Optimization of process conditions for drying of catfish(Clarias gariepinus)using Response Surface Methodology(RSM)

Elijh George Ikrng,Kingsley Chrles Umni

a Department of Agricultural and Food Engineering,Faculty of Engineering,University of Uyo,Uyo,Akwa Ibom State,Nigeria

b Department of Agricultural Engineering,Faculty of Engineering,Akwa Ibom State University,Mkpat Enin,Akwa Ibom State,Nigeria

Keywords:

ABSTRACT

1. Introduction

Fish is among a class of aquatic vertebrates which is an important source of high quality protein in human diet.It contains about 80% of water in its fresh state and it is a highly perishable food product with a very short shelf life. In Nigeria, fish is consumed fresh, preserved or processed (smoked) and form a much cherished delicacy that cuts across socio-economic, age, religious and educational barriers [1]. While living through the water, the fish takes a large number of bacteria into its gut from water sediment and food [2]. Fish is ideal for human consumption and increased shelf life when subjected to some form of processing. When the fresh fish is not utilised by consumers and converted into finished product then it remains surplus and goes to waste. Drying of fish is important due to the fact that it preserves fish by inactivating enzymes and removing the moisture necessary for bacterial and mould growth [3,4,7]. Fish is a food product with excellent nutritional value, providing high quality protein and a wide variety of vitamins and minerals including vitamins A and D, phosphorus,magnesium, selenium and iodine. Fish in its dried form is one of the most important exported marine products in many countries such as Turkey, Iran, India, Thailand, Russia, China, Malaysia and United states. The fishery sector is estimated to contribute 5% of Nigeria’s Gross Domestic Product (GPD) and provides direct and indirect employment to over six million people[5].

The physico-chemical changes in the fish product after harvest leads to spoilage which begins as soon as the fish dies.Spoilage is a metabolic process which renders food product undesirable or unacceptable for human consumption due to changes in sensory and nutritional characteristics[6].In other to prevent spoilage in food product, several important preservative techniques to maintain quality is employed and these include processes like smoking,cooling, sun-drying, and drying in electrical and solar dryers and also the use of pre-treatments such as salt,which helps to retard bacterial action and,in addition,it aids the removal of water by osmosis.The need for the development of fish preservation and processing machinery and techniques for effective fish handling, harvesting,processing and storage can never be over-emphasized especially now that aquaculture production is growing rapidly in Nigeria[30].Efficient preservation of fish is important when top quality,maximum yield and highest possible profits are to be achieved.

Multivariate analysis is a statistical method that measures relationships between two or more response variables [17]. Multivariate techniques allow researchers to look at relationships between variables in an overarching way and to quantify the relationship between variables,by attempting to model reality where each situation, product or decision involves more than a single factor. Multivariate techniques control the association between variables by using cross tabulation,partial correlation and multiple regressions, and introduce other variables to determine the links between the independent and dependent variables or to specify the conditions under which the association takes place.Multivariate analysis in a broader scope gives the researcher the ability to collect a more realistic picture than looking at a single variable.Furthermore, multivariate techniques provide a powerful test of significance compared to univariate techniques[17,31].

Experimental design methodology is an important approach to solving scientific and engineering problems.It application has been used by researchers such as Arabi et al.[18]to evaluate the influence of pH of the sample solution, the amount of adsorbent, sonication time,eluent and washing solvent volumes on the cleanup and extraction efficiency of hydrochlorothia zide(HCT)in human urine.Ostovan et al.[19]adopted central composite design with rapidity and reliability to investigate the effect of multitemplate molecularly imprinted biopolymer (mt-MIBP) mass, sonication time and eluting solvent types and volume on ultrasound- assisted dispersive solid-phase extraction(d-SPE)efficiency for simultaneous recognition and separation of B-family vitamins in juice samples.

Ostovan et al. [20] on the other hand used technique such as SEM, VSM, FT-IR, XRD and TGA to verify the high suitability of biopolymer network with unprinted cavity grafted on the surface of Fe3O4cores which possesses an influential SiO2layer for trapping and accumulation of selective dispersive solid phase extraction(d-SPE) and selective separation of baclofen from urine samples.Ostovan et al.[21]employed experimental resign methodology to investigate the influence of sonication time, pH, sorbent dosage,volume of eluent and washing agents as well as the interaction on the extraction efficiency of ultrasonic-assisted dispersive solid phase extraction of urine sample using glibenclamide(GB)as template, methacrylic acid (MAA) as functional monomer, ethylene glycol dimethacrylate as cross-linker (EGDMA) and mesoporous MCM-48 nanospheres as support in a hollow porous molecularly imprinted polymer.

