Influence of Bedding and Mineral Composition on Mechanical Properties and Its Implication for Hydraulic Fracturing of Shale Oil Reservoirs1

WANG Xiaoqiong ,XU Jianguo ,ZHAO Chenxu ,LIU Tongyuan ,GE Hongkui ,SHEN Yinghao ,WU Shan,YU Jiayao and HUANG Rongyan

1) State Key Laboratory of Petroleum Resources and Prospecting,China University of Petroleum (Beijing),Beijing 102249,China

2) The Unconventional Oil and Gas Institute,China University of Petroleum (Beijing),Beijing 102249,China

3) Research Institute of Oil and Gas Engineering,PetroChina Jilin Oil and Gas Field Company,Songyuan 138001,China

The premise of hydraulic fracturing is to have an accurate and detailed understanding of the rock mechanical properties and fracture propagation law of shale reservoirs.In this paper,a comprehensive evaluation of the mechanical properties of the shale oil reservoir in the south of Songliao Basin is carried out.Based on the experiments and the in-situ stress analysis,the fracture propagation law of three types of shale reservoirs is obtained,and the suggestions for fracturing are put forward.The results have shown that the fracture propagation of pure shale and low mature reservoir is easy to open along the bedding plane under compression loading,which is greatly influenced by the bedding.Sand-bearing shale is slightly better,the fractures of which are not easy to open along the bedding plane.The mechanical experimental results show that all the samples have the characteristics of low compressive strength,low Young's modulus and strong anisotropy,indicating that the shale oil reservoir is certain plastic,which is related to its high clay mineral content and controlled by the bedding development.Compared with pure shale and low mature shale,the sandbearing shale has less clay content and less developed bedding,which maybe the main reason for its slightly better brittleness.Overall,the expansion of hydraulic fracture is controlled by in-situ stress and bedding.Because of the development of bedding,it is easy to form horizontal fractures.Thus it is not suitable for horizontal well fracturing.Because of the high content of clay minerals,the applicability of conventional slick hydraulic fracturing fluid is poor.It is suggested to use vertical well or directional wellto carry out volume fracturing.In this way,the effect of bedding can be effectively used to open and connect the bedding and form a larger fracture network.

Key words:Shale reservoir; Mechanical properties; Fracture; Hydraulic fracturing;Horizontal well; Bedding

INTRODUCTION

Hydraulic fracturing is the key technology of shale oil and gas development.Through large-scale volume fracturing of shale oil and gas reservoir,a dispersion volume fracture network (volume fracturing) is formed (Cipolla C.L.et al.,2008),so that shale oil and gas stored in ultra-low permeable shale reservoir can be developed industrially(Cipolla C.L.et al.,2008; Sierra R.et al.,2010; Guo Tiankui et al.,2014).The premise of hydraulic fracturing is to have an accurate and detailed understanding of the rock mechanical properties and their influences on hydraulic fracture (Vernik L.et al.,1992,1997;Clarkson C.R.et al.,2013).The parameter that refers to the degree of difficulty in which shale gas plays can form complex fracture.Networks under hydraulic fracturing is called the fracability of the rock (Wang Xiaoqiong et al.,2017,2018).The evaluation of the fracability of the reservoir is one of the basic work for the evaluation of the tight reservoir,and it is important to optimize the hydraulic fracturing process.So far,with reference to the evaluation method of fracability of tight oil and gas reservoirs in the United States,the evaluation method of fracability is almost equivalent to the evaluation of “brittleness coefficient” (Rickman R.et al.,2008; Sondergeld C.H.et al.,2010; Chong K.K.et al.,2010).But in fact,brittleness is not equal to fracability.In addition,the geological conditions and development conditions of unconventional oil and gas reservoirs in China and the United States are quite different.The burial depth of shale oil and gas reservoirs in China is generally larger,and the in-situ stress situation is more complex.The structure of the reservoir and the development of bedding and fracture are also typically different with those of marine reservoirs in the United States.Therefore,it is necessary to develop a fracability evaluation method suitable for the complex geological conditions in China.Overall,the formation and extension mechanism of hydraulic fracture in shale oil reservoir is complex.It is of great significance to master the formation mechanism of artificial fracture network for evaluating the effectiveness of hydraulic fracturing.

