A heuristic design method for batch water-using networks of multiple contaminants with regeneration unit☆

Aihong Li,Changzhan Liu,Zhiyong Liu*

1 Department of Chemical Engineering,Chengde Petroleum College,Chengde 067000,China

2 School of Chemical Engineering,Hebei University of Technology,Tianjin 300130,China

Keywords:Water-using network Batch process Regeneration Optimal design Wastewater minimization

ABSTRACT This work develops a heuristic method for the design of batch water-using networks of multiple contaminants with regeneration unit based on the concepts of concentration potential.A water-using network involving regeneration unit can be formed by adding the regenerated stream(s)into the network involving reuse only.In the design procedure of the network operated in a single batch mode,time is taken as the primary factor and concentration potentials as the secondary one.For the networks operated in a repeated mode,the design procedure is similar to that for continuous processes,besides designing the storage tanks with the rules proposed.Continuous regeneration unit is selected in this work.With the proposed method,the network structure corresponding to the minimum freshwater consumption can be obtained.It is shown that the method proposed in this article is simple,effective and has clear engineering meaning.

1.Introduction

For the integration of water systems,most of the early research work focused on continuous processes.The main reason is that continuous processes consume much larger amount of freshwater and generate the corresponding amount of wastewater.In fact,it is also very important to develop water integration techniques for batch processes due to the following reasons[1].First,batch processes are usually poorly designed for the lack of generic design methodology. Second, batch processes are becoming more active due to the growing demand for fine and special chemicals.Third,batch processes will generally produce more amount and higher toxicity wastewater than their continuous counterparts.In designing a continuous water-using system,contaminant concentration is the main constraint. In designing a batch one,apart from concentration constraint,time constraint needs to be considered simultaneously. Therefore, the research on the integration of batch water-using processes is more challenging than that of continuous processes. Regeneration units have commonly been introduced into continuous water networks for wastewater minimization[2]. It is essential to extend the approaches developed for the continuous water-using networks with regeneration units to batch processes.This work mainly discusses the integration techniques for water-using systems with regeneration unit in batch processes.

For the synthesis of continuous water-using networks, there are mainly two kinds of methods:pinch analysis methods and mathematical programming methods.For the systems discussed in this work,due to the inherent complexity in simultaneously considering both time and concentration constraints,as well as the introduction of regeneration unit,the pinch-based methods are not often used,even for the systems of single contaminant.Foo et al.[3]extended water cascade analysis technique,which was originally presented for targeting and designing continuous water networks[4], to batch total resource conservation networks.

Mathematical programming methods are the preferred design approaches for the batch water-using networks with regeneration unit.Liu et al.[5]proposed a superstructure for discontinuous waterusing networks of single contaminant,in which one central continuous regeneration unit was involved.They established mathematical models under the framework of continuous time representation and presented a two-step solving strategy. Shoaib et al. [6] provided a three-stage procedure to sequentially minimize the consumption of freshwater,the number of tanks,and the number of network interconnections for the batch water systems of single contaminant.Finally,the placement of a regeneration unit was discussed based on the insights obtained from pinch analysis.Lee et al.[7]extended the work of Shoaib et al.[6]to the systems of multiple contaminants involving mass-transfer and non-mass transfer operations, in which the optimization procedure increased to four steps.

El-Halwagi and his coworkers initiated a property-based synthesis of water networks. For the synthesis of batch water networks with interception devices, Ng et al. [8] built a source-tank-interception-tank-sink superstructure and formulated it as a mixed integer nonlinear programming(MINLP)model.By solving the model,they obtained a network with minimum total annualized cost.Chen et al.[9]presented a unified model for the synthesis of property-based batch and/or continuous resource conservation networks.In the model,the material reuse/recycle,interception, and waste treatment were all taken into consideration.

Tokos and Pintarič[10]optimized the water network of a brewery plant by installing on-site batch or semi-continuous regenerators based on the model of Kim and Smith[11].Tokos et al.[12]extended the superstructure of Tokos and Pintarič[10]to total water network with changing daily production schedule.To solve the large-scale industrial problem,they presented two alternative multilevel strategies by means of temporal decomposition.

Adekola and Majozi[13]developed a method for wastewater minimization of multi-contaminant batch water networks with a regenerator.The method did not require the production schedule to be given beforehand. A two-step procedure proposed by Majozi and Gouws[14]was used to solve the MINLP model of the system.Dong et al.[15]presented a modified state-space superstructure for the synthesis of batch water networks with multiple regeneration modules. They adopted a rule-based solution strategy to reduce the computation complexity.

