Waste production in aquaculture:Sources,componentsand managements in different culture systems

Akeem Baatune Daua,Aullateef Ajai,Aenike Susan Tola-Faunmi,Ayoola Olusegun Akinwole

a Laboratory of Aquaculture,Department of Fisheries and Aquaculture,Federal University Dutsinma,P.M.B.5001,Dutsinma,Katsina State,Nigeria

b Laboratory of Pathology,Department of Veterinary Pathology,Faculty of Veterinary Medicine,University of Ilorin,P.M.B.1515,Ilorin,Nigeria

c National Centre for Genetic Resources and Biotechnology,Federal Ministry of Science and Technology,P.M.B.5382,Moor Plantation,Ibadan,Oyo State,Nigeria

d Laboratory of Aquaculture,Department of Aquaculture and Fisheries Management,University of Ibadan,Ibadan,Nigeria

Keywords:Fish farming Aquaculture effluents Environmental degradation Waste management Sustainable aquaculture

A B S T R A C T The intensif ication of aquaculture has emerged as a viable alternative for increasing aquaculture production due to competition that arose from the use of natural resources,such as land and water,by other production and developmental sectors.However,intensif ication demandsincreased inputs,such asf ish and feed per unit culture area and,therefore,increased waste generation from the aquaculture production systems.The impact of waste products from aquaculture has increased public concern and threatens the sustainability of aquaculture practices.The need for increasing the production of aquaculture products cannot be overemphasized and,therefore,there is a need to develop culture systems that will increase f ish production with efficient waste management in order to limit environmental degradation resulting from aquaculture wastes and ensure its sustainability.This paper reviewed various aspects of waste production from aquaculture,their sources,components,and methods of management,in different culture systems,primarily discussing waste production from feed,chemicals,and pathogens.We aimed to establish the sources of wastes,their contents,and potential harms to both the f ish culture and the environment.Suggestions for managing wastes in different culture systems were made to ensure an improved and sustainable aquaculture production.

1.Introduction

The increase in aquaculture production has been necessitated by a reduction of wild f ish catch(Dauda,Folorunso,&Dasuki,2013).The global human population increase has resulted in a consequential increase in the demand for f ish(FAO,2016).However,the same increase in population that necessitated an increase in demand for f ish and f ish products has led to an increased competition for the basic needs of aquaculture development,including water,land,and other natural resources.The intensif ication of production is an alternative for the needed development in aquaculture (Crab,Defoirdt,Bossier,&Verstraete,2012).Intensif ication of aquaculture production will require the use of more inputs,especially feed per unit area of land(Henriksson,Belton,Murshed-e-Jahan,&Rico,2018),leading to an increase in waste generation from the production systems.

Aquaculture is like any other production enterprise where there are inputs to generate products.There are always wastes in such systems,which are either unused inputs or by-products.These wastes have little or no economic value and are often a nuisance to the environment.The waste generation from aquaculture has made its sustainability a public concern(Buschmann et al.,2006;Martins et al.,2010).The amount of waste generated from aquaculture production in Japan,irrespective of type of f ish culture,is so high that one ton of f ish generate 0.8 kg of N and 0.1 kg of phosphoruson average,equivalent to the waste generated by 73 people per day(assuming 11 g N per person per day(Suzuki,Maruyama,Numata,Sato,&Asakawa,2003).Furthermore,the pollutants(metabolic wastes)discharged by 63,000 tons of f ish produced were equivalent to the waste generated by 5 million people in Japan in 1999(Suzuki et al.,2003).This underscores the need for proper methods to ensure the sustainable intensif ication of aquaculture.Godfray et al.(2010)described a sustainable intensif ication asa system of production where more food is produced from the same area of land without increasing the environmental impacts.This paper focuses on waste production from aquaculture,sources,components,and management methods in different culture systems.

2.Sources of w aste from aquaculture

2.1.Feed

Feed is an extremely important factor of production in aquaculture and its level of importance depends on the type of culture technique(Biswas,Jena,Singh,&Muduli,2006;Dauda,Ibrahim,Bichi,&Tola-Fabunmi,2017a).In an extensive system,feed supply to f ish is mainly dependent on the environment.The f ish are left in low density over a large culture area and feed primarily on naturally occurring organisms,with some aid from pond fertilization(Ajani,Akinwole,&Ayodele,2011).This type of culture system is primarily outdoors and does not meet the current demand for aquaculture products.In semi-intensive culture,f ish are stocked at a moderate to relatively high density and rely on both food from natural production and supplemental feed from the culturists(Dauda et al.,2017a).In intensive systems,natural food production is not relied upon,using very high quality artif icial feed targeted towards fast growth instead(Ajani et al.,2011).Feed has been reported to be the major source of waste in aquaculture systems(Akinwole,Dauda,&Ololade,2016;Martins et al.,2010).The effect of waste production due to f ish feed varies with the amount of supplemental feed.Waste production from feed depends on so many factors,including its nutrient composition,method of production(extruded vs pelleted),ratio of feed size to f ish size,quantity of feed per unit time,feeding method,and storage time(Miller&Semmens,2002).

