3D numerical simulation and analysis of railgun gouging mechanism

Jin-guo WU*,Bo TANG,Qing-hua LIN,Hai-yuan LI,Bao-ming LI

National Key Laboratory of Transient Physics,Nanjing University of Science and Technology,Nanjing 210094,Jiangsu,China

3D numerical simulation and analysis of railgun gouging mechanism

Jin-guo WU*,Bo TANG,Qing-hua LIN,Hai-yuan LI,Bao-ming LI

National Key Laboratory of Transient Physics,Nanjing University of Science and Technology,Nanjing 210094,Jiangsu,China

A gouging phenomenon with a hypervelocity sliding electrical contact in railgun not only shortens the rail lifetime but also affects the interior ballistic performance.In this paper,a 3-D numerical model was introduced to simulate and analyze the generation mechanism and evolution of the rail gouging phenomenon.The results show that a rail surface bulge is an important factor to induce gouging.High density and high pressure material f l ow on the contact surface,obliquely extruded into the rail when accelerating the armature to a high velocity,can produce gouging.Both controlling the bulge size to a certain range and selecting suitable materials for rail surface coating will suppress the formation of gouging.The numerical simulation had a good agreement with experiments,which validated the computing model and methodology are reliable.

Impact dynamics;Gouging;Finite element simulation;Rail damage;Railgun

1.Introduction

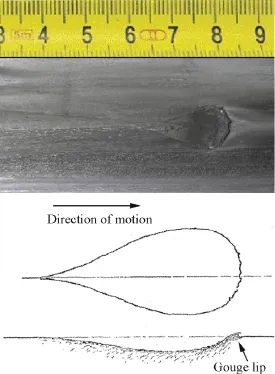

The electromagnetic railgun is a kinetic energy weapon utilizing an electromagnetic force produced by a high power pulse current to accelerate a projectile to a high speed.It has wide applications in military and civil f i elds [1-3].How to extend the lifetimeofthelauncherisakeytechnologyofarailgun.Itdepends on the solutions of arc ablation [4,5]and gouging problems. Gouging is a material damage phenomenon appeared in hypervelocity sliding contact,which has been reported in rocket sled,light-gas gun and railguns [6-8].Gouging in a railgun will result in the following main hazards:reducing the energy utilization,shortening the rail’s lifetime and affecting the accuracy of projectile.The typical teardrop shaped gouging morphology observed during post-shot inspections of rails is illustrated in Fig.1.The depth varied along the length of the gouge and was shallowest close to the point of initiation.In addition,armature depositswereobservedattheraisedgougelip.Wattetal.[9]found that both galling and gouge craters initiated from existing microscopic defects and the microscopic defects had no measurable effects on the threshold velocity for either galling or gouging damage.Barker et al. [10]and Bourell et al. [11]conducted numerical simulations for the gouging mechanism utilizing CTH and EPIC codes respectively,but both of them were 2D models.

This paper is intended to carefully describe the formation of gouging and better understand the gouging mechanism through 3D thermal mechanical coupling simulations.And parameter studies were presented in the simulations.Some factors affecting the gouging,such as the bulge size and materials,were discussed.

2.Computing model and parameters for railgun gouging

2.1.Computing model

Many researchers have explored the mechanism of gouging[12-16].A prevalent hypothesis is that rail surface defects and the dynamic response of the rail,often microscopic in size,are the importance causes of rail gouging.The impact between the armature and the local asperities or rail bulge leads to a local pressure far exceeding the yield strengths of the contact materials,and hence a micro-crater is formed.

