Impact of recycling improvement on the life cycle of phosphorus

Mohammad El Wali,Saeed Rahimpour Golroudbary,*,Andrzej Kraslawski,2

1 School of Engineering Sciences,Industrial Engineering and Management(IEM),Lappeenranta University of Technology,P.O.Box 20,FI-53851 Lappeenranta,Finland

2 Faculty of Process and Environmental Engineering,Lodz University of Technology,ul.Wolczanska 213,90-924 Lodz,Poland

Keywords:Critical material Phosphorus Dynamic modelling Dynamic simulation Recovery Recycling

ABSTRACT Access to natural resources is increasingly more difficult and more costly,partly due to their economic significance and to continuous increase of their global consumption in the recent years.In the case of phosphorus(P),which is a critical raw material,geological distribution of its primary nonrenewable source(phosphate rock)is concentrated in particular regions leading to high supply risk of this raw material.In Europe(EU-28),where phosphate rock reserves are scarce,import of phosphorus has been the main source of supply.It means that Europe relies highly on the foreign exporters.From decision makers'perspective,recycling of phosphorus was taken into account as one of the possible solutions to decrease the dependence on imports and extraction of reserves.The question,however,is to what extent does the recycling of phosphorus help in reducing the reliance on typical supply resources?Hence,the main objective of this paper is to quantify the dynamic flow of phosphorus and show potential benefits of its recycling in Europe. This article presents a system dynamics model for representation of the element P flow and helps to quantify to what extent the recycled phosphorus could mitigate its criticality. Analysis of the results supports previous studies indicating the high reliance of EU on P imports,estimating around 96%as the reliance percentage on imports.The results imply that improving P recycling has the potential to decrease the level of P imports to a certain extent,which may reach 79%.

1.Introduction

1.1.Phosphorus as a critical material

One of the main concerns for raw materials is the supply risk which has been the most common aspect of criticality of a material according to the previous studies[1-3].It is a result of disruptions in the supply chain due to physical shortage of resources[4].They are often a result of continuous extraction of non-renewable natural resources leading to the scarcity of resources [5]. These concerns are driving for new methodologies for assessing criticality of materials[6].Critical materials (a) ensure the specific properties of the advanced products or systems, (b) are subject to supply risk, (c) have no obvious substitutes, and (d) are substantial for environment-friendly technologies[7-9]. However, due to the differences in methodologies applied for criticality assessment,there is no overall definition of critical materials [1,10]. The EU assessment of material criticality is based on two factors: supply risk and economic importance [11]. The economic importance is determined by assessing the contribution of a given material to the industrial mega sectors in Europe. This process focuses primarily on the role of each material in the European manufacturing industries [3].

Phosphorus (P) plays a prominent role for all living creatures and organisms [12,13]. The essentiality and unequal distribution on global scale through regional surplus of phosphorus(P)highlight significant challenges in phosphorus life cycle for worldwide community[14]. Globally, a potential scarcity of phosphorus does not seem to occur[15-19].However,considering the lack of any substantial reserves in Europe,the main challenge faced by decision makers is the complete dependency on raw phosphorous exporters.The European Union remarkably is a region with only a few deposits, in which the main part is found in Finland[20].This imbalanced distribution of P could potentially cause geopolitical issues for European governments and firms[14].

Globally,phosphate rock(PR)reserves are concentrated in particular regions.Morocco holds 73%of the global reserves[21].Such geological distribution of PR stock might affect the price of fertilizers and food[22],or it can also disrupt the continuous supply of the ore material[20].The geographic concentration of current PR supply in a few major producing countries is also underlying the increase in the vulnerability of a region such as Europe(EU-28)that relies on imports for its primary P inputs.

Europe is about to develop new strategies to lessen the dependency on import of phosphorus due to the already mentioned issues and very limited substitutability of phosphorus[14,23].It is planned to emphasise the role of recycling and recovery as the major factor reducing Europe dependency on imports [22,24]. Therefore, the research on sustainable supply chain management has largely focused on monitoring its reversibility.

Increasing recycling and improving sustainable management of phosphorous is one of the top priorities of the EU, as emphasised in the EU 2020 Strategy [25,26]. Hence, the main motivation of this paper is to calculate the current level of recycling through the various waste streams (solid waste, water treatment and manure) and to estimate the degree to which it could be enhanced. Also, we present the possible impact of this improvement on the criticality of P in Europe.

