Vacuum press drying studies on two fast-growing Indian wood species

Shailendra Kumar•Rushikesh R.Topare•Jitendra Nagar

Introduction

Vacuum press drying is an efficient technology for the rapid drying of wood.It is faster than conventional drying as the boiling temperature of water in the wood is lower under low pressure,resulting into rapid moisture evaporation.The use of aluminium hollow platen for heat transfer through conduction,as in the vacuum press dryer(VPD),is regarded as an efficient technique compared with convection vacuum drying because drying is possible on a continuous basis.Many investigators have tried to understand the drying mechanism under vacuum pressure.The difference is a main drying force which becomes dominant at higher temperatures(Moyne and Martin 1992).Drying front(Perre et al.2004)and boiling front(Chen and Lamb 1995)have been advocated to occur during vacuum wood drying.Sasaki et al.(1987)attempted to measure the pressure distribution in wood during vacuum drying and concluded that there was a pressure differential across the length and width of the wood.However,the permeability of the wood is considered as the most important factor that in fluences the rate of drying to a large extent.For the conditions of boiling of water inside wood,permeability becomes an important factor,as it provides windows for escaping water vapour.

Melia compositaandEucalyptus tereticornisare both are fast-growing plantation timber species known to grow under varied agro-climatic conditions.Meliawood has a moderate density(oven dry weight/green volume)range from 0.3 to 0.5 g/cm3(Kumar et al.2016)whileEucalyptushas higher densities ranging from 0.5 to 0.7 g/cm3(Rajpoot et al.1996).Meliais a permeable wood(Kumar et al.2016)whileEucalyptuspossesses low permeability(Bahri and Kumar 1982).In the present study,an attempt was made to understand the drying behaviour of the two different species under vacuum press drying.The experiment was carried out under two sets of conditions i.e.,below and above boiling points of water by keeping temperature constant and pressure levels variable accordingly.

Materials and methods

The VPD

Vacuum press drying(VPD)consists of a rectangular steel chamber with rubber sheet roof.The chamber is connected with liquid ring-type vacuum pump.

Hollow aluminium platens are placed inside the chamber,which in turn are connected with an electric water boiler.When a vacuum is created inside the chamber,the rubberised roof of chamber presses the aluminium platens from the top as shown in Fig.1d.

Collection and preparation of wood specimens

Straight and defect-free logs ofM.composita(approximately 15 years old)andE.tereticornis(8 years old)were sawn into 12.5 cm wide and 2.5 cm thick planks.TheM.compositaandE.tereticornisplanks were further converted into lengths of 45 and 30 cm lengths respectively.

The experiments

Pressure measurement at wood core

In order to measure pressure levels at the wood core,holes were drilled into specimens on radial faces as shown in Fig.1h.Brass pipes (outer Ø=9 mm and inner Ø=6 mm)7.5 cm long(Fig.1h)with pointed ends,were inserted fully in the specimen.The pipes were sealed with a silicon-based adhesive to eliminate any air leakage.The fixed brass pipes(Fig.2b)were then connected(Fig.2a)through a pipe to a pressure gauge(Fig.1g)placed outside the VPD chamber.

This arrangement allowed direct measurements of relative pressures at the wood core during drying.Absolute pressure of 400 mm of Hg in VPD and temperature of 75°C was maintained at the core during a drying run and relative pressures were recorded at the cores ofM.compositaandE.tereticornisat regular intervals.The experiment was carried out over four consecutive days by drying 6 h per day.

Wood drying

A temperature sensor was af fixed on the aluminium platen to monitor its temperature.Another temperature sensor was placed in the core by drilling a hole as shown in Fig.1h.A multi-channel temperature monitoring system was used to record the two temperatures.

