基于感官品质的油梨常温后熟进程预测模型

李汴生,彭红梅,张德润,阮 征

基于感官品质的油梨常温后熟进程预测模型

李汴生,彭红梅,张德润,阮 征※

(华南理工大学食品科学与工程学院,广州 510640)

针对中国油梨市场油梨进口储运过程中储藏时间和品质变化难以把控及油梨损坏严重等问题,对常温常湿 ((25±1 )℃、75%相对湿度) 条件下果皮色泽、果肉硬度及感官品质指标进行测定,监测其在常温后熟过程中的内在变化规律,对色差、硬度、呼吸速率、质量损失率与果肉受喜爱程度进行皮尔逊相关性分析,利用无损检测指标色差*值与储藏时间之间logistic方程,建立油梨后熟时间预测模型。结果表明:油梨平均单果质量随储藏时间的延长而减少,每日质量损失率和呼吸速率均呈现先增加后减少的趋势,果皮色泽在储藏时间小于3 d时显著增加,其后趋于平衡,而果肉硬度表现相反的趋势,干基质量损失率、色泽(L,a和b值)和硬度均与感官喜爱度呈显著相关性(<0.01)。基于色差测定的无损、快速、便捷,选取色差*值进行预测模型的建立,色差*值的logistic方程拟合效果较好,2为0.993。模型的检验发现,在色差*值<4时,模型预测值与实测值有很好的线性相关性,决定系数为0.996,说明该模型在果皮色差*值<4时可以用于油梨常温后熟期的预测,研究结果可为油梨品质控制提供指导和依据。

预测;模型;农产品;油梨;常温;后熟

0 引 言

果蔬品质是指能满足消费者要求和期望的综合属性,包括感官品质、营养品质等多个方面[1],果蔬采后随储藏时间的延长,其品质会逐步变化、甚至老化、衰败,最后失去商品性。感官品质作为重要的品质特性具有判断直观、快速的特点,同时其品质变化与储藏时间、储藏温度、处理条件等密切相关,因此在果蔬的采后储藏过程中,感官品质变化成为研究重点。如采后猕猴桃硬度变化的研究[2-4],香蕉风味、硬度、表皮颜色变化的研究[5],芒果硬度、风味等的变化研究[6-8]。随着传感器技术、数学统计、化学分析、微生物分析及感官分析技术的发展,基于果蔬感官品质特性[9]及其衰变理论[10]而建立的预测模型被广泛应用于果蔬采后储藏管理,以预测、评估果蔬储藏过程中的品质变化。如利用芒果储藏过程力学指标[11]、颜色值、硬度[12]等建立的储藏期预测模型和品质预测模型,基于质量损失率国产猕猴桃储藏期预测模型[13],利用近红外光谱测定猕猴桃硬度的预测模型[14-15],基于番茄果实采后色泽、质构等建立的采后品质及货架期预测模型[16-18]等等。预测模型的建立能有效并全面的掌握果实的后熟进程,做到有效调控、监管,从而为果蔬采后储藏、流通、加工等提供依据,具有重要的生产应用价值[19]。

油梨又名鳄梨、酪梨、樟梨、牛油果,富含脂肪(脂肪含量可高达其干物质量的70%),含2%的蛋白质及多种糖类(葡萄糖,果糖、蔗糖、庚酮糖),纤维素、矿物质、维生素、类胡萝卜素、甾醇等多种生物活性成分,具有降低胆固醇含量,提升免疫功能,控制体质量、降低冠心病风险等多项生理作用[20-21]。随着国民生活水平及健康意识的提升,油梨已成为中国消费者热捧的水果,中国油梨的进口量从2011年的31.8 t上升至2017年的3.21万t。

油梨是一类呼吸跃变型的水果,具有呼吸变化明显、成熟快、后熟时间短等特点。伴随后熟过程一系列的生理生化反应,其果实的硬度、乙烯生成量、果皮色泽、PPO (polyphenol oxidase)活力、细胞壁降解酶活力、口感、风味等[22-28]均会随果实成熟度变化,现有的研究发现油梨感官品质是表征果实成熟情况的重要指标,也是油梨研究的重点。为加强油梨储藏过程中的管理,国外已有通过色差Hue值预测模型[29]、近红外无损检测建立PLS回归模型等[30]来预测管理油梨的品质变化。但对于中国3.21万t的油梨市场,如何科学有效的进行油梨的市场流通 (储藏、运输),成为中国油梨发展的产业问题。因此本试验旨在探究常温 (25 ℃) 储藏条件下易于监控、测定的品质指标,通过其变化规律及动力学特性的分析而建立预测模型,揭示各品质指标常温 (25 ℃) 条件下内在的变化规律性,从而实现通过简单、快速的测定预测油梨的后熟进程,为油梨常温 (25 ℃) 储运、销售、生产加工过程中品质的计算机模拟与控制提供依据。

1 材料与方法

1.1 材料与试剂

油梨:Hass品种,购买于广州五山某水果超市。同一批次,整果无机械损伤,依据形状、质量、成熟度的均一性选择样品[24]。

试验样品选择:果形、果皮色泽基本一致,整果呈绿色,单果质量(195±2) g。

1.2 仪器与设备

物性测定仪(TA. XT. Plus),英国 Stable Micro System 公司;色差仪(CR-400),日本 Konica Minolta 公司;电子天平(PL203),梅特勒-托利多仪器上海有限公司。

1.3 试验方法

将果形、色泽、大小一致的一批油梨放置在(25± 1) ℃、相对湿度75%条件下储存,每间隔24 h测定其各品质指标直至其果蒂处果肉呈白色结束试验(本试验储藏第9天)。

