多缸柴油机汽油均质混合气引燃的排放特性

张海燕,李思远,王志坚,李 明,于 超,任烁金,孙 柯,李国祥,王建昕

多缸柴油机汽油均质混合气引燃的排放特性

张海燕1,李思远2,王志坚1,李 明1,于 超1,任烁金3,孙 柯2,李国祥2※,王建昕3

(1. 潍柴动力股份有限公司,潍坊261061;2. 山东大学能源与动力工程学院,济南250061; 3. 清华大学汽车安全与节能国家重点实验室,北京100084)

为探究均质引燃技术对柴油机整机排放特性的影响,该文在某六缸柴油机上,实现了均质引燃模式的多缸运行。试验以转速1 438 r/min、平均指示压力0.7 MPa的工况为代表,通过分析该工况下汽油比例与废气再循环EGR(exhaust gas recirculation)率对多缸均质引燃的影响,确立了汽油比例与EGR率优化的基本原则,并以此为依据完成整机ESC(European steady state cycle)测试。汽油比例及EGR率的分析指出:汽油比例高达90%时燃烧相位仍可有效控制;增大汽油比例可以带来NOx与炭烟(Soot)排放同时降低的显著效应,但汽油比例过大会导致最大压升率陡增;随EGR率增大,作为燃油主体的汽油均质混合气燃烧改善,适量EGR的引入可以优化缸内燃烧;随EGR率增大,NOx排放减少而Soot基本不变,可使用大比例EGR以进一步降低NOx排放。ESC测试结果最终表明:在仅借助柴油氧化催化转化器DOC(diesel oxidation catalyst)的情况下,NOx、一氧化碳CO(carbon monoxide)与总碳氢THC(total hydrocarbon)加权排放低至1.89、0.90、0.12 g/(kW·h),分别满足国Ⅴ标准2.00、1.50、0.46 g/(kW·h)的限值,由各点不透光烟度与加权系数乘积之和计算的Soot加权值也处于0.034 m-1的极低水平。多缸均质引燃对降低柴油机整机排放成效显著,具备稳态测试全面达到国Ⅴ排放标准的潜力。

柴油机;排放控制;试验;均质引燃;多缸运行;ESC测试

0 引 言

传统压燃式柴油机,受以扩散燃烧为主的固有燃烧模式所限,NOx与Soot之间存在难以克服的相悖关系。为满足排放法规,仅通过机内净化技术已无法实现欧Ⅳ及以上阶段要求,只能匹配复杂的后处理装置[1-3],既增加了制造成本与使用成本,也造成了燃油、尿素等附加能源与物质的消耗,一定程度上损坏了柴油机经济性好的固有优势。

HCCI(homogeneous charge compressed ignition)作为一种先进的燃烧理念,同时具备高热效率、低NOx、低Soot排放的优势,理论上可以解决上述问题。但其燃烧相位、燃烧速度难以控制,只能在较窄的工况范围内运行[4-6],因此并未得到实际应用。为实现内燃机可控的高效、清洁燃烧[7-8],各国学者围绕均质混合气引燃做了大量研究,并取得了显著成果。威斯康星大学活性可控压缩着火燃烧模式(RCCI,reactivity controlled compressed ignition)[9-14],通过改变燃油活性控制燃烧相位,通过燃油活性分层控制放热规律,部分试验工况下NOx排放量低于欧Ⅵ限值而Soot近零排放。清华大学汽油均质混合气柴油引燃燃烧模式(HCII,homogeneous charge induced ignition),通过引燃柴油喷射时刻控制燃烧始点,通过引燃柴油喷射量和分布形态控制燃烧速率,实现了对燃烧相位的有效控制,获得了NOx与Soot排放同时降低而基本不出现相悖关系的效果,指示热效率在部分工况下也超过传统柴油机水平[15-17]。此外,美国西南研究院[18-19]、天津大学[20-22]、上海交通大学[23-24]、伯明翰大学[25]等,在试验工况下也均取得了NOx与Soot排放同时大幅降低的显著成果。但上述研究均局限在单缸机上进行,或试验单缸机由多缸机改造而成,在进排气状况、EGR(exhaust gas recirculation)-增压器耦合效应、机械损失等方面与发动机实际工作状态存在一定差异。

为反映均质引燃技术的真实特性,本文在一台产品化的六缸柴油机上实现了均质引燃模式的多缸运行,通过典型工况探究了汽油比例与EGR率对多缸均质引燃基本特性的影响,并据此进行参数优化完成整机ESC(European steady state cycle)测试。本文试验条件更加接近多缸机实际工作状况,以期为均质引燃技术的产品化应用提供参考。