2.2.Chemicals

Current aquaculture practices strictly limit the use of chemicals in f ish farms,however,some chemicals are still used in the form of medications,disinfectants,and antifoulants(Read&Fernandes,2003).The medications are used for chemotherapeutic purposes,which include the antibiotics being used for prophylaxis and curative purposes(Ajadi,Sabri,Dauda,Ina-Salwany,&Hasliza,2016),anaesthetics,ectoparasiticides,endoparasiticides,and vaccines,being used for the treatment and control of parasites(internal and external),as well as microbial infections(Costello et al.,2001).Salts,mainly,are used to reduce stressin f ish,lime isbeing used to treat pond bottomsfor acidity during pond preparation,and other chemicals considered not harmful to f ish are also used.Although these chemicals are important to f ish culture,they may also constitute a nuisance to the environment(Boyd&McNevin,2015).Asthe water is released from the ponds,it f lows into natural water bodies.The effect of these chemical wastes upon these natural water systems depends on the concentration of chemicals used,the farm size,and the size of the receiving water bodies.

2.3.Pathogens

This group of waste is rarely considered in aquaculture systems,especially when it is below the level that affects the cultured f ish.However,discharging pathogens with the wastewater(Goldburg&Triplett,1997)may negatively affect the aquatic organisms in the natural water bodies.Natural water bodies have their own pathogenic load and receiving additional loads from f ish culture systemsmay cause stress or the outright death of aquatic organisms.The discharge of pond effluent is rampant in semi-intensive pond aquaculture,which is more common in Africa(FAO,2009),where organic fertilizers used in aquaculture resulted in a high level of pathogens(Ansah,2010).Four organic fertilizers(blood cow waste,cow manure,pig manure,and poultry manure)contribute to a high level of fecal streptococci(Ampofo&Clerk,2003).

3.Components of w aste from aquaculture systems

Componentsof waste produced from aquaculture systemshave been characterized by many authors(Akinwole et al.,2016;Piedrahita,2003;Timmons,Ebeling,Wheaton,Summerfelt,&Vinci,2002).Our focus will be narrowed to those major aquaculture wastes from feed.Generally,wastes from aquaculture can be classif ied into solid wastes and dissolved wastes.

3.1.Solid wastes

Solid wastes are primarily derived from the uneaten feed and fecal droppings of cultured f ish(Akinwole et al.,2016).They occasionally include those f ish that do not survive the culture process.Solid wastes can be further classif ied as suspended solids and settled solids.The suspended solids are f ine particles and remained suspended in the water,except when a method of coagulation or sedimentation is employed,and are the most difficult type of solids to remove from culture systems(Cripps&Bergheim,2000).The settled solids are larger particlesthat settle within a short period of time and can be easily removed from the culture column(Ebeling&Timmons,2012).Solid wastes have been classif ied as the most dangerous waste in f ish culture systems and should be effectively removed as quickly as possible(Timmons&Summerfelt,1997).Solid wastes are regarded to be very dangerous because they can clog the f ish gills and lead to death,especially in the case of large settled particles(Akinwole et al.,2016).If left for a long time and allowed to decompose,these wastes lead to increases in both the total suspended and total dissolved solids.They may also increase the nitrogenous compounds and stress the cultured f ish(Akinwole et al.,2016).If solid wastes in aquaculture remain within the culture system,their aerobic bacterial activity will increase the chemical oxygen demand and biochemical oxygen demand and deplete oxygen within the culture column(Timmons&Lorsodo,1994).In a properly managed farm,(i.e.,feeds are properly stored,effectively fed,and the right size is being used)approximately 30 percent of the feed will become solid wastes(Miller&Semmens,2002).This is subject to the type of culture system,as it is easier to remove solid wastes from recirculating aquaculture systems than from f low through systems(d'Orbcastel et al.,2009).