1.3.1 呼吸速率的测定

25 ℃条件下,将试验油梨放置在2 L磨口瓶内2 h,用橡胶塞密封,事先用打孔器在橡胶塞上打2个孔,安装玻璃管、乳胶管和止水夹为测气装置。用气体测定仪测定放置前后瓶内CO2的含量。利用密闭系统法方程计算呼吸速率,单位用mg/kg·h表示,每组试验设3个重复[31]。

1.3.2 平均单果质量的测定

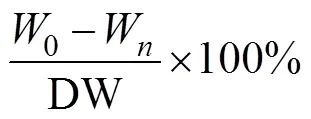

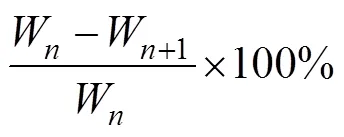

随机取样3个果,采用电子天平(PL203)进行质量测定,计算平均单果质量、干基质量损失率和每日质量损失率[24, 32]。

油梨果肉干物质质量的测定:随机取刚买到的3个油梨,每个油梨均分为4份,选取1/4果肉去核混匀制浆,称取20 g样品置于70 ℃烘箱中烘干至恒质量,3组平行,计算油梨果肉干物质质量[33](dry weight,DW)。

式中0为初始平均单果质量,g;W为第天平均单果质量,g;DW为果肉干物质质量,g;W+1,第(+1)天平均单果质量,g。

1.3.3 果皮色泽的测定

随机取样3个果,采用色差仪(CR-400)测定果实赤道处对角线4个点的色差值表示果皮色泽。色差测定结果用L、a、b表示,平行测定4次。其中L表示亮度,a表示红绿度,b表示黄蓝度[26-27]。每组试验设3个重复。

1.3.4 硬度的测定

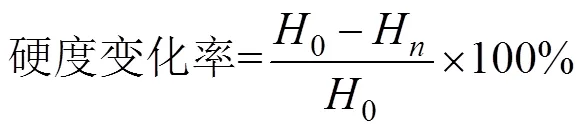

随机取样3个果,将油梨果实赤道处对角线上4点的外层果皮削去,采用TA. XT. Plus物性测定仪测定果肉硬度[21, 28, 34]。测定条件:采用P/2n针状探头,测前速率5 mm/s,贯入速度1 mm/s,测后速度5 mm/s,最小感知力5 g,穿刺深度8 mm。计算硬度变化率。

式中0为初始硬度值,N;H为第天的硬度值,N。

1.3.5 油梨风味及喜爱检验

取不同后熟期的油梨,选取果核区域果肉,切成大小一致的正方体(13 mm)果肉块,采用任意组合的3位数编号,分装于一次性纸碟中。挑选6位评价员对果肉进行评分,选取6种风味术语,分别是多汁感、脂肪感、平滑感、坚果味、黄油味、青草味[23]来进行评价,每种风味特性的强度总分定5分,得分越高表明此种风味强度越高。果肉喜爱检验评分采用0~9分,0分表示非常不喜欢,9分表示非常喜欢。各评价员独立评定,每评定一个样品,用清水漱口,间隔 6 min 后再品评下一个样品,每个试样重复 3 次,最后收集评定结果进行统计分析。

