Application of transient burning rate model of solid propellant in electrothermal-chemical launch simulation

Yan-jie NI,Yong JIN,Gang WAN,Chun-xia YANG,Hai-yuan LI*,Bao-ming LI

National Key Laboratory of Transient Physics,Nanjing University of Science and Technology,Nanjing,Jiangsu 210094,China

Application of transient burning rate model of solid propellant in electrothermal-chemical launch simulation

Yan-jie NI,Yong JIN,Gang WAN,Chun-xia YANG,Hai-yuan LI*,Bao-ming LI

National Key Laboratory of Transient Physics,Nanjing University of Science and Technology,Nanjing,Jiangsu 210094,China

A 30 mm electrothermal-chemical(ETC)gun experimental system is employed to research the burning rate characteristics of 4/7 high-nitrogen solid propellant.Enhanced gas generation rates (EGGR)of propellants during and after electrical discharges are verif i ed in the experiments.A modif i ed 0D internal ballistic model is established to simulate the ETC launch.According to the measured pressure and electrical parameters,a transient burning rate law including the inf l uence of EGGR coeff i cient by electric power and pressure gradient(dp/dt)is added into the model.The EGGR coeff i cient of 4/7 high-nitrogen solid propellant is equal to 0.005 MW-1.Both simulated breech pressure and projectile muzzle velocity accord with the experimental results well.Compared with Woodley’s modif i ed burning rate law,the breech pressure curves acquired by the transient burning rate law are more consistent with test results.Based on the parameters calculated in the model,the relationship among propellant burning rate,pressure gradient (dp/dt)and electric power is analyzed.Depending on the transient burning rate law and experimental data,the burning of solid propellant under the condition of plasma is described more accurately.

Solid propellant;Electrothermal-chemical launch;0D internal ballistic model;Transient burning rate law

1.Introduction

Electrothermal-chemical (ETC)propulsion is considered to be an attractive technology to improve the projectile muzzle kinetic energy [1].The ignition delay time can be reduced by adjusting the electric power [2,3],and a compensation for the variation in initial charge temperature is possible [4-6].

Closed comb experimentsaretaken to analyzethe phenomena of propellant combustion with or without plasma[7,8].EGGRofpropellantsduringandafterelectricaldischarges wereverif i edintheexperiments.AnEGGRcoeff i cientisusedto evaluate the effect of electric power [9,10].Because of EGGR,pressure gradient changes rapidly.The effect of pressure gradient(dp/dt)onburningrateshouldbeconsidered,especially at a large ratio of input electric energy to propellant impetus.

In this paper,the f i ring tests using a 30 mm ETC gun are described.A 0D internal ballistic model is used to simulate the ETC launch.A transient burning rate law including the inf l uence of EGGR coeff i cient by electric power and pressure gra-dient (dp/dt)is added into the model.The accuracy of the simulated data is analyzed.

2.30 mm ETC gun f i rings

2.1.Experimental setup

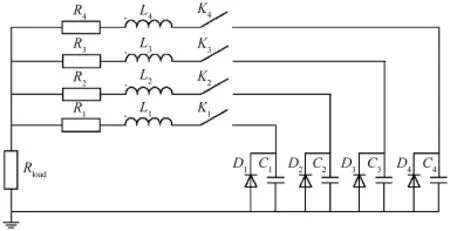

Fig.1 shows a diagram of a pulse forming network (PFN)used in ETC launch.It contains four modules which can be used independently as a system circuit.Each module contains a 1220 μF capacitor,a 40 μH inductance,a high power switch,a crowbar circuit and a surge protection resistor.In the 30 mm ETC gun experimental system,the load is a capillary plasma generator (CPG)with 72 mm in length and 8 mm in diameter. The structure diagram of the 30 mm ETC gun is shown in Fig.2.The chamber volume is 356 cm3and the length of the barrel is 2.75 m.A pressure sensor is added at the breech of the gun,and velocity measuring screens are used to measure the projectile velocity.

Fig.1.Circuit of the 30 mm ETC gun experimental system.