The specimens of both species were placed between aluminium platens randomly so that both were subjected to the same conditions of drying.The first drying cycle was carried out at a temperature of 75°C and pressure at 300 mm of Hg which is above the boiling point of water(Haar et al.1984).The second drying cycle maintained temperature at 75°C and pressure of 450 mm of Hg which is below the boiling point of water.Two drying cycles were run for 4 days each.In both,9 specimens ofM.compositaand 7 specimens ofE.tereticorniswere used.Before the cycle started,pre-heating was done until the wood core temperatures reached the required level of 75°C.The preheating time is excluded from drying time reported in this study.The initial moisture contents(IMC)and final moisture contents(FMC)were calculated using following equations:

Fig.2 Wood specimen fitted with core pressure measurement arrangement(a)and a brass pipe connected with pressure gauge(b)

The first drying cycle(ABP)consisted of 4 days of drying.In the second drying cycle(BBP),drying was done for 0.8,1,4 and 4 h successively on four consecutive days.The initial weights and weights of the samples after drying were recorded on all days of drying before pre-heating.

Thus,four drying runs for ABP and four for BBP were carried out.Out of a total of eight,six runs(4 of ABP and 2 of BBP)had durations of 4 h while 2 runs(BBP)had durations of 0.8 and 1 h.

Results and discussion

Since the duration of the drying treatments(ABP and BBP)were different,holistic comparison has not been attempted.Only the behaviour of the two different species under vacuum drying is analysed.Specimens showing outlier values have been excluded from analyses.