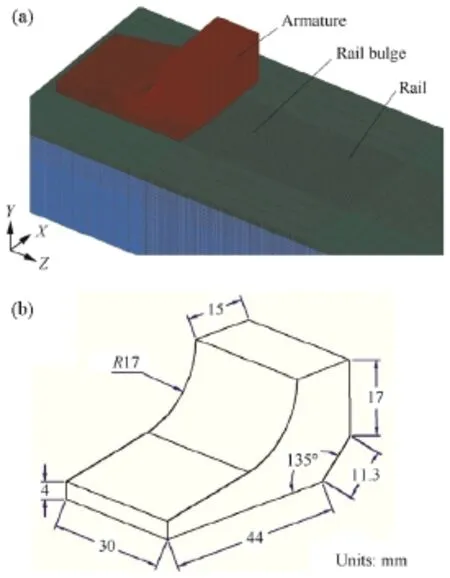

In the paper,a 3D model of a rail bulge impacted by a C shaped armature (Fig.2)was established for the simulation with the f i nite element method.The rail was divided with 80,809 elements and the armature was divided with 30,380 elements.For more accurate calculation,dense meshes were constructed around the rail bulge (Fig.2a).The specif i c armature sizes are illustrated in Fig.2b,the same as the armature used in the experiment.Due to the symmetry of physical structure,along the symmetrical plane only half of the armature and one rail were adopted in the model.A displacement constraint in the y direction was applied on the symmetrical plane of the armature.And insulating and supporting materials wereomitted in the model,instead displacement constraints were applied on the sides of the armature.According to some studies[17,18]on the dynamic response of the rail,a bulge size of 1 mm was supposed on the rail in the simplif i ed model,which would induce the impact with the armature.

Fig.1.Typical teardrop shaped gouge crater in railgun experiment.