2.2.Experimental results

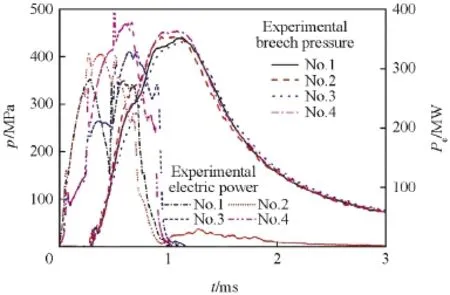

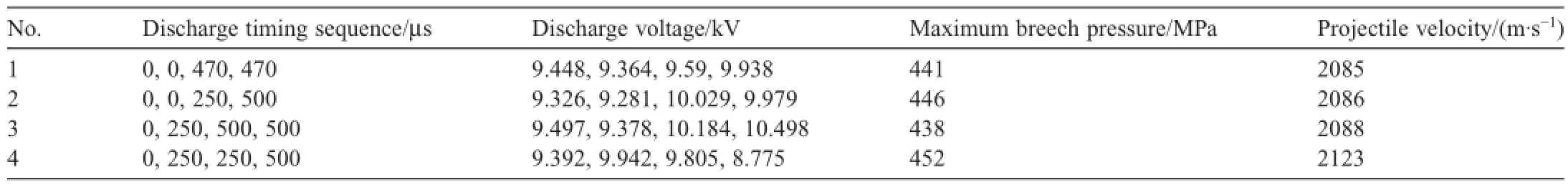

The standard projectiles of 72.1 g were f i red with 4/7 highnitrogen propellant of 260 g in the experiment.The 4/7 highnitrogen propellant is a homogeneous single-based propellant mainly containing nitrocellulose.The experimental conditions and results are listed in Table 1.

At a transferred energy of 192 kJ,the maximum breech pressure was about 441 MPa,and the muzzle velocity of the projectile reached 2085 m/s.At a transferred energy of 182 kJ,the maximum breech pressure was about 446 MPa,and the muzzle velocity of the projectile reached 2086 m/s.At a transferred energy of 200 kJ,the maximum breech pressure was about 438 MPa,and the muzzle velocity of the projectile reached 2088 m/s.At a transferred energy of 220 kJ,the maximum breech pressure was about 452 MPa,and the muzzle velocity of the projectile reached 2123 m/s.The discharge timing sequence can be adjusted to control the peak pressure and increase the projectile muzzle kinetic energy.

The breech pressures and transferred electric powers in the case of 4 different discharge timing sequences are shown in Fig.3.For each case,a pulse current was applied for 1 ms,but the transferred energies were different because of different discharge timing sequences.An obvious pressure plateau is shown in the pressure curves in Fig.3.

Fig.3.Measured breech pressures and electric powers.

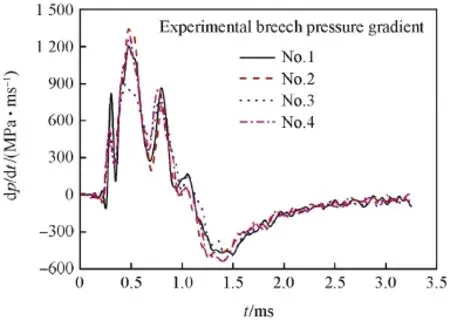

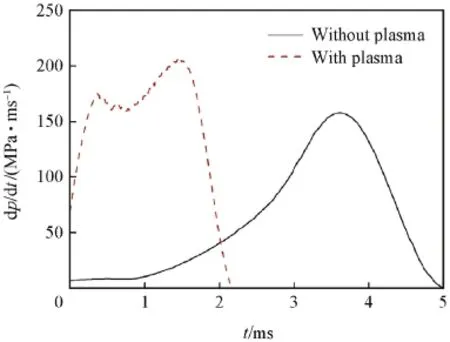

Fig.4 shows the breech pressure gradient (dp/dt)curves in the case of 4 different discharge timing sequences.It can be seen from Fig.4 that 3 spikes appear in the rising phase of pressure.The pressure gradient(dp/dt)is inf l uenced by plasma,propellant burning process and projectile motion.At the beginning of the ignition process,there is a spike in the pressure gradient (dp/dt),which may be caused by the interference of CPG’s electromagnetic f i eld and pressure gradient (dp/dt)in the chamber.Then,the pressure gradient (dp/dt)increases rapidly during the electrical discharge.With the increase in pressure,the projectile begins to move.At this time,the propellant just begins to burn,and the inf l uence of propellant combustion on chamber pressure can be ignored,while the motion of projectile makes the pressure gradient (dp/dt)decrease.Along with propellant combustion,the inf l uence of propellant combustion on pressure increases.So the pressure gradient (dp/dt)increases again.At the end of the electrical discharge,the pressure gradient(dp/dt)decreases with the elec-tric power.The pressure gradient (dp/dt)increases with propellant combustion after the electrical discharge.Meanwhile,the increase in space volume in the rear of projectile makes the pressure gradient (dp/dt)decrease due to the high projectile velocity.