1.4 数据处理与分析

采用Excel 2010进行数据处理和图形绘制,方差分析采用新复极差分析法Duncan,取95%的置信区间(0.05),结果采用“均值±标准差”的形式表示。

2 结果与分析

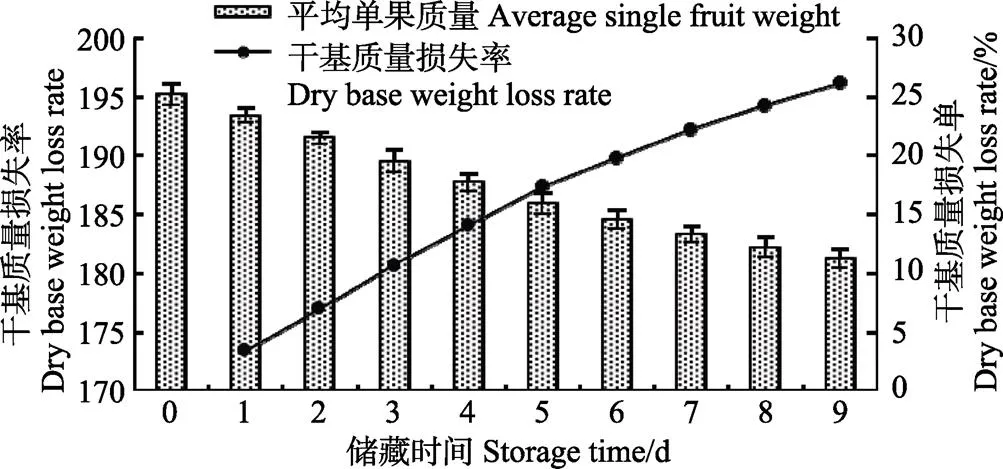

2.1 平均单果质量及呼吸速率的变化情况

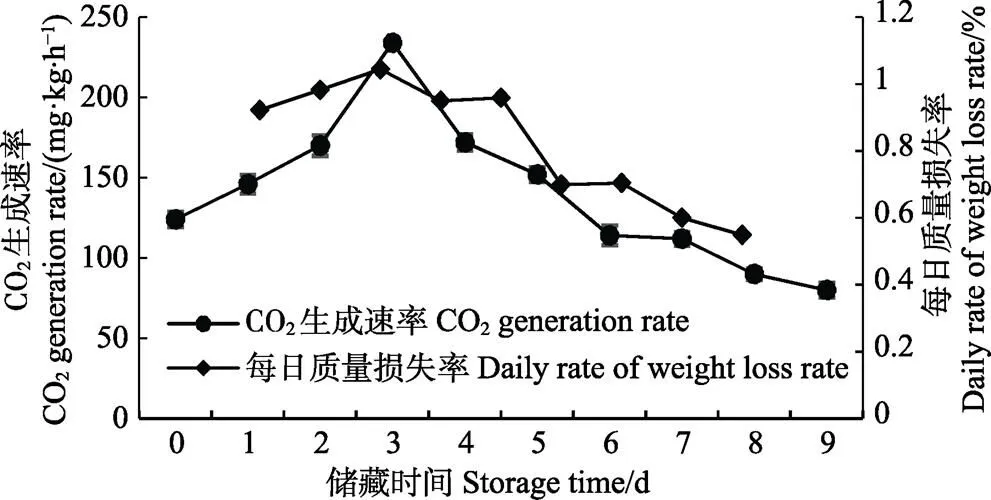

油梨平均单果质量及呼吸作用的变化如图1、图2所示。如图1可知随储藏时间的延长,平均单果质量不断减少,干基质量损失率不断增加[24, 35]。图2反映了油梨常温 (25 ℃)条件下呼吸产生的CO2量随时间的变化情况,CO2生成速率随时间先不断增加,第3天达最大,此时呼吸速率最大,随后CO2生成速率减少,呼吸速率下降。如图可知呼吸产生的CO2量有明显的峰值,油梨常温 (25 ℃)储藏过程有明显的呼吸跃变点。此试验的第3天为其呼吸跃变点。伴随后熟过程的呼吸作用,油梨每日质量损失率呈先增加后减少的趋势,呼吸跃变点处每日质量损失率最大,且图中反映每日质量损失率与呼吸速率呈正相关。

图1 平均单果质量、干基质量损失率的变化情况

图2 CO2生成速率和每日质量损失率的变化情况

2.2 果皮色泽的变化情况

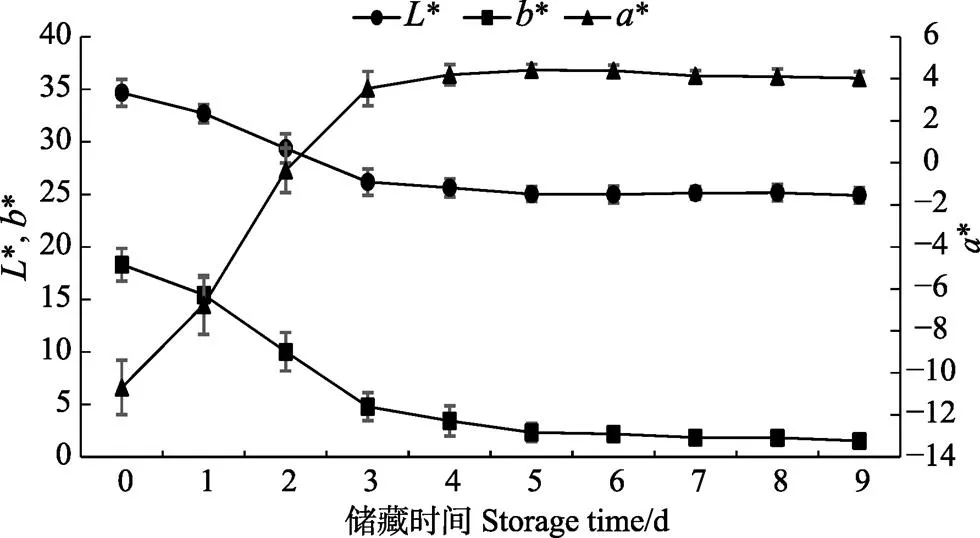

果皮色泽通常被作为判断油梨成熟的一个重要指标[25]。果皮色差测定结果如图3所示。随储藏时间的延长,色差*、*值不断减少,*值不断增大,色差曲线拐点出现在试验的第3天,即油梨的呼吸跃变点,此时果皮色差*=26.18±1.25、*=3.54±0.81、*=4.80±1.32,其变化率分别为24.46%、133.11%、73.78%,果皮色差*值变化率最大。第4天开始,果皮色差*、*、*值基本保持不变。色泽变化与其果皮中所含色素有关,研究发现油梨果皮色泽主要由其果皮中所含叶绿素决定[25],而叶绿素的降解主要发生在呼吸跃变点之前,因此本试验条件下果皮色泽变化主要发生在第0~3天。