1 试验设备与试验方法

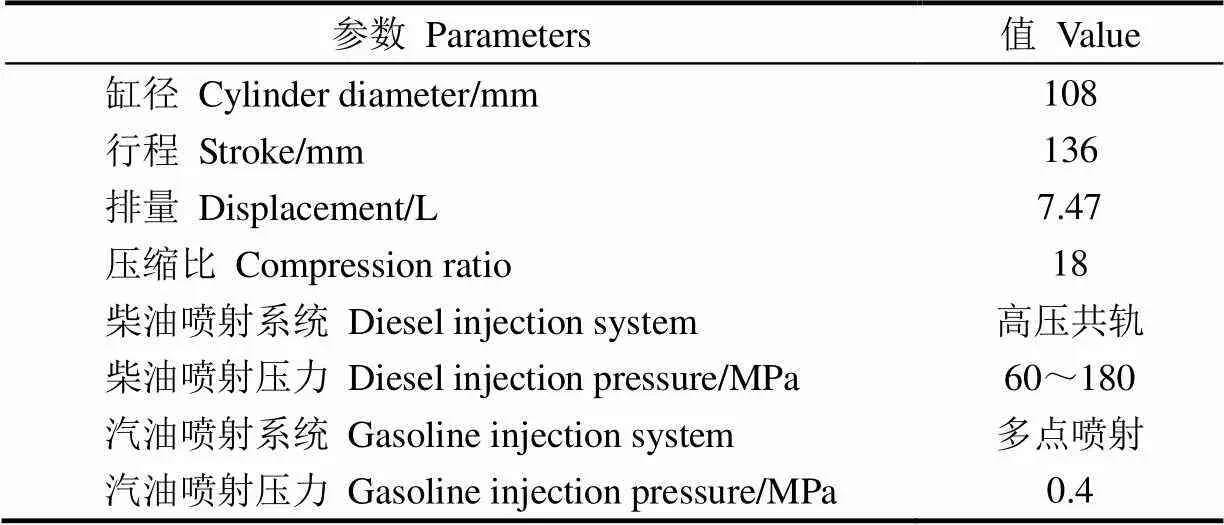

试验发动机由某六缸增压柴油机改造而成,一至六缸进气歧管处加装汽油喷嘴、使用ECKA公司开放式双燃料电子控制单元ECU(electronic control unit)替代原机ECU,主要参数如表1所示。经改造后,汽油喷射时刻、喷射脉宽,柴油喷射压力、喷射次数、喷射时刻、喷射脉宽,增压器涡轮流通截面,EGR阀开度等,均可通过双燃料ECU灵活设定。

表1 试验发动机主要参数

试验系统如图1所示。发动机第一、第六缸均装有缸压传感器。燃烧特性分析,使用AVL公司INDICOM621型燃烧分析仪(采样间隔0.1 °CA)。气态排放物NOx、CO、THC及EGR率的测量,使用HORIBA公司MEXA-1600DEGR型排气分析仪。Soot排放测量,使用AVL公司439型不透光式烟度计(分辨率2.5×10–3m–1)。

1. 汽油 2. 汽油油耗仪 3. 汽油喷油器 4. 柴油 5. 柴油油耗仪 6. 柴油喷油器 7. 测功机 8. 缸压传感器 9. 角度传感器 10. 涡轮增压器 11. EGR冷却器 12. EGR阀 13. 空气 14. 空气质量流量计 15. 中冷器 16. 排气分析 17. 燃烧分析仪 18. 双燃料ECU