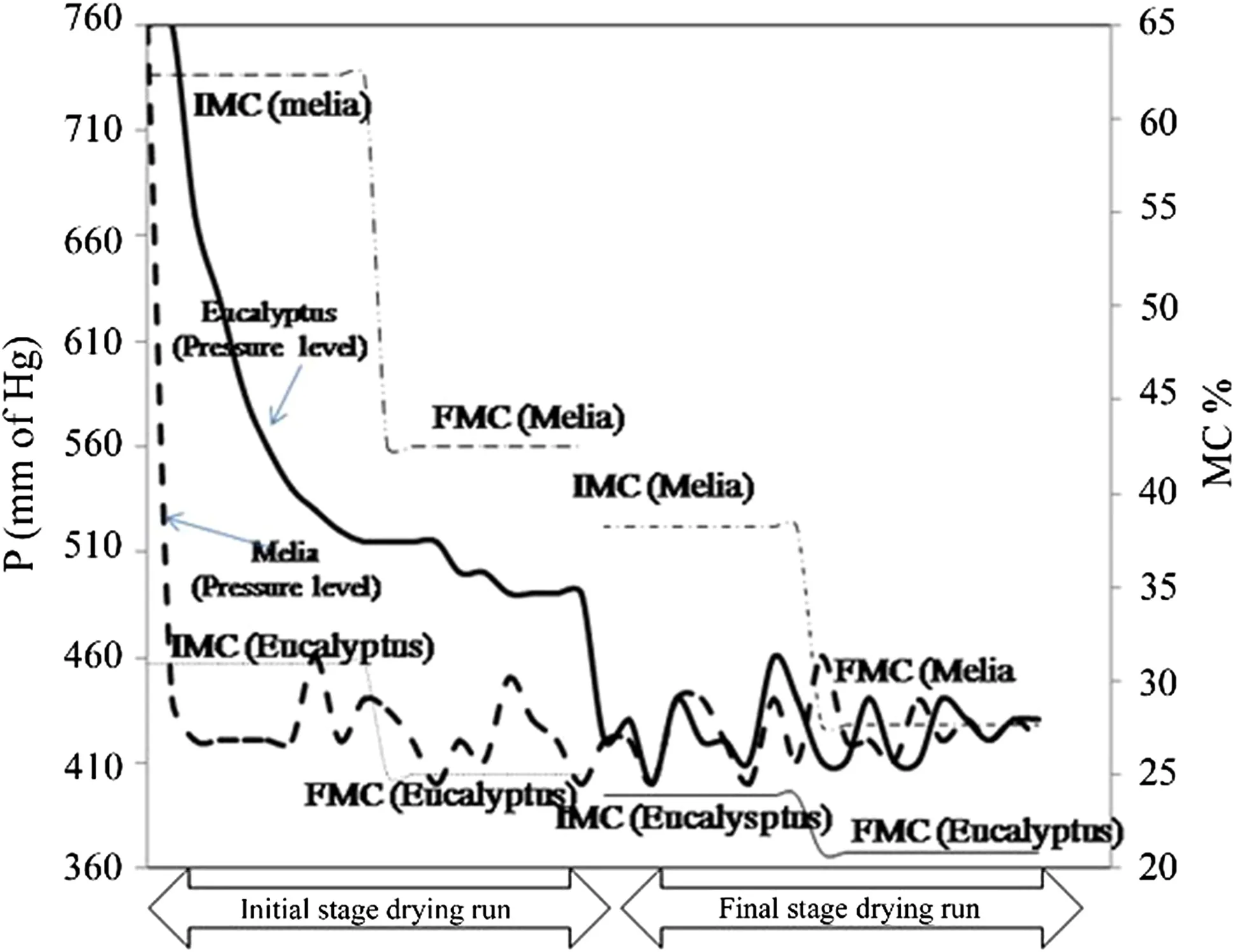

Pressure levels at wood core during vacuum press drying

Figure 3 shows core pressure levels at the initial and final drying stages while pressure inside VPD was maintained at 400 mm of Hg(approximately).

Figure 3revealsthattheM.compositawoodcoreattained equilibrium pressure to VPD pressure immediately,while theE.tereticorniscore pressure decreased slowly.TheE.tereticorniscore did not attain pressure equilibrium in the initialdryingphase.However,pressurelevelsofbothspecies were equal in the later stage of drying.This happened as a result ofthe generationof numerous surface cracks on theE.tereticorniswood surface which advanced to the core where the brass pipe was fitted(Fig.1h).This indicates that the generationofsurfacecracksincreasesthepermeabilityofthe wood which may result in faster drying.

Fig.3 Pressure levels at wood core

Drying above the boiling point(ABP)