Fig.2.Structure diagram of the 30 mm ETC gun.

Table 1Conditions and results of the experiment.

Fig.4.Pressure gradient(dp/dt)of measured breech pressure.

3.Propellant burning rate law

The propellant used in the 30 mm ETC gun was tested in an improved closed vessel into which electrical energy was discharged.Fig.5 shows the pressure gradient(dp/dt)in the closed vessel tests.The pressure gradient (dp/dt)of CPG is much larger than that of the conventional ignition.The phenomenon of EGGR during the electrical discharge was verif i ed.Clive R. Woodley added an EGGR coeff i cient into the Vieille’s law to simulate the effect of EGGR in the 155 mm ETC launch [11]. In the 30 mm ETC launch,the peak of pressure gradient(dp/dt)is higher than 1000 MPa/ms,while the peak of pressure gradient (dp/dt)in conventional ignition is just about 500 MPa/ms. The pressure gradient changes rapidly under the condition of plasma ignition.The inf l uence of pressure gradient (dp/dt)on the burning rate of solid propellant should be taken into consideration [12,13].A semi-empirical equation of propellant burning rate,including the inf l uence of pressure gradient (dp/ dt)and EGGR coeff i cient by electric power,is presented.

Fig.5.Pressure gradient (dp/dt)in the closed vessel tests.

whereu1is the burning rate coeff i cient of the solid propellant,n1is the burning rate exponent,α(t)is time variable function of pressure and f l ame structure,Peis the electric power (in MW),βeis the EGGR coeff i cient (in MW-1).

结合河南省的平原地势、温润气候以及良好的饲草条件,上庄乡所选择的舍饲饲养繁殖品种主要包括了小尾寒羊、无角道赛特、萨福克、波尔山羊等品种,这些品种首先适合于舍饲养殖,而且多品种羊群在优良杂交后还能确保母羊每一胎的断乳羔羊至少增加3头,且每头可增重至少20%,饲料利用率也相应提高至少10%。近年,上庄乡舍饲养殖优良品种羊群时也发现其比本地羊群的生长速度更快、饲养周期也相对较短,可有效提升经济效益,确保羊群后代的高繁殖率与优良品质。