Previous research shows that the fracability of the reservoir is not only affected by the rock brittleness,but also by the bedding,clay contents and maximum and minimum principal stresses,interlaminar stresses,fracture development degree and other factors(Wang Xiaoqiong et al.,2017,2018; Li Qinghui et al.,2013; Jahandideh A.et al.,2014).Therefore,in this paper,a systematic and comprehensive evaluation of the mechanical properties of shale rock is carried out based on the shale oil reservoir in the south of Songliao Basin,Jilin Province.Based on the analysis of the microstructure,rock mechanics characteristics,acoustic emission characteristics and brittleness characteristics of three types of shale reservoirs,combined with the field fracturing,logging data and the in-situ stress,the fracability of the three types of shale are evaluated.And the fracture propagation law of the three types of reservoirs is obtained,and the suggestions for fracturing are put forward.It provides theoretical and methodological basis for unconventional oil and gas development.

1 EXPERIMENTAL SAMPLES AND METHODOLOGY

1.1 Experimental Samples

In this paper,the study block is located in the south of Songliao Basin,Jilin Province.The shale oil reservoir is mainly composed of Qingshankou group and Nenjiang group of Cretaceous formation.Shale oil reservoir samples from 7 wells are divided into three types:①the shale type with thin sandstone interbedded,which is called sand-bearing shale for short; ②Pure shale without interbedded sandstone; ③Low mature shale.The three types of shale samples come from different wells.Sand-bearing shale comes from H1,H2,H3wells.Pure shale comes from X1,T1and C1wells.Low mature shale comes from D1wells.Core samples are mainly taken from the depth of 2 000-2 500 m.The bedding of the reservoir in the study area is very developed and the core is easy to be flaky.Fig.1(a),Fig.1(b) and Fig.1(c) show the condition of coring in the field.Due to the strong anisotropy of shale reservoirs,the cylindrical shale samples with diameter 25mm and length 50 mm were cored from the three types of shale along the bedding-parallel and beddingvertical direction (Fig.1(d)).The surfaces of all samples were rectified and polished to 10 μm to ensure parallelism and minimum friction during testing.It can also be seen from the core samples that have strong bedding (Fig.1(e)).

Figure 1 The condition of coring in the field

1.2 Experimental Methodology and Procedure

The propagation velocity of ultrasonic wave in rock is affected by the physical characteristics of rock such as cracks,composition,and mechanical properties.For this reason,we first carried out wave velocity measurement experiments under room temperature and pressure for three types of shale oil reservoirs.The wave velocities along the beddingparallel and bedding-vertical directions were first obtained.Then the dynamic elastic modulus and Poisson's ratio of each core is obtained,as well as wave velocity anisotropy according to the wave velocity in different directions to evaluate the development degree of bedding.A classical ultrasonic pulse transmission technique was used for P-and S-wave velocity measurements between an emitting and a receiving transducer (Ougier-Simonin A.et al.,2011).It consists of measuring the travel time of an elastic pulse through the rock sample for a known travelling path length.First an electric pulse was generated with an Olympus 5077PR pulse-generator and transmitted successively to emitting transducer.Then the waveforms were recorded using a digital oscilloscope.

After that,the rock mechanics experiments of uniaxial and triaxial compression are carried out in the laboratory.The elastic modulus,compressive strength,plastic parameters of rock can be obtained through the compression test.The key factors affecting the mechanical properties of rocks in the study area are also discussed.The test results and the subsequent interpretation model can provide the basis for the hydraulic fracturing design.The characteristics of acoustic emission in the process of sample loading and failure are obtained.Through the analysis of acoustic emission characteristics,the fracture propagation law of reservoir has been studied comprehensively.Fig.2(a) is the ZTR-1000 rock multifunctional testing machine.The testing machine has independently controlled axial stress,confining pressure.The maximum axial loading force of the ZTR-1000 servo testing system is 1 000 kN.And the maximum confining pressure is 50 MPa.We have also equipped 8-channel acoustic emission testing system in the laboratory,which can be used for acoustic emission testing under high pressure.Fig.2(b) and Fig.2(c) are acoustic emission monitoring systems and the monitored acoustic emission waveforms.

