回填土质材料对地下换热器冻胀特性的影响研究

王有镗,郑 斌,王春光,李成宇,毛明明,刘旭阳

回填土质材料对地下换热器冻胀特性的影响研究

王有镗,郑 斌,王春光,李成宇,毛明明,刘旭阳

(山东理工大学交通与车辆工程学院,淄博 255049)

以地源热泵技术在寒区设施农业中的应用为背景,开展地下换热器低温冻胀特性研究。通过岩土埋管冻胀试验,基于冻结半径追踪和管体应变测量,开展冻结区发展规律以及埋管变形收缩特性的研究,对比砂土基和黏土基回填料对冻胀的影响,并进一步考察换热管容积与流阻变化。结果表明,冻结区在进出水2管中心连线方向发展速度大于其垂直方向,受冻胀影响,U型换热管产生椭圆化变形与收缩,砂土基回填比黏土基回填具有更大的冻结范围,但前者换热管变形和收缩程度却小于后者。换热管在100 h内持续由0降至−10 ℃后,测得管容积减小率为0.4%,流阻增大率为6.5%,由此可知,埋管冻胀的变形与收缩成为循环流量减小和系统效率下降的原因之一。

热泵;传热;冻胀;地下换热器;回填料;埋管变形

0 引 言

近年来,地源热泵技术在设施农业领域中得以广泛应用[1],其中以日光温室的应用最为典型[2-3]。然而为了达到良好的采光效果,温室的外围护结构通常采用单层玻璃或塑料膜,因此在光照条件不佳时,地下换热器的运行温度受大气温度影响较大。对于中国广大的北方严寒地区而言,地下换热器(埋管)运行温度常持续低于0 ℃,由此致使换热岩土发生冻胀,冻胀作用不但会挤压埋管发生变形,而且也影响到系统运行效率及安全性[4-8]。

对于冻胀岩土挤压管道的研究,成果主要体现在油气运输和管渠输水等工程领域中。理论研究方面,学者们主要应用管-土模型计算管土作用[9-11]、预测管位移[12-13]、分析管变形应力和应变[14-16]。在试验研究方面,研究者已针对埋管冻胀变形,开展了许多大规模的工程测试,诸如加拿大Calgary冻胀试验[17]、法国Caen全尺寸管线冻胀测试[12,18]、美国Fairbanks高速路管线冻胀试验[19-20]以及美国UAF冻胀隆起管线测试[21-22]。此外,学者们也在农业设施的抗冻设计方面进行了一系列的理论探索[23-25]与验证[26-27]。近年来,尽管有学者对与地下换热器相似的垂直埋管[28]和管道温变影响[29]进行了管土冻胀研究,但由于应用背景不同,对地热热泵工程仍缺乏针对性。目前针对寒区地下换热器运行中易出现的冻胀问题开始得到关注,最初由加拿大工程师Lenarduzzi等[7]结合工程实际指出该问题的研究意义,此后中国学者郑平等[30]提出了考虑冻胀的土壤源热泵水热力耦合数值模型,笔者通过建立岩土冻胀试验系统探讨了换热管形态对其冻胀变形的影响[31],同时基于孔隙增长率函数建立了地下换热器的冻胀变形模型[32]。

本文基于前述研究基础,针对工程中常用的砂土基与黏土基回填料,试验研究竖埋U型管周围土壤(以下简称围土)冻胀以及管截面变形特性;对比2种回填料的影响;考察管变形给循环系统带来的影响,为指导工程应用提供参考。

1 试验装置及方法

1.1 试验系统

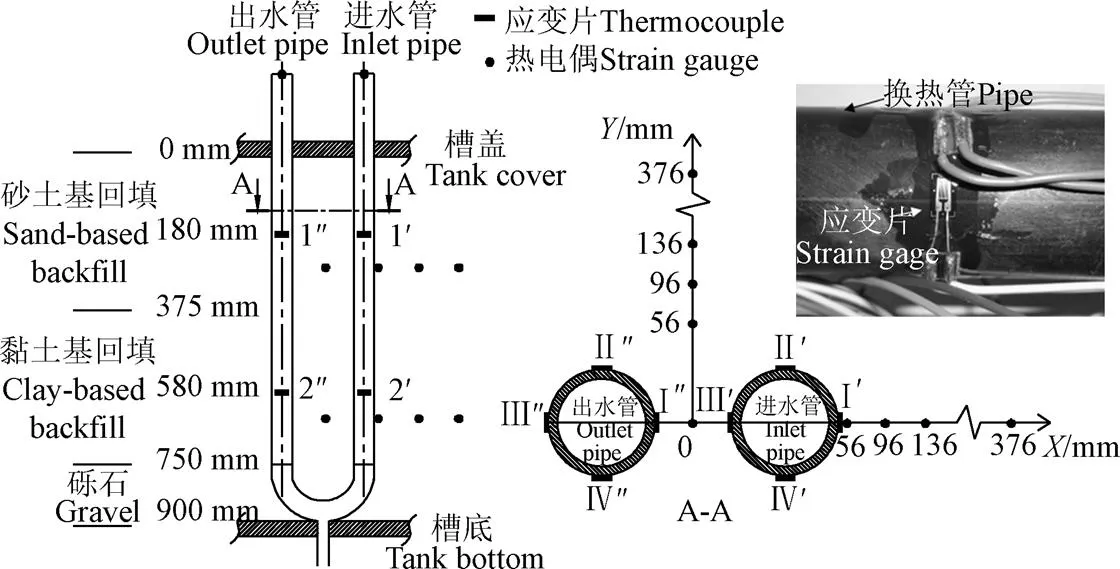

本试验模拟地下竖埋U型换热器在饱和岩土环境中的低温运行过程,U型埋管内循环流动低温液体,土壤由此发生冻胀而使换热管受力变形。通过追踪土体内0 ℃冻结锋面发展,研究冻结区发展特性,利用应变测试手段研究换热管截面变形特性。试验系统主要包括岩土槽、围土、U型换热管和冷源循环系统等,如图1所示。