It can be seen from the above discussion that the research on the synthesis of batch water-using networks with multiple contaminants involving regeneration unit is relatively less than the research on that of continuous water-using networks. Mathematical programming methods were generally adopted to study this topic. However, the mathematical models established are usually very complex and global optimal solutions might not be guaranteed. If much simpler models are taken, although global optimal solutions might be obtained, the practical significance of the solutions will be weakened.The purpose of this article is to provide a design method which is simple and has clear engineering meaning for the batch water-using networks of multiple contaminants with regeneration unit.The new method is developed based on the concepts of concentration potential proposed by Liu et al.[16]for multi-contaminant water networks and a simple insight of Liu et al.[17]on the water systems involving regeneration units.Both Liu et al.[16,17]were originally proposed for continuous processes.

A batch plant can run in a single batch mode or in a repeated mode.For a system operated in a single batch mode,the wastewater produced at a later time cannot be reused by a process even if the concentration of the wastewater is lower than the limiting inlet concentration of the process[1].Therefore,time should be taken as the primary factor and concentration as the secondary one.For a system operated in a repeated mode,the design procedure is similar to that for continuous processes,besides designing the storage tanks with the proposed rules.The continuous regeneration unit is selected in this work.Two examples will be investigated to show the design procedure proposed.

2.Problem Statement

Given are the following information:(i)the limiting inlet and outlet concentrations and the removed mass loads for every water-using process, (ii) the predetermined production schedule or the duration for every water-using process,(iii)the regeneration units running in continuous mode and being installed storage tanks before and after the regeneration units,and(iv)the regeneration units can be modeled by either the fixed regenerated concentration(RC)or the fixed removal ratio(RR)type.

Assume that: (i) the contaminant concentration of freshwater is zero,(ii)there is no water loss in water-using processes and regeneration units,and(iii)the maximum inlet concentrations of regeneration units are not constrained.

The objective is to (i) minimize the freshwater consumption,(ii)minimize the number and capacity of storage tanks,and(iii)determine the production schedule for water-using processes,if necessary.

3.The Concepts of Concentration Potential

Liu et al.[16]proposed the concepts of concentration potential based on the overall allocation possibility of source(outlet)streams to demand(inlet)streams analogous to the systems of single contaminant.The maximum quasi-allocation ratio Ri,j,defined in Eq.(1),reflects the possibility of 1 ton of demand Djto reuse source Si.The contaminant that determines the value of Ri,jis called as the reuse key contaminant(RKC).The concentration potential of demand Dj,CPD(Dj),is defined as Eq.(2)and the concentration potential of source Si,CPS(Si),as Eq.(3).

The order of concentration potentials agrees with that of conventional concentrations[16].In the design procedure,the value of CPD will be used as an important factor in identifying the precedence order of the processes.The value of CPS will be used as an indicator to select the sources to be regenerated.

Li et al. [18] applied the concentration potential concepts to the design of batch water-using networks involving reuse only.By manual calculation, Li et al. [18] obtained the results that are comparable to those obtained by mathematical programming methods.

4. Design Procedure for the Water-using Networks Operated in a Single Batch Mode

For the water-using networks with regeneration units,Liu et al.[17]obtained an insight that the difference between a network involving regeneration reuse and a network involving reuse only is that there is one or a few additional sources,the regenerated streams,in the former network.If the flow rates and concentrations of the regenerated streams can be determined and the regenerated streams are added into the network involving reuse only,the network involving regeneration reuse can be formed and then be designed with the methods proposed for the network involving reuse only.This insight has been applied to the design of continuous water networks involving regeneration reuse[17],regeneration recycling[19],the regeneration recycling systems with internal water mains[20],and the hydrogen systems involving regeneration reuse[21].In addition,the insight contributed to solving the MINLP model formulated for the water networks involving regeneration reuse/recycling[22].

In this section,a three-step procedure based on the insight of Liu et al.[17]will be introduced to design a water-using network operated in a single batch mode. The network involving reuse only is first designed.Then,the flow rate and concentrations of the regenerated stream are estimated. Finally, the design of the network involving regeneration reuse can be obtained.

4.1.Designing the network involving reuse only

4.1.1.Determination of the precedence order of water-using processes

The schedule-related constraint should be given higher priority in determining the precedence order of the processes for the integration of a water-using network operated in a single batch mode. The processes will be performed in the order of their start moments.

(a) If the production schedule is given,the precedence order can be determined by the start moments of processes directly.

(b) If the production schedule needs to be assigned according to the principle of maximizing wastewater reuse,such as Example 1,the precedence order should be determined by combining the start moments and the CPD values.