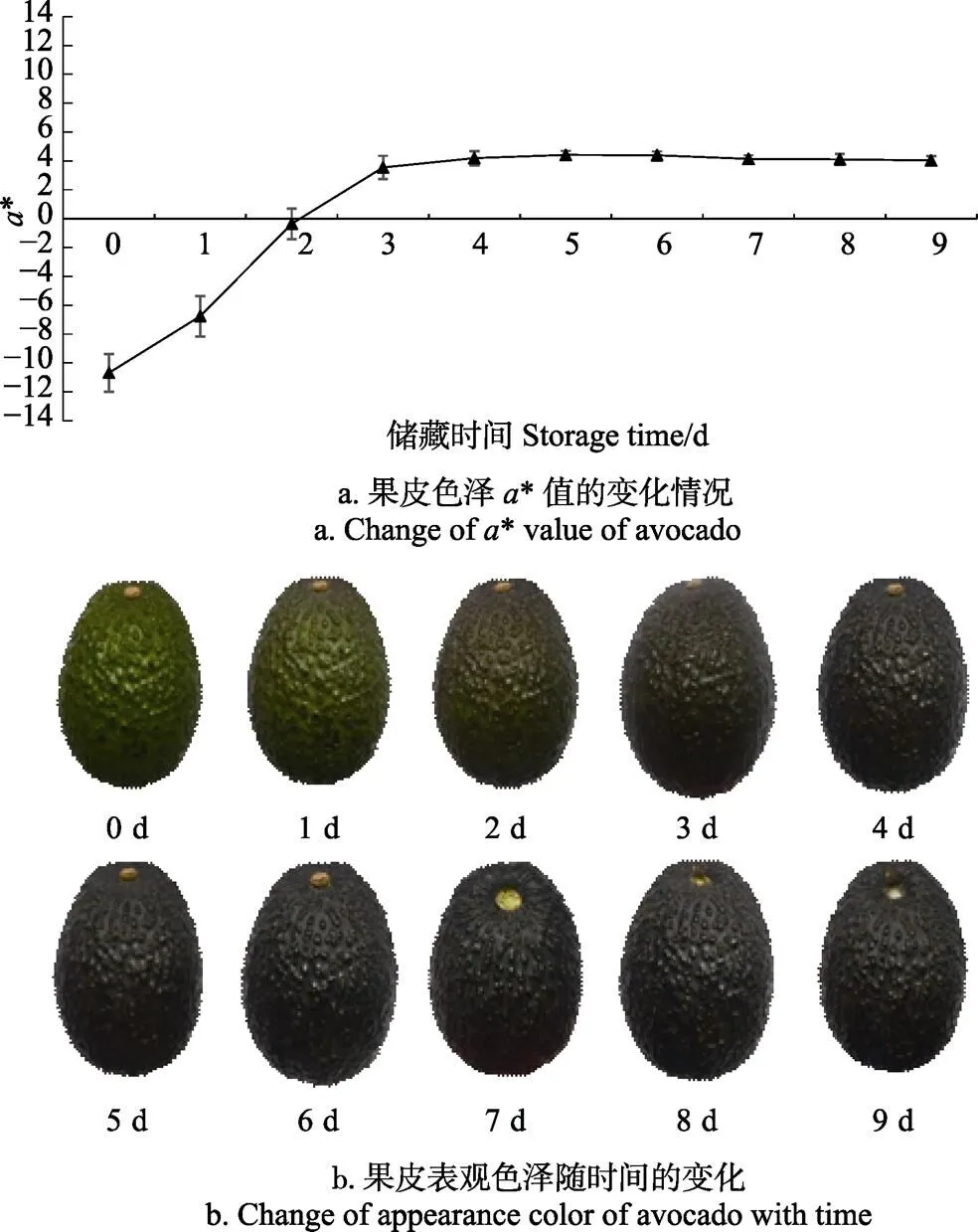

常温(25 ℃)储藏条件下色差*值与果皮外观色泽变化情况如图4所示。试验发现,色差*值伴随果皮外观色泽的变化其值从-10.69不断上升至4.0,并维持这一值不变。如图所示当果皮色泽呈绿色时,此时色差*值<0;伴随果皮由绿色变化至紫色,*值不断增加,第2天,果皮呈深紫色,此时果皮色差*=0;从试验第3天开始,油梨的果皮呈黑色,此时色差*≥4.0。

注:L*、a*、b*为亮度、红绿度、黄蓝度,下同。

2.3 果肉硬度的变化情况

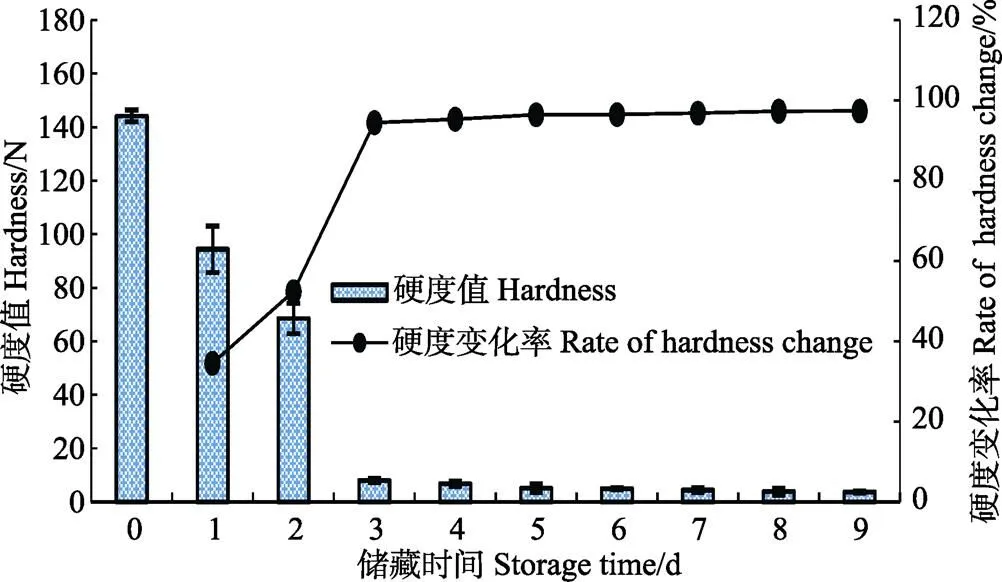

果肉硬度是反映油梨采后成熟行为的一个重要指标[35-36],图5反映了不同储藏时间硬度的变化情况,随着储藏时间的延长,油梨果肉硬度不断下降,前3天硬度下降明显,从最初的(144.20±2.23) N下降至第3天的(8.04±0.83) N,硬度下降94.4%。从后熟的第4天开始,油梨的硬度值达到Donetti等[21-24]定义的最佳可食硬度(4.4~6.7)N。硬度下降、果肉变软源于储藏过程中伴随时间的延长细胞壁中各类酶对果胶和半纤维素的作用,原果胶不断被降解成果胶酸、果胶[28],同时细胞薄层消失,原纤维细胞大量减少等[37]。

