Degradation Analysis of Mid-power GaN-based LEDs with Different Package Materials

FU Jia-iia, CAO Hai-cheng, ZHAO Li-xia, WANG Jun-xi, LI Jin-min

(Semiconductor Lighting Research & Development Center, Institute of Semiconductors, Chinese Academy of Sciences, Beijing 100083, China)

*Corresponding Authors, E-mail: lxzhao@semi.ac.cn; jmli@semi.ac.cn

Degradation Analysis of Mid-power GaN-based LEDs with Different Package Materials

FU Jia-iia, CAO Hai-cheng, ZHAO Li-xia*, WANG Jun-xi, LI Jin-min*

(SemiconductorLightingResearch&DevelopmentCenter,InstituteofSemiconductors,ChineseAcademyofSciences,Beijing100083,China)

*CorrespondingAuthors,E-mail:lxzhao@semi.ac.cn;jmli@semi.ac.cn

Highly stress tests were carried out for mid-power GaN-based LEDs encapsulated with silicone and green/red mixed phosphors. Except for the optical and electrical measurement, the reflection spectroscopy and time of flight-secondary ion mass spectrometry (TOF-SIMS) were also used to investigate the failure mechanism. Our results show that the high temperature and humidity play an important role in determining the failure mode for mid-power blue and white LEDs. The decrease of the blue emission is related to the degradation of the transparent silicone and the reflectivity by the oxidation and the contamination of sulfide and chlorine. While the dissolution of the phosphors in white LEDs will lead to the decrease of the conversion efficiency and deteriorate the photometric and colorimetric properties of mid-power white LEDs.

mid-power LEDs; package materials; degradation behaviors

1 Introduction

Because of the energy-saving, high efficiency and environmental-protecting capabilities, GaN-based white light-emitting-diodes (LEDs) have developed significantly and are fast replacing the traditional lighting in many kinds of applications such as display and general lighting. Except for the high power white LEDs, a relatively new category of LED light source, mid-power white-light LEDs, has been widely used in the indoor illumination with the requirement for the cost reduction and a simpler design for the distributed light systems[1-3]. This type of mid-power LEDs is typically driven within a range of 0.2 to 1 W. Different from the high-power LEDs, mid-power LEDs use plastic package and copper-based lead frames instead of the traditional ceramic substrate. But the reliability is still one important issue to prevent the development of mid-power white LEDs. During the operation, both the decay of optical power and the color shift will influence the reliability. Except for the degradation of the chip material, the package materials, including silicone and phosphor, play a key role in the reliability of the white LEDs. The reasons for the package-related degradation of high power GaN-based LEDs can be related to carbonization of encapsulation[4-6], encapsulation yellowing[7-10], and phosphor thermal quenching[11-13]. But for mid-power LEDs, there is limited studies on its reliability, especially very few reports are focused on diffusion phenomenon in the encapsulation.

In this study, highly stress tests were carried out on the mid-power blue and white LEDs under different temperatures and relatively humidities(RH). The mid-power white LEDs were encapsulated with green and red mixed phosphors to improve the color quality[14-16]. Except for the electroluminescence (EL) spectra, the reflection spectroscopy and Time of Flight-Secondary Ion Mass Spectrometry (TOF-SIMS) were also used to analyze the degradation behaviors and failure mechanisms. Our findings will be helpful to understand the reasons for the degradation of mid-power white LEDs.

2 Experiments

GaN-based mid-power LEDs coated with and without green/red mixed phosphors (G/R) were fabricated using the LED chip purchased at the same time with a good reproducibility. The referential chemical components of green and red phosphor are Sr0.9Ca0.1AlSiN3∶Eu2+and SrSi2O2N2∶Eu2+, respectively. For the LED structure, the 0.8 mm×0.27 mm blue LEDs chip was mounted on the silver lead-frame, which was used to improve the reflectivity and light extraction efficiency. After gold wire bonding, green/red/silicone mixture was coated on the lead-frame and chip to achieve white emission. Then, silicone encapsulation was dispensed into the package housing. Finally, the packaged white LEDs were assembled onto the aluminum based metal core printed circuit boards (MCPCB) using reflow soldering. Fig.1 shows the cross-section schematic diagram of these two kinds of white LEDs. The blue LEDs were packaged with similar process flow to that of G/R LEDs but without green/red phosphor. The blue and white LED are named as sample A and sample B, respectively.

