Analyses toward factors in fluencing sealing clearance of a metal rubber seal and derivation of a calculation formula

Yan Hui,Zhao Yalei,Liu Jianguo,Jiang Hongyuan

School of Mechatronics Engineering,Harbin Institute of Technology,Harbin 150001,China

1.Introduction

Seals play a crucial role in many aeronautics and astronautics devices,and their failure may result in catastrophic events,such as the Challenger disaster.1,2Because of the easy aging of rubber,the range in which it can work in some special situations such as high temperature and high pressure is limited.Arubber seal is hardly competent for the seal in special situations of high temperature and high pressure in the field of aeronautics and astronautics.3,4The application of a metal seal is limited because when it works in a high-temperature situation,its springback ability will decrease,and it needs additional resilience to improve performance.Metal rubber is made of metal wire by a special process and its interior forms a space grid structure that depends strongly on the plentiful micro springs which are arranged in a certain mode,so it has many similar characteristics between metal and normal rubber.Metal rubber shows many advantages such as resistance properties of high temperature,high pressure,high vacuum,ultralow temperature,and radiation,and if metal rubber is made of a special metal wire,it can work in corrosion environment.5Therefore,some rubber products that could not be competent in special working conditions of aeronautics and astronautics fields can be replaced by metal rubber ones.At present,metal rubber technology has been successfully applied to many fields such as vibration isolation,sound absorption,throttling,and filtering.Furthermore,in the engineering application of special conditions in aeronautics and astronautics fields,metal rubber shows many signi ficant advantages.6–9Thus,the application of metal rubber in seals is very helpful to solve the technological problem and improve the reliability of aeronautics and astronautics devices.

A metal rubber seal cladded with stainless steel is made up with metal rubber inside and stainless steel outside.When the seal is working,the stainless steel contacts with the surfaces which are needed to be sealed,so the seal clearance will be blocking.10The circular metal rubber core is an elastic part and it provides the contact stress between the seal and the sealing surface.The kind of seal that is studied in this paper is static seal.When the contact stress is less than the medium pressure,the metal rubber will deform under the action of the medium pressure and then the sealing clearance will increase.11Leakage rate is the most important index for estimating sealing effect,as the flow of fluid in the sealing clearance is complicated,and the changes of the sealing clearance have a heavy in fluence on the leakage rate.12,13As we can know from the calculation formula of metal rubber seal leakage rate,the sealing clearance has a third-power relationship with the leakage rate,so research about the change rule of the sealing clearance has a great signi ficance for the study about the leakage rate of a metal rubber seal.14

In this paper,various factors in fluencing the sealing clearance have been analyzed,according to the theory of elastic mechanics that when the medium pressure works on a metal rubber seal,elastic deformation will occur.The calculations formula about the sealing clearance has been derived,and the values of the sealing clearance and the leakage rate in certain situations have been calculated.Then we compare the results of a test with those of theoretic calculations.This study can provide reliable theoretic basis for the stainless steel cladding metal rubber seal application in aeronautics and astronautics devices.

2.Analyses toward factors in fluencing sealing clearance

2.1.In fluence of temperature on sealing clearance

The variation of temperature can lead to the metal rubber’s thermal deformation.The experiment of thermal expansion can only measure the deformation in the axial direction,but the seal’s circumferential size has been fixed when it is working in the slot,so the deformation can only happen in the radial direction.If we want to study the in fluence of temperature on the sealing clearance,we need to calculate the radial deformation value of the seal accurately.Based on the principle of volume invariably,we can convert the deformation in the axial direction to one in the radial direction.15–17Fig.1 shows the schematic of a metal rubber cylinder specimen’s volume expansion.

The relationship between the deformations in the axial direction and the radial direction can be expressed as follows:

whered1isthemetalrubberspecimen’sdiameterbeforethetemperature rise;lis the metal rubber specimen’s length before the temperaturerise;Δd1isthemetalrubberspecimen’sradialincrement and Δlis its axial increment after the temperature rise.

