Biosynthesis of phycocyanobilin in recombinant Escherichia coli*

MA Chengbo , LI Wenjun , GE Baosheng , LIN Jian , QIN Song

1 College of Life Sciences, Yantai University, Yantai 264005, China

2 Yantai Institute of Coastal Zone Research, Chinese Academy of Sciences, Yantai 264003, China

3 Center for Bioengineering and Biotechnology, China University of Petroleum (East China), Qingdao 266580, China

4 Center for Ocean Mega-Science, Chinese Academy of Sciences, Qingdao 266071, China

Abstract The recombinant expression of phycocyanobilin (PCB) was carried out in Escherichia coli, and the best fermentation conditions of recombinant E. coli biosynthesized PCB are optimized in the response surface methodology to improve PCB production. The recombinant PCB is extracted, isolated, and purif ied by methanol and chloroform extraction. Recombinant PCB is validated in UV-vis spectroscopy,high-pressure liquid chromatography, and mass spectrometry. In addition, the anti-oxidant activities of the recombinant PCB are determined. The best induction conditions that optimized by Design Expert 8.0 software include: lactose concentration 4 mmol/L, induction temperature 24.69°C, induction time 4.6 h, and induction duration 13.57 h, under which the PCB expression level reached approximately 13 mg PCB/L,which is more than four times of previously reported 3 mg PCB/L. The maximum absorption peak of the recombinant PCB is located at 680 nm with a high f luorescence intensity of 470 nm. The recombinant PCB has a good ability to scavenge 2,2-diphenyl-1-picrylhydrazyl (DPPH) free radicals.

Keyword: combinational biosynthesis; phycocyanobilin; response surface methodology; antioxidant

1 INTRODUCTION

To capture effi ciently light energy, photosynthetic organisms have developed light-harvesting antenna systems with unique structures and functions, such as the light-harvesting antenna systems in chlorophyll proteins of higher plants and that in phycobiliproteins of cyanobacteria and red algae (phycobilisomes)(MacColl, 1998; Adir, 2005). The light-harvesting function of phycobiliproteins is mainly due to the presence of phycobilins. As a type of phycobilin, PCB is a linear tetrapyrrole derived from heme as a lightharvesting pigment in cryptophycean algae and cyanobacteria (Alvey et al., 2011). It has been found that PCB inSpirulinacould inhibit strongly the activity of nicotinamide adenine dinucleotide phosphate (NADPH) oxidase (Sotiroudis and Sotiroudis, 2013). Thus, supplementation of PCB may help prevention and therapy against various diseases with NADPH oxidase in aff ected tissues. In addition, studies have also shown that PCB can eff ectively inhibit the proliferation of inf lammatory cells and the production of inf lammatory factors(Basdeo et al., 2016).

The PCB chromophore can be cleaved from phycocyanin apoprotein by hot methanol for a long time (Carra and Heocha, 1966; Beuhler et al., 1976),which is the key technology for extracting PCB from cyanobacteria. BecauseSpirulinais rich in phycocyanin, it can be used as a good raw material for extracting PCB (Marín-Prida et al., 2013). However,this long-term pyrolysis of phycocyanin consumes much methanol and energy. Therefore, a good genetic engineering technology has been demanded, in which single and pure product of PCB can be extracted via fermentation of recombinateE.coli, thus avoiding complicated process of extracting phycocyanin fromSpirulina, saving the cost in the cleavage of phycocyanin.

In cyanobacteria, ferredoxin-dependent heme oxygenase (Ho1) and phycocyanobilin: ferredoxin oxidoreductase (PcyA) are two key enzymes used to generate PCB in two-step enzymatic reaction (Willows et al., 2000; Frankenberg and Lagarias, 2003). First,Ho1 catalyzes the ring-opening reaction of cyclic tetrapyrrole heme at the α-mesocarbon bridge, yielding open-chain tetrapyrrole biliverdin IX α (BV) (De Montellano, 2000). Second, BV is further reduced to PCB by PcyA. Gambetta and Lagarias. (2001) had successfully co-expressedho1andpcyA two genes from the bilin biosynthetic pathway ofSynechocystistogether with PCB from the same organism to produce holophytochome inE.coli. Recently, Ge et al. (2013)produced recombinant PCB via shake-f lask culture by fermentation. Under the optimized conditions of culture medium, induction time, concentration of isopropyl β-D-thiogalactoside (IPTG), and the addition of 5-aminolevulinic acid (ALA), the rate of PCB production could reach ~3 mg/L.

IPTG is a very eff ective inducer of lactose operon.However, due to the potential toxicity of IPTG to humans, if IPTG is used to induce the expression of recombinant drugs, the f inal product may harm the human body. In addition, IPTG is expensive, so is the fermentation. On the contrast, lactose is a disaccharide,non-toxic and inexpensive; it is likely to be used as the inducer to substitute IPTG and as a carbon source for metabolism as well. After enters the cells, lactose is converted to allolactose via catalyzing β-galactosidase after which the Lac promoter is activated (Jobe and Bourgeois, 1972; Müller-Hill et al., 1964). The non-toxic and low-cost nature makes lactose as a potential material for industrial production of recombinant genetic engineering drugs.

In addition to the inducer, many other factors may aff ect the expression effi ciency of recombinantE.coli, such as the time, duration, and temperature of the induction. To determine the optimum fermentation conditions for PCB production and possible combined eff ects of other variables, the response surface methodology (RSM) proposed by Lee and Gilmore (2006) was introduced for the biotechnology production. Learnt from RSM design, three interactive parameters (time, duration, and temperature) are chosen for the combined impact on the absorbance of PCB at 680 nm to optimize the condition of PCB production.