1.2 试验及测试装置

圆柱形岩土槽的高为900 mm,内径为800 mm,槽身下部开4个补水口,控制槽内湿岩土水位,槽内底部铺垫一层150 mm厚砾石,以利于补水均匀渗入,砾石上部添置试验围土(包含地层土壤和回填料),为更好体现冻胀特性,试验采用均匀的饱和围土。用PE板制作环套,使岩土槽外围形成环腔空间,为槽内岩土提供4 ℃恒定的边界温度,槽盖和槽底做绝热处理。U型换热管竖向埋置于岩土槽中央,壁厚3.5 mm,外径32 mm,U型间距为80 mm。循环液采用30%乙二醇溶液,由其将热量从岩土槽运送至冷源。

1.地层土壤 2.U型管 3.砂土基回填 4.黏土基回填 5.砾石层 6.排液管 7.岩土槽 8.补水口 9.温控单元 10.循环泵 11.流量计 12.冷源 13.水箱 14.球阀 15.软连接 16.压差计 17.槽盖 18.接线出口 19.环套

1.Ground soil 2.U-pipe 3.Sand-based backfill 4.Clay-based backfill 5.Gravel 6.Bleeder pipe 7.Soil tank 8.Water supply 9.Temperature control unit 10.Pump 11.Flowmeter 12.Cold source 13.Water tank 14.Ball valve 15.Flexible connection 16.Differential pressure gauge 17.Tank cover 18.Wiring channel 19.Annular sleeve

a. 结构示意图

a. Structure diagram

b. 试验布置

在U型管进出口布置热电偶测试循环液温度,在换热管埋深200 mm(砂土基回填层)处和600 mm(黏土基回填层)处的水平面上分别布置热电偶,以测试围土温度,如图2所示。以进、出水2管中心连线为方向,与其垂直方向为方向,2管的中间位置为原点,建立直角坐标系,在和方向上各对称布置10个测点,相邻测点间距为40 mm。电阻应变片测试换热管外壁周向应变,利用应变变化判断管截面的变形,测试位置1′、1″和2′、2″分别在换热管埋深180 mm(砂土基回填层)处和580 mm(黏土基回填层)处的进、出水管上,每处在和方向对称布置Ⅰ、Ⅱ、Ⅲ和Ⅳ 4个应变测点。U型压差计接U型管同一水平高度的进口与出口,测量其间压差变化。主要试验测试仪器型号及规格见表1。

注:1′、1″和2′、2″为应变测试位置,Ⅰ、Ⅱ、Ⅲ和Ⅳ为应变测点,上角标′和上角标″分别表示进水管和出水管。

1.3 试验方法

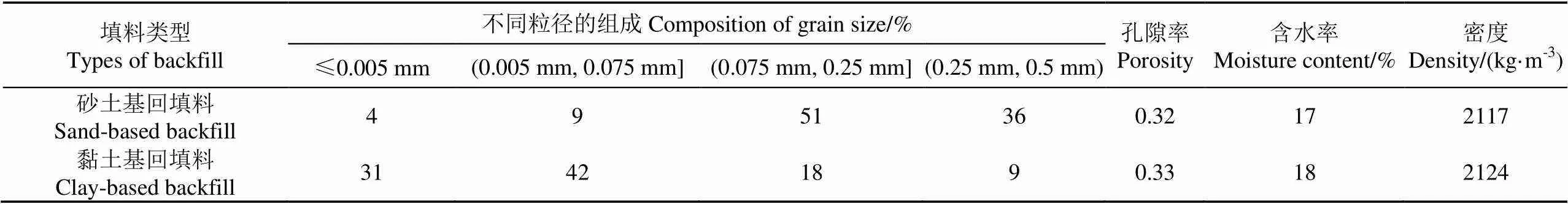

《地源热泵工程技术规范》中已经指出:细砂和膨润土的混合浆或专用灌浆材料宜作为回填材料,以实现保水防渗功能;然而,由于成本或施工便利等原因,工程中也存在回收使用钻孔屑黏土基回填料的情况,因此,本文选择以上2种回填料进行分析。地层土壤与黏土基回填料选用天然细粒黏土,砂土基回填料选用细砂和膨润土混合物(质量比为7:3),其基本特性参数见表2,模拟回填孔直径为150 mm。试验过程中,对围土分层作填充-夯实-填充处理,回填料的填充以回填高度的一半为界(埋深375 mm处),下半部为黏土基回填,上半部为砂土基回填,如图2所示。最后,通过补水口使土体达到饱和状态。

表2 回填料基本参数

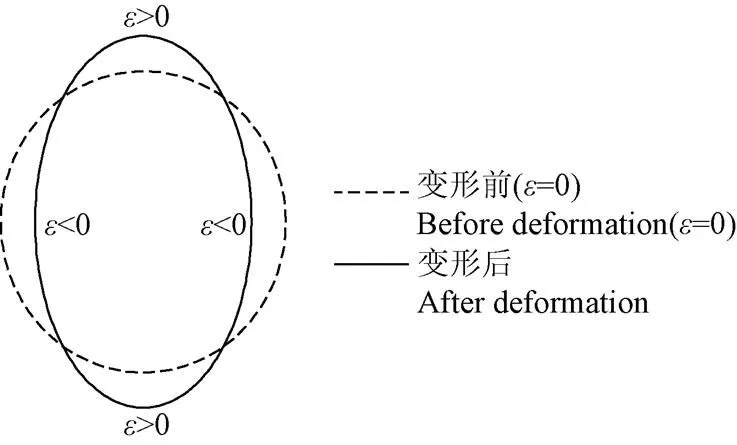

试验主要基于变形的应变测量,分析变形的基本形态。初始截面为圆形的换热管(此时应变=0)受到挤压后,如果其截面为椭圆化变形,则椭圆化向外凸出的管壁曲率变大时,该处外壁面将承受拉应力,即表现为拉应变(>0);椭圆化向内收缩的管壁曲率变小时,该处外壁面将承受压应力,即表现为压应变(<0),如图3所示。

