质子交换膜燃料电池金属双极板改性碳基涂层技术研究进展

辛洋,郭鹏,李昊,陈仁德,孙丽丽,马冠水,汪爱英,3

质子交换膜燃料电池金属双极板改性碳基涂层技术研究进展

辛洋1,2,郭鹏1,李昊1,陈仁德1,孙丽丽1,马冠水1,汪爱英1,3

(1.中国科学院宁波材料技术与工程研究所 a.中国科学院海洋新材料与应用技术重点实验室 b.浙江省海洋材料与防护技术重点实验室,浙江 宁波 315201;2.中国科学技术大学 纳米科学技术学院,江苏 苏州 215123;3.中国科学院大学 材料与光电研究中心,北京 100049)

对比了碳基涂层改性金属极板、未涂覆的金属极板和传统石墨极板性能的优劣,阐述了碳基涂层在优化金属极板导电耐蚀性能方面取得的最新成果,以及在质子交换膜燃料电池(Proton exchange membrane fuel cells, PEMFCs)环境长期运行后,碳基涂层出现性能失效及寿命受限等问题。通过分析影响碳基涂层性能的因素,指出由于非晶碳材料设计、微观结构等对其性能影响规律的系统化研究不足,导致非晶碳涂层/金属极板损伤及退化机理不明确。重点阐述了国内外关于PEMFCs金属极板改性碳基涂层材料技术的研究进展,包括调控本征碳基涂层(a-C)微观形貌优化涂层性能;采用理论计算与实验相结合的方法制备金属掺杂碳基涂层(a-C: Me),解决涂层与特定金属基体间粘附性差、压应力高等问题;设计多层结构碳基涂层以减少贯穿性缺陷。探讨了几类涂层失效机制,并对金属极板改性用碳基涂层技术进行了展望。

质子交换膜燃料电池;双极板;碳基涂层;导电性能;耐腐蚀性能

近年来,随着工业的不断发展,能源枯竭和环境污染等问题日益突出,氢能与燃料电池技术是公认的有效解决方案之一[1-2]。其中,质子交换膜燃料电池(Proton exchange membrane fuel cells, PEMFCs)具有低运行温度、零排放、高比功率和高能量转换率等优点,在车用动力电源、便携设备和航空等领域前景广阔[3-4]。PEMFCs主要由双极板、膜电极组件、端板和密封件等组成[5]。双极板作为PEMFCs的核心多功能组件,起到均匀分配气体、排水、导热、导电等作用,其质量占整个燃料电池的60%,成本占15%~20%[6-9],其性能和成本会直接影响电池的使用寿命和商业化进程。传统石墨极板由于体积大、制造成本高以及力学性能较差,逐渐被可加工性强、导电导热性优、力学性能好的金属双极板取代[10-12]。然而在电池酸性工作环境中,金属极板易腐蚀,腐蚀过程中形成的金属离子会导致质子交换膜离子传输效率下降,同时在金属双极板表面形成的钝化膜会增大界面接触电阻(Interface contact resistance, ICR),从而导致燃料电池性能下降[13-15]。

表面涂层材料技术可以在保持金属极板优异的力学性能和加工性能的基础上,提高金属极板的电导率和耐蚀性[16]。Wang等[17]研究了金涂层改性钛金属双极板的短期性能,可减少金属氧化物的形成和金属离子的溶出。Feng等[18]利用离子注入技术,将Ag离子注入到316L不锈钢基体,成功制备出厚度45 nm富银层。相比于基体,富银表面层改善了基体耐腐蚀性和抗极化性。该团队[19]还通过相同的方法在SS316L表面制备了富镍层,改善极板导电耐蚀性,但由于成本较高,贵金属层技术不适合大批量商业生产。Mohammadi等人[20]利用二氧化铅(PbO2)具有成本低和在H2SO4中电导率高的特点,通过电沉积技术在SS316L上制备PbO2涂层。在模拟PEMFCs环境下,PbO2涂层易发生局部腐蚀,难以满足极板的耐蚀性能需求。Gonzalez-Rodriguez等人[21]利用电化学沉积法在SS304极板上制备的聚吡咯涂层具有较高的耐腐蚀性,但长时间运行后,出现涂层降解。A. Orsi等[22]通过物理气相沉积工艺将氮化钛(TiN)涂层沉积到SS316L基体上,并对其耐蚀性能和ICR进行评估。在0.8~1.4 V(vs. SHE)的范围内测量电位对TiN涂层的影响,恒电位极化数据表明,电流密度随电势的降低而降低。另外,与未涂覆的SS316L相比,在1.4 V(vs. SHE)电位下,涂覆TiN涂层的SS316L的ICR从12.9 mW·cm2增大到287 mW·cm2。Zhang等[16]使用两种表面改性技术制备TiN涂层,即通过磁控溅射技术制备SS304/Ti2N/TiN涂层和通过脉冲偏压电弧离子镀技术制备SS304/TiN涂层,两种涂层均具有较好的耐蚀性能,但改性极板界面接触电阻较大,不能满足2020年美国能源部(United States Department of Energy, DOE)燃料电池技术指标(腐蚀电流密度小于1.00 μA/cm2,ICR小于10 mW·cm2)。N. D. Nam等人[23]研究了射频磁控溅射技术制备的TiN/CrN多层涂层的电化学行为与TiN/CrN涂层厚度比的关系。在模拟燃料电池(1 mol/L H2SO4+2 mg/L F–, 70 ℃)阴极环境下进行10 h动电位极化测试后,不同厚度比的TiN/CrN多层涂层的腐蚀电流密度均增加到15 μA/cm2左右。综合考虑成本与性能改善,由于非晶碳涂层兼具优异的导电性和耐腐蚀性能,且规模化成本优势显著,在PEMFCs金属极板的应用中引起了广泛关注。非晶碳(Amorphous carbon, a-C)[24]是一大类无定型碳的总称,其结构主要由sp2杂化(类石墨结构)和sp3杂化(类金刚石结构)的原子碳组成。sp3杂化能有效阻止腐蚀离子的侵蚀,而sp2杂化主要影响导电性。因此通过平衡sp2和sp3杂化的比例,可以获得高导电、高耐蚀并且具有良好力学性能的非晶碳涂层。

目前,国内外多个科研团队已经开发了多种方法制备金属双极板改性碳基涂层(见表1),主要包括物理气相沉积[25-28]和化学气相沉积[3,29]等方法。通过化学气相沉积(CVD)法在SS304基体上制备a-C涂层,涂层耐蚀导电性能满足美国DOE指标。Chung等[29]使用CVD技术在SS304表面制备了碳涂层,发现涂层的表面形态取决于CVD沉积过程中气体碳源的浓度。该方法可以通过调控气相组成制备具有不同化学成分的涂层,从而获得梯度或复合镀层,但CVD技术的沉积功率较低,且成膜时工件温度高,在应用上受到一定限制。相比之下,物理气相沉积(PVD)法制备的涂层ICR均小于CVD涂层(8.90 mW·cm2),具有较好的电导率[3]。Bi等[30]研究了偏置电压对闭合场非平衡磁控溅射离子镀(Closed field unbalanced magnetron sputter ion plating, CFUBMSIP)沉积的a-C涂层微观结构和性能的影响,成功制备出具有致密结构的a-C涂层。Wu等[31]通过脉冲偏压电弧离子镀(PBAIP)在SS316L上沉积一系列含铬的碳涂层。涂层中sp3和sp2碳原子的含量受掺杂铬的影响很大,且ICR与sp3和sp2碳原子的含量密切相关。Cr0.23C0.77涂层获得最低的ICR(压实压力为1.20 MPa,ICR为2.8 mW·cm2)以及最佳的耐腐蚀性。与CVD法相比,PVD沉积工艺过程简单,且成膜均匀致密。此外,Y. J. Ren等[9]通过高能微弧合金化(HEMAA)技术获得的涂层比PVD方法制备的涂层结构更致密,该涂层的腐蚀电流密度仅为0.034 μA/cm2,且在模拟PEMFCs的阴极工作环境下浸泡30天后,仍然具有较高的稳定性。因此,与PVD涂层相比,由HEMAA制备的TiC涂层可以更有效地阻止腐蚀物质到达基体,成为阻止腐蚀物质向内渗透的有效屏障。总体上,对于含氢、无氢非晶碳,采用PVD沉积工艺获得的涂层材料具有更好的耐蚀性与更低的接触电阻,这可能与H组分、电阻率有关。Asri等[32]充分探讨了双极板涂层与表面处理方法间的联系,客观评估了涂层制备方法和涂层性能。Yi等[33]、Bi等[30]和Wang等[34]从涂层结构设计和组分调控等多方面研究了碳基涂层性能。在产业方面,上海YOOGLE(佑戈)公司和常州翊迈新材料科技有限公司等也开发了系列碳基涂层改性的金属双极板产品。研究结果表明,采用非晶碳涂层材料技术可以显著提高多种金属极板的耐蚀性与导电性,同时部分产品已应用于上汽集团的荣威750、950及大通V80系列车型上,实测性能良好,市场应用潜力巨大。

表1 不同沉积方法对双极板碳基涂层性能的影响

Tab.1 Effects of different deposition methods on the performance of bipolar plate carbon-based coating

碳基涂层改性金属极板具有良好的机械性、优异的耐蚀导电性能和较低的价格,适合大批量商业生产。由于国内外研究的具体应用工况和需求不同,涉及的金属极板种类多样,包括SS316L、SS304、Ti、Ti6Al4V等金属极板,研究团队针对不同的金属极板所开发的耐蚀导电非晶碳材料技术差异巨大。本文从非晶碳涂层材料组分、结构设计角度出发,综述了本征非晶碳涂层、金属掺杂非晶碳涂层以及多层结构非晶碳涂层在该领域的研究进展,并对碳基涂层改性金属极板的研究方向进行了展望。

