轴向及内压复合作用下Zr-Sn-Nb/Zr-Nb合金的多轴棘轮效应研究

陈 刚,瞿 欢,崔 云, 2,陈 旭

轴向及内压复合作用下Zr-Sn-Nb/Zr-Nb合金的多轴棘轮效应研究

陈 刚1,瞿 欢1,崔 云1, 2,陈 旭1

(1. 天津大学化工学院,天津 300072;2. 天津大学仁爱学院,天津 301636)

为了模拟锆合金包壳在发生反应性引入事故(RIA)时的多轴应力状态,对Zr-Sn-Nb/Zr-Nb合金进行了单轴对称循环试验以及在内压及轴向载荷复合作用下的多轴试验,研究了两种合金轴向/环向棘轮应变的累积特性与内压及轴向应力的相关性.单轴拉伸试验结果表明,Zr-Sn-Nb合金和Zr-Nb合金的弹性模量相近均为85GPa,屈服强度大约均为490MPa.单轴棘轮试验结果表明,Zr-Sn-Nb合金和Zr-Nb合金在较小应力幅值下,由于无法启动孪生-退孪生机制,Zr-Sn-Nb合金和Zr-Nb合金都处于安定状态.当轴向应力幅大于325MPa时,孪生-退孪生机制启动,Zr-Sn-Nb合金和Zr-Nb合金的轴向棘轮应变都在正方向上快速增加.由于泊松效应,环向棘轮应变则在负方向上累积.多轴棘轮试验结果表明,在恒定内压和不同轴向应力幅值的循环作用下,Zr-Sn-Nb合金和Zr-Nb合金的环向棘轮应变随轴向应力幅值的增大而增大.当轴向应力幅值大于325MPa时,轴向棘轮应变呈现先负向累积、后正向累积的特殊现象;同时环向棘轮应变也随应力幅值增大而增大.在相同轴向应力幅值和不同内压加载下,内压对轴向棘轮应变呈现抑制作用,并且随内压的增大,其抑制作用更为显著.同时,内压对环向棘轮应变有明显的促进作用,导致环向应变快速正向累积.在轴向力和内压加载条件相同的情况下,Zr-Sn-Nb合金的轴向和环向棘轮应变比Zr-Nb合金小,说明Zr-Sn-Nb合金包壳管抵抗棘轮变形的能力更强.

锆合金;多轴;内压;棘轮应变;循环载荷

锆合金具有机械强度高、抗腐蚀和抗蠕变能力强以及热中子吸收截面小等优异性能,在核反应堆中被广泛应用[1-4].作为典型的压水堆核燃料包壳材料,锆合金的服役环境极为苛刻,外壁与冷却水接触,内壁与高温高压核燃料接触[5-6].在服役过程中,包壳管会受到中子辐射、热应力和机械应力等联合作用.尤其是发生控制棒失控或弹出等两类反应性引入事故(RIA)时,锆合金包壳的受力状态趋向于平面拉伸应力状态,环向应力在诱发锆合金管发生变形、破坏过程中占主要因素[7].研究表明,材料在多轴加载下的力学问题[8]相比单轴更加具有现实性和复杂性,锆包壳材料在多轴载荷下的力学响应与单轴载荷也明显不同[9].

