Experimental study of bullet-proo f i ng capabilities of Kevlar,of different w eights and number of layers,w ith 9 mm projectiles

Riaan Stopforth ,Sarp Adali

a Stopforth Mechatronics,Robotics and Research Lab,Discipline of Mechanical Engineering,University of KwaZulu-Natal,Durban,South Africa b Centre for Composite Materials and Structures,Discipline of Mechanical Engineering,University of KwaZulu-Natal,Durban,South Africa

Keyw ords:Kevlar 9 mm Parabellum bullet Ballistic impact Ballistic gel Material testing

A B ST R A C TKevlar is the most commonly used material as armour for protection against bullets used in hand guns because of its impact resistance,high strength and low w eight.These properties make Kevlar an ideal material to be used in bullet-proof vests as compared to other materials.In the present study,different numbers of layers of Kevlar with different w eights are tested to determine the w eights and the number of layers needed to design a safe bullet-proof vest.For this purpose,several ballistic tests w ere performed on combinations of ballistic gel and Kevlar layers of different w eights.Ballistic impacts are generated by 9 mm Parabellum ammunition.The objective is to assess the characteristics of high-speed ballistic penetration into a combination of a gel and Kevlar and determine the number of layers needed to safely stop the 9 mm bullet and thereby contribute to the design of safe bullet-proof vests.The tests provide information on the distances the bullets can travel in a gel/Kevlar medium before they are stopped and to identify the resistance capabilities of Kevlar of different grams per square meter(GSM).The tests were conducted w ith the use of a chronograph in a controlled test environment.Speci f i cally,results identify the number of layers of Kevlar required to stop a 9 mm Parabellum projectile,and the effectiveness of using different number of layers of GSM Kevlar material.

1.Introduction

The concept of body armour w as developed in 1538 and comprised of steel plates.Fully steel bullet proof vests w ere progressively used and improved up until the 20th century[1].Today's body armour systems may still incorporate steel(but at a minimal amount),but consist mostly of Kevlar[2].The use of Kevlar w as integrated into vests in the mid-1970's and a fully developed vest w as produced in 1976 after the discovery of Kevlar by Stephanie Kw olek in 1971[3].This new material greatly reduced the overall w eight of the body armour system and drastically improved the mobility of the person w earing the vest,resulting in the modern bulletproof vests utilised today.

Kevlar used in the vests is comprised of a w oven fabric consisting of synthetic f i bres made through polymerisation.It is a high strength material know n for its high strength to w eight ratio,and in comparison to the strength to w eight ratio of steel,Kevlar is f i ve times stronger[4].The lightw eight property of Kevlar in conjunction w ith its high tensile strength(3620 MPa)[5]and its capacity for energy absorption[6]in comparison to other materials,makesit an ideal material for use in body armours.Ballistic applications of Kevlar based composites mostly include protective clothing[7,8].The effect of ballistic impact on Kevlar and other composites,and the mechanical properties of the material,have been investigated in several studies[9-18]w ith a view tow ards assessing its characteristics and effectiveness under impact loading.These studies involved both experimental testing[9-18]and numerical modelling[19-21]and established the effectiveness of Kevlar as an impact resistance material.Experimental ballistic tests performed w ith the samples of the Kevlar-Phenolic composite,used in Ref.18,show ed that the results did not correlate w ith the ones given in current publications,and they therefore indicated that further controlled experiments w ere needed.In the previous experimental studies,various methods of impact w ere used including gas guns[9,12],9 mm bullets[10,14]and armour piercing projectiles[11].An active area of research concerning the impact resistance of Kevlar materials involved the study of the effect of shear thickening f l uids on the ballistic performance of Kevlar reinforced composites[22-25].Review s on shear thickening f l uids and their applications w ere given in a number of publications[26-28].A number of high velocity projectile tests have been performed before as noted above,but in many cases,different methods of inducing motion,such as compressed air,or dropped w eight[29]w ere implemented.These motion induction methods do not correlate w ith the uncertainty characteristics of ammunition,the explosion of gun pow der,and the ri f l ing used in the f i rearm barrels.

The present study aims at investigating the ability of Kevlar fabric of different w eights to stop a projectile of common calibre,and the distance the projectile can travel through a gel/Kevlar combination to prevent life-threatening incidents.The contributions of this paper can be summarized as follow s:

1)Identify the effectiveness of different layers of three grades of Kevlar layered,namely 160 GSM,200 GSM and 400 GSM Kevlar fabrics.

