华润总部中国深圳

业主:华润

规模/建筑高度:21万平方米/400米

功能:总部,总体规划,超高层

合作设计单位:中建国际(当地设计地院)

摄影:Brian Chung (p100, 101),Tim Griffith (p99, 100, 101)

Client: China Resources

Size / Height: 210,000 m2 / 400 m

Program: Headquarters, Master Plan, Supertall

Team: CCDI (LDI)

Photography: Brian Chung (p100, 101),Tim Griffith (p99, 100, 101)

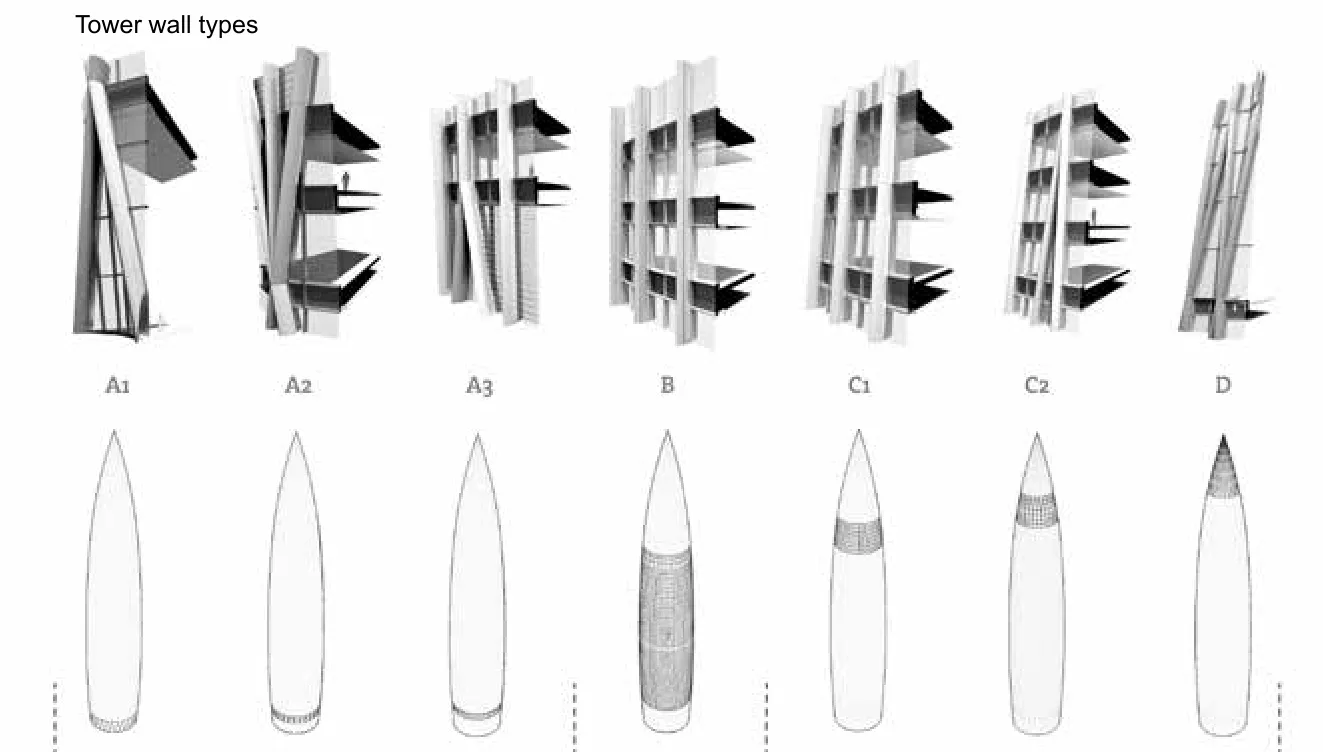

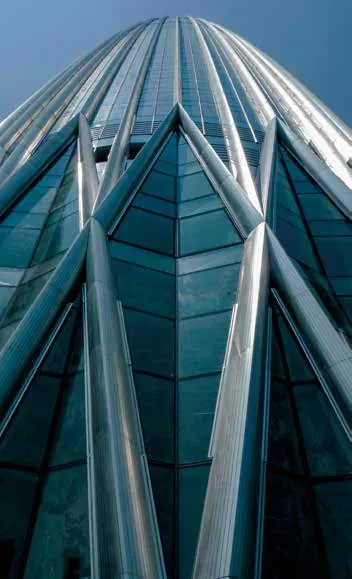

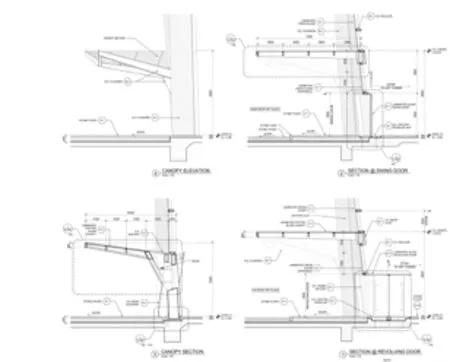

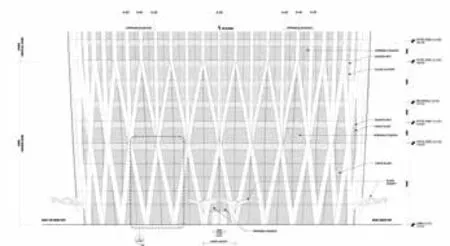

设计采用不锈钢包裹外柱,强调塔楼的锥形造型,并为斜肋构架系统提供支撑,顶部空中大堂可提供独特的视野景观。

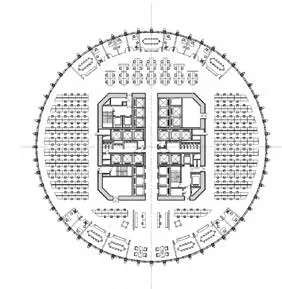

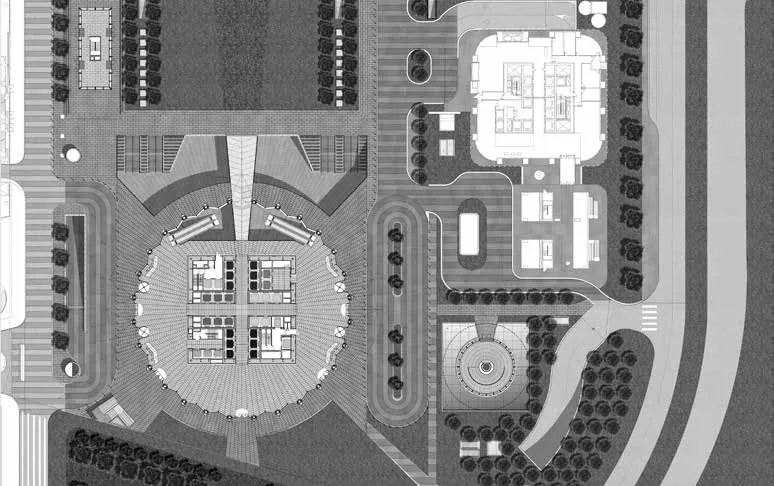

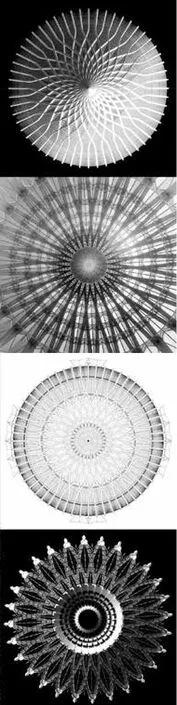

华润总部大楼是深圳最新的垂直地标,标志着城市的文化发展,大楼造型独特,功能多样,可满足租户和大众的不同需求。几何斜肋构架形成无柱室内空间和开放的楼层平面,确保圆形平面呈辐射式对称。建筑设计灵感源自竹笋的有机形态,56根立柱在塔楼低区和高区汇合成28根柱子,形成斜肋系统。400米高的尖塔顶部为一整块不锈钢制成的不锈钢尖顶。这种精确的几何表达在地面层呈镜像,斜肋系统立柱相联结在锥形锚固点之间形成一系列的入口门廊。建筑底部和尖顶采用多面三角形玻璃面板,当夜幕降临,面板点亮,建筑则如宝石一般照亮整个深圳滨海商务区。

所有钢构件均在项目所在地附近制成,确保KPF团队能够逐个微调其复杂的装配。通过比选,KPF聘请了多个合作伙伴,并仔细审查样板,确保整个项目使用最高品质的材料和工艺。KPF与照明设计师,机电 / 消防工程师和厂商密切合作,协调外框架设计。这种对工艺的关注使得建筑物的雕塑感造型得以实现 ---依靠斜肋的几何造型来确保结构径向的对位。

Stainless steel cladded exo-columns emphasize the tower’s tapered form and support its diagrid system, culminating at a sky hall with a unique interior view of the spire.