3.2.Dissolved wastes

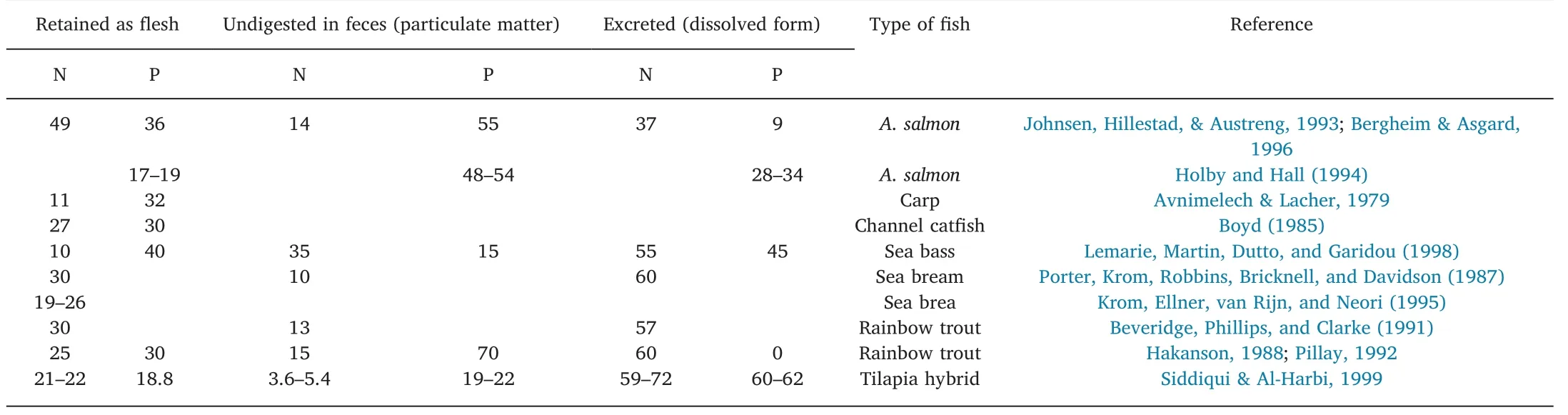

Dissolved wastes are products of food metabolism in f ish or decomposed,uneaten feed.In dissolved wastes,the two major components of concern are nitrogen(N)and phosphorus(P)products(Boyd&Massaut,1999).These two elements constitute important components of protein,which is the main component of f ish feed.Fish,irrespective of species,require a high dietary crude protein ranging from 25 to 50%.The high protein f ish feeds contain high amounts of nitrogen and phosphorus,yet less than 50%of these potential water pollutants(nitrogen and phosphorus)are retained in the body of the f ish(Piedrahita,2003).Hence,a large percentage is transferred into the culture water,where it becomes a nuisance,and,when f inally released,has a lot of environmental impacts.The amount of nitrogen and phosphorus retained by the f ish varies,with average nitrogen retained ranging from between 25%and 30%(Boyd,2003)to 10%-49%(Piedrahita,2003)and 17-40%for phosphorus retention(Piedrahita,2003)(Table 1).Piedrahita(2003)went further to reveal that f ish fecal droppings contained 3.6%-35%N and 15%-70%P,while the amount of N and P as the excretory products were 37%-72%and 1%-62%,respectively.The nitrogen is mainly excreted in dissolved form as ammonia,while phosphorus is excreted as particulate matter(Bureau&Cho,1999;Sugiura,Raboy,Young,Dong,&Hardy,1999).

Fish are unable to utilize a substantial percentage of N and P,which are primarily the main nutrients(components)of the feed,giving aquaculture a high potential for environmental pollution(Lazzari&Baldisserotto,2008),hence its categorization as industrial waste.These nutrients enter the systems and are eventually released into the environment as waste(Stephens&Farris,2004).These nutrients,when released into water,can harm f ish and other inhabitants of aquatic ecosystem at high concentrations.They can also lead to increase in both dissolved solids and total suspended solids,as well as water turbidity(Boyd et al.,2000;Teichert-Coddington,Rouse,Potts,&Boyd,1999).It is possible that these dissolved nutrients have little or no signif icant effect on the cultured f ish,depending on the concentrations(Ansah,2010).However,releasing of culture water of poor quality may have a signif icant impact on the aquatic organisms in the receiving water bodies(Boyd&Massaut,1999;Piedrahita,2003;Stephens&Farris,2004).

Table 1Nutrient(nitrogen and phosphorus)retention and excretion rates(as a percentage of the feed consumed).Source:Piedrahita(2003),with little modif ication.