Fig.1 Schematic diagram of two kinds of mid-power GaN-based LEDs. The under one contain green/red mixed phosphors, while the upper one not.

The stress tests were carried out on these mid-power LEDs with different aging temperature and relative humidity(RH), including 25 ℃(21% RH), 65 ℃(10% RH) and 85 ℃, respectively. 10 pieces were selected for each stress condition, and totally 60 pieces of LEDs were prepared. 20 mA rated current was used for all the mid-power LEDs during the aging test. The electroluminescence (EL) spectra of each LED were measured using the integrating sphere at certain time interval under 20 mA and 25 ℃ After the aging tests, the reflectivity spectroscopy (UV-2600) was used to evaluate the package materials. X-ray photoelectron spectroscopy (XPS) and time of flight secondary ion mass spectrometry (TOF-SIMS) were also measured to characterize the chemical degradation. XPS was performed on the Thermo Scientific ESCALab 250Xi using 200 W monochromated Al Kα radiation. TOF-SIMS was performed on TOF SIMS 5 by using the positive secondary ion polarity mode and a pulsed 30 keV Bi3+primary ion beam for ion detection.

3 Results and Discussion

3.1 Degradation Behaviors

Fig.2 shows the normalized average light outputs of the blue and white LEDs as a function of the aging time at different stress conditions. For the blue LEDs, there was a increase of the light outputs at the initial stage at 25 ℃ and 65 ℃. The reason is due to the activation of the Mg dopant in p-GaN[17]. But at 85 ℃, the light output decreased significantly. The decrease was up to 60% in 1 000 h. This degradation behavior indicates that the LEDs degraded at the high temperature 85 ℃ with different failure mechanisms compared with the blue LEDs aged at 25 ℃ and 65 ℃.While for white LEDs, because of the relative high humidity, the light output stressed at 25 ℃ decreased even faster than those aged at 65 ℃. In addition, comparing blue and white LEDs, at 65 ℃ and 85 ℃ with less humidity, the blue LEDs degraded even faster than those white LEDs. The reason may be due to the prolonged exposure to much stronger short wavelength radiation (blue light) in the high temperature than the white LEDs[5,10].

Fig.2 Normalized average optical power measured at 20 mA and room temperature of blue LEDs (a) and white LEDs (b) with green and red mixed phosphors

EL spectra of the typical blue and white LEDs stressed at 25, 65, 85 ℃ were also measured at different aging time, as shown in Fig.3. For blue LEDs, the decay of the peak intensity became obvious with the stress temperature increasing, especially at 85 ℃. In addition, no peak shift was observed for blue LEDs stressed at 25 ℃ and 65 ℃, but at 85 ℃, there was a red shift. This indicates that the failure mechanism of the blue LED aged at 85 ℃ may be different from those at 25 ℃ and 65 ℃. While for white LEDs, at 65 ℃ and 85 ℃, the decrease of the blue emission was similar to that of the blue LEDs, but at 25 ℃, the decay is much stronger than the corresponding blue LEDs. Furthermore, the light emission of the phosphors was also different. The degradation of the light emission of the phosphors at 25 ℃ was larger than that at 65 ℃ after ~2 000 h, especially for the green phosphor. Although the stress temperature 25 ℃ was lower, the relatively humidity was 21%, which was larger than that at 65 ℃ and 85 ℃ (10%). This indicates that humidity will also strongly influence the degradation of LEDs, especially for white LEDs. The high humidity can accelerate the decay rate of the phosphors, especially for the green phosphor.

