聚合物驱后注气稳定重力复合驱数值模拟

高明王强马德胜刘朝霞刘皖露

1.提高石油采收率国家重点实验室;2.中国石油勘探开发研究院

聚合物驱后注气稳定重力复合驱数值模拟

高明1,2王强1,2马德胜1,2刘朝霞1,2刘皖露1,2

1.提高石油采收率国家重点实验室;2.中国石油勘探开发研究院

引用格式:高明,王强,马德胜,刘朝霞,刘皖露. 聚合物驱后注气稳定重力复合驱数值模拟[J].石油钻采工艺,2016,38(4):494-498.

聚合物驱后剩余油分布高度零散、顶部油层剩余油难以动用,而聚驱后的主导技术尚无明确方法。在原油受力分析的基础上,提出了油藏顶部注气、底部三元复合驱的思路。针对大庆聚合物驱后区块,进行了不同驱替方式的预测对比研究。结果表明,注气稳定重力复合驱效果最好,提高采收率幅度达到了13.53%。对比不同驱替方式的顶部油层剩余油饱和度,注气稳定重力复合驱能够将顶部低渗透油层有效动用,剩余油大幅减少。分析不同时间点的纵向剩余油饱和度分布,顶部注气后利用纵向压差驱替剩余油向下运移,底部实施三元复合驱利用平面压差驱替剩余油,实现了立体驱替。注气稳定重力复合驱技术为聚驱后提高采收率技术的发展提供了新思路。

聚合物驱后;注气稳定重力复合驱;数值模拟;剩余油分布

大庆油田实施聚合物驱的区块陆续进入后续水驱阶段,聚合物驱结束后的采出程度为50~60%,仍有近一半的地质储量残留地下[1-5]。近年来,针对聚驱后如何进一步提高采收率,在室内和现场开展了微生物采油、泡沫复合驱油、热力采油、聚表剂驱油和挖掘分流线剩余油等方法的探索性研究,取得了初步性认识和成果,但聚驱后主导技术尚不明确[6-11]。

从机理上看,聚合物驱后非均质变强、后续驱油剂面临“二次波及”的问题,相对聚驱前难度更大。聚合物吸附于岩石表面、滞留于小孔喉,后续驱油剂接触残余油条件变差。针对这一难题,提出了聚合物驱后注气稳定重力复合驱技术,并利用数值模拟技术进行了分析计算,研究结果能够为聚合物驱后进一步提高采收率技术的应用提供一定的理论依据。

1 聚合物驱后油藏剩余油分布特点Distribution features of residual oil in reservoirs after polymer flooding

剩余油分布规律是聚驱后进一步提高采收率技术研究的基础,搞清聚合物驱后剩余油分布特征对于研究聚驱后进一步提高采收率方法和途径至关重要。利用聚驱前、聚驱后密闭取心井多个岩样块资料,统计分析了聚驱前后剩余油变化特征及剩余储量潜力。聚驱后纵向上弱未水洗段与中强水洗段交互分布,油层顶部剩余油富集,纵向剩余油可分为4种类型:油层顶部型、层内夹层型、层内韵律型、薄差油层型。聚驱后水洗厚度比例接近90%,油层动用状况得到明显改善,聚驱前强水洗厚度占比18.6%,聚驱后强水洗厚度高达41.8%,比水驱增加23.2%,27.6%的厚度处于水驱残余油状态。

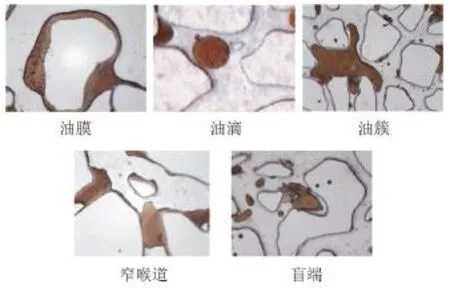

平面上剩余油分布更加零散,剩余油主要分布在河道边部和砂体变差部位。聚驱前含油饱和度主要分布为45%~65%,聚驱后含油饱和度主要分布为35%~45%,聚驱前平均含油饱和度52.8%,聚驱后平均剩余油饱和度40.9%,较聚驱前降低了11.9个百分点。聚驱后仍有一定的物质基础和潜力,还有进一步挖潜的余地。如图1所示,通过室内微观实验分析,聚驱后油藏微观剩余油分布以油膜、油滴、窄喉道和盲端等非连续高度零散形态赋存[12-13]。