材料在非零循环应力作用下,会发生塑性应变累积,即棘轮效应[10].棘轮变形会显著缩短材料的疲劳寿命[11],在设计与预测材料的寿命时应予以重点考虑.已有对Zr-4合金(Zr-Sn系)的单轴棘轮研究表明,应力幅值和平均应力在常温[12]和高温[13]下都会加快其棘轮应变的累积,而且在相同等效应力加载条件下,高温下Zr-4合金的棘轮应变累积量比常温下小.Zr-2合金(Zr-Sn系)的棘轮疲劳研究[14]表明,应变幅值的增加会降低其棘轮疲劳寿命,应力率的增加则会增加其棘轮疲劳寿命.Zr-2合金(Zr-Sn系)低周疲劳研究[15]表明,应力率的减小会降低其低周疲劳寿命.最近Chen等[16]对M5合金(Zr-Nb系)在多轴载荷下的棘轮行为进行了研究,表明轴向应力和环向应力对M5合金的多轴棘轮应变都有显著的影响.此外,一些学者发现,在锆合金添加某些元素,将极大改善材料的机械性能与抗腐蚀性能.Tao等[17]发现Sn含量的增加能提高锆合金的机械强度和抗蠕变性能.Garner等[18]通过对比Zr-Sn-Nb合金和Zr-Nb合金的氧化物微观结构,发现Sn能抑制氢在合金内部的堆积,从而提高Zr-Sn-Nb合金的耐氢蚀能力.Wei等[19]发现Sn能抑制Zr-Sn-Nb合金中四方相氧化物到单斜相氧化物的转化,而四方相能以极小的晶体形式稳定存在于锆合金被腐蚀过程,因此能促进Zr-Sn-Nb合金的抗腐蚀性能.Francis等[20]发现Nb含量的增加会增强锆合金的抗腐蚀和抗辐射性能.Kim等[21]研究了ZIRLO(Zr-Sn-Nb系)和Zr-4在蒸汽环境下的氧化性能,研究表明由于Nb含量增加使得ZIRLO合金的高温抗氧化性能优于Zr-4很多.综上,微量元素对锆合金性能有很大的影响.

目前针对Zr-Sn-Nb系合金的研究非常有限,特别是内压和轴向力复合作用下Zr-Sn-Nb合金的多轴棘轮行为研究还鲜见报道.本文针对Zr-Sn-Nb合金包壳管开展轴向及内压复合循环加载,主要研究多轴载荷作用下材料的棘轮效应,并在此基础上,引入前人关于Zr-Nb系锆合金包壳多轴棘轮变形的相关研究,旨在探究轴向载荷、内压以及合金元素Zr-Sn-Nb/Zr-Nb两种锆合金包壳多轴棘轮变形行为的影响.

1 试验材料和设备

试验材料为Zr-Sn-Nb合金包壳管,材料主要组成元素的质量分数如表1所示.试验研究所采用的Zr-Sn-Nb合金包壳管试样的外径为9.5mm,壁厚为0.6mm,管长为120mm.试验前,首先对试样进行热处理,将Zr-Sn-Nb合金包壳管在真空加热炉中加热到580℃,保温3h后随炉冷却.图1给出了Zr-Sn-Nb合金和Zr-Nb合金反极图.从图中可知,两种锆合金都为等轴晶,且晶粒大小都约为2.5μm.

表1 Zr-Sn-Nb合金组成成分

Tab.1 Composition of Zr-Sn-Nb alloy %

试验在天津大学CARE实验室的多轴电液伺服试验系统上进行.轴向采用常规电液伺服系统,最大轴向载荷为20kN.内压采用单端作动液压缸实现.作动缸将液压油经油管送至如图2(a)所示的自主设计的新型夹具[16].试样与夹具内腔紧密配合,最高可加载至30MPa而不泄漏.试验中的轴向和环向应变采用中航工业电测仪器股份有限公司提供的双轴应变片(型号为BF350)测量,应变片精度达到0.02%,量程为±2%.由于双轴应变片的敏感栅本身呈90°排列,测量时将应变片粘贴在试样中间位置,使轴向与其中一个方向的应变敏感栅平行,则环向自然与另一方向一致.粘贴好应变片的试件如图2(b)所示.控制系统采用自主开发的多轴动态控制器,支持包括载荷、位移、内压、应变等8个信号输入,可同时实现轴向与内压通道的全闭环同步控制.试验过程中的所有数据,如轴向载荷、内压、位移、轴向应变和环向应变等,均由控制系统持续采集、存储,采样频率为每循环200个点.

图1 锆合金的反极图

图2 夹具结构和试件示意

单轴拉伸试验采用应变控制,应变率为10-3/s.单轴棘轮试验采用轴向应力控制,加载率为100MPa/s,波形为三角波.多轴棘轮试验是在单轴循环加载的基础上,对薄管试样施加一个恒定内压.为了保证轴向应力的对称加载,各组多轴试验均在轴向施加一个与内压水平对应的压缩应力,用以抵消由于内压产生的轴向拉应力.试验加载条件见表2.