Fig.4(b) shows the relative correlated color temperature (CCT) variation during the stress test. Delta CCT is the difference of CCT subtracted from the value before aging test. For white LEDs aged at 25 ℃, there is a transition point for the color shift (as the inset graph shown) after 400 h, a blue shift initially followed by a prolonged red shift. This is related to the different degradation of the LED blue as well as the phosphor emissions, as the spectra shown in Fig.3. While with the temperature increased to 65 ℃, the delta CCT decreases gradually because of a faster decay of green phosphor compared with red phosphor, which will increase the relative contribution of red light in the white emission, as shown above. This result suggests that the green phosphor is much more sensitive to moisture than red phosphor. However, for green/red mixed phosphor white LEDs aged at 85 ℃ with 10% RH, the delta CCT increases with the aging time, and the reason is due to the degradation of both green and red phosphors.

Fig.4 (a) Average color coordinate shift with the increase of the aging time at different stress conditions. (b) Delta CCT (K) as a function of the aging time at different temperature stress.

3.2 Failure Analysis

To further understand the different failure mechanism of blue and white LEDs, failure analysis were further investigated. Fig.5 shows the coefficient of reflection as a function of wavelength and EL spectra for the blue LEDs aged at 85 ℃ before and after stress test. The inset is the optical images before and after degradation. It is shown that the interface color between silver lead-frame and encapsulation became black and correspondingly the coefficient of reflection decreases, especially at 452 nm, which is more pronounced at the blue emission range, roughly 7.3% at 452 nm. But compared with the initial value, the peak intensity of the EL spectrum after degradation decreased by 64.5%. This demonstrates that the decrease of the optical power is not mainly due to the change of the reflection.

Fig.5 Coefficient of reflection on the surfaceversuswavelength in the blue LEDs and EL spectra before and after stress test at 85 ℃. The inset is the optical image of packaged LED before and after stress test at 85 ℃.