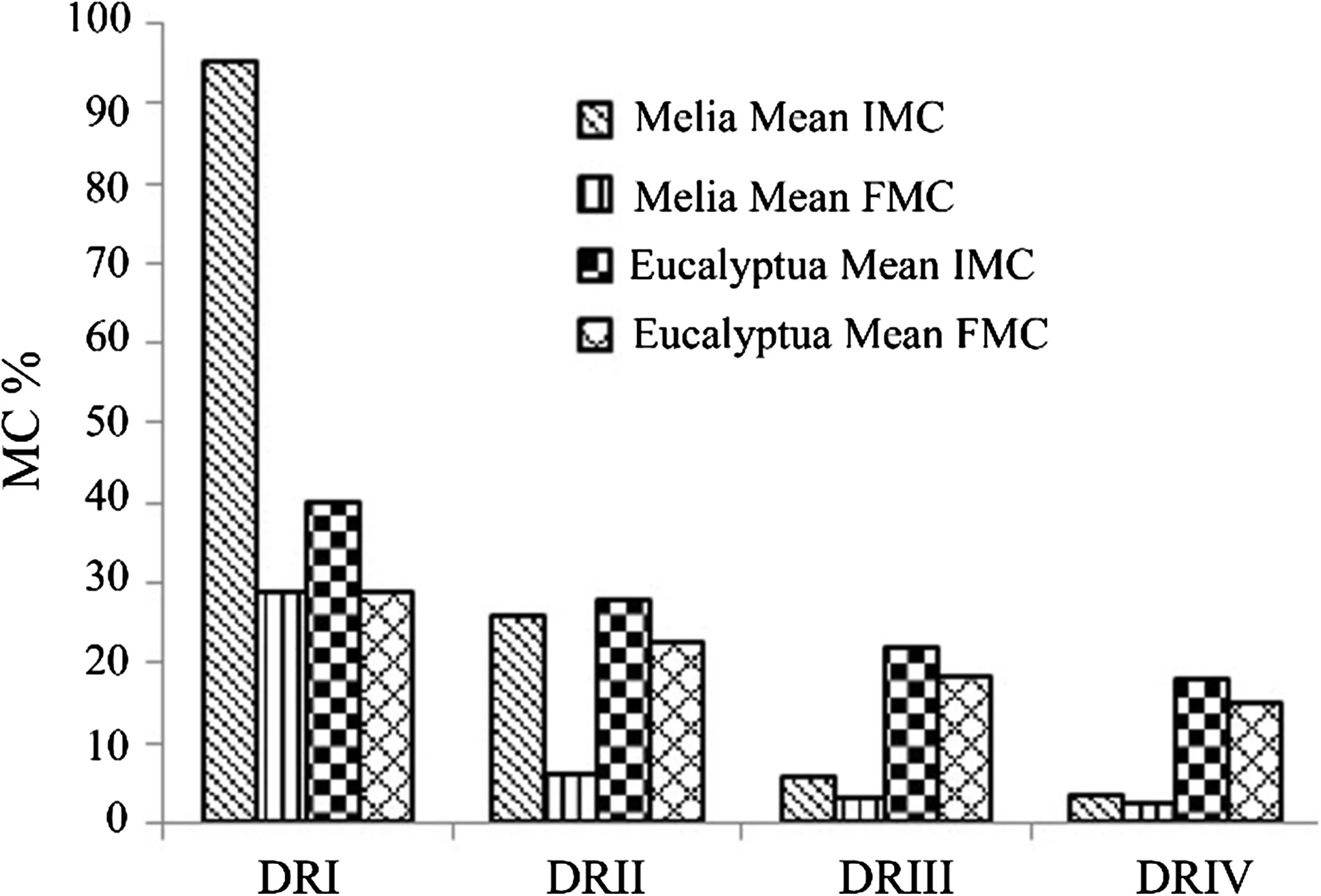

Fig.4 Drying of M.composita and Eucalyptus tereticornis under conditions of above boiling point

Figure 4showsadecreaseinmoisturecontentofbothspecies whenthetemperature–pressureconditionsresultedinboiling of water in all four drying runs(4 days)of 4 h each.M.compositalost moisture at higher rates thanE.tereticornisand attained 6.0%(SD=1.9%)moisture content after the second drying run.On other hand,the decrease in moisture content ofE.tereticorniswas gradual.The mean initial moisture content IMCs ofM.compositaandE.tereticorniswere95.2% (SD=18.4%)and40.1% (SD=1.9%)respectively,in first drying run;however,the final moisture content FMCs after one run were 28.7%.This probably was the stage in which the free water within both species was removed early(Fig.5).

Likewise,the IMCs ofM.compositaandE.tereticorniswere similar but the FMC much lower forM.composita(6.0%,SD=1.9%)than forE.tereticornis(22.5%,SD=1.7%)after the second drying run.The reason for the low drying rate ofE.tereticornisis apparently lower permeability.

M.compositais reported to have sapwood and heartwood longitudinal permeability of 3.38 darcy(a practical unit of measure for permeability)and 2.02 darcy,respectively(Kumar et al.2016).Longitudinal permeability of heartwood ofEucalyptusis 5.91×10-3darcy which is 5645 times lower than for the sapwood(Bahri and Kumar 1982).The lower permeability ofE.tereticornisis attributed to the occurrence of tyloses in the vessels.DRIII and IV show that the IMC ofM.compositais already very low(2.8%,SD=0.6%)and the magnitude in the drop in moisture content is also small since bond strengths between water and wood are high at lower moisture contents.Although DRIII and IV forE.tereticorniswere marked by increases in permeability due to surface checks and cracks,the magnitude of moisture content fall was still very low.

Fig.5 Drying of Melia composita and Eucalyptus tereticornis under conditions of below boiling point