表2 试验加载条件

Tab.2 Experimental loading conditions

2 试验结果与分析

2.1 单轴拉伸试验

Zr-Sn-Nb合金的单轴拉伸结果如图3所示.为便于比较,将Zr-Nb合金单轴拉伸力学性能曲线[16]也放在图内.由图3可知,两种锆合金的弹性模量相似,均为90GPa左右.抗拉强度也大致相同,均为490MPa左右.不同的是,Zr-Sn-Nb合金单轴拉伸曲线出现明显的屈服平台,并且Zr-Sn-Nb合金的延伸率比Zr-Nb合金小很多.表3给出了Zr-Sn-Nb合金和Zr-Nb合金的单轴拉伸力学性能.

图3 Zr-Sn-Nb合金和Zr-Nb 合金拉伸应力-应变曲线

表3 Zr-Sn-Nb合金和 Zr-Nb合金材料拉伸力学性能

Tab.3 Tensile mechanical properties of Zr-Sn-Nb and Zr-Nb alloys

2.2 单轴棘轮试验

大量研究表明,锆合金属于各向异性材料[12-16],即使在单轴对称循环应力作用下,锆合金也会表现出棘轮效应.因此本部分对锆合金的单轴棘轮行为进行了研究.

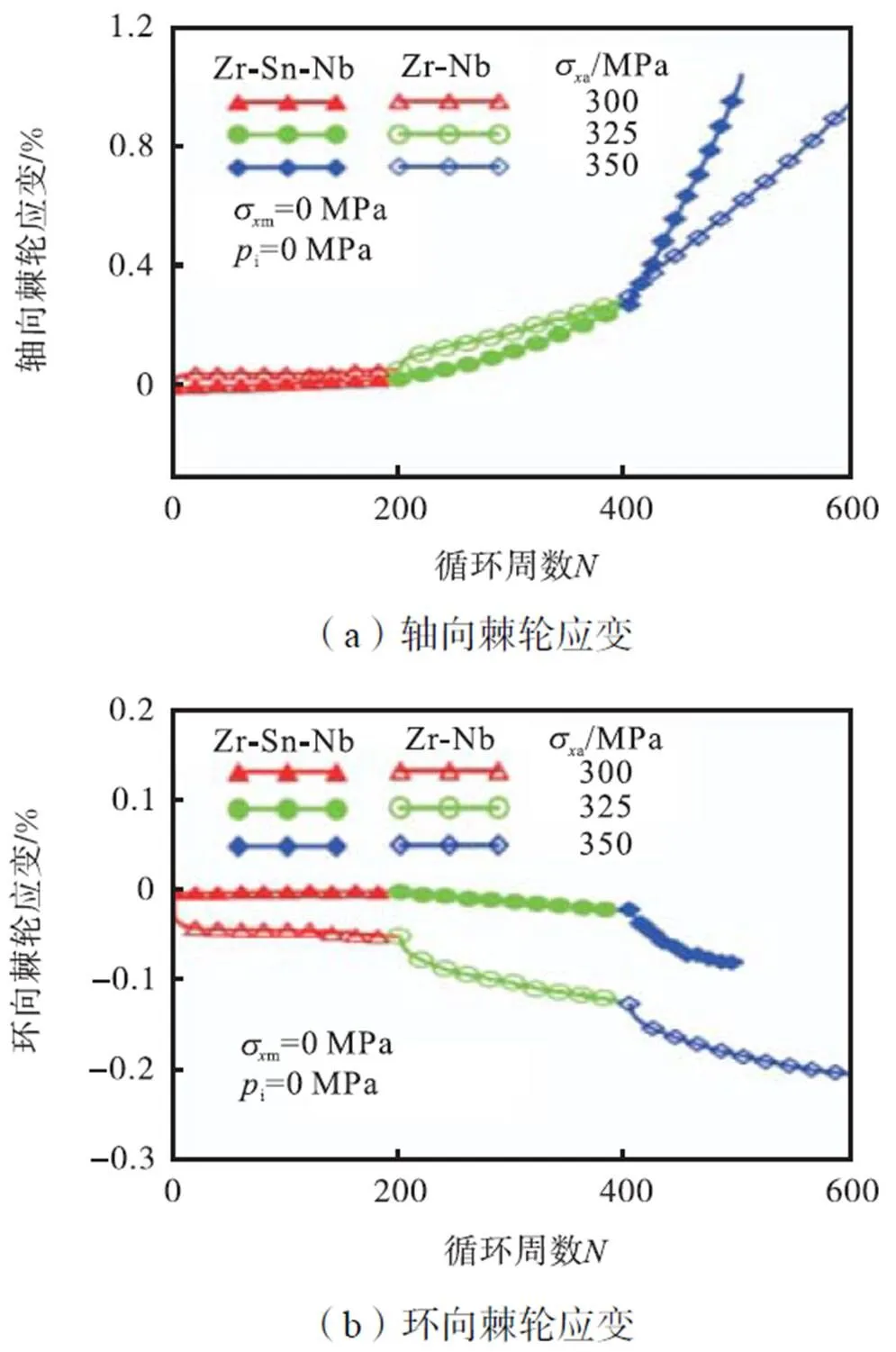

单轴棘轮试验在轴向应力循环下分3步加载,应力幅值分别为300MPa、325MPa和350MPa,如表2中试件2所示.图4给出了两种合金轴向和环向棘轮应变随循环周数的演化曲线.由图4(a)可以看出,当轴向应力幅值为300MPa时,两种锆合金轴向棘轮应变都处于安定状态.