Intelligent Transformation and Upgrading of Oil Refining& Petrochemical Industries in China: Investigation &Application

Wu Qing

(CNOOC Oil & Petrochemicals Co., Ltd, Beijing 100010)

Abstract: The oil refining and petrochemical industry in China has made great achievements after decades of development,and its capacity has already ranked second in the world. However, the refining industry is suffering some challenges, such as severe overcapacity at present, and has entered a new economic normal, in which the technological progress develops rapidly, the demand for green and low-carbon development is stricter, the market competition is increasingly fiercer and the profit margins are gradually narrowing. In such a situation, informatization and its new technologies are driving the significant reforming of manufacturing patterns, marketing patterns, management and decision-making patterns. Intelligent development is the inevitable choice for the transformation and upgrading of oil refining and petrochemical industry.It is suggested that the intelligent evaluating model and method should be adopted to enterprise's intelligentializing transformation and upgrading by laying a solid foundation of digital refinery and implemenation of digital upgrading.

Key words: plant oil; oil refining and petrochemical enterprise; intelligent informatization diagnoses model; intelligentializing transformation and upgrading; digital refinery; intelligent refinery; smart refinery

1 Introduction

Being a most important part of the process industry, the refining and petrochemical industry is the pillar industry of modern economy and the cornerstone of modern society. After decades of development, both the oil refining and ethylene production capacity of China has ranked second all over the world. This is achieved by making rapid progress in refinery distribution, crude oil adaptability, plant configuration and product slate adjustment, product quality upgrade and cleaner production. To support this progress, the corresponding technologies such as catalyst manufacturing and process development as well as the equipment fabrication have also made considerable progress[1]. However, since China's economic development has entered a new normal, the oil refining industry is encountering problems of overcapacity.The Chinese refining and petrochemical industry has to accelerate their refining-chemical integration process, upgrade the product mix, and optimize the regional supply chain. In general, sustainability and high efficiency are the directions of future refining and petrochemical industry.

The rapid and explosive development of informatization and its new technologies has far-reaching implications for modern society. Under the guidance of national strategies such as “Industry 4.0”, “Made in China 2025” and the national plans such as “Special Project on Intelligent Equipment Manufacturing”, the widespread use of information technology, especially the Internet, not only has changed our daily life but also brought about a revolution to the traditional refining industry. The Internet has enabled the integration of various devices and information in the manufacturing process to become increasingly networked, industrialized, and informatized to form new production methods, industrial patterns, business models,and economic growth points. The traditional manufacturing industry and the Internet will move toward digitalization, networking and intelligent control—a new generation of intelligent manufacturing[2]. The various changes that have occurred in the refining industry, including the production mode, the control decision-making mode and the marketing mode[3], are overwhelming. Numerous facts have also proved that development will inevitably lead to transformation and upgrading. Therefore, integration and innovation will always lead the development of the times.Informatization of refining companies and their intelligent transformation and upgrading are the core technologies for improving the overall competitiveness of the oil refining and petrochemical industry, in order to achieve the high efficiency and sustainability and improve the business quality and efficiency[4]. As a result, the informatization of refinery companies and their intelligent transformation and upgrading are currently in full swing and will also make the future of refining companies fundamentally change their face.

2 Current Status of Refinery Informatization and the Driving Force of Intelligent Development

2.1 Status of informatization

In general, informatization of refineries is to comprehensively adopt the information technology, the computer technology, the communications technology,the automatic control technology, and the modern management methods in upgrading and transforming refineries. Meanwhile, it can comprehensively improve the capabilities of production technology, business management and market resilience in three levels,namely: the resource planning, the manufacturing execution, and the process control.

The informatization framework of the refinery companies has followed the three-level model structure proposed by AMR for decades[5]. Only a few of them select the Enterprise Information Portal (EIP) as a single level and regard it as the fourth level.