图3 变形与应变

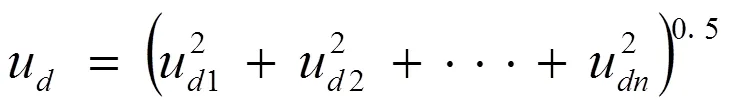

试验过程中,直接测量参数的不确定度可由公式(1)确定

式中u为参数的不确定度,u1,u2, …, u为相互独立的不确定因素。

本试验中,温度测量的不确定度为±2.02%,应变测量的不确定度为±4.08%,液柱差测量的不确定度为±4.54%。

2 结果及分析

2.1 冻结区发展分析

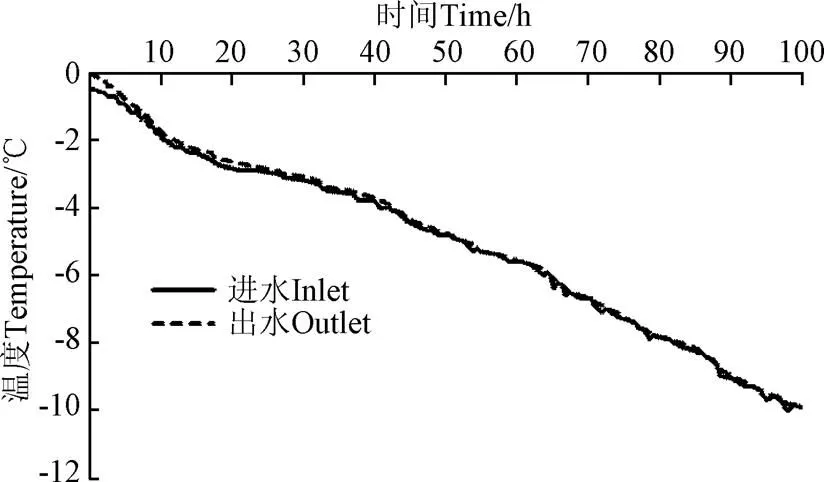

使系统连续运行100 h,换热管内流体温度由0 ℃逐渐降低至−10 ℃,如图4所示。由于U型换热管的长度仅为0.9 m,运行过程中其进、出口的温度差异不大(不超过0.5 ℃),进、出水2管及其轴向温度可视为均匀一致。

图4 换热管进出口温度

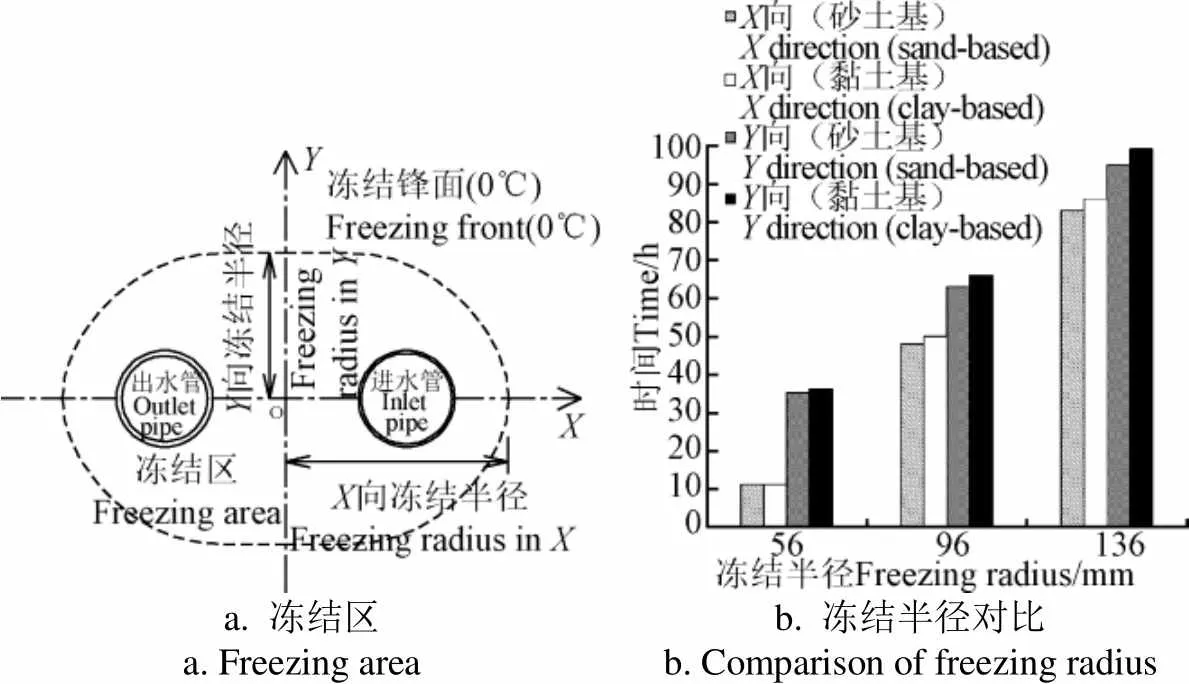

以点为基准点,定义冻结锋面的0 ℃点与基准点之间的距离为冻结半径,如图5a所示,以衡量冻结区范围。围土内和方向的冻结半径发展如图5b所示,可见冻结半径在不同回填层内发展规律一致。以黏土基回填层为例,和方向的冻结半径发展至56 mm所用时间分别为11和36 h,二者相差25 h,此后2方向冻结半径发展至96和136 mm位置的时间差分别为16和13 h,可见冻结区在方向的发展速度始终大于方向,同时随着冻结范围的扩大,2方向的发展差异逐渐减小。显然,不对称的冻结区发展特性源于换热管的布置方式,进、出水2管位于方向上,冻结范围较小时,冻结区形态受到管结构的影响较大,随着冻结区边缘(冻结锋面)距离换热管越远,其形态受管结构的影响逐渐减弱。