1 本征非晶碳涂层

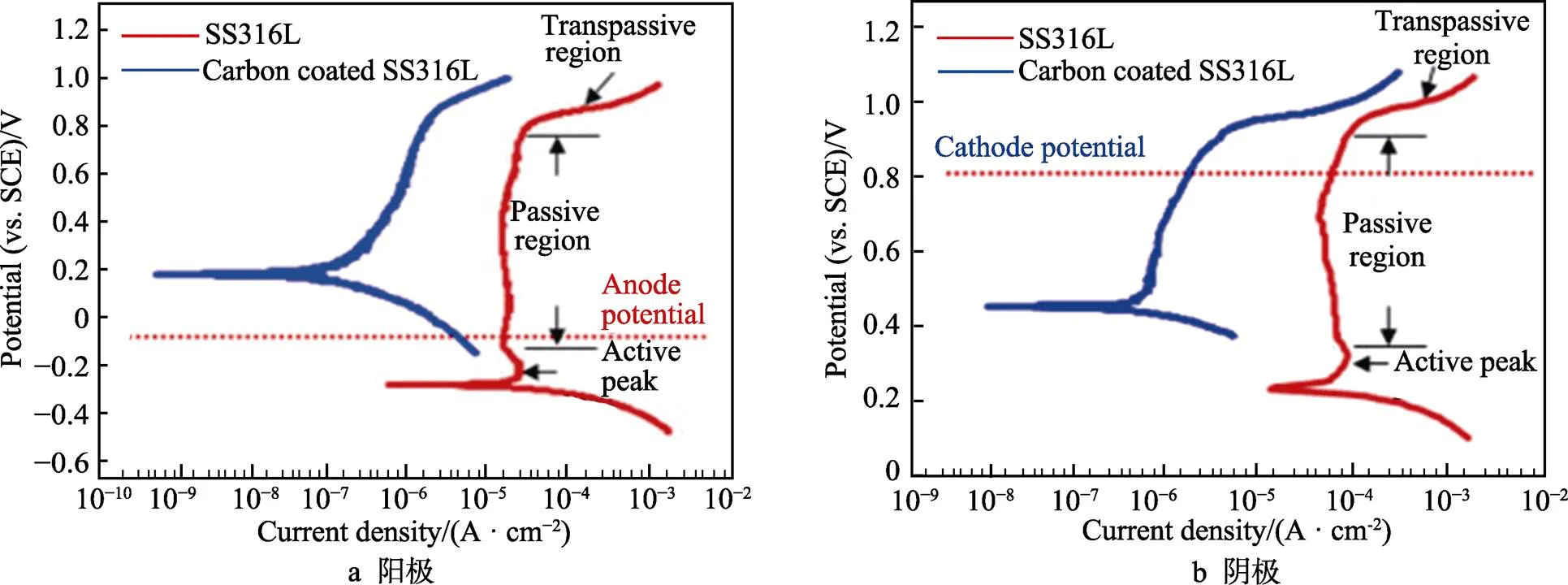

Lee等[45]利用低温加速C60离子束技术制备纳米复合碳改性316L不锈钢。如图1所示,在模拟电池阴极环境(0.5 mol/L H2SO4+2 mg/L HF,80 ℃)下,涂层改性极板的腐蚀电流密度降低为0.23 μA/cm2;而在模拟电池阳极环境下,碳涂层的腐蚀电流密度为0.05 μA/cm2,有效地抑制了基体的腐蚀。改性极板界面接触电阻降低有限,仍大于10 mW·cm2。Afshar等[27]考察了基板温度对碳涂层结构和电化学性能的影响。如拉曼光谱(图2a)所示,随着基体温度的增加,D峰强度增加,碳涂层中小尺寸纳米晶石墨或短程有序石墨结构增多。不同基板温度下,经碳涂层涂覆的316L不锈钢的动电位极化测试结果如图2b所示。基板温度会改变纳米晶石墨的晶粒尺寸、缺陷和粗糙度,从不同程度影响了涂层导电耐蚀性能。类似地,Show等[46]研究对比了a-C涂覆钛极板在550、600 ℃时的性能。与未处理的基体相比,a-C涂层可将接触电阻降低1/2。

图1 改性碳涂层与SS316L在阳极和阴极环境下的动电位极化曲线

图2 不同温度沉积的非晶碳涂层拉曼光谱和动电位极化曲线

Feng等[47]利用闭合场非平衡磁控溅射技术在316L不锈钢表面涂覆纯a-C涂层,并在80 ℃下浸泡在0.5 mol/L H2SO4+2 mg/L HF的腐蚀液中进行动电位极化测试。与未涂覆SS316L相比,涂层改性的SS316L表现出更高的耐腐蚀潜能,腐蚀电流密度显著降低至1.85 μA/cm2,ICR低于未处理的SS316L。同时,该团队[48]制备出连续且致密的a-C涂层,纯a-C涂层改性不锈钢极板具有比石墨极板更好的性能。

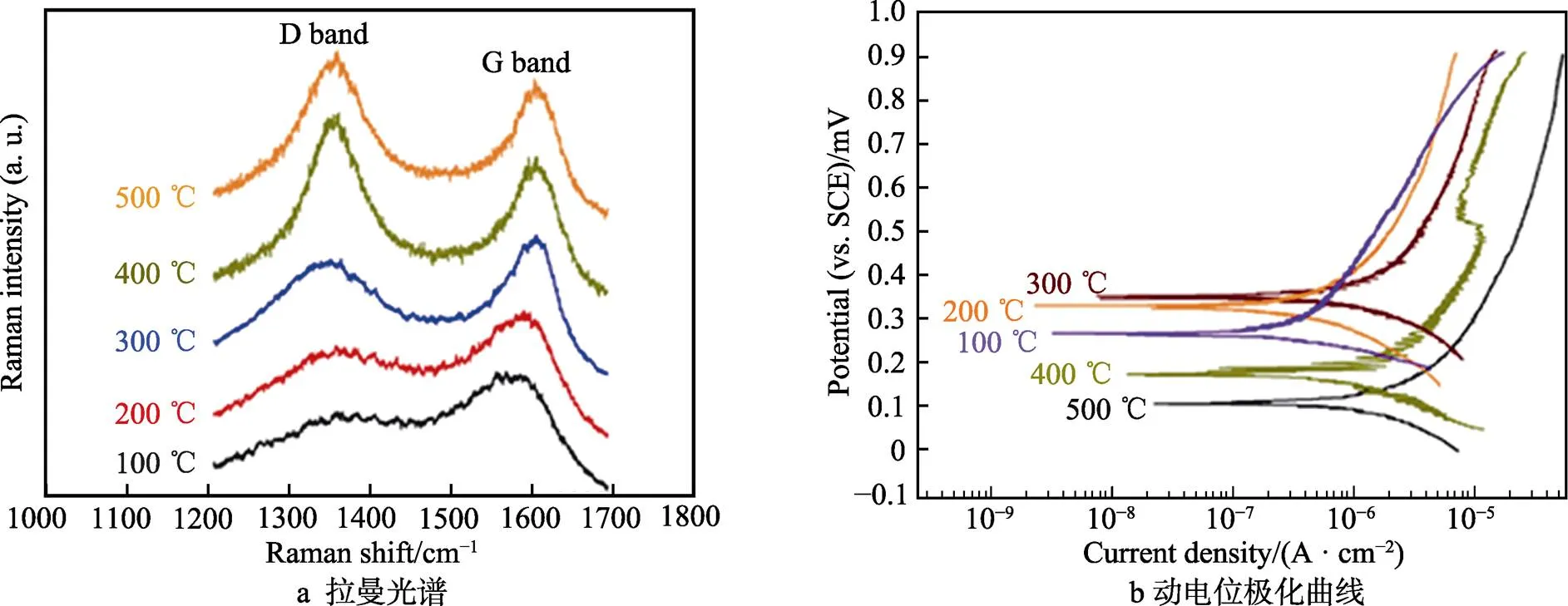

此外,在考虑到结合力等实际需求,本征非晶碳涂层在使用中涉及到过渡层的使用。Li等[49]采用模拟计算分析常用W、Ti、Cr等金属层对于非晶碳的催化作用。如图3所示,在a-C@Ti系统中,a-C结构中的sp2-C含量随着温度升高到900 K而逐渐升高,随着温度进一步升高到1500 K而降低。在a-C@Cr和a-C@W系统中,随着温度的变化,sp2-C含量的变化趋势与a-C@Ti相反。因此,在较低的温度(<900 K)下,Ti比Cr或W对a-C结构的催化作用更好;而在较高的温度(>900 K)下,Cr或W更易使a-C转变为石墨化结构。人们从原子尺度上比较研究这三种过渡层与a-C涂层之间的界面结构,明确了界面处金属-碳作用情况以及沿涂层厚度方向sp3/sp2键态含量演变规律。Wu等人[50]通过直流磁控溅射技术在SS304上制备Cr/a-C涂层,发现在Cr过渡层与a-C涂层界面处形成了互锁结构,Cr/a-C涂层的内部缺陷成功地从互锁结构中错开,有效地阻止了腐蚀液到达基体,提高了电极相关性能。