The aim of this study is to determine the optimum conditions in the course of induction by the inducer lactose; the time, induction duration, and temperature of the induction are determined for achieving a higher production of recombinant PCB. First, we introduced the philosophy of RSM for getting a specif ic protocol of recombinant PCB, and then the purif ication of recombinant PCB is extracted with chloroform effi ciently. Finally, the recombinant PCB with high anti-oxidative activity is established by DPPH antioxidant experiment.

2 MATERIAL AND METHOD

2.1 Recombinant E. coli construction

Ge et al. (2013, 2018) described the plasmid pET-28a-ho1-pcyA. According to their studies, genesho1 andpcyAthat cloned in the pET28a expression system are both controlled by a T7 promoter. In addition, the plasmid is transformed intoE.coliBL21 (DE3) to cause overexpress. The bioengineerE.coliis cultured at 37°C in the LB medium with 50 mg/L kanamycin until OD600nm=0.8-1.0. IPTG is added into fermentation liquid until the concentration with 0.1 mmol/L and the expression is induced in 20 h at 27°C. Cells are obtained by centrifugation of 13 000×gfor 10 min at 4°C.

2.2 Quantitative analysis of PCB production

Cells are collected in a 100-mL fermentation broth via above-mentioned centrifugation. The cells are then heated in 5-mL methanol at 50°C for 1 to 2 h in a water bath until the cell pellets turn white,centrifuged again at 13 000×gfor 10 min, and the supernatant is taken. The supernatant is added with appropriate amount of concentrated hydrochloric acid(VCH3OH:VHCl=95:5) and the absorption spectrum is measured with UV-Vis spectrophotometer at 0.5 wavelength intervals (Bennett and Bogorad, 1973; Ge et al., 2018). The molecular of PCB diacids is weighted as 586 and 588 Da (Beuhler et al., 1976).The production of PCB is determined from theA680value with the following equation (Glazer and Fang,1973):

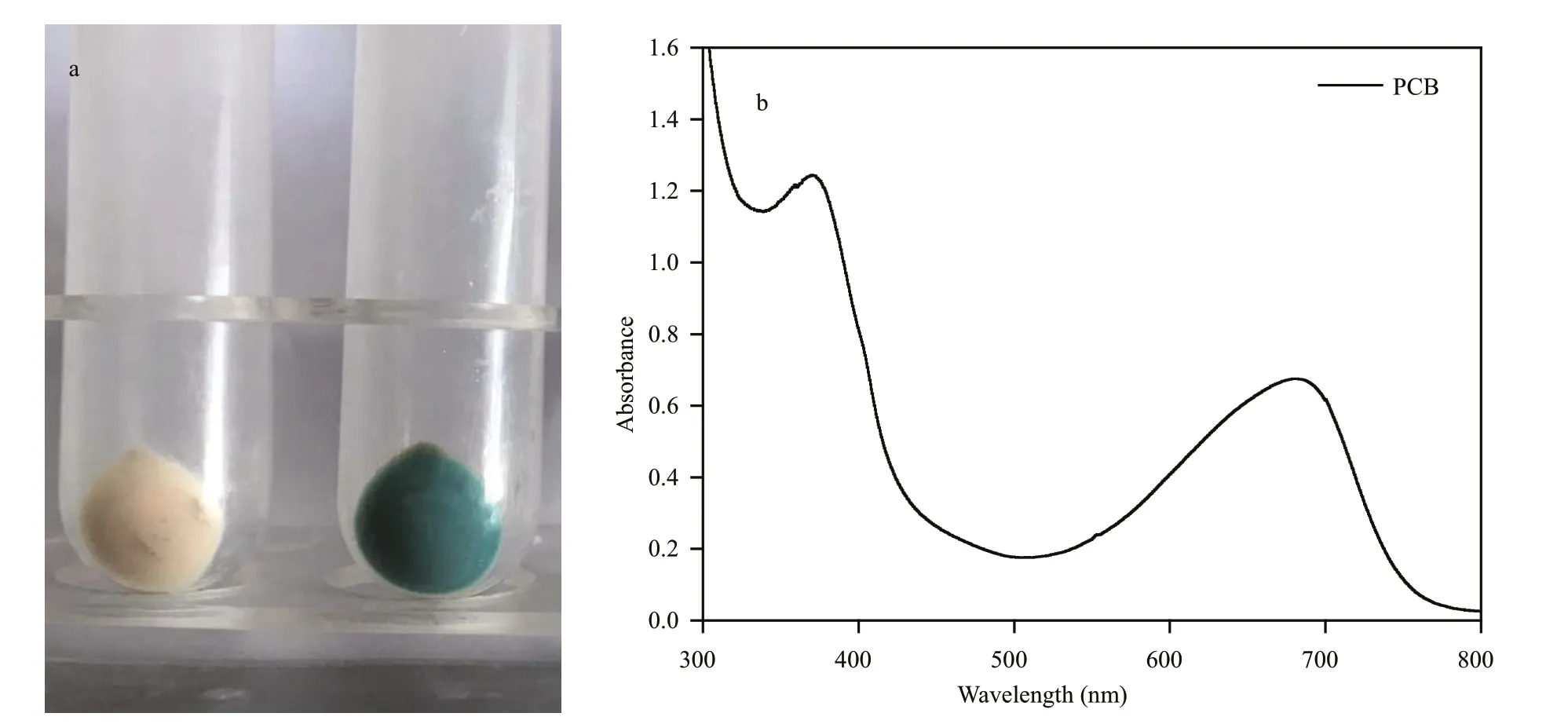

in whichcis the molarity of PCB solution in unit of mmol/L;A680is the absorbance of PCB solution at 680 nm; and the dilution factor can be determined by the dilution ratio of the original PCB solution.