Figure 2 (a) ZTR-1000 servo system; (b) acoustic emission instrument;(c) the monitored acoustic emission waveforms

2 EXPERIMENTAL RESULTS

2.1 The Physical Properties and Microstructure of Testing Samples

Fig.3 is the ternary plot representation of the material compositions of the three types of shale samples determined by X-ray powder diffraction analysis (XRD).Mineral composition has a great influence on the properties of rock mechanics.Through the analysis of the mineral composition of the shale samples with the method of X-ray powder diffraction,we can see that the mineral composition of shale reservoir mainly includes quartz,feldspar,calcite,plagioclase,calcite,clay minerals and a small amount of dolomite,pyrite,etc.When the clay minerals in shale reservoirs are relatively high,the plasticity of the rocks is strong,while the plastic reservoirs are not suitable for hydraulic fracturing.When there are more brittle minerals such as quartz and feldspar,shale is more brittle and suitable for hydraulic fracturing (Rickman R.et al.,2008).From Fig.3,brittle minerals and clay minerals account for a large proportion.The average content of quartz and feldspar in pure shale reservoir is 36.77%,and the average content of clay is 47.9%.The content of quartz and feldspar in low mature shale is relatively low,about 35.52%,and the content of clay mineral is about 42%.Compared with the other two types of reservoirs,the content of quartz and feldspar in the sand-bearing shale reservoir is the highest,about 47.64%,and the proportion of clay is less,about 36%.The clay content of three types of shale is relatively high.In the clay types,illites and montmorillonites account for an important proportion which are larger than 50%.

The porosity and permeability of the samples were also measured in the laboratory,and the microstructure of the pore throat of the samples was studied by mercury intrusion method.The porosity test results show that the porosity of the three types of shale reservoirs are all distributed below 5%,which belongs to low porosity and low-permeable tight reservoirs.The porosity distribution of pure shale reservoir is generally between 2%-5% with an average value of about 3.1%.The porosity of sand-bearing shale reservoir ranges from 1% to 4% with an average value of about 2.3%.The average porosity of low mature shale reservoir is about 3%,and the variation range is generally between 2%-5%.The permeability is measured by transient pulse method.The results show that the permeability is generally lower than 10-3mD.The permeability of pure shale reservoir is about 10-4mD and that of sand-bearing shale reservoir is about 10-3mD.The permeability of low mature shale reservoir is between 1.5×10-4mD.Some reservoirs have high permeability,which is due to the presence of large amount of microcracks in the test samples.The results obtained by the mercury intrusion method show that the pore throat radius of the three types of reservoirs are mainly distributed in the range of nano scale,between 3 -100 nm.And the pore throat radius below 10 nm accounts for a large proportion of the low mature shale reservoir.

The organic matter content and maturity of shale samples were measured by LECO cs330 carbon sulfur analyzer with combustion method.The results show that the TOC contents of shale reservoir in the target area of Songliao Basin is relatively low,with an average content of 2.7%.The organic carbon content of low mature shale reservoir ranges from 1.69% to 13%,with the highest average content of 4.4%.The organic carbon content of sand-bearing shale reservoir distributes in the range of 0.34% and 4.32%,with an average content of about 1.8%.The organic carbon content of pure shale reservoir is between 0.23% and 5.09% with an average organic content of about 2.5%.The maturity test results show that the maturity (Ro) and the degree of hydrocarbon generation and evolution of this area is relatively low (both lower than 1%),which is in the stage of oil generation (Walls J.D.et al.,2011).

Figure 3 Ternary plot representation of the three types of shale sample material compositions

We measured the oil saturation of the reservoir in the laboratory.Compared with shale oil and tight oil reservoirs in other areas of China,we found that the oil saturation is low,less than 60%.The basic average physical property parameters of these three types of reservoirs are shown in Table 1.