In recent years, the information technology has been extensively applied in Chinese oil refining and petrochemical industry. It has been playing a positive role in promoting the competitiveness of refineries. For example, the DCS/PLC/FCS systems are widely used in the underlying process control level. In addition,the domestic DCS products have a wide range of applications and have achieved good results. The major production processes of large and medium oil refineries are running by automatic control system with perfect basic instrumentation, which has enhanced the operating stability and improved the product quality. Particularly,the application of Internet of Things (IOT) in hazardous chemical logistics, and the automatic control with radio frequency identification device (RFID) in warehousing have all achieved good results.

At the manufacturing execution level, the management level and working efficiency has been improved through the construction and application of the manufacturing execution systems (MES), the production optimization technologies, and the production scheduling systems.By combining the plant models with the information platforms, the company headquarters can realize online scheduling and resource allocation, which can promote the optimization of refinery planning and improve the overall efficiency of resource utilization. By means of the scheduling optimization software, we can improve the predictability and efficiency of planning and scheduling.In addition, some enterprises have achieved the integration of planning and scheduling.

At the operational management level, most enterprises have applied the enterprise resource planning system(ERP) to improve the efficiency of business management by supporting the procurement, sales, finance, and capital business operations. By virtue of the decision-making analysis pattern, the business intelligence analysis system has been used in various fields to realize the unified extraction and processing of source system data. Based on the establishment of departmental applications and the realization of finance, sales, procurement, and analysis application cases, it can satisfy the full-caliber and multidimensional comparative analysis of the production and management information of enterprises.

2.2 Driving force of informatization intelligent development

After several decades of development coupled with upholding the concept of “safety, health, environmental protection, green, and low carbon” as well as the ideas of recycle economy and sustainable development, the refining and petrochemical industry is transforming into the direction of “large-scale, clean, integrated, base, differentiated, high value-added, and intelligent” mode. However, there still exist the following major challenges:

1) Optimization and control of product quantities(including structure and distribution), product quality,production costs and energy consumption become more complicated, because of the ever-changing market demand and raw materials.

2) There are contradictions between the efficiency improvement and reliability of production, stability control, and process safety.

3) The global economic integration has led to a more complex business environment for companies. The complexity of supply chain barriers and links is increasing.

4) The growth of energy consumption has slowed down, declining the profit margin of refining and selling businesses.

5) In order to implement a low-carbon society, pressures on environmental protection, energy-saving, and emissions reduction increase sharply.

The above challenges have accelerated the development of intelligentization and information of refining industry and promoted its transformation and upgrading. It should be noted that progress has already been achieved in areas such as the petroleum fraction modeling[6], the hydrogen network optimization[7-10], and the energy and water network design[11-12]. In addition, the following two factors are also being regarded as the driving forces for refining industry intelligentization development.

2.2.1 Changes in refinery production and service mode

International oil companies are actively transforming themselves into comprehensive energy companies,while expanding new energy businesses and extending the petrochemical industry chain. Some companies propose the strategies in energy internet establishment and distributed and concentrated energy utilization.Through integration and distribution of intelligent networks, they can maximize the effective energy usage.A novel flat type of economic network is also adopted to share the new models of energy saving. The internet of energy collaboratively built by Internet technology and renewable energy will change the patterns of energy production and social distribution. People can produce green energy at nearly zero marginal cost and share it with IOT. The development of the Internet of Energy has also become a new business model, which would prompt the energy companies to change their traditional business models.

In addition, the upgrading directions include the refining to petrochemical transformation[13]. The development of petrochemical products has been shifted to fine chemicals of high performance and high added value. Due to its good economic benefit as well as being close to the user side, fine chemicals has become the orientation of refining industry transformation and upgrading. At the same time, cloud manufacturing has become a new mode of production, which causes the reform of the production and service mode in refinery and gives birth to a rapid development of intelligent enterprises.

2.2.2 Production uncertainty control

The extension of the refining supply chain in refining production process has increased the uncertainty of production control. Uncertainty factors mainly come from the following aspects:

1) The uncertainty in supply system is caused by the diversity of raw materials.

2) The uncertainty in production process is mainly affected by requirements for upgrading of product quality,and the multi-variety, low-volume production mode of high value-added products.

3) The uncertainty of the sales cycle comes from changes in payment methods and changes in demand patterns of customers.