2)Investigate the relationship of GSM w ith the number of layers needed to stop a 9 mm bullet.

3)Investigate the relationship of the type of ammunition w ith its penetration depth

4)Assess the number of Kevlar layers needed to stop a projectile.

In the tests,the layers of Kevlar that a projectile can penetrate are considered as the layers that are damaged.The calibre of the ammunition used is 9 mm Parabellum ammunition as they are used extensively.The tests w ere performed w ith a Glock 17 handgun inside a Roni carbine conversion kit.It is noted that the authors are not associated w ith the companies manufacturing the ammunition and obtained no f i nancial gain for performing the tests.The results given are unbiased,and are purely as observed in the tests conducted.Due to many uncertainties in ballistic tests,many of the tests conducted in the present study had to be repeated numerous times,for example,w hen the projectiles deviated out of the ballistic gel,or external interference w as observed that might have an effect on the results.

2.Ballistic gel and Kevlar sam ples

The description of how the ballistic gel and the Kevlar samples w ere constructed are described below.

2.1.Ballistic gel

The ballistic gel w as made from un f l avoured gelatine.The density and consistency of the gel have to be the same as that used by the Federal Bureau of Investigation(FBI).To achieve the same consistency,instructions given in Ref.[30]w ere followed and it has been tested against the standards described in Ref.[31].

8 cups(250 ml)of un f l avoured gelatine pow der(approximately 1.25 kg)is mixed w ith 8 Lof w ater(1 part gelatine for every 4 parts of w ater)until all the pow der is dissolved.After the solution w as poured into the containers(2×5 L containers w ere used for the above mixture),5 drops of essential oil(cinnamon leaf essential oil)w as poured over the solution and gently stirred into it.The reason for the essential oil is to allow for the bubbles in the solution to dissipate,and to give the ballistic gel an improved smell.The solution is set in the containers placed in a fridge.The ballistic gel w as ready to be used 36 h after it w as made and then it w as w rapped in cellophane w rapping.A video show ing the details to make the ballistic gel is available from https://w w w.youtube.com/w atch?v=0n LWq Jau FEw.

Density of the ballistic gel w as calculated as 996 km/m3(99.6%of w ater density).The average density of human blood,fat and muscle[32],w hich is the consistency of the human f l esh,is 1004 kg/m3.A 0.8%difference in the densities is considered as acceptable for the ballistic gel to replicate the f l esh of a human body.

2.2.Kevlar samples

Three w eights of Kevlar fabric w ere used in the tests,namely,160 GSM,200 GSM and 400 GSM.Since Kevlar can be used as a w oven material,the highest strength of the material could be utilised in a 0-90 orientation.The samples w ere stacked w ith a-45/+45(quasi-isotropic)orientation w hich absorbs more energy upon impact than 0-90 orientations stacked on each other[33].The samples that w ere used in the tests w ere made in multiples of 3 layers w here each sample w as layered in the order of 90/±45/90.When tw o or three samples w ere placed on top of each other,it w as done such that the last layer of one sample w as placed at 45°to the next layer of the next sample.

The Kevlar sheets w ere divided and cut into A4 size sheets to prepare them to be bound together using the recommended epoxy resin and hardener.The samples w ere left to dry.The samples w ere cut after the resin had set and bolted to each other and w ere placed into position for the tests to be conducted.

3.Tests and experim ents

The experimental setup and ammunition used are discussed next follow ed by the experimental results that w ere obtained.

3.1.Experimental setup

Ballistic tests w ere carried out using tw o different kinds of ammunition,namely,full metal jacket(FMJ)and jacketed hollow point(JHP)of the 9 mm Parabellum(Por Para for short)calibre.The method used to test the samples is described next:

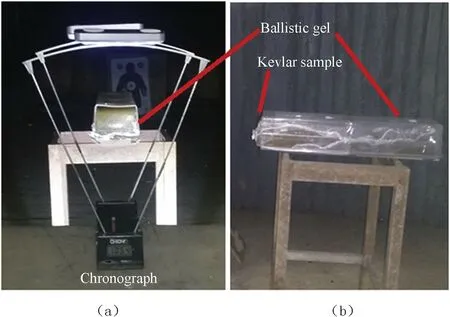

1)A f i rearm chronograph w as set up to measure bullet speeds.The chronograph w as placed 2 m from the muzzle of the f i rearms to prevent the muzzle f l ame to give inaccurate readings.