Table 1 Basic physical parameters of testing shales

Figure 4 The SEM images of (a) low mature shale; (b) sand bearing shale; and (c) pure shale samples

Fig.4 is the SEM images of the three types of shale oil reservoir in Songliao Basin.It can be seen from the pictures that clay minerals (gray in Fig.4) and brittle minerals in the reservoir of the study area are developed,and organic matter is also relatively developed(black in Fig.4).Microcracks are developed,with more inorganic pores visible.And organic pores are not visible in most cases.Clay and organic matter are alternately distributed in some pictures.

In a word,shale reservoirs in the study area have the characteristics of low porosity and low permeability.Pore throats are dominated by nano-pores,which make crude oil production difficult.At present,the maturity of the reservoir is in the immature or low maturity stage.The lower maturity may lead to the problems of insufficient hydrocarbon generation evolution and poor oil-bearing property.The shale reservoir has high clay content and obvious symbiotic relationship between organic matter and clay minerals,which makes shale have stronger water sensitivity.The expansion of clay will block the pores of organic matter and is not conducive to oil and gas production.Overall,the reservoir has poor physical properties with the characteristics of high clay content,low oil saturation,poor resource endowment and high development difficulty.

2.2 Bedding Development Evaluation

The measurement of wave velocity anisotropy is one of the important parameters to characterize the development degree of reservoir bedding.The larger the wave velocity anisotropy is,the more developed the bedding is.The P-wave velocity and S-wave velocity(vPHandvSH) along the bedding-parallel direction and the P-wave velocity and S-wave velocity (vPV,vSV) along the bedding-vertical direction were measured in the laboratory.Fig.5 shows that although shale samples are selected from different wells,the P-wave velocity and S-wave velocity can still be relatively well matched.Using the least square method to linearly fit the P-wave velocity and S-wave velocity,an empirical formula is obtained:vP=1.54vS+197.28.Thevp/vSratio value is 1.54.The correlation coefficient of fitting is as high as 0.92.It can also be seen from Fig.5 that the wave velocity along bedding-parallel direction (empty circle) is greater than that along bedding-vertical direction (solid circle).The variation range of P-wave velocity is 1 000-5 000 m/s,and the variation range of S-wave velocity is 800-3 000 m/s,indicating that shale oil reservoirs in this area have great difference in physical properties.It also has large variation range of wave velocity and strong anisotropy.

Thomsen (1986) introduced three dimensionless parameters,γ,δ,ε,which characterized the extent of anisotropy in a suitable way.Thomsen's parameters are equal to zero in the case of isotropy.If all of them are much smaller than 1,the anisotropy is considered to be weak.According to Thomsen parameter,the definition of P-wave anisotropy ε and S-wave anisotropyγis as follows:

WherevPHandvSHrepresents the P-wave and S-wave velocity along the bedding-parallel direction,vPVandvSVmeans the P-wave and S-wave velocity along the bedding-vertical direction measured in the laboratory.The anisotropy of shale core is calculated according to Eq.(1).The results show that the wave velocity anisotropy coefficient is more than 0.3.The wave velocity anisotropy of sand-bearing shale is significantly lower than that of pure shale and low mature shale reservoir,and the anisotropy of low mature shale is stronger than that of pure shale (Fig.6),indicating that the bedding of shale oil reservoir is relatively developed,and the order of bedding development is:pure shale >low mature shale >sand bearing shale.Compared with typical unconventional oil reservoirs in China (Changqing tight sandstone and Jimusaer shale oil),the shale oil reservoirs in Songliao Basin,Jilin Province are generally characterized by strong anisotropy (Fig.6).The results of bedding development in the study block are consistent with the results of field coring as shown in Fig.1.