In order to reduce the above-mentioned uncertainties, we can improve the resilience through global optimization and knowledge accumulation. The specific methods include: making use of effective observation of control points and real-time management control to track uncertainties effectively and ensure the stability of production; increasing the equipment load rate and operational reliability to reduce costs and increase efficiency continuously.

2.3 Informatization intelligent application

The application of information-based intelligent projects mainly includes:

1) Integrating the supply chains from upstream to downstream, optimizing the profits cross regions. We can quickly respond to changes in raw materials and market demand to ensure the timeliness and consistency of information. Integrated production management services will significantly improve the business automation levels and work efficiency.

2) Online optimizing of the plants and increasing the agility of production.

3) Comprehensive management in environmental protection, energy conservation and safety. For example,energy conservation and emissions reduction can be achieved by strengthening the energy management and optimization. Through the energy plan and index decomposition, energy-saving dispatching targets across all operating points are established and monitored. For the changes in production and processing plans, the intelligent application of informatization can realize the real time adjustment of energy consumption in the energy pipe network and guarantee the supply as well as optimize the energy operation. By means of energy evaluation,it is possible to establish a horizontal benchmarking of industry advancement, which can analyze the best practices and guide the improvement work.

4) Improve the intelligence level in production operations For example, we can improve the scientific decisionmaking capabilities by the overall monitoring of the KPI system. A unified organization and performance of theme-based information can be realized by building up an integrated dashboard. The intelligent application of informatization will contribute to the achievement of a role-based, flexible, dynamic visual decision that can assist and support the mobile applications, so that the ontap information is available.

Another example is building up an enterprise-level integration framework to support the operational excellence, such as,establishing an open enterprise integration platform based on SOA architecture; introducing the reference models and data standards to achieve the standardized data exchange; realizing the full integration and continuity of data from real-time level to enterprise operation level; realizing the process integration and business collaboration at the enterprise-level; setting up a fully integrated enterprise-level integration framework for heterogeneous systems at the production and operation process. An enterprise-level integration architecture will make it possible to display the information of each role in business activities on an as-needed basis, meanwhile, to ensure the isogenous, accurate and reliable use of displayed information.Flexible and scalable information system architecture can quickly respond and support the business changes at the enterprises.

In addition, the rapid and explosive development of informatization and its new technologies such as Cloud Computing, Big Data, Mobile Internet, Internet of Things,augmentation and virtual reality (AR/VR), artificial intelligence (AI), etc., can offer technological possibilities for development and transformation of refining informatization and intelligentization. Meanwhile,countless facts have proved that these technologies are often forced into developing and upgrading the intelligentization in production[3].

3 Vision and Evaluation of Refining Industry Intelligentization and Informatization

3.1 Vision

With the introduction of national strategies and special plans such as “German Industry 4.0”, “U.S. Industrial Internet” and “Made in China 2025” and macro guidelines for the future development of manufacturing, as well as the promotion of new technology industrial revolution characterized by “digitalization, networking, and intelligence” and the requirement for transforming China's national economic development from emphasizing quantity to emphasizing quality, the oil refining industry should adopt a new generation of intelligent manufacturing[2]or intelligent optimization manufacturing[14]to meet the challenges and adapt to internal and external changes. This new model can realize the intelligentization of the refining industry.

Industrial intelligence not only refers to the optimization of devices and units, but also includes regional optimization, plant-wide optimization, and optimization of the entire industrial chain. More importantly, it is necessary to adopt and integrate core technologies and systems, such as smart supply chain, raw material agile optimization, advanced planning and the entire industrial chain collaborative optimization, equipment life cycle management, and QHSE (quality, health, safety, and environment management) monitoring and traceability.Upon utilizing these methods, we can make the oil refining industry more efficient and greener to realize the perfect promotion of value chain.

3.2 Evaluation

The evaluation of refining industry's intelligentization and informatization achievements includes two aspects,namely: the assessment model of the development level of intelligentized informatization in the refining industry and the economic (benefit) evaluation.

1) Development level assessment model for oil refining industry's informatization and intelligentization achievements

By means of the refining and information-based intelligent development level assessment model, we can find out the status of enterprise informatization development and find out the gap for further developments (such as intelligentization),so as to indicate the direction of further development and the implementation roadmap for transformation and upgrading of the enterprise's informatization and intelligentization degree.