图1 聚驱后微观剩余油分布状态Fig.1 Microscopic distribution of residual oil after polymer flooding

2 聚合物驱后注气稳定重力复合驱基本思路Fundamental thought of gas injection for stable gravity flooding after polymer flooding

目前大庆油田已经对多项聚驱后进一步提高采收率技术进行了积极的探索,自2005年以来,共开展了聚表剂驱、热力采油、微生物采油、二元复合驱、残余聚合物调剖5种类型10项现场试验,依据对聚驱后开展时机、井网方式和驱油体系的研究得出,聚驱后走“调、堵、驱”相结合的技术路线可以提高采收率5%~8%,虽有效果但不甚理想;有效的升级换代技术应该进一步提高采收率达10%~15%以上。

针对聚驱后剩余油分布的状况,提出了油藏顶部注气、底部三元复合驱的思路。如图2所示,在厚油层内部或无隔层小层间,油层顶部水平井注气,并通过气顶扩张来驱替原油,剩余油向下驱替,避免了水平气驱因储层非均质性和气体黏性指进引起的气窜、波及效率低等问题,实现顶部剩余油的动用。油层底部注入三元复合驱油体系,驱替底部以及顶部气驱驱替下来的剩余油,实现油藏的立体开发。

图2 聚驱后稳定重力复合驱技术思路Fig.2 Thought of stable gravity flooding after polymer flooding

在高含水期,油层经过长期水洗,流体相互之间的浮力,经过对流体长期而持久的作用,使油水产生上下分离的趋势,在孔隙中油、水不断上、下分离运动,从而造成油层上部剩余油富集,上部剩余油无法受到较好的水驱作用。在近注水井和生产井一定区域内,压力下降很快,驱替压力梯度较高,浮力所起的作用很小,浮力和重力的合力与水平方向的夹角很小,有利于使原油驱向水平方向;但逐渐到了离井点一定距离的油层内部,从注水井到油井方向过渡过程中驱替压力梯度变得很小,驱替压力梯度的方向是从水井指向油井,但浮力没有大的变化,水对单位体积的浮力与油的重力差在高含水条件下可以看作是恒定的,浮力和重力的合力与水平方向的夹角有所增加且方向向上倾斜,使原油慢慢移向上方。

注气稳定重力复合驱通过气顶扩张来驱替油层顶部剩余油,使剩余油从油层顶部流向油层底部。在油层底部进行三元复合驱驱替时,气体驱动力与重力的联合作用,克服流体的浮力及流动阻力,抑制油的向上移动,使油层底部三元复合驱能保证较好的驱替效果。

3 聚合物驱后提高采收率技术对比分析Comparison of available EOR techniques after polymer flooding

利用大庆某聚驱后正韵律沉积区块进行了数值模拟研究,区块面积1.51 km,平面网格步长为10 m,油层厚度24 m,模型纵向划分为20个模拟层,聚驱后采出程度51.48%。