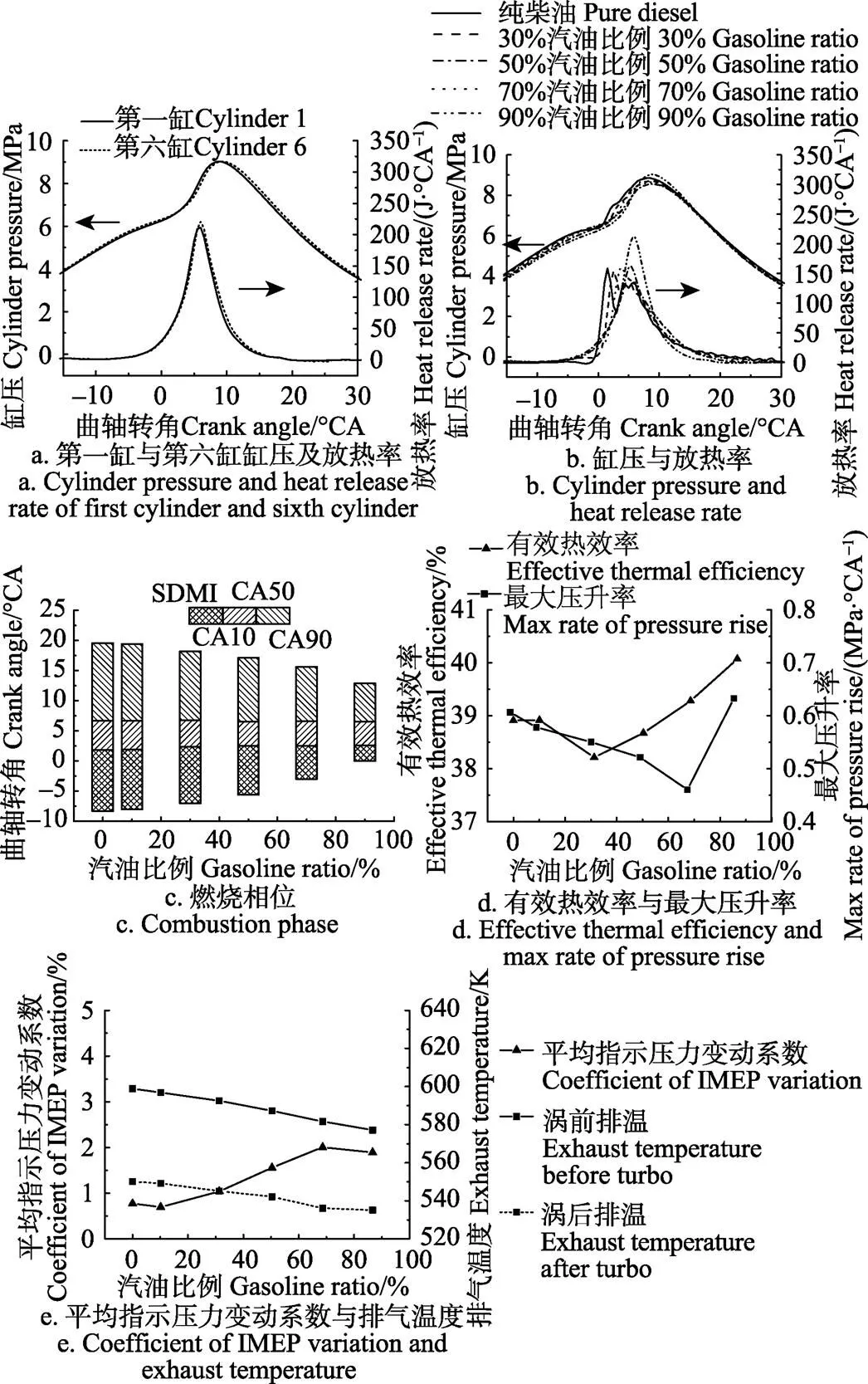

所用主要参数定义如下:柴油主喷时刻SDMI(start of diesel main injection);CA10、CA50、CA90分别为10%、50%、90%累积放热量所对应的曲轴转角;滞燃期,SDMI至CA10所经历的曲轴转角;燃烧持续期,CA10至CA90所经历的曲轴转角;最大压升率,为缸压曲线斜率的最大值。

汽油比例GR(gasoline ratio),为无量纲量,定义为燃油消耗量中汽油热量与总燃油热量之比,即

式中g、d分别为汽油与柴油的燃油消耗量,kg/h;ug、ud分别为汽油与柴油的低热值,kJ/kg。

平均指示压力IMEP(indicated mean effective pressure),Pa,计算公式为

式中为缸内压力,Pa;为气缸容积,m3;s为单缸排量,m3。

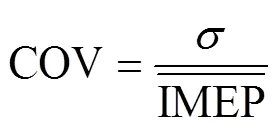

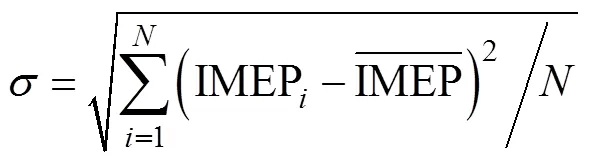

平均指示压力变动系数COV(coefficient of IMEP variation),计算公式为

式中e是发动机有效功率,kW。

试验过程分两步进行,在=1 438 r/min、IMEP=0.7 MPa工况下验证各缸工作一致性并完成汽油比例与EGR率探究;匹配DOC(diesel oxidation catalyst)完成整机ESC测试。由于CA50在燃烧相位中具有典型意义,因此汽油比例与EGR率探究过程中将保持CA50一定,发动机试验参数设定如表2所示。

表2 发动机试验参数设定(汽油比例与EGR率探究)

注:EGR表示废气再循环,下同。

Note: EGR represents exhaust gas recirculation, the same below.

2 试验结果及分析

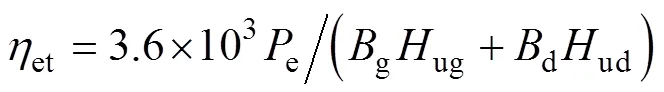

由图2a可知各缸工作一致性较好,因此,下文基于缸压传感器及燃烧分析仪获得的缸压、放热率、CA10、CA50、CA90、IMEP、COV、最大压升率结果均取自第一缸数据,各试验数据如图2所示。

注:试验条件:转速1 438 r·min–1、IMEP 0.7 MPa;图2a中汽油比例为90%;SDMI表示柴油主喷时刻;CA10、CA50、CA90分别表示10%、50%、90%累积放热量对应的曲轴转角,下同。

2.1 汽油比例对多缸均质引燃的影响

汽油比例对缸压与放热率的影响如图2b所示。在70%汽油比例内,放热率曲线呈现出典型的两阶段燃烧特征。第一阶段为柴油在滞燃期内形成的可燃混合气及卷吸入的部分汽油快速燃烧所致,峰值较大但持续时间较短;第二阶段视为柴油的扩散燃烧,由于燃烧缓慢、持续时间较长,峰值小于第一阶段。随汽油比例增大,第一阶段峰值位置后移,且第二阶段持续时间缩短。第一阶段峰值位置后移,是由于柴油喷射量减少导致引燃面积减小,初期放热速率降低。第二阶段持续时间缩短,则主要归因于扩散燃烧占比减小。汽油比例超过70%后,两阶段燃烧完全耦合,形成了一个以预混燃烧为主体的单峰放热曲线,且峰值大小陡增。随汽油比例增大,在70%汽油比例内,缸压峰值逐步降低且峰值位置后移。超过70%后,由于两阶段燃烧耦合,缸压峰值转而上升,并超越纯柴油水平。