To be specific,when a few processes can be performed within the same time period,the process with the lowest CPD value is performed first.Furthermore,if several processes have the same CPD values,the process with the lowest CPS value will be performed first to provide high-quality internal source(outlet stream of a process)for the downstream processes[16].

4.1.2.Allocation of source streams to demand streams

Similar to the determination of precedence order,time has priority in allocating source streams to demand streams as well.

(a) Only the sources produced before the start moment of a process can be listed as the reuse candidates for the process.Before the first internal source is produced,only freshwater can be used.The minimum freshwater consumption for satisfying demand Djis calculated with Eq. (4),where mkremis the removed mass load of contaminant k in Djandis the limiting outlet concentration of contaminant k in Dj. The contaminant that determines the value ofis called as the freshwater key contaminant(FKC)[16].

(b) When the time constraint can be met, the allocation rules of

source streams to demand streams in designing batch networks involving regeneration reuse are identical to those in continuous networks[19].They are briefly stated as follows:

· When satisfying Dj,the source with the largest Ri,jvalue should be reused first. If a few sources have the same Ri,jvalue, the source with the largest CPS value should be used to save the freshwater consumption of downstream processes.

· If the RKC and the FKC are the same contaminant,and the concentration of this contaminant in a source is not lower than the limiting outlet concentration of Dj,the source should not be reused and freshwater is used solely,because the freshwater consumption cannot be reduced by reusing the source[16].

· If a few sources meet the condition of Ri,j>1,reuse the source with sufficient flow rate.This can simplify the network structure.

· When Djcannot be satisfied by one single source,select the next one according to the same rules,till Djis satisfied totally.

4.1.3.Design of storage tanks for reuse

If source Siis selected to satisfy demand Djand the discharge moment of Sidoes not coincide with the charge moment of Dj,a storage tank is required to meet the time constraint.The design principle is to reduce the number and capacity of storage tanks.

(a) For a system with flexible production schedule,make the charge moment of Djcoincide with the discharge moment of Sias much as possible.

(b) Use the shared tank, in other words, the tanks with nonoverlapping storing period can be merged into one.

(c) Although a storage tank is not empty,if the original wastewater in the tank and the wastewater to be discharged to the tank will be reused to the same processes, they can certainly be mixed in the tank.

4.2.Estimating the flow rate and concentrations of regenerated stream

For the regeneration unit modeled as the fixed RC type,the regenerated concentrations are known,and the flow rate of regenerated stream will be determined as discussed in Section 4.3.For the regeneration unit modeled as the fixed RR type,the flow rate and concentrations of regenerated stream need to be estimated before iteration.

To estimate the flow rate and concentrations of regenerated stream in a continuous water network,Liu et al.[17]divided the whole network into the subnetwork before regeneration and that after regeneration according to the concentration characteristics of water-using processes.By designing the subnetwork before regeneration, the flow rate and concentrations of the regenerated stream can be obtained.Similar to the method of Liu et al.[17],this work divides the whole batch water network into the subnetwork before regeneration and that after regeneration,with time as the primary factor and concentration characteristics as the secondary factor.

In the design procedure, the sources are listed in the order of their production moments first. The processes ranking close to the top of the source-list are classified as the subnetwork before regeneration, and those close to the bottom as the subnetwork after regeneration. For a process in the middle of the source list, if its inlet concentrations are lower,it usually needs to use regenerated stream and therefore is classified as the subnetwork after regeneration;if its outlet concentrations are higher, it usually needs to be regenerated and therefore is classified as the subnetwork before regeneration.The division of subnetworks is shown in Fig.1 and will be illustrated in detail in Example 1.

Then,the un-reused sources from subnetwork before regeneration are selected in the increasing order of CPS values.In the first iteration,the flow rate of the regenerated stream(Fr0eg)is unknown,the sources which are suitable for regeneration will be regenerated, with some“outlier”of high concentrations being excluded[19].Then,the regenerated concentrations of contaminant k, Cre0g,k, can be obtained with Eq.(5),where Cin0,kis the concentration of contaminant k at the inlet of regeneration unit.