Therefore,the relationship between the metal rubber specimen’s coef ficients of linear expansion in the radial direction and the axial direction can be expressed as follows:

where αrand α are the coef ficients of linear expansion in the radial and axial directions,respectively.

The coef ficient of linear expansion can be measured through a thermal expansion experiment.The coef ficient of expansion in the axial direction can be measured by a DIL 402C thermal dilatometer produced by NETZSCH.The coefficient of expansion in the radial direction and the radial increment can be calculated.The results of calculation of radial deformation are shown in Table 1,wheretis the temperature of the experiment and Δdis the deformation that is converted to the radial direction.

The leakage experiments of a metal rubber seal were done in a heating cabinet and the experiment would begin when the temperature of the heating cabinet was stable.We assumed that each work temperature of the metal rubber seal was constant and didn’t consider the dynamic temperature variance in system modeling.

2.2.In fluence of elastic modulus on sealing clearance

When the working pressure of the seal increases,the medium which needs to be sealed will squeeze into the sealing clearance,at the same time the pressure of the medium will press the seal,and then the deformation of the seal leads to the sealing clearance increasing.As an elastomer,the metal rubber’s elastic modulus can in fluence the sealing clearance directly.The metal rubber’s elastic modulus include the friction stress modulus and the elasticity stress modulus,and because a static seal’s elasticity stress modulus is more important,the friction stress modulus is the main research object of dynamic performance of metal rubber.In this paper,when we study the metal rubber seal,we only think about the elastic stress modulus.Metal rubber is a kind of anisotropic materials of which the elastic modulus doesn’t remain constant and changes with the strain’s change.Because the sealing clearance’s variation is very small,we can use the elastic modulus under the pre-compression state instead of metal rubber’s elastic modulus when it’s working.The friction stress and elasticity stress can be calculated as follow:

where σ1is the elastic stress,σ2is the friction stress,σLis the load stress,σULis the unload stress,ε is the strain of the metal rubber seal,andEis the elastic modulus used in this paper.

Fig.1 Metal rubber cylinder specimen’s volume expansion deformation.

Table 1 Calculation of deformation in radial.

Fig.2 Specimen hysteresis loop.

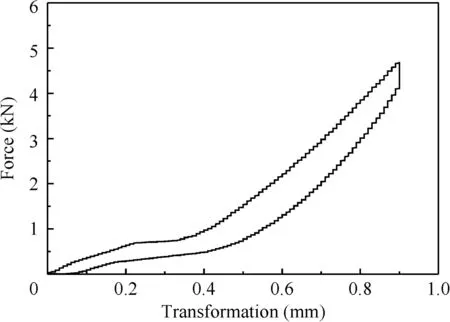

Metal rubber’s elastic modulus has a close relationship with the material,the diameter of metal wire which has been chosen,the knitting technology,and its relative density.Metal rubber’s elastic modulus can be calculated through the hysteresis loop.Through the experiment,we obtain specimen’s hysteresis loop as shown in Fig.2.The specimen’s bore is 135 mm,outer diameter is 141.4 mm,and relative density is 0.35.

3.Derivation of calculations formula of sealing clearance

Because the sealing problem of this paper is from a static seal and the leakage of the seal system will lead to a decrease of system pressure.We can know from the experiment that the volume of leakage is small so the pressure variation due to the leakage is small too,and we assume that the pressure in the sealing system is equal everywhere.Therefore,we don’t consider the in fluence of the dynamic pressure field on the sealing clearance.