3.1剩余油分布研究

Distribution of residual oil

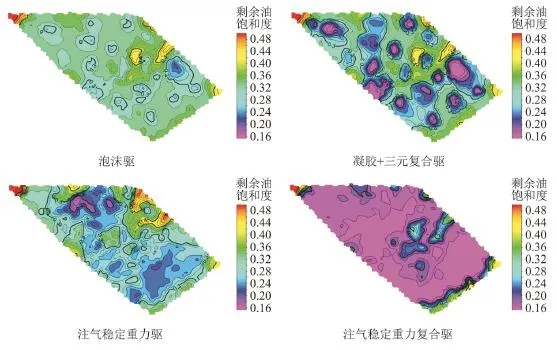

(1)平均剩余油饱和度场。将各层剩余油饱和度加和平均,得出平均剩余油饱和度场,对比不同驱替方式剩余油饱和度场,如图3所示。

图3 聚驱后剩余油饱和度场Fig.3 Residual oil saturation field after polymer flooding

从图中可以看出,泡沫驱可以有效扩大波及体积,但提高驱油效率有限,总体剩余油饱和度较高;凝胶+三元复合驱、注气稳定重力驱存在局部剩余油;注气稳定重力复合驱驱替效率高,剩余油较少,且驱替均匀。

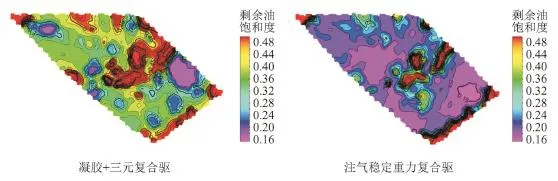

(2)顶部小层剩余油饱和度场。将顶部1~5小层剩余油饱和度场加和平均,得出顶部小层平均剩余油饱和度场,如图4所示。常规化学驱技术顶部油层驱替效果差、剩余油较多,注气稳定重力复合驱将顶部低渗透油层有效动用、剩余油大幅减少。

图4 1~5层平均含油饱和度场(共20层)Fig.4 Average oil saturation field of layer 1-5 (with 20 layers in total)

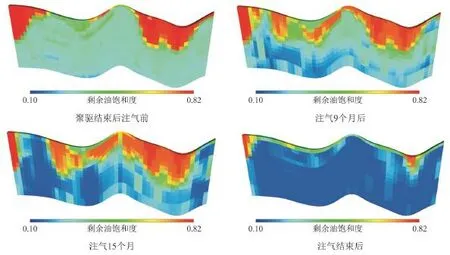

(3)纵向剩余油饱和度场。切取注气稳定重力复合驱不同时间纵向剖面,顶部注气降低残余油饱和度,利用纵向压差驱替剩余油向下运移,底部实施复合驱驱替剩余油,利用平面压差开采,实现立体驱替,如图5所示。

图5 注气稳定重力复合驱纵向剖面剩余油饱和度场Fig.5 Residual oil saturation field in vertical profile after gas injection for stable gravity flooding