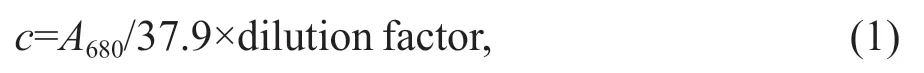

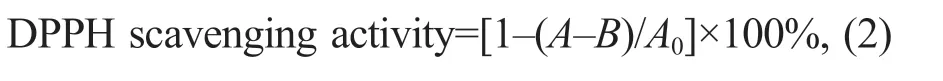

Table 1 Independent variables in the RSM experimental design

2.3 Single-factor optimization of expression condition

An amount of 1-mL strain stored in -80°C refrigerator is taken for culture in 100-mL LB medium at 37°C until OD600nm=0.8-1.0 and shaken, which is then used as the seed liquid and inoculated in 100-mL TB medium at 1% inoculum. Every 100-mL culture medium contains 100-μL kanamycin.

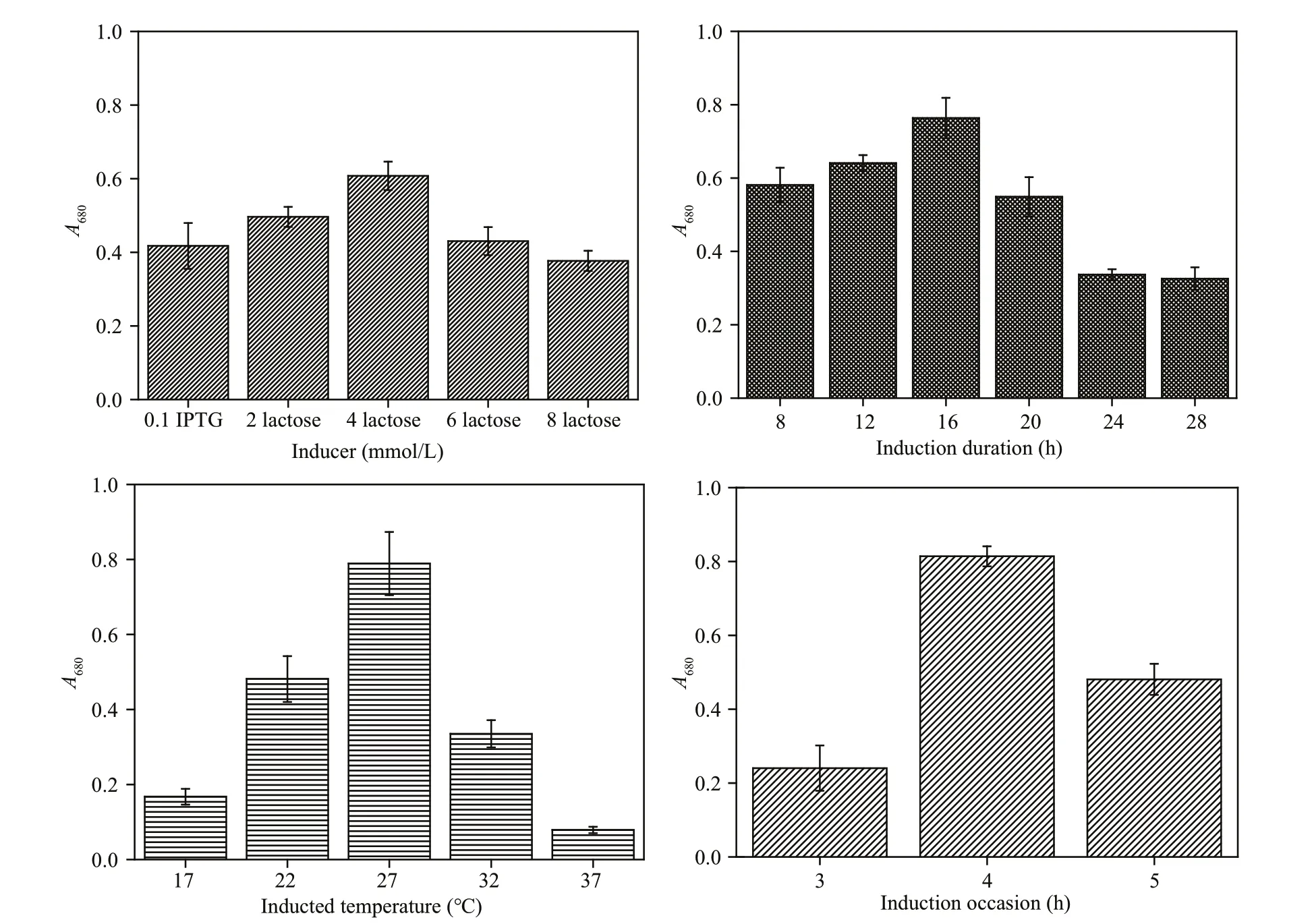

To optimize the culture conditions for PCB production with recombinantE.coli, diff erent inducer concentration, induction duration, induction temperature, and induction time are tested. The cultures of TB medium are shaken at 170 r/min and 37°C until OD600nmreaches 0.6-0.8, cool down to 25°C, and be induced at 0.1 mmol/L IPTG and 2, 4, 6,or 8 mmol/L lactose for 20 h, individually. The corresponding inducer is added into the culture when OD600nmof the fermentation broth reaches 1.0-1.2,and be induced at 27°C for 8, 12, 16, 20, 24, and 28 h.And the optimal induction temperature and induction time are determined in a procedure similar to that of induction duration at the points of 17, 22, 27, 32, and 37°C, and 3 h (OD600=0.6-0.8), 4 h (OD600=1.0-1.2),and 5 h (OD600=more than 1.5) after inoculation.