图3 温度升高过程中三种过渡层与a-C涂层的杂化碳结构演变

在本征非晶碳损伤机理方面,Bi等[30]通过对涂层沉积技术参数进行调控,成功制备出具有不同微观形貌的a-C涂层。结构最致密涂层的腐蚀电流密度仅为0.6 μA/cm2,远小于2020年美国DOE技术指标。涂层ICR值也仅为2 mW·cm2,是具有最疏松结构涂层的ICR值的1/20。基于测试前后非晶碳表面组分分析,该团队提出了表层钝化作用以及类石墨组分(sp2)氧化导致极板性能退化的机制,在金属双极板改性碳基涂层机理研究方面处于领先地位。Li等[51-52]利用直流磁控溅射技术制备了系列SS316L/a-C极板,发现在模拟PEMFCs工作条件下,a-C涂层可显著提高SS316L的耐蚀导电性能。通过优化溅射功率和磁场强度,发现在0.9 kW沉积的a-C涂层具有最低腐蚀电流密度(7.52×10–3μA/cm2)和初始接触 电阻(2.91 mΩ·cm2)。12 h腐蚀测试后,ICR增至4.00 mΩ·cm2,且可在a-C/SS316L界面处观测到Cr2O3的富集(如图4所示)。这种氧化物具有良好的化学惰性和绝缘性,在抵抗基体腐蚀的同时,也一定程度上阻碍了电流的传输,是导致接触电阻上升的主要原因之一,从而提出了界面损伤导致a-C/SS316L性能退化的机理。

2 金属掺杂非晶碳涂层

上述非晶碳涂层虽使金属极板具有良好的导电耐蚀性能,但仍然存在应力高、易剥落等问题。涂层中的残余应力会显著影响到涂层的结合强度、抗疲劳、耐蚀等性能,也是引起涂层表面裂纹、剥落的重要因素。如果涂层中残余应力较高,则会在涂层中产生更多的裂纹缺陷,涂层也更容易脱落。尤其是在腐蚀过程中,腐蚀性介质通过涂层中的裂纹、通孔等缺陷到达膜基界面位置,形成点蚀,进而加速膜基界面失效。金属掺杂后可有效地减少涂层中的残余应力,这是因为金属原子与碳原子之间存在电负性的差别,使得键中存在离子部分的贡献,降低了键的方向性和对键角畸变的敏感度[53-54]。金属元素掺杂非晶碳会产生离子键、共价键、非键和反键四类成键特征,键的离子相互作用导致残余应力大大降低[55-58]。因此,金属(Ti、Mo、Cr、Al或W等)元素掺杂a-C涂层的方法可解决涂层因应力较高而剥落失效的问题,同时也优化了涂层与基体的电导率或化学亲和力[59-61]。Hou等人[36]利用第一性原理计算揭示了Nb掺杂a-C涂层中sp2/sp3的变化规律,并对碳原子键合、结构、掺杂碳原子状态以及电荷密度分布进行了模拟,并利用CFUBMSIP方法制备了Nb掺杂a-C涂层。结果表明,涂覆极板的腐蚀电流密度均低于未涂覆基体SS316L,经过恒电位极化测试24 h后,腐蚀电流密度随着掺杂Nb含量增加而降低。在1.40 MPa测试条件下,掺Nb样品的ICR值均低于纯a-C涂层。

