Lubricating Performance of Rapeseed Oil Under Electromagnetic Field

Jiang Zeqi; Liu Ping; Fang Jianhua; Chen Boshui; Gu Kecheng; Wu Jiang

(1. College of Pharmacy, Army Medical University, Chongqing 400038; 2. Department of Oil, Army Logistics University, Chongqing 401311)

1 Introduction

The recent decades have witnessed the rapid development of petroleum re fining industry, and the conventional petroleum-based lubricants represented by mineral oil have posed irreversible and undesirable damages on the ecosystem due to their unreadily biodegradable nature[1-2].The increasing awareness of environmental protection has stimulated the urgent needs to develop environmentally friendly lubricants in order to make them more or less compatible with the natural environment[3-5]. It has been proven that vegetable oils are potential candidates for replacement of mineral oils thanks to their inherent characteristics such as biodegradability, non-toxicity and outstanding lubricity[4-5], since they have been employed to play the role of lubricants in early times. In the research of vegetable oils used as lubricants, scholars have devoted themselves to the improvement of poor oxidation stability of vegetable oils caused by C=C bonds via the chemical modification technology, which enables vegetable oils to possess the advantages of excellent lubricity,antioxidant stability, and biodegradability[6-8]. The ability of vegetable oils to reduce friction and wear of machine parts has been reported to be in fluenced by the fatty acid composition within them. It can be explained that the anti-wear properties of fatty acids is the result of complex interactions between molecules of the acids and particular types of hydrocarbons[9]. In our previous work, vegetable oils were chemically modified by the phosphorus-nitrogen-incorporated and boron-nitrogen-incorporated method to synthesize a variety of biodegradable lubricating oil additives with excellent anti-wear and friction-reducing properties[10-11].

On the other hand, with the development of mechanical equipment, an increasing number of mechanical systems are operated by electromagnetic techniques. The motor bush, the contactor in electric transmission systems and the magnetic cylinder in magnetic storage systems are typical tribomates working in the electromagnetic field[12-14]. Besides, Self Generated Voltage (SGV) would be induced due to the differences of free electron density and electron work function of metals during the friction duration in order to stimulate the electromagnetic effect on the frictional interface[15]. It has been generally known that the electromagnetic-induced physico-chemical effect will certainly influence the lubrication performance and mechanisms of lubricants[16-18]. Also over the recent years,the authors have investigated the effect of electromagnetic

field on the tribological characteristics of widely applied lubricating additives, and the lubrication mechanisms were discussed by considering the active elements and molecular structure from the perspective of electromagnetics[19-22]. Thus, extending the research idea to the tribological studies of vegetable oils would be of great signi ficance to accommodate the electrification development of machines and the increasing awareness of environmental protection. Furthermore, it will be a bene ficial exploratory work for improving the research level of green lubricating materials with the electromagnetic field impact.

In the present paper, a four-ball tribo-tester was modified to simulate the working condition of electromagnetic field. Rapeseed oil, a readily available and low cost vegetable oil, was selected as the lubricant. The effect of electromagnetic field on tribological behaviors of rapeseed oil was reported.

2 Experimental

2.1 Tribotester Modification

The MMW-1 four-ball tribo-tester was modified by assembling a loop around the frictional region (Figure 1a).The loop is a self-made copper loop with 800 windings wrapped around the aluminum alloy sleeve. The loop was electrified to produce a certain intensity of electromagnetic field by controlling the intensity of electric current during the test duration, with the magnetic induction lines being mostly perpendicular to the frictional contact surfaces, as presented in Figure 1b.

Figure 1 Schematic of the modified tribotester

2.2 Materials

The rapeseed oil employed in the experiments was produced by the Jiali Cereals & Oils Co., Ltd., Chongqing Branch.The main component of rapeseed oil is triacyl glyceride,with its chemical structure shown in Figure 2.