图4 果皮色泽的变化情况

图5 硬度变化情况

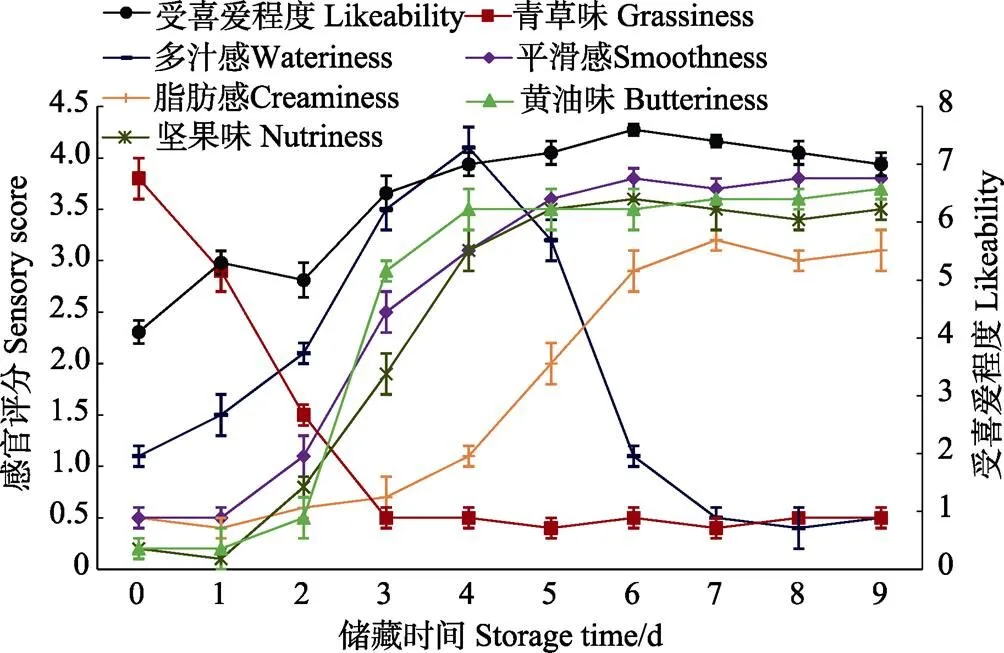

2.4 果肉风味、受喜爱程度的变化情况

油梨常温(25 ℃)条件下储藏风味变化情况如图6所示。如图可知,果肉脂肪感、平滑感、坚果味、黄油味均随常温(25 ℃)储藏时间的延长而增强,平滑感、坚果味、黄油味从第4天开始基本保持不变,脂肪感在第7天趋于平缓。青草味在储藏开始阶段感觉明显,储藏至第3天青草味基本消失。果肉多汁感随储藏时间呈先增强后减弱的趋势,第4天多汁感最为明显。油梨受喜爱程度随油梨果肉脂肪感、平滑感、坚果味、黄油味的增强、果肉青草味的降低而增加,后熟至第3天果肉喜爱程度评分为6.5,被品评人员接受,随后熟时间的延长,果肉喜爱度增强并趋于平缓[23]。

图6 油梨感官品质的变化

2.5 预测模型的建立

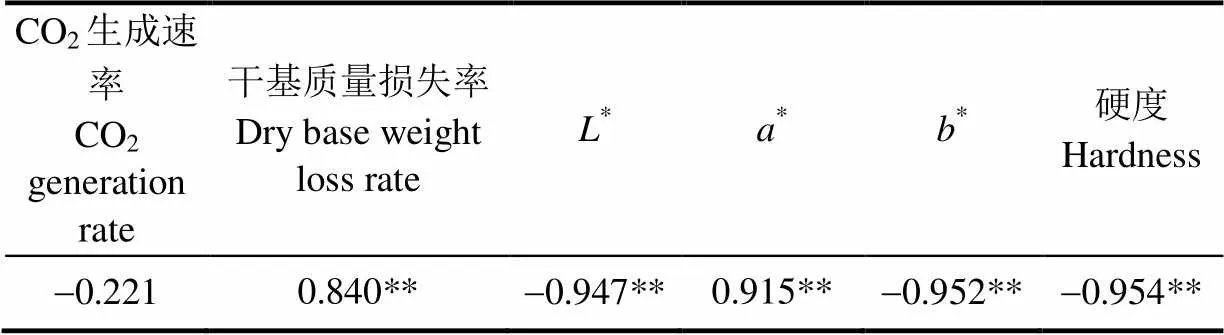

2.5.1 果肉各测定感官品质指标与感官喜爱程度评分之间的相关性

常温(25 ℃)储藏条件下各测定指标与感官喜爱度评分之间的相关性如表1所示。由表可知:在所有相关检测指标中,呼吸速率与感官喜爱度没有显著相关,而干基质量损失率、色差值、硬度值与感官评分在0.01水平下显著相关,其中干基质量损失率、色差a值与感官喜爱程度呈正相关,伴随干基质量损失率、色差a值的增加,感官喜爱程度评分增大。为实现无损、快捷、方便预测油梨后熟,本研究最终选取色差a值作为油梨常温(25 ℃)储藏过程品质变化和储藏时间动力学预测模型的关键因素。

表1 各品质指标与感官喜爱度之间的皮尔逊相关系数表

注:**代表显著性水平为0.01。

Note:**represents significant level at 0.01.

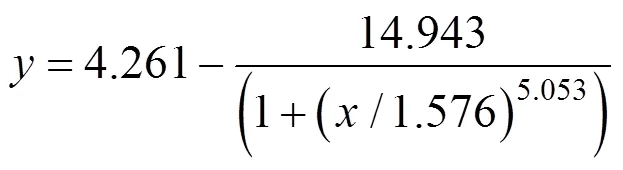

2.5.2 色差值Logistic方程的建立

通过对色差*值随时间变化的观察,以色差*值为因变量,使用Logistic方程对原始的*测定数据在Origin中进行拟合分析,结果如图7所示,得到的Logistic方程为

=2(1-2)/(1+(/0)) (4)