当应力幅值增加到325MPa时,轴向棘轮应变累积明显加快.当应力幅值增大到350MPa时,轴向棘轮应变迅速累积达到应变片量程.这是由于室温单轴作用下,锆合金管材存在的独立滑移系较少,为使材料发生塑性变形而不致破坏,需要通过孪生-退孪生等机制来协调变形.孪生启动需要一定的临界应力,因此在较大应力幅值下材料内孪生-退孪生机制才启动,导致了棘轮应变的快速累积.在镁合金[22]的研究中也有类似现象.还可以看到在棘轮应变较大时,Zr-Sn-Nb合金的轴向棘轮应变比Zr-Nb合金增加得更快.由图4(b)可知,环向棘轮应变在不同的加载幅值下始终沿负向累积,这主要是泊松效应作用的结果.随着轴向应力幅值增大,环向棘轮应变负向累积越大,且累积速率越快.而且Zr-Sn-Nb合金在不同的加载条件下对应的环向棘轮应变明显比Zr-Nb合金小很多,说明前者在单轴加载条件下承受环向变形的能力更强.

图4 不同应力幅值下Zr-Sn-Nb合金和Zr-Nb合金的单轴棘轮应变

2.3 多轴棘轮试验

2.3.1 轴向应力幅值对多轴棘轮行为的影响

图5(b)给出了两种锆合金环向棘轮应变随循环周数的演化特性.可以看出,Zr-Sn-Nb合金在多轴加载下环向棘轮应变都为正,且随着轴向应力幅值加大,环向棘轮应变累积有所加快.在350MPa下,环向棘轮应变累积最快.这一结果与Zr-Nb合金[16]类似.但Zr-Nb合金环向棘轮应变在相同加载条件下,环向棘轮应变更大,环向棘轮应变累积更快,说明Zr-Sn-Nb合金在环向上抵抗棘轮变形的能力更强.