Figure 5 the fitting curve of vP and vS

Figure 6 Anisotropy comparison of typical unconventional oil reservoirs in China

2.3 Mechanical Properties under Uniaxial Loading and Triaxial Loading

The uniaxial and triaxial compression experiments were carried out in the laboratory.During the uniaxial loading,the samples were loaded until failure.The triaxial compression experiments of the companion samples were also conducted in the laboratory.The confining pressure was set between 25-40 MPa according to the depth of the samples,and the axial stress was loaded until the sample broke.During loading,the stress-strain curve and acoustic emission were measured.Fig.7 is the typical stress-strain curve of the testing samples.According to the stress-strain curve,the rock mechanical parameters can be obtained,including compressive strength,Young's modulus,Poisson's ratio,etc.,and the rock brittleness can be analyzed by using the curve.The experimental results show that the uniaxial compressive strength (UCS) range of sand-bearing shale is 21.5-71.58 MPa,Young's modulus and Poisson's ratio range are 3.17 -15.52 GPa and 0.12 -0.36,respectively.The UCS range of pure shale reservoir is 14.84-63.50 MPa,the Young's modulus is 1.92-20.08 GPa,the Poisson's ratio is 0.10-0.37.The bedding of low mature shale (D1well) is very developed.The UCS range of low mature shale is 26.23-54.15 MPa,Young's modulus is 4.17-8.46 GPa,Poisson's ratio is 0.14-0.38.The triaxial compressive strength range of sand bearing shale is 111.09-219.34 MPa,Young's modulus is 15.39-25.44 GPa,Poisson's ratio is 0.13-0.35.The triaxial compressive strength range of pure shale reservoir is 73.41-432.27 MPa,the Young's modulus is 2.75-44.40 GPa,the Poisson's ratio is 0.12-0.28.

The mechanical properties of low mature shale and pure shale reservoir are similar.Whether the samples are taken along the bedding-parallel direction or along the beddingvertical direction,the fractures are easy to open along the bedding plane under compression loading (Fig.8).And there are oil-bearing scale insects on the open fracture plane(Fig.8(a)).Sand-bearing shale is slightly better.The fractures are not easy to open along the bedding plane.However,compared with well H3,the core of well H1is easier to break in the direction of bedding.

It can also be seen from the stress-strain curve that compared with pure shale and low mature shale,the stress of sand-bearing shale falls faster after the peak,whether under uniaxial or triaxial loading.Fig.9 is a schematic diagram showing that the faster the stress drop rate is under the same stress drop condition,the stronger the brittleness should be,wherein OAB brittleness is significantly greater than OAC (Zhang Decheng et al.,2016).Therefore,the plasticity of pure shale and low-mature shale is stronger than that of sandbearing shale.In a word,the experimental results show that all the samples have the characteristics of low compressive strength,low Young's modulus and strong mechanical heterogeneity.

2.4 Acoustic Emission Characteristics and Fracture Morphology

Acoustic emission (AE) in laboratory is similar to field earthquake,which was caused by cracks generated in rocks to release elastic energy and was detected by transducers,except that frequency is different from earthquake.Thus,the based rules of the micro seismic and the acoustic emission are the same.Fig.10 is the stress strain,cumulative acoustic emission numbers and acoustic emission rate curve of pure shale sample from X1well and sand bearing shale samples from H3wells.More AE numbers are detected in H3well than in X1well under uniaxial loading.And the stress-strain curve of H3well has large and sudden jump,indicating that cracks are generated.

The relationship between earthquake magnitude and frequency proposed by Gutenberg and Richter (1954) is as follows:

WhereMis the magnitude of the earthquake,Nis the cumulative number of earthquakes with magnitude greater than or equal toM.The valuesaandbin Eq.(2) are positive constants,anda-value represents the seismicity,which mainly depends on the maximum earthquake magnitude,b-value is the slope of the curve,usually close to 1,reflecting the proportional relationship between the number of large and small earthquake events.