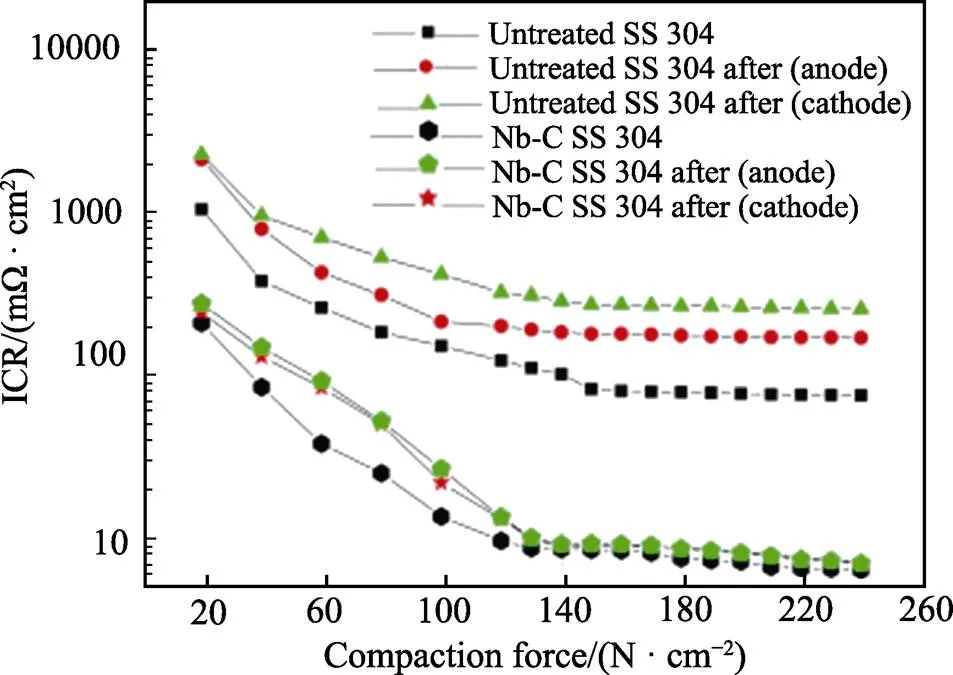

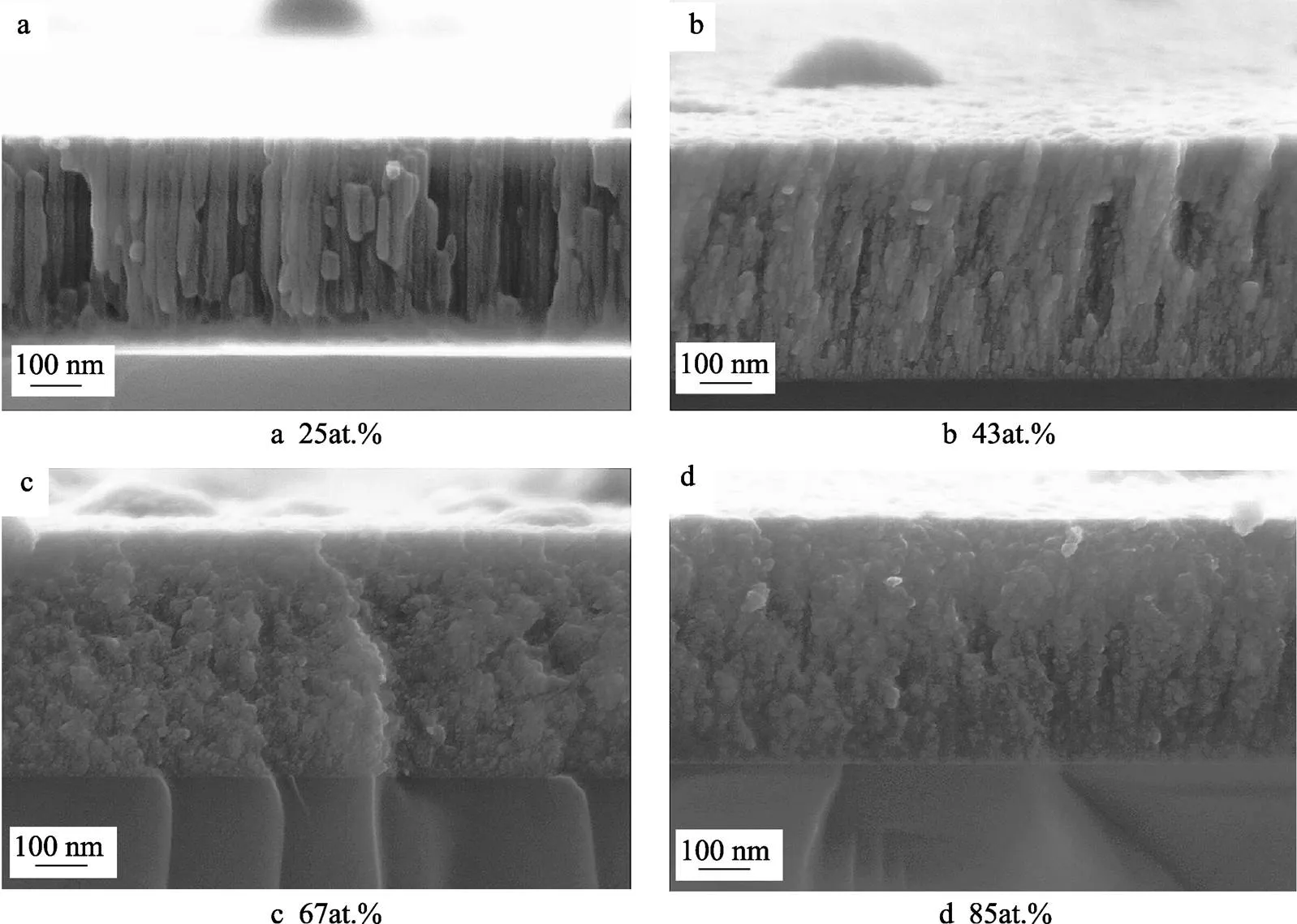

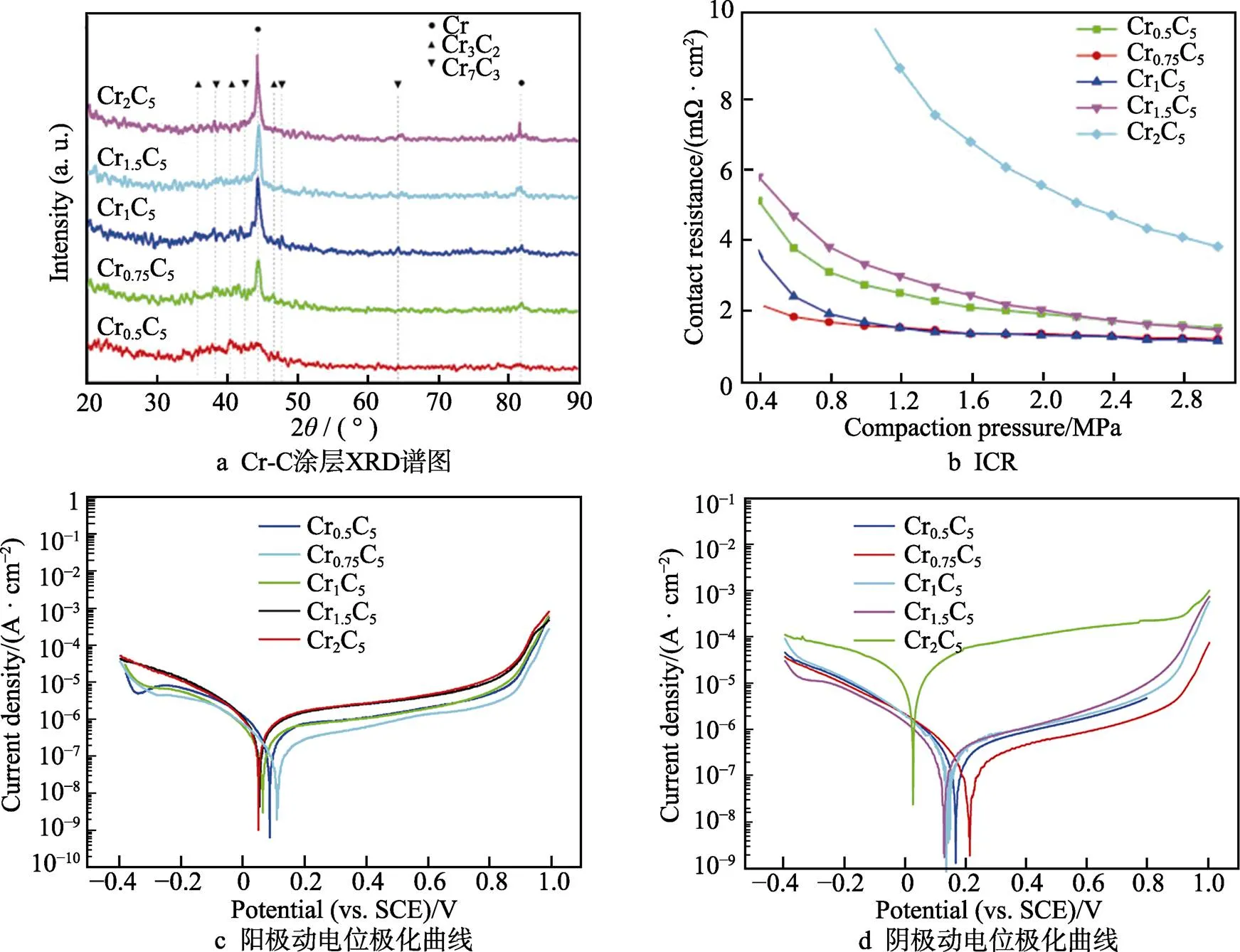

Wang等人[62]在SS304表面制备了铌掺杂a-C涂层,使改性极板具有8.47 mΩ·cm2的低界面接触电阻和良好的耐腐蚀性(如图5所示)。在模拟燃料电 池(0.5 mol/L H2SO4+2 mg/L HF,70 ℃)阴极环 境下进行动电位极化测试,涂层的腐蚀电流密度为0.051 μA/cm2。极化10 h后,接触电阻增至9.04 mΩ·cm2。Andersson等[63]使用非反应直流磁控溅射技术分别沉积了不同碳含量的金属掺杂碳基涂层。不同碳含量涂层的微观结构有明显不同(如图6所示),并导致涂层的导电耐蚀性能具有较大差异。该课题组[15]将低成本电镀工艺应用到金属掺杂碳基涂层制备中,随着涂层中碳含量增加,ICR值降低。类似地,研究者[1]通过CFUBMSIP技术沉积了具有不同碳含量的金属掺杂碳基涂层,其电化学性能如图7所示。随着Cr靶电流的增加,涂层中Cr含量增加,且金属碳化物减少。在模拟电池阴极环境下,各涂层耐蚀性顺序依次为Cr0.75C5>Cr0.5C5> Cr1C5>Cr1.5C5>Cr2C5。因此,通过工艺参数调控碳含量得到相似结论:涂层的耐蚀性与涂层组成密切相关,即随着C含量增加,耐蚀性也增加。Wang等人[37]通过CFUBMSIP技术制备W掺杂非晶碳涂层,发现了涂层具备自钝化能力。掺W的a-C涂层结构致密,并且随着W浓度的不同,涂层的相组成和表面形貌也发生了略微变化。在1.50 MPa压实压力下,掺杂浓度不同,ICR在6.25~ 7.21 mW·cm2内波动。在丰富的理论计算指导下和大量的实验研究中,研究人员成功制备出各种单元金属掺杂非晶碳涂层。实验结果表明,通过改变工艺参数可制备出具有良好耐腐蚀性和导电性的金属掺杂非晶碳涂层,且通过微量掺杂金属粒子,可有效地改善极板涂层的表面电导率和耐腐蚀性能。