2.4 Response surface optimization

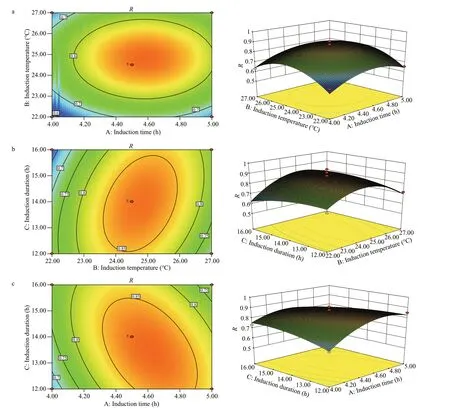

A model of 33RSM is designed to optimize theA680of PCB in the experimental range. The induction time(A), temperature (B), and duration (C) are chosen as three independent input variables, and theA680of PCB(R) is the output variable (Tables 1 and 2). Seventeen experiments were conducted with 5 points at the center and the impact of random errors on the experimental results is accessed.

2.5 Extraction of recombinant PCB

The expression of the strain is induced under the optimized conditions, i.e., induction time 4.60 h,24.69°C, and in 13.57 h. After 1-L fermentation broth is centrifuged at 13 000×gfor 10 min, bacteria are suspended in 100-mL methanol to form a bluemethanol solution. The supernatant is concentrated to 10-mL using a rotary evaporator and f iltered through 0.22-μm membrane. Multiple extractions are carried out in 10-mL chloroform and 20-mL water until the color of chloroform layer turned into any colors but blue. The chloroform layer is washed several times in 20-mL water until the color of water layer stays and then dried in N2. In all programs, PCB is covered with aluminum foil to protect it from light.

Table 2 The RSM experimental design with three independent variables

2.6 Absorbance and f luorescence spectrometry

Absorbance spectra are measured using a computercontrolled spectrophotometer (Agilent Cary 60 UVVis, Agilent, USA). The f luorescence emission spectra are measured by Cary Eclipse Fluorescence Spectrophotometer (excitation wavelength: 370 nm;emission wavelength range: 380-700 nm; emission slit width: 10 nm; and excitation wavelength: 10 nm).

2.7 High pressure liquid chromatography (HPLC)analysis

HPLC analysis is performed using an UltiMate 3000 (Thermo Scientif ic, USA). The reversed phase C18 Eclipse (5 μm, 250 mm×4.6 mm) column was used. HPLC chromatogram is recorded at 380 nm.The mobile phase consisted of buff er A (deionized H2O containing 0.1% formic acid) and buff er B(acetonitrile containing 0.1% formic acid). The following gradient is used: 40% B at 0 min and 55%B at 30 min. The column temperature is 25°C and the f lowrate is 0.8 mL/min.

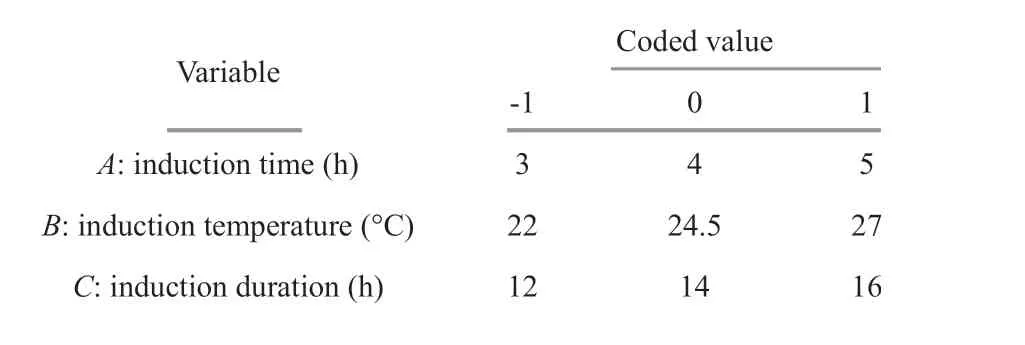

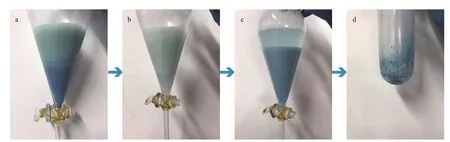

Fig.1 The fermentation liquid (a) and the absorption spectrum (b) in test tubes

2.8 Liquid chromatography - mass spectrometry(LC-MS) analysis

Further analysis of the results of the liquid phase is performed via LC-MS. The same column and solvent gradient as in HPLC analysis (see Section 2.7) were used. LC-MS analysis was performed on a LCQ FLEET (Thermo Scientif ic, USA) device.