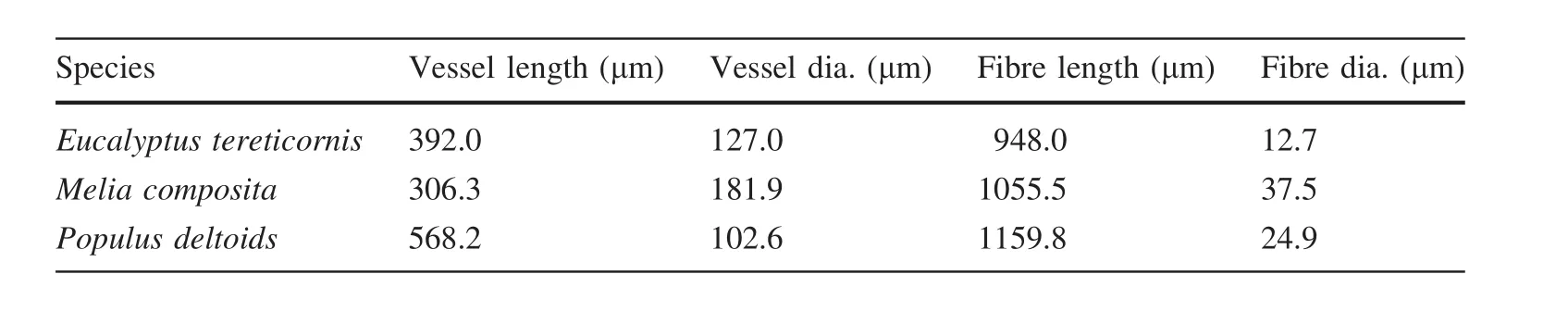

Anatomical properties of both species are presented in Table 1 along withPopulus deltoids(Srivani and Rao 2015;Swaminathan et al.2012;Pande et al.2012).

Table 1 shows thatE.tereticornispossess vessel lengths of392.0 μm which arelongerthanM.composita(306.3 μm)and shorter thanPopulus(568.2 μm).However,E.tereticornisvessel diameter(127.0 μm)is smaller than that ofMelia(181.9 μm).It can be seen thatM.compositahas vessel diameters even larger thanPopulus(102.6 μm).The fibre diameter ofM.compositais almost three times larger than that ofEucalyptus.Large diameter wood elements allow for ease of flow of water vapours generated during the drying process which results in the faster drying of the wood.

Drying below boiling point of water

Figure 4 shows four drying runs under conditions in which water did not boil but faster drying occurred under lower pressures.Since DRI and DRII of Fig.4 are for short durations of 0.8 and 1 h,these two drying runs have not been compared to that of Fig.3.

SinceM.compositaandEucalyptuswere dried under the sameconditions,acomparisonmaybedonebetweenspecies inDRIandDRII.ThemagnitudeofmoisturecontentlossforM.compositawas higher than forE.tereticornisfor all drying runs.DRIV shows that the IMC ofM.compositawas higher than that ofE.tereticornisbut the FMC was lower.Evenafter9.8 hofcumulativedrying(afterDRIV),theFMC ofM.compositaandE.tereticorniswere 14.3(SD=3.1%)and 16.0%(0.4%)respectively.Whereas in the case of drying above the boiling point,the FMCs were 6.0%(SD=1.9%)and 22.5%(SD=1.7%)only after 8 h of drying(DRI and DRII).