According to the research on the development trend of the industry (refining industry, information industry) and operating practices, we have proposed an information capability level assessment model for the intelligent construction in the oil refining industry[5]. This model mainly implements information-based intelligent capacity assessment through detailed evaluation of six capability indicators, such as “the automation level, the digitization level, the system optimization level, the integration level,the basic support level, and the personnel management level”. Each level (capacity) can be subdivided into several corresponding ability factors. Each ability factor can be further divided into 6 subdivision levels (0 to 5 levels).

2) Economic evaluation

The evaluation of the economic benefits of refining intelligentization mainly addresses positivity and sustainability issues.

The intelligent refinery construction involves investment,and naturally it is necessary to consider the input-output and economic returns. The implementation of intelligent construction can improve the efficiency of the enterprise,and meanwhile, it will achieve sustainable development by reducing the energy and material consumption. Based on the informatization and new-technicalization for refining system data and information, we can improve the efficiency of resources utilization. Intelligent refinery construction also makes the supply chain more rational,so as to maximize the value of resources. In addition,employee reduction is another benefit brought in by intelligentization and informatization activities in the oil refining industry.

However, if the economic benefits are calculated according to certain mandatory targets, many companies may come to a standstill when they implement intelligent refinery construction. Therefore, we must try to get rid of the “misunderstanding of benefits”. Realization of the development and upgrading of information-based intelligence may need a long-time period of technique accumulation. Consequently, it is quite time-consuming to recover the investment. With an increasing emphasis on sustainable development, continuous normalization in safety production, and gradual disappearance of the labor force dividend, intelligent refinery construction can achieve the energy-saving mode of emission reduction,the human-computer interaction, and the remote control in current situation. These accompanying significant social benefits are also a part of benefits brought about by intelligent refinery construction.

Therefore, while refining companies use some easily quantifiable indicators to evaluate the benefits of intelligent refinery construction, they may also consider some auxiliary assessment indicators, such as reducing manual operations and boosting staff morale (when work becomes more interesting with a higher value-added meaning) or strengthening employee loyalty.

Due to the differences in the environment and construction content of the companies, the suitable evaluation models for individual refining enterprises should be adopted or developed, and the corresponding post-evaluation methods should also be distinguished.

4 Intelligentization of Refinery Enterprises and Their Transformation and Upgrading

Due to the rapid development and application of information technology, informatization and new technologies have gradually evolved from the supporting tools in manufacturing into the supporting force; meanwhile, they gradually play a leading role in certain aspects. The widespread utilization of the Internet has changed the human life and brought about revolutionary changes to traditional industries. Refining companies have been deepening the adoption of “Integrate IT Application with Industrialization” and “Internet Plus”technologies. Through the information practices based on the core technology of “Oil Resources Agile Optimization and Advanced Planning System, Production and Sales of Entire Industry Chain Collaborative Optimization, and Equipment Life Cycle Management with QHSE visual monitoring and traceability”, they can support the enterprises to further enhance their production, management, operation control and decision-making capabilities. Significant practical results have been achieved in terms of high efficiency and greenization, security control, and integrated applications.The company production organization, operation methods,and management efficiency have increased to a new level.Among these companies, a few of them are moving from digitization to smart refinery through rapid development of intelligentization.

Intelligent construction of refinery can be divided into three stages: digital refinery, intelligent refinery and smart refinery. Among them, digitization is the foundation, intelligence is the core, and smartness is the goal[5]. Most Chinese refining companies are currently in the digitalization stage[15], and only a few or very few companies are in a stage of attempting and demonstrating in pursuit of the intelligent construction.

To implement the intelligent refinery construction,we must pay attention to consolidating the digital basis. Digital construction of refinery companies can be carried out from the perspectives of the strategy implementation and top-level design of a digital refinery,the management determination intensification and the technological capabilities improvement, and setting up good examples[16].

The transformation and upgrading of intelligent informatization in refineries is inevitable and can be discussed in the following two aspects.

4.1 Intelligent manufacturing

At present, intelligent manufacturing is very popular.