2.2.Material model and parameters

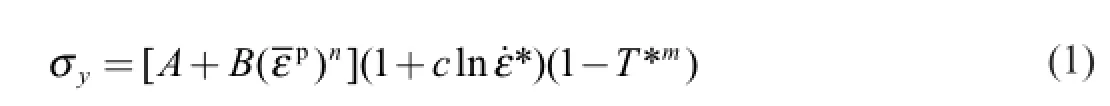

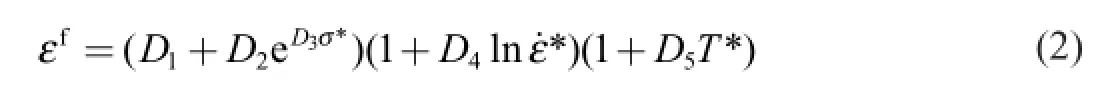

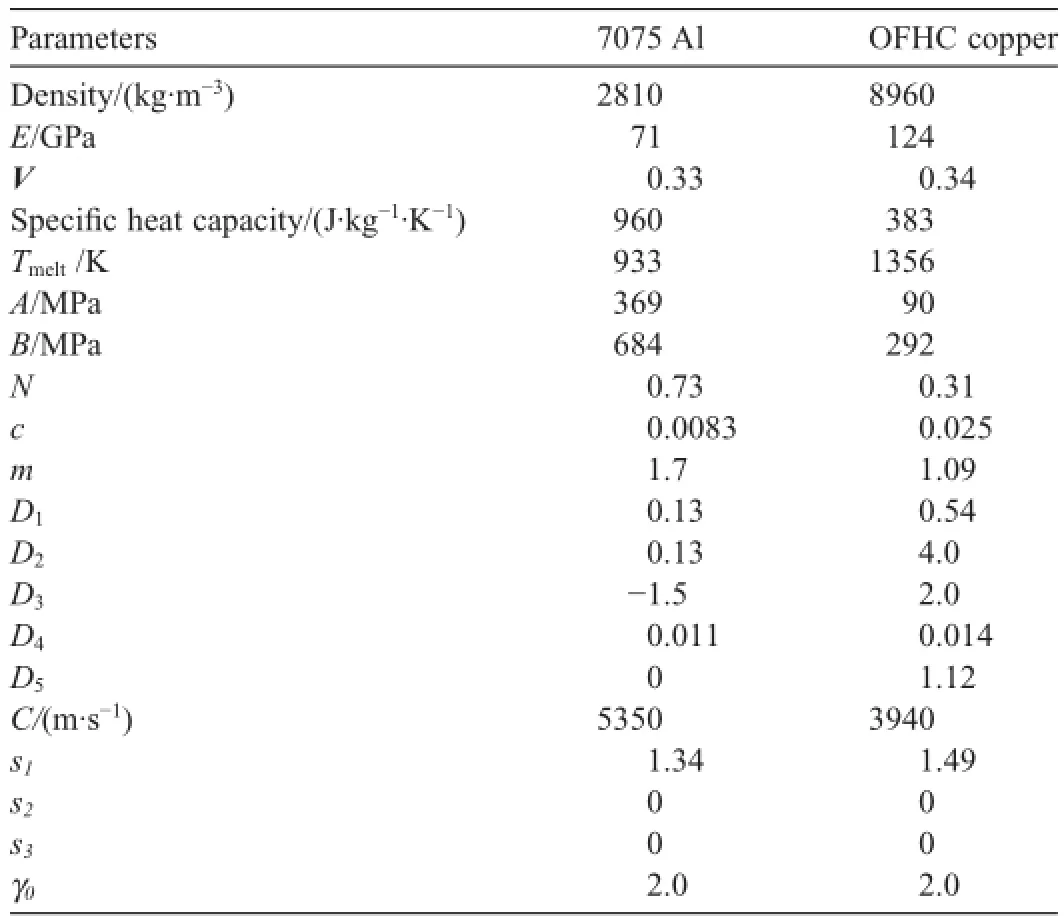

The Johnson-Cook model,i.e.,the strain and temperature sensitive plasticity material model,was used for the computation,which is described as follows:

Fig.2.3D computing model for railgun gouging.

whereA,B,n,c,mare input constantsis the effective plastic strain;ε.*is the normalized effective plastic strain rate;is the melting temperature of materials andTroom is the environment temperature.

The strain at fracture is expressed as

reaches the value of 1.

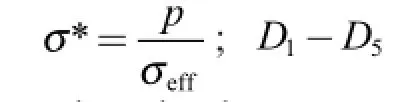

The Mie-Grüneisen equation of state was adopted to describe the thermodynamic behavior of materials at high pressure.The pressure for compressed materials is def i ned as

and for expanded materials,is

whereCis the intercept of thevs-vpcurve (vsis the shock velocity andvpis the particle velocity);s1,s2,s3are unitless coef fi cients of the slope of thevs-vpcurve;e0is the initialinternal energy per unit volume;γ0is the unitless Grüneisen gamma;a is the fi rst order volume correction toγ0,and

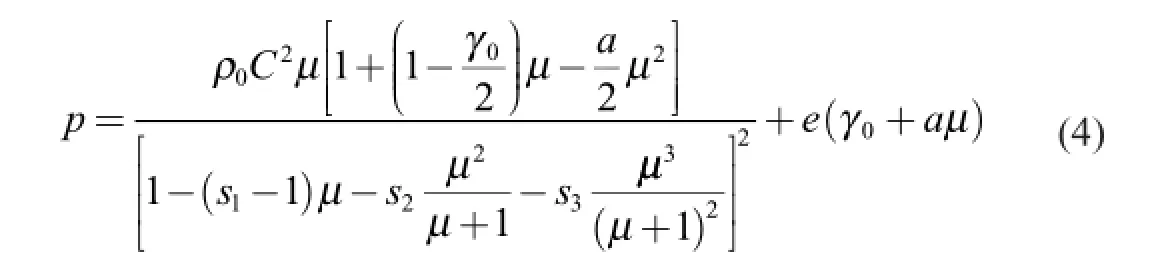

Table 1Material parameters of armature and rail.

For railgun experiments,the slider and rail materials are typically aluminum and copper alloys.In the computation,the materials for armature and rail are 7075 aluminum and OFHC copper respectively.Their parameters are shown in Table 1.

3.Results and discussion

3.1.Simulation of gouging process

Fig.3.Mises stress during gouging formation process.

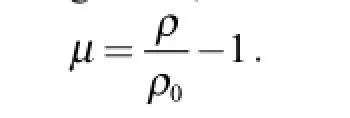

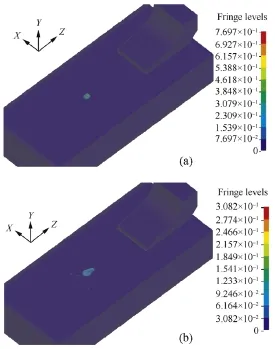

Fig.4.Contour of effective plastic strain after impacting is f i nished:(a)rail;(b)armature.