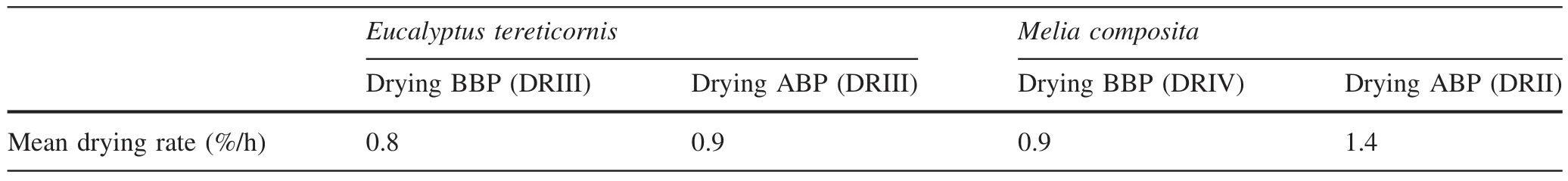

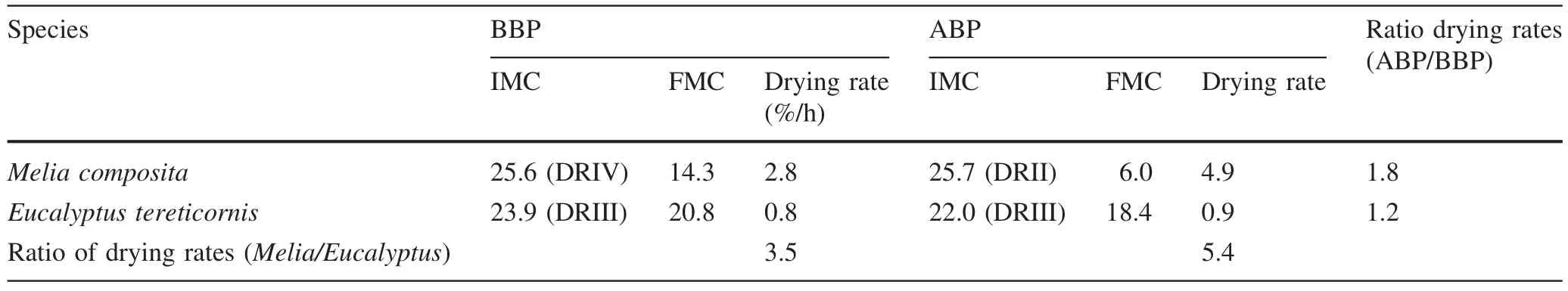

Effect of boiling point on drying rates

Table 2 shows the mean drying rates under both types of treatments.Similar drying rates were chosen on the basis of similar IMCs for both species.Independent samplettest at 0.05 level of alpha forE.tereticornisshows that mean IMCs,DRIII of BBP(23.9%,SD=0.6%)and DRIII of ABP(22.0%,SD=1.6%)were not the same(DF=10,p≤0.001).However,their mean drying rates were found to be same for BBP(0.8%/h,SD=0.4%/h)and ABP(0.9%/h,SD=0.1%/h),(DF=10,p=0.462)at alpha level 0.05.

Table 1 Anatomical parameters of Eucalyptus,Melia and Populus

Statistical analysis shows that forE.tereticornis,the use of boiling point does not have any signi ficant impact on the rate of drying.This is of particular interest in vacuum wood drying because,at higher drying temperatures,E.tereticornisis likely to show severe defects like surface cracks,end checks,and collapse.The quality of theE.tereticorniswood dried under the two conditions was similar.

Table 2 Comparison of drying rates with each rate of 4 h

Table 3 Boiling point and drying rates

Independent samplettest at 0.05 level of alpha for IMCs ofM.compositadriedunderBBP(DRIV,24.6%,SD=3.0%)and ABP(DRII,25.7%,SD=6.6%)confirms the means of IMCs were same(DF=11,p=0.7).However,drying rates of ABP(4.9%/h)and BBP(2.6%)were significantly different at 0.05% level of alpha(DF=11,p=0.002).Thus,it may be concluded that use of boiling point conditions for drying ofE.tereticornisis not effective while forM.composita,it is significantly effective.

Table 3 presents a comprehensive summary of the drying rates forM.compositaandE.tereticorniswood at both conditions of drying.For comparison purposes,it was ensured that the means of all IMCs being compared were statistically the same at 0.05 alpha levels.However,there was an exception.The mean IMCs ofE.tereticornis(DRIII)of BBP(23.9%)and DRIII of ABP(22.0%)were not significantly same at 0.05 alpha level(DF=10,p≤0.001).

The ABP drying rate ofM.compositais 1.8 times higher than that of the BBP drying,while the ABP forE.tereticornisis only 1.2 times higher than that of BBP.However,when interspecies comparison is made,the difference is quite large.The BBP drying rates ofM.compositais 3.5 times higher than the BBP drying rate forE.tereticornis.Likewise,the ABP drying rate ofM.compositais 5.4 times higher than the ABP rateE.tereticornis.Furthermore,the ratio of drying rates i.e.,Melia/Eucalyptus(ABP)is 1.5 times higher than that ofMelia/Eucalyptus(BBP).