2.9 Ability of DPPH (2,2-diphenyl-1-picrylhydrazyl) free-radical scavenging

The method of scavenging free radicals with DPPH was proposed by Blois (1958) and since then it has been widely used to determine the antioxidant ability of biological samples and foods. The method takes advantage that DPPH free radical has a single electron and a strong absorption at 517 nm; and its alcohol solution is purple. When a free radical scavenger is present, its absorption gradually disappears due to its single electron pairing, and its degree of fading is related quantitatively to the number of electrons it receives. Therefore, a rapid quantitative analysis can be performed with a microplate reader. The radical scavenging activity is determined using DPPH method, i.e., 100-μL test sample is mixed with DPPH at a diff erent density. After being vigorously mixed and incubated for 30 min,A517is measured using microplate reader, and the scavenging activity is calculated using Eq.1 above-mentioned.

To calculate DPPH scavenging activity, 0.1-mmol/L DPPH solution in absolute ethanol is prepared and preserved in the dark, and Eq.2 is used:

in whichAis the absorbance of 100-μL DPPH plus 100-μL sample at 517 nm;A0is the absorbance of 100-μL DPPH plus 100-μL alcohol andBis the absorbance of 100-μL sample plus 100-μL alcohol.

3 RESULT

3.1 Characterization analysis of recombinant PCB

The fermentation broth was centrifuged after induction of expression, from which bacterial sludge was obtained (Fig.1a). The blue slime was treated with acidic methanol, from which a blue methanol solution formed and its absorption spectrum is shown in Fig.1b. The absorption spectrum shows two absorption peaks at about 680 nm and 380 nm.Comparing previous studies in the color and spectrum of the solution (O’Carra and Heocha, 1980; Ge et al.,2013), we could conf irm that the recombinant strain was successfully constructed and the expression product was PCB. The expression level of PCB can be characterized by measuring theA680.

3.2 Optimization

Fig.2 Optimization of culture conditions for high-level expression of recombinant PCB in E. coli

To improve the production of PCB, the culture conditions are optimized. Due to the high background absorbance of cell lysate at 680 nm, the expression conditions are scrutinized using absorbance at 680 nm. As shown in Fig.2,A680reached a maximum when induced by 4-mmol/L lactose after 4 h of inoculation at 27°C for 16 h.

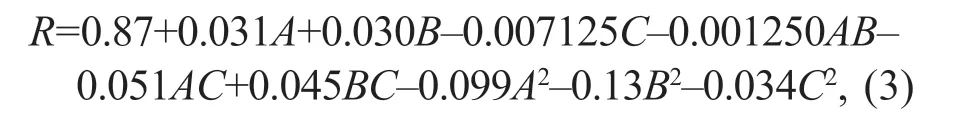

For a single-factor optimization involving inducer,induction duration, induction temperature, and induction time, we conducted 17 experiments in diff erent variable combinations according to the central composite design. Equation 3 is the result of regression that f its the empirical evidence ofA680(R):

in whichRisA680;Ais the induction time (h);Bis the temperature (°C); andCis the duration (h).