Figure 2 Structural formula of triacyl glyceride

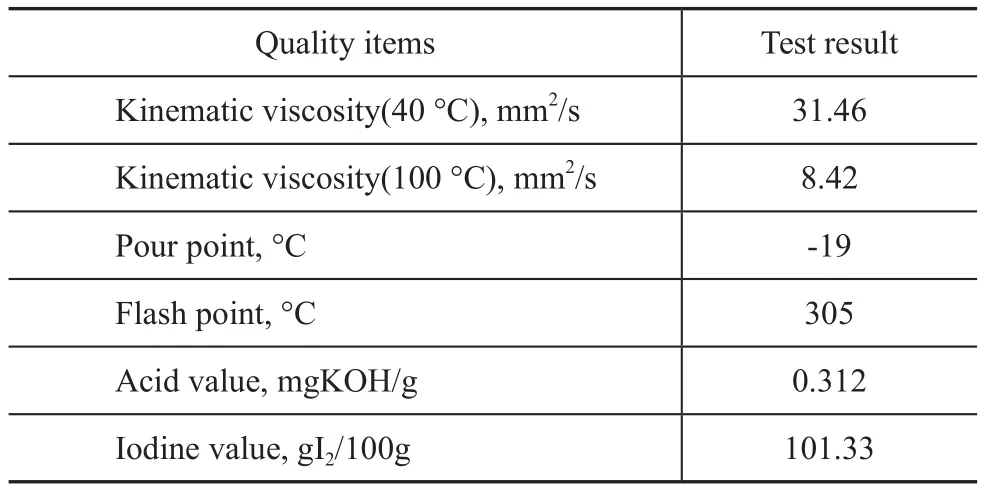

The physicochemical indices of rapeseed oil are listed in Table 1.

Table 1 Physicochemical properties of rapeseed oil

2.3 Friction and wear tests

The tribological tests were conducted on the modified tribo-tester according to the procedures of SH/T 0189―1992, a Chinese standard method for testing the friction and wear properties of lubricants. In order to evaluate the in fluence of the intensity of electromagnetic field and loads on tribological properties of rapeseed oil,the tests were divided into the following two sets:

Investigating the tribological characteristics of the rapeseed oil under a load of 392 N, a rotary speed of 1200 r/min, and a current intensity of 0, 0.5 A, 1 A, and 1.5 A,respectively, for 30 min at room temperature.

The tribological performance of the rapeseed oil was studied at a rotary speed of 1200 r/min, a current intensity of 1 A, and a load of 196 N, 392 N and 490 N, respectively, for 30 min at room temperature.

The tribo-pairs used in the tests were GCr15 standard steel balls, 12.7 mm in diameter, 59—61 HRC in hardness, and Ra0.040 μm in surface roughness. The electromagnetic intensity (measured by a HT201 portable digital Tesla meter) was produced by a current of 0, 0.5 A, 1 A,and 1.5 A corresponding to 0T, 0.05 T, 0.1 T, and 0.12 T,respectively.

Prior to the test, the steel balls were ultrasonically cleaned in petroleum ether for 10 minutes and then dried with a hair dryer. After each test run, the wear scar diameters(WSDs) were measured with an optical microscope, with the friction coefficients being recorded by the system automatically. It should be noted that at least three tests for each condition should be carried out to ensure the repeatability, and additional tests should be duplicated if the three WSDs showed a relative error of above 10%.Then the average value of the WSDs and the friction coef ficients were calculated as the reported value. The specimens of the tester should be electrified with a reverse current to demagnetize to avoid any in fluence of residual electromagnetism after each test run.

2.4 Surface analysis

The surface morphologies and the elemental detection of the worn surface after four-ball testing were examined on a TESCAN Vega 3 LMH scanning electron microscope(SEM) with an energy dispersive spectrometer (EDS).The tribochemical species of typical elements on the worn surfaces were analyzed by an PHI-5100 X-ray photoelectron spectrometer (XPS), with Mg Kα radiation used as the exciting source and the binding energy of contaminated carbon (C1s:284.60 eV) serving as the reference. Prior to the analysis, the steel balls were ultrasonically rinsed in petroleum ether for 10 min.

3 Results and Discussion

3.1 Friction and wear characteristics

3.1.1 Friction and wear properties under different intensity of electromagnetic field

The variation of the friction coef ficients (COF) and wear scar diameters (WSD) with an intensity of electromagnetic field (0, 0.05 T, 0.1 T, and 0.12 T) at a load of 392 N and a rotary speed of 1200 r/min is shown in Figure 3.

It can be seen from Figure 3 that the friction coef ficients and wear scar diameters decreased with an increasing intensity of electromagnetic field. This fact indicated that the electromagnetic field could effectively facilitate the anti-wear and friction-reducing performance of rapeseed oil. The higher the intensity of the electromagnetic field was, the better the anti-wear and friction-reducing properties of the rapeseed oil would be.

