from 2015 to 2019 are summarized in Table 3.

Table 3 Notable ANN-based models for damage diagnosis and prediction

Zhang et al.(2019) used an ANN model to present a survey about the mechanical attributes of single-layer graphene under different loading and boundary conditions in addition to vacancy defect and chirality.Jafari-Marandi et al.(2019) proposed a decision-making framework for formulating micro-SDs and relative control actions based on ANN and self-organizing error-drive neural networks(SOEDNNs).Gomes et al.(2019) proposed damage identification methods for carbon fibre reinforced polymer (CFRP) plates using genetic algorithm (GA)-ANN methods.Finotti et al.(2019) investigated statistical indicators in damage identification for direct acceleration measurements characterized by comparing two ML algorithms of ANN and SVMs.Wong and Kim (2018) predicted VIV in a marine riser using ANN.Lin et al.(2017) proposed an approach to evaluate the support design for considering rock excavation damaged zone (EDZ) based on simulation of rock cavern performance in ANN.Taking into account health monitoring in mooring lines,Rezaniaiee Aqdam et al.(2018) proposed a radial basis function(RBF) neural network for damage identification.Recently,computer vision-based techniques were used to identify SHM.Cha et al.(2018) considered multiple damage points using a CNN based on a faster region.Krummenacher et al.(2018) proposed two ML methods for detecting wheel defects using sensors installed on a railway.A similar study was performed by Choi et al.(2016) in which the size andlocation of SDs were identified using hybrid vector components in hidden Markov model (HMM).Çalık et al.(2017) outlined a method for predicting induced polymer electrolyte membrane fuel cell (PEMFC)damage using an ANN.Tan et al.(2017) proposed a vibration method for predicting damage features in steel beams using ANN.Gordan et al.(2017) proposed a method based on data mining techniques(DMTs) and ANN for identifying damage configurations.Alves et al.(2015) proposed a method representing the concept of symbolic data analysis (SDA)for structural degradation processes by combining three well-known classification techniques,Bayesian decision trees (BDTs),ANN,and SVM.Due to the slow rate of learning when a large number of parameters are required when using ANN in damage assessment,a new real-time algorithm based on transmissibility functions of damage assessment was proposed by Meruane and Ortiz-Bernardin (2015).However,for several materials like bearing and gears,hybrid ANN methods can be more efficient.Not only ANN,but also hybrid ANN methods have several applications in studying isotropic and orthotropic materials and various composite materials.Gordan et al.(2018) proposed a data mining-based damage detection method for solid I-beam structures using a hybrid algorithm including ANN and ICA.Table 4 presents the results of notable hybrid and single ANN,mean square error (MSE),and mean absolute error(MAE) applications for damage assessment.

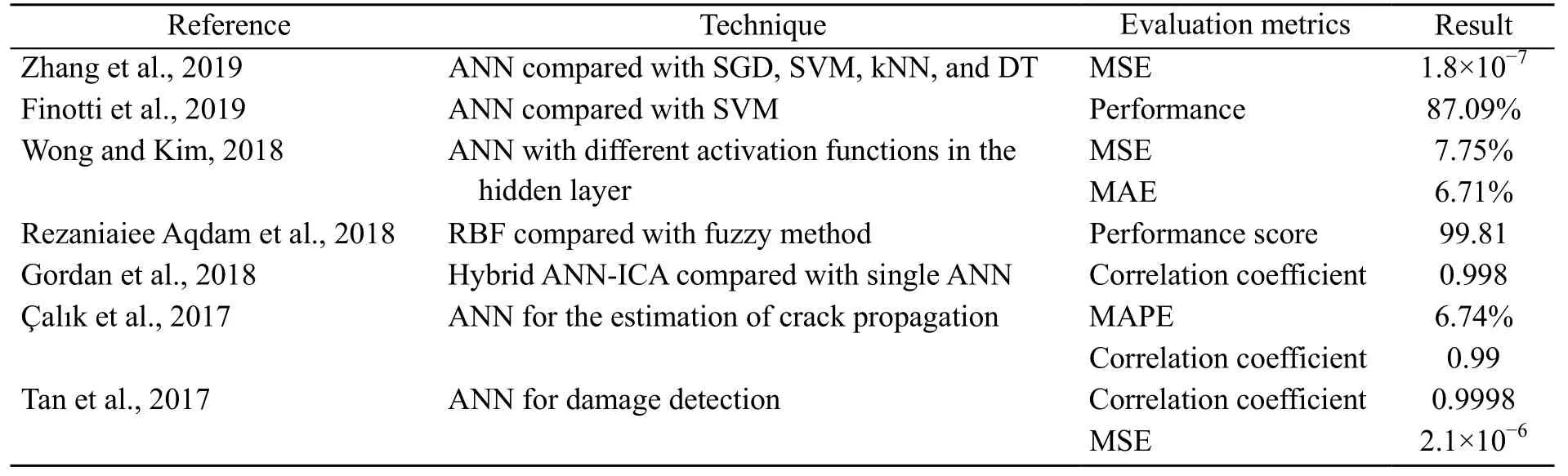

Table 4 Results of notable developed ANN techniques indicated by evaluation metrics

Zhang et al.(2019) compared an ANN method with stochastic gradient descent (SGD),SVM,k-nearest neighbors (kNN),and DT.The ANN was developed in four categories including two with one hidden layer and two with two hidden layers of either 20 or 40 neurons (ANN-20,ANN-40,ANN-20-20,and ANN-40-40).Results were compared using MSE as an evaluation metric.The ANN-40-40 had the lowest MSE (30%) compared with single-layer ANN and kNN (about 45%).The best model for the estimation of the fracture strain was DT (MSE 9.3×10−6)followed by SVM (MSE 1.5×10−5).In (Finotti et al.,2019),an ANN classifier was compared with an SVM classifier in terms of a performance factor,for monitoring structural health.The ANN contained a multilayer perceptron (MLP) with feed-forward topology.MLP with five neurons provided the best performance,about 8.5% better than that of the SVM classifier in the hidden layer.In the study of Wong and Kim (2018),an ANN was developed to estimate the top tensioned riser (TTR) fatigue damage targeted to short-term VIV generated by SHEAR7.The ANN was trained by linear,sigmoid,leaky rectified linear unit (ReLU),Tanh or ReLU as the activation function in the hidden layer.The evaluation metrics were MAE and MSE factors.The best predictor was ANN with the Tanh activation function.Using this predictor,the MAE was 6.71% and the MSE 7.75% better than those of the other activation functions.