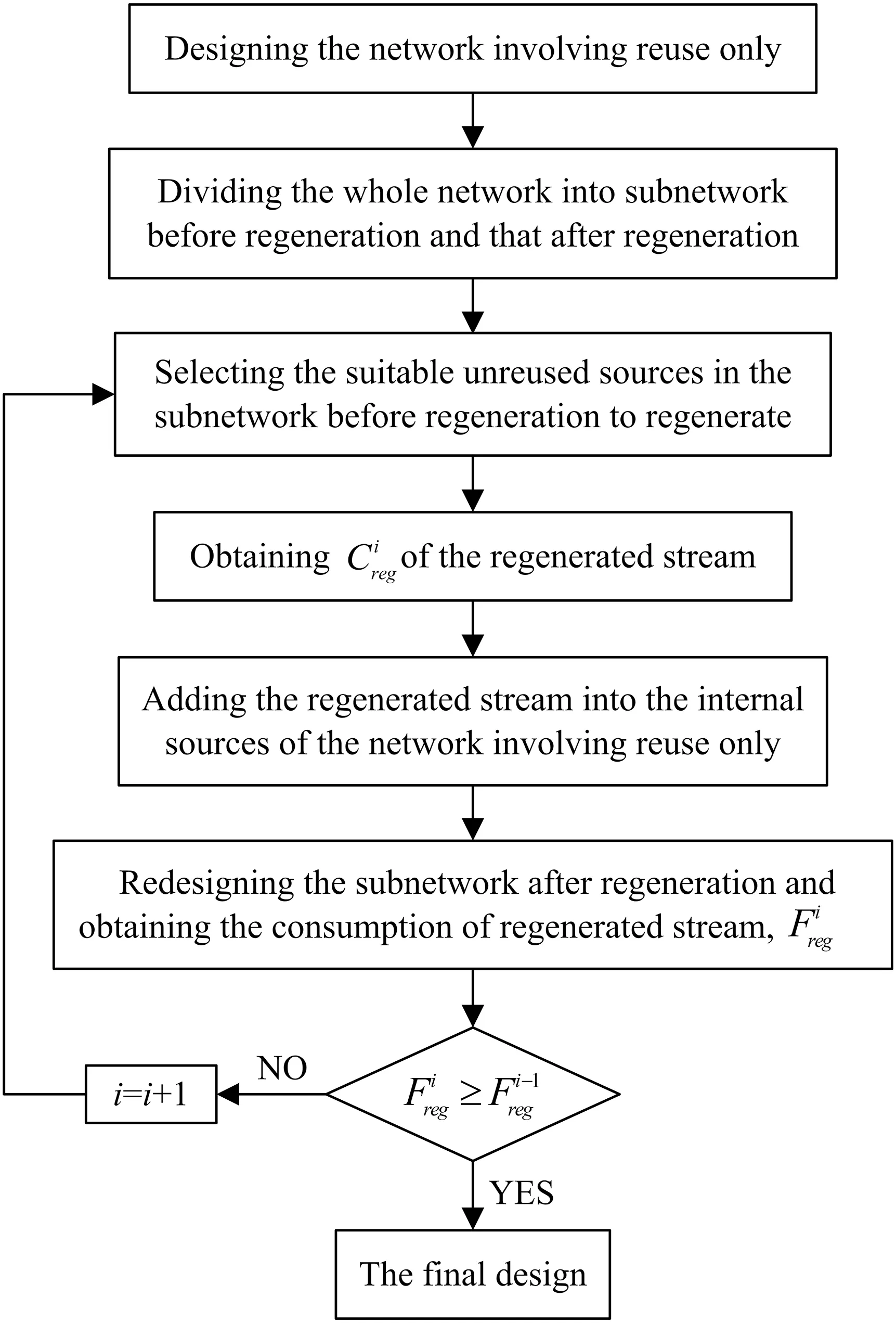

4.3.Obtaining the network involving regeneration reuse

The network involving regeneration reuse can be formed by adding the regenerated stream into the internal sources.The subnetwork after regeneration should be redesigned with the method for the network involving reuse only described in Section 4.1.When iteration i is finished, if the consumption of regenerated stream, Frieg, is equal to or larger than Frieg-1,which means that the un-reused streams are fully utilized,the network obtained is the final design;if Friegis less than Frieg-1,which means that the regeneration amount is surplus and might lead to higher regenerated concentrations, the freshwater consumption will therefore be increased.In this case,take the flow rate of regenerated stream obtained in the current iteration as Frieg+1,reselect the sources to be regenerated and do the next iteration,till Frnegis equal to or larger than Frneg-1.The design procedure discussed above is shown in Fig.2.

Fig.1.The division of subnetworks for the water-using networks operated in a single batch mode.

Fig.2.Design procedure for the water-using networks operated in a single batch mode.

5.Design Procedure for the Batch Water-using Networks Operated in a Repeated Mode

Foo et al.[23]pointed out that wastewater can be reused between adjacent batches by intermediate storage tanks.Thus,the integration of the batch water-using networks operated in a repeated mode can be similar to that of continuous water networks.Based on the insight of Liu et al.[17],Pan et al.[19]proposed an iterative method to design the continuous water-using networks involving regeneration recycling.This article adopts the method of Pan et al.[19],combining the rules for setting storage tanks proposed in Section 4.1.3, to design the batch water-using networks operated in a repeated mode.The detailed procedure will be illustrated in Section 6.2.