2)A baseline test w as performed to determine the bullet velocity directly into the ballistic gel.The kinetic energy equation E=(1/2)m v2w as used to determine the energy and distance of penetration into the ballistic gel.

3)The Kevlar samples w ere then placed in front of the ballistic gel and this w asplaced 1 m aw ay from the chronograph.The reason for the distance of 1 m is to replicate the w orst case scenario w here a person or object is shot at a close distance.

4)The sample w as shot w ith the projectile going through the chronograph to determine itsinitial speed.After this,the sample is penetrated and the projectile is lodged in the ballistic gel.The velocities of the tests w ere used to obtain an average velocity reading w hich w as used to update the values in step 2.

5)The distance of penetration into the ballistic gel w as measured and recorded.

6)Step 2 w as repeated for each type of ammunition used in the tests.Step 3 to step 5 w asrepeated for each Kevlar sample.Atest w ith speci f i c ammunition w as repeated if the projectile did not travel straight w ithin the ballistic gel,or if it penetrated the Kevlar sample in an area that w as considered not to be structurally sound.

The setup con f i guration is show n in Fig.1.

Fig.1.Front(a)and side(b)view of the chronograph and ballistic gel for the experiments.

3.2.Ammunition characteristics

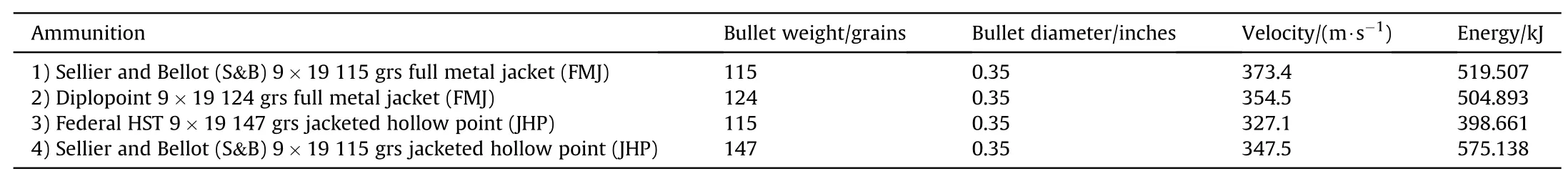

Information on the ammunition is given in Table 1.The ammunitions used in the tests are of common types and makes,used by the majority of f i rearm users.To compare the effects of different 9 mm Parabellum projectiles,different makes and types are considered.It is noted that the w eight of ammunition is measured in grains(grs),w here 15.432 grs is equal to 1 g.The w eight indicated on the ammunition box is the w eight of the projectile only and does not include the gun pow der or cartridge.The characteristics of the ammunition are show n in Table 1.The velocities indicated in Table 1 are average velocities recorded in the experiments.The number correlating to each ammunition in Table 1 is used for the respective results in the graphs in this paper.

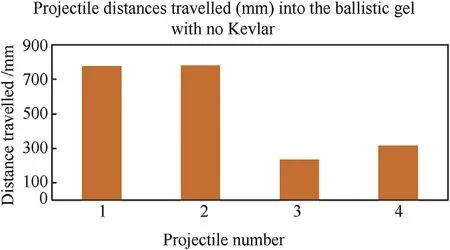

Tests w ere conducted by means of shooting the ammunition into the ballistic gel to replicate the characteristics of the impact in the event that a person w as shot(bare chest).The pictures of different projectiles recovered from the ballistic gel can be seen in the YouTube video available at:https://w w w.youtube.com/watch?v=Wv WsfDiVUiA.The distances that the projectiles travelled into the ballistic gel w ith no Kevlar are show n in Fig.2.