1.2.State of the art phosphorus recycling

Recycling has recently emerged to be one of the main possible factors for developing closed-loop supply chains[27],particularly for critical materials,which might be subject to supply disruptions if a circular economy is not effectively planned and implemented[28].The recycling of phosphorus has been already proposed as one of the viable alternatives to mining[29-31].Both solid wastes and wastewaters offer an excellent opportunity for more efficient use of phosphorus[32,33].Recycling of phosphorous from the waste streams has a potential for decreasing the reliance on other sources and could significantly reduce this material's imports[18,33-35].

Most phosphorus flow studies are commonly conducted using methods such as substance/material flow analysis(SFA/MFA)[14].To quantify the P stocks and flows,researches on the material flow of phosphorus were done in different studies considering various geographical scales,e.g.,regional[36,37],national[34,38,39]and global[40-43].The potential and the need for improving P recycling were the common recommendations among all these researches.

1.3.Objective of the study

Considering material flow analysis in the European community scale, the structural model of the phosphorus life cycle to quantify the flows has been studied by several researches [14,24,44]. Ott and Rechberger [44] use the SFA to quantify the flow of P by considering the 15 state members of the EU. Withers et al. [24] suggest a 5R stewardship to resolve the European concerns on the P life cycle.Van Dijk et al. [14] go further by considering the P flow in the 27 member states of the EU, which concludes the high dependency on primary P imports, long-term P accumulations in the soil, P losses due to societal consumption, limited recycling and low use efficiency of P.

In this study, using system dynamics modelling, we analyse and quantify the phosphorus flows in detail for the European Union(EU-28). The necessity of systems approach to phosphorous supply chain management has been presented in several studies [40-42].System dynamics modelling is a useful approach to show evolution trends of the given system[45].In the case of phosphorus,system dynamics models have been used to examine dynamic interactions among various components of the system being studied, e.g. solid waste management [46], phosphorus mass flow [47], a decoupled aquaponics system [48] and phosphorus flows in food and waste chains [49]. In this study, a system dynamics model is built to show the dynamics of phosphorous supply chain in years 2000-2050.System dynamics modelling adopts a top-down approach,conceptualizing a complex system at aggregate level.This method is useful for modelling dynamic changes over time as well as modelling large and complex systems[50,51].It offers an approach supporting businesses and government institutions in development of strategy and designing policy interventions[52].System dynamics modelling helps to consider that many objects interact with one another(complex),their interaction produces the distinctive behaviour of the system (interactive) and their distinctive behaviour varies over time (dynamics). The methodology will be explained in the next section.In this study,P flows from non-food and non-agricultural sectors are also considered. The model also presents the impact of the dynamic characteristics of the P flow and the demographic changes of the EU population.The results estimate the amount of P mined,imported,exported,produced,consumed,lost and recycled.Previous suggestions on improving P recycling[24,34,53,54]are taken into consideration through scenario development of the model. It provides a scenario-based analysis to assess the impact of recycling on the P life cycle in the EU.

2.Materials and Methods

Necessary data input for the model was obtained from various database sources in addition to related literature(Supplementary Material Table S2).The required data should represent phosphorus content inside the materials.The available datasets show data on phosphorus in the form of chemical compounds(e.g.P pentoxide,phosphoric acid,and sodium triphosphates). The approach was to calculate the exact phosphorus composition inside each compound considering the total molar mass of the compound and the molar mass of P element(Supplementary Material,Table S2).

The system dynamics method introduced by Forrester[55]is used in this study due to the high level of complexity and interdependencies between the stages and variables[51].The need of system dynamics is important to understand the behaviour of the model and build a structural representation of stocks,flows and interacting parameters[56]with the passage of time under different scenarios[57].The model of the life cycle of phosphorus in Europe has been constructed to enable quantitative estimation of the amount of phosphorus recycled from solid wastes and wastewater streams.The model focuses on the main predictors of the flow changes and thus leads to dynamic behaviour of the whole system.

2.1.Model description and system definition

The developed model is a dynamic stock-flow diagram.All the equations associated with every component are provided in the Supplementary Material(Table S1-S3). This model is dynamic and is subject to change with time.Historical data starts from different years(2000 the latest)and ends in 2015 or 2016.Therefore,the model duration corresponds to two periods,the historical period(2000-2015)and the future estimated period(2016-2050).Historical data were used to form the structure of the variable variation,and to determine the behaviour of these variables over time(Fig.1).