6.Case Studies

6.1.Example 1

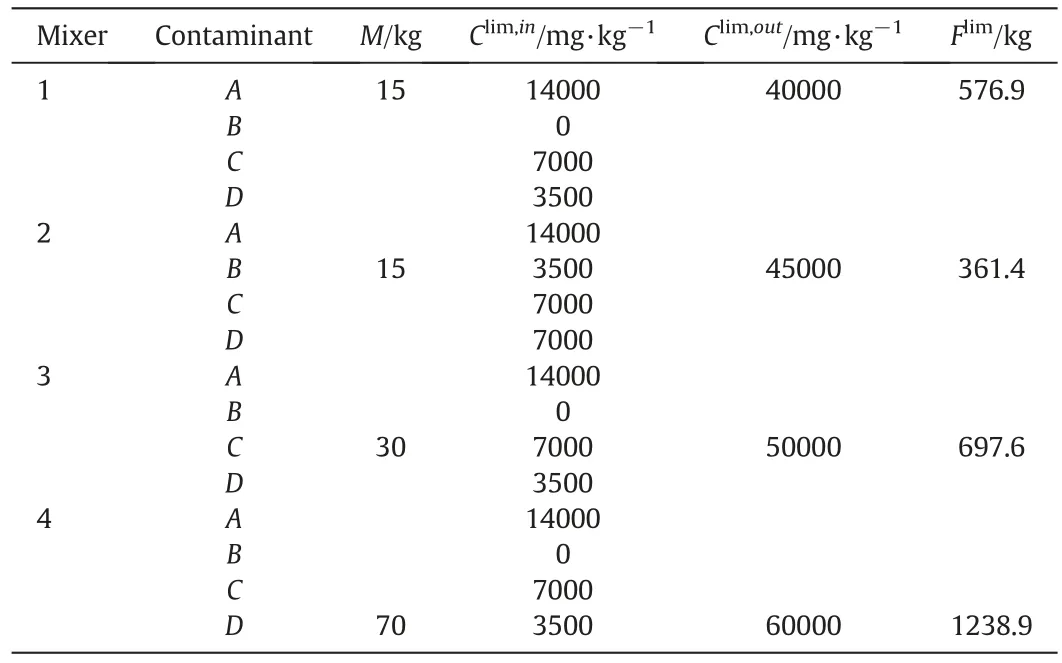

This example taken from Adekola and Majozi[13]shows the design of the networks of flexible schedule and regeneration unit with fixed RR model.Four mixers produce products A,B,C and D,respectively. The production duration and the number of batches in 24 h(24 h is considered as a production cycle)are shown in Table 1.In this example,only the water used for washing mixers is considered.Once each batch of production has been completed,the washing of mixer to remove residual product (contaminant) takes 0.5 h. The charge and discharge of washing water are supposed to be finished instantly.The contaminant loads(M)and the limiting inlet and outlet concentrations are shown in Table 2.The RR values of regeneration unit for contaminants A,B,C and D are(95%,99%,96%,98%),respectively.

Table 1 Production data for Example 1

Table 2 Limiting data for Example 1

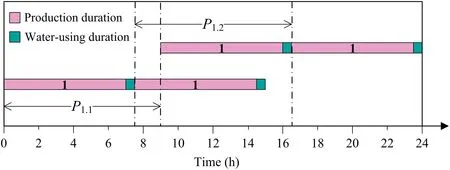

In this example,the different batches of the same product in 24 h are considered as the separate water-using processes.For example,there are processes P1.1and P1.2in Mixer 1,the inlet stream of P1.1is denoted as D1.1and the outlet stream as S1.1.The design procedure is as follows.

6.1.1.Designing the network involving reuse only

Fig.3.The boundaries of the start moments of processes in Mixer 1 for Example 1.

Determine the start moment of every water-using process.Because the production schedule is not given directly, the boundaries of the start moment of every process need to be determined first based on the number of batches,the production duration and the washing duration.For example,in Mixer 1,as shown in Fig.3,for P1.1,the earliest start moment is 0.0 h and the latest start moment is 9.0 h;for P1.2,the earliest start moment is 7.5 h and the latest start moment is 16.5 h.Similarly, the boundaries of the start moments of other processes can be determined,as listed in Table 3.Because water is only used for washing equipment in this example, the start moment of a process(e.g., 0.0 h for P1.1) plus the production duration (7 h) is the water charge moment of the process(7.0 h),and continually plus the washing duration(0.5 h)is the water discharge moment(7.5 h).