The calculations were accomplished by LS-DYNA using Lagrange algorithm.And the erosion contact was adopted.The armature was given an initial velocity of 2.0 km/s.It had a parallel impact with the bulge on the rail.The interaction time of impacting was about 28 μs.Fig.3 shows the dynamic contour of Von Mises stress during the impacting process(a longitudinal section along the gouge was cut out for convenient observation).The stress gradient was remarkable in the impacting region.The peak value of the Mises stress in the interaction core reached over 700 MPa and the pressure reached about 7 GPa,which far exceeded the yield strength of the materials.Therefore,the materials in the interaction core behaved in a f l uid-like state.The heat generated by impact plastic work can raise the local temperature by nearly 300 °C,coupled with the rise of temperature by joule heating,both aggravated the softening and f l ow of materials.The impact between the armature and rail bulge at high speed leads to an instantaneous energy exchange.Part of the rail bulge was changed into high density and high pressure material f l ow and extruded into the rail obliquely.As a result,the local rail material experienced a rapid plastic deformation and a teardrop shaped gouge with the tip facing upstream was f i nally formed.Simultaneously,the other part of the rail bulge was sheared away by the armature,raising up the rail material to form a gouge lip.

Fig.4(a)shows the simulated teardrop shaped gouge after impacting is f i nished.The gouge crater is 14 mm in length,5.6 mm in width and 0.5 mm in depth,with a tip pointing to breech and an arc pointing to muzzle.The simulation results coincide well with the gouge morphology from experiment(Fig.1).The impact created craters in both the guide rail and the slider.But unlike the rail material,the armature material was less able to withstand a large plastic strain.It showed the feature of brittle fracture and experienced more damage during the impacting with rail bulge,as shown in Fig.4(b).

3.2.Preliminary analysis of gouging inf l uence factors

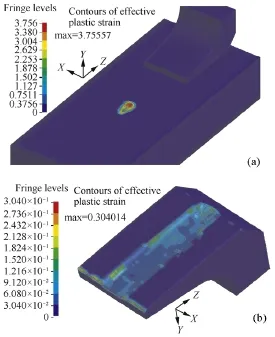

Fig.5.The gouging shapes at different impacting velocities (a)v=3.0 km/s;(b)v=1.0 km/s.

According to the paragraph above,the parallel impact between armature and rail bulge at high speed produces high density and high pressure material f l ow.The material f l ow is extruded into the rail obliquely and consequently the gouge is formed.What’s more,we need to know how is the formation of gouging affected by some factors such as the velocity,the materials and others.In this paper,through parameter studies,the inf l uences of armature velocity,rail bulge size and rail coating material on gouging were presented and discussed.

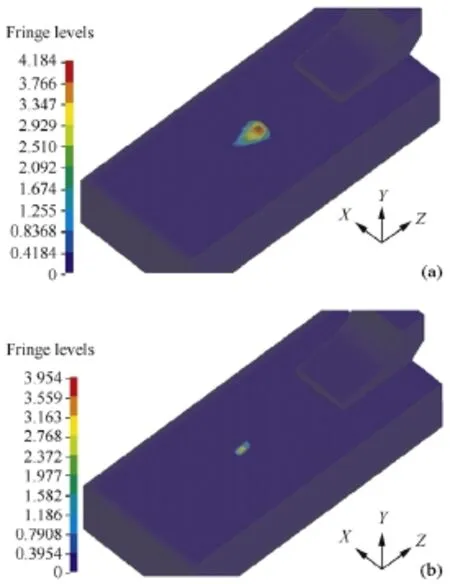

The velocity of armature was changed to analyze its effect on gouging by keeping the geometries of the armature and rail unchanged.Results show that,with the increase in armature velocity,the gouge shape becomes wider and deeper(Fig.5(a)). The damage area of armature damage area is also increased.On the contrary,when the armature velocity is decreased to a certain extent,gouging disappears,and rail galling appears(Fig.5(b)).It is not diff i cult to understand that,with the armature velocity decreasing,the kinetic energy of the material f l ow is reduced and thus the material f l ow’s penetration into the rail is also weakened.Fig.6 shows that the interaction force between the armature and rail changes with time at different velocities.The interacting force rose sharply during the time of the armature impacting with the rail bulge,and the interaction force increased as the velocity of armature increased.Thethreshold gouging velocity for 7075 aluminum and OFHC copper in our simulation was about 1.4 km/s,which is close to the experimental results from Persad et al.[19]and Stefani et al.[20].They reported the gouging velocities for 7075 aluminum and ETP copper were 1.35 km/s and 1.3 km/s respectively.