The model has two major assumptions.First,the system boundaries were fixed by taking into account only 28 member states of European Union.The system covers seven main stages of phosphorous life cycle.Those stages are:mining,beneficiation,processing,production,consumption,waste generation and recycling.In addition,import and export are considered in this study.Import and export correspond to the material traded between the EU and countries or groups outside the EU.The material trade within the system boundaries(within the EU)is not considered.The material trade(import and export)is analysed in mining, processing, production and consumption. In the mining stage,the material trade corresponds to import and export of mined phosphate ores.In the processing stage,the material trade corresponds to import and export of phosphoric acid.In the production stage,the material trade is shown separately for each production sector.These sectors are:phosphate fertilizers,feed additives,food additives,laundry detergents,and phosphate obtained from iron ores and concentrates.In the consumption stage,the material trade represents the import and export of crops,livestock,dairy products,fish and food.The second basic assumption concerns the time of analysis. Basing on historical data,we assumed the distribution of phosphorus in the different sectors.Table S3 in Supplementary Material represents distributions for the production of feed,crop and animals.

Fig.1.Overview of the phosphorus life cycle in the EU.

2.2.Phosphorus life cycle in the EU

2.2.1.Mining and processing of phosphorus

The life cycle of phosphorus is strongly affected by human activities, where over 90% of P intakes go for the agro-food production, including fertilizers and food additives [58]. The first stage is the mining of raw materials (apatite) from phosphate rock. Europe does not extract any significant amounts of phosphorus, except a small amount (about 54800 t P) extracted in 2015. The major suppliers of phosphate ores are based in Morocco, Tunisia, the US, Jordan, Russia,and China [21]. Supply of phosphate ores corresponds to the mining of phosphate rock, which has been so far the largest source after WWII, containing around 11%-15% of P [59]. Besides, iron ores represent a secondary source for obtaining phosphorus.The phosphorus obtained from iron ores is used as a phosphate fertilizer [60]. Europe is highly dependent on imports with a reliance percentage of 88% [11].The trend of primary material imports is essential to identify the pattern of EU imports from other countries. Data analysis shows, in 2009, the imports of apatite to the EU experienced a dramatic decline because of the global economic crisis, when the amount of imported apatite accounted for 389269 t. Then, the traded amount recovered rapidly until 2016.The reduction in 2009 is considered a sudden rather than a gradual change.

After the mining process,the mined material goes for beneficiation.The beneficiation process results in P effluents to the water[13],and the beneficiated material goes for the next stage(processing stage).This stage corresponds to the processing of phosphorus into phosphoric acid [43]. In this stage, P loss also occurs; where around 10% of the processed material is lost [61]. The domestic production is not the only source for obtaining phosphoric acid.The European trade of phosphoric acid appears in the imports that have been stable for the past ten years (2006-2016), except for the sharp decline in 2009, when the imported amount accounted for 301523 t.The exports,however,have been considerably stable in this period, without any significant increases or decreases.Trends in import and export activities are equally useful to understand the EU trade behaviour regarding the material processed in the life cycle of phosphorus.

2.2.2.Production stage of phosphorus life cycle

After processing, the next stage is the production of different products.Fertilizers is the major sector where phosphorus is used for[62].Other sectors include feed additives, food additives,detergents and other industrial uses[63].In the food additives sector,phosphorus is added as preservatives into processed food [64]. They are used as preservatives for different categories of food including meat preparations, cheese products, vegetables, fruits and different kind of beverages [65]. In the feed additives sector, phosphorus is used for production of compound feeds for the livestock. The use of phosphorus in detergents corresponds to the production of sodium triphosphates (STPP) [66]. The production of STPP in Europe is subject to change in the future. Even though there exists STPP production in Europe,there is a serious plan to completely ban the use of this material in detergents and replace it with other detergent builders because of the damage it causes towards surface water.Thus,the use of STPP will no more occur after several years [67]. The trend of the European STPP trade significantly reflects the effect of policies adopted to ban the use of this material in the detergent industry.Trade in this material(exports and imports)has been dramatically decreasing.This process is important in this study particularly because it helps to estimate the contribution of the detergent industry to the European life cycle of phosphorus in the upcoming years.

2.2.3.Phosphorus consumption

The use of phosphorus in agriculture starts from fertilizer production,crop production,agri-commodities,food and human consumption[68].Schoumans et al.[22]show a comparison between 1961-2012 and 2008-2012,when the average consumption of phosphorus fertilizers in Europe (1 kg P2O5per hectare) was 13 and 7, respectively.After the application of fertilizers,a significant amount of phosphorus is lost into aquatic systems while being in the soil.This loss is due to the runoff of fertilizers[69].Throughout the use of phosphorus in the soil,the element drains or leaks because there is a surplus of phosphorus after its required amount is consumed by agriculture[70].Besides the produced compound feed, grass cut and some crops are used as feed for the livestock consumption[71,72].In addition,livestock is an important contributor to the food industry.The amount of phosphorus going for food comes from crops,fishery and animal production.In the EU,some of this food reaches the end consumers,whereas the rest is lost[73].