Arabi et al. [22] employed central composite design to investigate and optimize the impact of influential variables such as pH amounting sorbent,sonication and eluent volume on recovery efficiency and reflection rate of acrylaride in potato chips in a magnetic dummy molecularly imprinted nanoparticles (MDMINPS).Arabi et al.[23]adopted central composite design under response methodology investigate and optimized the effects of parameters such as sample-to-dispersant-ratio and eluent volume on extraction recovery in a dummy molecularly imprinted based on functionalized silica nanoparticles for determination of acrylamide in processed food using matrix solid phase dispersion.Arabi et al. [24] also adopted experimental design methodology under response surface methodology to optimize the effects of sample pH amount of sorbent and eluent,and washing solvent volumes on the extraction efficiency for the solid phase extraction of hippuric acid(HA)from human urine using 3-aminopropyl trimethoxysilane as the functional monomer,tetraethoxysilane as the cross-linker and hippuric acid as template in a molecularly imprinted nanoparticles(MINPS).

In an experiment for the synthesis and application of functionalized silica monolithic as artificial receptor of gallic acid at micro-pipette tip, Arabi et al. [25] employed experimental design methodology to investigate and optimize the effective parameters in extraction recovery of micro extraction for the separation and determination of gallic acid in orange juice samples using tetraethyl orthosilicate (TEOS) as cross-linker, 3-aminopropyl trimethoxysilane (APTMS) as functionalized monomer, gallic acid as template and thiourea as precursor.

Drying is a complex thermal process in which unsteady heat and moisture transfer occur simultaneously. Diffusivity is used to indicate the flow of moisture out of material during drying and is considered to be a relevant transport property necessary for the correct modelling and understanding of the food drying process[12]. In addition, improving drying processes by reducing energy consumption and providing high quality product with minimal increase in economic input has become the goal of modern drying[28].As catfish is one of the most consumed fish food product in Akwa Ibom State of Nigeria, it can be preserved by employing better processing techniques to increase its shelf life while still retaining its nutritional content. Hence the present study aim to use central composite rotatable design(CCRD)of response surface methodology(RSM)as a tool to optimize the processing conditions(drying temperature,thickness,salt concentration and drying time)to obtain a minimum moisture content for dried catfish.

2. Materials and methods

The methodology involved drying of the catfish at different process treatment combinations, determination of moisture content and optimization of response parameters with RSM.

2.1. Determination of moisture content

The initial moisture content of the fish used for the study was determined using the oven drying method as described by ASABE[32]and adopted by Oparaku and Mgbenka[26];Ichsani and Dyah[9];Ikrang et al.[10];Jain and Pathare[11]in Eq.(1).

Where M is the moisture content of the sample, %w.b; M1is the initial mass of the sample or wet mass, g; M2is the final mass of the sample or dry mass,g.

2.2. Experimental design and statistical analysis

The ranges of the levels of the experimental conditions were selected based on preliminary trials and literatures. The independent variables considered in this study were Drying temperature,DT(50, 60 and 70◦C), Thickness, T (10, 15 and 20 mm), Salt concentration, Sc(0, 10 and 20%) and Drying time, Dt(480, 520 and 600 min.). A 4×3 central composite rotatable design (CCRD) of Response Surface Methodology[13,16]was used to understand the individual and interactions effect of drying temperature,thickness,salt concentration and drying time on the moisture content of the dried catfish.

The CCRD involved thirty experiments for each of the four drying process factors with 4 axial points and 6 replications at the center points[14].Coded values of the independent variables(-1,0,1)were used,the coded values-1,0 and 1 represent the lowest,medium and highest levels respectively. The coded values are set out in Table 1,while the independent variables,the coded variables and their coded and actual levels are shown in and Table 2. Theresponse function Y (dependent variable) was moisture content,MC.The following second-order polynomial model for the response is represented in Equation 2 as:

Table 1 Codes, actual levels and intervals of the independent variables for drying process parameters.