汽油比例对燃烧相位的影响如图2c所示。随汽油比例增大,为保持CA50不变,SDMI推后,主喷时刻逐渐靠近上止点,柴油喷入时缸内的温度、压力逐步升高,故滞燃期缩短。随汽油比例增大,燃烧持续期缩短。若以CA50为界将燃烧划分为前后两部分,可以看出CA10- CA50变化较小,而CA50-CA90最大减小50.8%,是燃烧持续期缩短的主导因素,这也与放热率曲线第二阶段持续时间显著缩短相一致。CA10-CA50变化较小,是由于虽然引燃面积减小导致初期放热缓慢,但汽油当量比增大又有利于提高引燃后汽油燃烧速度,二者综合作用导致CA10-CA50变化不大。CA50-CA90大幅减小,则是由于扩散燃烧占比减小且两阶段放热逐步耦合,具有更快的燃烧速度。

汽油比例对有效热效率与最大压升率的影响如图2d所示。随汽油比例增大,有效热效率先降低后升高。汽油比例较小时,由于汽油当量比低,部分汽油燃烧恶化。一定范围内,汽油比例的增大未能有效改善此种情况,反而带来更多的未燃产物,导致有效热效率降低。而当汽油比例超过临界点后,在汽油燃烧改善的条件下,随着燃烧持续期缩短,有效热效率增大,最终超越纯柴油1.2个百分点。随汽油比例增大,在70%汽油比例内,第一阶段放热率峰值位置后移,故最大压升率降低。汽油比例超过70%后,由于两阶段燃烧完全耦合,最大压升率陡增,最终达到0.63 MPa/°CA。

汽油比例对COV与排气温度的影响如图2e所示。随汽油比例增大,引燃面积减小导致着火不稳定,故COV上升。但在0至90%的汽油比例范围内,COV始终维持在2%以内,说明汽油比例高达90%时燃烧相位仍可有效控制。随汽油比例增大,排气温度降低,发动机热负荷下降。

汽油比例对NOx与Soot排放的影响如图3a所示。随汽油比例增大,NOx排放大幅降低,在90%汽油比例下NOx排放低至0.79 g/(kW·h),相比纯柴油降低了78%。均质引燃模式下,最高燃烧温度出现在柴油油束区域,而NOx的生成也集中在该区域[26-28]。随着柴油当量比降低,由柴油引发的初期放热减缓,此外汽油汽化吸热进气温度降低,均导致最高燃烧温度下降,NOx排放减少。随汽油比例增大,Soot排放初期小幅上升,超过30%汽油比例后转而大幅降低,至90%汽油比例时达到0.023 m–1,仅为纯柴油的32.3%。Soot排放初期上升,是由于滞燃期缩短加强了柴油因局部缺氧而生成Soot的条件。而汽油比例超过30%后,柴油的有效减少使得预混燃烧占据主导,因此Soot排放降低。

汽油比例对CO与THC排放的影响如图3b所示。随汽油比例增大,CO排放先上升后下降。同有效热效率的作用原理类似,仅当汽油混合气当量比超过临界点后,汽油比例增大才能有效改善汽油燃烧。随汽油比例增大,THC排放一直上升。THC排放主要来源于狭隙效应与容积淬熄。同点燃机类似,压缩行程中被挤入燃烧室缝隙的汽油混合气即成为THC排放的重要来源。同时,由于稀薄燃烧的特点,汽油混合气易发生容积淬熄生成THC。总体而言,均质引燃模式的CO与THC排放水平远高于传统柴油机,而由图2e可知,涡后排气温度最低为535 K,满足DOC起燃要求[29],因此均质引燃模式的CO与THC排放问题可藉由DOC解决。