When the medium’s pressure is higher than the contact stress between the seal and the seal face,the medium will be squeezed into the sealing clearance which leads to leakage.When leakage occurs,the pressure which works on the seal at the sealing face and leads to the seal’s deformation can be expressed as follows:1

whereP0is the pressure which leads to the seal’s deformation,Pis the pressure of the medium,σ is the total contact stress between the seal and the seal face,σ0is the contact stress produced by pre-lode,andKis the pressure transfer coef ficient.In the contact area between the seal and the seal face,the contact stress is approximate to parabolic distribution,and the maximum contact stress appears at the center line.While the pressure of the medium is higher than the maximum contact stress,the metal rubber seal will generate deformation.The sealing clearance is constituted by the deformation which is caused by the medium pressure and the deformation in the radial direction is caused by thermal expansion.The sealing clearance’s calculation formula is shown as follows:

where Δδ is the deformation caused by the medium pressure and Δdis the value in Table 1.

The relationship between pressure and deformation in the radial direction of cylindrical metal rubber can be expressed as follows:18

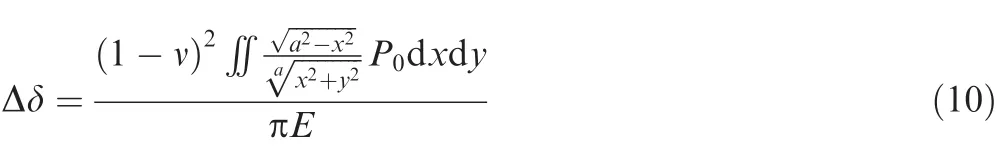

where Δδ is the deformation in the radial direction of cylindrical metal rubber,Eis the elastic modulus of the metal rubber seal,2ais the contact width between the seal and the seal face,and ν is the metal rubber’s Poisson’s ratio.

The metal rubber seal is working in a slot,so its circumferential size has been fixed.Because of this,Poisson’s ratio of the metal rubber seal can be ignored,so Eq.(10)can be transformed to the following equation:

whereE1is the elastic modulus when the metal rubber seal’s deformation is 0.75 mm,and λ1is the shape coef ficient of the metal rubber seal in the pre-compression state.

From the above,thinking about the in fluence of pressure on thermal deformation introduces a coef ficient λ2,so we obtain the calculation formula of seal clearance as follows:

Fig.3 Integral and stress work area.

In the formula,the integral area of double integral can be simpli fied as a square area whose side length is 2a.This area is where the contact stress works between the seal and the seal face,as shown in Fig.3.In Fig.3,we consider the distribution of pressure in the contact area approximately a circle,and when point M moves to center of the circle,we thought its pressure is maximum.

4.Example of sealing clearance calculation

In this paper,taking the example of the metal rubber seal covered with stainless steel whose relative density is 0.35,we calculate its sealing clearance and leakage rate at different pressure and temperature conditions.The calculation formula is expressed as follows14:

whereqis the leakage rate(the fluid flow passing the sealing clearance per unit time),ΔPis the pressure difference between both sides of the sealing surface,ϑ is the temperature coef ficient viscosity of the medium,θ0is the temperature of the medium,his the value of the sealing clearance,μ0is the dynamic viscosity of the medium under room temperature,andR0andRiare the outer and inner diameters of the area where the seal contacts the sealing surface.

A metal rubber seal special test-bed used in the leak testing is designed and developed by our research group,and it can measure the leakage through a measuring cylinder which has been equipped with a magnetostrictive displacement sensor.