Figure 7 The stress-strain curves of (a) pure shale sample under uniaxial loading;(b) pure shale sample under triaxial loading; (c) low mature shale sample under uniaxial loading;(d) low mature shale sample under uniaxial loading; (e) sandbearing shale sample under uniaxial loading; (f) sand-bearing shale sample under triaxial loading

In acoustic emission testing,magnitude is represented by amplitude,and the evolution formula is used to calculatebvalues from AE test results (Colombo I.S.et al.,2003):

Figure 8 The fracture morphology of (a),(b); (c)low mature shale;(d) pure shale;(e) sand-bearing shale from H1 well; (f) sand-bearing shale from H3 well

Figure 9 Schematic diagram of typical stress-strain curves for rocks

Figure 10 The stress strain,cumulative acoustic emission number and acoustic emission rate curve of (a) pure shale-X1 sample; (b) sand-bearing shale-H3 sample

WhereAdBis the level in dB used to indicate the maximum amplitude of an acoustic emission hitAmax,which is in units of μV.During the rock failure process,different levels of AE events were generated.Generally,it is believed that large-amplitude AE events are related to the formation of main cracks,and small-amplitude AE events are related to the formation of branched fractures.Thus,b-value can reflect the complexity of fracture.The larger theb-value is,the more complex the fracture network is (Wu Shan et al.,2017).

In the laboratory,we use the characteristic parameters of acoustic emission to obtain theb-value,and the results are shown in Fig.11.The results show that the rock in H3well has largeb-value than that of X1well sample,indicating that the sand bearing shale from H3well is easier to form complex-fracture network.The results is consistent with the section 3.3.

2.5 Brittleness Evaluation

Mullen M.J.et al.(2007) described an application of rock petro-physical properties to the optimization of the hydraulic fracturing design and presented a method to calculate the rock brittleness index “BRIT” with Young's modulus and Poisson's ratio.When BRIT is larger than 40,the rock is brittle.When BRIT is much more than 60,the rock is highly brittle.Using the static Young's modulus and static Poisson's ratio of rock measured by uniaxial compression experiments,the brittleness index is obtained as shown in Fig.12(a).The results show that the brittleness index is generally lower than 40.This result is also consistent with our stress-strain curve,that is,all the samples have the characteristics of plasticity.

Another method for evaluating rock brittleness is the mineral composition method(Jarvie D.M.et al.,2007).Sondergeld C.H.et al.(2010) developed a method for determining the brittleness index of rocks by minerals as:BI(%)=Quartz/(Quartz+Carbonates+Clays).Matthews H.L.et al.(2007) thought that,compared with clay and quartz,carbonate and feldspar are more brittle and should belong to brittle mineral,and hence there is no uniform standard for the presence of mineralogical methods (Wu Qinghong et al.,2011).In this study,we use Sondergeld C.H.et al.(2010) method to estimate the brittleness index based on mineralogy (Fig.12(b)).In a word,the brittleness is not very strong.The brittleness of sand-bearing shale is slightly better than that of pure shale and low mature shale,which is consistent with the results of Fig.7.The brittleness index of pure shale reservoir and low mature shale reservoir changes little.

2.6 In-Situ Stress Evaluation

The formation ability of fracture network is closely related to in-situ stress.The determination and application of in-situ stress run through the whole process of oil and gas field development.Generally,the in-situ stress is expressed by three principal stresses:vertical stressσv,horizontal maximum principal stressσHand horizontal minimum principal stressσh.The hydraulic fracture is affected by the horizontal stress difference coefficient.When the horizontal stress difference is greater,the fracture is easier to expand to the direction of the maximum horizontal principal stress,and it is not easy to form a complex fracture network.On the contrary,the smaller the difference of horizontal stress is,the easier it is to form complex fracture network.Therefore,the horizontal stress difference coefficient is used to evaluate the ability of forming complex fracture network in the horizontal direction of the reservoir.

WhereKhis horizontal stress difference coefficient.WhenKh<0.13,it is conducive to form complex fracture network.When 0.13<Kh<0.25,it is conducive to form complex fracture network under the condition of high pressure.WhenKh>0.25,it is not conducive to form complex fracture network.

We use hydraulic fracturing data and logging data to study the in-situ stress in this area.The fracture curves of X1,H3and D1wells are analyzed to determine the fracture pressure and fracture closure stress.The calculated in-situ stress results are shown in the Table 2.