Rezaniaiee Aqdam et al.(2018) compared an RBF method with a fuzzy method for health monitoring of floating structures using rod theory and FE method.Results were evaluated by scoring the number of damaged and undamaged samples for each method.The RBF method gave the highest performance.Gordan et al.(2018) extended a hybrid ANNICA method to the prediction of damage severity and compared it with a single ANN technique.The correlation coefficient was used as the evaluation metric.The ANN-ICA method proved to be robust,giving a 6.23% improvement in prediction performance compared with the single ANN technique.Çalık et al.(2017) extended an ANN for the prognosis of crack propagation.An ANN architecture with five neurons in the hidden layer was selected as the network with the highest performance,with a mean absolute percentage error (MAPE) of 6.74% and a correlation coefficient of 0.99.Similarly,Tan et al.(2017) used ANN for the estimation and detection of damage in steel beams.Different numbers of neurons in the hidden layer were used to train a proper ANN network,and accuracy was evaluated using the correlation coefficient.The best network was selected to be ANN with 10 neurons in the hidden layer (correlation coefficient 0.9998 and MSE 2.1×10−6).

3.2 Support vector machine

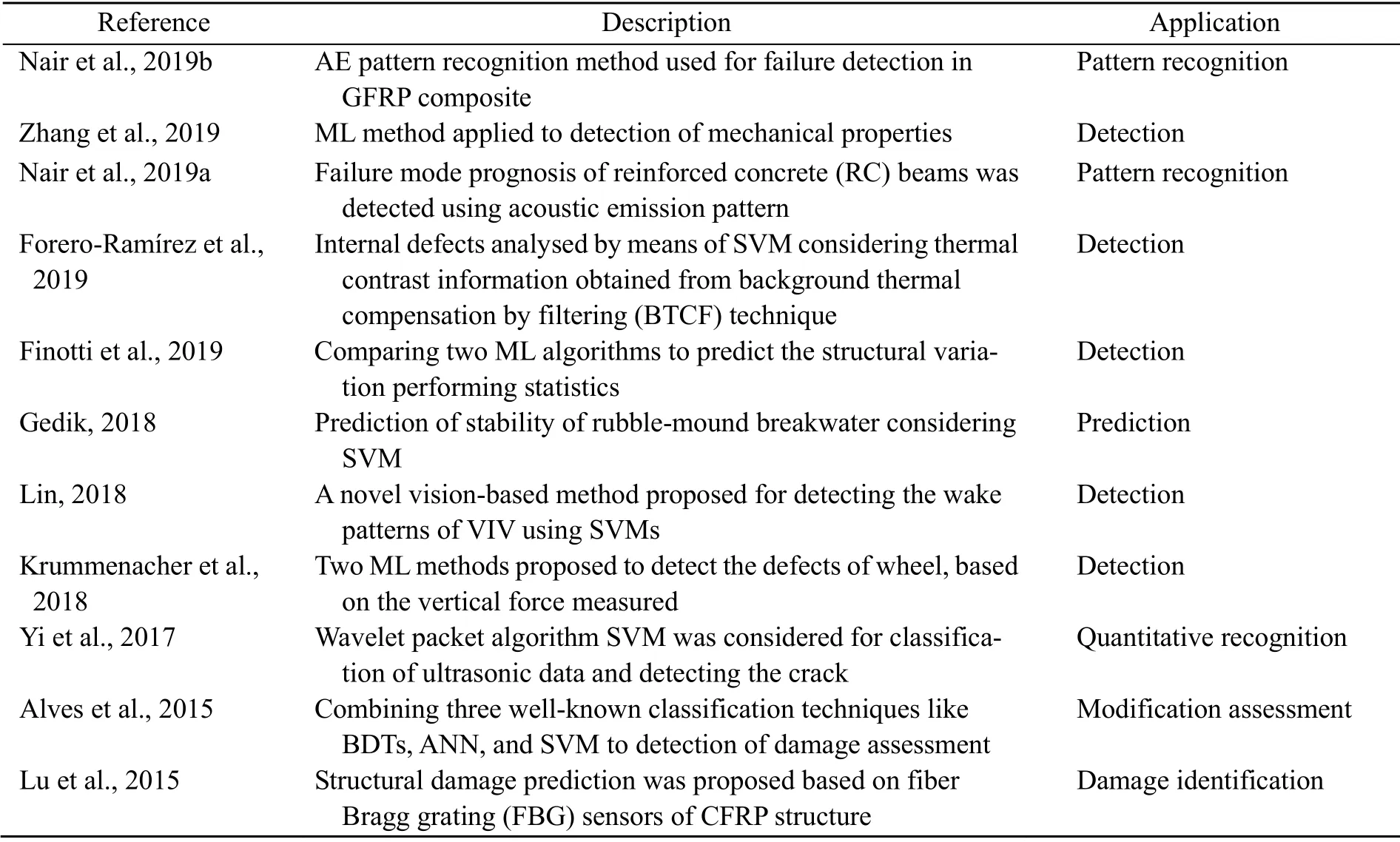

SVMs are ML algorithms built on statistical learning theory for structural failure analysis (SFA).A comparison of the number of documents and trends from 1981 to 2021 shows that SVM has been a popular technique compared with ANN in damage detection.Table 5 presents some important papers in the field of damage detection by the SVM method.

Table 5 Notable SVM-based models for damage detection and prediction

Recently,ANNs based on MLP and SVM methods were developed for failure analysis of glass fibre reinforced polymer (GFRP) by Nair et al.(2019b) and Lu et al.(2015).Forero-Ramírez et al.(2019) outlined an SVM method for identifying internal defects in CFRP.Moreover,Finotti et al.(2019) derived a method for SHM based on ANN and SVMs.Due to the importance of damage induced by VIV,Lin et al.(2017) proposed SVM methods for damage monitoring.Not only defects caused by vibration (Alves et al.,2015;Lin,2018),but also railway defects (Krummenacher et al.,2018) can be measured by SVM.Moreover,least squares SVM(LS-SVM) (Suykens and Vandewalle,1999;Suykens et al.,2002) is an alternative model of SVM (Vapnik,1995) that comprises a compatible technique for predicting engineering failure using an advanced mathematic method (Zhao et al.,2014).However,LS-SVM predicts accurate quantities for data given only by testing.For complex estimations,LS-SVM can use the following equation in the so-called primal weight space (Suykens et al.,2002):

wherew,Xi,andbrepresent the adjustable weight vectors,basic input data,and bias,respectively.Table 6 presents the results and findings of notable studies involving SVM techniques and evaluation metrics.