The analysis of variance(ANOVA)Table was generated,the effect and regression coefficients of individual linear,quadratic and interaction terms were determined.The significance of all the terms in the polynomial was judged statistically by computing the p-value(Prob.> F) at 5% significance level. Response surfaces plots were generated with the help of commercial statistical package,Design-Expert — version 6.0.6 Stat-Ease Inc., Minneapolis, MN 55413,USA.

2.3. Preparation of sample for experiment

The fresh African catfish specie(Clarias gariepinus)was obtained from Domita Farms Nigeria Ltd., Uyo, Akwa Ibom State, Nigeria.The samples were thoroughly washed with tap water to remove dirt and other foreign materials. In order to preserve its original quality, they were stored in a refrigerator at -20◦C until drying experiment was carried out. The fresh catfish samples were then removed from the refrigerated storage and kept under surrounding environmental conditions for the ice to thaw and they were cut into the desired thickness of 10, 15 and 20 mm by a manual dicer to maintain relatively equal size and salt was applied to each thickness of the fish at 0,10 and 20%concentration and made ready for the actual drying experiment. Then samples were weighed using electronic weighing balance to an accuracy of 0.01 g. The number of samples were prepared as specified in Table 2.

2.4. Experimental procedure

The prepared samples were subjected to the drying experiments at different treatment as presented in Table 2.For each treatment or experimental run, the oven was set at a specified drying temperature of 50, 60 or 70◦C and the fish thickness of 10, 15 or 20 mm blended at salt concentration of 0, 10 or 20% was kept in the oven and allowed to dry for a specified drying time of 480,520 or 600 min,according to the factors combinations of the experimental design(Table 2).For each batch of dried sample,the weight of the sample and moisture content were recorded. The runs were replicated three times.

2.5. Optimization

Numerical and graphical optimization methods of optimization were carried out for the independent variables to obtain the fish moisture content with minimum percentage moisture using Design Expert software. Conventional graphical method was applied to obtain minimum moisture level. Predictive models were used to graphically represent the systems. Response surface plots of the response variables were utilized to select optimum combinations of drying temperature,thickness,salt concentration and drying time for the drying of catfish.

Table 2 Results for moisture content in the processed catfish observed under varying drying process conditions.

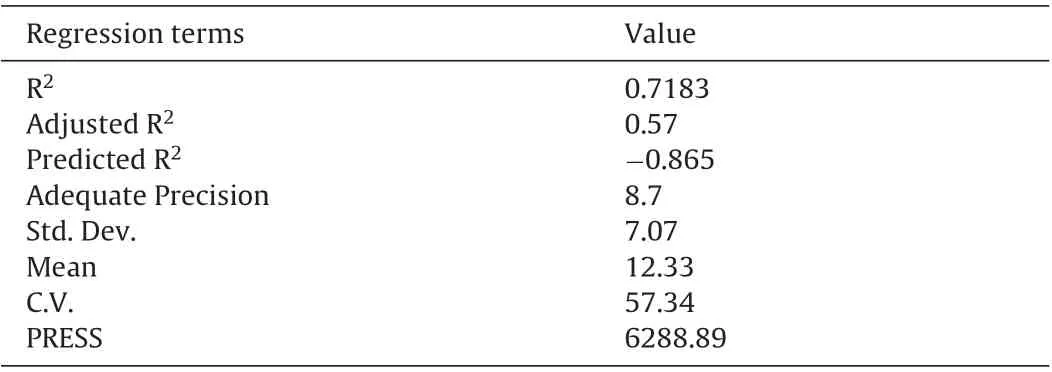

Table 3 Regression analysis for response surface 2FI model.