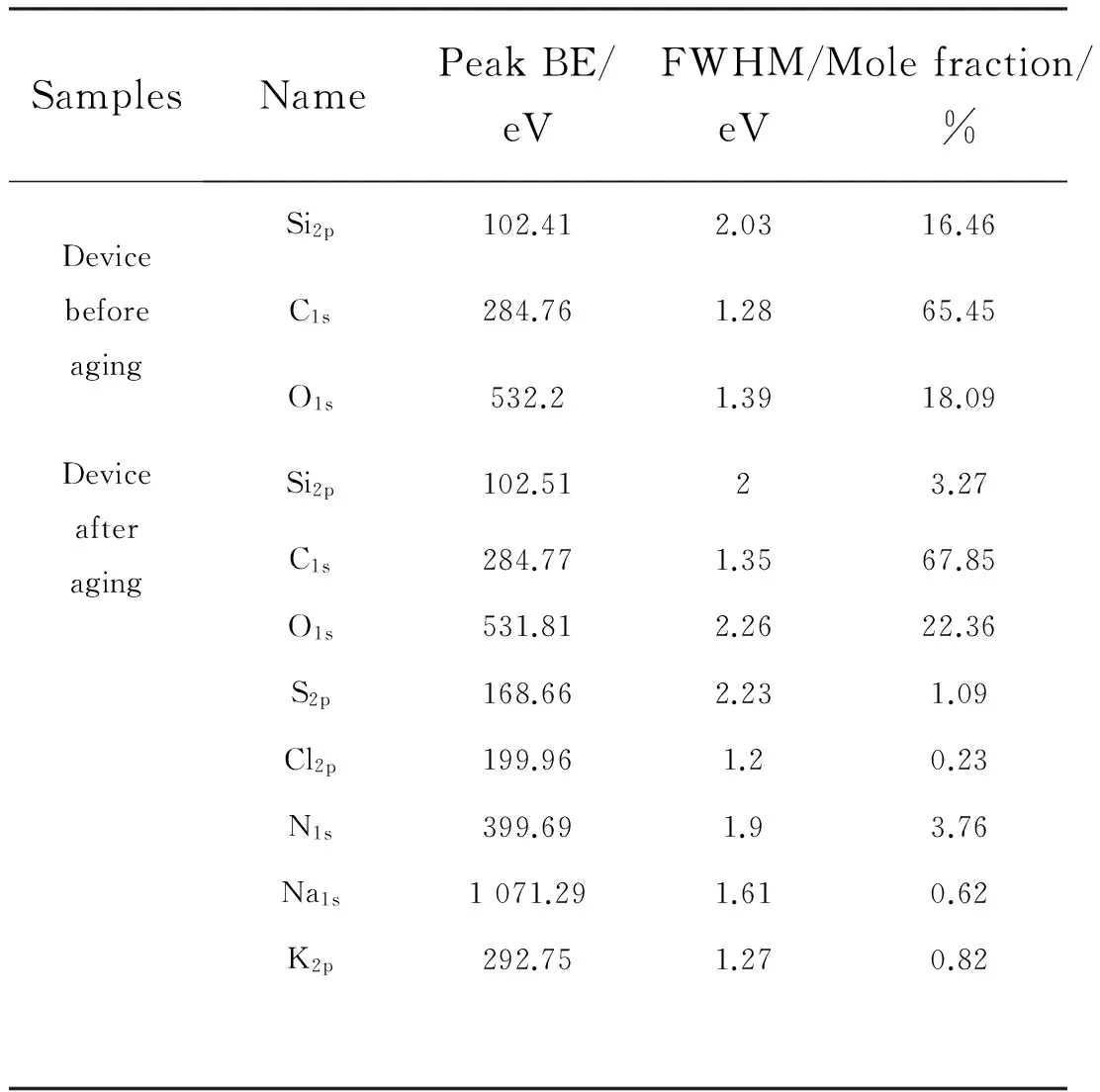

Tab.1 Silicone encapsulation XPS results for blue LEDs before and after stress test at 85 ℃

SamplesNamePeakBE/eVFWHM/eVMolefraction/%DevicebeforeagingSi2p102.412.0316.46C1s284.761.2865.45O1s532.21.3918.09DeviceafteragingSi2p102.5123.27C1s284.771.3567.85O1s531.812.2622.36S2p168.662.231.09Cl2p199.961.20.23N1s399.691.93.76Na1s1071.291.610.62K2p292.751.270.82

Furthermore, a uniform browning appeared in the transparent encapsulation, in order to understand the chemical information difference after the degradation, X-ray photoelectron spectroscopy(XPS) was measured, as shown in Tab.1. The element S and Cl could be observed and the amount of oxygen signal increases for the LEDs aged at 85 ℃, which demonstrates that the silicone surface was corroded by the contamination of sulfide and activated oxygen. Therefore, the above results suggest that the decrease of the reflectivity and degradation of the transparent silicone may lead to the decrease of the blue emission.

However, for the white LEDs aged at 85 ℃, optical images (Inset of Fig.6) show that the silicone encapsulation with phosphor becomes dark, and a browning color around the chip appears compared with the device before the stress test. The reflection coefficient of encapsulation surface shows a uniform decay 8.1% at the wavelength ranged from 380 to 780 nm (Fig.6). Combining with the above analysis of color quality, the package-related degradation in the white LEDs with green/red mixed phosphors could be mainly related to the dissolution of green and red phosphor powders in the area around the chip[11].

Fig.6 Coefficient of reflection as a function of wavelength in the white LED. The inset is camera image of LED before and after aging test at 85 ℃.