Table 6 Results of notable developed SVM techniques indicated by evaluation metrics

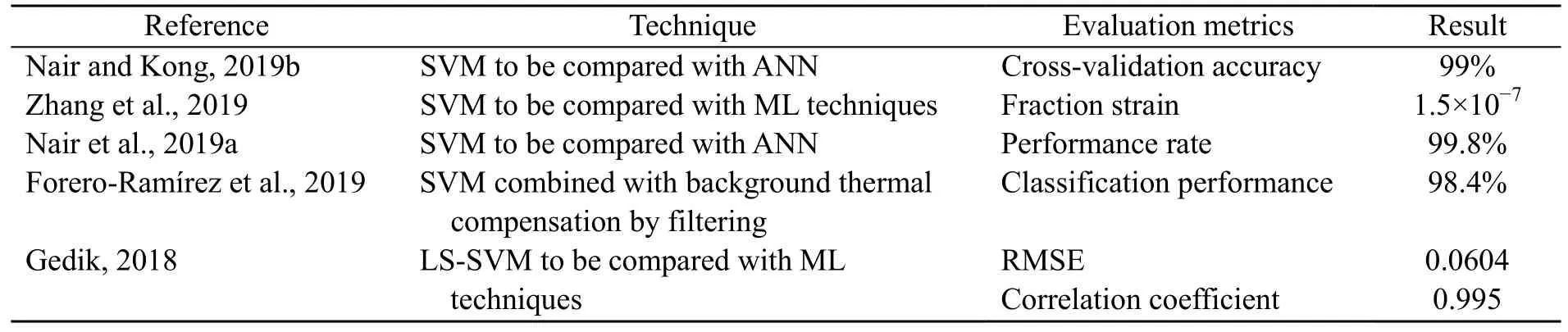

Nair et al.(2019b) used SVM to estimate the failure of glass fiber reinforced polymer.SVM was compared with ANN as control.A direct comparison was made of the performance accuracy of the two methods for each of three species of glass fiber reinforced polymer.The results showed that SVM was more accurate than ANN.Zhang et al.(2019) expanded the SVM approach by making comparisons with SGD,ANN,kNN,and DT.SVM was introduced as a powerful tool for estimation and modeling tasks.Results of ML techniques were compared using the MSE factor.According to the results,the best performance was specified by DT (MSE 9.3×10−6) followed by SVM (MSE 1.5×10−5).Nair et al.(2019a)compared the SVM with an ANN technique in terms of their performance rate for beam failure pattern diagnosis.In general,SVM could successfully cope with detection tasks with about 1.0% to 1.5% more accuracy than the ANN technique.Forero-Ramírez et al.(2019) used SVM to classify defects created in CFR plastic slabs.Performance was evaluated as the percentage of successfully detected pixels.SVM combined with thermal contrast enhancement could successfully detect about 22 of the 23 defects,indicating high performance.Gedik (2018) used an LSSVM technique for estimating the stability of rubblemound breakwaters.The LS-SVM was compared with multiple LR models and other ML techniques in terms of the correlation coefficient and root mean square error (RMSE).Based on the results,LS-SVM performed better than the other techniques.This indicates that LS-SVM is a more reliable technique for researchers and policy makers in this field.

3.3 Tree-based models

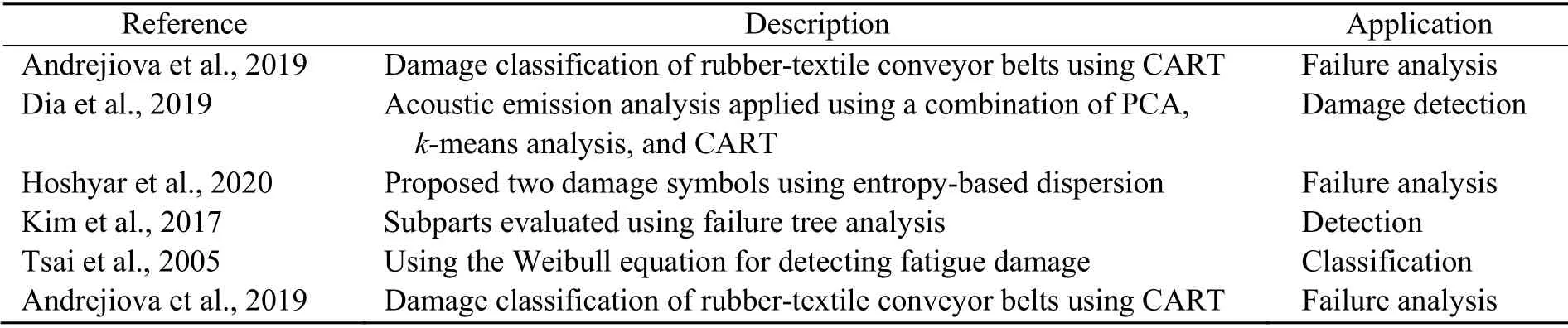

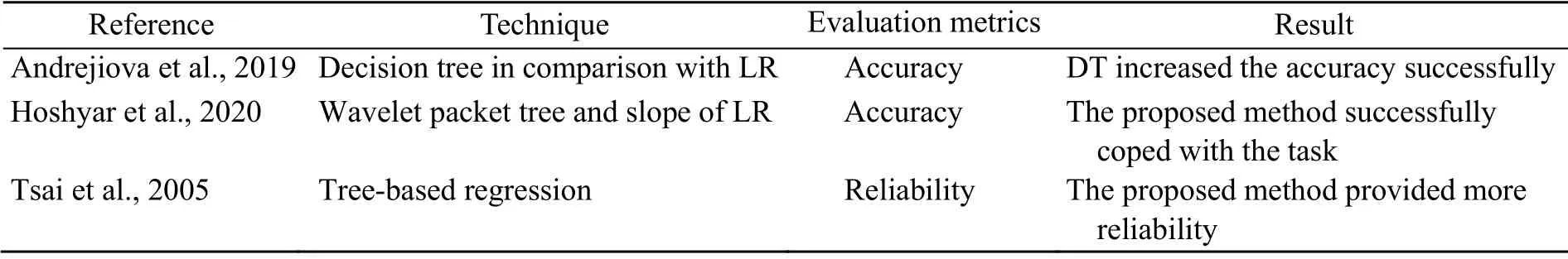

DTs,classification and regression trees (CART),and other model types can also be useful methods for damage detection.Tree-based models can be used for damage detection not only in engineering,but also in other areas.Table 7 presents the most notable recent studies in which DT-based techniques have been used for the purpose of damage diagnosis.

Table 7 DTs and CART models for damage detection and prediction

Andrejiova et al.(2019) proposed a classification of damage from impact loadings on rubber-textile conveyor belts that occurs due to the impact of transported material.Dia et al.(2019) proposed a combination of principal components analysis (PCA),k-means analysis,and CART for identifying damage to hybrid laminate aluminum/glass under quasi-staticand fatigue loading.Similar studies have been carried out by Kim et al.(2017) for CFRP materials.Moreover,a baseline-free approach was proposed by Bhowmik et al.(2019) for the detection of damage in multi-degree vibrating mechanisms using spectral analysis.Hoshyar et al.(2020) proposed two damage indices,entropy-based dispersion and beta,for damage identification purposes.Tsai et al.(2005) presented an approach for the identification of fatigue damage using a three-based method.Table 8 presents the results and findings of the notable studies developed by DT-based techniques assessed by evaluation metrics.

Table 8 Results of notable developed DT-based techniques indicated by evaluation metrics

Andrejiova et al.(2019) compared the accuracy and predictability of DT and LR for classifying the damage to a rubber-textile conveyor using 48 samples as training sets.Results indicated that the DT technique successfully coped with the task and was more precise than the LR method.In another study,Hoshyar et al.(2020) proposed a modified wavelet packet tree and slope of LR to monitor and diagnose structural damage accrued under loading conditions.Results under test conditions were evaluated using an accuracy factor.The proposed method accurately coped with the task.Tsai et al.(2005) used a threestage Weibull equation for fitting purposes for fatigue damage analysis in a beam test.A tree-based regression technique was used to handle the data structure of the predicted parameters by considering material properties,temperatures,conditioning methods,and strain levels.Results indicated that the proposed method could provide reliable indexes to assess fatigue performance.