棘轮行为过程中滞环宽度和滞环面积随着循环周数的变化可以很好地表征应力应变演化规律.图6给出了在350MPa轴向应力作用下Zr-Sn-Nb合金的典型应力-应变滞环曲线.图7给出了相同轴向应力幅值下对应Zr-Sn-Nb合金的应变能密度[23](滞环面积)随着循环周数的演化曲线.从图6中可以看出,随着循环周数增加,应力应变滞环宽度前100周内快速增加,随着循环继续,滞环宽度增加的速率减小.从图7可以看到,应变能密度也是前期快速增加,后续增加速率下降.影响滞环宽度和应变能密度的因素主要有两个:应力应变滞环不封闭程度与材料的循环硬化和循环软化特性.从图6中可以明显看出前几个滞环的不封闭性,即当应力达到极值后应变却没有达到极值而是继续增大.滞回环面积也代表着每次循环过程中能量的损失.在循环前期,滞环宽度和面积的变化是由于滞环的不封闭程度主导的.随着循环继续进行,滞环不封闭程度逐渐减小,材料本身的循环软化特性开始占主导,表现为应变能密度不断增加(如图7所示).当循环进行到一定程度,材料软化接近饱和,应变能密度增加也变缓最后趋于 稳定.

图5 Zr-Sn-Nb合金和Zr-Nb合金在不同应力幅值多轴棘轮应变

图6 应力幅值350MPa下Zr-Sn-Nb合金的应力-应变滞环曲线

图7 应力幅值350MPa 时Zr-Sn-Nb合金的应变能密度随循环数的变化

2.3.2 内压对多轴棘轮行为的影响

图8给出了Zr-Sn-Nb合金和Zr-Nb合金在轴向应力幅值为325MPa,不同内压下的多轴棘轮应变曲线.由图8(a)可以看出,Zr-Sn-Nb合金在较小内压(3.37MPa)的作用下,轴向棘轮应变以较快速率正向累积.当内压为6.74MPa时,轴向棘轮应变累积缓慢.当内压增加到10.10MPa时,轴向棘轮应变先沿负向快速累积,到第30个循环时转向正向累积,且累积速率较大,最后轴向棘轮应变超过了内压为6.74MPa下的棘轮应变峰值.这是因为内压较高时,环向应变受内压作用正向累积较快,而轴向棘轮应变由于泊松效应的作用而发生快速负向累积.同样地,Zr-Nb合金在相同内压加载条件下,轴向棘轮应变负向累积得更为明显.特别是当内压达到10.10MPa时,Zr-Nb合金由于轴向棘轮应变急速负向累积,几个循环后就发生了破坏失效.

图8(b)给出了内压作用下不同锆合金的环向棘轮应变演化特性.可以看出,随着内压增大,Zr-Sn-Nb合金环向棘轮应变累积增大.当内压增大到10.10MPa时,环向棘轮应变累积速率显著提高.在同样的加载条件下,Zr-Nb合金的环向棘轮应变相比Zr-Sn-Nb合金更大.综上,锆合金包壳管的多轴棘轮行为与内压密切相关,内压将引起锆合金管的环向棘轮应变快速累积,同时也引起轴向棘轮应变快速负向累积,这些均会导致材料提前失效.

图8 不同内压下的Zr-Sn-Nb合金和Zr-Nb合金多轴棘轮应变

图9 不同内压下的Zr-Sn-Nb合金轴向和环向棘轮应变

3 结 论

(1) 在不同轴向力和恒定内压共同作用下,Zr-Sn-Nb合金包壳的轴向棘轮应变随着轴向应力幅值的增大而增加.当轴向应力幅值达到325MPa时,材料出现明显的轴向棘轮应变先负向累积,后转为快速正向累积的现象.这是由于锆合金的变形机制由泊松效应主导转变为孪生-退孪生机制主导.类似的现象也发生在Zr-Nb合金上.随着轴向应力幅值的增加,两种锆合金的环向棘轮应变均沿正向累积,且棘轮应变速率也都随之增大.

(2) 在相同的轴向应力幅值和不同内压共同作用下,Zr-Sn-Nb合金包壳的轴向棘轮应变受内压抑制而增长缓慢.当内压达到10.10MPa时,内压对轴向棘轮应变的抑制作用导致轴向棘轮应变前期负向累积.这是由于内压较高时,环向应变受内压作用正向累积较快,而轴向棘轮应变由于泊松效应的作用而发生快速负向累积所致.

(3) 在相同加载条件下,Zr-Nb合金的轴向棘轮应变负向累积更为明显,且其环向棘轮应变相比Zr-Sn-Nb合金更大.这说明Sn元素的加入导致Zr-Sn-Nb合金抵抗棘轮变形的能力更强.