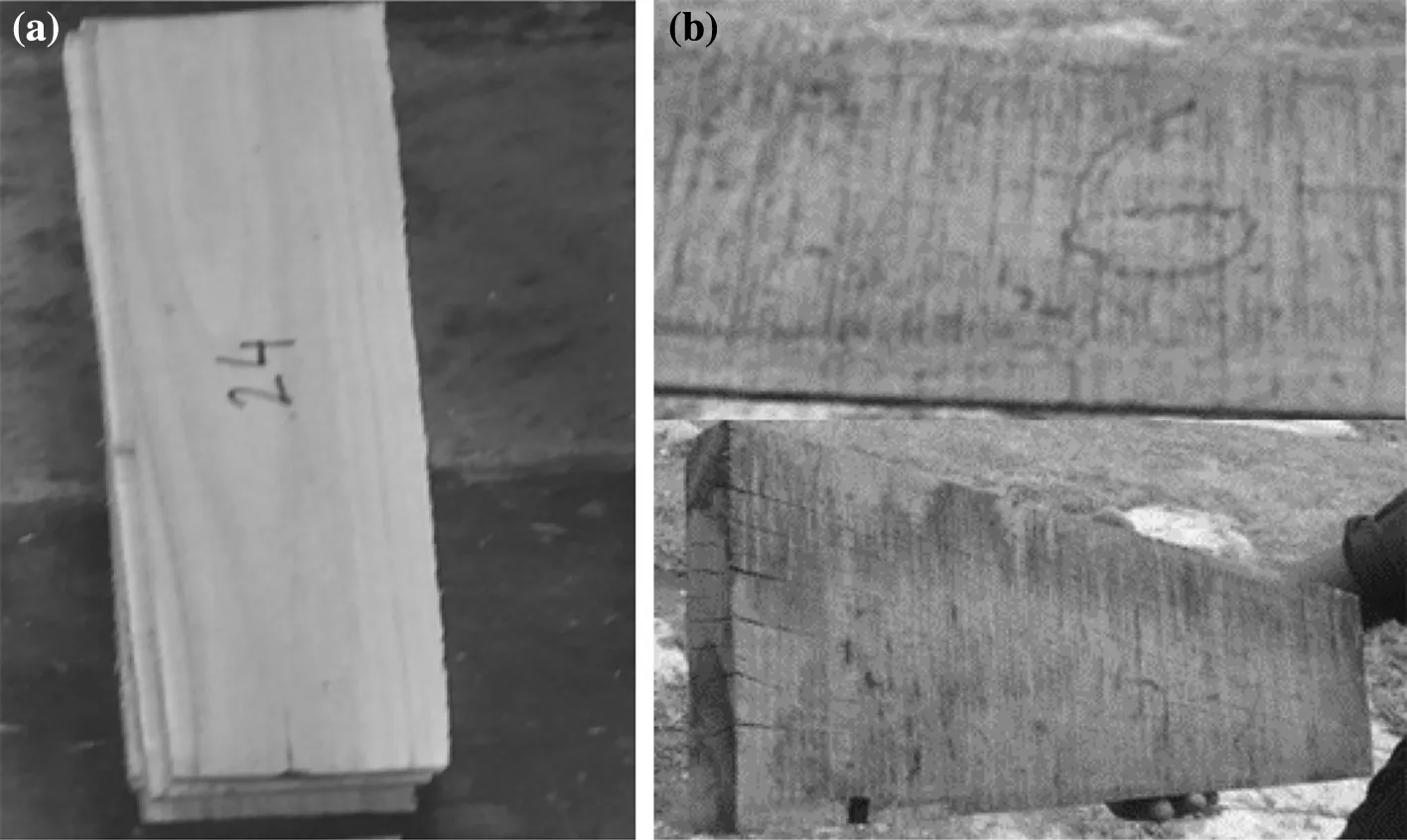

Fig.6 Dried planks of Melia composita showing small end cracks(a)and E.tereticornis showing numerous surface and end cracks(b)

Figure 6 shows the quality of the wood dried in VPD.Meliashows occasional end cracks(not prominent)but no surface cracks or other defects.E.tereticornisshows numerous surface cracks on the tangential face of the boards.End cracks were also prominently associated withE.tereticornis.