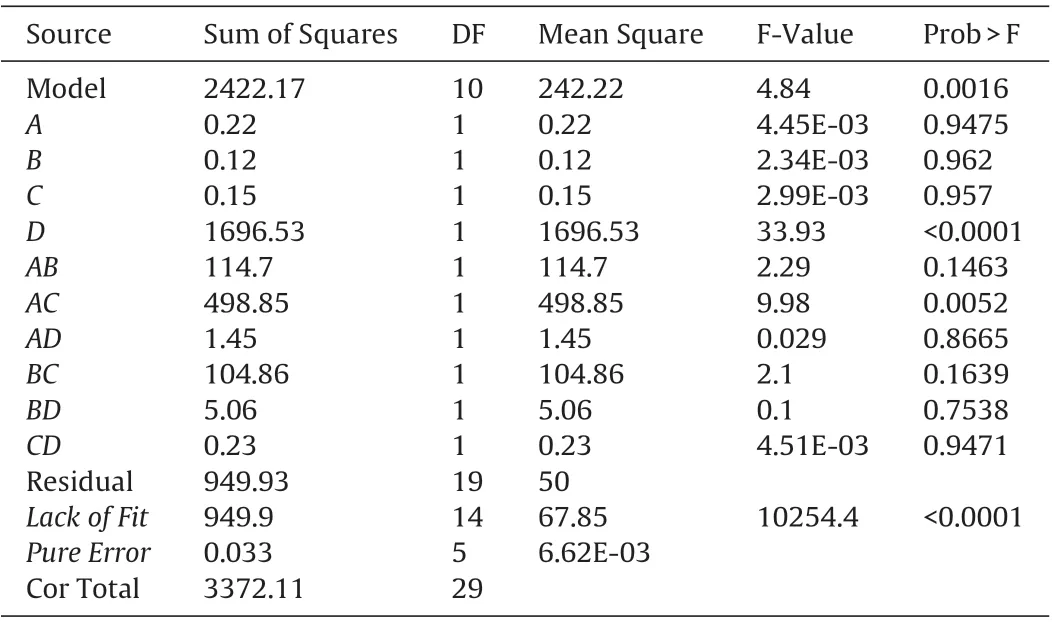

Table 4 ANOVA for response surface 2FI model for moisture content of dried fish.

3. Results and discussion

The effects of variation in moisture level of the catfish was studied by changing the drying temperature,thickness of the product,salt concentration and duration of drying and a second order polynomial equation was fitted with the experimental data.

3.1. Statistical analysis of result on model fitting

The experimental response(moisture content)as a function of drying process conditions like Temperature(A),Thickness(B),Salt Concentration (C) and Drying Time (D) during drying of catfish slices are presented in Table 2.

The value of moisture content (% w.b) was within the range of 2.64–45.86%. Regression analysis and ANOVA results of the 2FI model are shown in Tables 3 and 4. The model F-values of the response was 4.84 implying that the model is significant. At the same time the moisture content showed significant Lack-of-Fit.These values indicated that the model for predicting the moisture level of dried catfish was fitted and reliable. The adequacy of the model was further checked by Coefficient of determination (R2)and was found to be 0.7183 (Table 3). High value of coefficient of determination obtained for response variable indicated that the developed model for MC accounted for and adequately explained 71.83% of the total variation. The value of adequate precision is 8.7, adequate precision obtained in this study is greater than 4.0 indicating that this response had better precision and reliability.

3.2. Effect of drying process variables on moisture content

Moisture level is an important parameter in sea food processing. It indicates the amount of water evaporated from the sample when subjected to any form of heat.The regression equation which describes the effects of drying process variables on moisture content in terms of actual values of the variable is given in Eq.(3).

Where MC=Moisture content,%w.b;A=Temperature,◦;B=Product thickness,mm;C =Salt concentration,%;D=Drying time,min.

The linear positive terms indicated that moisture level in the fish increased with increase in temperature,thickness,salt concentration and drying time. The presence of positive interaction terms between temperature and salt concentration as well as temperature and drying time indicated that increase in their levels increased moisture content of the product. While, the negative interaction terms between drying temperature and product thickness, thickness and salt concentration, thickness and drying time as well as salt concentration and drying time indicated that increase in their levels further decreased moisture content of the product during the drying process.