The China Resources Headquarters tower is Shenzhen’s latest vertical icon, marking the city’s cultural development with its distinctive form and diverse uses for tenants and the public at large. The geometric diagrid structure allows the building’s interior floorplan to be free of columns, opening its floorplates to express the radial symmetry of the circular footprint. Inspired by the organic form of the bamboo shoot,the building’s 56 vertical columns converge into 28 columns at the lower and upper sections of the tower to form the diagrid system. Tapering to its 400 meter pinnacle, the tower is topped by a stainless steel spire that was fabricated in a single piece. This geometric precision is mirrored at the ground level, where the diagrid system’s columns unite to create a series of entry portals between precisely tapered anchor points. Faceted, triangulated glass panels form the base and the pinnacle of the building’s sculptural form,illuminating at night and reflecting with a jewel-like brilliance across Shenzhen’s waterfront business district.

By fabricating each steel element near the project’s location, the KPF team was able to fine tune its complex assembly piece by piece. Using a comparative process, KPF engaged multiple partners and closely reviewed prototypes to ensure the highest quality materials and processes were used throughout the project. The exoskeleton required extensive coordination with lighting designers, MEP/FP engineers,and fabricators. This attention to craft allowed the realization of the building’s sculptural form – relying on the diagrid’s ambitious geometry to facilitate the structure’s radial alignment.