R1234ze(E)与R32混合工质在热泵系统中替代R410A的实验研究

王路路张华邱金友

(1上海理工大学能源与动力工程学院 上海 200093;2福建工程学院生态环境与城市建设学院 福州 350118)

R1234ze(E)与R32混合工质在热泵系统中替代R410A的实验研究

王路路1张华1邱金友2

(1上海理工大学能源与动力工程学院 上海 200093;2福建工程学院生态环境与城市建设学院 福州 350118)

新型制冷剂R1234ze(E)因较低的GWP备受制冷行业关注,其与R32的混合工质作为热泵系统制冷剂的研究也在逐步展开,本文以R1234ze(E)/R32(质量配比:27%/73%,命名为L-41b,GWP=493)混合工质为研究对象,在人工环境室中设计并搭建了空气源热泵测试系统,对比研究了L-41b与R410A在热泵系统中的性能系数COP、压缩机功耗、制热量、排气温度和循环压比。结果表明:当恒定冷凝温度,蒸发温度从5℃增加到13℃时,R410A和L-41b的COP偏差从8.6%缩小到2.8%。当恒定蒸发温度,冷凝温度从30℃提高到42℃时,L-41b的运行性能系数COP的降幅小于R410A,变工况实验表明在相对高温区L-41b替代R410A具有较好的替代性能。

R1234ze(E)/R32;混合制冷剂;空气源热泵;运行工况

在目前经济与技术的条件下,研究低GWP的混合替代制冷剂是当前制冷剂的替代趋势之一[1-4]。新型制冷剂 R1234ze(E)(trans-1,3,3,3-tetrafluoropropene)因较低的GWP备受制冷行业关注,近期的研究报告[5]表明R1234ze(E)的GWP小于1,其作为空调、热泵的替代品已初步得到认可[6-8]。 但R1234ze(E)单一成分的热力学性能和传输特性并不理想,若直接应用于空调和热泵系统,其系统性能系数(COP)和容积制冷量(VCC)均会低于目前常用工质R134a和R410A。R32属于HFCs类物质,但其GWP并不高(GWP R32=675),拥有较高的汽化潜热和良好的传输性能[9-10],在R1234ze(E)中混入R32成分可以有效改善其热力学性能和传输性能[11]。

目前国内外对于环保制冷剂 R1234ze(E)和R1234ze(E)/R32混合工质的研究近几年才逐步展开。K.Tanaka等[12]开展对R1234ze(E)及其与R32的混合物的热力学特性和制冷循环性能系数与其组分关系的研究,其所获得的COP和容积制冷量VCC与R1234ze(E)的质量分数的依赖关系,对于指导正确配置R1234ze(E)与R32混合制冷剂有参考价值。S.Koyama等[13]对纯R1234ze(E)及质量比为0.5:0.5的R1234ze(E)/R32混合工质在R410系统上进行直接充灌研究,并与R410A比较。证明在R1234ze(E)中添加R32可以提高系统性能系数COP,且可提高系统制冷量。国内张志巍等[14]对不同 R1234ze(E)/R32混合比进行系统循环性能分析,指出R410A的替代方案应从R32适合配比与减少系统压力损失着手。邱金友等[15]指出需要进行大量的实验室充灌与改型实验,获得对比性能数据,找出存在的问题,并根据R1234ze(E)及其与R32混合物的特点对压缩机、换热器的传热面积与传热方式、连接管、节流装置等方面进行优化设计,确保其性能达到或超过原有的设计水平,为下一步产品的优化设计奠定基础。

初步的研究论证了环保制冷剂R1234ze(E)及其与R32的混合工质具有与R410A相似的热物性和传输性能,有望成为新一代低GWP替代制冷剂,三者基本物性如表 1所示。本文从 AHRI Low-GWP AREP项目[16-17]第一阶段对R134a和R410A的替代候选制冷剂中选择 L-41b(R1234ze(E)/R32(27%/73%))作为研究对象,探索其混合物在热泵系统中的运行性能。

表1 R410A、R32和R1234ze(E)的基本物性Tab.1 Physical properties of R410A,R32 and R1234ze(E)

1 实验装置与实验方案

1.1 人工环境室简介

人工环境室主要由实验室外围保温结构、空气处理机组、温湿度采样装置、空气流量测试装置、系统控制系统及测量数据采集系统等组成。其中,空气调节处理系统主要由室内空气处理机组、水冷压缩冷凝机组、循环风机、电加热器、电加湿器及相关的控制设备组成。人工环境室的主要用途是提供测试机组性能时所需的各种工况,主要是保证室内的空气的温度、湿度、空气流动速度等达到实验所需的工况条件,使测试在一个稳定环境下进行,以准确测试空调器的性能。环境室内的温度和湿度参数采用两个PID控制器调节制冷系统、电加热器和加湿器来实现,表2列举环境室所能达到的测试工况。