Table 3 The boundaries of the start moments of processes for Example 1

Determine the first process to be performed. It can be seen from Table 3 that P1.1,P2.1,P3.1,and P4.1can be performed at 0.0 h.Therefore,the CPD values of the four demands need to be calculated. The CPD value of D1.1is the lowest, thus P1.1should be performed first. The freshwater consumption is 375 kg and the outlet concentrations are(40,000,0,0,0)mg·kg-1.

Calculate the CPD values of P2.1,P3.1,and P4.1based on S1.1.The values of the three processes are the same,thus their CPS values need to be calculated.Process P3.1,whose CPS value is the smallest,should be the second process to be performed. Because the production duration of Mixer 3(11 h)is longer than that of Mixer 1(7 h),D3.1can reuse S1.1in terms of time.The flow rate of D3.1is determined by contaminant C, and the concentration of contaminant C in S1.1is 0 mg·kg-1.Therefore,the reuse amount of D3.1is the same as that when it only uses freshwater,i.e.600 kg.The reuse amount of S1.1to D3.1is 210 kg,D3.1thus still consumes freshwater 390 kg.

Similar to P3.1,P4.1is identified as the third process to be performed.It reuses the remnant S1.1(165 kg)and 163.3 kg of S3.1,and consumes 838.4 kg of freshwater.

Process P2.1is obviously the fourth process.Now,the exact production schedule of the performed processes have been able to be determined. The latest start moment of P2.1is 6.0 h, as can be seen from Table 3. Correspondingly, the latest water-using moment of P2.1is 11.5 h(6.0+5.5=11.5).This moment should be set as the discharge moment of P3.1to facilitate the direct reuse of S3.1to D2.1. It can be inferred that the water-using moment of P3.1is 11.0 h and the start performing moment is 0.0 h. According to the water-using moment of P3.1, combining with the stream allocation determined, the exact production schedule of the performed processes can be obtained:the discharge moment of P1.1is 11.0 h, and the water-using moment of P4.1is 11.5 h.In addition,it can be known from the performing moment of P2.1that the start moments of P2.2and P2.3are 12.0 and 18.0 h,respectively.

According to the above production schedule obtained,D2.1can reuse S3.1but cannot reuse S4.1.Demand D2.1reuses 41.2 kg S3.1and consumes 292.1 kg freshwater.

The performing of the rest processes is similar to those discussed above.The network involving reuse only is shown in Fig.4.The freshwater consumption is 3405.2 kg,which is 5.07%lower than the result(3587 kg)of Adekola and Majozi[13].

The storage tanks for reuse needs to be designed.A tank(Tank 1)is required to store 165 kg of S1.1and drain it to D4.1at 11.5 h.Thus,Tank 1 is empty when S3.1is produced at 11.5 h. For S3.1, a total of 245.7 kg needs to be stored and will be reused to D2.2, D1.2, D4.2and D2.3at 17.5,22.5, 23.0 and 23.5 h,respectively.Similarly,Tank 2 can be designed for S4.1. The water storage situation in Tanks 1 and 2 is shown in Fig.4.

6.1.2.Designing the network involving regeneration reuse

Firstly,the whole network needs to be divided into the subnetwork before regeneration and that after regeneration. Table 4 lists the sources ranked in the order of their production moments: the processes listed close to the top of Table 4,P1.1to P2.2,are classified into the subnetwork before regeneration and the rest into the subnetwork after regeneration.Then,the sources to be regenerated in the subnetwork before regeneration should be identified: S1.1has very low concentrations and has been reused totally; S2.1and S2.2should be discharged to the wastewater treatment system because they contain contaminant B which is not permitted at the inlet of other processes; thus, un-reused S3.1and S4.1are identified as the sources to be regenerated.The consumption of the regenerated stream is 1482.1 kg and the regenerated concentrations are(457,0,691,913)mg·kg-1.

Add the above regenerated stream into the sources and redesign the subnetwork after regeneration. Demand D1.2is totally satisfied by the regenerated stream and the consumption is 379.3 kg.Demand D4.2reuses all of S1.2and 805.4 kg of regenerated stream.Demand D2.3reuses 34.4 kg of S4.2, the remaining regenerated stream (297.4 kg),and still needs to consume 1.54 kg of freshwater. The regenerated stream being used up,the result obtained is the final design,as shown in Fig. 5. The final inlet and outlet concentrations in each mixer are shown in Table 5.The flow rate of regeneration unit is 61.754 kg·h-1.The freshwater consumption of the network involving regeneration reuse is 2150.2 kg,which is 18.97% lower than the result of Adekola and Majozi[13](2653.5 kg).