试验过程中,砂土基回填层的冻结半径发展平均速度(向:1.64 mm/h;向:1.43 mm/h)要略快于黏土基回填层(向:1.58 mm/h;向:1.37 mm/h)。事实上,除了砂土导热性能良好之外,在初始含水率相差不大的情况下,由于砂土基回填料内膨润土中亲水矿物的作用,使得回填料会吸收地层土壤中的水,这种水分迁移作用,可使正在冻结的区域冰晶含量不断增大[33],冰的导热系数大于水和土颗粒。因此冰晶较多的砂土基回填层具有更大的冻结范围。

a. 冻结区a. Freezing areab. 冻结半径对比b. Comparison offreezing radius

2.2 管截面变形分析

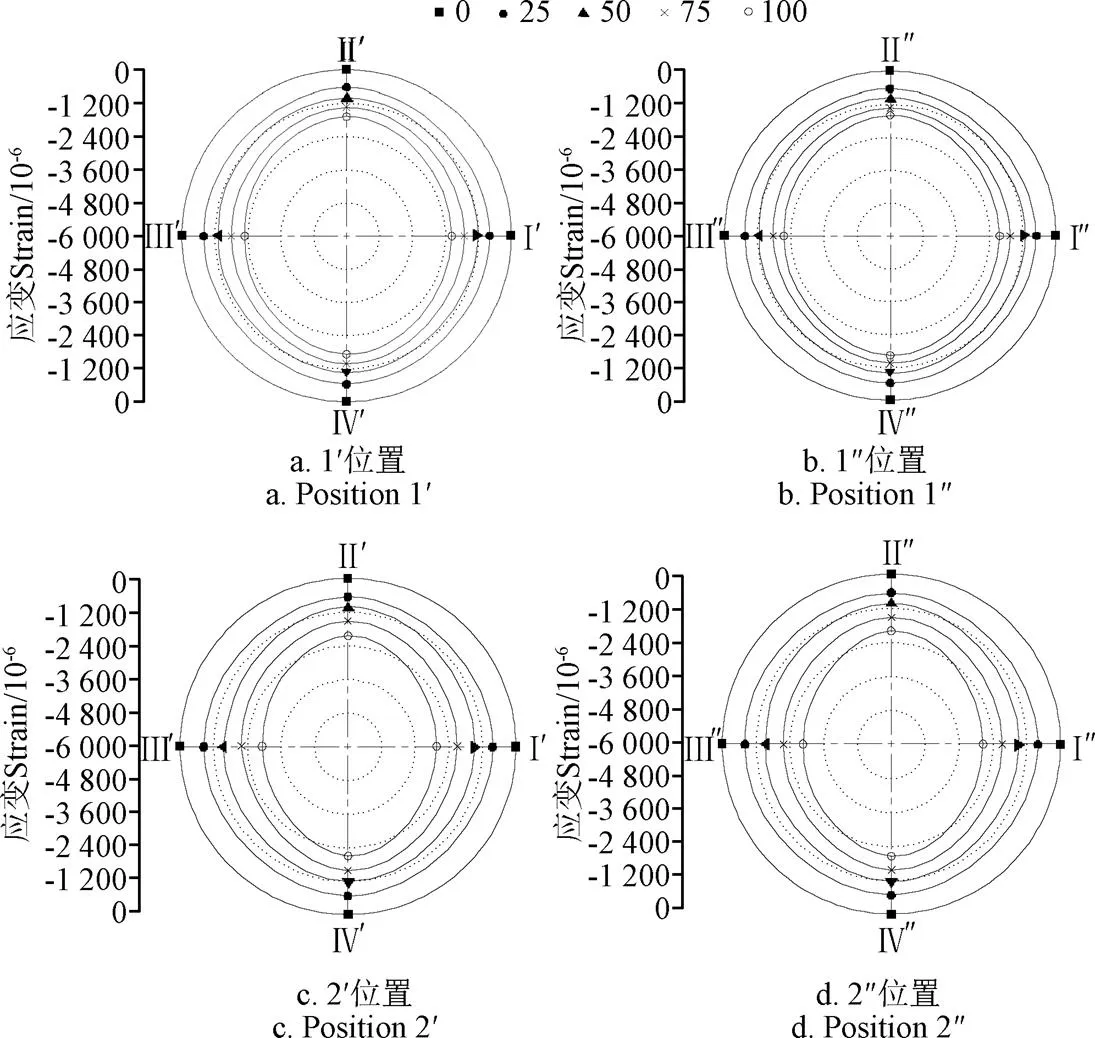

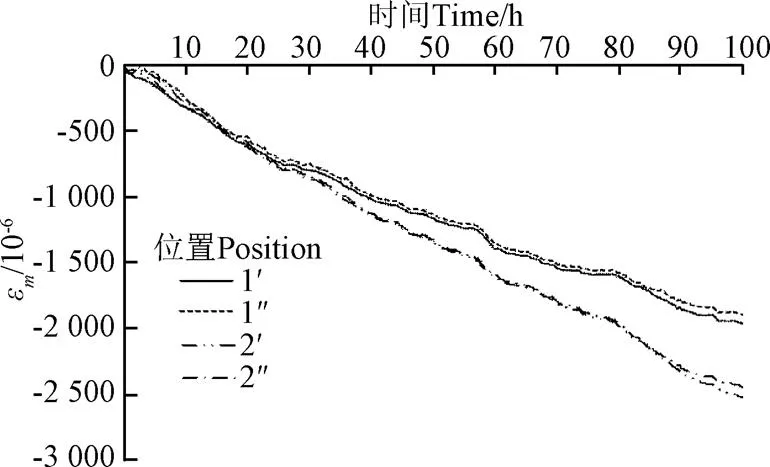

取各应变测试位置处每25 h的应变变化,如图6所示。

图6 管体应变变化

由图6可以发现,各处测点均为负应变(压应变),且应变值不断增大,然而各测点变化规律却有所差异,Ⅰ和Ⅲ测点应变值普遍大于Ⅱ和Ⅳ测点。事实上,所测管体应变取决于2个因素:温度和变形,管壁不断的降温收缩使得压应变值不断增大,而变形使管壁附加了额外的拉压应力。由应变测试结果及前述变形与应变关系可知,相当于Ⅰ和Ⅲ测点附加了压应变,Ⅱ和Ⅳ测点附加了拉应变,管段发生了椭圆化变形,且椭圆长轴在向。

冻结区的不均匀发展导致了冻胀力的不均匀产生,由管截面的变形可知,来自向的冻胀力大于向,这也与所测冻结区发展特性相一致。同时,随着运行时间增加,Ⅰ和Ⅲ测点压应变与Ⅱ和Ⅳ测点压应变的差距也在不断增大,表明管截面椭圆化变形程度不断加重。

对比可知,1′和1″在各个测试时间的变形都要小于2′和2″位置,处于砂土基回填层的管段,其椭圆化变形程度要小于黏土基回填层的管段。这表明相同条件下,黏土基回填层冻结所产生的冻胀力要比砂土基回填层的大。由于进出水2管温差不大,2管周围冻结区的发展较相似,因此相同埋深位置处,进出水2管段的变形程度差别不大。

2.3 管截面收缩分析