表2 环境室参数控制及精度Tab.2 Working condition of environmental chamber

图1 空气源热泵系统及测点布置图Fig.1 Schematic diagram of experimental bench and measuring points

1.2 空气源热泵系统实验台

图1所示为设计搭建的空气源热泵实验系统流程图及测点布置图。此系统包括两个循环回路:热泵系统制冷剂循环回路和冷凝器侧水循环回路。热泵系统制冷剂循环回路主要包括压缩机、水冷冷凝器、回热器、电子膨胀阀和翅片管式蒸发器等;冷凝器侧水循环回路主要包括恒温水箱、循环水泵和流量计等。压缩机采用变频滚动转子式压缩机,冷凝器采用水冷套管冷凝器,膨胀阀采用电子膨胀阀;蒸发器采用翅片管的形式,回热器两端连接旁通管路。

1.3 实验工况方案设定

考虑到系统运行的工况未必恒定不变,同时也为了更全面的掌握新型工质L-41b的运行性能,研究了R410A与L-41b两种工质在固定蒸发温度或冷凝温度下运行性能随另一侧温度的变化情况。实验的方式通过改变人工环境室的温度、蒸发器风机风量、冷凝器进口载热流体温度和冷凝器载热流体流量的参数来实现对工质侧的蒸发温度和冷凝温度的控制。为了避免冷凝温度过高导致压缩机停机,设定冷凝温度在38℃附近。同时考虑到人工环境室工况的限制,蒸发温度设定在4℃以上,以此分别设定了三组实验方案,如表3所示,改变蒸发温度,保持冷凝侧参数恒定。如表4所示,改变冷凝温度,保持蒸发侧工质参数恒定。

表3 变蒸发温度工况表Tab.3 Variable evaporation temperature working condition

表4 变冷凝温度工况表Tab.4 Variable condensation temperature working condition

2 实验结果及性能对比分析

2.1 循环性能系数COP的对比

图2和图3分别给出了R410A和L-41b在固定一侧温度,循环性能系数COP随另一侧的变化规律。以图2分析为例,在固定冷凝侧温度为38℃附近的工况下,蒸发温度从5℃左右提高到13℃左右时,R410A和L-41b的COP分别从3.52和3.30提升到3.92和3.81,R410A和L-41b的COP偏差从8.6%缩小为2.8%,说明随蒸发温度的升高,L-41b的COP的增幅大于R410A。在图3中同样可以看出L-41b的COP随冷凝温度升高时的降幅小于R410A,相互印证了在较高温区间L-41b与R410A具有更相似的运行性能,且随着温区的提高,L-41b表现出了一定的优越性。

图2 COP随蒸发温度的变化Fig.2 COP varies with evaporation temperature

图3 COP随冷凝温度变化Fig.3 COP varies with condensation temperature

图4 压缩机功耗随蒸发温度的变化Fig.4 The work of compressor varies with evaporation temperature

2.2 压缩机功耗的对比

图4和图5所示分别为R410A和L-41b在固定一侧温度,压缩机功耗随另一侧的变化规律。由图4可知,当冷凝侧温度固定约为38℃时,两者的压缩机功耗均随蒸发温度的增大而增加,这是因为当蒸发温度提高时,循环压比降低,工质流量减小,从而功率降低,但R410A的运行功率始终大于L-41b。由图5可知,R410A的运行功率始终大于L-41b,而且当冷凝温度从30℃左右升高到42℃时,R410A运行功率的增幅大于 L-41b,表明在相对高温区 L-41b替代R410A有一定的优越性。

图5 压缩机功耗随冷凝温度变化Fig.5 The work of compressor varies with condensation temperature

2.3 制热量的对比

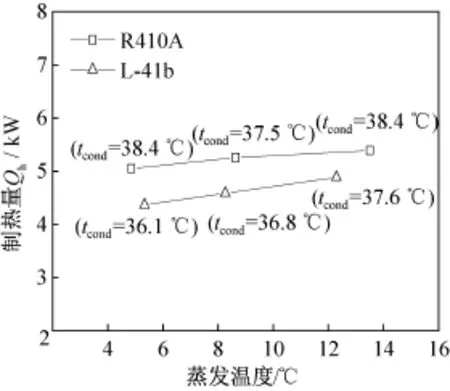

图6和图7所示分别为R410A和L-41b在固定一侧温度,制热量Qh随另一侧的变化规律。其中制热量是通过载热流体的进出口温度和载热流体回路循环流量计算得到。由两图可知,两者工质的制热量均随着蒸发温度或冷凝温度的升高而增大,总体上L-41b的制热量小于R410A,但同时由上可知其总体功耗也比R410A小,因此L-41b的COP与R410A总体偏差不大。

