Preparation of Fe3O4/M nOOH core-shell nanoparticles by a high-frequency im pinging stream reactor☆

Dongguang W ang*,Baikang Zhu,Hengcong Tao

Petrochemical&Energy Engineering School,Zhejiang Ocean University,Zhoushan 316022,China

Keyw ords:High-gravity Im pinging stream s M u lti-scale mixings Film-coating Nanocom posite

ABSTRACT W ell-defined Fe3O4/MnOOH nanoparticles with 61.1 em u·g-1 in magnetization intensity and 90.53 m2·g-1 in surface area have been syn thesized by a new-style of high-frequency im pinging stream(HFIS)reactor.In this reactor,two stream s first collided together toform nano Fe3O4 suspension,which subsequen tly flew through an S-shaped main channel to generate high-frequency reversing high-gravity fields.At the sam e time,24 thin liquid sheets im pingedin to the main channel at the frequencies higher than 100 Hz to create nano Fe3O4/M nOOH colloids.The ob tained pow ders were characterized by transm ission electron microscopy/energy dispersive spectrometer(TEM/EDS),X-ray diffraction(XRD),Brunner-Emmet-Teller(BET)and vibrating sam ple magnetometer(VSM).Experimental results indicated that low coating ratio prolonged the induction period of heterogeneous nucleation.The high-frequency im pingements of 24 thin liquid sheets greatly accelerated the macro-m ixing and the initial dispersion.The high-frequency reversing high-gravity fields prom oted the mesoand micro-m ixing.As a result,nano Fe3O4 cores were fleetly and uniform ly covered by MnOOH precu rsor.As a con tinuously operated and static high-gravity reactor,the high-frequency im pinging stream(HFIS)reactor is being developed to the large-scaled and low-cost production of various nanocom posites.

1.Introduction

Core-shell nanoparticles are high ly functional nanom aterials with modified properties[1].In recent years,they are attracting more and moreatten tion inm any im portantfieldssuch as ferrofl uids[2],biom edicals[3],photonic catalysis[4],solar cells[5],Microw ave absorption[6],m agnetoelectric materials[7]and semiconductors[8].Although several coating methods including precipitation[9],po lym erization[10],Micro-em u lsion[11]and sol-gel condensation[12]as w ell as layer by layer adsorption techniques[13]have been estab lished,the coating processes are often very slow due to slow mass transfer and batch operation.three prob lem s also arise from the slow mass transfer,including(1)agglom eration of core particles in the reaction media;(2)p referential form ation of separate particles of shell material rather than coating the core,and(3)incom plete coverage of the core surface[1].Batch operation not only low ers the yield bu t in terferes with the con tinuity of product quality.

In the field of process in tensification,the im pingements of thin liquid sheets[14-16]as w ell as high-gravity(HIGEE)technology[17,18]have been applied for many years.Inelastic im pingements of thin liquid sheets were an effective method for producing high local rates of energy dissipation,leading to rapid mixing on the molecu lar scale.The thickness of thin sheets was often low er than 0.1 mm,the im pingement angles were lim ited to less than 60°,and the typical sheet velocities were of the order of 10 m·s-1.Rotating packed bed(RPB)reactor as the original high-gravity reactor was em ployed to produce various nanom aterials on large scale[19-21].In RPB reactor,the rotating mesh packing broke feed liquidin to innum erab le liquid film s and droplets,which greatly in tensified the gas-liquid mass transfer and micro-m ixing[22].How ever,as the macro flow pattern in the RPB reactor was close to the dispersed plugflow,the liquid-liquidm acro-m ixingwasw eakened[23].

In view of these,a new-style of high-gravity reactor is being explored,which is nam ed as high-frequency im pinging stream s(HFIS)reactor.In this reactor,the S-shaped flow pattern of the main stream generates high-frequency reversing high-gravity field toform in tense secondaryflow[24].Meanwhile,24 branch stream sare instan taneously dispersedin to the main stream by the means of high-frequency im pingements of thin liquid sheets.Their flow pattern is similar to the accumulated plug flow.The above two flow patterns are beneficial to the liquid-liquid mu lti-scale mixings,which include macro-,m esoand micro-m ixings as w ell as initial dispersion.Thus,the attem pt is to continuously prepare core-shell nanom aterials by the HFIS reactor.