Results indicate that in vacuum press drying,impermeable wood likeE.tereticornisdo not offer any advantages in drying above the boiling point of water.Lower temperatures and higher pressures should be applied for such species.On the other hand,for permeable wood likeM.composita,boiling point conditions affect the drying process significantly.In such species,strategies should be adopted to create boiling point conditions and remove moisture as quickly as possible without damaging the quality.

Conclusions

Boiling point conditions during vacuum press drying may not be achieved across the thickness of low permeable wood as such wood may not attain pressure levels applied during drying.The drying rate ofMelia compositais higher than forEucalyptus tereticornisunder both drying conditions,i.e.,above and below boiling point of water.The uses of temperature and pressure sets which may result in the boiling of water do not have any signi ficant impact on drying rates of low permeable wood.Lower temperatures and higher pressure levels are suitable for dryingEucalyptuswhile higher temperatures and lower pressure levels may be suitable for dryingM.compositaunder vacuum.This study suggests that,for drying of species likeEucalyptusunder vacuum,boiling point conditions of temperature and pressure may not be helpful,rather,slower extraction of moisture under low temperatures and pressures may do equally well.Highly permeable wood likeM.compositashould be dried as rapidly as possible by creating boiling temperatures and pressure conditions.

References

Bahri S,Kumar S(1982)Permeability studies onEucalyptushybrid.J Timber Dev Assoc(India)28(3):32–40

Chen Z,Lamb FM(1995)The concept of boiling front in vacuum drying.In:Vacuum drying of Wood’1995,Slovakia,pp 110–116

Haar L,Gallagher JS,Kell GS(1984)NBS/NRC steam tables:thermodynamic and transport properties and computer programs for vapour and liquid states of water in SI units.Hemisphere Pub.Corp,Washington,DC

Kumar S,Kelkar BU,Mishra AK,Jena SK(2016)Study of variability in some physical properties of plantation grown progenies ofMelia compositeWilld.and determination of a kiln drying schedule.J For Res(in press)

Moyne C,Martin M(1992)In fluence of a total pressure gradient in gaseous phase on drying with particular reference to wood.Int Heat Mass Transf 25(12):1839–1845

Pande PK,Aziz M,Uniyal S,Dhiman RC(2012)Variation in wood anatomical properties and speci fic gravity in relation to sexual dimorphism inPopulus.Curr Sci 102(11):1580–1585

Perre P,Mosnier S,Turner IW(2004)Vacuum drying of wood with radiative heating:I.Exp Proced AICHE J 50(1):97–107

Rajpoot SS,Shukla NK,Gupta VK,Jain JD(1996)Timber mechanics-strength classi fication and grading of timber.ICFRE,New Forest,p 189

Sasaki K,Kawabe J,Mori M(1987)Vacuum drying of wood at high frequency(II),pressure within the lumber during evacuation and drying.Bull Kyushu Univ For 57:245–265

Srivani P,Rao RV(2015)Wood anatomical structure of the clones ofEucalyptus TereticornisSm.(Mysore Gum).Int J Sci Technol Res 4(1):156–159

Swaminathan C,Rao RV,Shashikala S(2012)Preliminary evaluation of variations in anatomical properties ofMelia dubiaCav.wood.Int J Biol Sci 1(4):1–6

Journal of Forestry Research2018年3期

Journal of Forestry Research2018年3期

- Journal of Forestry Research的其它文章

- In vitro propagation of conifers using mature shoots

- ‘Relationships between relationships’in forest stands:intercepts and exponents analyses

- Effects of application date and rate of foliar-applied glyphosate on pine seedlings in Turkey

- Assaying the allelopathic effects of Eucalyptus camaldulensis in a nursery bed incorporated with leaf litter

- Effects of soil compaction on growth variables in Cappadocian maple(Acer cappadocicum)seedlings

- Variation and selection analysis of Pinus koraiensis clones in northeast China