4.1.Calculation under different pressure conditions

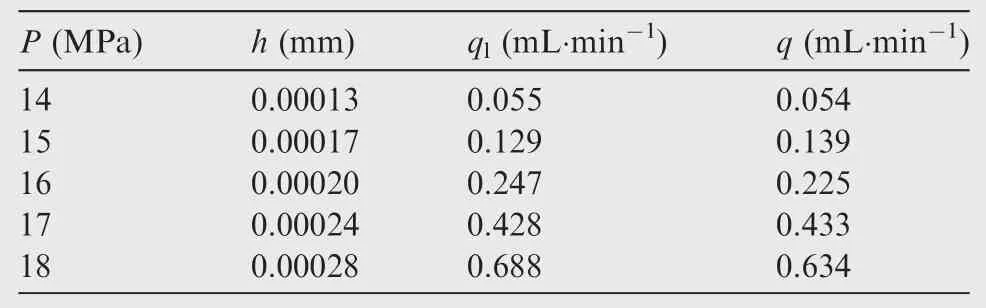

The bore of the metal rubber seal is 135 mm,the outer diameter is 141.1 mm,the pre-deformation is 0.75 mm,the compressibility is 23.4%,the contact width can be calculated,and the result is 2a=2.8 mm,although the calculations that we can obtain areR0=70.5 mm andRi=67.7 mm.Calculated by the hysteresis loop as shown in Fig.3,we can get the metal rubber seal’s elastic stress as σ1=2.394 MPa and the friction stress as σ2=0.374 MPa when its deformation is 0.75 mm,and then we can calculate the elastic modulusE1=10.2 MPa. We have already known that σ1= σ2=2.394 MPa.In the formula of the sealing clearance,the value of double integral is 0.00963,λ1=0.3,and λ2=8.67/P.We chose TOTAL HYDRANSAFE HFDU 46as the medium,and its dynamic viscosity is μ0=0.431 Pa·s.The experiment of metal rubber seal leakage has been done in normal temperature,and the results we get are the sealing clearance and leakage rate at different pressure conditions,as shown in Table 2.In Table 2,qlis the value of theoretical calculation andqis the value of test.

Table 2 Leakage rate at different pressure conditions.

Table 3 The leakage on different temperature conditions.

4.2.Calculation under different temperature conditions

We only change the pre-deformation to δ=0.5 mm,then the contact width to 2a=2.1 mm,and the size of contact area has been changed toR0=70.15 mm andRi=68.05 mm.While the pre-deformation is 0.5 mm,by the hysteresis loop,we can get the elastic stress as σ1=1.245 MPa and the friction stress as σ2=0.422 MPa.In addition,the calculation result of the elastic modulus isE1=7.968 MPa.We also choose the TOTAL HYDRANSAFE HFDU 46 as the medium,while in the experiment of metal rubber seal leakage,we keep the pressure asP=14 MPa and then change the temperature.The results of calculation and experiment are shown in Table 3 as follows.In Table 3,qltis the value of theoretical calculation andqtis the value of test.We compare the results of calculation and experiment finding that the leakage rate of theoretical calculation coincides with the experiment result roughly.The inaccuracy between testing and theoretical calculation was caused by the inaccuracy of the sensor which was inevitable.During the process of formula deduction,we proposed some hypothesis and for simplifying the formula,we ignored some factors that were not important.That’s why there are errors between the results of experiment and theoretical calculation.It is proven that the formula of sealing clearance calculation which has been deduced in this paper can be used in the leakage rate analysis of metal rubber sealing systems.

5.Conclusions

In this paper,the in fluence factors that result in the change of the sealing clearance at the work process of a metal rubber seal cladded with stainless steel have been analyzed.A thermal expansion experiment has been done,through which we know that the radial expansion of metal rubber increases with the increase of temperature and then leads to a decrease of the sealing clearance;the elastic modulus of metal rubber is nonlinear,and the larger elastic modulus of metal rubber,the more dif ficulty for the increase of the sealing clearance.In this paper,the calculation formula of the sealing clearance has been derived,and we calculate the sealing clearance and leakage rate of the metal rubber seal with that formula.We compare the results of calculation and experiment and have found that the leakage rate of theoretical calculation coincides with the experiment result roughly.The sealing clearance is a very important parameter for the calculation of leakage,and the calculation formula that we derived can provide some theoretical basis for the design of metal rubber seals which can work in special environments.

Acknowledgements

The authors thank the anonymous reviewers for their critical and constructive review of the manuscript.This study was supported by the Programme of Introducing Talents of Discipline to Universities(No.B07018)and the Air Force Armament Department Pre-Research Foundation.