3.2提高采收率预测结果对比分析

Comparison of predicted EOR performance

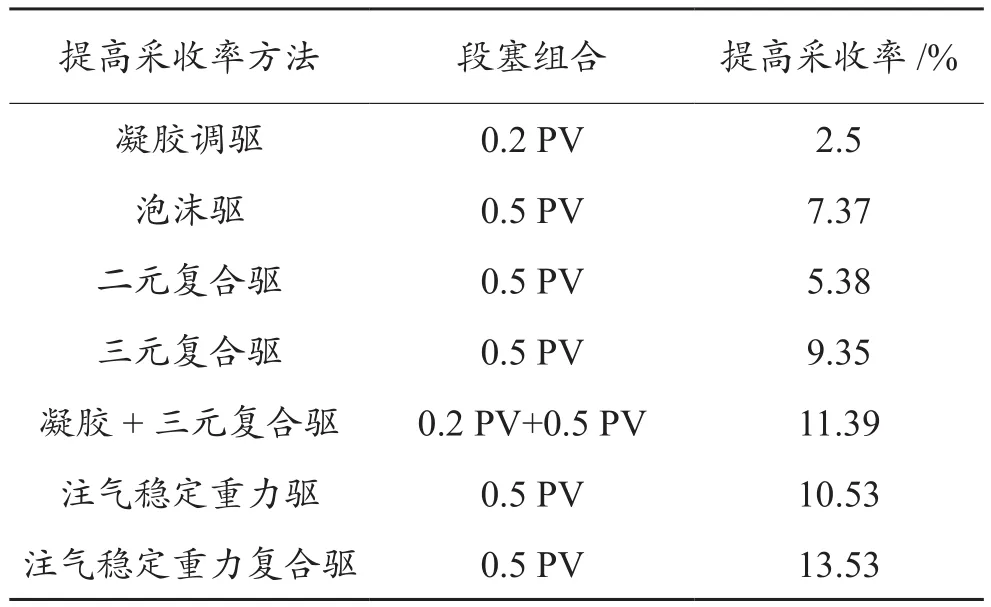

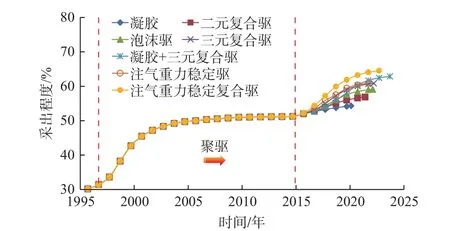

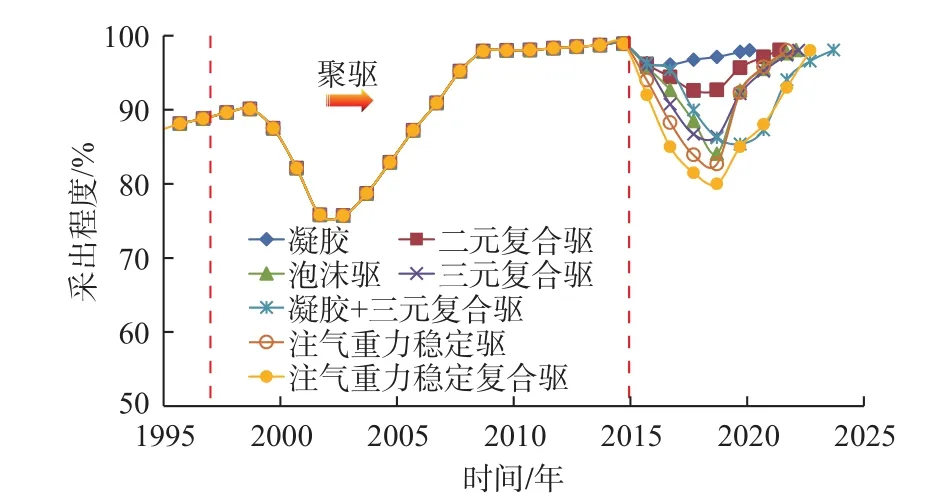

进行了凝胶调驱、泡沫驱等不同驱替方式的效果预测,结果见表1。聚驱后不同方法提高采收率差异较大,在凝胶调驱的基础上进行三元复合驱采收率可达到11.39%,而注气稳定重力复合驱效果最好,提高采收率达到了13.53%,降水增油效果良好,结果如图6、图7所示。

表1 聚驱后不同驱替方式提高采收率结果Table 1 EOR performance of different displacement techniques after polymer flooding

4 结论Conclusions

(1)针对聚驱后宏、微观剩余油高度分散,油层顶部剩余油富集的特点,提出了注气稳定重力复合驱的思路。进行了不同技术的平均剩余油饱和度场、顶部小层剩余油饱和度场和纵向剩余油饱和度场的分析,结果表明聚驱后注气稳定重力复合驱有效驱替油藏顶部剩余油,实现油藏的立体开发。

图6 聚驱后不同驱替方式提高采收率预测结果Fig.6 Predicted EOR of different displacement techniques after polymer flooding

图7 聚驱后不同驱替方式含水变化预测结果Fig.7 Predicted changes in water cut of different displacement techniques after polymer flooding

(2)对比不同驱替方式的数值模拟结果,提高采收率差异较大,聚驱后注气稳定重力复合驱效果最好,提高采收率幅度达到了13.53%,为聚驱后提高采收率技术的探索提供了新思路。

[1] 朱友益,侯庆锋,简国庆,马德胜,王哲.化学复合驱技术研究与应用现状及发展趋势[J].石油勘探与开发,2013,40(1):90-96. ZHU Youyi, HOU Qingfeng, JIAN Guoqing, MA Desheng, WANG Zhe.Current development and application of chemical combination flooding technique [J]. Petroleum Exploration and Development, 2013, 40 (1): 90-96.