由各测试位置的管体应变(图6)可以看出,管截面在不断椭圆化的同时,也在不断收缩。管体平均应变(ε)反映了截面周长的变化率,进而可反映管截面胀缩程度。试验中采用4个测点应变的平均值近似表示测试位置处的管体平均应变(ε),如图7a所示。可见在前30 h内,4处测试位置的ε基本维持在相同的水平,而大约运行至30 h时,2′和2″位置的ε开始大于1′和1″位置,且差距逐渐增大,最终前者的ε值达到−2 500×10-6左右,后者仅为−1 900×10-6左右。表明当冻结发展至一定程度时,黏土基回填层内的管截面收缩程度要比砂土基回填层内的大。

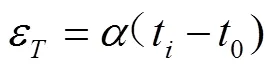

事实上,在低温运行环境下,管截面的收缩取决于温降和冻胀挤压作用的大小。温降引起的截面收缩应变ε可由公式(2)求得。

因此,试验中各测试位置的ε与ε之差可体现冻胀挤压作用对管体应变的影响,如图7b所示。可见在前30 h内,4处测试位置的冻胀应变值不断增大且增幅水平相当,从30 h至100 h,1′和1″处冻胀应变值由−400×10-6仅下降至−500×10-6左右,而在2′和2″处冻胀应变值却降至−1 000×10-6以下。表明当冻结区发展超过一定范围,黏土基回填对换热管的冻胀作用将大于砂土基回填,且差距逐渐增大。砂土基回填料中的膨润土存在遇水膨胀软化特性,从而使其强度降低[35],冻胀力对换热管的作用相对减弱,因此在砂土中适量添加膨润土,可减轻冻胀产生的换热管变形与收缩程度。对于寒区地源热泵工程,从地下换热器安全运行角度而言,按照规范使用砂土基回填料显得尤为必要。

a. 管体平均应变ε

a. Mean strains in pipe surfaceε

b. 冻胀作用应变εm-εT

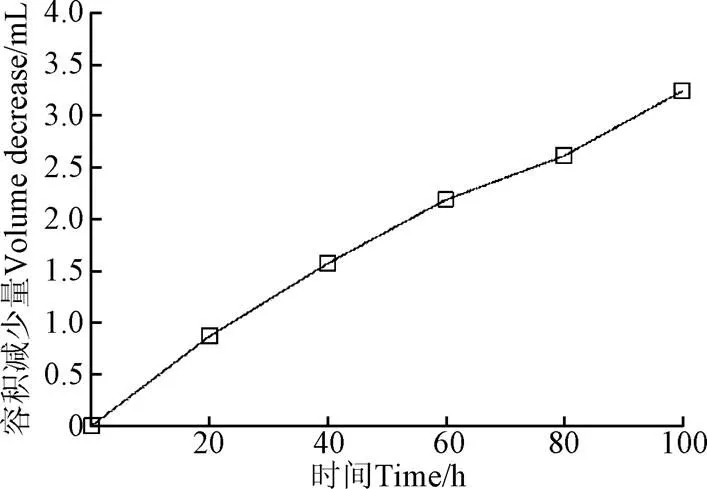

2.4 管容积与流阻分析

在运行温度不断降低和冻胀作用力不断加大的情况下,换热管降温收缩和椭圆化变形会使截面面积减小,从而导致管容积减小。对于内径为25 mm的换热管,结合4个应变测点的平均值ε,可求得冻胀变形后管体容积,再根据初始管容积0,可得容积变化量=0−,如图8所示。可见随着运行时间的增加,管容积呈现不断减小的趋势,运行最终,换热管有约3.3 mL的容积减少量,与计算管段(管长750 mm)的初始容积0=736 mL相比,减少了0.4%。