3.3.160 GSM Kevlar

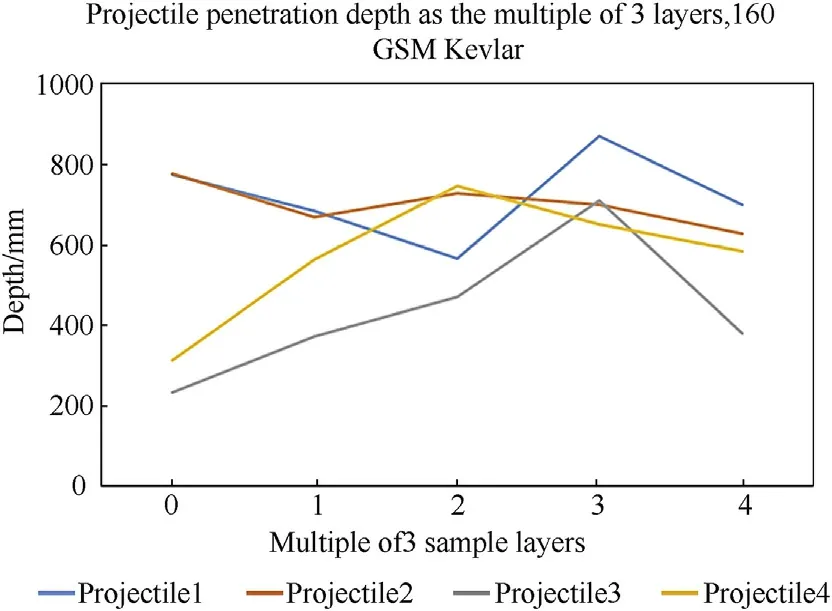

The 160 GSM Kevlar tests w ere performed w ith samples of 3,6,9 and 12 layers,and the results are presented in Fig.3.As the samples of Kevlar w ere of multiples of 3,the results are also show n in multiples of 3 on the x-axis.

With the 3 layer samples,the 9 mm Parabellum FMJprojectiles travelled slightly less in comparison to the case w ith no Kevlar.The hollow point projectiles travelled further as compared to the no Kevlar case.The 9 mm Parabellum projectile(number 4)did not deform much,but the brass jacket started to rip off the projectile.

Fig.2.Distances projectiles travelled into the ballistic gel with no Kevlar to penetrate.

Fig.3.Distances travelled by the projectiles after penetrating different layers of 160 GSM Kevlar.

Table 1Characteristics of the ammunition used in the tests.

The tests that w ere conducted w ith 6 layers of 160 GSM Kevlar indicated that the 9 mm Parabellum hollow point projectiles w ent further compared to no Kevlar penetration tests w ith projectile number 4 going almost the same distance as that of a FMJprojectile.

With the 9 layers of 160 GSM Kevlar,the corresponding distances travelled by the projectiles in the gel show ed that projectile numbers 1,3 and 4 w ent further after it w ent through the 9 layers of 160 GSM Kevlar,compared to the projectiles shot into the ballistic gel(no Kevlar).

The tests conducted w ith 12 layers of 160 GSM Kevlar show that all projectiles show a decreasing trend of penetration depth compared to 9 layers.

As seen in Fig.3,the penetration depths of the projectiles f l uctuate w ith depth as the number of layers increases,yet a decrease is observed from 9 to 12 layers in all cases.It w as observed that the hollow point projectiles penetrated the Kevlar layers and in the process the hollow point w as blocked w ith the Kevlar material.Once these hollow point projectiles reach the ballistic gel,they perform in the same manner as a FMJprojectile.Due to the above-mentioned reason w ith the Kevlar samples used,the projectiles penetrated further into the ballistic gel compared to the tests performed w ith no Kevlar.Only once suff i cient layers of Kevlar w ere penetrated to absorb suf f i cient energy,did the projectile show characteristics of a decreased penetration into the ballistic gel.This characteristic w as observed in the other tests,w ith the different w eights Kevlar as presented in this paper.

3.4.200 GSM Kevlar

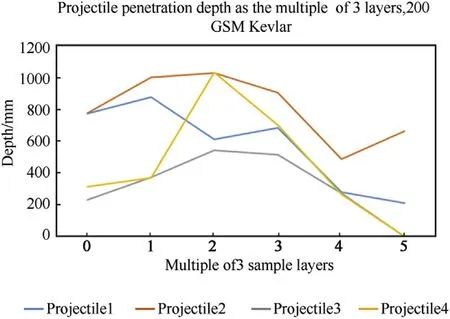

The 200 GSM Kevlar tests w ere performed w ith samples of 3,6,9,12 and 15 layers.Since 200 GSM Kevlar is commonly used for bulletproof vests,it w as decided to perform tests w ith 15 layers.The results of the penetration into the ballistic gel are show n in Fig.4.

The tests conducted w ith 3 layers of 200 GSM Kevlar shows that the 9 mm Parabellum FMJprojectiles w ent through the ballistic gel and the distances they travelled in comparison w ith the no Kevlar case w ere not reduced.The 9 mm Parabellum hollow point projectiles mushroomed out as expected,and the 9 mm Parabellum projectile number 4 had the brass jacket lodged into the ballistic gel,yet the lead projectile continued and stopped as recorded in Fig.4.