注:不透光式烟度计测量结果为光吸收系数,m–1;THC表示总碳氢;转速为1 438 r·min–1;平均指示压力为0.7 MPa,下同。

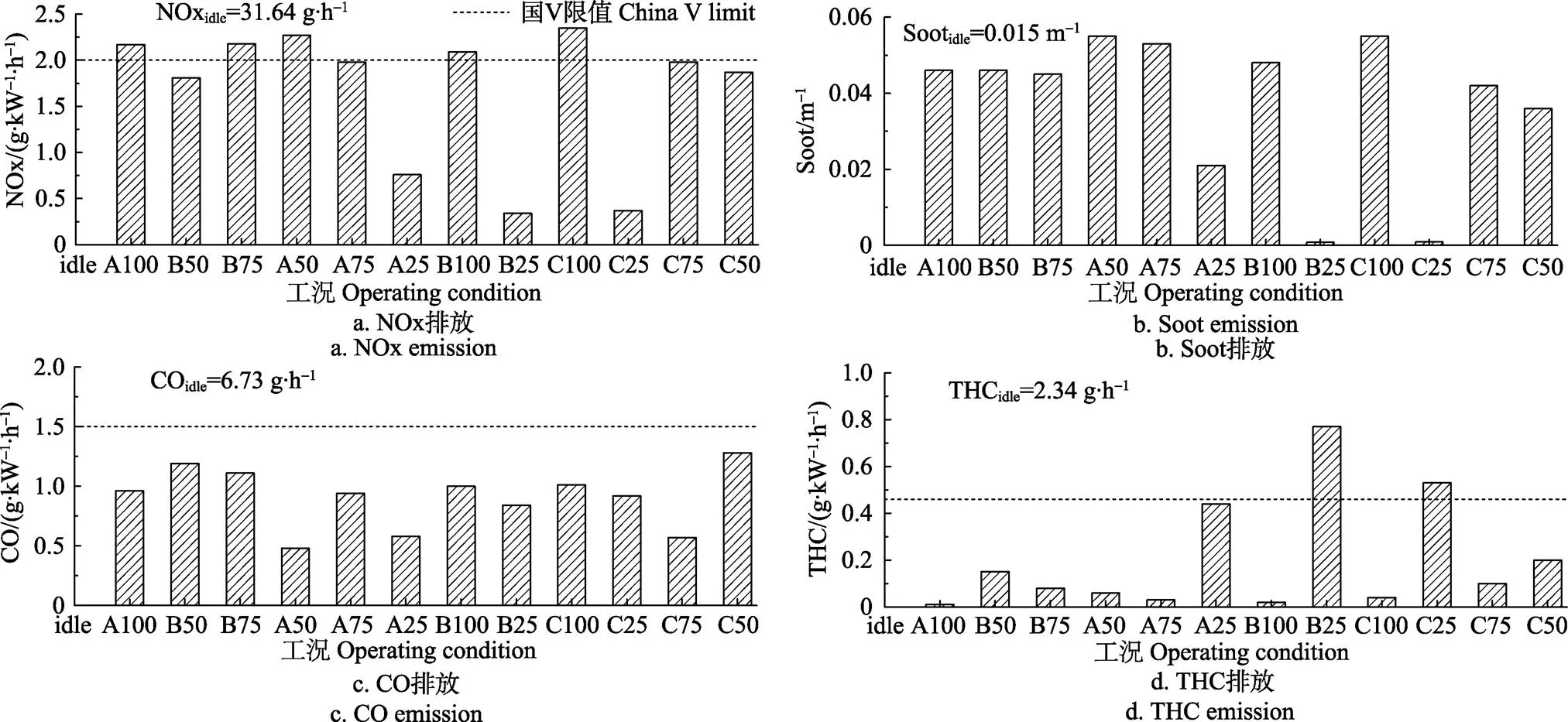

2.2 EGR率对多缸均质引燃的影响

EGR率对燃烧相位的影响如图4a所示。随EGR率增大,滞燃期缩短,但在EGR率超过30%后转而上升。EGR中冷后温度显著高于增压空气中冷后温度,二者混合导致进气温度提高,故滞燃期缩短。但在EGR率超过30%后,氧气体积分数降低的效应对柴油影响显著,滞燃期转而增长。随EGR率增大,CA10-CA50缩短,CA50-CA90增大。由于稀薄燃烧的特点,EGR的引入反而提高了汽油混合气当量比,汽油燃烧改善,因此CA10- CA50缩短。在汽油燃烧改善前期耗氧量增加的条件下,惰性气体对柴油扩散燃烧的稀释作用进一步加剧,CA50- CA90持续时间增长。随EGR率增大,在30%EGR率内,燃烧持续期基本不变;至40%EGR率时,由于CA50-CA90增幅显著,燃烧持续期略有增长。

EGR率对燃烧效率与有效热效率的影响如图4b所示。随EGR率增大,作为燃油主体的汽油燃烧改善、燃烧速度加快,因此燃烧效率与有效热效率上升。但在EGR率超过30%后,由于柴油扩散燃烧减慢的效应显著,燃烧持续期增长导致有效热效率降低,因此最大EGR率应控制在30%左右。

EGR率对NOx与Soot排放的影响如图5a所示。随EGR率增大,NOx排放大幅降低,在40%EGR率下NOx排放低至1.42 g/(kW·h),较未引入EGR时降幅高达76%。EGR的引入减慢了柴油的燃烧速度,故最高燃烧温度降低、NOx排放减少。随EGR率增大,Soot排放基本不变,始终维持在0.035 m–1的极低水平。Soot的生成集中在柴油的扩散燃烧阶段,由于汽油比例高达70%,预混燃烧占据主导地位,故Soot排放始终处于极低水平。

EGR率对CO与THC排放的影响如图5b所示。CO与THC排放主要来源于汽油混合气的不完全燃烧,随EGR率增大,汽油燃烧改善,二者同时降低,较未引入EGR时降幅均超过50%,这也是燃烧效率提高的直接证明。

注:汽油比例为70%。

图5 EGR率对排放特性的影响

2.3 ESC测试

由前述分析可知,汽油比例与EGR率的设定应在满足最大压升率及有效热效率的前提下尽可能增大。本节将在最大压升率不超过0.6 MPa/°CA、有效热效率不低于纯柴油模式的限制条件下,基于此两项参数优化完成整机ESC测试,测试过程依据GB17691-2005[30]进行,两参数取值如表3所示。同时,为解决CO与THC排放过高的问题,发动机将匹配DOC装置。