[2] 程杰成,吴军政,陈国,韩培慧,赵昌明.化学驱实用数学模型及其应用[J] .大庆石油地质与开发,2014,33 (1):116-121. CHENG Jiecheng, WU Junzheng, CHEN Guo, HAN Peihui, ZHAO Changming.Practical mathematical model and its application for chemical flooding[J].Petroleum Geology and Oilfield Development in Daqing, 2014, 33 (1): 116-121.

[3] 赵凤兰,岳湘安,侯吉瑞,李凯.碱对复合驱油体系与原油乳化作用的影响[J].石油钻探技术,2010,38(2):62-66. ZHAO Fenglan, YUE Xiang’an, HOU Jirui, LI Kai. Impact of alkali on emulsification of compound flooding system and crude oil [J].Petroleum Drilling Techniques,2010, 38(2): 62-66.

[4] 沈平平,袁士义,邓宝荣,宋杰,沈奎友.化学驱波及效率和驱替效率的影响因素研究[J].石油勘探与开发,2004,31(1):1-4. SHEN Pingping, YUAN Shiyi, DENG Baorong, SONG Jie, SHEN Kuiyou.Influence factors of oil displacement efficiency and sweep efficiency in chemical flooding[J]. Petroleum Exploration and Development, 2004, 31(1): 1-4.

[5] 张继成,张彦辉,战菲,孙丽艳.聚驱后油田剩余油潜力分布规律研究[J].数学的实践与认识,2010,40(13):57-62 ZHANG Jicheng, ZHANG Yanhui, ZHAN Fei, SUN Liyan.Investigation on the distribution rule of potential of remaining oil after polymer flooding[J].Mathematics in Practice and Theory, 2010, 40(13): 57-62.

[6] 曹瑞波,韩培慧,高淑玲.不同驱油剂应用于聚合物驱油后油层的适应性分析[J].特种油气藏,2012,19(4):100-103. CAO Ruibo, HANG Peihui, GAO Shuling. Adaptability of different oil displacement agents in reservoir formations after polymer flooding [J]. Special Oil and Gas Reservoirs, 2012, 19 (4): 100-103.

[7] 韩培慧,苏伟明,林海川,高淑玲,曹瑞波,李宜强.聚驱后不同化学驱提高采收率对比评价[J].西安石油大学学报:自然科学版,2011,26(5):44-48. HAN Peihui, SU Weiming, LIN Haichuan, GAO Shuling,CAO Ruibo, LI Yiqiang.Evaluation and comparison of different EOR techniques after polymer flooding[J]. Journal of Xi’an Shiyou University: Natural Science Edition, 2011, 26(5): 44-48.

[8] 孙灵辉,刘卫东,赵海宁,吴文祥.聚合物驱油后高弹性聚合物驱油方法探索[J].西南石油大学学报,2007,29 (6):112-115. SUN Linghui, LIU Weidong, ZHAO Haining, WU Wenxiang. Oil displacement by using high-elastic polymer after polymer flooding [J]. Journal of Southwest Petroleum University, 2007, 29 (6): 112-115.

[9] 李丽娟.大庆油田一类油层聚驱后聚表剂驱油技术[J].大庆石油地质与开发,2013,32(3):118-122. LI Lijuan.Oil displacing technique by polymer and surfactant after polymer flooding for typeⅠoil reservoir in Daqing Oilfield[J]. Petroleum Geology and Oilfield Development in Daqing, 2013, 32(3): 118-122.