Nitrogen is released into culture water in the form of ammonia,which may be further decomposed to nitrite and nitrate(Dauda,Akinwole,&Olatinwo,2014;Piedrahita,2003),depending on the biological activity in the culture column.Ammonia(NH3)is highly toxic to both the f ish cultured in the system and those in receiving water bodies,if not treated before released into the environment(Romano&Zeng,2013).Ammonia existsin two forms,the un-ionized form and the ionized form(NH3and NH4+).In water,the two exist in equilibrium at ratios determined by water temperature and p H(Ebeling&Timmons,2012).The un-ionized form is highly toxic,the ionized form is slightly less toxic,and the summation of the two is total ammonia nitrogen(TAN).The second critical pollutant of f ish culture water is ammonianitrogen,most especially in the un-ionized form(Romano&Zeng,2013).Cultured f ish have varying tolerances of ammonia-nitrogen which depends on f ish species,age,and physiological status.Warm water f ish are more tolerant than cold water f ish,while adult f ish are more tolerant than the f ingerlings and juveniles.Ammonia is generally recommended to be below 1 mg/L in culture tanks(Ajani et al.,2011).According to Boyd(2003),Global aquaculture alliance(GAA)recommended total ammonia nitrogen(un-ionized ammonia+ionized ammonia)of 5 mg/L in the aquaculture effluents as part of the guidelines for aquaculture effluents management.

Nitrite is the intermediate product of ammonia oxidation to nitrate,is also toxic,and the level below 0.5 mg/L is generally desirable in f ish culture systems(Ajani et al.,2011).However,nitrite is not stable and further oxidizes to nitrate.

Nitrate is the end product of ammonia oxidation and it is generally regarded as safe because it is not toxic to most f ish species even at a concentration as high as 200 mg/L(Dauda&Akinwole,2015).However,it constitutes a nuisance to the environment because it is capable of enriching the receiving water and,with phosphorus,causing eutrophication(Dauda et al.,2014).Fish culture systems where water is being treated for ammonia reduction,mainly in recirculating aquaculture systems,employ biof ilters for oxidation of ammonia to nitrate(Dauda&Akinwole,2014;Dauda et al.,2014;Suzuki et al.,2003;van Rijn,Tal,&Schreier,2006).Nitrate can accumulate over time to levels as high 300-400 mg/L(van Rijn,1996)and,depending on the frequency of water exchange and when such water is released,will negatively impact the receiving water body(Dauda et al.,2014).

Phosphorusisanother important metabolite or decomposed product of aquaculture feed that is also poorly utilized.Unlike ammonia,phosphorus is not toxic to cultured f ish,but when released to the environment,it enrichesnatural water bodiesand leadsto eutrophication,depending on its concentration,frequency of release,and the size of the receiving water body(Wong,2001).Unlike nitrogen that is released into the water mainly in dissolved form,a larger percentage of P is released as particulates in feces.This varies with species,with Tilapia hybrid releasing major phosphorus(60-62%)in dissolved form through excretion(Piedrahita,2003).Phosphorus in culture water is primarily released as phosphate,which is an important nutrient for receiving water along with its nitrate counterpart from nitrogen(Lazzari&Baldisserotto,2008).Unfortunately,when the concentration is high,the two cause eutrophication in the receiving water bodies.

4.Management of w aste in aquaculture systems

The primary solution for managing the environmental impacts of aquaculture is the management of feed(Martins et al.,2010;Turcios&Papenbrock,2014).Feed and feeding systems can effectively reduce wastes resulting from the f ish feed through proper management of the inputs into the culture system.d'Orbcastel et al.(2009)reported that a reduction in feed conversion ratio(FCR)by 30%in a f ish farm will bring about 20%reduction in environmental impact from the f ish culture system.In order to reduce waste from aquaculture,Westers(1995)recommended the following:

●That the species and f ish size-specif ic potential performance of any diet to be supplied must be known.This may necessitate labeling feed with necessary information on feed digestibility and waste production,including the quantity of solids,phosphorus,and nitrogen.There may also be information on FCRobtained under a trial condition with optimized system;

●There should be knowledge of the biomass of the f ish in the system;

●Adequate information on health and physiological status of the f ish must be available;

●Uniformity in size of f ish is very important,in order for them to accept the same size of pellet;

●The feed should be sieved to remove dust and broken pellet before being fed;and

●The feed must be fed effectively to ensure little or no waste resulted from the uneaten feed.