图5 不同压实压力下Nb-C/SS304和SS304腐蚀前后的ICR

图6 碳含量不同的CrxCy涂层的截面形貌

图7 碳含量不同的金属掺杂碳基涂层的电化学性能

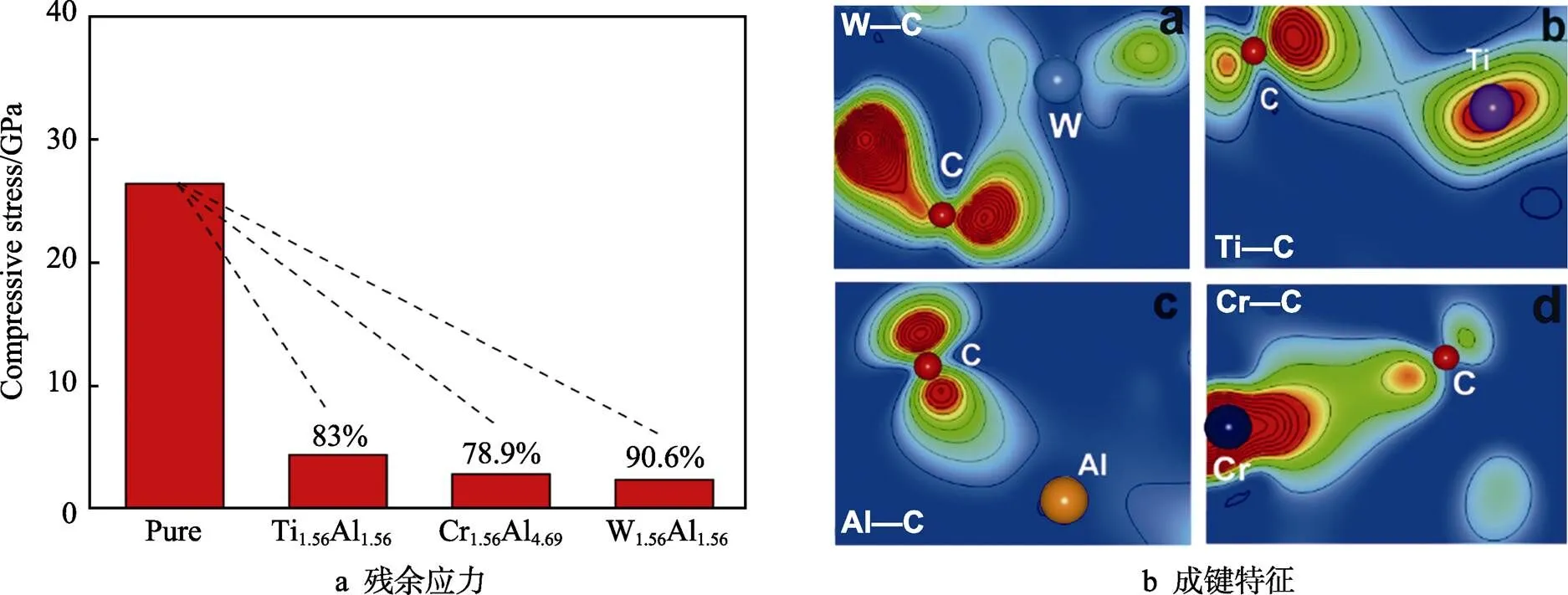

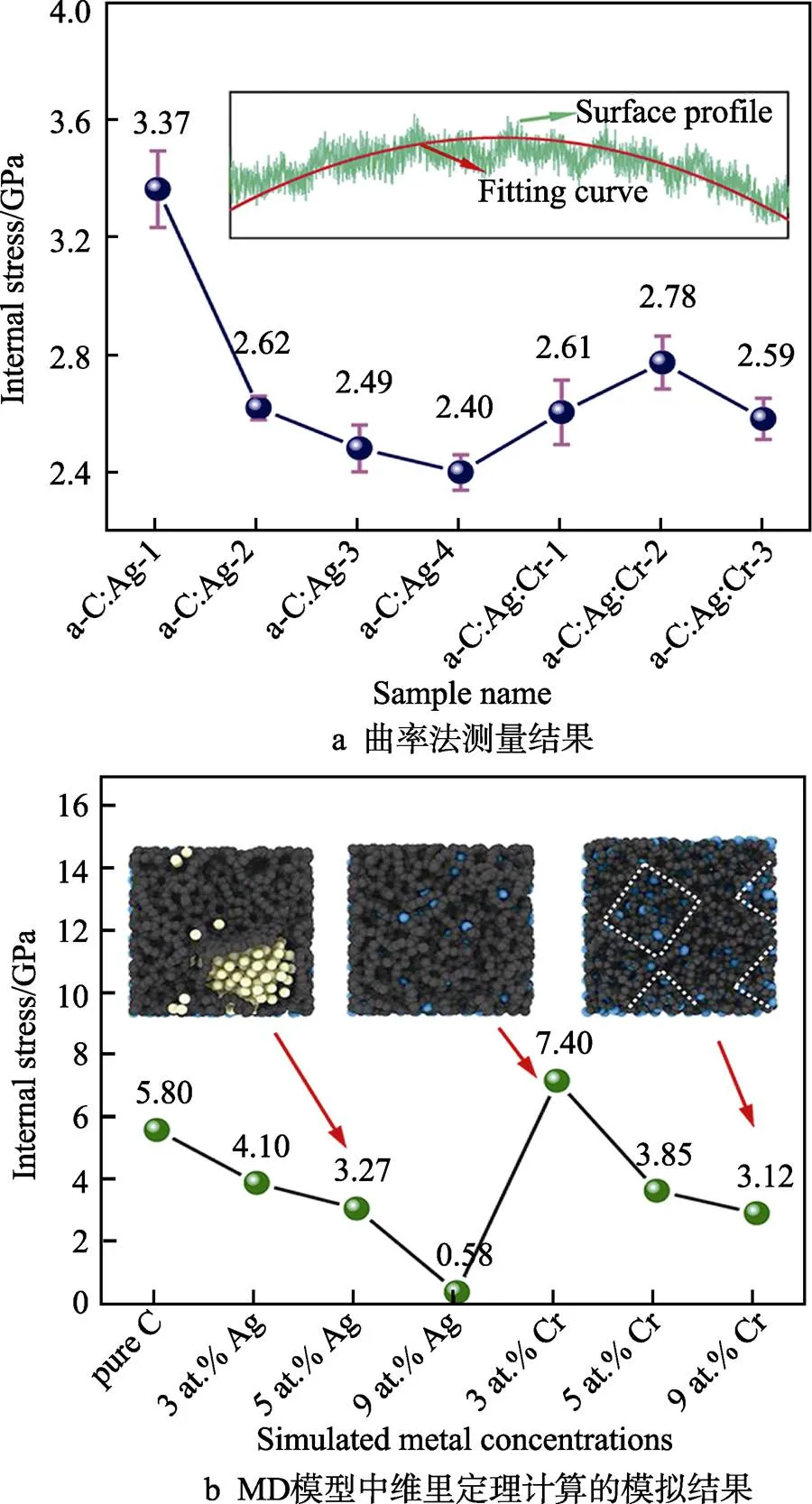

基于单一元素掺杂的理论研究与实验结果,研究人员对多元掺杂非晶碳涂层在金属极板改性方面也做了探索。Li等[58]基于不同掺杂金属之间的特性互补和材料计算学优势,进行了多元掺杂复合涂层的组分优化设计。Ti/Al、Cr/Al或W/Al共掺杂a-C涂层的残余压应力和成键特征如图8所示。与纯a-C涂层相比,Ti/Al、Cr/Al或W/Al共掺杂的a-C涂层具有降低应力的总体趋势。Ti/Al、Cr/Al或W/Al共掺杂的a-C涂层会严重扭曲C—C键长度,并形成弱的共价键,从而形成Ti—C、Cr—C、W—C以及Al—C键的离子相互作用,导致残余应力大大降低,如图8b所示。Zhang等[64]将Ag和Cr原子掺杂到a-C涂层,结合分子动力学模拟掺杂a-C涂层的沉积过程和涂层结构变化。通过同时掺杂一定量Ag和Cr,可降低a-C涂层内应力,并提高致密性,如图9所示。共掺杂Ag和Cr涂层样品的ICR(0.87 mW·cm2)低于单独掺杂Ag涂层(1.07 mW·cm2),经过耐久性测试后,ICR约为2.14 mW·cm2。结果表明,将适量的金属组元复合,可以进一步提高a-C涂层的耐腐蚀性,相关研究还有待进一步深入。

图8 多元共掺杂涂层残余应力和成键特征

图9 不同金属含量下涂层内应力

3 多层结构非晶碳涂层

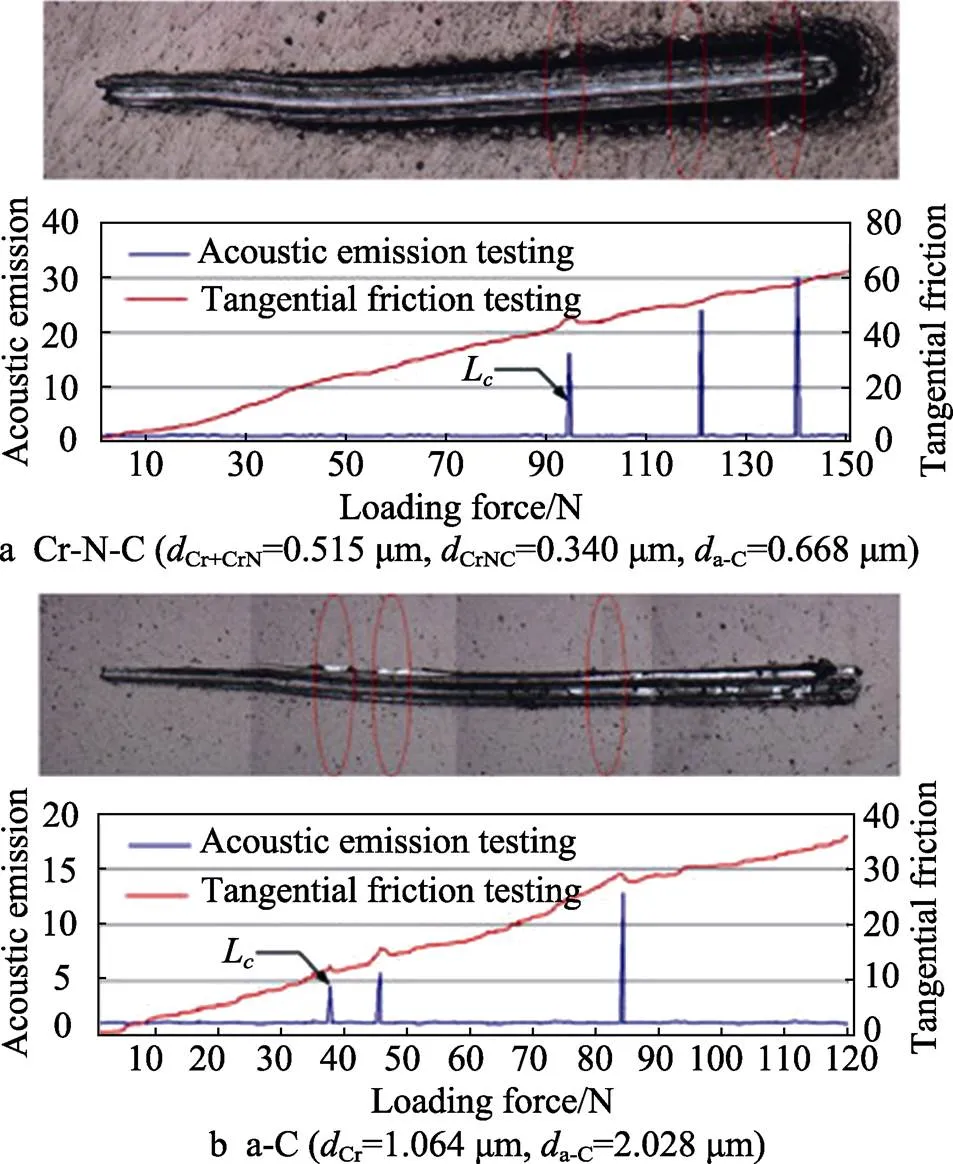

与涂层腐蚀相关的大量研究表明,具有柱状结构和孔洞等缺陷是导致涂层耐蚀性能明显降低的原因之一。人们普遍认为多界面涂层可以减少贯穿性缺陷。因此,设计多层结构涂层有利于提高耐蚀性。Yi等[41]采用CFUBMSIP技术在0.1 mm厚的SS316L表面制备了强结合梯度多层Cr/CrN/CrNC/a-C涂层,通过划痕测试评估对比了该多层体系与SS316L以及a-C与SS316L之间的结合强度(如图10所示)。在模拟电池(0.5 mol/L H2SO4+5 mg/L HF,70 ℃)阳极(0.1 V(vs. SCE))和阴极(0.6 V(vs. SCE))环境下恒电位极化10 h后,改性极板的极化电流密度均低于1 μA/cm2,且界面接触电阻为2.64 mΩ·cm2(压实压力为1.40 MPa)。Bi等人[42]采用相同技术在SS316L表面制备了多层Zr-C/a-C涂层。在模拟电池(pH=3, H2SO4+0.1 mg/L HF,80 ℃)条件下测试改性极板,与a-C涂层相比,阴极和阳极环境中的腐蚀电流密度都降低了1个数量级。在1.40 MPa的测试条件下,Zr-C/a-C涂层的ICR仅为3.63 mΩ·cm2。