According to the calculation of in-situ stress profile,theKhof pure shale and sandbearing shale is relatively small,indicating that it has the potential to form complex fracture network.TheKhin D1well is large,which is not conducive to form complex fracture network.For pure shale reservoir and low mature shale reservoir,the fracture closure stress gradient is close to or higher than 0.024 MPa/m,which is easy to form horizontal fracture during hydraulic fracturing,so it is not suitable for horizontal well fracturing.The fracture closure stress gradient of sand-bearing shale is also high,but lower than 0.024 MPa/m,so the hydraulic fracturing potential is slightly better.These results are consistent with the mechanical property results.

Figure 11 b-value diagram of sand bearing shale (H3 sample) and pure shale (X1 sample)

Figure 12 (a) Brittleness index based on mineral composition; (b) brittleness index based on elastic moduli

Table 2 Basic physical parameters of testing shales

3 DISCUSSION

Horizontal stress difference and the angle of natural cracks (or bedding) are the main geological factors that determine whether a natural fracture can be induced to open by hydraulic fracture.The permeability (or width) and bond strength (cohesion,friction coefficient and tensile strength) of natural fractures have an important influence on their opening.Zou Yushi et al.(2016) has discussed the principle of natural fracture opening in detail.According to Moore Couloms law:τ=τ0+Kf(σn-P)(Fig.13):

Figure 13 Two dimensional stress diagram of natural fracture

τ0is the aggregate strength inside the rock which is called cohesion in engineering.Kfis the internal friction coefficient of rock.σnis the normal stress on the natural fracture surface formed by in-situ stress.Pis the fluid pressure brought by hydraulic fracture.When the fluid is injected into the natural fracture,the shear stress of the fracture surface decreases.And when the shear criterion is reached,the natural fracture is activated by sliding.After the natural fracture slips,the fluid will leak off along the fracture surface and the fluid pressure will drop.Thus,the conditionP>σ3cannot be achieved in a certain period of time.Therefore,when the natural fracture is easy to be activated,the hydraulic fracture is easier to expand along the natural fracture surface or bedding surface.In the block we studied,the bedding of shale oil reservoir is very developed,and horizontal fractures are easy to form during fracturing.

Through the analysis of the mechanical experiments,we found that all the samples have the characteristics of low compressive strength,low Young's modulus and strong anisotropy indicating that the shale oil reservoir is certain plastic,which is related to its high clay mineral content.Thus,it is not easy to form complex fracture network.The shale oil reservoir in the block we studied has developed bedding,and the fractures are easy to expand along the bedding plane under compression loading.

For pure shale and low mature shale,the fracture closure stress gradient (Table 2) is close to or higher than 0.024 MPa/m,indicating that the vertical stress is close to the horizontal minimum stress.The in-situ stress conditions and the developed bedding make it easier to form horizontal fractures when the reservoir is hydraulically fractured.A simple schematic representation in Fig.14 shows that in order to form a larger fracture network,for horizontal wells,it is best to expand the fracture longitudinally.And for vertical wells,it is best to expand the fracture horizontally.As for the fractures are not easy to communicate vertically,which makes the stimulated volume fracture is limited for pure shale and low mature shale.

Figure 14 (a) Fracturing diagram of horizontal well;(b) Fracture diagram of vertical well

For sand-bearing shale,the fracture closure stress gradient is lower than 0.024 MPa/m,but it is also higher.Thus,sand-bearing shale is slightly better,the fractures of which are not easy to open along the bedding plane.Overall,the expansion of hydraulic fracture is controlled by in-situ stress and bedding.Because of the development of bedding,it is easy to form horizontal fractures.Thus it is not suitable for horizontal well fracturing.Because of the high content of clay minerals,the applicability of conventional slick hydraulic fracturing fluid is poor.It is suggested to use vertical well or directional well to carry out volume fracturing.In this way,the effect of bedding can be effectively used to open and connect the bedding and form a larger fracture network.