The use of grains that are low in phytate is also encouraged in f ish feed production to reduce the amount of phosphorus released into the water through uneaten feed or f ish metabolic waste.Hardy(2010)reported that majority of the phosphorus in plant protein cannot be utilized by f ish,which are monogastric animals.Researchers have also suggested the increase of phytase in the feed formulation to increase bioavailability and utilization of the phosphorus in f ish feed(Baker,Smith-Lemmon,& Cousins,2001;Orisasona & Ajani,2015;Papatryphon,Howell,&Soares,1999).Rodehutscord and Pfeffer(1995)noted that increased phytase in f ish feed formulation also increased bioavailability and utilization of phosphorus in f ish diets.They also noted that this process was more effective in warm water f ishes,as the impact of phytase is impaired by lower temperature in cold water f ish culture.Baker et al.(2001)reported a level of 3-phytase between 500 and 2000 phytase units per kilogramme(FTU/kg)of feed as being effective in increasing the utilization of phosphorus in trout,a cold water f ish species.The performance of Clariasgariepinus f ingerlings was improved when fed a diet including phytase between 5000 FTU and 7500 FTU/kg with toasted lima beans as the plant protein source(Orisasona&Ajani,2015).The development of high-energy extruded feed has also improved feed utilization and reduced FCR and safe wastage in f ish feeding.The high-energy extruded feed also increases the fat content of the feed without using the coating method,hence,limiting the leaching of fat into culture water.It also allowed for the production of sinking and f loating feed that are regular and stay longer in water without nutrient leaching(Miller&Semmens,2002).Bender et al.(2004)reported a low FCR in trout cultured with high-energy extruded feed.The moderate size and tight compaction of the highenergy feed also limits f ines and reduces the potential waste that is associated with irregular feed sizes and f ines(Turcios&Papenbrock,2014).

4.1.Solid wastes

Solid wastes have been implicated as the most deleterious waste in f ish culture systems and,systems that can remove them rapidly and effectively are given higher priority(Akinwole et al.,2016).The two major sources of solid wastes in aquaculture are uneaten feed and undigested substances,which are passed asfecal waste in f ishes(Turcios&Papenbrock,2014).The amount of solid wastes in f ish culture systems and those f inally released to the environment varies with f ish culture system type(Bergheim&Asgard,1996),the amount of feed supplied,and effectiveness of feeding process.Thus,general waste management will be discussed with reference to these different culture systems.

4.1.1.Pond systems

Pond systems are the traditional system of f ish culture(Akinwole,Bankole,Dauda,&Ayanlere,2014)and are used globally.According to the United States Department of Agriculture(USDA,2000),63%of all f ish culture in the United Statesisstill done in pond culture system and,in the north central region of United States of America,65%is done in pond culture(Yeo,Binkowski,&Morris,2004).Pond culture systems are static and have no special means of water treatment.The pond system relies mainly on internal processes,where solid wastes settle at the bottom of the pond and accumulate over time(Yeo et al.,2004).The microbes in the system act on the settled waste and convert it to less toxic material.However,if the settled waste has accumulated over time,any natural activities,such as erosion,can cause mixing of the highly nutritious pond bottom and may lead to algal blooms.The only way of removing solid waste from the pond culture is by desilting,which is done after two or more f ish culture rounds.Lack of adequate waste management techniquesin pond culture systemshas limited their use to semi-intensive culture operations.The production capacity of ponds depends on the amount of feed that can be added daily without the degeneration of the water quality.Tucker,Hargreaves,and Boyd(2001)reported a daily feeding rate of 30-50 kg/ha and this limited the annual production to 2000-3000 kg/ha.

4.1.2.Flow through/raceway system

Unlike the pond systems,where the solid waste is settled within the system,the f low through system experiences a high level of water exchange where most of the wastes produced are discharged from the culture unit.In most f low through systems,the water retention time is less than an hour.The solid wastes are usually collected at quiescent areas into an offline basin(Ebeling&Timmons,2012).The f low through system,if properly designed,can provide fast collection and concentration of solid wastes before fragmentation(Miller&Semmens,2002).According to Summerfelt and Timmons(2000),a round tank can be designed with dual effluent areas,containing a high exit at the upper perimeter for high-volume low-density solids and another exit at the center of the tank for low-volume high-density solid wastes.A properly designed circular tank with inlets,drains,and f ilters can remove majority of the solid wastes from the tank.Wong(2001)also proposed a raceway system where a device is inserted to create a circular f low at the center for collection and concentration of most of the solid wastes and this may allow exit of 10-20%of the wastes at the center.The major problem of solid wastes management in f low through systems is that it remediates the culture unit at the expense of the environment.The solid wastesremoved through f low through system are difficult and expensive to manage because of a high f low rate of weakly-concentrated effluents.The f low through systems has a f low rate 10 to 100 times higher than recirculating systems,while the waste concentration method is 10-100 times less than that of the RAS(Blancheton et al.,2007).