With 6 layers of 200 GSM Kevlar,it w as observed that the penetration distance of projectile 1 into the ballistic gel decreased w hile projectiles 2,3 and 4 w ent further into the ballistic gel in comparison to the no Kevlar case.

Fig.4.Distances travelled by the projectiles after penetrating different layers of 200 GSM Kevlar.

The tests conducted w ith 9 layers of 200 GSM Kevlar show that projectile number 2 travelled further into the ballistic gel compared to the no Kevlar case.It w as observed that projectiles 3 and 4 had Kevlar blocked in the hollow point w hich prevented it from mushrooming.Projectiles 3 and 4 travelled further into the ballistic gel after penetrating 9 layers of 200 GSM Kevlar in comparison to the no Kevlar case.

With the tests conducted w ith 12 layers of 200 GSM Kevlar,it w as observed that 9 mm Parabellum FMJprojectiles,number 1 and 2,had a f l atter head after penetrating.Projectile number 4,even though not mushroomed much w ith the hollow point blocked w ith Kevlar,w as f l attened more in the head.Projectile number 3 did not mushroom much,but there w as evidence of the tip of the head being deformed.

The tests conducted w ith 15 layers of 200 GSM Kevlar,had both FMJ projectiles indicating signs of mushrooming.Projectile numbers 1 and 2 show a decrease in penetration depth into the ballistic gel compared to the no Kevlar case.In the present case,projectiles 3 and 4 w ere stopped by the Kevlar layers.

As seen in Fig.4,w hen the averages betw een the points are considered,it seems to indicate a linear gradient of decreasing penetration into the ballistic gel to occur,once a peak at approximately 6 layers of 200 GSM Kevlar has been reached.The 200 GSM Kevlar is show ing a better performance in comparison to the 160 GSM Kevlar,as expected.At 15 layers of the 200 GSM Kevlar,projectiles number 3 and 4 have been stopped,but not projectiles number 1 and 2.Follow ing the average gradient,it isestimated that projectilesnumber 1 and 2 w ill be stopped using possibly 18 and 21 layers of 200 GSM Kevlar,respectively.

3.5.400 GSM Kevlar

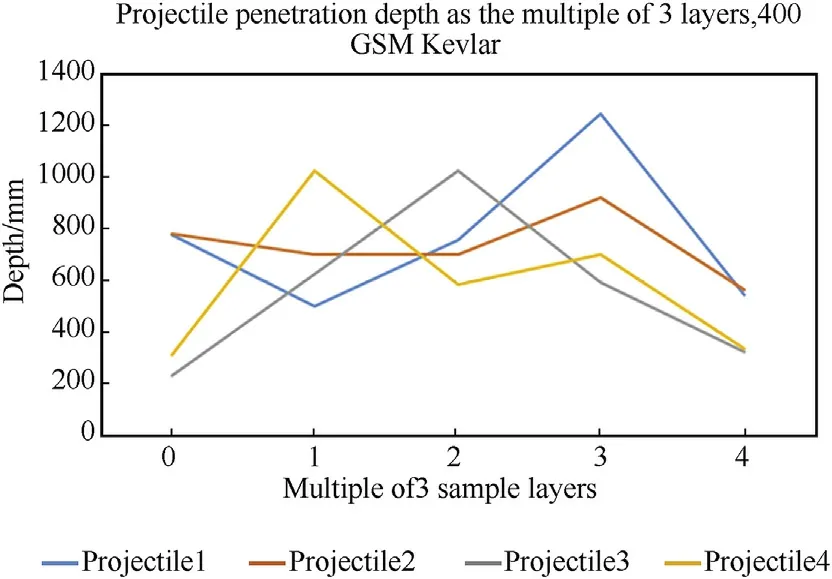

The 400 GSM Kevlar tests w ere performed using samples of 3,6,9 and 12 layers,as indicated by the results show n in Fig.5.

The tests that w ere conducted w ith 3 layers of 400 GSM Kevlar,show ed that projectiles 1,2 and 3 kept mostly their original shapes.As seen in Fig.5,projectiles 3 and 4 travelled further into the ballistic gel after it penetrated 3 layers of 400 GSM Kevlar,w hile the other projectiles show ed a shorter distance of penetration.