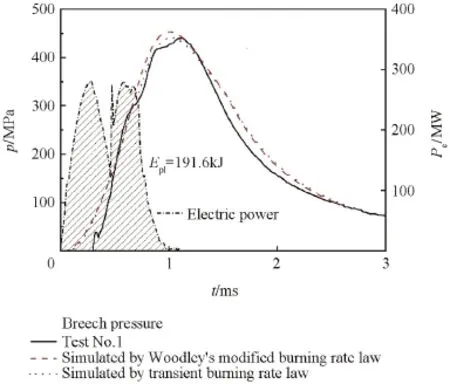

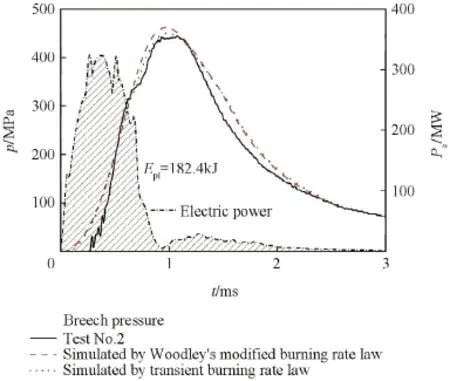

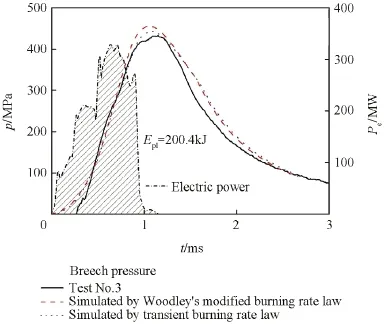

4.0D simulation

The transferred electric power and the predicted and measured breech pressures are shown in Figs.6-9,respectively.The predicted breech pressures are simulated by Woodley’s modif i ed burning rate law and transient burning rate law in Eq. (1). The enhancement of burning rate during the electrical discharge can be simulated with the help of the EGGR coeff i cient. It can be seen from Figs.6-9 that the predicted breech pressures are in good agreement with the measured pressures when the EGGR coeff i cient is equal to 0.005 MW-1.Compared with the breech pressures simulated byWoodley’s modif i ed burning rate law,the breech pressures simulated by the transient burning rate law are more coincident with the measured breech pressures especially at the end of electrical discharge.In the 30 mm ETC launch,the ratio of the input electric energy to propellant impetus is higher than 0.65,which is much larger than the ratio in Woodley’s 155 mm ETC launch [14].A higher ratio leads to a greater effect on the burning rate of propellant.The enhanced burning rates during and after electrical discharge should not just depend on EGGR coeff i cient by electric power,and the inf l uence of the pressure gradient(dp/dt)should be considered.

Fig.6.Breech pressure and electric power of Test No.1.

Fig.7.Breech pressure and electric power of Test No.2.

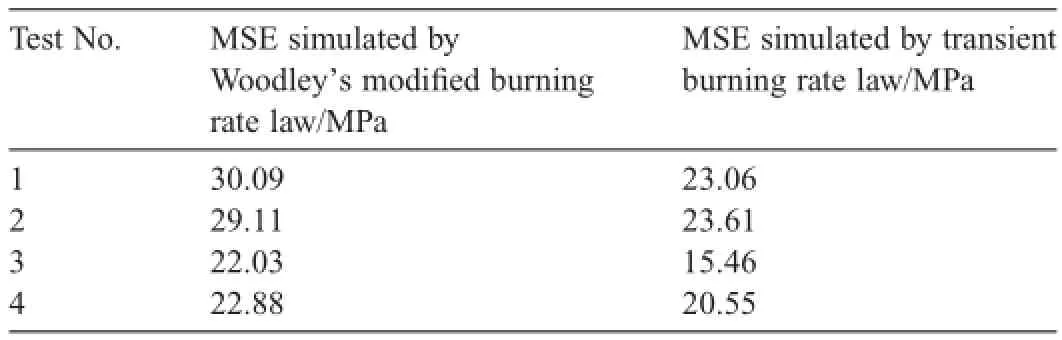

Table 2 shows the mean square error (MSE)between the simulated and measured breech pressures.The MSE of the pressure simulated by the transient burning rate law is about 1 MPa less than that simulated by Woodley’s modif i ed burning rate law.In order to analyze the simulation accuracies of the different burning rate laws,the MSEs of simulated breech pressure within 1.2 ms are listed in Table 3.It can be known from Table 3 that the MSE of pressure simulated by the transient burning rate law decreases,while the MSE of the pressure simulated by Woodley’s modif i ed burning rate law decreases only slightly or increases.It proves that the pressure simulated by the transient burning rate law is more accurate.The projectile muzzle velocity and relative error are listed in Table 4.The simulated projectile muzzle velocity is larger than the measured muzzle velocity.In particular,the simulation accuracy of transient burning rate law is better.Depending on the simulated pressure and projectile muzzle velocity,the simulation accuracy of thetransient burning rate law is better than that of Woodley’s modif i ed burning rate law in the 30 mm ETC launch.

Fig.8.Breech pressure and electric power of Test No.3.

Table 2MSEs of simulated breech pressure.

Table 3MSEs of simulated breech pressure within 1.2 ms.

Table 4Simulated projectile muzzle velocity and relative error.

5.Conclusions and further work

The 30 mm ETC gun experimental system was employed to research the burning rate characteristics of 4/7 high-nitrogen solid propellant.EGGRs of propellants during and after electrical discharge were shown in the experiment.Compared with conventional ignition,the pressure gradient(dp/dt)with plasma ignition is much larger,and the inf l uence of pressure gradient cannot be ignored.The peak pressure can be controlled and the projectile muzzle kinetic energy is increased by adjusting the discharge timing sequence.