图10 Cr-N-C和a-C涂层划痕测试图

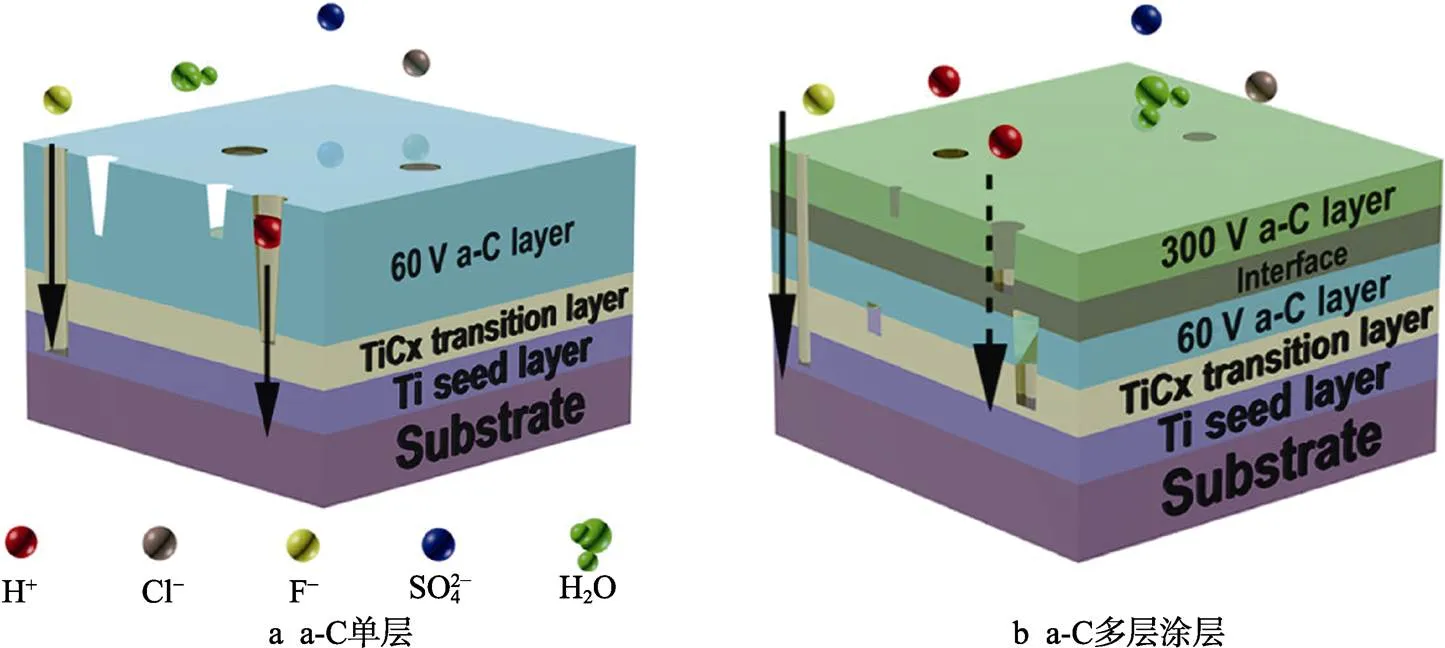

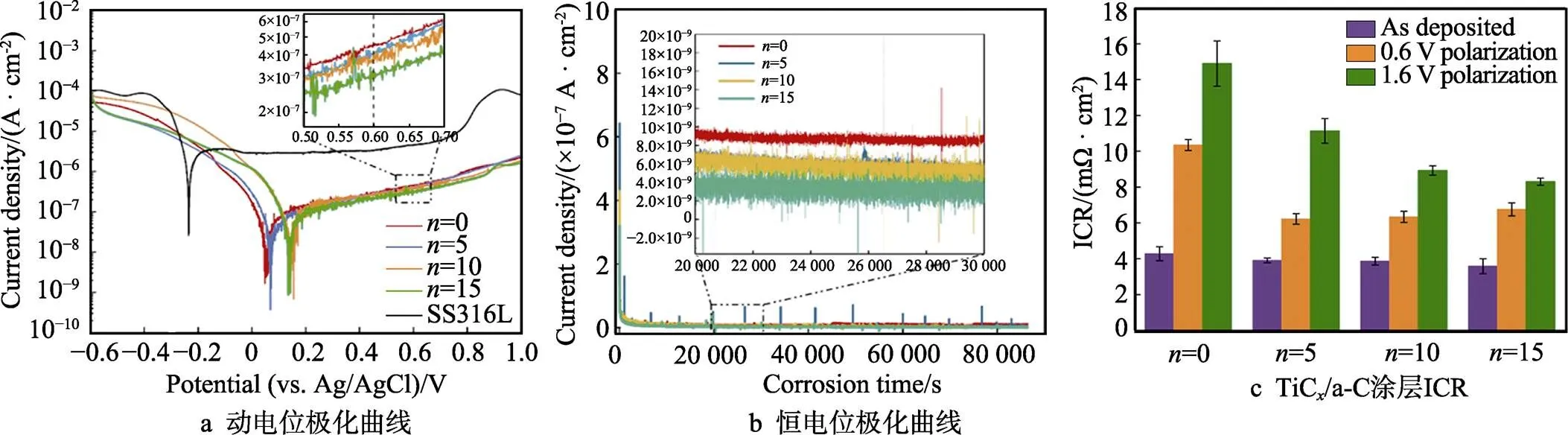

Yi等[39]提出一种在磁控溅射过程中通过不同负衬底偏压的协同作用沉积TiC/a-C多层涂层的新方法。不同负衬底偏压使多层涂层表面形貌、sp2/sp3等发生改变,且抑制柱状微结构和微孔,可获得ICR为1.85 mΩ·cm2、腐蚀电流密度为0.32 μA/cm2的涂层。在PEMFCs阴极环境下,单层涂层和多层涂层之间不同的腐蚀行为如图11所示。在此基础上,该团队[33]进一步开发了多层碳化铬/铬掺杂非晶碳(Cr-C/ a-C: Cr)新型涂层。在1.50 MPa时,Cr-C/a-C:Cr涂层改性的SS316L极板的ICR仅2.89 mΩ·cm2。在阴极工作电位(0.6 V(vs. SCE))下,多层涂层涂覆的SS316L的钝化电流密度为0.276 μA/cm2。该多层涂层的耐蚀性比本征a-C涂层提高了1个数量级,满足美国DOE的2020年技术指标。Zhang等人[44]利用衬底偏置电压逐层沉积的方法制备了多层TiC/a-C涂层。以15个交替周期沉积的涂层在0.6 V电势下,腐蚀电流密度为0.297 μA/cm2,ICR值为3.58 mΩ·cm2(如图12所示),在双极板的商业应用中显示出巨大的潜力。以上研究表明,通过设计多层碳基涂层改性双极板,可有效减少涂层缺陷而提高极板的耐腐蚀性能。

图11 PEMFCs阴极环境中a-C单层和a-C多层涂层不同的腐蚀行为

图12 TiCx/a-C多层涂层性能

4 结语

随着工业的迅速发展,对质子交换膜燃料电池性能的要求越来越高,通过表面改性技术,可赋予双极板更加优异的表面性能,从而满足质子交换膜燃料电池的使用寿命要求。研究人员通过不同制备技术,设计涂层结构,调控制备工艺等方法研究改性双极板,以保证改性后的极板具有良好的耐腐蚀能力和导电性能。以上研究表明,碳基涂层可表现出较好的耐腐蚀性能和低接触电阻,具有一定的应用前景,但仍然存在很多挑战:

1)目前各类碳基涂层在PEMFCs腐蚀环境下,都面临着ICR不断增加的问题,显著影响涂层性能和寿命。因此开发出性能优异并实现稳定低ICR的非晶碳涂层技术在该领域仍是巨大挑战。同时长时间运行时,非晶碳/金属极板性能退化与损伤机理不明确,仍需要进一步系统研究涂层组分、结构、致密性等与性能的相关性,阐明相关损伤机制。

2)围绕具体工况需求,针对不同材质与形状的金属极板材料,开展针对性的a-C改性技术研发,突破强结合、耐蚀、良导电的低成本非晶碳涂层技术,对于商业化推广十分必要。

3)在评价方法上,美国DOE提出金属极板改性涂层性能的评估方法。然而,质子交换膜燃料电池的实际运行环境非常复杂,很难直接监测沉积在双极板上的涂层变化。国内外研究中,以模拟电池腐蚀环境测试为主,与燃料电池实际运行环境存在差异。因此,将非晶碳涂层改性的金属极板组装成电池,开展实际工况下的性能评价是实现其商业化推广的关键。

[1] ZHAO Yong, WEI Lin, YI Pei-yun, et al. Influence of Cr-C film composition on electrical and corrosion properties of 316L stainless steel as bipolar plates for PEMFCs[J]. International journal of hydrogen energy, 2016, 41(2): 1142-1150.

[2] MARCINKOSKI J, KOPASZ J, BENJAMIN T. Progress in the US DOE fuel cell subprogram efforts in polymer electrolyte fuel cells[J]. International journal of hydrogen energy, 2008, 33(14): 3894-3902.

[3] FUKUTSUKA Tomokazu, YAMAGUCHI Takayuki, MIYANO Shin-ichi, et al. Carbon-coated stainless steel as PEFC bipolar plate material[J]. Journal of power sources, 2007, 174(1): 199-205.

[4] TU Zheng-kai, ZHANG Hai-ning, LUO Zhi-ping, et al. Evaluation of 5 kW proton exchange membrane fuel cell stack operated at 95 ℃ under ambient pressure[J]. Journal of power sources, 2013, 222: 277-281.