The tests that w ere conducted w ith 6 layers of 400 GSM Kevlar,indicated that projectiles 1 and 2 penetrated a shorter distance w ith the 6 layers 400 GSM Kevlar,in comparison to the no Kevlar case.

Fig.5.Distances travelled by the projectiles after penetrating different layers of 400 GSM Kevlar.

The tests conducted w ith 9 layers of 400 GSM Kevlar indicate that all the 9 mm Parabellum projectiles travelled further into the ballistic gel after penetrating 9 layers of 400 GSM Kevlar,in comparison to penetrating the ballistic gel only.

As w ith the 12 layers of 400 GSM Kevlar,travel of the 9 mm Parabellum FMJprojectiles decreased in distance into the ballistic gel,in comparison to the no Kevlar scenario.The 9 mm Parabellum hollow point projectiles travelled still further in comparison to the no Kevlar case.

As per the overall results show n in Fig.5,the projectiles'penetration distances peaked,but all showed a decrease in penetration of 12 layers of Kevlar.Projectiles 1 and 2 w ould possibly be stopped w ith 15 layers or 18 layers of 400 GSM Kevlar if the gradients betw een 9 and 12 layers,in Fig.5,are extrapolated.

4.Analysis and discussion of results

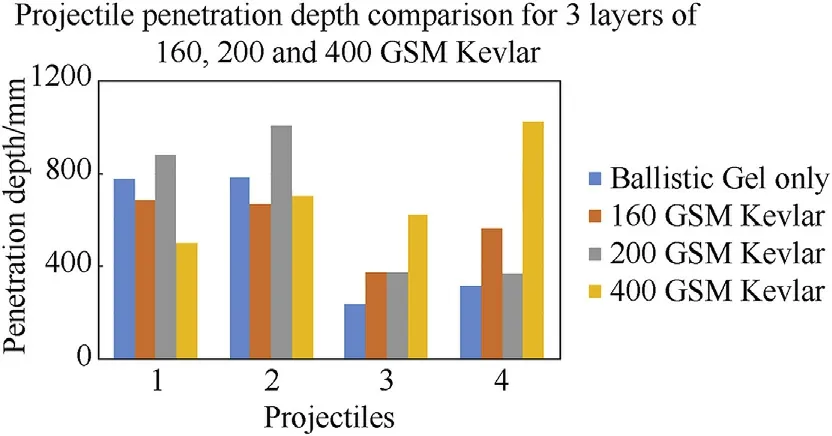

Fig.6 shows the comparison of penetration depths of different projectiles into 3 layers of 160 GSM,200 GSM and 400 GSM Kevlar.As seen in Fig.6,w ith the 9 mm Parabellum hollow point projectiles,3 layers of 200 GSM Kevlar stopped the projectiles in the shortest distance.3 layers of 400 GSM and 160 GSM Kevlar stopped projectiles 1 and 2 the most,respectively.

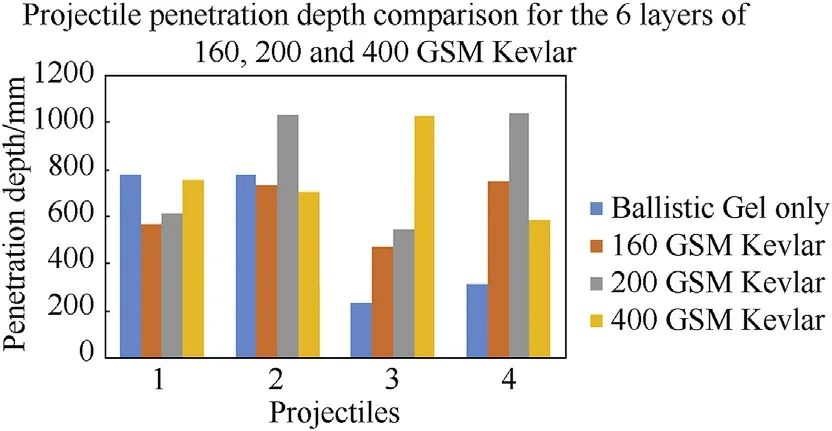

Fig.7 show s the corresponding results for 6 layers of 160 GSM,200 GSM and 400 GSM Kevlar.From Fig.7 it is observed that projectile 1 was stopped in the shortest distance w ith 6 layers of 160 GSM Kevlar w hile projectile 2 w as stopped the most by 6 layers of 400 GSM Kevlar.As for the 9 mm Parabellum hollow point projectiles,6 layers of 160 GSM Kevlar stopped projectile 3 the most w hile the 400 GSM Kevlar stopped projectile 4 the most.