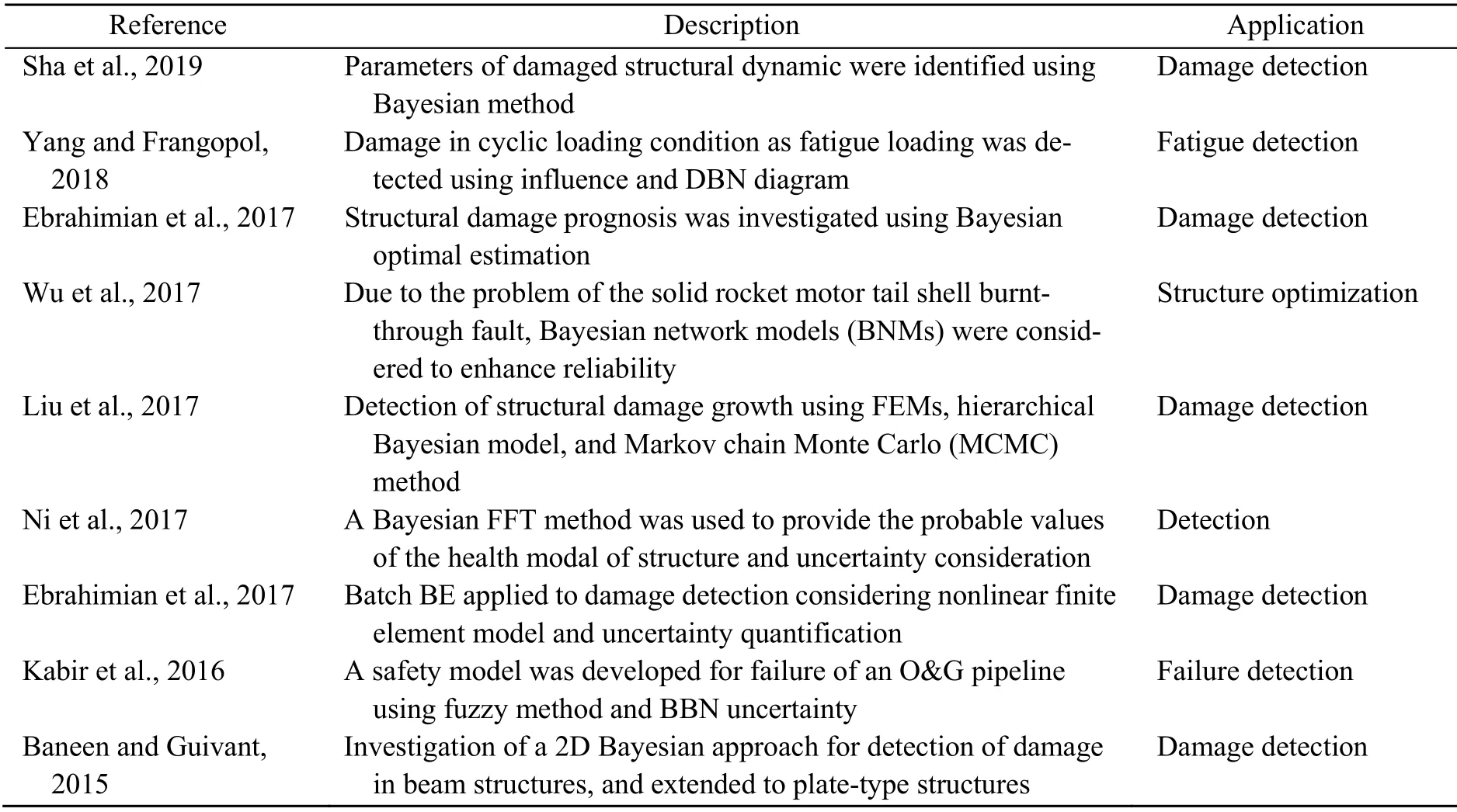

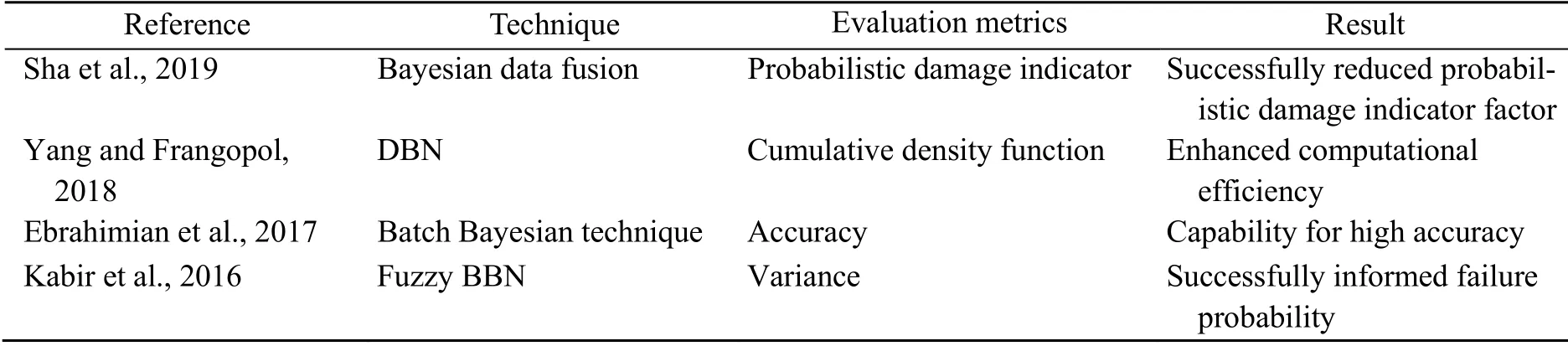

3.4 Bayesian models

Bayesian estimation (BE) can provide novel models for the investigation of damage in structures.Table 9 lists newly developed Bayesian models used for damage detection.

Table 9 BEs for damage detection and prediction

Concentrated damage in a beam can be detected based on the vibration of structural parameters.Sha et al.(2019) proposed a method of relative natural frequency change (RNFC) for local damage detection considering novel probabilistic damage of Bayesian data fusion for RNFC curves and mode shapes.Baneen and Guivant (2015) presented a 2D Bayesian approach based on a 2D gapped smoothing method(GSM) algorithm.Ebrahimian et al.(2017) outlined an SHM frame for damage detection considering nonlinear FE analysis and batch BE method.A fuzzy logic Bayesian belief network (BBN) model was considered to detect the damage in an O&G pipeline(Kabir et al.,2016).Moreover,Ni et al.(2017) used a high rate Bayesian fast Fourier transform (FFT)analysis for detection of damage.The method provided modal parameters in addition to uncertainty evaluation.Ebrahimian et al.(2018) proposed a nonlinear FE model using Bayesian inference and sequential maximum likelihood estimation for identifying damage in civil structures.Table 10 presents the most notable recent studies using Bayesian-based techniques for damage diagnosis.