Figure 3 Variation of WSD and friction coef ficient with the intensity of electromagnetic field

3.1.2 Friction and wear properties under different loads

Shown in Figure 4 is the variation of wear scar diameters and friction coef ficients under different load (196 N, 392 N, and 490 N) at a rotary speed of 1200 r/min in an electromagnetic field intensity of 0 or 0.1 T.

It can be seen from Figure 4a that the wear scar diameter(WSD) increased with an increasing load, while the WSD with electromagnetic field impact was smaller than that without electromagnetic field affection, illustrating that the applied electromagnetic field was capable of fortifying the anti-wear properties of rapeseed oil.

It can be seen from Figure 4b that the variation trend of friction coefficient increased at first and then decreased with an increasing load. It is also interesting to find out that the friction coefficients obtained under an electromagnetic field of 0.1 T was smaller than that obtained without the impact of an electromagnetic field, indicating that the electromagnetic field was bene ficial to improving the friction-reducing properties of the rapeseed oil.

3.2 Surface topography of worn surface

Figure 4 Variation of WSD (a) and COF (b) with loads operating with or without the impact of electromagnetic field

It can be clearly observed from Figure 5 that the surface obtained with electromagnetism impact (Figure 5b) was characterized by milder wear and smoother topography than that obtained without the impact of an electromagnetic field (Figure 5a), which demonstrated that the electromagnetic field could improve the lubrication performance of rapeseed oil. The SEM observations could well describe the ability of electromagnetic field in fortifying the anti-wear and friction-reducing capabilities of rapeseed oil as reported previously.

Figure 5 SEM morphologies of worn surface lubricated by rapeseed oil with and without the impact of electromagnetic field

3.3 Elemental detection

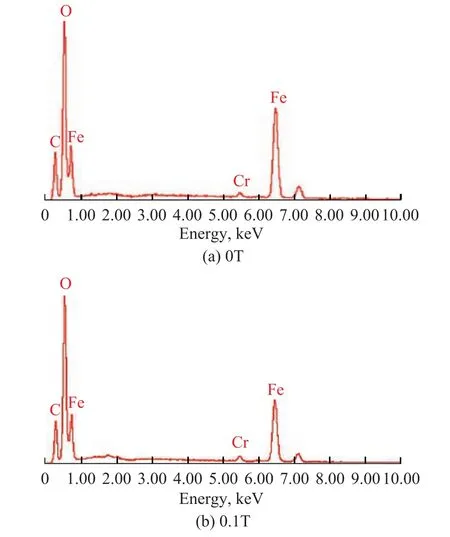

To clarify the differences of the surface film with and without the in fluence of electromagnetic field, the energy dispersive spectrometry (EDS) was used to analyze the elements on the worn surface.

The results of EDS analysis of worn surfaces lubricated by rapeseed oil with and without the impact of electromagnetic field (0.1T) are shown in Figure 6. It can be seen from Figure 6 that oxygen element was found on the surface of the abrasive spots, demonstrating that the oxygen element in rapeseed oil or air took part in the friction process.

Figure 6 EDS analysis of worn surfaces lubricated by rapeseed oil with or without the impact of electromagnetic field