[1] Guo D,Li M,Shi Y,et al. High strength and ductility in multimodal-structured Zr[J]. Materials and Design,2012,34:275-278.

[2] Lin J,Li H,Szpunar J A. Analysis of zirconium oxide formed during oxidation at 623 K on Zr-2.5Nb and Zircaloy-4[J]. Materials Science and Engineering A,2004,381:104-112.

[3] Mallipudi V R,Stéphane V,Bertsc J. Meso-scale analysis of the creep behavior of hydrogenated Zircaloy-4 [J]. Mechanics of Materials,2012,51:15-28.

[4] Cai S,Daymond M R,Holt R A. Modeling the room temperature deformation of a two-phase zirconium alloy [J]. Acta Materialia,2009,57:407-419.

[5] Pupier P,Bernaudat C. A new analytical approach to study the rod ejection accident in PWRs[C]//Proceedings of ANS International Meeting on LWR Fuel Perform-ance. Kyoto,Japan,2005.

[6] Waeckel N,Bernaudat C,Salles B. EDF-proposed safety domain for rod ejection accident in PWR[C]// Proceedings of ANS International Topical Meeting on LWR Fuel Performance. Park City,USA,2000.

[7] Glendening A,Koss D A,Motta A T,et al. Failure of hydrided zircaloy-4 under equal-biaxial and plane-strain tensile deformation[J]. Journal of ASTM International,2005,2(6):1-16.

[8] 韩庆华,王培鹏,芦 燕. 考虑全平面损伤参量的多轴低周疲劳预测方法研究[J]. 天津大学学报:自然科学与工程技术版,2018,51(增):49-56.

Han Qinghua,Wang Peipeng,Lu Yan. Multiaxial low-cycle fatigue prediction method considering damage parameter of plane in every direction[J]. Journal of Tianjin University:Science and Technology,2018,51(Suppl):49-56(Chinese).

[9] Desquines J,Koss D A,Motta A T,et al. The issue of stress state during mechanical tests to assess cladding performance during a reactivity-initiated accident (RIA) [J]. Journal of Nuclear Materials,2011,412(2):250-267.

[10] Gaudin C,Feaugas X. Cyclic creep process in AISI 316L stainless steel in terms of dislocation patterns and internal stresses[J]. Acta Materialia,2004,52:3097-3110.

[11] Kang G. Ratcheting:Recent progress in phenomenon observation,cosititutive model and application[J]. Inter-national Journal of Fatigue,2008,30(8):1448-1472.

[12] Wen M,Li H,Yu D,et al. Uniaxial ratcheting behav-ior of Zircaloy-4 tubes at room temperature[J]. Materials and Design,2013,46(4):426-434.

[13] Cheng H,Chen G,Zhang Z,et al. Uniaxial ratcheting behaviors of Zircaloy-4 tubes at 400℃[J]. Journal of Nuclear Materials,2015,458:129-137.

[14] Rajpurohit R S,Rao G S,Chattopadhyay K,et al. Ratcheting fatigue behavior of Zircaloy-2 at room temperature[J]. Journal of Nuclear Materials,2016,477:67-76.

[15] Rao G S,Chakravartty J K,Nudurupati S. Low cycle fatigue behavior of Zircaloy-2 at room temperature[J]. Journal of Nuclear Materials,2013,441:455-467

[16] Chen G,Zhang X,Xu D K,et al. Multiaxial ratcheting behavior of zirconium alloy tubes undercombined cyclic axial load and internal pressure [J]. Journal of Nuclear Materials,2017,489:99-108.

[17] Tao B,Qiu R,Zhao Y. Effects of alloying elements (Sn,Cr and Cu)on second phase particles in Zr-Sn-Nb-Fe-(Cr,Cu)[J]. Journal of Alloys and Compounds,2018,748:745-757.

[18] Garner A,Hu J,Harte A,et al. The effect of Sn concentration on oxide texture and microstructure formation in zirconium alloys[J]. Acta Materialia,2015,99:259-272.