Table 10 Results of notable Bayesian-based techniques and their evaluation metrics

Sha et al.(2019) developed a novel Bayesian data fusion to analyze the localization and estimate the probability of damage.This issue was considered from two viewpoints:damage identification and damage growth monitoring.Results evaluated using a probabilistic damage indicator confirmed the value of the technique for damage monitoring and detection.Yang and Frangopol (2018) proposed a dynamic Bayesian network (DBN) for fatigue identification in real-time conditions.Results evaluated using a cumulative density function showed that the proposed technique could enhance computational efficiency and system reliability.Ebrahimian et al.(2017) used a batch Bayesian technique for damage identification in civil structures.Results assessed using a convenient factor showed the technique was capable of high accuracy.Kabir et al.(2016) outlined a fuzzy BBN for pipeline failure consideration and monitoring under uncertainty as a safety assessment model.Results obtained using a variance factor showed the model successfully informed failure probability with high accuracy.

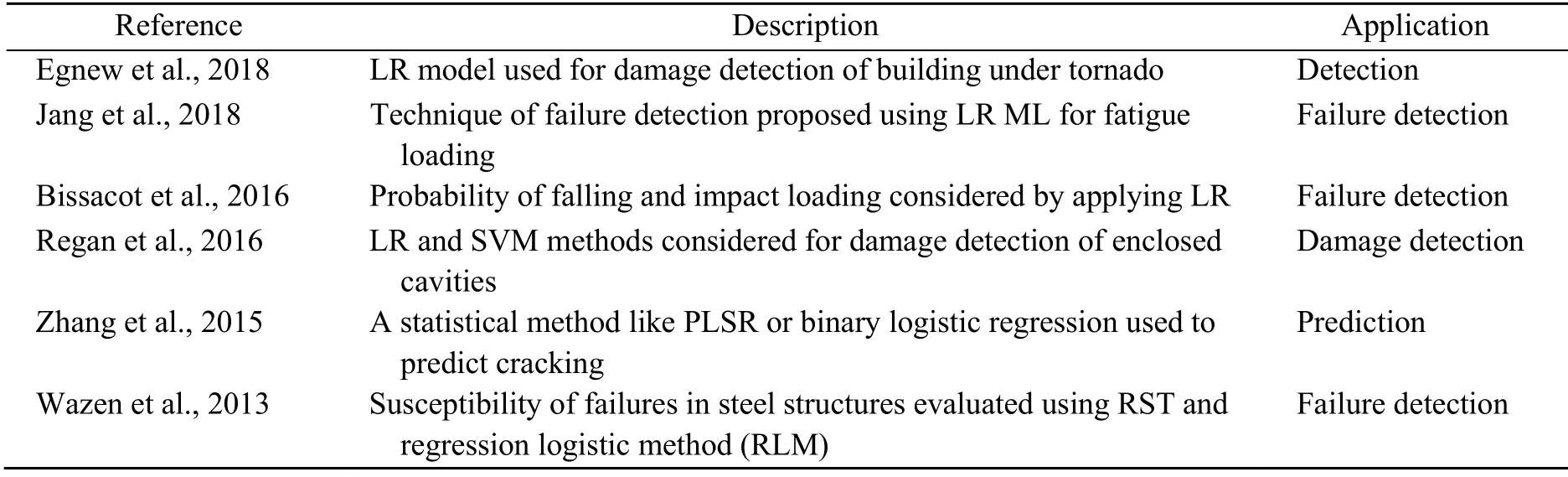

3.5 Logistic regression models

LR models have been used for dynamic representation of failure detection.This method is also compatible with other ML methods for failure detection.The use of regression methods in damage detection is seen as an increasing trend.Some logistic regressions for damage diagnosis and prediction are listed in Table 11.

Table 11 Logistic regressions for damage detection and prediction

Wazen et al.(2013) used the rough sets theory(RST) and the LR method for damage detection in transmission lines of two thousand steel structures.Similarly,Bissacot et al.(2016) investigated the use of ANN and LR in failure detection of steel structures in transmission lines.Jang et al.(2018) proposed a failure detection method for random cyclic loading,applying dual-sensing on an asymmetric structure and logistic regression ML.Zhang et al.(2015) proposed statistical methods for detecting and controlling transverse crack initiation and propagation based on partial least squares regression (PLSR) and binary LR.

3.6 Logistic regression models

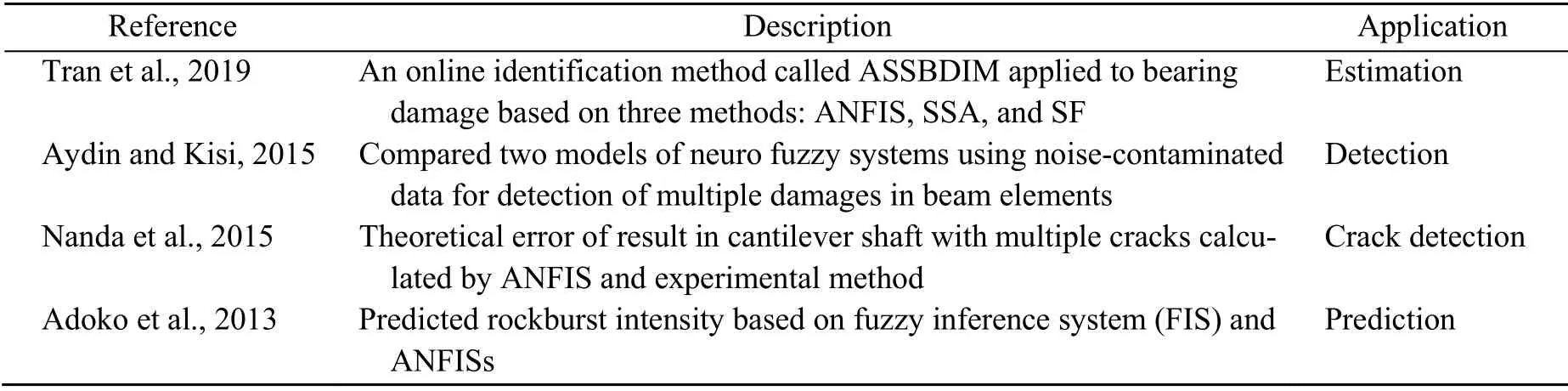

Neuro-fuzzy methods,including adaptive neurofuzzy inference system (ANFIS),are a convenient and applicable approach for the detection of damage.Because neuro-fuzzy methods are accessible,they can be readily applied to damage detection.Table 12 presents neuro-fuzzy methods recently applied to damage detection.