Fig.4.The network involving reuse only for Example 1(where the numbers are the amount of water in kg).

Compared to the network involving reuse only,the introduction of a regeneration unit with RR of(95%,99%,96%,98%)reduces freshwater consumption by 36.85%.The comparison of the results obtained in this work and those of Adekola and Majozi [13] is listed in Table 6. The reasons why this work can reduce the consumption of freshwater is:(a)increasing the chance of direct reuse by adjusting the performing time of some processes,for example,arranging the discharge time of P1.2as the charge time of P4.2can reuse 379.3 kg S1.2to D4.2;(b)saving high-quality sources for downstream processes,for example,reusing part of S1.1for D3.1and the reminder for D4.1. It can be seen from the above design procedure that the method proposed is simple and effective.

Table 4 Division of subnetworks for Example 1

6.2.Example 2

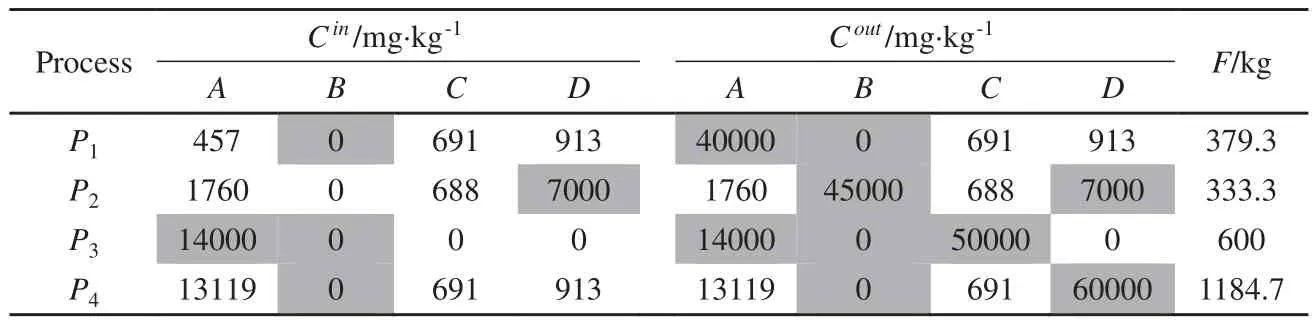

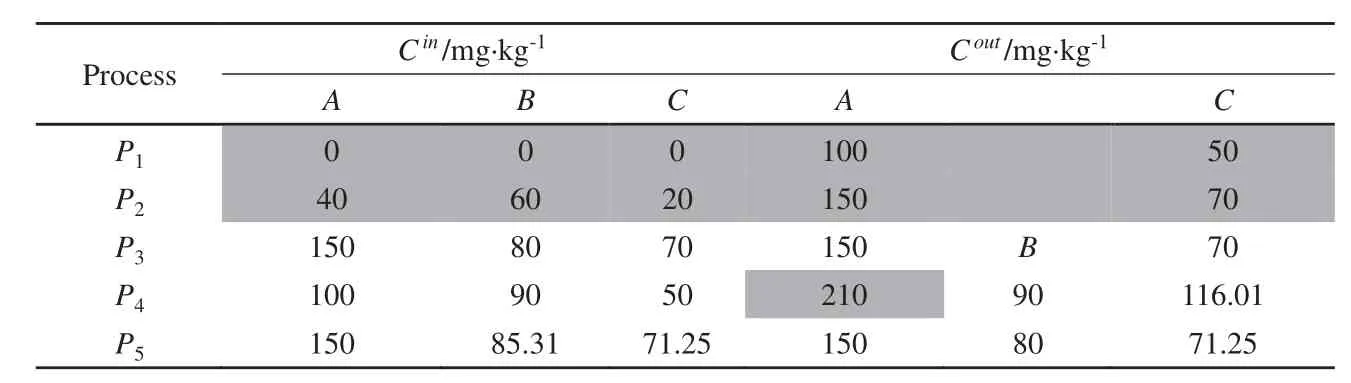

This example taken from Li et al.[18]is intended to illustrate the design of the networks of fixed production schedule and the regeneration unit with fixed RC model. The batch water network is operated in a repeated mode.The limiting data for one production cycle is listed in Table 7. Processes 1, 2, and 4 are fixed mass-load operations, and processes 3 and 5 are fixed flow rate operations.The regenerated concentrations are(40,60,20)mg·kg-1.

The design procedure is as follows.

Add the regenerated stream with concentrations of (40, 60, 20)mg·kg-1into the internal sources. Calculate the CPD values and list the demands in the increasing order of CPD values,as shown in Table 8.