4.1.3.Recirculating aquaculture system(RAS)

The RASis a culture system that allows reuse f ish culture water and has been proven to be better at removing solids than the f low-through system.According to Pedersen et al.(2008),RAShas the potential of reducing environmental impacts from aquaculture waste when compared with f low through systems.RAS removes solid wastes through sedimentation and screen f ilters(Ebeling&Timmons,2012).Though RAScan remove a large portion of solid wastes through sedimentation,it is not effective in removing f ine solids from the system(Piedrahita,2003),hence,the need for a supplementary screen f ilter along with the sedimentation technique.Singh,Ebeling,and Wheaton(1999)reported no differences in water quality between RASwith screen f ilter and that of settling basins,though the needed make-up water volume was signif icantly higher in RAS with settling basins.Generally,screen or f loating bead f ilters have better solid removal efficiency compared to sedimentation basins,though total solid removal is not also possible with screen f ilters(Patterson,Watts,&Timmons,1999).A substantial amount of solid particles in RAS are less than 10μm and can cause problems in RAS,if not effectively removed.They can clog biof ilters,lead to secondary production of ammonia,have negative impacts on other components of the systems,and health of the cultured f ish(Patterson et al.,1999).Neither screen f ilters,nor settling basins,can remove particles less than 50μm effectively from the culture tank,but the removal efficiency of granular media or foam fractionator f ilters may be better(Waller,2001).Even though solid waste removal is considered to be comparatively cheaper and easier than other types of waste in the f ish culture system,it is extremely important to employ effective techniques that will remove it as quick as possible.Effective removal of solid wastesmay ensure reduction of some other nutrientsin culture water,most especially phosphorus and organic matter,which are released largely as particulate matter(Piedrahita,2003).According to Martins et al.(2010),RAS has tendency of removing 85-98%of organic matter and suspended solids and 65-96%of phosphorus through effective removal of solid wastes.

4.2.Dissolved wastes

Dissolved organic wastes in f ish culture systems are primarily nitrogen and phosphorus.While there are different techniques for nitrogen removal in f ish culture systems(section 4.3),there is hardly a specially designed technique for removal of phosphorus in f ish culture systems.This may be partly due to the fact that phosphorus is not toxic to culture f ish,unlike nitrogen,which has toxic derivatives,such as ammonia and nitrite.Phosphorusisreduced in culture systemsthrough:reduction of phosphorus in the feed;inclusion of phytase to increase bioavailability and utilization of dietary phosphorus(Orisasona&Ajani,2015);or through efficient and quick removal of solids,since larger amounts of phosphorus are released in particulate form(Bergheim&Asgard,1996;Martins et al.,2010;Piedrahita,2003).Though Abeysinghe,Shanableh,and Rigden(1996)designed a model RASwith total nutrientsremoval that wasable to reduce ashigh as 40% phosphorus from culture system,there has not been a record of any such system used for commercial purpose.

4.3.Nitrogen removal from culture systems

4.3.1.Pond systems

The pond systems rely on natural process for purif ication and maintenance of water in f ish culture.The pond biological community,mainly microbes,work on dissolved organic matter and ammonia(Yeo et al.,2004).The ammonia is converted by nitrobacter and nitrosomonas to less toxic nitrate(Dauda et al.,2014),while the nitrate and phosphate in the waste serve as nutrientsfor the phytoplankton and macroalgae in the pond ecosystem.The phytoplankton are fed upon by the zooplankton and f inally harvested by the f ish.However,the pond system's ability to manage aquaculture waste is limited and depends directly upon the amount of waste that can be recycled by the pond daily(Tucker et al.,2001).Any amounts beyond this may lead to excessive nutrient enrichment of the pond,eutrophication,and the death of f ish in the culture unit.This limits the use of pond to extensive to semi-intensive f ish culture systems.

4.3.2.Flow through system>

This system has no special provision for nitrogen removal except for expedited removal of the solids and water with the dissolved nutrients from the culture unit.