1.Cai RL.Fluid sealing technology-principle and engineering application.1st ed.Beijing:Chemical Industry Press;2013.p.65–80 Chinese.

2.Gillen KT,Bernstein R,Wilson MH.Predicting and con firming the lifetime of O-rings.Polym Degrad Stab2005;87(2):257–70.

3.Chen GD,Wang LN,Yu QP,Su H.Dynamic analysis of C/C composite finger seal.Chin J Aeronaut2014;27(3):745–58.

4.Liu WK,He GQ.Storage life of silicone rubber sealing ring used in solid rocket motor.Chin J Aeronaut2014;27(6):1469–76.

5.Ma YH,Zhu HX,Zhang DY,Liu BL,Hong J.Experiment investigation on shape memory alloy metal rubber.Sci Chin(Technol Sci)2013;56(8):1949–55.

6.Nikas GK,Sayles RS.Nonlinear elasticity of rectangular elastomeric seals and its effect on elastohydrodynamic numerical analysis.Tribol Int2004;37(8):651–60.

7.Jiang HY,Xia YH,Ao HR,Yan H.Research on the application of special metal rubber components used in aero-engine.Gas Turbine Exp Res2003;16(3):1–4 Chinese.

8.Yan H,Zhang WJ,Jiang HY,Chen L.Energy dissipation of a ring-like metal rubber isolator.Chin Phys B2014;23(4):198–201.

9.Jiang HY,Dong CF,Ao HR,Xia YH,Ulanov AM.Research on dynamic and static characteristics of metal rubber isolator used in aero-engine.ActaAeronautAstronautSin2004;25(2):140–2 Chinese.

10.Yan H,Xia YH,Ao HR,Jiang HY.Research on the manufacturing technology of metal rubber sealing ring with large diameter and small section.Lubr Eng2003;4:31–6 Chinese.

11.Persson BNJ,Yang C.Theory of the leak-rate of seals.J Phys Condens Matter2008;20(31):1959–64.

12.Persson BNJ,Albohr O,Creton C,Peveri V.Contact area between a viscoelastic solid and a hard,randomly rough,substrate.J Chem Phys2004;120(18):8779–93.

13.Yang C,Persson BNJ.Contact mechanics:contact area and interfacial separation from small contact to full contact.J Phys Condens Matter2008;20(21):4656–8.

14.Zhang WJ.Leakage rate analysis and experimental research on metal rubber seal[dissertation].Harbin:Harbin Institute of Technology;2014[Chinese].

15.Li DC,Hong JP,Yang QX,Wang XT.Motion state analysis and seal ability study on the magnetic fluid Seal of reciprocating shaft.Chin J Aeronaut2002;15(2):115–20.

16.Yan H,Jiang HY,Zhao HY,Liu WJ,Ulanov AM.Temperature characteristics of metal rubber material.Rare Met Mater Eng2011;40(12):2092–5 Chinese..

17.Zhu B,Ma YH,Zhang DY,Hong J.A constitutive model of metal rubber based on hysteresis property.Acta Phys Sin2012;61(7):474–81 Chinese.

18.Wang L.Metal rubber sealing system model establishment and simulation analysis[dissertation].Harbin:Harbin Institute of Technology;2010[Chinese].

CHINESE JOURNAL OF AERONAUTICS2016年1期

CHINESE JOURNAL OF AERONAUTICS2016年1期

- CHINESE JOURNAL OF AERONAUTICS的其它文章

- Plastic wrinkling prediction in thin-walled part forming process:A review

- Progress of continuously rotating detonation engines

- Microstructure control techniques in primary hot working of titanium alloy bars:A review

- A hybrid original approach for prediction of the aerodynamic coefficients of an ATR-42 scaled wing model

- Dynamic modeling and analysis of vortex filament motion using a novel curve- fitting method

- Boundary-layer transition prediction using a simpli fied correlation-based model