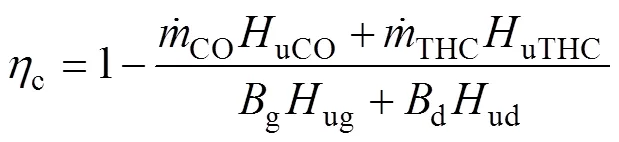

ESC测试各工况主要参数如表3所示,各工况单点排放如图6所示。为对表征Soot排放的不透光烟度进行整体衡量,Soot加权值由式(7)计算

式中Soot与WF分别表示第工况的Soot排放值与加权系数,S表示对ESC所有工况进行求和,WF值见表3。

由ESC测试结果知,各工况单点排放基本位于国Ⅴ限值内,NOx、CO与THC加权排放分别低至1.89、0.90、0.12 g/(kW·h),均满足国Ⅴ标准,Soot加权值也处于0.034 m–1的极低水平。可见,多缸均质引燃对降低柴油机整机排放成效显著。

表3 ESC测试各工况参数设定

注:1. ESC表示欧洲稳态测试循环,下同;2. A25表示A转速下25%负荷点,其余含义相同。

Note: 1. ESC represents European steady state cycle, similarly hereinafter; 2. A25 represents the engine operation at 25% of full load and speed A. Others are the same.

注:怠速工况下发动机不输出功率,因此图中所示NOx、CO与THC的怠速排放为质量流量。

3 结 论

1)汽油比例增大,预混燃烧占比增加,放热率曲线由预混-扩散燃烧分界明显的双峰放热,变为以预混燃烧为主体的单峰放热。

2)汽油比例90%时燃烧相位仍可有效控制。增大汽油比例可以带来NOx与Soot排放同时降低的成效,但汽油比例过大会导致最大压升率陡增,汽油比例应低于90%。

3)适量EGR(exhaust gas recirculation)的引入使得作为燃油主体的汽油均质混合气燃烧改善,燃烧效率与有效热效率同时上升,但EGR率过大会导致柴油燃烧恶化的效应凸显,最大EGR率应控制在30%左右。

4)随EGR率增大,NOx排放大幅减少而Soot排放基本不变,多缸均质引燃相比纯柴油模式可使用较大比例EGR。

多缸均质引燃对降低柴油机整机排放成效显著,在仅借助DOC的情况下,整机ESC测试NOx、CO与THC加权排放分别达到1.89、0.90、0.12 g/(kW·h),Soot加权值也处于0.034 m–1的极低水平,具备稳态测试全面达到国Ⅴ排放标准的潜力。

[1] 帅石金,唐韬,赵彦光,等. 柴油车排放法规及后处理技术的现状与展望[J]. 汽车安全与节能学报,2012,3(3):200-217. Shuai Shijin, Tang Tao, Zhao Yanguang, et al. State of the art and outlook of diesel emission regulations and aftertreatment technologies[J]. Automotive Safety and Energy, 2012, 3(3): 200-217. (in Chinese with English abstract)

[2] Johnson T V. Diesel emission control in review[C]//SAE Paper. Michigan: SAE International, 2007.

[3] Johnson T V. Vehicle emissions review[C]//Directions in Engine-Efficiency and Emissions Research(DEER) Conf. Washington: U. S. Department of Energy, 2011.

[4] 尧命发,刘海峰. 均质压燃与低温燃烧的燃烧技术研究进展与展望[J]. 汽车工程学报,2012,2(2):79-90. Yao Mingfa, Liu Haifeng. Review and prospect of the combustion technology of homogeneous charge compression ignition and low temperature combustion [J]. Chinese Journal of Automotive Engineering, 2012, 2(2): 79-90. (in Chinese with English abstract)

[5] 莫春兰,卢正辉,许明疆,等. 乙醇柴油均质压缩燃烧反应特点及边界条件分析[J]. 农业工程学报,2011,27(12):291-296. Mo Chunlan, Lu Zhenghui, Xu Mingjiang, et al. Analysis of combustion characteristics and boundary condition effects on HCCI engine fueled with ethanol/diesel blends[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2011, 27(12): 291-296. (in Chinese with English abstract)

[6] Dec J, Hwang W. An investigation of thermal stratification in HCCI engines using chemiluminescence imaging[C]//SAE Paper. Michigan: SAE International, 2006.

[7] 王建昕. 高效车用汽油机的技术进步[J]. 内燃机学报,2008(1):83-89. Wang Jianxin. Technology progress in high efficiency gasoline engine for vehicle[J]. Transactions of CSICE, 2008(1): 83-89. (in Chinese with English abstract)

[8] 苏万华,赵华,王建盺. 均质压燃低温燃烧发动机理论与技术[M]. 北京:科学出版社,2010:2-10.

[9] Benajes J, Molina S, Garcia A, et al. An investigation on RCCI combustion in a heavy duty diesel engine using in-cylinder blending of diesel and gasoline fuels[J]. Applied Thermal Engineering, 2014, 63: 66-76.

[10] Kokjohn S L, Hanson R M, Reitz R D, et al. Fuel reactivity controlled compression ignition (RCCI): A pathway to controlled high-efficiency clean combustion[J]. International Journal of Engine Research, 2011, 12: 209-226.

[11] Splitter D A, Reitz R D. Fuel reactivity effects on the efficiency and operational window of dual-fuel compression ignition engines[J]. Fuel, 2014, 118: 163-175.