Fig.6.The interaction forces at different impacting velocities.

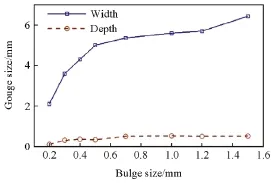

Fig.7.Size of the gouge crater changing with rail bulge size.

The armature still had an impact with the rail bulge at a speed of 2.0 km/s.However,the rail bulge size was changed to analyze its effect on gouging.With the increase in bulge size,a bigger gouge crater was generated (Fig.7).Simulations show that the formation of gouging can be suppressed by controlling the bulge size to a certain extent.

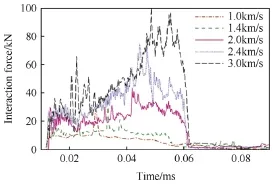

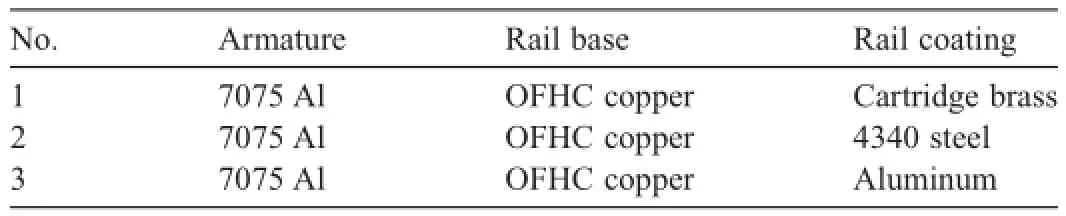

In order to analyze the effect of materials on gouging,a 2 mm thick coating material of the rail surface was distinguished from the base material(Fig.2).Three kinds of coating materials (Table 2)were selected to compare the differences through simulations.In the f i rst group,gouging was formed on the cartridge brass coating after the armature impacted at the velocity of 2 km/s.However,in the next two groups gouging was not formed on the rail coatings (Fig.8).For 4340 steel,the reason may be that the coating material was too hard to generate plastic deformation.By contrast,the armature material was easier to yield and be damaged.And for pure aluminum,it was too soft to sustain the interaction pressure of the armature and the rail bulge was sheared away by the armature directly.Watt et al. [9]also found that thin aluminum coatings appeared effectively to prevent gouging in his experiments.However,in fact,the electrical conductivity and mechanical properties of materials should be considered comprehensively to select suitable materials for a railgun to prevent gouging.

4.Conclusion

Based on the rail gouging mechanism and the theory of impact thermodynamics,a 3D thermal mechanical coupling gouging model was established using f i nite element method to simulate and analyze the generation mechanism and evolution of rail gouging phenomenon.The results show that the micro-impact between armature and rail surface bulge at a high speed results in instantaneous energy exchange.High density and high pressure material f l ow on the contact surface,obliquely extruded into the rail,promotes the formation of gouging.For any combination of contact materials,there is a threshold velocity for gouging formation.The formation of gouging can be suppressed by controlling the rail bulge size within a certain range and selecting the suitable materials for rail surface coating.

Table 2Three kinds of coating materials.

Fig.8.The gouging shape affected by different coating materials (a)4340-steel;(b)aluminum.

[1]Fair HD.Guest Editorial:The past,present,and future of electromagnetic launch technology and the IEEE International EML Symposium.IEEE Trans Magn 2013;41(1):1024-7.

[2]Bair S,Cowan R,Kennedy G,Neu R,Siopis M,Streator J et al.A survey of railgun research at the Georgia Institute ofTechnology (USA).In:16th International Symposium on Electromagnetic LaunchTechnology (EML),Beijing;2012.