图6 制热量随蒸发温度的变化Fig.6 Heating capacity varies with evaporation temperature

2.4 压缩机排气温度的对比

图8和图9所示分别为R410A和L-41b在固定一侧温度,压缩机排气温度随另一侧的变化趋势。由两图可知,在整个工况温区内,L-41b的压缩机排气温度始终低于R410A。且当固定冷凝侧温度,两者工质排气温度随蒸发温度的变化时,L-41b的排气温度平均较R410A低9.6℃。压缩机排气温度较低有助于延长压缩机的使用寿命,从排气温度角度考虑L-41b替代R410A具有较优的性能。

图7 制热量随冷凝温度变化Fig.7 Heating capacity varies with condensation temperature

图8 压缩机排气温度随蒸发温度变化Fig.8 The discharge temperature of compressor varies with evaporation temperature

图9 压缩机排气温度随冷凝温度变化Fig.9 The discharge temperature of compressor varies with condensation temperature

2.5 循环压比的对比

表5和表6所示为R410A和L-41b在固定一侧温度,循环性能另一侧的变化趋势。由表6可知,当蒸发温度恒定为5℃时,两种工质的压缩机吸排气压比均随冷凝温度的提高而逐渐增大,当冷凝温度为30℃左右时,R410A的循环压比小于R1234ze(E),偏差为8.2%。随冷凝温度的提升,当冷凝温度提高到43℃左右时,R410A循环压力大于L-41b,偏差为3.1%。其压比的变化规律与变蒸发温度实验相似,即两工质在较高温度区运行时,L-41b的循环压力小于R410A,有利于系统运行性能的提高,表明在较高循环温区中L-41b替代R410A的可行性。

表5 变蒸发温度实验测试数据表Tab.5 The test results in the condition of variable evaporation temperature

表6 变冷凝温度实验测试数据表Tab.6 The test results in the condition of variable condensation temperature

3 结论

本文在人工环境室中设计和搭建了空气源热泵测试实验系统,对比研究了L-41b与R410A在热泵系统中的运行性能,为L-41b在热泵系统中的应用提供参考和必要的数据基础,得出如下结论:

1)在整个工况温区内,两者工质的制热量均随着蒸发温度或冷凝温度的升高而增大,总体上L-41b的制热量小于 R410A,但同时总体功耗也小于R410A,所以L-41b与R410A总体的COP偏差不大。而L-41b的压缩机排气温度始终低于R410A,从压缩机排气温度较低有助于延长压缩机使用寿命的角度,L-41b替代R410A具有较好的可行性。

2)两工质在较高温度区(工况Z3和N3)运行时,L-41b与R410A的COP已较为接近,且随着温区的提高,L-41b的COP表现出了一定的优越性。同时L-41b的循环压比小于R410A,有利于L-41b运行性能的提高,表明在相对高温区L-41b替代R410A具有较优的替代性能。

[1]李连生.制冷剂替代技术研究进展及发展趋势 [J].制冷学报,2011,32(6):53-58.(LI Liansheng.Research progress on alternative refrigerants and their development trend[J].Journal of Refrigeration,2011,32(6):54-57.)

[2]马一太,王伟.制冷剂的替代与延续技术[J].制冷学报,2010,31(5):11-17.(MA Yita,WANG Wei.Substitution and postponable technology of refrigerants[J].Journal of Refrigeration,2010,31(5):11-17.)

[3]Mclinden M O,Kazakov A F,Brown J S,et al.A thermo-dynamic analysis of refrigerants:Possibilities and tradeoffs for Low-GWP refrigerants[J].International Journal of Refrigeration,2013,38(1):80-92.

[4]Wang X D,Amrane K.AHRI low global warming potential alternative refrigerants evaluation program (low-GWP AREP)-summary of phase I testing results[J].Journal of the Taiwan Institute of Chemical Engineers,2014,45(3):996-1000.

[5]Calm M J.The next generation of refrigerants historical review consideration and outlook[J].International Journal of Refrigeration,2008,31(2):1123-1133.

[6]Atilla G D,Vedat O.Characteristics of some new generation refrigerants with low GWP[J].Energy Procedia,2015,75:1452-1457.

[7]Molés F,Navarro-Esbríet J,Peris B,et al.Theoretical energy performance evaluation of different single stage vapour compression refrigeration configurations using R1234yf and R1234ze(E)as working fluids[J].International Journal of Refrigeration,2014,44(1):141-150.

[8]Lai N A.Equations of state for HFO-1234ze(E)and their application in the study on refrigeration cycle[J].International Journal of Refrigeration,2014,43(7):194-202.