2.2.4.Phosphorus waste generation

The amount of P in waste comes from food wastes,animal wastes and wastes from households.Food waste originates from six main sectors including primary production, processing, wholesale and retail,food service and households[74].The EU Commission is trying to reduce food waste generation to enhance a circular economy[75].Also,P in wastes comes from human excreta and household waste included in the wastewater stream[76].Waste coming from wastewater goes into a wastewater collecting system that can be divided into urban wastewater collecting systems(UWWCS)and independent wastewater collecting systems(IWWCS)depending on the source of waste.

2.2.5.Phosphorus treatment and recycling

Waste treating is performed differently for different types of waste.Waste from the UWWCS goes to urban wastewater treatment plants(UWWTP),and waste from IWWCS goes to either the UWWTP or the independent wastewater treatment plants(IWWTP).The recycling of P from wastewater is done through treatment operations from WWTP. So far, the main method applied is the anaerobic digestion method [22]. Production of sludge occurs in wastewater treatment plants after wastewater has already been treated.Sludge is disposed in a variety of ways including its use in agriculture. Collected solid waste is immediately treated and then either recycled or used in other applications(e.g.landfilling).Composting is one of the main methods applied for solid waste recycling to obtain necessary nutrients for fertilizers[77].

After the treatment of phosphorus originated from waste,some of them go for recycling.Recycled P is used in fertilizers,where the largest amount of recycled P comes from manure.The recycling processes for manure to agriculture include anaerobic digestion and composting[78].Other sources(wastewater and solid waste)are also considerable sources of recycled P.They contain a considerable amount of phosphorus ranging from 2%to 6%in wastewater sludge and around 4 g of P per 1 kg of total food waste generated[35].Mateo-Sagasta et al.[32]estimate the amount of P2O5included in sludge to be from 1.5%to 4%of dry sludge mass.In sewerage systems,however,where dry sludge is not yet extracted,the concentration of phosphorus ranges from 1 to 2 mg·L-1[79].The recycling of phosphorus takes place through wastewater treatment and recycling of sewage sludge,which is then applied to soil as fertilizer. Phosphorus originating from solid waste is also used in fertilizers[35,80].

2.3.Mathematical formulations

The mathematical representation of the equations is based on the system dynamics model of the P life cycle in the EU.Stocks and flows are so far the foundations of the system dynamics modelling.In system dynamics,a stock(i.e.stock of material)corresponds to an entity that is subject to accumulate or drain with the passage of time.The dynamic behaviour of stock in the period t - t0is given by a time integral of the net inflows of input rate minus the net outflows of output rate.The general mathematical representation of stocks and flows is given by the following equation:

Flows correspond to the rates at which a stock changes at time t.Some flows lead to the increase in a stock (Inflow), while other flows lead to the decrease in the stock(Outflow).The general dynamic behaviour of a flow is given by a time derivative of the amount of units(i.e.material)in the stock at time t.

where x is the amount of units in the stock.In this section,the equations that were used to obtain the graphical and statistical estimations are explained.The complete list of mathematical formulations and equations can be seen in the Supplementary Material(Table S1).

The first activity that occurs in the P life cycle is the mining production from phosphate rock(MR(t)).Mathematical representation of the total imports to the life cycle of phosphorus (TIR(t)) corresponds to the summation of all imports of P into the system.

where,MIR(t)is the mined P import rate,PIR(t)is the phosphoric acid import rate,FIR(t)is the fertilizers import rate,DIR(t)is the detergents import rate,CIR(t)is the crops import rate,FAIR(t)is the food additives import rate,FEIR(t)is the feed additives import rate,LIR(t)is the livestock import rate,AFIR(t)is the animal food import rate,FSHIR(t)is the fish products import rate and IPIR(t)is the iron ores import rate.The cumulative amount of total P imports to the system follows this mathematical formulation:

Material that exits the system boundaries(TER(t))corresponds to the total exports of P at different life cycle stages.The mathematical formulation of the total exports is as follows:

where,MER(t)is the mined P export rate,PER(t)is the phosphoric acid export rate,FER(t)is the fertilizers export rate,DER(t)is the detergents export rate,CER(t)is the crops export rate,FAER(t)is the food additives export rate,FEER(t)is the feed additives export rate,LER(t)is the livestock export rate, AFER(t) is the animal food export rate, FSHER(t) is the fish products export rate and IPER(t)is the iron ores export rate.