[19] Wei J,Frankel P,Polatidis E,et al. The effect of Sn on autoclave corrosion performance and corrosion mechanisms in Zr-Sn-Nb alloys[J]. Acta Materialia,2013,61:4200-4214.

[20] Francis E,Babu R P,Harte A,et al. Effect of Nb and Fe on damage evolution in a Zr-alloy during proton and neutron irradiation[J]. Acta Materialia,2019,165:603-614.

[21] Kim H H,Kim J H,Moon J Y,et al. High-temperature oxidation behavior of zircaloy-4 and zirlo in steam ambient[J]. Journal of Materials Science & Technology,2010,26(9):827-832.

[22] Hasegawa S,Tsuchida Y,Yano H,et al. Evaluation of low cycle fatigue life in AZ31 magnesium alloy[J]. International Journal of Fatigue,2007,29(9/10/11):1839-1845.

[23] Hassan T,Kyriakides S. Ratcheting in cyclic plasticity,Part I:Uniaxial behavior[J]. International Journal of Plasticity,1992,8(1):91-116.

A Study on Multiaxial Ratcheting Behavior of Zr-Sn-Nb/Zr-Nb Alloys Under a Combined Axial Load and Internal Pressure

Chen Gang1,Qu Huan1,Cui Yun1,2,Chen Xu1

(1. School of Chemical Engineering and Technology,Tianjin University,Tianjin 300072,China;2. Ren’ai College of Tianjin University,Tianjin 301636,China)

In order to simulate the multiaxial stress state of zirconium alloy cladding in the event of a reactivity-initiated accident(RIA),uniaxial symmetric cyclic tests and multiaxial tests under a combined internal pressure/axial cyclic load were carried out on Zr-Sn-Nb and Zr-Nb alloys the correlation between the accumulated characteristics of the axial/hoop ratcheting strain of the two zirconium alloys and the internal pressure and axial stress were investigated.The results of the uniaxial tensile tests showed that the elastic modulus of Zr-Sn-Nb and Zr-Nb alloys were about 85GPa,and the tensile strengths were about 490MPa.Results of uniaxial ratcheting tests showed that,under small stress amplitude,Zr-Sn-Nb and Zr-Nb alloys were in a stable state since the twinning-detwinning mechanism could not be activated.When the stress amplitude was greater than 325MPa,the twin-detwinning mechanism was activated,so that the axial ratcheting strains of the Zr-Sn-Nb and Zr-Nb alloys increased rapidly in the positive direction.The hoop ratcheting strains accumulated in the negative direction due to the Poisson effect.The multiaxial experimental results showed that under a combined constant pressure and different axial stress amplitudes,the hoop ratcheting strain of Zr-Sn-Nb and Zr-Nb alloys increased with increasing axial stress amplitude.When the axial stress amplitude was greater than 325MPa,the axial ratcheting strain accumulated negatively in the initial stage,then accumulated positively,and the hoop ratcheting strains also increased with increasing stress amplitude.Under the same axial stress amplitude and varying internal pressures,the internal pressure significantly restrained the axial ratcheting strain,and the restrain effect was more significant with increasing internal pressure.At the same time,the internal pressure had an obvious promoting effect on the hoop ratcheting strain,resulting in its rapid positive accumulation.The axial and hoop ratcheting strain of the Zr-Sn-Nb alloy were smaller than those of the Zr-Nb alloy under the same axial stress and internal pressure,which indicated that the Zr-Sn-Nb alloy was more resistant to the ratcheting deformation than the Zr-Sn alloy.

zirconium alloy;multiaxial;internal pressure;ratcheting strain;cyclic loading

O341

A

0493-2137(2020)02-0162-07

10.11784/tdxbz201903043

2019-03-20;

2019-05-10.

陈 刚(1979— ),男,博士,教授,agang@tju.edu.cn.

崔 云,yunctju@163.com.

国家自然科学基金资助项目(51471116,51875398).

Supported by the National Natural Science Foundation of China(No. 51471116,No. 51875398).

(责任编辑:金顺爱)