得到的拟合结果中,1=-10.681,2=4.261,0=1.576,=5.053,得到的Logistic方程为

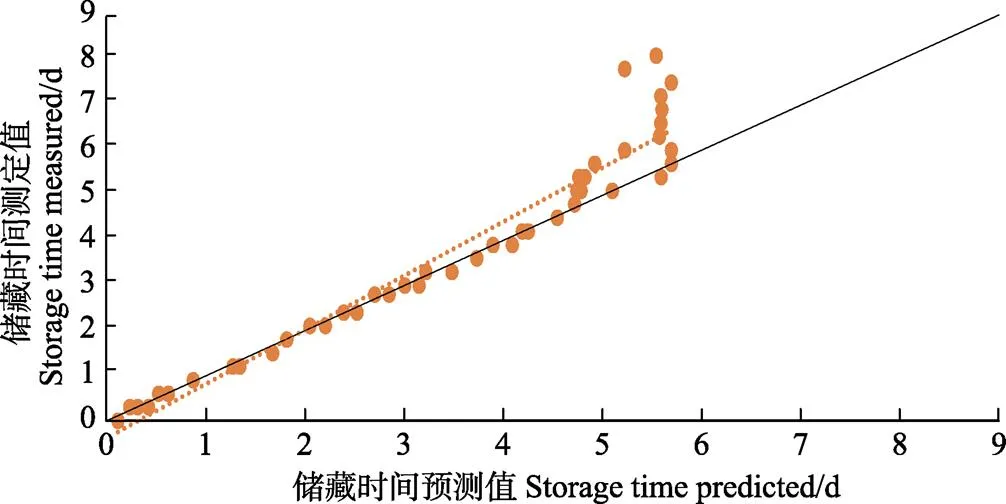

2.6 模型的检验

模型的检验选取同一批次中果皮呈绿色、紫色和黑色的油梨,测定果皮色差值,通过色差值的logistic方程对油梨储藏时间进行预测,然后将果实放置在温度为(25±1) ℃、相对湿度为75%的试验条件下,每8 h观察一次,当油梨果蒂处果肉呈白色时结束试验,此时间段即为油梨的可放置时间(用1表示),油梨储藏时间的测定值用表示,其中=9-1。预测值与测定值的线性关系如图8所示,从图中散点图的分布情况可知,油梨储藏时间在第0~4天时,预测值与测定值均匀分布在对角线两侧,预测值和测定值有很好的线性相关性,此阶段的决定系数为0.996,此时果皮色差<4。而在油梨储藏的第5~9天,储藏时间的测定值往往大于其预测值,预测准确性下降,此时果皮色差≥4。这与油梨果皮后熟过程中色泽的变化有关,后熟过程中伴随叶绿素的降解,果皮色泽从绿色逐渐变化成黑色,并随储藏时间的延长而维持不变,此时色差值不变,通过果皮色差值的logistic方程得到的预测值不变,因而所建立的模型无法应用于色差≥4的情况。

图7 色差a*值logistic曲线

图8 模型检验组预测值与实测值的散点图

3 结 论

对于油梨这类呼吸跃变型水果,为延长果实的储藏期,通常会选取果实成熟度较低时进行采摘,以减少机械损伤和微生物侵扰,但此时的果实并不处于最佳的食用期,通常需要储藏期间的后熟,保证果实的实用品质。

本文充分研究了油梨常温(25 ℃)储藏条件下果实色泽、硬度、风味等的变化。试验结果表明随储藏时间的延长,油梨感官品质逐步完善,硬度下降至最佳可食硬度值(4.4~6.7)N、果皮颜色从绿色变化至黑色,果肉青草味消失,坚果味、黄油味凸显,果肉受喜爱程度增加,后熟对于油梨果实品质是一个必要的过程。

常温(25 ℃)储藏条件下,油梨有明显的呼吸跃变点,且呼吸跃变点与色泽、硬度、感官品质的变化密切相关。结合储藏过程感官品质与呼吸速率发现,油梨常温(25 ℃)储藏条件下其感官品质的变化主要发生在呼吸跃变点及之前的阶段,此时硬度、色泽、风味等变化明显。

油梨的感官品质受成熟情况影响,通过储藏过程色差、硬度、呼吸速率、质量损失率与果肉受喜爱程度之间的皮尔逊相关系数的比较分析,确定色差*值为油梨储藏预测模型关键指示因素,并建立色差*值logistic方程,方程的拟合效果2为0.993,在色差*<4时,模型预测值与实测值的决定系数为0.996,表明此模型在色差*<4时具有较高的拟合度,对实际应用具有一定的参考价值。

[1] 汪琳,应铁进. 番茄果实采后贮藏过程中的颜色动力学模型及其应用[J]. 农业工程学报,2001,17(3):118-121. Wang Lin, Ying Tiejin. Kinetic model on surface color in tomato fruits during the post-harvest storage and its application[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2001, 17(3): 118-121. (in Chinese with English abstract)

[2] 罗静,郭琳琳,黄玉南,等. 猕猴桃PG基因在果实贮藏过程中的表达及其与硬度的关系[J]. 园艺学报,2018,45(5):865-874. Luo Jing, Guo Linlin, Huang Yunan, et al. Relationship between PG gene expression and fruit firmness during kiwifruit storage[J]. Acta Horticulturae Sinica, 2018, 45(5): 865-874. (in Chinese with English abstract)

[3] 俞静芬,尚海涛,凌建刚,等. 1-MCP结合微孔保鲜膜对猕猴桃出库货架期品质影响研究[J]. 农产品加工,2018,2:4-5. Yu Jingfen, Shang Haitao, Ling Jiangang, et al. 1-MCP combined with microporous preservative film influence on kiwifruit storage shelf quality[J]. Farm Products Processing, 2018, 2: 4-5. (in Chinese with English abstract)

[4] 曹森,马超,吉宁,等. 1-MCP对不同成熟度红阳猕猴桃保鲜效果及后熟品质的影响[J]. 食品科技,2018,43(11):29-37. Cao Sen, Ma Chao, Ji Ning, et al. Effects of 1-MCP on preservation and ripening quality of “hongyang” kiwifruit with different maturity[J]. Food Science and Technology, 2018, 43(11): 29-37. (in Chinese with English abstract)