In this study, the total recycled material rate (TRR(t)) represents rate of recycled material from solid wastes (SWRR(t)), wastewater(WWRR(t))and manure(MRR(t)).The recycled material rate is given by the following equation:

The total flow of material loss(TLR(t))corresponds to the loss of P from different sources.Those are mining losses(MLR(t)),beneficiating loss (BLR(t)), processing loss (PLR(t)), P runoff from the soil (PRR(t)),animal food loss (AFLR(t)), crops loss (CLR(t)), fish loss (FSHLR(t)),uncollected wastewater (UWWR(t)), and non-treated wastewater(NWWR(t)).

The consumption of phosphorus in the P life cycle is considered through the human consumption of food commodities and laundry detergents.Thus,the mathematical representation of the P consumption in the EU(PCR(t))is as follows:

where FOCR(t)is the total food consumption rate,and DCR(t)is the detergents consumption rate.To determine the reliance of the EU on the P imports, the following mathematical formula which was provided by the EU Commission is used:

2.4.Verification and validation of the model

The verification of the model was done through checkin g each component in the model,its definition,its description and its purpose forthis study.Next,the logic of the flows was investigated.After having all inputs to the developed model, the model was run and analysed simultaneously.

Table 1 Comparison table between historical data(tonne)and model estimations

The aim for the validation of the model is to make sure that the model represents the system under study.In system dynamics,the outputs of the model represent the trend of the dynamic behaviour of the actual system in real life.In this study,the validation method applied is the behavioural validation. The outcomes of the main variables in the system are compared with historical data of the same variables.The aim of this method is to check how closely do model outcomes reflect the real historical data[81].The validation process was conducted by considering three variables;those are feed production,crop production and animal production.The outcomes of the model are obtained and compared with real historical data between the years 2000 and 2015(Table 1).

3.Results and Discussion

The results of the simulation model show a quantitative estimation of phosphorus flows in the EU-28 between 2000 and 2050.These results are based on the current recycling efficiencies in the EU for manure, solid waste and wastewater. Table 2 demonstrates the estimated results of the model regarding the major P flows in the system.

Between the years 2000 and 2015, the results estimate that P imports correspond to the largest P flow to the EU, where mined and processed P corresponds to around 42%of total imports,and fertilizers imports correspond to around 48% of the total P imported. The recycling rates come next to the P imports with around 87% coming from manure recycling, and the rest comes from wastewater and solid waste recycling. The model estimations show that P production mainly comes from fertilizers production (60% of the total P production).The rest comes from feed compounds,food additives and sodium triphosphates production.P exports from the EU are mainly characterized by fertilizers,contributing to around 60%of the total P exported. Around 15% of the total exports come from domestically mined and processed P.The rest(around 25%of total P exports)come from exports of food commodities (crops, fish, livestock, animal dairy),chemical derivatives(feed and food additives)and laundry detergents.The results show a significant loss of phosphorus throughout the P life cycle. This loss is estimated to be around 1.3 Mt P, where around 40% is caused by food, crops and animal production loss,and around 22%is caused by phosphorus runoff from the soil.The loss of P caused by mining,beneficiating and processing of primary phosphorus is estimated around 16%of the total P loss.Households,human wastes, animal wastes and wastewater treatment activities also contribute around 22% of P loss.

Table 2 provides the quantitative estimations of the P flows in a time interval of 50 years(2000-2050).Based on these results,the fertilizer imports continue to be the largest amount among other imports,with around 53%of the total P imports.Around 28%of the total imports is expected to come from mined and processed P.Whereas the rest(19%)comes from imports of detergents,crops,fish,livestock,animal dairy,feed and food additives.The loss of P is estimated to decrease,reaching an average of around 1 Mt P.the model results show that around 53%of P loss comes from crops,food and animal production.The runoff of P from the soil is estimated to cover around 24% of the total material loss.On the other hand,the mining,beneficiating and processing loss is estimated to decrease reaching around 8% of total P loss. The rest of P loss(up to 15%)comes from households,human wastes,animalwastes and wastewater treatment activities.In the upcoming years,the P production is estimated to decrease,having an average of 1.7 Mt P annually. From which around 50% comes from fertilizers production,34% from feed production, 14% from food additives production and the rest comes from sodium triphosphates production. The results of this study show an increase of the total P exports starting from 2016. Up to 57% of total exports comes from fertilizer exports,whereas only around 8% comes from mined and processed P. The rest comes from exports of crops, livestock, fish, detergents, feed and food additives. The recycling of P is estimated to grow in the future,reaching an average of around 2.3 Mt P annually.Manure is estimated to be the largest source of recycled P, with around 89% of the total recycled phosphorus.