[3]Li J,Cao R Shizhong L.The development of EML technology in China. IEEE Trans Plasma Sci 2013;41(5):1029-33.

[4]Peng X,Zhan Z,Li Z.Experimental study of railgun aluminum armature electrical contact ablation.Int J Appl Electrom 2014;46(3):511-18.

[5]Chen LX,He JJ,Xiao Z,Xia SG,Feng D,Tang LL.Experimental study of armature melt wear in solid armature railgun.IEEE Trans Plasma Sci 2015;43(5):1142-6.

[6]Graff KF,Dettloff BB.The gouging phenomenon between metal surfaces at very high sliding speeds.Wear 1969;14(2):87-97.

[7]Wolfe T,Spiegelberg W,Evangelist M.Exploratory metallurgical evaluation of worn rails from a 90 mm electromagnetic railgun.IEEE Trans Magn 1995;31(1):770-5.

[8]Cinnamon JD.Hypervelocity gouging impacts.Reston:American Institute of Aeronautics and Astronautics;2009.

[9]Watt TJ,Clay CE,Bassett PM,et al.The effect of surface indentations on gouging in railguns.Wear 2014;310(1-2):41-50.

[10]Barker LM,Trucano TG,Susoeff AR.Gun barrel gouging by sliding metal contact at very high velocities.IEEETrans Magn 1989;1(25):83-7.

[11]Bourell DL,Persad C.Simulation of railgun gouging.IEEE Trans Magn 1999;35(1):274-6.

[12]BarkerLM, Trucano TG, SusoeffAR.Railgun railgouging by hypervelocity sliding contact.IEEE Trans Magn 1989;25(1):83-7.

[13]Watt TJ,Bourell DL.Sliding instabilities and hypervelocity gouging. IEEE Trans Plasma Sci 2011;39(1):162-7.

[14]Zhu RG,Zhang Q,Li ZY,Jin LW,Wang RL.Impact physics model and inf l uencing factors of gouging for electromagnetic rail launcher.In:17th International Symposium on Electromagnetic LaunchTechnology (EML),La Jolla,CA;2014.

[15]Jerome TT,Wei S.Dynamic response of cantilevered rail guns attributed to projectile/gun interaction theory.IEEE Trans Magn 2007;43(1):207-13.

[16]Rickerd GS,Palazotto AN,Cinnamon JD.Investigation of a simplif i ed hypervelocity gouging model.AIAA 2005_2355;2005.

[17]Johnson AJ,Moon FC.Elastic waves and solid armature contact pressure in electromagnetic launchers.IEEE Trans Magn 2006;42(3):422-9.

[18]Daneshjoo K,Rahimzadeh M,Ahmadi R,Ghassemi M.Dynamic response and armature critical velocity studies in an electromagnetic railgun.IEEE Trans Magn 2007;43(1):126-31.

[19]Persad C,Prabhu G,White G,Yeoh A,Eliezer Z.Characterization of hypervelocity gouge craters in rail conductors.IEEE Trans Magn 1997;33(1):401-5.

[20]Stefani F,Parker JV.Experiments to measure gouging threshold velocity for various metals against copper.IEEE Trans Magn 1999;35(1):312-16.

Received 15 September 2015;revised 21 December 2015;accepted 22 December 2015 Available online 19 January 2016

Peer review under responsibility of China Ordnance Society.

*Corresponding author.Tel.:+8615195985767.

E-mail address:wujg8848@163.com (J.G.WU).

http://dx.doi.org/10.1016/j.dt.2015.12.006

2214-9147/© 2016 China Ordnance Society.Production and hosting by Elsevier B.V.All rights reserved.

© 2016 China Ordnance Society.Production and hosting by Elsevier B.V.All rights reserved.

- Defence Technology的其它文章

- The ballistic performance of the bombard Mons Meg

- Innovative boron nitride-doped propellants

- Application of transient burning rate model of solid propellant in electrothermal-chemical launch simulation

- Calculation of propellant gas pressure by simple extended corresponding state principle

- Mechanism of plasma ignition in electrothermal-chemical launcher