[5] 侯明, 衣宝廉. 燃料电池技术发展现状与展望[J]. 电化学, 2012, 18(1):1-13. HOU Ming, YI Bao-lian. Development status and prospect of fuel cell technology[J]. Journal of electrochemistry, 2012, 18(1): 1-13.

[6] KUMAGAI Masanobu, MYUNG Seung-taek, ICHIKAWA Takuma, et al. Applicability of extra low interstitials ferritic stainless steels for bipolar plates of proton exchange membrane fuel cells[J]. Journal of power sources, 2010, 195(21): 7181-7186.

[7] HUANG N B, YU H, XU L S, et al. Corrosion kinetics of 316L stainless steel bipolar plate with chromium carbide coating in simulated PEMFC cathodic environment[J]. Results in physics, 2016, 6: 730-736.

[8] NAM Nguyendang, KIM Junggu, HWANG W S. Effect of bias voltage on the electrochemical properties of TiN coating for polymer electrolyte membrane fuel cell[J]. Thin solid films, 2009, 517(17): 4772-4776.

[9] REN Y J, ZENG C L. Corrosion protection of 304 stainless steel bipolar plates using TiC films produced by high- energy micro-arc alloying process[J]. Journal of power sources, 2007, 171(2): 778-782.

[10] ZHANG Hua-bing, LIN Guo-qiang, HOU Ming, et al. CrN/Cr multilayer coating on 316L stainless steel as bipolar plates for proton exchange membrane fuel cells[J]. Journal of power sources, 2012, 198: 176-181.

[11] KUMAR A, RICKETTS M, HIRANO S. Ex situ evaluation of nanometer range gold coating on stainless steel substrate for automotive polymer electrolyte membrane fuel cell bipolar plate[J]. Journal of power sources, 2010, 195(5): 1401-1407.

[12] WANG Jian-li, SUN Jun-cai, LI Song, et al. Surface diffusion modification AISI 304SS stainless steel as bipolar plate material for proton exchange membrane fuel cell[J]. International journal of hydrogen energy, 2012, 37(1): 1140-1144.

[13] HEINZEL A, MAHLENDORF F, NIEMZIG O, et al. Injection moulded low cost bipolar plates for PEM fuel cells[J]. Journal of power sources, 2004, 131(1-2): 35-40.

[14] SONG Yu-xi, ZHANG Cai-zhi, LING Chun-yu, et al. Review on current research of materials, fabrication and application for bipolar plate in proton exchange membrane fuel cell[J]. International journal of hydrogen energy, 2019(In press).

[15] WANG Hsiang-cheng, HOU Kung-hsu, LU Chen-en, et al. The study of electroplating trivalent CrC alloy coatings with different current densities on stainless steel 304 as bipolar plate of proton exchange membrane fuel cells[J]. Thin solid films, 2014, 570: 209-214.

[16] ZHANG Dong-ming, DUAN Liang-tao, GUO Lu, et al. Corrosion behavior of TiN-coated stainless steel as bipolar plate for proton exchange membrane fuel cell[J]. International journal of hydrogen energy, 2010, 35(8): 3721-3726.

[17] WANG Szu-hua, PENG Jin-chyau, LUI Wai-bun, et al. Performance of the gold-plated titanium bipolar plates for the light weight PEM fuel cells[J]. Journal of power sources, 2006, 162(1): 486-491.

[18] FENG Kai, LI Zhu-guo, CAI Xun, et al. Silver implanted 316L stainless steel as bipolar plates in polymer electrolyte membrane fuel cells[J]. Materials chemistry and physics, 2011, 126(1-2): 6-11.

[19] FENG Kai, SHEN Yao, MAI Jian-ming, et al. An investigation into nickel implanted 316L stainless steel as a bipolar plate for PEM fuel cell[J]. Journal of power sources, 2008, 182(1): 145-152.

[20] MOHAMMADI N, YARI M, ALLAHKARAM S R. Characterization of PbO2coating electrodeposited onto stainless steel 316L substrate for using as PEMFC's bipolar plates[J]. Surface and coatings technology, 2013, 236: 341-346.

[21] GONZALEZ-RODRIGUEZ J G, LUCIO-GARCÍA M A, NICHO M E, et al. Improvement on the corrosion protection of conductive polymers in pemfc environmets by adhesives[J]. Journal of power sources, 2007, 168(1): 184- 190.

[22] ORSI A, KONGSTEIN O E, HAMILTON P J, et al. An investigation of the typical corrosion parameters used to test polymer electrolyte fuel cell bipolar plate coatings, with titanium nitride coated stainless steel as a case study [J]. Journal of power sources, 2015, 285: 530-537.

[23] NAM N D, HAN J H, KIM J G, et al. Electrochemical properties of TiNCrN-coated bipolar plates in polymer electrolyte membrane fuel cell environment[J]. Thin solid films, 2010, 518(22): 6598-6603.

[24] 胡仁涛, 陆境莲, 朱光明, 等. PEMFC用非晶碳膜金属双极板的研究进展[J]. 电源技术, 2019, 43(4): 710-712. HU Ren-tao, LU Jing-lian, ZHU Guang-ming, et al. Research progress of amorphous carbon-coated mental bipolar plate for PEMFC[J]. Power technology, 2019, 43(4): 710- 712.

[25] LARIJANI M M, YARI M, AFSHAR A, et al. A comparison of carbon coated and uncoated 316L stainless steel for using as bipolar plates in PEMFCs[J]. Journal of alloys and compounds, 2011, 509(27): 7400-7404.

[26] MIRZAEE SISAN M, ABDOLAHI SERESHKI M, KHORSAND H, et al. Carbon coating for corrosion protection of SS-316L and AA-6061 as bipolar plates of PEM fuel cells[J]. Journal of alloys and compounds, 2014, 613: 288-291.

[27] AFSHAR A, YARI M, LARIJANI M M, et al. Effect of substrate temperature on structural properties and corrosion resistance of carbon thin films used as bipolar plates in polymer electrolyte membrane fuel cells[J]. Journal of alloys and compounds, 2010, 502(2): 451-455.

[28] ZEHNDER Thomas, PATSCHEIDER Jörg. Nanocomposite TiC/a-C: H hard coatings deposited by reactive PVD [J]. Surface & coatings technology, 2000, 133: 138-144.

[29] CHUNG Chih-yeh, CHEN Shi-kun, CHIU Po-jen, et al. Carbon film-coated 304 stainless steel as PEMFC bipolar plate[J]. Journal of power sources, 2008, 176(1): 276-281.

[30] BI Fei-fei, HOU Kun, YI Pei-yun, et al. Mechanisms of growth, properties and degradation of amorphous carbon films by closed field unbalanced magnetron sputtering on stainless steel bipolar plates for PEMFCs[J]. Applied surface science, 2017, 422: 921-931.

[31] WU Bo, LIN Guo-qiang, FU Yu, et al. Chromium-containing carbon film on stainless steel as bipolar plates for proton exchange membrane fuel cells[J]. International journal of hydrogen energy, 2010, 35(24): 13255-13261.

[32] ASRI Nurfawwaz, HUSAINI Teuku, SULONG Abubakar, et al. Coating of stainless steel and titanium bipolar plates for anticorrosion in PEMFC: A review[J]. International journal of hydrogen energy, 2017, 42(14): 9135- 9148.

[33] YI Pei-yun, PENG Lin-fa, ZHOU Tao, et al. Development and characterization of multilayered Cr-C/a-C: Cr film on 316L stainless steel as bipolar plates for proton exchange membrane fuel cells[J]. Journal of power sources, 2013, 230: 25-31.

[34] WANG Hsiang-cheng, SHEU Hung-hua, LU Chen-en, et al. Preparation of corrosion-resistant and conductive trivalent Cr-C coatings on 304 stainless steel for use as bipolar plates in proton exchange membrane fuel cells by electrodeposition[J]. Journal of power sources, 2015, 293: 475-483.

[35] BI Fei-fei, LI Xiao-bo, YI Pei-yun, et al. Characteristics of amorphous carbon films to resist high potential impact in PEMFCs bipolar plates for automotive application[J]. International journal of hydrogen energy, 2017, 42(20): 14279-14289.

[36] HOU Kun, YI Pei-yun, PENG Lin-fa, et al. Niobium doped amorphous carbon film on metallic bipolar plates for PEMFCs: First principle calculation, microstructure and performance[J]. International journal of hydrogen energy, 2019, 44(5): 3144-3156.

[37] WANG Zhi-yuan, FENG Kai, LI Zhu-guo, et al. Self- passivating carbon film as bipolar plate protective coating in polymer electrolyte membrane fuel cell[J]. International journal of hydrogen energy, 2016, 41(13): 5783- 5792.

[38] YI Pei-yun, ZHANG Di, PENG Lin-fa, et al. Impact of film thickness on defects and the graphitization of nanothin carbon coatings used for metallic bipolar plates in proton exchange membrane fuel cells[J]. ACS Applied materials & interfaces, 2018, 10(40): 34561-34572.

[39] YI Pei-yun, ZHANG Wei-xin, BI Fei-fei, et al. Enhanced corrosion resistance and interfacial conductivity of TiC/ a-C nanolayered coatings via synergy of substrate bias voltage for bipolar plates applications in PEMFCs[J]. ACS Applied materials & interfaces, 2018, 10(22): 19087- 19096.

[40] YI Pei-yun, PENG Lin-fa, ZHOU Tao, et al. Composition optimization of multilayered chromium-nitride-carbon film on 316L stainless steel as bipolar plates for proton exchange membrane fuel cells[J]. Journal of power sources, 2013, 236: 47-53.