Table 2 Model estimations of the major P flows(tonne)in the EU(2000-2050)

Fig. 2 shows the dynamic behaviour of the annual major flows of P by considering the total population and per capita. From 2015 afterwards, the results correspond to the quantitative estimations based on the developed model of the P life cycle in the EU. The imports of P are predominantly the largest flows in the EU. Recycling is the next largest flow of P in the EU. Fig. 2(a) shows a declining trend for the imports and a growing trend for recycling.This can be clearly shown in Fig. 2(c,d) as the cumulative flow of material recycling is growing exponentially.Whereas the cumulative flow of imports shows a logarithmic growth. The year-by-year change of the annual P consumed is considerably stable compared with other flows of P in the EU.The P consumption is primarily related to the population growth in the EU.Although the estimation of P mined shows an increasing trend,the mining activities are not enough to cover the P demand in production and consumption,as can be shown from Fig.2(a,b).Fig.2(c,d)shows the growing gap between different P flows in the EU.There is a growing difference between the amount of P loss and the P consumption.This gap has been addressed by Withers et al.[24]because of inefficient use of P.Therefore,policies on reducing the material loss are recommended.Considering food losses from the food supply chain,there is a potential to decrease waste losses from the food chain to a significant level by changing the consumption behaviour and food chain adjustments[13].In addition, reducing P losses from fertilizer runoff helps in dealing with the total loss in the life cycle stages.P loss from fertilizer runoff has been already discussed in several researches[36,82-84].Suggestions have been made to treat P rich soils and to regulate the application of fertilizers to the soil[36,84].

4.Improving Recycling Outputs

Higher recycling rate is probably the best solution to handle the phosphorous challenge in Europe[85].As shown in other works,there are many possibilities for recycling waste and by-products,including animal manure,human excreta,food waste,crop losses,and sewage sludge [41],which were presented in other works. For example, the scale of P recovery in wastewater treatment plants was analysed in detail by Schoumans et al.[22].The comparison of 19 relevant P recovery technologies was discussed in detail by Egle[86].Moreover,different possible processes and technologies for obtaining P from recycling were discussed by a range of studies[22,24,35,87].There are several options to recover P.However,many techniques still have to be tested in practice at pilot and full scale,especially those for recovering P from manure[22].In this paper,we do not make any statement regarding the likelihood of technology implementation or the costs associated with the different recycling options.The technological and economic evaluation of phosphorus recovery has been carried out by other researchers[86,88].

Fig.2.Estimations of the major P flows from 2000 to 2050.(a)Annual flows.(b)Annual per capita flows.(c)Cumulative flows.(d)Cumulative per capita flows.

4.1.Scenario development

Several studies have shown the significance of improving P recycling to lessen the dependency on phosphate rock extraction.The continuous emergence of new technologies shows the significance of improving P recycling [53]. This improvement can be done on the various P recovery sources [54]. In the EU particularly, improving the quality of P recycling is one of the potential options to resolve the concerns on the European phosphorus life cycle. This includes the implementation of new technologies to remove P from household wastes and improving the quality of manure treatment and separation[24]. Moreover, Cooper and Carliell-Marquet [34] suggested that reducing the reliance on imports of fertilizers can be done through developing new methods for recycling manure, food waste and sewage sludge.

The need to develop and establish new technologies for phosphorous recovery has been identified in many works[89-91].The feasibility of achieving a higher rate of P recycling has been studied by several authors,e.g.Shu[88]and Cordell[92].In Europe,the recycling of phosphorus from waste streams is low.For example,about 37%of P in municipal sewage sludge is currently recovered and reused in agriculture [25].New processes and technologies to recover phosphorus from surplus manure are under development in the Netherlands[93].In Sweden,it is anticipated that improving P recycling is one of the main solutions to meet at least 30% of future demand [92]. Based on the survey by the Stockholm Environment Institute (SEI), the current reliance on imported rock-based phosphorus (‘3 kg P per European citizen per year’)cannot be continued for a very long time.They suggested that for achieving sustainability in each step of the agriculture and food supply chain,the efficiency of phosphorus use must approach a level close to 100%. Therefore,there should be recommended a full recycling of phosphorous in Europe[94].

The scenario-based approach has been deployed by Mourad et al. [95] to determine the impact of recycling on greenhouse gas emissions through applying different recycling scenarios. Evaluation of various recycling scenarios was also performed by Giannis et al. [96]. They assessed alternative strategies for solid waste management by implementing a system dynamics model. In this study,modifications to the model include three different scenarios for improving recycling by: 15% (Scenario A), 30% (Scenario B) and 45%(Scenario C). These scenarios take into consideration the current recycling output of P from solid waste, wastewater and manure.The main reason for considering these values is the technological possibilities of phosphorus economic recycling. The recently introduced technologies, e.g. struvite fertilizers [97,98], allow obtaining phosphorous recycling at the level of 15%. Therefore, it is probable that economic recycling of phosphorus reaches the 50% level in the next 12 to 15 years[99].