The structure and chemical information of silicone encapsulation were also investigated using the flight secondary ion mass spectrometry (TOF-SIMS) on the region just above the chip. Fig.7 shows the spectra in the positive polarity mode. Comparing the result before and after the stress test, a high counts rates of [Ca]+, [CaOH]+and [CaNOH]+, which are red highlighted as shown in Fig.7(b), were detected compared with the sample before the stress test. Similarly, the spectra of [Sr]+, [Ca2OH]+and [SrOH]+were also detected with a higher counts. However, there is no [Ca]+and [Sr]+in the intrinsic silicone encapsulation. Therefore, the [Ca]+and [Sr]+were likely to be diffused from the G/R phosphors into silicone encapsulation, and the [CaOH]+, [CaNOH]+, [Ca2OH]+and [SrOH]+were probably formed as a result of the reaction between Sr2+and Ca2+with OH group and H2O from the silicone encapsulation and surrounding atmosphere. Because of the diffusion of [Ca]+and [Sr]+, a mount of micro-defect may appear in the green/red mixed phosphors[18], and the increasing defects will decrease the conversion efficiency of blue light and deteriorate the photometric and colorimetric coordinates of the mid-power white LEDs.Fig.7 Positive TOF-SIMS spectra of silicone encapsulation surface before (a) and after (b) aging test

4 Conclusion

In this work, 60 pieces of mid-power white LEDs and corresponding blue LEDs were highly stressed at ambient temperature 25 ℃ (21% RH), 65 ℃ (10% RH) and 85 ℃ (10% RH). For white LEDs with green/red phosphors, the degradation was faster at 25 ℃ with higher humidity than that at 65 ℃, indicating that LEDs with green/red phosphors are more sensitive to the humidity than blue LEDs, especially for green phosphors. Furthermore, a failure analysis was carried out for the blue LEDs and white LEDs with green/red phosphors systematically. For the blue LEDs, the decrease of the reflectivity and degradation of the transparent silicone are related to the decrease of the blue emission, and the uniform browning in the silicone degraded optical output was due to the generation of S, Cl element and the increase of O elements. By using TOF-SIMS, the diffusion of [Ca]+and [Sr]+and the formation of corresponding hydroxide in the white LEDs with green/red phosphors were detected to be one of the underlying origins, which reduce the light output and the conversion efficiency of phosphors.

[2] BUFFOLO M, DE SANTI C, MENEGHINI M,etal.. Long-term degradation mechanisms of mid-power LEDs for lighting applications [J].Microelectron.Reliab., 2015, 55(9-10):1754-1758.

[3] BING Q C, CORNELISSEN H J, HU N C. Dual phosphors-converted white LEDs modeling by using near-field chromatic luminance data [J].SPIE, 2014, 9003:900304-1-10.

[4] TREVISANELLO L, MENEGHINI M, MURA G,etal.. Accelerated life test of high brightness light emitting diodes [J].IEEETrans.Dev.Mater.Reliab., 2008, 8(2):304-311.

[5] MENEGHESSO G, LEVADA S, ZANONI E,etal.. Reliability of visible GaN LEDs in plastic package [J].Microelectron.Reliab., 2003, 43(9-11):1737-1742.

[6] MCCLUSKEY P, MENSAH K, O’CONNOR C,etal.. Reliable use of commercial technology in high temperature environments [J].Microelectron.Reliab., 2000, 40(8-10):1671-1678.

[7] FU J J, ZHAO L X, CAO H C,etal.. Degradation behavior of GaN-based LEDs encapsulated with different phosphors [C].ProceedingsofThe2014 11thChinaInternationalForumonSolidStateLighting,Guangzhou,China, 2014:111-113.

[8] NARENDRAN N, GU Y, FREYSSINIER J P,etal.. Solid-state lighting: failure analysis of white LEDs [J].J.Cryst.Growth, 2004, 268(3-4):449-456.

[9] TORIKAI A, HASEGAWA H. Accelerated photodegradation of poly(vinyl chloride) [J].Polym.Degrad.Stab., 1999, 63(3):441-445.

[10] DOWN J L. The yellowing of epoxy resin adhesives: report on high-intensity light aging [J].Stud.Conserv., 1986, 31(4):159-170.