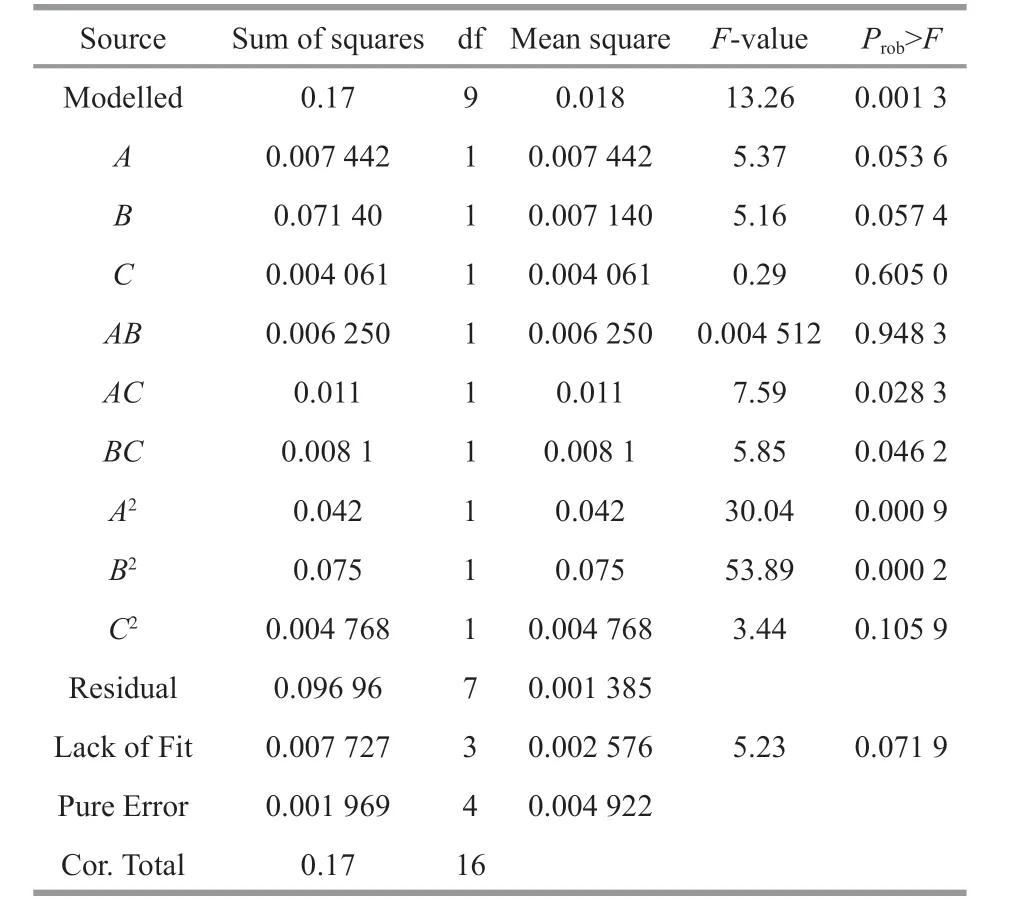

The predicted results and the regression model in ANOVA by Eq.3 are shown in Table 3. The value of‘‘Prob>F” below 0.01 suggests that the model term is extremely signif icant, and above 0.05 indicates that the regression equation has a good f it. CV%=4.97 indicates that the operation can be trusted. The correctedRadj2of the model is 0.873 3, which explains 87.33% of the response variability. Figure 3 is the three-dimensional contour plots for the optimizationof formulation. As shown in Fig.3a,Rincreases f irst and then decreases as the value ofAorBincreases.However, the curves ofAandRare similar to the steepness of the curves ofBtoR. This indicates that the interaction betweenAandBhas a little eff ect onR. Figure 3b shows that the interaction betweenBandCis greater, and the eff ect ofBonRis greater than the eff ect ofConR. Figure 3c shows that the eff ect ofConRis less thanA. As shown in Table 3, the order of inf luence of each factor on the response isA>B>C.Moreover, there is interaction among the factors.Pvalues of the interaction termsACandBCare below 0.05, and the impact is signif icant. In addition,Pvalues of the secondary termsA2andB2are less than 0.01. The eff ect is extremely signif icant, while the other items are not signif icant. The signif icance of the interaction term and the quadratic term further indicates that the inf luence of each inf luence factor on the response value is not in a simple linear relationship and cannot be optimized by single-factor experiment alone.

Table 3 ANOVA statistics of the entire quadratic model

Fig.3 The three-dimensional contour plots of RSM for the maximum R

Fig.4 The procedure of the PCB powder extraction

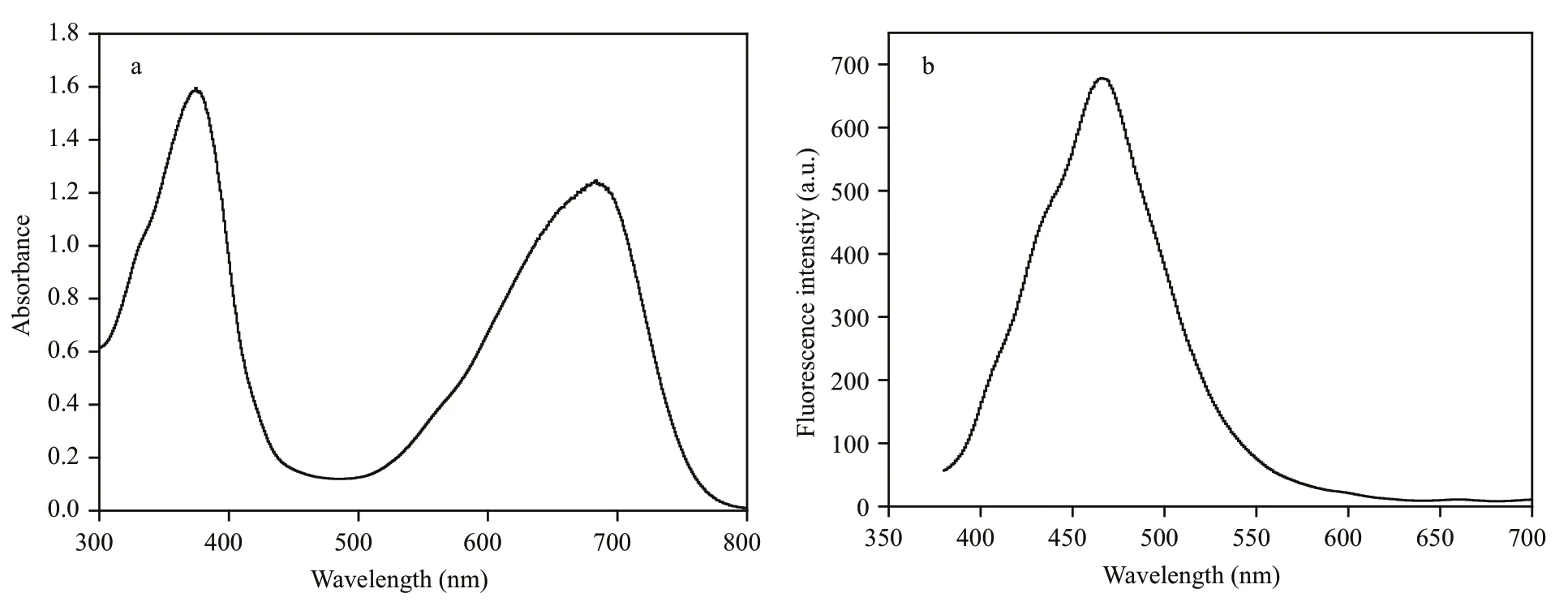

Fig.5 The absorption spectrum (a) and f luorescence emission spectrum (b) of the PCB powder

Therefore, we applied the RSM method to reduce the workload and determine the optimal conditions of multiple factors, i.e., the induction time, induction temperature, and induction duration in our case. The predicted optimum conditions are: induction time at 4.60 h, the temperature at 24.69°C, and the duration of 13.57 h, under which the predicted maximumA680is 0.879. The predicted optimum conditions have been verif ied in a trial run, reaching excellent agreement with the predicted value of theA680for 0.862 with a relative error of 2%.