Woodley’s modif i ed burning rate law was employed in the 30 mm ETC launch simulations.According to the experimental data,the EGGR coeff i cient of 4/7 high-nitrogen solid propellant is equal to 0.005 MW-1.Because of the large ratio of input electric energy to propellant impetus,the pressure gradient(dp/dt)changed rapidly during and post electrical discharge. Woodley’s burning rate law was improved by taking the pressure gradient (dp/dt)into account.At a high ratio of input electric energy to propellant impetus,the MSEs of parameters simulated by transient burning rate law were less than those simulated by Woodley’s burning rate law.

Further work needs to be conducted at different kinds of propellant to determine the corresponding value ofα(t).Work is underway to add the transient burning rate law into 1D and 2D simulations.

[1]Kim SH,Yang KS,Lee YH,Kim JS,Lee BH.ETC ignition research on 120 mm gun in Korea.IEEE Trans Magn 2009;45(1):341-6.

[2]Goldenberg C,Zoler D,Shaf i r N,Roshu S,Wald S,Shapira M. Plasma-propellant interaction at low plasma energies in ETC guns.IEEE Trans Magn 2003;39(1):227-30.

[3]Beyer RA,Brant AL.Plasma ignition in a 30-mm cannon.IEEE Trans Magn 2007;43(1):294-8.

[4]Zoler D,Shaf i r N,Forte D,Kot E,Ravid A,Wald S,Sudai M.Study of plasma jet capabilities to produce uniform ignition of propellants,ballistic gain,and signif i cant decrease of the “temperature gradient”.IEEE Trans Magn 2007;43(1):322-8.

[5]Weise THGG,Kruse J,Schaffers P,Haak H-K.Status and results of the German R&D program on ETC technologies.IEEE Trans Magn 2001;37(1):46-51.

[6]Alimi R,Bakshi L,Kot E,Sudai M.Temperature compensation and improved ballistic performance in a solid-propellant electrothermalchemical(SPETC)40-mm gun.IEEE Trans Magn 2007;43(1):289-93.

[7]Kaste P,Birk A,Kinkennon A,Lieb R,Del Guercio M,Schroeder M,et al.Analysis of burning rate phenomena and extinguished solid propellants from an interrupted closed bomb with plasma igniter.IEEE Trans Magn 2001;37(1):173-7.

[8]Brik A,Del Guercio M,Kinkennon A,Kooker DE,Kaste P. Interrupted-burning tests of plasma-ignited JA2 and M30 grains in a closed chamber.Propell Explos Pyrot 2000;25(3):133-42.

[9]Li HY,Li BM,Li HZ,Ning GJ,Wang ZL,Yang CX.Propellant burn rate characteristics in closed bomb ignited with plasma.Explos Shock Waves 2004;24(2):145-50.

[10]Taylor MJ,Woodley CR.Variation in enhanced gas generation rates in electrothermal-chemical closed chamber studies.In:19th International Symposium of Ballistics,Switzerland;2001.179-86.

[11]Woodley CR,Billett SJ.Modeling enhanced gas generation rates in a 155-mm ETC gun.IEEE Trans Magn 2001;37(1):207-10.

[12]Krier H.Solid propellant burning rate during a pressure transient. Combust Sci Technol 1972;5(2):69-73.

[13]Osborn JR.Evaluation of solid propellant ballistic properties.Combust Flame 1973;20(2):193-7.

[14]Woodley CR.Mixing processes of plasmas in electrothermal-chemical guns.In:12th Electromagnetic LaunchTechnology Symposium,America;2004.338-43.

Received 11 September 2015;revised 26 October 2015;accepted 28 October 2015 Available online 26 November 2015

Peer review under responsibility of China Ordnance Society.

*Corresponding author.

E-mail address:Li_haiyuan@163.com (H.Y.LI).

http://dx.doi.org/10.1016/j.dt.2015.10.003

2214-9147/© 2016 China Ordnance Society.Production and hosting by Elsevier B.V.All rights reserved.

© 2016 China Ordnance Society.Production and hosting by Elsevier B.V.All rights reserved.

- Defence Technology的其它文章

- Mechanism of plasma ignition in electrothermal-chemical launcher

- 3D numerical simulation and analysis of railgun gouging mechanism

- Calculation of propellant gas pressure by simple extended corresponding state principle

- Innovative boron nitride-doped propellants

- The ballistic performance of the bombard Mons Meg