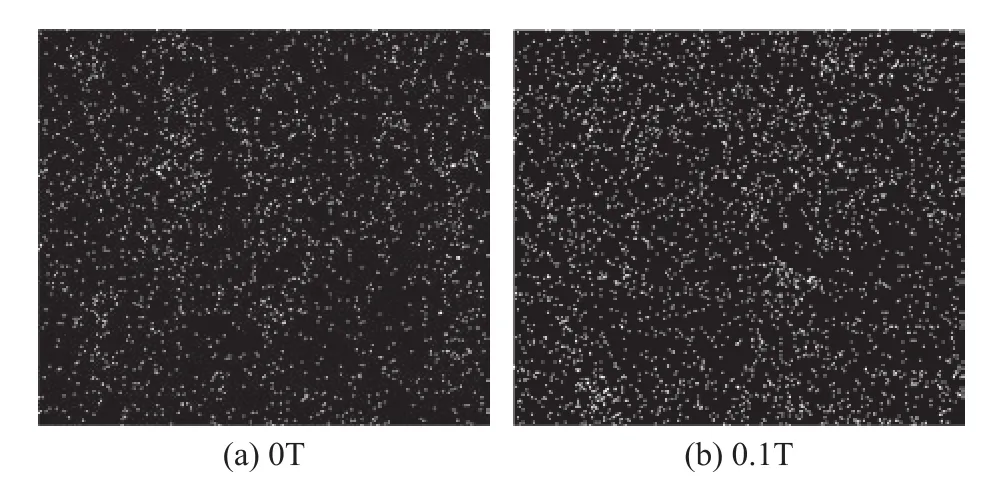

The distribution of the oxygen element on the worn surfaces is shown in Figure 7. It can be observed clearly from Figure 7 that the oxygen element identified under electromagnetism impact was more densely distributed than that obtained from specimen obtained without the impact of electromagnetic field. This fact was supported by the data of Table 2 that the concentration of oxygen element in the specimen exposed to electromagnetic field(45.79%) was higher than that in the specimen without being exposed to electromagnetic field (39.79%). The above results indicated that the electromagnetic field contributed to the interaction of O element with the friction surface, resulting in the formation of a thicker and compacter oxidation film to improve the anti-wear and friction-reducing ability of rapeseed oil.

Figure 7 Distribution of oxygen element on the worn surface lubricated by rapeseed oil under the impact of nonelectromagnetic field (a) and electromagnetic field (b)

Table 2 Content of elements on the worn surfaces with and without the impact of electromagnetic field

3.4 Chemical characteristics of worn surfaces

Figure 8 shows the XPS spectra of some typical elements on the worn surface of steel balls lubricated by the rapeseed oil operating at a load of 392 N and a rotary speed of 1200 r/min under an electromagnetic field intensity of 0 and 0.1 T.

The binding energy of C1s in the binding energy range of 284.6—288.6 eV (Figure 6a) was ascribed to the chemical species of C―H,―C―C―or―O―C=O, which illustrated that the rapeseed oil molecules were adsorbed on the worn surface, and ester compounds were formed on the worn surface under the investigated conditions[23]. In the spectra of Fe2p (Figure 8b), the peak at a binding energy of 711.0 eV was assigned to Fe2O3, while the detected binding energy located at 708.3 eV of the worn surface obtained after being exposed to the electromagnetic field was oxidized to Fe3O4, along with the binding energy of O1s at around 532 eV that was attributed to the organic species of iron oxides[24]. The XPS analysis further evidenced that the boundary lubrication film mainly consist-

Figure 8 XPS spectra of worn surfaces lubricated with rapeseed oil under electromagnetic and non-electromagnetic field

ing of ester compounds and iron oxides was generated to function as an anti-wear and friction-reducing reducer,and the iron oxide film (Fe3O4) consisting of high valence iron could be promoted by electromagnetic field.

(3)训练后的GMM模型分别统计来自电晕态模型的概率P11~P1R和来自高压放电态的概率P21~P2R,分别将R帧语料在两个类别中的概率分别相乘,得到识别样本在电晕态的总概率值P1和在高压放电态的总概率值P2。

3.5 Mechanisms analysis

As we know, vegetable oils are effective boundary lubricants, because their high polarity allows for the strong interactions with the friction interface. It has been proven that the boundary lubrication performance depends on the attraction of lubrication molecules to the surface and also on the chemical reaction with the surface[10-11].

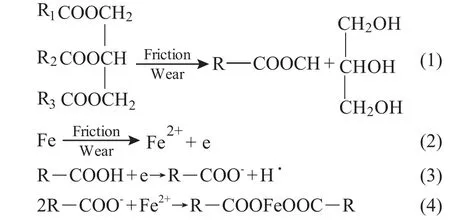

Thus, it could be inferred that the physical or chemical adsorption films in the form of fatty acid glyceride would play a dominant role in reducing friction and wear under a relatively low loads. The reaction process could be suggested as follows:

While under a relatively high load, the tribo-chemical reaction film should be responsible for the improved anti-wear and friction-reducing properties, the reaction could be deduced as follows:

Especially, the electromagnetic field could contribute to the generation of Fe3O4by the following process:

In the meantime, the fortified anti-wear and friction-reducing performance of the rapeseed oil might be explained from the following aspects:

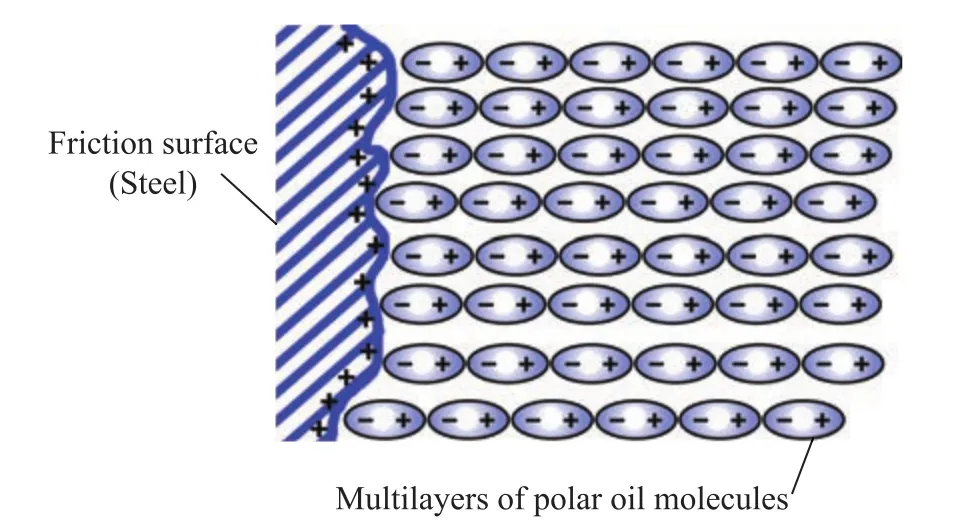

(1) The adsorption effect of adsorption film could be enhanced by the electromagnetic field. The unmatched dielectric constant between particles and vegetable oil would stimulate the polarization of the metal interfaces[25],and could result in the sequential arrangement of rapeseed oil molecules, which would contribute to the adsorption of multilayers of polar oil molecules to protect the metal surface from contacting directly and therefore would delay the friction and wear (Figure 9).

Figure 9 Multilayer oil molecules adhered to the friction surface under electromagnetic field

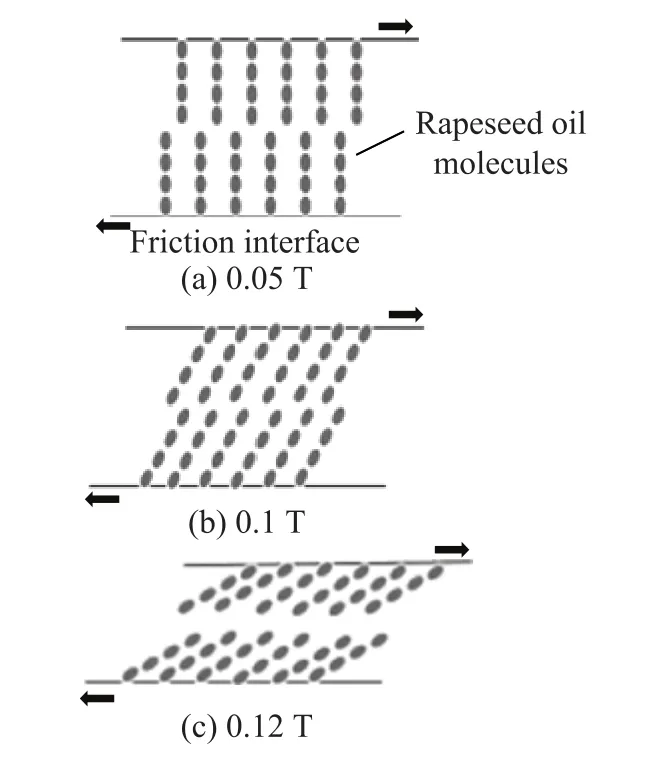

(2) The adsorption morphology of rapeseed oil molecules at the frictional interface would change with the intensity of the electromagnetic field. It is reported by Shana[26]that the double stranded DNA molecules presented different adsorption morphologies at metal interfaces with different voltage as identified by the atomic force microscopy (AFM). Liu[27]calculated the flexibility of friction modifiers with different alkyl chain lengths by the Kier compliance calculation method, and demonstrated a good correlation between the friction coef ficients and the molecular flexibility. It can thus be inferred that the adsorption morphology of rapeseed oil would be altered with the impact of electromagnetic field. As presented in Figure 10, the adsorption angle between the rapeseed oil molecules and the friction interface would decline with an increasing intensity of electromagnetic field, which could enable better flexibility of the adsorped molecules to provide a superior friction-reducing capability.