3.3 PCB extraction and spectral analysis

The PCB extracted in hot methanol contains many impurities. To purify the PCB, we use chloroform to extract the PCB and remove its water-soluble impurities and other substances. On the other hand, as chloroform is highly volatile, a blue PCB powder can be obtained by nitrogen-blowing. The procedure of the PCB powder extraction is shown in Fig.4. An amount of 1-L fermentation broth can produce about 10.6 mg of blue PCB powder. The blue powder was dissolved in acidic methanol, and its absorption spectrum and f luorescence emission spectrum were analyzed (Fig.5). The absorption spectrum of PCB has two absorption peaks at 380 and 680 nm (Fig.5a),which is consistent with the report by O’Carra et al.(1980) and Ge et al. (2013). When excited at 370 nm,the f luorescence emission spectrum shows a strong emission at about 470 nm (Fig.5b).

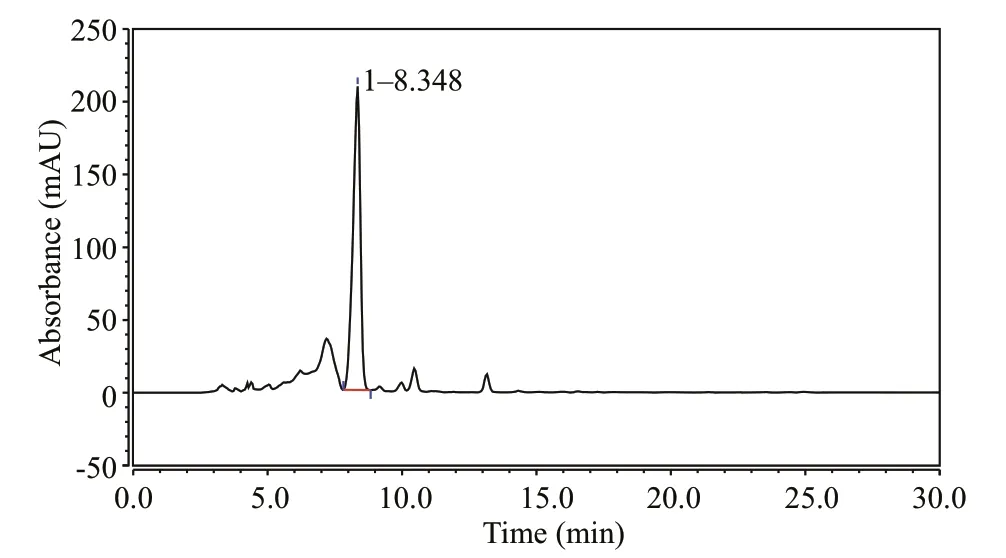

3.4 Product validation via HPLC and LC-MS

The chromatogram of the extracted PCB is shown in Fig.6. The main peak found in all cases has retention time of ~8.348 min. Upon LC-MS analyses, this respective peak gives a signal at m/z=587 (positive ionization). The molecular weight of the PCB is 586-588 Da, thus the product we obtained was PCB.

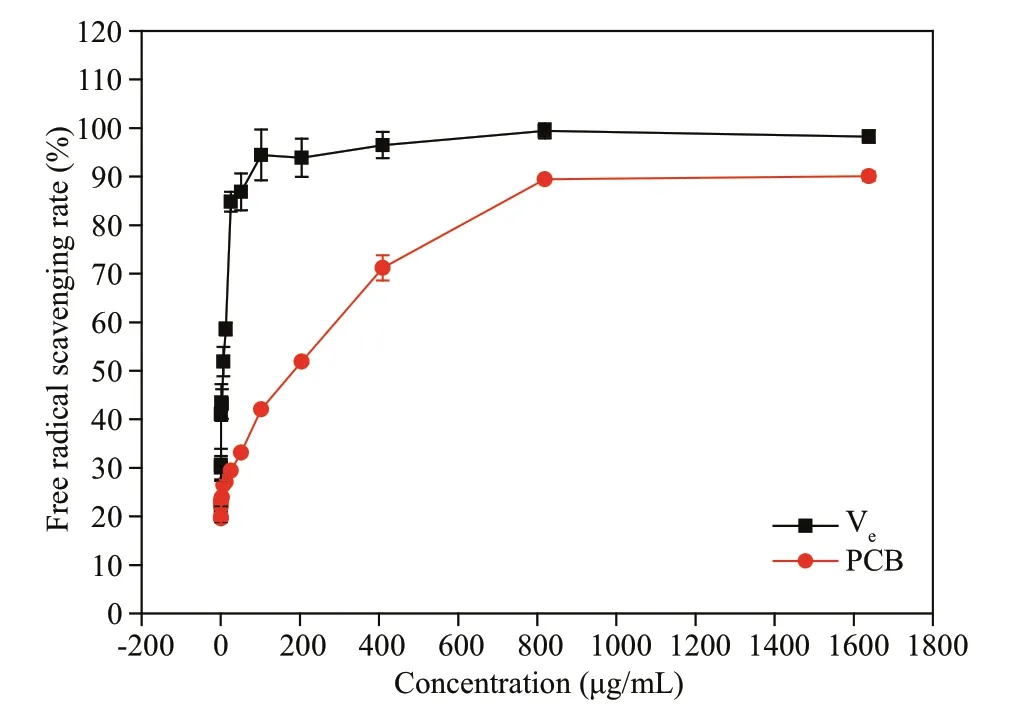

3.5 Antioxidative activity of recombinant PCB

Fig.6 Analytical HPLC chromatograms of the purif ied recombinant PCB

Vitamin E (Ve) is a fat-soluble vitamin with a strong antioxidant eff ect. As shown in Fig.7, the recombinant PCB has a good scavenging eff ect on DPPH free radicals. As the concentration increases, the ability of the recombinant PCB to scavenge DPPH free radicals gradually increases. When the concentration of recombinant PCB was 0.1-819.2 μg/mL, the free radical scavenging rate was 19.8%-89.5%. However,when the concentration of the recombinant PCB is greater than 819.2 μg/mL, the DPPH free radical scavenging rate will remain at 90%.