Table 12 Neuro-fuzzy methods used for damage detection and prediction

Tran et al.(2019) proposed an online damage detection method for bearings considering ANFIS,singular spectrum analysis (SSA),and sparse filtering(SF).SSA and SF methods were used for measuring noisy big data and the ANFIS method for identifying the dynamic response of the mechanical system.Naderpour and Mirrashid (2019) introduced a method based on the group method of data handling and ANFIS for damage detection in strengthening beam-column joints.The results confirmed the capability of the RC shear joints with high accuracy.Aydin and Kisi (2014) used network models of RBF and MLP to investigate structural Timoshenko beam damage.

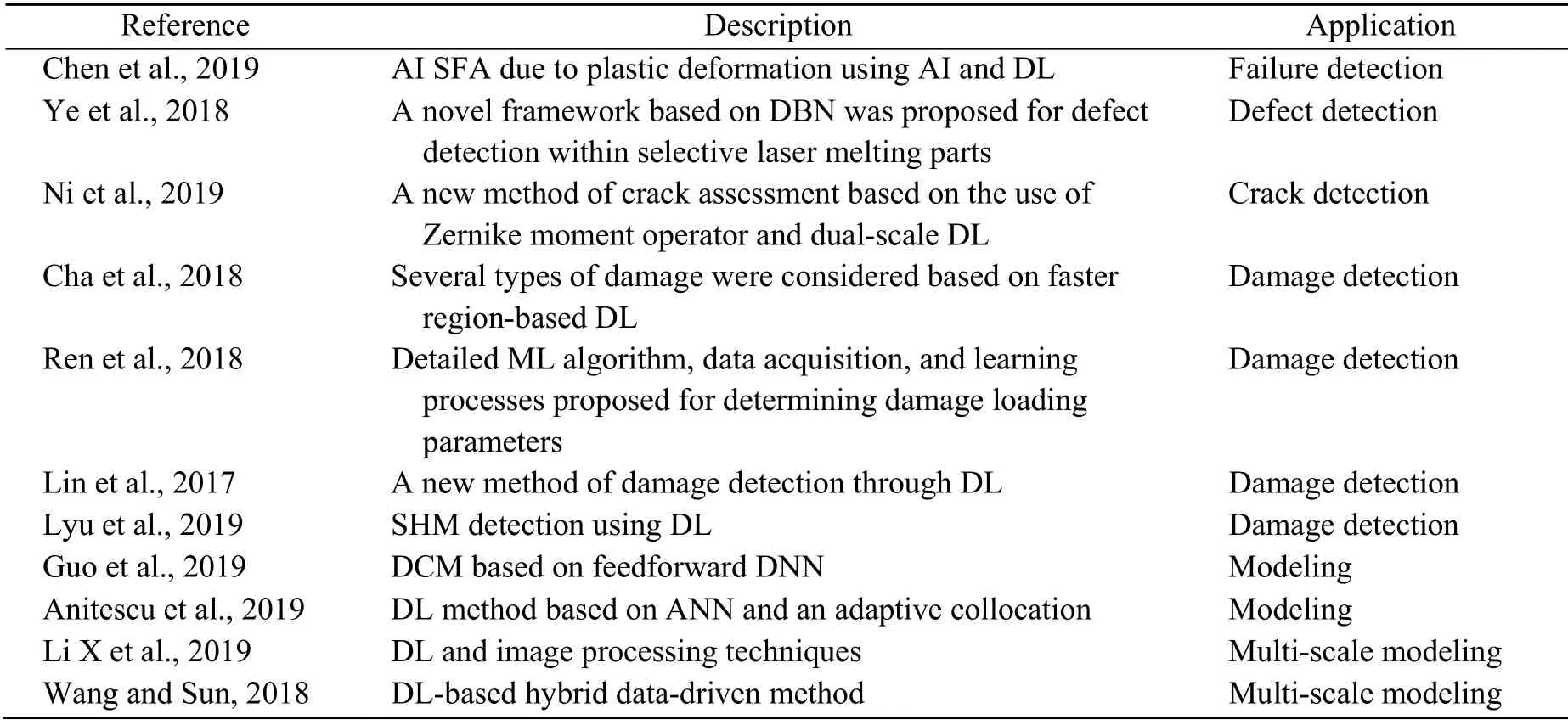

3.7 Deep learning

DL aims to model hierarchical characterization for data prediction and can be applied to damage identification.Most studies in this field started in 2015 and have since played an increasingly significant role in damage detection.Taking into account the application of DL to structural identities,Table 13 presents some recent studies in which DL methods were used for characterizing material damage.