[41] YI Pei-yun, PENG Lin-fa, ZHOU Tao, et al. Cr-N-C multilayer film on 316L stainless steel as bipolar plates for proton exchange membrane fuel cells using closed field unbalanced magnetron sputter ion plating[J]. International journal of hydrogen energy, 2013, 38(3): 1535- 1543.

[42] BI Fei-fei, PENG Lin-fa, YI Pei-yun, et al. Multilayered Zr-C/a-C film on stainless steel 316L as bipolar plates for proton exchange membrane fuel cells[J]. Journal of power sources, 2016, 314: 58-65.

[43] WANG Lun, TAO You-kun, ZHANG Zhen, et al. Molybdenum carbide coated 316L stainless steel for bipolar plates of proton exchange membrane fuel cells[J]. International journal of hydrogen energy, 2019, 44(10): 4940- 4950.

[44] ZHANG Wei-xin, YI Pei-yun, PENG Lin-fa, et al. Strategy of alternating bias voltage on corrosion resistance and interfacial conductivity enhancement of TiC/a-C coatings on metallic bipolar plates in PEMFCs[J]. Energy, 2018, 162: 933-943.

[45] LEE S H, PUKHA V E, VINOGRADOV V E, et al. Nanocomposite-carbon coated at low-temperature: A new coating material for metallic bipolar plates of polymer electrolyte membrane fuel cells[J]. International journal of hydrogen energy, 2013, 38(33): 14284-14294.

[46] SHOW Yoshiyuki. Electrically conductive amorphous carbon coating on metal bipolar plates for PEFC[J]. Surface and coatings technology, 2007, 202(4-7): 1252-1255.

[47] FENG Kai, CAI Xun, SUN Hai-lin, et al. Carbon coated stainless steel bipolar plates in polymer electrolyte membrane fuel cells[J]. Diamond and related materials, 2010, 19(11): 1354-1361.

[48] FENG Kai, SHEN Yao, SUN Hai-lin, et al. Conductive amorphous carbon-coated 316L stainless steel as bipolar plates in polymer electrolyte membrane fuel cells[J]. International journal of hydrogen energy, 2009, 34(16): 6771-6777.

[49] LI Xiao-wei, LI Lei, ZHANG Dong, et al. Ab initio study of interfacial structure transformation of amorphous carbon catalyzed by Ti, Cr, and W transition layers[J]. ACS Applied materials & interfaces, 2017, 9(47): 41115- 41119.

[50] WU Ming-ge, LU Cong-da, HONG Tao, et al. Chromium interlayer amorphous carbon film for 304 stainless steel bipolar plate of proton exchange membrane fuel cell[J]. Surface and coatings technology, 2016, 307: 374-381.

[51] 李昊, 汪爱英, 张栋, 等. 一种金属双极板高导电耐蚀防护涂层及其制备方法与应用: 中国, 2019110809392 [P]. 2020-01-14. LI Hao, WANG Ai-ying, ZHANG Dong, et al. A metal bipolar plate highly conductive corrosion-resistant protective coating and its preparation method and application: China, 2019110809392[P]. 2020-01-14.

[52] LI Hao, GUO Peng, ZHANG Dong, et al. Interface- induced degradation of amorphous carbon films/stainless steel bipolar plates in proton exchange membrane fuel cells[J]. Journal of power sources, 2020,469: 228269.

[53] CHOI Jung-hae, LEE Seung-cheol, LEE Kwang-ryeol. A first-principles study on the bond characteristics in carbon containing Mo, Ag or Al impurity atoms[J]. Carbon, 2008, 46(2): 185-188.

[54] LI Xiao-wei, KE Pei-ling, WANG Ai-ying. Probing the stress reduction mechanism of diamond-like carbon films by incorporating Ti, Cr, or W carbide-forming metals: Ab initio molecular dynamics simulation[J]. The journal of physical chemistry C, 2015, 119(11): 6086-6093.

[55] LI Xiao-wei, GUO Peng, SUN Li-li, et al. Ti/Al co- doping induced residual stress reduction and bond structure evolution of amorphous carbon films: An experimental and ab initio study[J]. Carbon, 2017, 111: 467- 475.

[56] LI Xiao-wei, GUO Peng, SUN Li-li, et al. Ab initio investigation on Cu/Cr Co doped amorphous carbon nanocomposite films with giant residual stress reduction[J]. ACS Applied materials & interfaces, 2015, 50(7): 27878- 27884.

[57] LI Xiao-wei, ZHANG Dong, LEE Kwang-ryeol, et al. Effect of metal doping on structural characteristics of amorphous carbon system: A first-principles study[J]. Thin solid films, 2016, 607: 67-72.

[58] LI Xiao-wei, SUN Li-li, GUO Peng, et al. Structure and residual stress evolution of Ti/Al, Cr/Al or W/Al co- doped amorphous carbon nanocomposite films: Insights from ab initio calculations[J]. Materials & design, 2016, 89: 1123-1129.

[59] BHARATHY Pvijai, NATARAJ D, CHU Paulk, et al. Effect of titanium incorporation on the structural, mechanical and biocompatible properties of DLC thin films prepared by reactive-biased target ion beam deposition method[J]. Applied surface science, 2010, 257(1): 143- 150.

[60] GAMBIRASIO A, BERNASCONI M. Ab initio study of boron doping in tetrahedral amorphous carbon[J]. Physical review B, 1999, 60(17): 12007-12014.

[61] CORBELLA C, VIVES M, PINYOL A, et al. Preparation of metal (W, Mo, Nb, Ti) containing a-C:H films by reactive magnetron sputtering[J]. Surface and coatings technology, 2004, 177-178: 409-414.

[62] WANG Li-xia, SUN Jun-cai, KANG Bin, et al. Electrochemical behaviour and surface conductivity of niobium carbide-modified austenitic stainless steel bipolar plate[J]. Journal of power sources, 2014, 246: 775-782.

[63] ANDERSSON Matilda, HÖGSTRÖM Jonas, URBONAITE Sigita, et al. Deposition and characterization of magnetron sputtered amorphous Cr-C films[J]. Vacuum, 2012, 86(9): 1408-1416.

[64] ZHANG Di, YI Pei-yun, PENG Lin-fa, et al. Amorphous carbon films doped with silver and chromium to achieve ultra-low interfacial electrical resistance and long-term durability in the application of proton exchange membrane fuel cells[J]. Carbon, 2019, 145: 333-344.

Research Progress of Carbon-based Coating for Metal Bipolar Plates of Proton Exchange Membrane Fuel Cells

1,2,1,1,1,1,1,1,3

(1.a.Key Laboratory of Marine Materials and Related Technologies, b.Zhejiang Key Laboratory of Marine Materials and Protective Technologies, Ningbo Institute of Materials Technology and Engineering, Chinese Academy of Science, Ningbo 315201, China; 2.Nano Science and Technology Institute, University of Science and Technology of China, Suzhou 215123, China; 3.Research Center of Materials and Photoelectricity, University of Chinese Academy of Sciences, Beijing 100049, China)

In this work, the performances of bare metallic plate, traditional graphite plate and metallic bipolar plate modified with carbon-based coating used in the proton exchange membrane fuel cells (PEMFCs) were compared; the latest achievements of carbon-based coatings in improving the conductivity and corrosion resistance of metallic bipolar plates were reviewed; and issues such as performance degradation and limited life of carbon-based coatings were discussed, especially after long-term operation in PEMFCs environment. By analyzing the factors that affect the performance of carbon-based coatings, it was found that systematic researches on the relationship between microstructure of carbon-based coating and its performance were insufficient, leading to an unclear damage and degradation mechanism of a-C carbon coating/ metallic bipolar plate. The research progress of modified carbon-based coating materials for PEMFCs metal plates at home and abroad was mainly discussed, including improving the coating performance by adjusting the microstructure of carbon-based coatings (a-C); preparing metal-doped carbon coating (a-C:Me) by combing theoretical calculation with practice; solving the poor adhesion, high pressure stress and other issues between coating and special metallic matrix, design multi-layer structures to reduce penetrability defects. The failure mechanism of several kinds of coatings was discussed and the development trend of carbon-based coating technology for metallic plate modification was prospected.

proton exchange membrane fuel cell; bipolar plate; carbon-based film; conductivity;corrosion resistance

2020-04-29;

2020-05-22

XIN Yang (1995—), Female, Master, Research focus: electrochemical properties of carbon-based coatings.

汪爱英(1975—),女,博士,研究员,主要研究方向为表面强化涂层材料与功能改性。邮箱:aywang@nimte.ac.cn

Corresponding author:WANG Ai-ying (1975—), Female, Doctor, Professor, Research focus: strengthening and functional modification for surface coating materials. E-mail: aywang@nimte.ac.cn

辛洋, 郭鹏, 李昊, 等. 质子交换膜燃料电池金属双极板改性碳基涂层技术研究进展[J]. 表面技术, 2020, 49(6): 22-33.

TM911.4

A

1001-3660(2020)06-0022-12

10.16490/j.cnki.issn.1001-3660.2020.06.003

2020-04-29;

2020-05-22

王宽诚率先人才计划卢嘉锡国际团队(GJTD-2019-13);国家自然科学基金(51801226);宁波市“科技创新2025”重大专项(2018B10014)

Fund:K. C. Wong Education Foundation (GJTD-2019-13); National Natural Science Foundation of China (51801226); Ningbo Science and Technology Innovation Project (2018B10014)

辛洋(1995—),女,硕士研究生,主要研究方向为碳基涂层的电化学性能。

XIN Yang, GUO Peng, LI Hao, et al. Research progress of carbon-based coating for metal bipolar plates of proton exchange membrane fuel cells[J]. Surface technology, 2020, 49(6): 22-33.