[5] 淡明,黄梅华,梁晓君,等. 不同催熟条件对香蕉后熟均匀性的影响研究[J]. 热带作物学报,2018,39(6):1095-1101. Dan Ming, Huang Meihua, Liang Xiaojun, et al. The effect of ethylene ripening conditions on the ripening uniformity of different harvest maturity banana fruit[J]. Chinese Journal of Tropical Crops, 2018, 39(6): 1095-1101. (in Chinese with English abstract)

[6] 徐方旭,柳叶飞,刘诗扬,等. 1-MCP结合壳聚糖处理延缓芒果果实后熟与衰老的研究[J]. 食品工业,2016,37(12):92-94. Xu Fangxu, Liu Yefei, Liu Shiyang, et al. Study on the delay of mango fruit ripening and senescence by using 1-MCP and chitosan coating treatment[J]. The Food Industry, 2016, 37(12): 92-94. (in Chinese with English abstract)

[7] 邵远志,张哲,李庚虎,等. 采收成熟度与后熟处理对红贵妃芒果贮藏品质和生理的影响[J]. 保鲜与加工,2010,3(10):17-21. Shao Yuanzhi, Zhang Zhe, Li Genghu, et al. Effects of harvest maturity on storage quality anphysiology of mango fruit (cv. Hongguifei)[J]. Storage and Process, 2010, 3(10): 17-21. (in Chinese with English abstract)

[8] 刘英. 热浸处理对芒果浆加工原料质量的影响[D]. 南宁:广西大学,2011. Liu Ying. The Effect of Hot Water Immersion Treatment on Quality of Raw Materials of Mango Pulp[D]. Nanning: Guangxi University, 2011. (in Chinese with English abstract)

[9] Pathare P B,Opara U L,AlSaid F A J. Colour measurement and analysis in fresh and processed foods: A review[J]. Food & Bioprocess Technology, 2013, 6(1): 36-60.

[10] 史波林,赵镭,支瑞聪. 基于品质衰变理论的食品货架期预测模型及其应用研究进展[J]. 食品科学,2012,33(21):345-350. Shi Bolin, Zhao Lei, Zhi Ruicong. Advances in predictive shelf life models based on food quality deterioration theory and their applications[J]. Food Science, 2012, 33(21): 345-350. (in Chinese with English abstract)

[11] 沈力,胥义,钮怡清. 小台农芒果力学特性及其贮藏期预测模型的研究[J]. 食品与发酵工业,2015,41(4):212-218. Shen Li, Xu Yi, Niu Yiqing. Research on mechanical properties and storage life prediction model of mango under storage temperatures[J]. Food and Fermentation Industries, 2015, 41(4): 212-218. (in Chinese with English abstract)

[12] 李敏,高兆银,苏增建,等. 基于芒果果肉颜色的品质检测技术[J]. 热带作物学报,2017,38(1):166-170. Li Min, Gao Zhaoyin, Su Zengjian, et al. Quality evaluation of mango by fresh colorimetric measurements[J]. Chinese Journal of Tropical Crops, 2017, 38(1): 166-170. (in Chinese with English abstract)

[13] 顾海宁,李强,陈晨,等. 猕猴桃储藏期品质变化研究及预测模型建立[J]. 食品工业,2014,35(6):7-10.Gu Haining, Li Qiang, Chen Chen, et al. Quality change and storage period forecast mode of domestic kiwi[J]. The Food Industry, 2014, 35(6): 7-10. (in Chinese with English abstract)

[14] 吕强,汤明杰,赵杰文,等. 近红外光谱预测猕猴桃硬度模型的简化研究[J]. 光谱学与光谱分析,2009,29(7):1768-1771.

[15] Arpaia M L, Collin S, Sievert J, et al. Influence of cold storage prior to and after ripening on quality factors and sensory attributes of ’Hass’ avocados[J]. Postharvest Biology & Technology, 2015, 110: 149-157.

[16] Obenlanda D, Sievert J, Negm F, et al. Influence of maturity and ripening on aroma volatiles and flavor in ’Hass’ avocado[J]. Postharvest Biology & Technology, 2012, 71: 41-50.

[17] ElAguirre-Joya J A, Ventura-Sobrevilla J, Martínez- Vazquez G, et al. Effects of a natural bioactive coating on the quality and shelf life prolongation at different storage conditions of avocado (Mill.) cv. Hass[J]. 2017, 14: 102-107.

[18] Cox K A, McGhie T K, White A, et al. Skin colour and pigment changes during ripening of ’Hass’ avocado fruit[J]. Postharvest Biology and Technology, 2004, 31(3): 287-294.

[19] Ge Yu, Si Xiongyuan, Cao Jianqiu, et al. Morphological characteristics, nutritional quality, and bioactive constituents in fruits of two avocado () varieties from Hainan Province, China[J]. Journal of Agricultural Science 2017, 9(2): 8-17.

[20] Vargas-Ortiz M, Rodríguez-Jimenes G, Salgado-Cervantes M, et al. Minimally processed avocado through flash vacuum- expansion: Its effect in major physicochemical aspects of the puree and stability on storage[J]. Journal of Food Processing and Preservation, 2017, 41(3): 1-10.

[21] Maftoonazad N, Ramaswamy H S. Effect of pectin-based coating on the kinetics of quality change associated with stored avocados[J]. Journal of Food Processing & Preservation, 2008, 32(4): 621-643.

[22] Hertog M L A T. The impact of biological variation on postharvest population dynamics[J]. Postharvest Biology & Technology, 2002, 26(3): 253-263.

[23] Olarewaju O O, Bertling I, Magwaza L S. Non-destructive evaluation of avocado fruit maturity using near infrared spectroscopy and PLS regression models[J]. Scientia Horticulturae, 2016, 199: 229-236.