[9]杨申音,王勤,唐黎明,等.常规空调热泵系统的R32替代研究述评[J].制冷学报,2013,34(6):59-68.(YANG Shenyin,WANG Qin,TANG Liming,et al.Review of the application of R32 on air conditioners and heat pump systems[J].Journal of Refrigeration,2013,34(6):59-68.)

[10]田镇,谷波,王婷,等.HFC-32制冷剂饱和液体热力性能参数计算模型[J].制冷学报,2013,34(2):28-32.(TIAN Zhen,GU Bo,WANG Ting,et al.Calculation model of thermodynamic properties of saturated liquid for HFC-32 refrigerant[J].Journal of Refrigeration,2013,34(2):28-32.)

[11]Onaka Y,Miyara A,Tsubaki K,et al.Cycle evaluation of refrigerant mixtures of CO2/DME and HFC-32/HFO1234ze(E)[C]//The 23rd IIR International Congress of Refrigeration,Prague,Czech Republic,2011.

[12]Tanaka K,Higashil Y,Akasaka R.Thermodynamic property modeling of HFO-1234ze(E)+HFC-32 mixtures for evaluating cycle performance[C]//The 23rd IIR International Congress of Refrigeration.Prague,Czech Republic:Chalmers Publication Library,2011.

[13]Koyama S,Takata N,Fukuda S.Drop-in experiments on heat pump cycle using HFO-1234ze(E)and its mixtures with HFC-32[C]//International Refrigeration and Air Conditioning Conference.Purdue,USA:Purdue University e-Pubs,2010.

[14]张志巍,李敏霞,马一太.HFC32/HFO1234ze二元混合工质的热物性模型[J].工程热物理学报,2014,35(2):218-222.(ZHANG Zhiwei,LI Minxia,MA Yitai.Thermophysical properties model for binary mixtures working fluid of HFC32/HFO1234ze[J].Journal of Engineering Thermophysics,2014,35(2):218-222.)

[15]邱金友,张华,祁影霞,等.新型制冷剂R1234ze(E)及其混合工质研究进展[J].制冷学报,2015,36(3):9-16,60.(QIU Jinyou,ZHANG Hua,QI Yingxia,et al.A study on new refrigerants R1234ze(E)and its mixtures[J].Journal of Refrigeration,2015,36(3):9-16,60.)

[16]汪训昌.AHRI低GWP替代制冷剂评价计划(第一阶段)成果综述[J].暖通空调,2014(5):55-65.(WANG Xunchang.Result summary of AHRI Low-GWP AREP(the first phase)[J].Journal of HV&AC,2014(5):55-65.)

[17]Amrane K,Wang X D.Overview of AHRI low global warming potential alternative refrigerants evaluation program[C]//JRAIA International Symposium,2012.

Experimental Investigation of R1234ze(E)/R32 Replacing R410A in Heat Pump System

Wang Lulu1Zhang Hua1Qiu Jinyou2

(1.School of Energy and Power Engineering,University of Shanghai for Science and Technology,Shanghai,200093,China;2.College of Ecological Environment and Urban Construction,Fujian University of Technology,Fuzhou,350118,China)

Nowadays,more and more attention is being paid to the new low Global Warming Potential(GWP)refrigerant R1234ze(E).Mixing this refrigerant with R32 has been studied in recent years.We focused on contrasting the actual performance of the R1234ze(E)/R32 mixture(mass ratio:27%/73%,named L-41b,with a GWP value of 493)with R410A in a heat pump system.A test system of an air source heat pump was designed and built in an environmental chamber in order to compare the differences between L-41b and R410A under a wide range of working conditions.The compressor energy consumption(COP),heating capacity,refrigeration cycle pressure ratio,and discharge temperature of the compressor were discussed and compared with R410A under similar working conditions.The results shows that,in the variable-condition experiments,the COP deviation decreased from 8.6%to 2.8%when the evaporation temperature increased from 5℃ to 13℃ at a constant condensation temperature of 38℃.The COP deviation was minimized when the condensation temperature increased from 30℃ to 42℃ at a constant evaporation temperature of 5℃.The results further demonstrate that the L-41b mixture can be used to replace R410A in a heat pump system,particularly at relatively high cycle temperatures.

R1234ze(E)/R32;mixed refrigerants;air-source heat pump;operating condition

TB61;TQ051.5;TB64

:A

0253-4339(2017)03-0030-06

10.3969/j.issn.0253-4339.2017.03.030

张华,男,教授,博士生导师,上海理工大学制冷与低温工程研究所,(021)55275542,E-mail:zhanghua3000@163.com。研究方向:制冷低温过程与系统。

2016年9月29日

About the corresponding author

Zhang Hua,male,professor,Ph.D.supervisor,Institute of Refrigeration and Cryogenics,University of Shanghai for Science and Technology,+86 21-55275542,E-mail:zhanghua3000@163. com.Research fields:system process of refrigeration and cryogenics.