Table 13 DL models used for damage detection,prediction,and multi-scale modeling

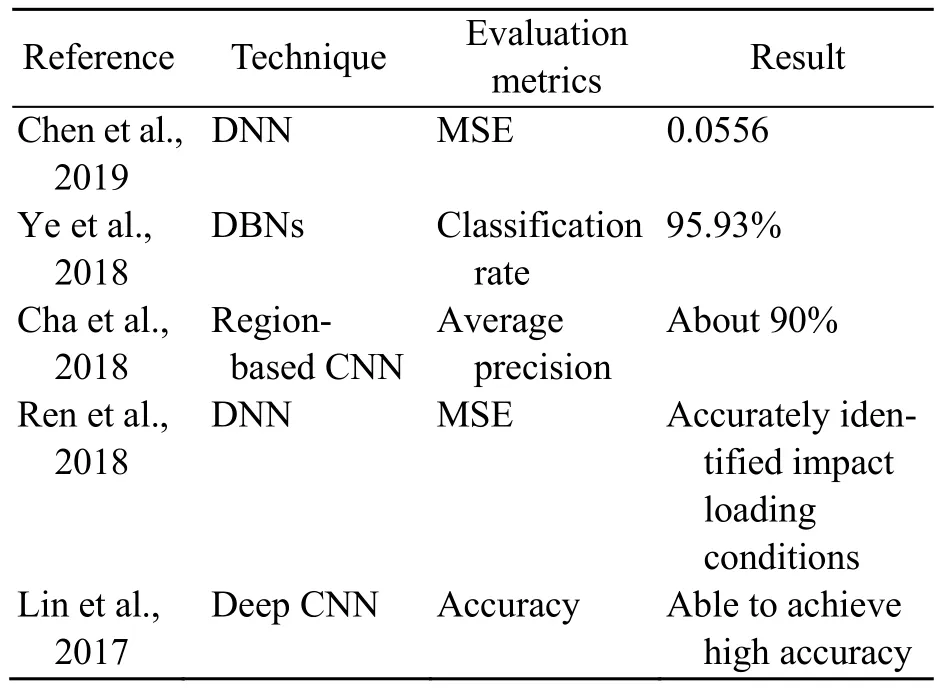

Lin et al.(2017) presented a damage diagnosis approach based on a neural network to identify damage features like locations.Ren et al.(2018)studied unidentified collision load conditions based on plastic deformation by applying a DL neural network.Also,Lin et al.(2017) presented a deep CNN for damage detection.Taking into account the timeconsuming crack inspection of civil infrastructures,overcoming the onset challenge of crack detection with DL method was considered by Ni et al.(2019).Damage detection can also be vital for offshore structures.In this context,Lyu et al.(2019) used a DL approach based on a discrete inverse network (deep belief network) for extracting the feature of the non-stationary output.Moreover,Cha et al.(2018)identified SHM using several types of region-based DL methods.Ren et al.(2018) developed a DL computational framework to identify damage loading parameters and residual plastic deformation.Recently,Guo et al.(2019) proposed a DCM based on feedforward DNN to evaluate the continuous transversal deflection in thin Kirchhoff plate bending problems.In other recent research,Anitescu et al.(2019) demonstrated a DL method based on ANN and an ACM to solve PDEs.Moreover,Li X et al.(2019)proposed DL and image processing techniques to evaluate the accurate representation of complexity in heterogeneous composite properties.A similar method was developed by Wang and Sun (2018) for a multi-scale geological porous medium (e.g.mudstone,limestone,and rock) with pores of various sizes using a DL-based hybrid data-driven method in which porous material was modeled by sub-scale simulations.Table 14 lists the most notable recent studies investigating the development of DL-based techniques for damage diagnosis.

Table 14 Results of notable Bayesian-based techniques and their evaluation metrics

Chen et al.(2019) developed a DNN for considering a shell cell’s behavior for impact load conditions as a kind of failure analysis.Results indicated that the proposed technique could successfullypresent a diagnostic technique for identifying damage under different conditions of failure events related to an accident.Ye et al.(2018) developed a DBN for analyzing acoustic signals to detect defects during the selective laser melting process.The performance of the model was evaluated using the classification rate and was compared with that of ANN and SVM techniques.Results indicated that DBN was better than ANN,but SVM gave the best performance.

Cha et al.(2018) compared a CNN technique with a structural visual inspection for detecting multiple damage types.Results were evaluated by the average precision factor.The proposed CNN technique provided a rapid test for the evaluation phase.Ren et al.(2018) proposed a new framework of DL techniques for the identification and determination of damage loading parameters for structures and materials.Results were evaluated by the MSE factor.The developed technique accurately identified the impactloading conditions,indicating that it is a robust technique for material and structural forensic diagnosis.Lin et al.(2017) developed a CNN technique for the identification of structural damage.Results evaluated by an accuracy factor showed that the proposed technique has a high performance related to its capability for training.

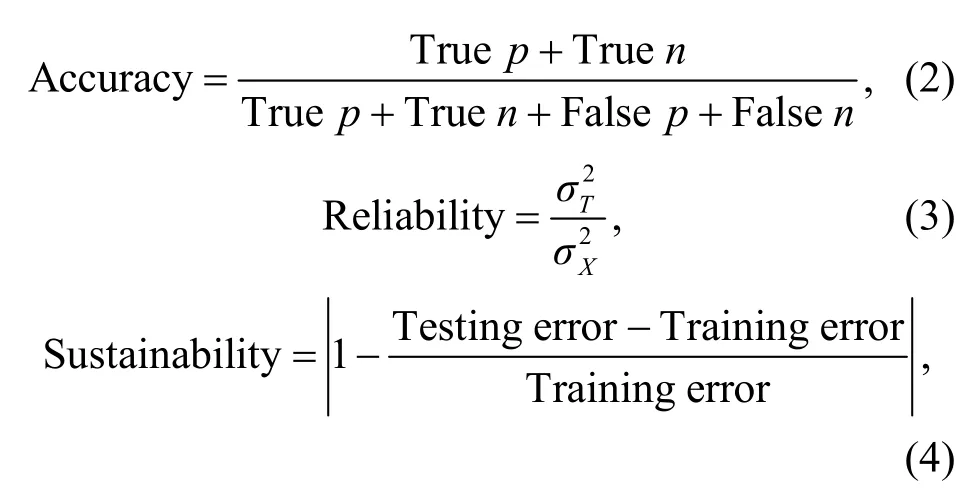

4 Evaluation criteria

Accuracy,reliability,and sustainability factors were used as evaluation criteria for considering ML and DL techniques applied in the damage diagnosis area:

wherepdenotes the positive values,ndenotes the negative values,Tdenotes the true scores,Xdenotes the errors of measurements and sustainability,which are in the range of 0 to 1 for rating the models under consideration,andσ2denotes the variance value.

5 Discussion

Damage mechanics in micro-mechanics and macro-mechanics is related mostly to crack initiation and propagation,and demonstrates as structural stability and safety prospecting.Taking into account the importance of damage analysis for failure analysis of industrial structures,a convenient experimental detection method should be identified.In this context,ML as a smart method can be used to develop trustworthy procedures for identifying the discontinuity in material structures.This section describes and summarizes some notable findings using ML and DL for handling damage diagnosis in different industrial fields.One of the significant factors of accuracy in an ML technique is the selection of a proper set of input variables.This was comprehensively discussed in a study by Forero-Ramírez et al.(2019) who successfully improved the accuracy of detection schemes by about 2% using SVM technique and changing the arrangement and number of selected features.To present a deep discussion about the performance of each method,two frequently used single techniques,ANN and support vector-based methods,were selected as the base techniques to be compared with other techniques developed in this area in terms of their performance in different applications such as detection,decision making,evaluation,monitoring,simulation,estimation,and pattern recognition.

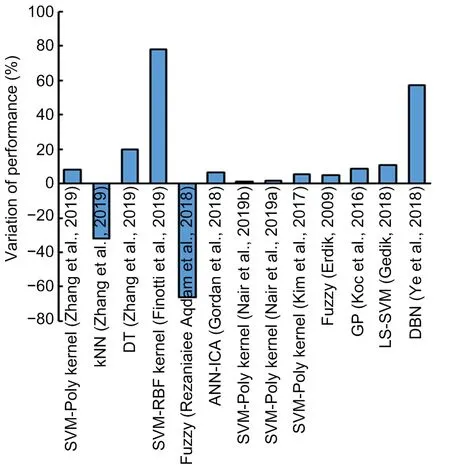

Fig.5 reports the variation in performance of ANN compared with other methods.The main architecture of the ANN methods was a single hidden layer ANN with a sigmoidal activation function.These variations were calculated by a simple linear equation.The graph takes ANN as the base method and compares it with other techniques to indicate the percentage increase or decrease in performance.