On the one hand, all companies have great demand for upgrading and transforming with digital and intelligent technologies, in order to reduce various costs and consumption such as labor costs. These companies also hope to generate new production modes as well as new production tools to improve product quality, target product quantity (benefit) and competitiveness from these new technologies. On the other hand, the development of these new technologies is expected to rev up at a prodigious rate around the world. Since many countries launch their national development strategies and plans,the intelligent manufacturing has become a competition focus of all nations.

Intelligent manufacturing is a highly fused product of manufacturing technology, digital technology, AI, and other new information technologies. It is oriented to the entire product lifecycle (including the entire process of design, manufacturing, and service), and aims to provide user service with short-time delivery, high quality, low cost and green products[2]. The main features of intelligent manufacturing are “Information Sensoring, Decisions Optimization, Control Optimization, and Deep Learning Function”. Among them, the artificial intelligence and deep learning function are the key to realizing the true intelligent manufacturing.

Western developed countries have undergone the process of industrialization from mechanization, and automation to digitalization. Currently, they are moving forward to intelligentization. In 2012, the proposition of “Intelligent Manufacturing Equipment Special Project” opened a new journey for China intelligent manufacturing development.In recent years, great benefits arising from the rapid development and widespread popularization of Internet technology in China, Chinese intelligent manufacturing has entered a new period of “Digitalization + Internet”[17].On July 8, 2017, the Chinese government formally issued the “New Generation Artificial Intelligence Development Plan”. The plan pointed out the direction and approach for the further development of intelligent manufacturing.The breakthrough of the new generation of artificial intelligence and its continuous expansion and deepening will bring about higher and higher levels of intelligent manufacturing. Further development and upgrading after digital integration with the Internet will help the transformation of industrial manufacturing from digital manufacturing and digital networked manufacturing to digital networking intelligent manufacturing (new generation of intelligent manufacturing)[2].

Judging from the view of intelligent manufacturing to survey the development and upgrading of digitization and informatization, we can find that the digitalization is the basis while digital networking is the process. After adding the artificial intelligence, we can achieve a new generation of intelligent manufacturing. This is the true meaning of intelligent manufacturing[17]. In other words, the development of intelligent manufacturing and the upgrading of informationization is a step-by-step process.

4.2 From digital refinery to smart refinery through Intelligent Refinery

The refining industry is facing the challenges due to geopolitics, resources, global climate change, new energy, and technology factors. The strategy of the two industries integration is changing the market structure of petrochemical products and consumer behavior. It also changes the business model of “production, sales,and management decisions” and promotes the digital transformation of refining companies[3].

On the one hand, transformation of digital refinery to smart refinery through intelligent refinery needs to apply new technologies including Internet of things, big data, and artificial intelligence to achieve horizontal collaborative optimization of entire supply chain (including crude oil production, transportation, warehousing, refinery production,oil storage, product logistics, and sales), which will enable the production and supply sectors to quickly respond to changes in the market and to set up a smart supply chain. On the other hand, based on petroleum molecular engineering and management technology vertically, it can realize the optimization of refinement planning and scheduling, and global online optimization. Finally, the agile optimization of resources, collaborative optimization of industry chain, and QHSE traceability and monitoring can be realized. Based on the integrated “Engineering-Production-Sales” platform(“EMM” platform)[15], the equipment preventive maintenance in the equipment entire life cycle management system and other service items can be accomplished. By integrating the above-mentioned projects and systems, we can improve the value chain of refining companies efficiently and greenly.

The goal of intelligent refinery construction is to realize the smart refinery[5]. To achieve this goal, we can divide the specific implementation into three stages:

First, digital refinery is the foundation. Construction,improvement, and consolidation of digital refinery are necessary. Digitization of employee, equipment,operation, automation of process, and informatization of management are the core applications of digital refinery. Based on the digital refinery construction,we can visualize the plant operations and improve the management efficiency of production and sales system

Second, an intelligent refinery is the core. Just like the development of intelligent manufacturing, the transformation of digital refinery will be upgraded to the second stage, viz.: the intelligent refinery. In this stage, the knowledge and optimization of production and operation are the main applications. Intelligent refinery emphasizes the establishment of enterprise model system, including planning and scheduling optimization models for production systems, optimization models for production operation, predictability analysis models for equipment, optimization model for storage logistics,and analysis models for customer cluster. Petroleum molecular engineering and management, industrial and sales big data analysis, etc., are new technologies adopted in establishing the enterprise model. They are also the emphatical application of current refinery companies.