图8 换热管容积减少量

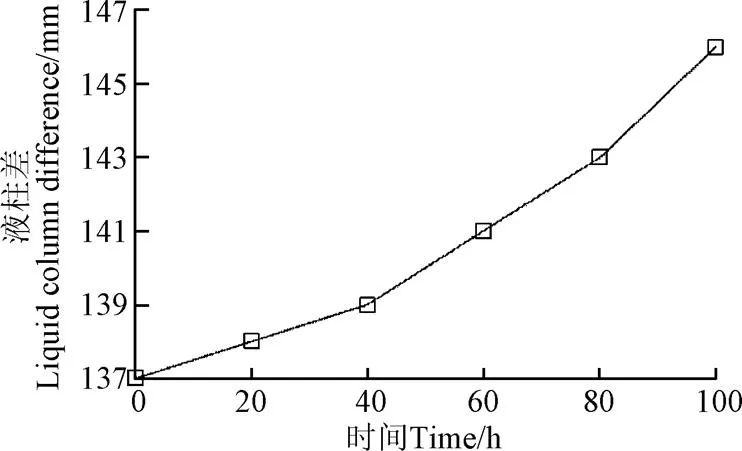

换热管的变形与收缩同样也会增大系统的流动阻力,系统流阻的变化可通过U型压差计的液柱差来反映。冻胀试验过程中的液柱差变化如图9所示,可见液柱差不断增大,且增幅随运行时间有增加的趋势,这与不断增大的管体变形程度有关。在100 h的运行时间内,液柱差由137 mm增至146 mm,表明U型换热管的流阻有6.5%的增加量。

事实上,换热管由于冻胀变形造成的容积减小以及流阻增大问题,在文献[6]和[7]中所阐述的工程问题中已有提及,由此所带来的诸如循环液溢流、系统流量减小以及COP(性能系数,coefficient of performance)下降等问题不容忽视,在工程设计中应加以考虑。

图9 液柱差增幅

3 结论与讨论

本试验基于U型埋管地下换热器的持续降温运行过程,针对不同回填土质材料(砂土基和黏土基),开展围土冻结区发展以及埋管变形特性等基础研究,得出如下结论:

1)受U型结构影响,围土冻结区域不均匀发展,冻结区在进出水2管中心连线方向发展速度大于其垂直方向,该差距随冻结范围增大而减小,砂土基回填可较黏土基回填具有更大的冻结范围。

2)换热管截面产生椭圆化变形和收缩,椭圆短轴在2管中心连线方向,随着冻结区发展,变形与收缩程度不断加重,黏土基回填料中由冻胀产生的换热管变形与收缩程度更为严重,对于寒区地源热泵工程,使用添加膨润土的砂土基回填料显得尤为必要。

3)岩土冻胀所致的换热管截面变形及收缩,会引发管容积减小以及流阻增大问题,运行100 h、温降10 ℃的试验条件下测得管容积减小率为0.4%,流阻增大率为6.5%,该问题应在工程设计中加以考虑。

事实上,冻胀特性主要取决于土壤、含水率和温度。工程中回填土质呈现多样化特点,土壤粒径和结构不尽相同,即使对于相同材质的回填料,土体强度也会由于回填深度不同而产生差异;孔隙含水率的变化可致使回填料热学和力学特性产生差异,同样,冻融变化也会对孔隙结构及含水率产生影响;此外,环境温度的变化也会影响地下换热器的低温运行模式。因此,上述因素均会影响地下换热器的结构冻变特性,进而作用于管土换热效率,限于篇幅,拟在后续对相关问题进行深入探讨。

[1] 方慧,杨其长,王柟,等. 浅层地热源节能技术及其在设施农业中的应用[J]. 农业工程学报,2008,24(10):286-290.

Fang Hui, Yang Qichang, Wang Nan, et al. Geothermal technology and its applications in protected agriculture[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of CSAE), 2008, 24(10): 286-290. (in Chinese with English abstract)

[2] 孙维拓,张义,杨其长,等. 温室主动蓄放热-热泵联合加温系统热力学分析[J]. 农业工程学报,2014,30(14):179-188.

Sun Weituo, Zhang Yi, Yang Qichang, et al. Thermodynamic analysis of active heat storage-release associated with heat pump heating system in greenhouse[J]. Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE), 2014, 30(14): 179-188. (in Chinese with English abstract)

[3] 石惠娴,任亦可,孟祥真,等. 植物工厂水蓄能型地下水源热泵供热系统节能运行特性研究[J]. 农业工程学报,2018,34(23):157-163.

Shi Huixian, Ren Yike, Meng Xiangzhen, et al. Research on energy-saving operating characteristics of water storage groundwater source heat pump heating system in plant factory[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(23): 157-163. (in Chinese with English abstract)

[4] 李南生,谢利辉,陈薛浩. 寒区浅埋输油管线冻胀安全性分析[J]. 结构工程师,2008,24(1):35-40.

Li Nansheng, Xie Lihui, Chen Xuehao. Frozen-heaving of frost-soil bed of shallow-buried oil-pipeline in cold region[J]. Structural Engineers, 2008, 24(1): 35-40. (in Chinese with English abstract)

[5] 胡宗柳,吴明,陈杨,等. 输油管道冻胀安全性研究现状与趋势[J]. 油气储运,2011,30(12):881-883.

Hu Zongliu, Wu Ming, Chen Yang, et al. Progress in the safety study of frost heaving of oil pipeline[J]. Oil and Gas Storage and Transportation, 2011, 30(12): 881-883. (in Chinese with English abstract)

[6] Gabrielsson A, Lehtmets M, Moritz L, et al. Heat storage in soft clay field tests with heating (70℃) and freezing of the soil[R]. Sweden: Swedish Geotechnical Institute, 1997.

[7] Lenarduzzi Frank J, Cragg Chris B H, Radhakrishna H S. Importance of grouting to enhance the performance of earth energy systems[J]. ASHRAE Transactions, 2000, 106: 424-434.

[8] Tafreshi S N M, Khalaj O. Laboratory tests of small-diameter HDPE pipes buried in reinforced sand under repeated-load[J]. Geotextiles and Geomembranes, 2008, 26: 145-163.