D1is satisfied first with 30 t of freshwater.Next,D2is satisfied with 75 t of regenerated water.The third demand,D4,is satisfied by 27.27 t of S1. The rest two demands, D3and D5, have the same CPD value.Because D3is performed before D5,D3is satisfied first by 40 t of S2.D5is satisfied by 2.73 t of remaining S1,35 t of remaining S2and 2.72 t of S4.The freshwater consumption is 75 t and the final inlet and outlet concentrations are shown in Table 9.

The un-reused sources are listed in the increasing order of CPS values as:40 t of S3,40 t of S5,and 25 t of S4.The sources to be regenerated are 40 t of S3and 35 t of S5and the regeneration concentrations are(150.00,82.48,70.58)mg·kg-1.The flow rate of regeneration unit is 8.824 t·h-1.

Fig.5.The network involving regeneration reuse for Example 1(where the numbers are the amount of water in kg).

Table 5 The final inlet and outlet concentrations in each mixer for Example 1

Table 6 Comparison of the results for Example 1

According to rules(b)and(c)described in Section 4.1.3,S1needs Tank 1(T1),S2and S4can share Tank 2(T2). The variations of water amount in T1and T2are shown in Fig.6.

The final design of this example is shown in Fig.7.The comparison between the results of this article and that for the network involving reuse only obtained by Li et al. [18] is shown in Table 10. It can be seen from Table 10 that the consumption of freshwater can be reducedby 62.5%by introducing a regeneration unit,whose inlet concentrations are (150.00, 82.48, 70.58) mg·kg-1and outlet concentrations are(40, 60, 20) mg·kg-1. The above design procedure shows that the proposed method is very simple.

Table 7 Limiting data for one production cycle for Example 2

Table 8 Order of the CPD values for Example 2

7.Conclusions

This article presents a heuristic method for the design of batch water-using networks of multiple contaminants with regeneration unit. For the design of a water-using network operated in a single batch,time is taken as the primary factor and the concentration potentials as the secondary one. The network involving reuse only is first designed by dividing the whole network into the subnetwork before regeneration and that after regeneration.Then,the flow rate and concentrations of regenerated stream are estimated.Finally,the network involving regeneration reuse can be obtained by adding the regenerated stream into the original network and designing the obtained network with the method for the network involving reuse only.For the design of a water-using network operated in a repeated mode,the design procedure is similar to that for the continuous network,besides designing the storage tanks with the rules proposed. The regeneration unit operated in continuous mode and it can be modeled either as fixed regenerated concentration model or as fixed removal ratio model.With the proposed method, the water-using network corresponding to the minimum freshwater consumption can be obtained.It is shown that the method is simple,effective and has clear engineering meaning.It should be indicated that the optimal solutions cannot be guaranteed in this article.They can be used as the initial structures for mathematical programming methods.

Fig.6.Storage profile of T1 and T2 for Example 2.

Nomenclature

C concentration of contaminant,mg·kg-1

CPD concentration potential of demand

CPS concentration potential of source

D demand stream

Table 9 The final inlet and outlet concentrations of each process for Example 2

Fig.7.Final design for Example 2(where the numbers are the amount of water in t).

F consumption of stream,kg

FKC freshwater key contaminant

M mass load of contaminant,kg

NC number of contaminants

ND number of demand streams

NS number of source streams

R the maximum quasi-allocation amount

RC regenerated concentration,mg·kg-1

RKC reuse key contaminant

RR removal ratio,%

S source stream

Superscripts

in inlet of a process

lim limiting value

min minimum value

out outlet of a process

rem removed mass load of a contaminant

Table 10 Comparison of the results for Example 2

Subscripts

fresh,f freshwater

i a source stream

j a demand stream

k a contaminant

reg regeneration

Chinese Journal of Chemical Engineering2019年5期

Chinese Journal of Chemical Engineering2019年5期

- Chinese Journal of Chemical Engineering的其它文章

- Assessment of the TFM in predicting the onset of turbulent fluidization☆

- CFD study on double-to single-loop flow pattern transition and its influence on macro mixing efficiency in fully baffled tank stirred by a Rushton turbine☆

- Simulation of drop breakage in liquid-liquid system by coupling of CFD and PBM:Comparison of breakage kernels and effects of agitator configurations☆

- Heat transfer characteristics of molten plastics in a vertical falling film reactor☆

- Stabilizing silica nanoparticles in high saline water by using polyvinylpyrrolidone for reduction of asphaltene precipitation damage under dynamic condition

- Numerical simulation and experimental study on dissolving characteristics of layered salt rocks