[11] XIE R J, HIROSAKI N. Silicon-based oxynitride and nitride phosphors for white LEDs—a review [J].Sci.Technol.Adv.Mater., 2007, 8(7-8):588-600.

[12] XIE R J, HIROSAKI N, KIMURA N,etal.. 2-phosphor-converted white light-emitting diodes using oxynitride/nitride phosphors [J].Appl.Phys.Lett., 2007, 90(19):191101-1-3.

[13] ARIK M, SETLUR A, WEAVER S,etal.. Chip to system levels thermal needs and alternative thermal technologies for high brightness LEDS [J].J.Electron.Packag., 2007, 129(3):328-338.

[14] YANG C C, LIN C M, CHEN Y J,etal.. Highly stable three-band white light from an InGaN-based blue light-emitting diode chip precoated with (oxy)nitride green/red phosphors [J].Appl.Phys.Lett., 2007, 90(12):123503.

[15] WU H, ZHANG X M, GUO G F,etal.. Three-band white light from InGaN-based blue LED chip precoated with green/red phosphors [J].IEEEPhoton.Technol.Lett., 2005, 17(6):1160-1162.

[16] SHEU J K, CHANG S J, KUO C H,etal.. White-light emission from near UV InGaN-GaN LED chip precoated with blue/green/red phosphors [J].IEEEPhoton.Technol.Lett., 2003, 15(1):18-20.

[17] LIU L L, LING M J, YANG J F,etal.. Efficiency degradation behaviors of current/thermal co-stressed GaN-based blue light emitting diodes with vertical-structure [J].J.Appl.Phys., 2012, 111(9):093110-1-9.

[18] SHAAT S K K, SWART H C, NTWAEABORWA O M. Investigation of luminescent properties of Ca0.3Sr0.7Al2O4∶ Tb3+, Eu3+excited using different excitation sources [J].J.ElectronSpectrosc.Relat.Phenom., 2014, 197:72-79.

符佳佳(1989-),男,浙江衢州人,博士研究生,2011年于兰州大学获得学士学位,主要从事GaN基LEDs可靠性及失效机理的研究。

E-mail: fujiajia@semi.ac.cn赵丽霞(1976-),女,山西太原人,博士,研究员,博士生导师,2005年于英国诺丁汉大学获得博士学位,主要从事GaN基微纳电子器件的研究。

E-mail: lxzhao@semi.ac.cn李晋闽(1957-),男,陕西西安人,博士,研究员,博士生导师,1991年于中科院西安光学精密机械研究所获得博士学位,主要从事第三代半导体材料及器件的研究。

E-mail: jmli@semi.ac.cn

2016-04-28;

2016-05-22

国家自然科学基金(11574306);中国国际科技合作计划(2014DFG62280);“863”国家高技术研究发展计划(2015AA03A101)资助项目

不同封装材料的中功率GaN基LED器件老化分析

符佳佳, 曹海城, 赵丽霞*, 王军喜, 李晋闽*

(中国科学院半导体研究所 半导体照明研发中心, 北京 100083)

针对中功率蓝光及相应的白光LED器件进行加速老化实验,并具体分析了器件中硅胶和绿红混合荧光粉等封装材料对老化行为的影响和失效机理。在测试器件的光电老化行为之后,利用反射光谱和飞行时间二次离子质谱对失效器件进行了结构分析。结果表明,温度和湿度对蓝光和白光器件老化行为具有不同的影响。对于中功率蓝光LED而言,其光衰的主要原因是由于S、Cl等元素的引入及氧化等因素引起的黄化导致了透明硅胶反射率的下降。而对于绿红混合荧光粉组成的中功率白光LED来说,其光衰和色漂问题主要归结于在高温特别是高湿环境下工作,器件中荧光粉和硅胶等封装材料发生了一些化学反应,使荧光粉发生分解,并引起了荧光转换效率的下降。

中功率LED; 封装材料; 老化行为

TN383+.1 Document code: A

10.3788/fgxb20163710.1230