Based on the optimization model, the intelligent refinery will achieve optimal control of production planning,scheduling, and operation, also for optimization of equipment life cycle management and predictive maintenance, and plant energy usage. In addition, the intelligent refinery can realize an integrated optimization of sales and logistics, and the smart gas stations construction as well.

In the end, a smart refinery is the goal. Ultimately, the refining companies must achieve full value optimization.Therefore, it is necessary to establish a smart supply chain.On the basis of smart supply chain, we can realize the visualization, coordination, and optimization of all links in the entire industry chain from market sales to crude oil procurement, as well as maximize the value chain. For refinery production and product sales, it is necessary to achieve cost optimization in all aspects of the refinery and sales, including variable cost management and value maximization in production, inventory optimization, and sales value maximization.

Therefore, the construction of intelligent refinery is a three-step process. A step by step strategy for the smart refinery construction is suggested so that the digital refinery should be constructed firstly, followed by the construction of the intelligent refinery, and then the smart refinery will emerge eventually.

5 Implementation and Prospect of Intelligent Refinery Construction

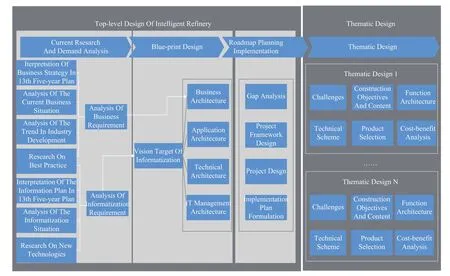

To control risks and ensure success during intelligent project implementation, it is necessary to do strategic planning and take safeguard measures. The strategic planning method for intelligent refinery construction can refer to the method adopted by China National Offshore Oil Corp (CNOOC) Refining & Chemical Co., Ltd.,which can be divided into Informatization Planning Methodology (top-level design) and Thematic Design Methodology, as shown in Figure 1.

Figure 1 Methodology of strategic planning for Intelligent Refinery

The top-level design of intelligent refinery construction can be divided into three stages: current research and demand analysis, the blue-print design, and the roadmap planning implementation. Upon taking the CNOOC Refinery Co., Ltd. as an example, based on the top-level design, it focuses on four topics: smart refinery, integrated platform for production-supply-storage-sales, digital sales, and information security. Detailed design has been applied to functional architecture, technical architecture,solution method, system implementation, and system reinvigoration.

6 Conclusions

The implementation of intelligent refinery construction and its transformation have solidified the digital foundation and integrated various information and related technologies, including engineering, crude oil procurement and transportation, refining, warehouse logistics, sales, etc. These technologies make up the core technological framework system of smart refinery construction and help the refinery companies to achieve the integration and optimization of decision-making in the links of “construction, supply, processing, storage and transportation, marketing, management and control”.Meanwhile, it maximizes the value of resources (including information resources) and the value of assets as well as achieves low-carbon, green, and high-efficiency in oil refining, production, and management and decisionmaking. Intelligent refinery also increases the level of comprehensive management and improves the comprehensive competitiveness of refining companies with informatization and intelligentization.

- 中国炼油与石油化工的其它文章

- Methane Storage and Synthesis of HKUST-1 Prepared with Different Solvent

- Optimization of Dividing Wall Column with Heat Transfer Process Across the Wall for Feed Properties Variation

- Novel BiVO4@C3N4@GO Composites with Higher Photocatalytic Performance

- Effect of the Morphology of ZnO Support on the Desulfurization and Regeneration Performance of Ni/ZnO Catalyst

- Research on Hydrogenolysis of Glycerol to 1, 2-Propylene Glycol by Using Supported Raney-Cu/Al2O3

- Research Progress in Refining Process for Production of Caprolactam by Beckman Rearrangement Reaction