Figure 10 Adsorption model of rapeseed oil molecules under different electromagnetic fields

The generation of oxidation film could be promoted by the electromagnetic field. In accordance with the principle of Mott-Cabrera mode that the paramagnetic oxygen atoms would cluster in the regions of high magnetic induction[16],and the concentration of oxygen element on the metal surface obtained at an electromagnetic field intensity of 0.1T was higher than that without electromagnetic field impact,which would accordingly promote the generation of oxidation film. On the other hand, the electromagnetic field could promote the generation of Fe3O4surface film with more dense structure and better lubricity.

Judging from what has been stated above, it can be concluded that the improved anti-wear and friction-reducing property of rapeseed oil was ascribed to the combined effect of enhanced adsorption of rapeseed oil molecules and the generation of tribo-chemical reaction film. It also can be deduced that the friction-reducing ability was related with the adsorption morphology of the long chain molecules of rapeseed oil.

4 Conclusions

The present work demonstrated the enhanced effect of electromagnetic field on the lubrication performance of rapeseed oil and discussed the influencing mechanisms from the perspective of electromagnetism. It is implied that considering electromagnetic effect when investigating the tribological properties of rapeseed oil would be bene ficial to the development of tribological theories and practices.

Based on the results given above, the following conclusions can be addressed.

The applied external electromagnetic field could improve the anti-wear and friction-reducing capability of the rapeseed oil under the investigated working condition. The higher the intensity of electromagnetic field was, the better the lubricity of the rapeseed oil would be.

Complicated boundary films mainly consisting of ester compounds and iron oxides were generated to protect the metal surface from being rubbed, and Fe3O4was identified on the worn surface of steel ball obtained after being exposed to the electromagnetic field.

The facilitated anti-wear and friction-reducing property of rapeseed oil was attributed to the combined action of the enhanced adsorption of adsorption film and the promoted reaction of oxygen element with the metal surface being induced by the electromagnetic field. Furthermore, the electromagnetic field could influence the friction-reducing performance of the rapeseed oil probably by altering the adsorption morphology of the long chain rapeseed oil molecules on the friction interface.

Acknowledgements:This study was financially supported by the National Natural Science Foundation of China (Project No.51375491) and the Natural Science Foundation of Chongqing(Project No. CSTC, 2014JCYJAA50021) and the Youth Fund of Logistical Engineering University (No. YQ16-420801). Special thanks go to Dr. Jiang Yang in Chongqing University for her creative efforts in conducting SEM measurements.

Reference

[1] Bartz W J. Lubricants and the environment[J]. Tribology International, 1998, 31(1/3): 35–47

[2] Nagendramma P, Kaul S. Development of ecofriendly/biodegradable lubricants: An overview[J]. Renewable and Sustainable Energy Reviews, 2012, 16(1): 764–774

[3] Vercammen K, Acker K V, Vanhulsel A, et al. Tribological behaviour of DLC coatings in combination with biodegradable lubricants[J]. Tribology International, 2004,37(1/2): 983–989

[4] Jain S, Sharma M P. Oxidation stability of blends of Jatropha biodiesel with diesel[J]. Fuel, 2011, 90(10):3014–3020

[5] Krzan B and Vizintin J. Ester based lubricants derived from renewable resources[J]. Tribology in Industry, 2004,26(1): 59–62

[6] He Z Y, Wu Y Q, Xiong L P, et al. Preparation and tribological performance of modified rapeseed oil[J].Journal of East China Jiaotong University, 2014, 31(4):105–110 (in Chinese)

[7] Filley J. New lubricants from vegetable oil: Cyclic acetals of methyl 9,10-dihydroxystearate[J]. Bioresource Technology, 2005, 96(5): 551–555

[8] Wang L Y, He H A, Xie Z F, et al. Transesterification of the crude oil of rapeseed with NaOH in supercritical and subcritical methanol[J]. Fuel Processing Technology, 2007,88(5): 477–481

[9] Carlton J. Reeves, Pradeep L. Menezes, Tien-Chien Jen, et al. The in fluence of fatty acids on tribological and thermal properties of natural oils as sustainable biolubricants[J].Tribology International, 2015, 90: 123–134

[10] Fang J H, Chen B S, Huang W J, et al. Tribological behavior of a boron-nitrogen modified castor oil as lubricant additive[J]. Petroleum Processing Petrochemicals,2002, 33(3): 9–12 (in Chinese)