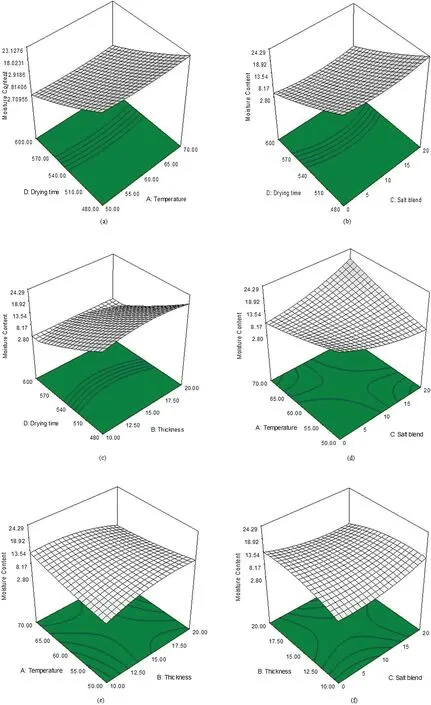

To visualize the combined effects of four variables on the moisture content of the product during the drying process,the response surface plots (Fig.1a–f) were generated for the fitted model as a function of two variables thereby keeping the third variable at its central point. The moisture content of the product decreased gradually during the drying process with increase in drying time,temperature and salt concentration(Fig.1a,b and d).Also,the moisture content decreased rapidly in the early stages of drying process,after which the rate of moisture loss from catfish slices sample considering the thickness of the product gradually slowed down with time(Fig.1c,e and f).Perry[27]reported that drying period during which the instantaneous drying rate continually decreased which was referred to as falling rate period and that the falling rate is affected by drying temperature,thickness of the product etc.

The higher temperatures and time seem to accelerate the rate of moisture loss (Fig.1a–d) through shrinking of cell membranes as well as the better moisture transfer characteristics on the product surface due to higher properties of the drying medium[4].The moisture level in the product decreased with increase in the drying temperature(Fig.1d and e)and also with a corresponding increase in the drying time(Fig.1a,b and c)throughout the entire drying process.Similar findings have been reported for oven drying of other fish products by Duan et al.[8];Rozainee et al.[29];Wu and Mao[33];Mwithiga and Mwangi[15].

3.3. Numerical optimization of drying process conditions

The criteria for the variables were set such that the independent variables (temperature, thickness, salt concentration and drying time)would be minimum looking at an economical point of view.The measures for constraints optimization was minimum possible moisture content in the fish product. The desired goals for each factor and response are shown in Table 5. For the optimization of the process parameters for the catfish drying process by numerical optimization which finds a point that maximizes the desirability function; equal importance of ‘3'was given to all the four drying process parameters and the response.

3.4. Verification of the model for drying of catfish

Fig.1. Response surface plot of MC during drying of catfish as a function of:(a)drying time and temperature(b)drying time and salt conc.(c)drying time and thickness(d)temperature and salt conc.(e)temperature and thickness(f)thickness and salt conc.

Table 5 Criteria and output for numerical optimization of oven drying process conditions.

Table 6 Optimum drying process parameters for the drying operation.

Drying experiments were conducted at the optimum drying process condition at temperature=63.43◦C, product thickness=14.81 mm, salt concentration=9.07% and drying time=600 min,for testing the adequacy of the model equation for predicting the response values. The predicted optimum and the measured values of the response(moisture content)by the model equation are presented in Table 6.It was observed that the experimental values are very close to the predicted values for moisture content. Therefore, it is deduced from the above discussion that the model is adequate enough to assess the behaviour of the drying process conditions of the catfish sizes.

4. Conclusion

It was concluded from this study that the solution temperature and drying time were the most pronounced factors affecting moisture content of catfish sizes during electrical oven drying process and closely followed by product thickness and salt concentration.Response surface methodology was effective in optimizing the drying process parameters for the drying process of the different sizes of catfish in an oven.

Analysis of variance has it that the effects of the drying process variables were statistically significant. Second order polynomial model was obtained for predicting the moisture content. The optimal conditions for minimum moisture loss correspond to temperature of 63.43◦C, product thickness of 14.81 mm, salt concentration of 9.07%and drying time of 600 min.,in order to obtain moisture content of 2.64% w.b. Conformation of the experimental results with the empirical model was evaluated using correlation coefficient (R2) which was found for the proposed model as,R2=0.994.

Competing interests

The authors declare that they have no competing interests.

- 食品科学与人类健康(英文)的其它文章

- Microalgae:A potential alternative to health supplementation for humans

- Autophagy-associated signal pathways of functional foods for chronic diseases

- Screening of potential GCMS derived antimigraine compound from the leaves of Abrus precatorius Linn to target“calcitonin gene related peptide”receptor using in silico analysis

- Rapid and easy determination of morphine in chafing dish condiments with colloidal gold labeling based lateral flow strips

- QSAR modeling of benzoquinone derivatives as 5-lipoxygenase inhibitors

- High uric acid model in Caenorhabditis elegans