[12] Reitz R D, Duraisamy G. Review of high efficiency and clean reactivity controlled compression ignition (RCCI) combustion in internal combustion engines[J]. Progress in Energy and Combustion Science, 2015, 46: 12-71.

[13] Benajes J, Molina S, Garcia A, et al. Effects of direct injection timing and blending ratio on RCCI combustion with different low reactivity fuels[J]. Energy Conversion and Management, 2015, 99: 193-209.

[14] Bhagatwala A, Sankaran R, Kokjohn S, et al. Numerical investigation of spontaneous flame propagation under RCCI conditions[J]. Combustion and Flame, 2015, 162: 3412-3426.

[15] 王建昕,蒋恒飞,王燕军,等. 汽油均质混合气柴油引燃(HCII)燃烧特性的研究[J]. 内燃机学报,2004,22(5):391-396. Wang Jianxin, Jiang Hengfei, Wang Yanjun, et al. Study on the combustion characteristics of homogeneous charge induced ignition (HCII) for gasoline engine[J]. Transactions of CSICE, 2004, 22(5): 391-396. (in Chinese with English abstract)

[16] 于超,王建昕,王志,等. 均质混合气引燃发动机的燃烧与排放特性[J]. 汽车安全与节能学报,2011,2(3):263-270. Yu Chao, Wang Jianxin, Wang Zhi, et al. Combustion and emission characteristics of homogeneous charge induced ignition engines[J]. Automotive Safety and Energy, 2011, 2(3): 263-270. (in Chinese with English abstract)

[17] Jiang Hengfei, Wang Jianxin, Shuai Shijin. Visualization and performance analysis of gasoline homogeneous charge induced ignition by diesel[C]//SAE Paper. Michigan: SAE International, 2005.

[18] Alger T, Hanhe S, Roberts C E, et al. The heavy duty gasoline engine: A multi-cylinder study of a high efficiency, low emission technology[C]//SAE Paper. Michigan: SAE International, 2005.

[19] Charles E R, James C S, Chad S, et al. The heavy duty gasoline engine: An alternative to meet emissions standards of tomorrow[C]//SAE Paper. Michigan: SAE International, 2004.

[20] 尧命发,马帅营,童来会,等. 燃烧参数对汽油/柴油双燃料HPCC性能和排放影响的试验[J]. 内燃机学报,2012,30(4):289-295. Yiao Mingfa, Ma Shuaiying, Tong Laihui, et al. An experiment on the effects of combustion parameters on HPCC combustion fuelled with gasoline/diesel dual fuel[J]. Transactions of CSICE, 2012, 30(4): 289-295. (in Chinese with English abstract)

[21] 马帅营,尧命发,童来会,等. 汽油/柴油双燃料高比例预混压燃燃烧与排放的试验[J]. 内燃机学报,2012,30(1):1-8. Ma Shuaiying, Yao Mingfa, Tong Laihui, et al. An experimental study on combustion and emissions of gasoline/ diesel dual fuel HPCC[J]. Transactions of CSICE, 2012, 30(1): 1-8. (in Chinese with English abstract)

[22] 马帅营,陈贵升,郑尊清,等. 汽油/柴油双燃料HPCC在不同转速下的高负荷研究[J]. 内燃机学报,2013,31(4):289-295. Ma Shuaiying, Chen Guisheng, Zheng Zunqing, et al. Study on high load of HPCC fuelled with gasoline/diesel dual fuel at different engine speeds[J]. Transactions of CSICE, 2013, 31(4): 289-295. (in Chinese with English abstract)

[23] 马骏骏,吕兴才,吉丽斌,等. 辛烷值和预混合率对双燃料发动机SCCI燃烧与爆震的影响[J]. 上海交通大学学报,2009,43(2):308-313. Ma Junjun, Lv Xingcai, Ji Libin, et al. Effects of octane number and premixed ratio on the knock and combustion characteristics of dual-fuel SCCI[J]. Journal of Shanghai Jiaotong University, 2009, 43(2): 308-313. (in Chinese with English abstract)

[24] Qian Yong, Ouyang Linqi, Wang Xiaole, et al. Experimental studies on combustion and emissions of RCCI fuled with n-heptane/alcohols fuels[J]. Fuel, 2015, 162: 239-250.

[25] Ma Xiao, Zhang Fan, Xu Hongming, et al. Throttleless and EGR-controlled stoichiometric combustion in a diesel- gasoline dual-fuel compression ignition engine[J]. Fuel, 2014, 115: 765-777.

[26] Li Yaopeng, Jia Ming, Chang Yachao, et al. Parametric study and optimization of a RCCI (reactivity controlled compression ignition) engine fueled with methanol and diesel[J]. Energy,2014, 65: 319-332.

[27] Desantes J M, Benajes J, Garcia A, et al. The role of the in-cylinder gas temperature and oxygen concentration over low load reactivity controlled compression ignition combustion efficiency[J]. Energy, 2014, 78: 854-868.

[28] Molina S, Garcia A, Pastor J M, et al. Operating range extension of RCCI combustion concept from low to full load in a heavy-duty engine[J]. Applied Energy, 2015, 143: 211-227.

[29] 龚金科. 汽车排放及控制技术[M]. 北京:人民交通出版社,2011:129-132.