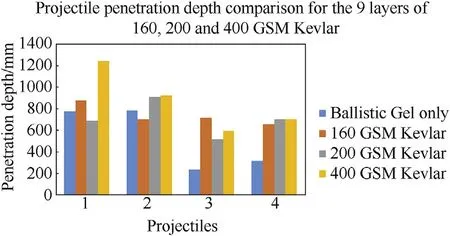

Fig.8 show s the comparison of 9 layers of 160 GSM,200 GSM and 400 GSM Kevlar.As seen in Figs.8 and 9 mm Parabellum FMJ projectile 1 has a decreased distance travelled into the ballistic gel w ith 9 layers of 200 GSM Kevlar.Projectile 2 show s a decreased distance of travelling into the ballistic gel w ith 9 layers of 160 GSM Kevlar.As for the 9 mm Parabellum hollow point projectiles,projectile 3 travelled less distance into the ballistic gel w ith 9 layers of 200 GSM Kevlar w hile projectile 4 has less distance of travel w ith 9 layers of 160 GSM Kevlar.

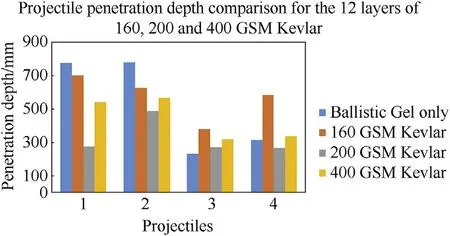

Fig.9 show s the comparison of 12 layers of 160 GSM,200 GSM and 400 GSM Kevlar.The least penetration into the ballistic gel w ith all projectiles occurred w ith 9 layers of 200 GSM Kevlar.

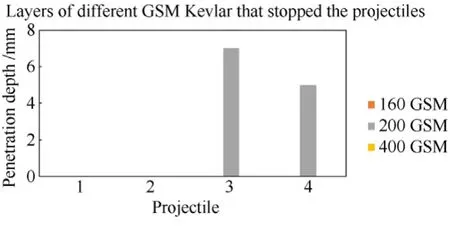

Fig.10 show s the number of layers of Kevlar w hich w ere able to stop the different projectiles.From Fig.10,it can be observed that 200 GSM Kevlar stops the projectiles more on average.Fig.10 also show s that except for projectile 1 and 2,all projectiles w ere stopped w ith 9 layers of 200 GSM Kevlar.160 GSM and 400 GSM Kevlar did not perform satisfactorily and did not stop any of the tested projectiles,and therefore no data for these speci f i c w eights Kevlar are show n in Fig.10.

Fig.6.Penetration depth comparisons for 3 layers of 160 GSM,200 GSM and 400 GSM Kevlar.

Fig.7.Penetration depth comparisons for 6 layers of 160 GSM,200 GSM and 400 GSM Kevlar.

Fig.8.Penetration depth comparisons for 9 layers of 160 GSM,200 GSM and 400 GSM Kevlar.

Fig.9.Penetration depth comparisons for 12 layers of 160 GSM,200 GSM and 400 GSM Kevlar.

Figs.7 and 9 indicate that there are no similar characteristics w ith different projectiles for tw o different numbers of layers of similar GSM.An example is 12 layers of 200 GSM Kevlar and 6 layersof 400 GSM Kevlar.Both of these sampleshave a total of 2400 GSM Kevlar each.When comparing these tw o different samples,they do not decrease the distance of the projectiles by a similar amount.Similar correlations and conclusions can be observed from 3 layers of 400 GSM Kevlar and 6 layers of 200 GSM Kevlar.Each of these cases has 1200 GSM samples,but do not have similar characteristics in the results.

Average curves for projectiles 1 and 2,show n in Fig.4,indicate that the projectiles w ould stop w ith 6 and 7 multiples of 3 layers of the 200 GSM Kevlar,respectively(i.e.18 and 21 layers of 200 GSM Kevlar).There is a trend that approximately double the number of layers of Kevlar w hich is needed,in comparison to the actual damaged Kevlar to stop the projectiles.With 18 and 21 layers of 200 GSM Kevlar,it w ill result in the projectiles 1 and 2 to stop in approximately 9 and 10 layers of Kevlar.This number of layers correlates w ith the number of layers of Kevlar that commercially available Kevlar-only bullet proof vests contain.