4.2.Results after application of scenarios

The improvements in recycling applied to the model are the same in each scenario because recycling efficiencies are modified with the same proportion by adding 15% after each iteration. Improving recycling streams of the P life cycle in the EU lessens the dependency on P imports to a certain extent. Fig. 3 shows the changes on the annual P flow following the different scenario applications. The annual flow of P recycling increases after each scenario by around 335000 t P(Fig. 3(a)). Consequently, the annual P imports decrease by the same proportion following the increase of P recycling(Fig.3(b)).The analysis of the flow estimations in different scenarios shows that in scenario A,the annual imports still exceed the annual P recycled, with an average amount of imports more than P recycled by around 65000 t P. In scenario B, the annual P recycling rate is estimated to exceed the annual imports starting from the year 2016. This improvement continues in scenario C.

Fig. 4 shows the estimated results of P cumulative flows with current recycling outputs and under developed scenarios in a time range of 50 years (2000-2050). Fig. 4(a) corresponds to the cumulative P flow estimations given the current recycling efficiencies. Fig. 4(b,c)illustrates the effect of recycling improvement in a longer perspective.Despite the significant increase of P recycling in scenarios A and B,the total P imports are still contributing more material to the P life cycle in the EU following a logarithmic growth. In scenario C, the annual increase on P recycling is estimated to reach around 1 mt P.Considering this growth in recycling, the cumulative amount of P recycled is subject to exceed that of the total P imports following an exponential growth. This result is possible given a long time horizon of 50 years (Fig. 4(d)).

Several techniques and methods for improving P recovery and recycling have been discussed in the literature. Guedes et al. [100]and Schütte et al. [101] show techniques related to the P recovery from sludge, such as electrodialytic process and nanofiltration.Methods on P recovery from wastewater has been also discussed.Enhanced biotechnological approaches for the P recovery from wastewater is an efficient process and can be utilized [87]. In addition,Kalmykova and Fedje [35] illustrate the acid and base leaching precipitation procedures to obtain P from solid waste incineration residues.

Fig.3.P annual flow estimations,with current recycling efficiencies and in different scenarios.

Fig.4.Cumulative P flow estimations for recycling and imports in the EU(2000-2050)with current recycling efficiencies and in different scenarios.

4.3.The EU reliance on imports

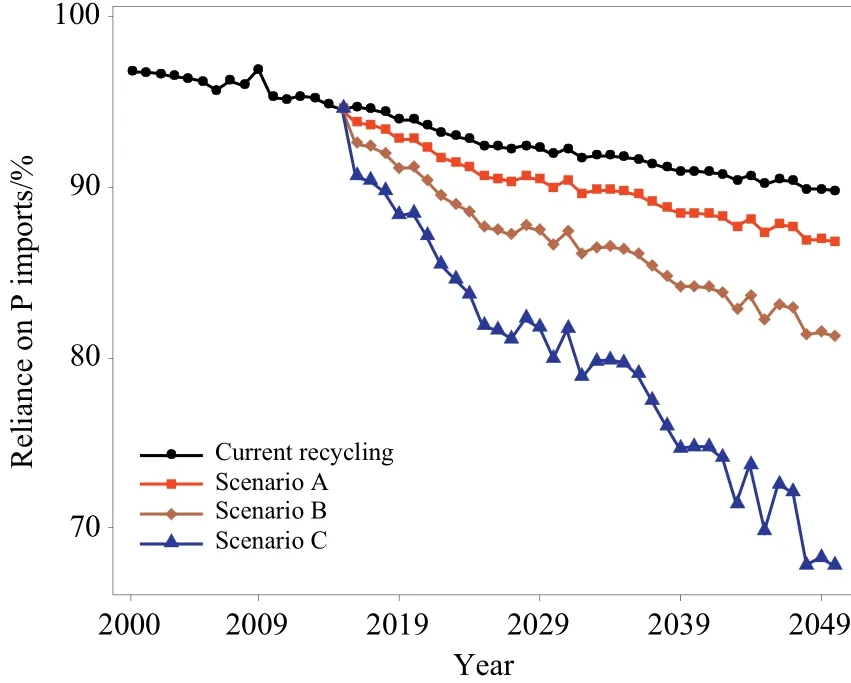

The results of this study go side by side with previous studies that show the high reliance of the EU on the P imports. The main aim of the EU is to lessen the reliance level on the P imports.The model estimates the dynamic behaviour of the reliance percentage with thepassage of time by considering equation 9.These estimates are given under the two periods,historical period(2000-2015)and future period(2016-2050).The model estimations on P import reliance are shown in Table 3.This includes estimations given current recycling efficiencies,and estimations given the different scenarios.Between the years 2000 and 2015,the results of the model show a decreasing trend in the reliance percentage on P imports.This decreasing trend is estimated to continue with all given scenarios from 2016 to 2050(Fig.5).