4 DISCUSSION

It is known that C-phycocyanin has antioxidant and anti-inf lammatory properties (Romay et al., 1998,2003). As the only chromophore of C-PC, PCB plays an important role in antioxidant activities (Benedetti et al., 2010). Orally administered PCB may have considerable potential for preventing or slowing down the progression of a range of neurodegenerative disorders which may be related to neuronal NADPH oxidase (McCarty et al., 2010). In addition, as the demand for natural foods is continuously growing,food and beverage industries turned to use natural pigments instead of synthetic colorants. This trend has been increasing after the publication of a study linking synthetic pigments to the changes in childhood behavior (McCann et al., 2007). As a natural pigment with antioxidant activity, the addition of PCB to food and cosmetics may be of concern.

Fig.7 Comparison in anti-oxidant activity between V e and recombinant PCB

The PCB chromophore can be cleaved from the phycocyanin apoprotein by hot methanol for a long time (Carra and Heocha, 1966; Beuhler et al., 1976).This is the key technology for extracting PCB from cyanobacteria. BecauseSpirulinais rich in phycocyanin, it can be used as a good raw material for extracting PCB (Marín-Prida et al., 2013). However,this long-term pyrolysis of phycocyanin consumes a great amount of methanol and energy. Therefore, a good genetic bio-engineering technology should be developed, with which single and pure product of PCB can be extracted via fermentation of recombinateE.coli, unlike complicated procures of extracting phycocyanin fromSpirulina, thus saving cost in the cleavage of phycocyanin. In addition, there are some other advantages to use recombinant PCB withE.coli. Since PCBs have been proved to have antioxidant eff ects reported in our research and other studies (Benedetti et al., 2010; Sotiroudis and Sotiroudis, 2013). And PCB can also eff ectively inhibit the proliferation of inf lammatory cells and the production of inf lammatory factors (Basdeo et al.,2016). Therefore, supplementation of PCB is important for human health.E.coliis a popular bacterium in humans and animals, and generally has no pathogenicity to the human body (Qaiser et al.,2018). Importantly, recombinantE.colicells expressing recombinant PCB may be propagated in the intestine, and the expressed PCB may improve the intestinal environment.

In order to obtain recombinant PCB, the method of combinant fermentation needs to be established. In a previous trial by Ge et al. (2013), the recombinant PCB’s production condition was optimized in a single-factor scheme, while the interaction among factors was ignored, so the yield of restructured PCB was low. In fact, there are many factors aff ecting the production of PCB via recombinantE.colifermentation, and the interaction among multiple factors can aff ect the PCB production.

Using RSM optimization method, we combine several inf luencing factors and improved the yield of recombinant PCB. Our results indicate that the interaction among several inf luential factors on the yield of recombinant PCB is signif icant. Ge et al.(2018) explored the biosynthetic pathway of PCB and found a feedback inhibition process that leads to low expression of recombinant PCB inE.coli. However,if the interaction of external factors aff ecting the production of recombinant PCB fermentation is fully considered, even if there is feedback inhibition, the production of recombinant PCB may be increased greatly to a relatively high level. Of course, solving the feedback suppression eff ect on the PCB synthesis process is a critical issue for realizing large-scale production of reorganized PCB, and may become a hot spot for PCB research.

5 CONCLUSION

In order to improve the recombinant PCB production, fermentation optimization method is established and implemented. The optimum culture conditions determined in the response surface methodology are: induction time 4.60 h, temperature 24.69°C, and induction duration 13.57 h, and the predicted maximumA680at 0.879. Under the conditions, the total PCB production reached about 13 mg/L. Additionally, recombinant PCB could be purif ied using methanol ref lux followed by chloroform extraction. Finally, the purif ied recombinant PCB exhibited a good antioxidative activity and a promising potential for industrial application.

6 DATA AVAILABILITY STATEMENT

The data supporting the f indings of this study are shown in this article. Otherwise, please contact the author for more information.

Journal of Oceanology and Limnology2020年2期

Journal of Oceanology and Limnology2020年2期

- Journal of Oceanology and Limnology的其它文章

- Contribution of surface wave-induced vertical mixing to heat content in global upper ocean*

- Upper ocean response to typhoon Kujira (2015) in the South China Sea by multiple means of observation*

- Inf luence of simulating deep-sea environmental factors on cathodic performance of seawater battery*

- Adsorption characteristics of chitooligosaccharides onto activated charcoal in aqueous solutions*

- Eff ects of hypoxia on survival, behavior, and metabolism of Zhikong scallop Chlamys farreri Jones et Preston 1904*

- Distinct inf luence of trimethylamine N-oxide and high hydrostatic pressure on community structure and culturable deep-sea bacteria*