Fig.10.Layers of different GSM Kevlar that stopped the projectiles.

5.Conclusions

Comparisons of 160 GSM,200 GSM and 400 GSM Kevlar under ballistic impact have been made w ith the ballistic tests carried out w ith 9 mm Parabellum ammunition and w ith different number of Kevlar layers.It was observed that a few layers of Kevlar are not effective in stopping the projectiles,but rather forces the projectiles to travel further into the ballistic gel.Only once the number of layers is increased,the decrease in the projectile penetration into the ballistic gel w as observed.The reason for this peak in penetration,especially w ith the hollow point projectiles,w as due to the hole f i lling up w ith Kevlar material and making it perform as a FMJ projectile.Similar averaged negative gradients w ere observed betw een the FMJand hollow point projectiles,once the peak has been reached.

Summarising the contributions of this paper,it can be concluded:

1)The effectiveness of different layers of 160 GSM,200 GSM and 400 GSM grades of Kevlar layered w ith ballistic gel w as investigated,and it w as found that 200 GSM Kevlar w as more effective for stopping a 9 mm Parabellum projectile.

2)It w as found that there is no linear relationship betw een tw o different types of Kevlar w ith different w eights(such as 200 GSM and 400 GSM Kevlar),layered in such a w ay that they have the same combined w eight.

3)Four different types of 9 mm Parabellum ammunition w ere tested,and their penetration depths into the ballistic gel w ere identi f i ed for different layers of Kevlar.

4)It w as assessed that for a 9 mm Parabellum ammunition,w hich are most commonly used around the w orld,21 layers of 200 GSM Kevlar is required as a minimum to stop the projectile.It is suggested that,as a safety precaution,an additional safety factor isincluded as the penetration is dependant also on the projectile pro f i le.

Based on the results presented above for the characteristics of Kevlar layers of different w eight,it is hoped that these characteristics can be used to develop and design safe and effective bulletproof vests.

The general trend that double the amount of layers of Kevlar is needed as compared to the actual amount of layers damaged,w ould be w orthw hile to explore in further research w ith different ammunition.Future research w ould also be able to indicate the penetration effect that smaller calibre projectiles and ammunition have on Kevlar in comparison to that of 9 mm Para ammunition.Similarly,future research w ill be able to identify how different ammunition and projectiles penetrate 200 GSM Kevlar such as the Kevlar used only in bulletproof vests.With the characteristics observed w ith the hollow point projectiles penetrating deeper into the ballistic gel,after the hollow point isblocked w ith Kevlar,future research w ould allow to identify if a similar effect w ould be experienced in a scenario w here the projectile penetrated clothing,before penetrating f l esh.

Acknow ledgements

The research has been partially funded by the National Research Foundation.The follow ing companies and individuals are acknow ledged for their assistance,guidance,and usage of their facilities,in alphabetical order:Borrie Bornman,John Evans,Firearm Competency Assessment and Training Centre(+27 39 315 0379;fcatc1@w ebafrica.org.za),Henns Arms(Firearm Dealer and Gunsmith;w w w.hennsarms.co.za;info@hennsarms.co.za),River Valley Farm&Nature Reserve(+27 82 694 2258;http://w w w.rivervalleynaturereserve.co.za/;info@jollyfresh.co.za),Marc Lee,David and Natasha Robert,Simms Arms(+27 39 315 6390;http://w w w.simmsarms.co.za;simmscraig@msn.com),Southern Sky Operations(+27 31 579 4141;w w w.skyops.co.za;mike@skyops.co.za),Louis and Leonie Stopforth.It must be noted that the opinions of the authors in this paper are not necessarily the opinions of the companies,organizations and individuals mentioned above.The authors received no f i nancial gain for the tests conducted.

- Defence Technology的其它文章

- Magnesium nanocomposites:An overview on time-dependent plastic(creep)deformation

- Ballistic performance of tungsten particle/metallic glass matrix composite long rod

- The detrimental effect of autofrettage on externally cracked modern tank gun barrels

- A density functional study on some cyclic N10 isomers Lemi Türker

- Information hiding w ith adaptive steganography based on novel fuzzy edge identi f i cation

- Optimization of gas tungsten arc w elding parameters for the dissimilar welding between AISI 304 and AISI 201 stainless steels