[9] Selvadurai A P S, Hu J, Konuk I. Computational modelling of frost heave induced soil-pipeline interaction I. Modelling of frost heave[J]. Cold Regions Science and Technology, 1999, 29(3): 215-228.

[10] Selvadurai A P S, Hu J, Konuk I. Computational modelling of frost heave induced soil-pipeline interaction II. Modelling of experiments at the Caen test facility[J]. Cold Regions Science and Technology, 1999, 29(3): 229-257.

[11] Michalowski R L, Zhu M. Frost heave modelling using porosity rate function[J]. International Journal for Numerical and Analytical Methods in Geomechanics, 2006, 30(8): 703-722.

[12] White T L. Pipelines in Permafrost and Freezing Ground, Engineering Resource Library and Database Indexes[M]. Canada: Permafrost Environmental Consulting Inc, 2006.

[13] Susan A T, Ian D, Moore, Muge Balkaya. Parametric study of frost-induced bending moments in buried cast iron water pipes[J]. Tunnelling and Underground Space Technology, 2016, 51: 291-300.

[14] Wu Yaping, Sheng Yu, Wang Yong. Stresses and deformations in a buried oil pipeline subject to differential frost heave in permafrost regions[J]. Cold Regions Science and Technology, 2010, 64(3): 256-261.

[15] Wang Jiabin, Niu Ditao, He Hui. Frost durability and stress–strain relationship of lining shotcrete in cold environment[J]. Construction and Building Materials, 2019, 198(2): 58-69.

[16] Razaqpur A G, Wang D. Frost-induced deformations and stresses in pipelines[J]. International Journal of Pressure Vessels and Piping, 1996, 69(2): 105-118.

[17] Carlson L E, Nixon, J F. Subsoil investigation of ice lensing at the Calgary, Canada, frost heave facility[J]. Canadian Geotechnical Journal, 1988, 25(2): 307-319.

[18] Williams P J, Riseborough D W, Smith M W. France-Canada joint study of deformation of an experimental pipe line by differential frost heave[J]. International Journal of Offshore and Polar Engineering, 1993, 3(1): 56-60.

[19] Nixon J F. The role of convective heat transport in the thawing of frozen soils[J]. Canadian Geotechnical Journal, 1975, 12(3): 425-429.

[20] Nixon J F. Discrete ice lens theory for frost heave in soils[J]. Canadian Geotechnical Journal, 1991, 28(6): 843-859.

[21] Huang S L, Bray M T, Akagawa S, et al. Field investigation of soil heave by a large diameter chilled gas pipeline experiment, Fairbanks, Alaska[J]. Journal of Cold Regions Engineering, 2004, 18(1): 2-34.

[22] Kim K, Zhou W, Huang S L. Frost heave predictions of buried chilled gas pipelines with the effect of permafrost[J]. Cold Regions Science and Technology, 2008, 53(3): 382-396.

[23] 谢崇宝,白静,吴志琴,等. 季节性冻土区灌溉管道排空防冻模式设计[J]. 农业工程学报,2018,34(21):82-88.

Xie Chongbao, Bai Jing, Wu Zhiqin, et al. Design of irrigation pipeline emptying anti-freezing mode in seasonal frozen soil region[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(21): 82-88. (in Chinese with English abstract)

[24] 唐少容,王红雨,潘鑫,等. U 形混凝土衬砌结构冻胀性能离心模型试验研究[J]. 农业工程学报,2019,35(1):157-163.

Tang Shaorong, Wang Hongyu, Pan Xin, et al. Frost heave performance of U-shaped canal concrete lining based on centrifuge model test[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2019, 35(1): 157-163. (in Chinese with English abstract)

[25] 白静,谢崇宝,吴志琴. 季节性冻土区管道浅埋换填防冻模式研究[J]. 水利学报,2018,49(5):588-597.

Bai Jing, Xie Chongbao, Wu Zhiqin. Research on anti-freezing pattern of shallow buried pipe by replacement filling of pipe trench in seasonal frozen area[J]. Journal of Hydraulic Engineering, 2018, 49(5): 588-597. (in Chinese with English abstract)

[26] 戴佳琦. 寒区村镇饮用水输配管道的保温防冻分析[D]. 哈尔滨:哈尔滨工业大学,2014.

Dai Jiaqi. Research on the Insulation of the Pipeline in Cold Area[D]. Harbin: Harbin Institute of Technology, 2014. (in Chinese with English abstract)

[27] 宋玲,欧阳辉,余书超. 混凝土防渗渠道冬季输水运行中冻胀与抗冻胀力验算[J]. 农业工程学报,2015,31(18):114-120.

Song Ling, Ouyang Hui, Yu Shuchao. Frozen heaving and capacity of frozen heaving resistance of trapezoidal concrete lining canal with water in winter[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(18): 114-120. (in Chinese with English abstract)

[28] 汪恩良,张安琪,包天鹅,等. 寒区不同材质垂直埋管土壤冻结深度测量差异性分析[J]. 水利学报,2017,48(1):86-95.

Wang Enliang, Zhang Anqi, Bao Tiane, et al. Variability analysis of freezing depth mode of vertical buried pipes with different materials in cold area[J]. Journal of Hydraulic Engineering, 2017, 48(1): 86-95. (in Chinese with English abstract)

[29] 陈继,李昆,盛煜,等. 季节冻土区埋地管道水温的变化规律及其影响因素分析[J]. 冰川冻土,2014,36(4):836-844.

Chen Ji, Li Kun, Sheng Yu, et al. Variations and influencing factors of the water temperature within the pipe buried in seasonally frozen ground areas[J]. Journal of Glaciology and Geocryology, 2014, 36(4): 836-844. (in Chinese with English abstract)

[30] 郑平,吴明,赵玲. 寒区土壤源热泵换热埋管的水热力耦合分析[J]. 土木建筑与环境工程,2011,33(3):100-106.