[10] 吴莉玲,王惠卫,杜勇,蒋彩红,段小坤.双河油田聚驱后二元复合驱效果评价—以核桃园组三段Ⅱ油组5层为例[J].石油天然气学报,2014,36(3):348-351. WU Liling, WANG Huiwei, DU Yong, JIANG Caihong,DUAN Xiaokun. Performance evaluation of surfactant/ polymer combined flooding after polymer flooding in Shuanghe Oilfield: a case study of 5 layers in No. II oilbearing formation of Interval 3, Hetaoyuan Formation [J]. Journal of Oil and Natural Gas, 2014, 36(3): 348-351.

[11] 王亮,卢祥国,邓庆军,肖龙.聚合物驱后进一步提高采收率方法及其技术经济效果评价[J].油田化学,2010,27(4):385-390. WANG Liang , LU XiangGuo, DENG QingJun, XIAO Long.EOR technology after polymer flooding and it’s technical and economic evaluation [J].Oilfield Chemistry, 2010, 27(4): 385-390.

[12] 宋考平,李世军,方伟,吴家文,穆文志.用荧光分析方法研究聚合物驱后微观剩余油变化[J].石油学报,2005,26(2):91-95. SONG Kaoping, Li Shijun, FANG Wei, WU Jiawen, MU Wenzhi.Fluorescence analysis on changeable rules of microscopic remaining oil after polymer flooding [J]. ACTA Petrolei Sinica, 2005, 26(2): 91-95.

[13] 白振强,吴胜和,付志国.大庆油田聚合物驱后微观剩余油分布规律[J].石油学报,2013,34(5):924-931 BAI Zhenqiang, WU Shenghe, FU Zhiguo.The distribution of microcosmic remaining oils after polymer flooding in Daqing Oilfield [J]. ACTA Petrolei Sinica,2013, 34(5): 924-931.

修改稿收到日期 2016-06-12

〔编辑 李春燕〕

Numerical simulation of gas injection for stable gravity flooding after polymer flooding

GAO Ming1,2, WANG Qiang1,2, MA Desheng1,2, LIU Zhaoxia1,2, LIU Wanlu1,2

1. State Kay Laboratory of Enhanced Oil Recovery, Beijing 100083, China;2. Research Institute of Petroleum Exploration and Development, Beijing 100083, China

Residual oil after polymer flooding is very scattered, and residual oil in top sections of reservoir formations is extremely difficult to develop, yet there is no prevailing technology suitable for development after polymer flooding. Based on analysis of stress on crude oil, the idea of injecting gas at the top section of the reservoir and conducting ASP flooding in bottom section has been proposed in this paper. Performances of different displacement modes have been predicted for some blocks of Daqing Oilfield after polymer flooding. The research results show gas injection for stable gravity flooding has the best performance, with a EOR increment of 13.53%. Comparing residual oil saturation obtained through application of different displacement modes, gas injection for stable gravity flooding can effectively develop low-permeability formations in the top section and reduce residual oil significantly. Vertical distribution of residual oil saturation at different time points was analyzed. After gas injection in the top section, differential pressure in vertical direction may drive residual oil to migrate downward, while ASP flooding conducted in bottom section may drive residual oil by horizontal differential pressure, thus realizing 3-dimensional flooding. Gas injection for stable gravity flooding may provide a viable option for EOR after polymer flooding.

after polymer flooding; gas injection for stable gravity flooding; numerical simulation; residual oil distribution

TE357

A

1000 - 7393( 2016 ) 04- 0494- 05

10.13639/j.odpt.2016.04.017

GAO Ming, WANG Qiang, MA Desheng, LIU Zhaoxia, LIU Wanlu. Numerical simulation of gas injection for stable gravity flooding after polymer flooding[J]. Oil Drilling & Production Technology, 2016, 38(4): 494-498.

中国石油“十三五”油气田开发重大科技项目“砾岩及断块油藏化学驱优化设计技术”(编号:2016B-1104);中国石油勘探开发研究院超前储备研究项目(编号:2015yj-03)。

高明 (1980-),博士,主要从事油气田开发方面的研究工作,工程师。通讯地址:(100083)北京市海淀区学院路20号中国石油勘探开发研究院采收率所。 E-mail:gaoming010@petrochina.com.cn