4.3.3.Recirculating aquaculture systems

RASemploys a biological system for management of nitrogen in the culture system.Crab,Avnimelech,and Defoirdt(2007)noted that the most important water treatment in RASis a biological process that uses the nitrif ication process to convert toxic ammonia to less toxic nitrate.Research on the nitrif ication processes of aquaculture effluents has led to the development of various media(biof ilters)with different properties,advantages,and disadvantages(Martins et al.,2010).Biof ilters are classif ied into two types:emerged and submerged f ixed-f ilm f ilters.The emerged f ixed-f ilm f iltersinclude rotating biological contactorsand trickling f ilters,while submerged f ixed-f ilm f ilters include f luidized bed f ilters and bead f ilters(Dauda et al.,2014;Malone&Pfeiffer,2006).Biof ilters provide a surface for the growth of microbes that come in contact with the wastewater and convert the toxic ammonia to nitrate(Ebeling&Timmons,2012).The conventional RAS does not remove nitrogen(ammonia)from the culture water,instead converting it to the less toxic nitrogenous product(nitrate)(Dauda et al.,2014).The use of RAShas contributed immensely to the development of aquaculture due to its various advantages,which includes:reduced water usage through partial reuse of culture water(Verdegem,Bosma,&Verreth,2006);reduced environmental impacts from f ish culture systems through improved waste management and nutrient recycling(Martinset al.,2010),improving the hygienic condition;reducing the emergence of diseases(Summerfelt,Sharrer,Tsukuda,&Gearheart,2009;Tal et al.,2009);and limiting biological control through escape of culture f ish(Zohar et al.,2005).In contrast,the use of RASis still small compared to the pond,f low through,and cage systems(Martins et al.,2010),due to the high cost of RAS installation(Dauda&Akinwole,2014;Schneider,Blancheton,Varadi,Eding,&Verreth,2006).Suzukiet al.(2003)noted that the volume of water exchange in RASdaily isvaried between 5 and 100%and this may minimize the effect on reducing pollution load.The use of biof ilters to achieve nitrif ication may lead to nitrate accumulation,especially when combined with a decreased frequency of water change(Dauda&Akinwole,2015).Though nitrate is relatively nontoxic,at a concentration above 200 mg/L,it may affect the growth of commercially cultured organisms such as eel(Kamstra,Van Der Heul,&Nijhof,1998)and,above 250 mg/L,African catf ish(Clarias gariepinus)(Ajaniet al.,2011).Nitrate levelsin RAScan be ashigh as400-500 mg/L and at this point it may affect the performance of cultured organisms and become unf it for direct discharge into open water bodies.

The development of denitrif ication in RAS has increased the performance of RASand progressed towards a zero-emission aquaculture system(van Rijn et al.,2006).Unlike the conventional RAS,where nitrogen is merely transformed from highly toxic(ammonia)to less toxic(nitrate),the incorporation of denitrif ication units ensures the removal of nitrogen from the systems.Therefore,nitrogen is removed from the system rather than accumulated as with conventional RAS(Dauda&Akinwole,2015;Dauda et al.,2014;Martins et al.,2010;Suzuki et al.,2003;van Rijn et al.,2006).Denitrif ication is the dissimilatory reduction of nitrate(NO3-)to nitrogen gas and is done primarily by heterotrophic bacteria in anoxic conditions,where nitrate is used as terminal electron receptor with carbon as an energy source(Dauda et al.,2014).Martins et al.(2010)listed the merits of incorporating denitrif ication bioreactor to the conventional RAS,which include:

●reduction of make-up water required for nitrate control;

●reduction of the nitrite discharge;

●reduction of energy consumption asa result of heat produced by the bacteria in the reactor as well as reduction in the amount of makeup water required to be heated;and

●concentration and reduction of solid f lows from drum f ilters, through in situ solid digestion,resulting in a reduction in the discharge fees for TAN,nitrate,organic nitrogen,and organic matter.

The use of denitrif ication is largely limited in commercial farms despite its numerous advantages.This is due to several reasons,including:

●high cost of installation;

●high level of expertise required;and

●accumulation of total dissolved solid on the farm.

Though reduced water use is seen as an important advantage of denitrif ication systems,this may also be considered a disadvantage.Reduced water exchange in the system may lead to the accumulation of certain growth-inhibiting factors,such as cortisol from the f ish itself,bacteria metabolites,and heavy metals from the feed(Martins et al.,2010).However,research reports showed no negative impact of low water exchange RASon growth performance of grow-out trout cultured in the denitrif ication incorporated RAS(Good et al.,2009;Martins,Ochola,Ende,Eding,&Verreth,2009).Schram et al.(2009)also reported no reduction in growth over 550 days(long-term experiment)for turbot culture(Scophthalmus maximus)in low water exchange RAS compared to re-use f low through systems.