Zheng Ping, Wu Ming, Zhao Ling. Thermal dynamic analysis of buried hent exchanger in ground-source heat pump system in cold region[J]. Journal of Civil, Architectural and Environmental Engineering, 2011, 33(3): 100-106. (in Chinese with English abstract)

[31] 王有镗,高青,朱晓林,等. 地下换热管冻胀变形实验研究[J]. 应用基础与工程科学学报,2014,22(4):744-751.

Wang Youtang, Gao Qing, Zhu Xiaolin, et al. Experimental research on deformation of ground heat exchange pipe due to frost heave[J]. Journal of Basic Science and Engineering, 2014, 22(4): 744-751. (in Chinese with English abstract)

[32] 白莉,王有镗,高青,等. 地下换热管土结构冻胀变形模拟[J]. 农业工程学报,2016,32(18):118-124.

Bai Li, Wang Youtang, Gao Qing, et al. Simulation on underground pipe-soil heat exchange structure deformation due to frost heave[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(18): 118-124. (in Chinese with English abstract)

[33] 赵学文. 冻胀融沉试验方法及粘土冻胀特性研宄[D]. 北京:北京交通大学,2014.

Zhao Xuewen. Research on Test Method of Frost Heave and Thawing Settlement and Frost Heave Characteristic of Clay[D]. Beijing: Beijing Jiaotong University, 2014. (in Chinese with English abstract)

[34] 天华化工机械及自动化研究设计院. 腐蚀与防护手册(第1卷)腐蚀理论、试验及监测[M]. 北京:化学工业出版社,2009.

[35] 贾迪,孙德安,张龙. 盐溶液及掺砂率对高庙子膨润土强度的影响[J]. 上海大学学报:自然科学版,2018,24(6):1002-1013.

Jia Di, Sun Dean, Zhang Long. Effects of saline solution and sand rate on strength of GMZ bentonite[J]. Journal of Shanghai University: Natural Science, 2018, 24(6): 1002-1013. (in Chinese with English abstract)

Effects of backfill materials on frost heave characteristic of ground heat exchanger

Wang Youtang, Zheng Bin, Wang Chunguang, Li Chengyu, Mao Mingming, Liu Xuyang

(255049,)

Based on the ground source heat pump technology (GSHP) application in facility agriculture in cold regions, the frost heave characteristics of ground heat exchanger were studied. The research, based on the freezing radius tracking and pipe surface strains measurement, was carried out by frost heave experimental system. The experimental system mainly included soil tank, surrounding soil (ground soil and backfill material), U-type heat exchange pipe and cold source circulation system. In order to reflect better the effects of soil frost heave on pipe, uniform and saturated surrounding soil was used, the initial temperature of which was 4 ℃. The effects of sand-based and clay-based backfill materials on frost heave were contrasted. The frost-susceptible natural clay was applied as ground soil and clay-based backfill material, the mixture of fine sand and bentonite was applied as sand-based backfill material. In the experiment, the cryogenic fluid circulated in the U-pipe for 100 hours continuously, the temperature of which reduced from 0 to -10 ℃. The research on the characteristics of freezing area growth, buried pipe deformation and contraction were developed. Moreover, the changes of heat exchange pipe volume and flow resistance due to pipe deformation were investigated. In this study, thedirection was defined as the line through two centers of inlet pipe and outlet pipe, thedirection was perpendicular todirection. It could be found in both backfill materials, the running time in thedirection was less than thedirection at the corresponding freezing radius. This was related to the structure of U-pipe with two side-by-side pipes. The difference decreased with the increase of freezing area. In contrast, the freezing radius growth rate in the sand-based backfill (the rates inanddirection were 1.64 and 1.43 mm/h respectively) was slightly larger than that of the clay-based backfill (the rates inanddirection were 1.58 and 1.37 mm/h respectively). This indicated the freezing area in the sand-based backfill was greater than that in the clay-based backfill. As the freezing area increased, the pipe surface strains in both backfills showed gradually increasing and regular difference, which indicated the pipes’ cross-sections became more and more elliptical. The major axes of elliptical cross-sections coincided with thedirection. Meanwhile, the decrease of the mean strains on the pipe surface indicated that the pipes’ cross-sections were contracting. It was found that the elliptical deformation and the contraction of the pipe in the clay-based backfill were more serious than that in the sand-based backfill. By eliminating the influence of temperature drop from the mean strains, it could be found that the frost heave effect on the heat exchange pipe in clay-based backfill could be greater than that in sand-based backfill, when the freezing area exceeded a certain range. After the temperature of U-pipe dropped from 0 to -10 ℃ within 100h, it could be found that the pipe volume reduced 0.4%, the flow resistance increased 6.5%. Consequently, the pipe deformation with ovalization and contraction could be one reason for the decrease in circulation flow rate and system efficiency.

heat pumps; heat transfer; frost heave; ground heat exchanger; backfill material; buried pipe deformation

2018-02-24

2019-06-28

国家自然科学基金资助项目(51806130);山东省自然科学基金资助项目(ZR2017LEE031);山东省重点研发计划资助项目(2019GHY112076)

王有镗,讲师,博士,主要从事浅层地能利用研究。Email:wyt@sdut.edu.cn

10.11975/j.issn.1002-6819.2019.14.026

S215; TK521

A

1002-6819(2019)-14-0205-07

王有镗,郑 斌,王春光,李成宇,毛明明,刘旭阳. 回填土质材料对地下换热器冻胀特性的影响研究[J]. 农业工程学报,2019,35(14):205-211. doi:10.11975/j.issn.1002-6819.2019.14.026 http://www.tcsae.org

Wang Youtang, Zheng Bin, Wang Chunguang, Li Chengyu, Mao Mingming, Liu Xuyang. Effects of backfill materials on frost heave characteristic of ground heat exchanger[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2019, 35(14): 205-211. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2019.14.026 http://www.tcsae.org