[11] Fang J H, Chen B S, Dong L, et al. Study on tribological behaviors of sulfurized rapeseed oil lube additives[J].Tribology, 2005, 25(5): 408–411 (in Chinese)

[12] Muju M K, Radhakrishna A. Wear of non-magnetic materials in the presence of a magnetic field[J]. Wear,1980, 58(1): 49–58

[13] Totolin V, Göcerler H, Rodríguez R M, et al. Triboelectrochemical study of stainless steel surfaces during chemical–mechanical polishing[J]. Lubrication Science,2016, 28(6): 363–380

[14] Zhai W J. Research progress in tribo-electrochemistry and tribo-electrochemical polishing[J]. Frontiers of Mechanical Engineering, 2007, 2(4): 463–467

[15] Jiang Z Q, Zheng Z, Fang J H, et al. Effect of magnetic field on frictional and wearing properties[J]. Synthetic Lubricants, 2016, 43(1): 23–25 (in Chinese)

[16] Han H B, Liu H, Zhang Y Z, et al.The electromagnetic induction phenomena in friction contact of pin and disk under DC magnetic field[J]. Tribology, 2015, 35(5): 557–561 (in Chinese)

[17] Jiang Z Q, Fang J H, Chen F, et al. Research progress on tribo-electrophysical and tribo-electrochemical mechanisms[J]. Tribology, 2017, 37(5): 695-706 (in Chinese)

[18] Park J Y, Ogletree, D F, Thiel P A, et al. Electronic control of friction in silicon p-n junctions[J]. Science, 2006,313(5784): 186

[19] Jiang Z Q, Fang J H, Chen B S, et al. Effect of magnetic field on tribological properties of lubricating oils with and without tricresyl phosphate[J]. China Petroleum Processing and Petrochemical Technology, 2016, 18(3):119–124

[20] Jiang Z Q, Fang J H, Chen B S, et al. Improvement of magnetic field on tribological properties of lubricating oils with zinc butyloctyldithiophosphate[J]. China Petroleum Processing and Petrochemical Technology, 2016, 18(4):92–98

[21] Jiang Z Q, Fang J H, Chen B S, et al. Tribological properties of base oil and lubricating oils containing tricresyl phosphate under magnetic field[J]. Tribology,2016, 36(5): 571–576 (in Chinese)

[22] Jiang Z Q, Fang J H, Zheng Z, et al. Tribological properties of base oil and lubricants with ammonium thiophosohate in magnetic field[J]. Petroleum Processing and Petrochemicals, 2016, 47(12): 76–79 (in Chinese)

[23] Huang W J. Tribological properties of benzothiazole derivatives as additives in rapeseed oil[J]. Tribology, 2003,23(1): 33–37 (in Chinese)

[24] Mcintyre N S, Zetaruk D G. X-ray photoelectron spectroscopic studies of iron oxides[J]. Analytical Chemistry, 1977, 49(1): 1521–1529

[25] Abdeljaber G T, Mohamed M K, Ali W Y. Effect of magnetic field on the friction and wear of polyamide sliding against steel [J]. Material Science Application,2014, 5(1): 46–53

[26] Shana O. Kelley, Jacqueline K. Barton, Nicole M. Jackson,et al. Orienting DNA helices on gold using applied electric fields[J]. Langmuir, 1998, 14(24): 6781–6784

[27] Liu Q, Long J, Wu Z Q, et al. Effect of alkyl chain characteristic of friction modifier on friction-reducing[J].Acta Petrolei Sinica (Petroleum Processing Section), 2014,30(2): 189–193 (in Chinese)

- 中国炼油与石油化工的其它文章

- Oxidation of Dibenzothiophene in Model Diesel Using Hydroperoxide Generated via In-Situ Reaction of Octane with Oxygen

- Bitumen Recovery from Indonesian Oil Sands Using ASP (Alkali, Surfactant and Polymer) Agent

- Study on Mechanical Performance and Wear Resistance of Halloysite Nanotubes/PTFE Nanocomposites Prepared by Employing Solution Mixing Method

- Study on a New Type of Lubricating Oil for Miniature Bearing Operating at Ultra-low Temperature

- Preparation and Modification of Micro-Mesoporous Carbon Materials for Toluene Adsorption

- Preparation and SO2 Adsorption Behavior of Coconut Shell-Based Activated Carbon via Microwave-Assisted Oxidant Activation