4.4.Biof loc technology system

Biof loc technology isan emerging technology in f ish culture systems that is progressing towards ensuring sustainable aquaculture(Bossier&Ekasari,2017;Dauda et al.,2018),unlike RASwhere the water treatment is done outside the culture column;biof loc technology is an in-situ water treatment method(Vinatea et al.,2018).Biof loc technology is similar to denitrif ication systems in which a carbon source is supplied to the culture system to stimulate the growth of heterotrophic bacteria that converts toxic ammonia to nitrogen gas instead of nitrates that accumulate in conventional RAS(Dauda&Akinwole,2015).However,while denitrif ication system is done ex-situ and requires a biof ilter for the development of bacteria,biof loc technology systems require no biof ilter nor external equipment(Vinatea et al.,2018).This saves aquaculturists from the high costs of initial investment associated with denitrif ication systems(Luo et al.,2014).Biof loc technology is a water quality management technique that is based on the development and controlling of heterotrophic bacteria within the culture system with minimal or zero water exchange(Ekasari,Crab,&Verstraete,2010;Sgnaulin et al.,2018).Emerenciano,Gaxiola,and Cuzon(2013)referred to biof loc technology as an environmental friendly aquaculture system.It isa sustainable alternative to the previously discussed culture systems,due to its potential to efficiently recycle and reuse nutrients within the culture system(Dauda et al.,2017b;Kumar et al.,2017).The system has been referred to as various names by different researchers and these include:zero exchange autotrophic heterotrophic systems(ZEAH)(Wasielesky,Atwood,Stokes,&Browdy,2006),suspended bacterial-based system or active sludge(Rakocy,Bailey,Thoman,&Shultz,2004),suspended growth systems(Hargreaves,2006),or microbial f loc systems(Avnimelech,2012).

The basic principle in biof loc systems involves a balance of carbon and nitrogen ratio(C/N)to a level that stimulates the growth of heterotrophic bacteria who in turn utilize ammonia for growth and give offnitrogen gas from the system(Dauda et al.,2017b;Dauda et al.,2018).A high C/N ratio of between 10 and 20 will stimulate the growth of heterotrophic bacteria,which will directly feed on the toxic ammonia from the culture system and in turn produce a cellular protein(Avnimelech,2012).The production of the cellular protein gives BFT additional advantage over other culture systems because the cellular protein is available as feed to the culture organisms(Bossier&Ekasari,2017;Gaona,Almeida,Viau,Poersch,&Wasielesky,2017).The microbial community(cellular protein)contains a heterogeneous mixture of microorganisms(f loc former and f ilamentous bacteria),particles,colloids,organic polymers,cations,and dead cells(Avnimelech,2012;Ekasari et al.,2010;Hargreaves,2006).This suspended heterogeneous protein particle is available as food to the culture organisms and has been found to be high-quality protein.In summary,biof loc technology is able to ensure maintenance of water quality through uptake of ammonia to produce microbial proteins and it also makes available food for the cultured f ish through utilization of the microbial protein produced,hence increased efficient utilization of feed supplied,decreased food conversion ratio,and decreased the cost of feeding in aquaculture.

5.Conclusion

The development of aquaculture as a source of affordable animal protein is essential to human existence.However,restrictions in some parts of the world,especially the developed world,requires a continuous effort to develop sustainable production methods that will not put the environment at risk.The use of pond systems can still be continued for extensive and semi-intensive aquaculture of farming.These systems can be maintained at a level that will not be toxic to f ish and the effluent from pond systems can easily be treated.These are concentrated effluents,especially if such pondsare so well-constructed that they cannot erode and produce accidental discharge.However,the output from extensive and semi-intensive systems cannot substantially help to achieve the output needed from aquaculture.Intensif ied systems,using conventional RAS and denitrif ication-incorporated RAS systems,may be able to serve the purpose of producing highly priced f ish because of the cost of installation and operation and,if wellmaintained,may put the environment at a lesser risk.The proper development of zero to minimal water exchange systemslike BFT will go a long way in enhancing sustainable aquaculture production.The system has the potential to produce both highly priced and low priced f ish species.It does not require a high cost of investment and it can be managed without special skillsor expertise.It is,therefore,important to intensify research on BFT for different species of f ish(f in and shellf ish)and ascertain all the necessary requirementsfor itssuccessto simplify it and encourage its usage by f ish farmers.

Declaration of interest

None.

Aquaculture and Fisheries2019年3期

Aquaculture and Fisheries2019年3期

- Aquaculture and Fisheries的其它文章

- The potential of Hoplias malabaricus(Characiformes:Erythrinidae),a Neotropical carnivore,for aquaculture

- Prokaryotic expression of goldf ish Tgf2 transposase with optimal codonsand its enzyme activity

- Molecular identif ication of oomycete species affecting aquaculture in Bangladesh

- Enhancing the immune response in the sea cucumber Apostichopus japonicus by addition of Chinese herbs Houttuynia cordata Thunb as a food supplement

- Estimating blue marlin(Makaira nigricans)sustainable yield in the Indian Ocean using a data-poor approach