[30] 国家环境保护总局. 车用压燃式、气体燃料点燃式发动机与汽车排气污染物排放限值及测量方法(中国Ⅲ、Ⅳ、Ⅴ阶段):GB 17691—2005,[S]. 北京:中国环境出版社,2005.

张海燕,李思远,王志坚,李 明,于 超,任烁金,孙 柯,李国祥,王建昕.多缸柴油机汽油均质混合气引燃的排放特性[J]. 农业工程学报,2017,33(19):108-114. doi:10.11975/j.issn.1002-6819.2017.19.014 http://www.tcsae.org

Zhang Haiyan, Li Siyuan, Wang Zhijian, Li Ming, Yu Chao, Ren Shuojin, Sun Ke, Li Guoxiang, Wang Jianxin. Emission performance of gasoline homogeneous charge induced ignition in multi-cylinder diesel engine[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(19): 108-114. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2017.19.014 http://www.tcsae.org

Emission performance of gasoline homogeneous charge induced ignition in multi-cylinder diesel engine

Zhang Haiyan1, Li Siyuan2, Wang Zhijian1, Li Ming1, Yu Chao1, Ren Shuojin3, Sun Ke2, Li Guoxiang2※, Wang Jianxin3

(1.261061,; 2.250061,; 3.100084,)

Homogeneous charge induced ignition (HCII) is an effective way to reduce NOx emission and soot emission simultaneously while keeping high thermal efficiency. However, the former research about it was limited to single cylinder engine which was original or modified by multi-cylinder engine. Usually, separate intake system, exhaust system and fuel supply system would be set up for the test cylinder, while fuel supply to the other cylinders was cut off. Thus, there was only the test cylinder working normally for the experimental engine. Besides, a fuel-free air compressor, as an external equipment not belonging to the engine body, was used to replace turbocharger. Therefore, the experimental condition of intake-exhaust, EGR (exhaust gas recirculation) - turbocharger coupling effect and mechanical loss was quite different from which engines actually worked in. To study the real emission performance of HCII, a six-cylinder turbocharged diesel engine was modified to achieve MHCII (multi-cylinder homogeneous charge induced ignition, which means all cylinders operate in HCII mode simultaneously) in this paper. The experimental engine incorporated an extra gasoline injection system, and the technology of intake port MFI (multi-point fuel injection) was used, while diesel injection kept the original high pressure common rail system without any change. Furthermore, a dual-fuel ECU (electronic control unit) that could be adjusted flexibly was equipped to control both of the fuels. The whole research in this paper included 2 aspects. Firstly, the influence of gasoline ratio and EGR ratio on MHCII was studied in a typical engine working condition, i.e. rotating speed of 1 438 r/min and IMEP (indicated mean effective pressure) of 0.7 MPa. Based on it, the basic principles of optimizing these 2 parameters were established. Secondly, DOC (diesel oxidation catalyst) device was matched to the experimental engine and the ESC (European steady state cycle) test was conducted under the guidance of those principles established in the first step. Test results of the first step showed that even 90% gasoline in total fuel energy could control the combustion phase sufficiently. With the gasoline ratio increasing, the percentage of pre-mixed combustion got larger and the shape of heat release rate curve changed from double peaks to one peak, in the meantime, NOx emission and soot emission both decreased dramatically. However, gasoline ratio could not get large indefinitely, or it would cause the problem of rise rate of maximum pressure increasing sharply. In the experimental condition, the maximum gasoline ratio should be less than 90%. With EGR ratio increasing, the combustion of lean gasoline homogeneous charge, as the major component of total fuel, was improved, in the meantime, combustion efficiency and effective thermal efficiency both got larger, so the combustion of MHCII could be optimized under suitable EGR ratio. However, similar to gasoline ratio, excessive EGR ratio would make the effect of diesel combustion deterioration prominent, so the maximum EGR ratio should still be controlled at around 30%. With EGR ratio increasing, the NOx emission decreased while soot emission remained nearly unchanged, and thus larger EGR ratio could be applied to inhibit NOx formation. Test results of ESC showed that the specific emissions of NOx, CO (carbon monoxide) and THC (total hydrocarbon) could reach 1.89, 0.90 and 0.12 g/(kW·h), meeting China Ⅴlimits of 2.00, 1.50, and 0.46 g/(kW·h) separately, only with the aid of DOC. In the meantime, the weighted value of soot, calculated from summing the product of soot emission and weighting coefficient at each ESC test point, was also at an extremely low level of 0.034 m–1. Therefore, MHCII can reduce the emission of whole diesel engine significantly and it is highly possible to meet all the requirements of China Ⅴ emission standard under steady state test.

diesel engines; emission control; experiments; homogeneous charge induced ignition; multi-cylinder operation; ESC test

10.11975/j.issn.1002-6819.2017.19.014

TK421+.1

A

1002-6819(2017)-19-0108-07

2017-04-28

2017-09-11

国家自然科学基金(51576116)

张海燕,工程师,主要从事柴油机前沿技术研究。 Email:zhanghaiyan@weichai.com

※通信作者:李国祥,教授,博士生导师,主要从事内燃机可靠性与排放控制技术及汽车混合动力系统研究。Email:liguox@sdu.edu.cn