[24] Villa-Rodríguez J A., Molina-Corral F J, Ayala-Zavala J F, et al. Effect of maturity stage on the content of fatty acids and antioxidant activity of ‘Hass’ avocado[J]. Food Research International, 2011, 44(5): 1231-1237.

[25] 高佳,王宝刚,冯晓元,等. 甜樱桃和酸樱桃品种果实性状的综合评价[J]. 北方园艺,2011,1(7):17-21. Gao Jia, Wang Baogang, Feng Xiaoyuan, et al. Composite appreciation of fruit charaters in sweet cherry and sour cherry cultivars[J]. Northern Horticulture, 2011, 1(7): 17-21. (in Chinese with English abstract)

[26] Ozdemir F, Topuz A. Changes in dry matter, oil content and fatty acids composition of avocado during harvesting time and post-harvesting ripening period[J]. Food Chemistry, 2004, 86(1): 79-83.

[27] 马庆华,王贵禧,梁丽松. 质构仪穿刺试验检测冬枣质地品质方法的建立[J]. 中国农业科学,2011,44(6):1210-1217. Ma Qinghua, Wang Guixi, Liang Lisong. Establishment of the detecting method on the fruit texture of dongzao by puncture test[J]. Scientia Agricultura Sinica, 2011, 44(6): 1210-1217. (in Chinese with English abstract)

[28] Arzate-Vázquez I, Chanona-Pérez J J, Perea-Flores M De J, et al. Image processing applied to classification of avocado variety hass (Mill.) during the ripening process[J]. Food and Bioprocess Technology, 2011, 4(7): 1307-1313.

[29] Magwaza L S, Tesfay S Z. A Review of destructive and non-destructive methods for determining avocado fruit maturity[J]. Food and Bioprocess Technology, 2015, 8(10): 1995-2011.

[30] Goulao L, Oliveira C. Cell wall modifications during fruit ripening: When a fruit is not the fruit[J]. Trends in Food Science & Technology, 2008, 19(1): 4-25.

Prediction model of avocado ripening process based on sensory quality at room temperature

Li Biansheng, Peng Hongmei, Zhang Derun, Ruan Zheng※

(510640,)

‘Hass’ avocado is enjoyed by consumers worldwide due to its rich flavor, high overall quality and health related attributes. The nutritional and dense phytochemical composition of avocado is attracting more consumers. Avocados do not ripen on the tree and must be ripened after harvest, which means that most or all of the ripening process needs to be carefully controlled in the commercial postharvest environment. In view of the problems that the storage time and quality changes of avocado during the storage and transportation in the Chinese avocado market are difficult to be controlled, as well as that avocado is easy to be damaged, the color of the avocado peel, the hardness of the avocado pulp, and the sensory quality indicators at room temperature (25±1 ℃, 75% RH) were measured to monitor their intrinsic variation during ripening in this study. The Pearson correlation analysis between the affection degree of avocado flesh and the color difference, hardness, respiration rate, weight loss rate, respectively, was also performed. At last, the prediction model for the ripening of avocado was developed based on first-order functional equation, logistic equation of dry weight loss rate-and the color differencevalue-storage time. The results showed that the weight of avocado fruit decreased from 195.2±0.9 to 181.2±0.8 with the prolongation of storage time (0-9 d), and the daily weight loss rate and respiration rate increased first at the storage time of 0~3 d and then decreased sharply. Conversely, the peel color, characterized by(34.66±1.27),a(-10.69±1.29) andbvalues (18.31±1.56), changed significantly when the storage time was less than 3 d, and then tended to constant (~25.63, ~4.19, and~3.45, respectively). However, the avocado flesh hardness decreased from 144.2N to 8.04N during storing for 3 d and reached equilibrium when the storage time exceeded 3 h. Additionally, apart from the respiratory rate (=-0.221), the dry weight loss rate, peel color (L,aandbvalues), and avocado flesh hardness during storing at room temperature were significantly correlated with sensory preference scores (<0.01), in which the dry weight loss rate (=0.840)andavalue (=0.915) were positively related to sensory preference scores, and flesh hardness (=-0.954),L(=-0.947), andbvalues (=-0.952) were negatively related to sensory preference scores. Based on determination of the color of avocado peel were nondestructive, fast, convenient, hereinvalue was selected as key indicators to establish the prediction model of avocado quality change during storing. At the storage time of 0-9 d, thevalue was fitted well based on logistic equation.2values was 0.993. In the validation experiments,whenvalue less than 4, thepredicted and the measured values have a good linear correlation,the decision coefficient is 0.996, indicating that the developed model can be used to predict the ripening period of avocado at room temperature whenvalue less than 4. The research results in this work can provide favorable guidance and basis for quality control of avocado.

prediction; models; agricultural products; avocado; room temperature; ripening

10.11975/j.issn.1002-6819.2019.13.034

TS255.3

A

1002-6819(2019)-13-0285-07

2018-11-10

2019-05-10

国家重点研发计划项目:食品高效冷冻解冻关键技术及装备开发(2017YFD0400404)

李汴生,教授,博士,主要从事食品加工和保藏研究。Email:febshli@scut.edu.cn

阮 征,副教授,博士,主要从事食品加工和保藏研究。Email:zhruan@scut.edu.cn

李汴生,彭红梅,张德润,阮征.基于感官品质的油梨常温后熟进程预测模型[J]. 农业工程学报,2019,35(13):285-290. doi:10.11975/j.issn.1002-6819.2019.13.034 http://www.tcsae.org

Li Biansheng, Peng Hongmei, Zhang Derun, Ruan Zheng. Prediction model of avocado ripening process based on sensory quality at room temperature [J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2019, 35(13): 285-290. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2019.13.034 http://www.tcsae.org