Fig.5 Variation of performance factors in comparison with ANN (GP:genetic programming)

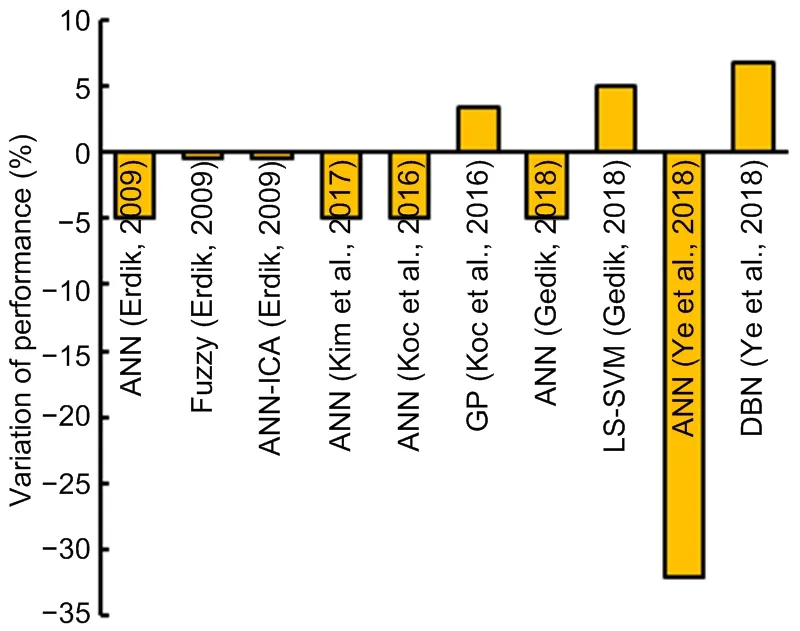

All the methods except kNN and fuzzy showed improved performance in comparison with ANN.We conclude that hybrid ANN is more accurate than single ANN methods.kNN can be considered a robust technique for different applications (Ardabili et al.,2020b;Mosavi et al.,2020),but the main reason for its lower performance compared with ANN is its sensitivity to the size of the dataset and its application(Dineva et al.,2019).Accordingly,when kNN is used in a proper task,it can provide a higher performance compared with simple ML techniques such as ANN.SVM and DBN (as a DL technique) performed better than the other techniques.SVM-based methods increased the prediction performance compared with the single ANN technique.SVM with RBF kernel type showed improved accuracy compared with the Poly kernel type.One of the main shortcomings of studies in which different ML techniques were developed for handling material damage detection has been a lack of discussion about the effects of the size of the dataset on performance and reliability.This subject could be an emergent task for future studies and policy makers who are trying to develop more efficient ML techniques for handling damage detection.Fig.6 shows the variation in performance factors of methods developed in different studies compared with support vector techniques.These variations were calculated using a simple linear equation.

Fig.6 Variation of performance factors in comparison with support vector-based techniques

In general,ANN methods have shown a lower performance than support vector-based methods.LS-SVM,as a hybrid support vector-based method,has performed better than single SVM methods.The best performance has been produced by the DL technique (DBN) followed by the hybrid SVM technique,and the lowest performance has been produced by the single ANN technique.

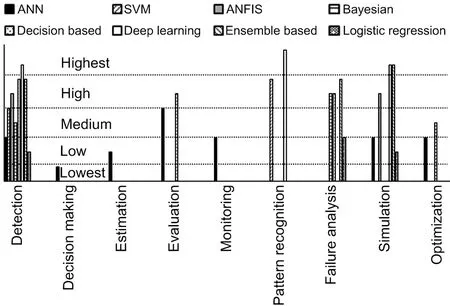

To complete our evaluation of the ML techniques used in material damage detection,we decided to carry out a qualitative analysis and comparison of each ML technique based on our results and those reported by other researchers.Recently,methods for comparing two or more learning algorithms in a single dataset have been scrutinized.In one review(Demšar,2006),theoretical and experimental methods were evaluated.A set of simple and accurate non-parametric tests were proposed for statistical comparison of classifiers.Two classifiers were considered within the Wilcoxon signed rank test.The Friedman method,considering the corresponding post-hoc tests,was scrutinized for comparison of more classifiers,mostly over multiple datasets(Demšar,2006).Learning algorithms such askcan be tested on specific datasets in which the performance of algorithms is compared.The Wilcoxon signed rank could be the proper comparison factor for comparing the performance of ML techniques.However,the main limitation of this task is the requirement for access to the main dataset of each surveyed paper.Therefore,this led us to use a qualitative comparison based on a collection of scores for accuracy,reliability,and sustainability which have been reported by each paper,separately.We assigned each method to one of five categories with the labels lowest,low,medium,high,and highest,based on an approach reported by Shamshirband et al.(2019) for detection,decision making,estimation,evaluation,monitoring,pattern recognition,failure analysis,simulation,and optimization purposes (Fig.7).

Fig.7 Ranking score based on applications

Fig.7 shows the distribution of applications and methods among the categories as well as their performance scores based on the evaluation criteria.DL techniques followed by ensemble-based techniques had the highest application and robustness in the field of damage diagnosis for detection,pattern recognition simulation,and failure analysis.In contrast,ANN had the lowest performance for decision making and medium performance for monitoring,simulation,and optimization purposes.Based on Fig.7,decisionbased methods can be successfully used for evaluation and failure analysis purposes.SVM-based methods can also be effective methods for detection and pattern recognition,with medium and highest performances.In material damage detection,detection followed by simulation had the highest concentration of applications for ML-based methods.

6 Conclusions

In this study,we carried out a comprehensive review of state-of-the-art ML and DL techniques developed for micro-mechanical damage diagnosis in isotropic and orthotropic materials.ML/DL methods can have a significant role in damage identification under various loading and material conditions.Therefore,in this study,we attempted to present a classification of ML-and DL-based models including ANN,DL,SVM,and other types of learning models for detection of damage in industrial structures.The progress of damage diagnosis is a function of the advancement of ML and DL techniques.The main common feature of all damage detection systems is their dependency on physical and chemical phenomena.Moreover,due to the extension of damage types and fixing costs,it is necessary to forecast damage and its occurrence.Therefore,ML and DL techniques have become important and are now required in structural failure analysis.The review has demonstrated the promising robustness of ML models considering these particular applications.Based on our findings,DL has the highest application and robustness in the field of micro-mechanical damage diagnosis,followed by ensemble-based techniques.Also,to the best of our knowledge,increasing the size of a dataset reduces the accuracy of LR,ANN,and SVM,but ensemble and DL techniques have the lowest sensitivity to data size and the highest robustness in big and small datasets.

Contributors

Shahab SHAMSIRBAND and Nabi MEHRI KHANSARI designed the research and wrote the first draft of the manuscript.Nabi MEHRI KHANSARI proceed the corresponding data.Shahab SHAMSIRBAND and Nabi MEHRI KHANSARI revised and edited the final version.

Conflict of interest

Shahab SHAMSIRBAND and Nabi MEHRI KHANSARI declare that they have no conflict of interest.

Journal of Zhejiang University-Science A(Applied Physics & Engineering)2021年8期

Journal of Zhejiang University-Science A(Applied Physics & Engineering)2021年8期

- Journal of Zhejiang University-Science A(Applied Physics & Engineering)的其它文章

- A deep neural network-based algorithm for solving structural optimization#∗

- Physics-informed neural networks for estimating stress transfer mechanics in single lap joints#∗

- Surrogate models for the prediction of damage in reinforced concrete tunnels under internal water pressure

- Deep learning-based signal processing for evaluating energy dispersal in bridge structures#