Table 3 Percentage of the EU reliance on P imports

Fig.5.Estimations for the EU reliance on P imports in different scenarios.

Currently,the model estimates the reliance percentage on P imports is around 96% between 2000 and 2015.By considering the historical data for the developed model,the model also shows that this percentage decreases with the passage of time between 2016 and 2050,with an average of 92%(Table 3).With the application of scenarios,this percentage decreases more to 90%,86%and 79%in scenarios A,B and C respectively.

The results of this paper support previous studies on the European phosphorus balance. Our calculations indicate a high inefficiency in the phosphorous supply chain with around 1.3 million tonnes (Mt)phosphorous lost in 2005.Previous studies e.g.Dijk et al.[14]estimated 1.22 Mt phosphorus loss in the same year.The total trade balance of phosphorus was estimated to be around 2.1 Mt in 2005.In our study,the trade balance of phosphorus reaches up to 2.8 Mt in the same year.The results of this study show an average of 86%reliance on phosphate rock between the years 2010 and 2014,compared with a reliance of 88%based on a report by the EU Commission considering the same time interval[11].Overall, the obtained results confirm previous research indicating a high dependency on P imports and a high inefficiency of the European phosphorous supply chain[22,44].

The EU Commission has already presented the reliance level[11].However,this corresponds particularly to the trade of phosphate rock.The results presented in this study determine the overall reliance level on P imports to 28 member countries of the EU by considering multiple sectors,including mining,processing of phosphorus into phosphoric acid, agriculture production, and detergents production. Our model could be useful not only to inform policy makers about the current situation of P recycling,but also to explore new options for further improvements of phosphorous recovery.It quantifies the potential impact of future developments in recycling technology on the phosphorous supply chain.

4.4.Limitations of the study

The limitation of the study is lack of the detailed analysis of white phosphorus(P4)flow.At present,phosphate rock is the only primary input material for phosphorus production [102]. Based on the study by the EU Commission [11] on the list of critical raw materials, P4 is an elemental form of phosphorus, produced from phosphate rock. The EU does not produce P4. Therefore, white phosphorous was not analysed in the EU study on critical raw materials in years 2011 and 2014. In consequence, there is not enough available data for a detailed analysis of its flow. Another limitation of this study is lack of the technical and economic assessment of technologies for improvement of phosphorous recycling as well as their environmental impact. These limitations are being addressed in research currently underway.

5.Conclusions

Due to the risk associated with the main source of the supply of phosphorus(phosphate rock)and its growing economic importance,recycling is considered one of the options to decrease the supply risk as much as possible,especially in Europe,the region that lacks the phosphate rock reserves.The aim of this study is to calculate the current level of recycling through the various waste streams (solid waste, water treatment and manure) and to estimate the enhancement degree of this level,which impacts on the criticality of the element P in Europe.To quantify the effects of recycling efficiency, a system dynamics model was constructed and applied to analyse different scenarios.The results show that with improving recycling, there is a potential to reach an annual decrease of around 1 million t P from total P imports.This achievement can lessen the EU reliance on imports from 96%to around 79%. Results of this study may potentially bring decisionmaking to a continental scale where decisions are designed to face the challenge of phosphorus supply chain in Europe. Consequently, it helps to tackle the problem of dependency on imports of phosphorus and the continuous resource extraction.

Supplementary Material

Supplementary data to this article can be found online at https://doi.org/10.1016/j.cjche.2018.09.004.

Chinese Journal of Chemical Engineering2019年5期

Chinese Journal of Chemical Engineering2019年5期

- Chinese Journal of Chemical Engineering的其它文章

- Assessment of the TFM in predicting the onset of turbulent fluidization☆

- CFD study on double-to single-loop flow pattern transition and its influence on macro mixing efficiency in fully baffled tank stirred by a Rushton turbine☆

- Simulation of drop breakage in liquid-liquid system by coupling of CFD and PBM:Comparison of breakage kernels and effects of agitator configurations☆

- Heat transfer characteristics of molten plastics in a vertical falling film reactor☆

- Stabilizing silica nanoparticles in high saline water by using polyvinylpyrrolidone for reduction of asphaltene precipitation damage under dynamic condition

- Numerical simulation and experimental study on dissolving characteristics of layered salt rocks