4 CONCLUSIONS

(1) The shale reservoirs in the study area have the characteristics of low porosity and low permeability.Pore throats are dominated by nano-pores,which make crude oil production difficult.The shale reservoir has high clay content,in which illites and montmorillonite accounts for an important proportion,and the shale reservoir has obvious symbiotic relationship between organic matter and clay minerals.Such characteristics make shale have stronger water sensitivity.The expansion of clay will block the pores of organic matter and is not conducive to oil and gas production.Overall,the reservoir has poor physical properties with the characteristics of high clay content,low oil saturation,poor resource endowment and high development difficulty.

(2) Compared with the typical unconventional oil reservoirs in China,the anisotropy coefficient of shale oil reservoir in Songliao Basin is significantly higher.Combined with the microstructure,it shows that the bedding is more developed.

(3) The mechanical experimental results show that all the samples have the characteristics of low compressive strength,low Young's modulus and strong mechanical heterogeneity.The low Young's modulus and the brittleness evaluation indicate that the shale oil reservoir in Songliao Basin shows certain plastic characteristics,which is related to its high clay mineral content and controlled by the bedding development.Compared with pure shale and low mature shale,the sand-bearing shale has less clay content and less developed bedding,which maybe the main reason for its slightly better brittleness.

(4) Combined with the fracture morphology of the core,the fracture propagation of pure shale and low mature reservoir is easy to open along the bedding plane under compression loading,which is greatly influenced by the bedding.Sand-bearing shale is slightly better,the fractures of which are not easy to open along the bedding plane.According to the results of in-situ stress calculation by hydraulic fracturing,combined with the classified evaluation of shale mechanical properties and acoustic emission evaluation of fracture law,horizontal fractures may be formed in multiple fracture sections,and the expansion of hydraulic fracture is controlled by in-situ stress and bedding.

(5) The shale resources in the studied block are generally endowed with poor exploitation,and the fracturing potential is controlled by the reservoir properties with great difference.There are two significant characteristics in the study area.One is the development of bedding,which is easy to form horizontal fractures.Influenced by bedding and in-situ stress,it is not suitable for horizontal well fracturing.The other is the high content of clay minerals,and the applicability of conventional slick hydraulic fracturing fluid is poor.It is suggested to use vertical well or directional well to carry out the hydraulic fracturing.In this way,the effect of bedding can be effectively used to open and connect the bedding and form a larger fracture network.

Earthquake Research Advances2020年2期

Earthquake Research Advances2020年2期

- Earthquake Research Advances的其它文章

- Progress and Prospect of Geophysical Research on Underground Gas Storage:A Case Study of Hutubi Gas Storage,Xinjiang,China1

- Analysis of Anomalous Characteristics of Regional Crustal Deformation before the September 16th,2019 Zhangye MS5.0 Earthquake,Gansu,China1

- Study of the Seismogenic Structure of the October 12th,2019 MS 5.2 Beiliu Earthquake,Guangxi,China1

- Analysis of Power Supply Interference of Geomagnetic Second Data Observation-Take Changli Seismic Station as An Example1

- New Understanding of Variation Characteristics of Well Water Level in Majiagou Mine,Tangshan City,Hebei,China1

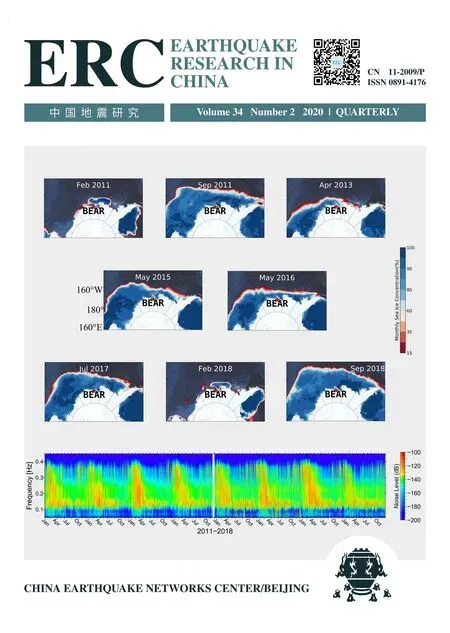

- Microseism Variations in Response to Antarctic Seasonal Changes in Sea Ice Extent1