This paper described a coupled process of hom ogeneous and heterogeneous nucleation perform edin the HFIS reactor to syn thesize Fe3O4/M nOOH nanocom posite.The product was the precursor of nano magnetic lithium ion sieves(Fe3O4/H1.6M n1.6O4)[25-27],which w ou ld be dispersedinto seawater to salvage extrem ely sm all quantities of lithium ions and then be concentrated by magnetic field.In the reactor,two opposing stream s collided toform nano Fe3O4stream,which subsequently clashed with 24 thin liquid sheetsunder the reversing high-gravityfield toform nano Fe3O4/MnOOH suspension.It was found that the swift coupling processes could avoid agglom eration of nano Fe3O4cores.Furtherm ore,the fast multi-scale mixings achieved uniform coverage of the cores rather than form ing separate particles.

2.Experimental

2.1.Equipm ents

The structure of the HFIS reactor and the experimental set-up at laboratory level are displayedin Fig.1.The inner structure of the HFIS reactor looks like a mother fish chaperoning a baby fish,therefore it is also called Pisces reactor(PR).Its inner structure consists of an S-shaped reaction(orm ain)channel,two opposing channels,two couples of lateral channels and tw en ty-four branch channels.

The reaction channel is main ly connected by 26 sem i-circle channels.The im pinging angles between the reaction channel and every branch channel are all 30°.All of the channels have sam e cross section with 1.1mm-width and 5mm-dep th.Redindicator isused to alternately indicate thebranchflux distributionsof the twofishesby a three-w ay valve.The in tegrated flow s in the PR cou ld be observed distinctly through a bu llet-p roof glass and a 0.5 mm-thickness of transparen t silicone rubber film,as show n in Fig.1(b).In addition,the outlet of every branch channels is plugged by a 1.0 mm-diameter of stain less steel rod toform thin liquid sheet,and the sam e rods are also pluggedin the branch channels and lateral channels to balance the fluxes,as show n in Fig.1(c)and Fig.2.Fig.2 indicates the distribu tion ofstructure parameters and the op tim ized rod distribution in the PR.The values of those structure parameters are presentedin Table 1.In short,being a statichigh-gravity reactor,the HFISreactorhasgood sealing performance.

Fig.1.Experim ental set-up(a)of synthesizing nano Fe3O4/M nOOH,photograph(b)of PR and diagram(c)of an im pinging point between the suspension stream and a branch stream as w ellas the high-gravity directions.I—am ixed solution of Fe2(SO4)3,FeSO4 and M nSO4;II—sodium hyd roxide solution;III,IV—am ixed solution ofM nSO4 and H2O2;V—redindicator;1-6—Entrances1-6;7—threew ay valve;8—pH/temperaturemeter;9-11—liquidflow meter;12—discharged suspension;13,14—gasflow meter;15—opposing channel;16—reactive channel;17—branch channel;18—lateral channel;19—bypass;20—lateral entrance;21—p ressure gauge Fn—total flux of branch stream s.

Fig.2.Diagram of the structure parameter distribution and the op tim ized rod distribution in the PR.Ln—lateral channel lengths;ln—branch channel lengths;Fn—total flux of branch stream s;rn—radius of the sem i-circle channel in the reaction channel.

Tab le 1 Values of the structure parameters in the PR

2.2.Materials

Fe2(SO4)3(Tian jin BASFChemical Co.,Ltd.),FeSO4·7H2O(Sinopharm Chemical Reagent Co.,Ltd.),NaOH(Sinopharm Chemical Reagent Co.,Ltd.),MnSO4·H2O(Sinopharm Chemical Reagen t Co.,Ltd.)and H2O2(W uxi Jingke Chemical Co.,Ltd.)as the raw materials were of analytical grade and used without purification.The indicator was redink(HERO brand,Shanghai fine Stationery Co.,Ltd.).Deion ized water was used throughout the study.High pressure N2gas was em ployed toforcefive stream s to flow and collide in the PR.

2.3.Experim ental procedure

Theexperiments included two stages:(1)regu lation offlux distribution and(2)p reparation of the products.The elementary experim ental procedu res were as follow s.

Five solutionswere prepared and pouredinto thefive containers from I to V,as show n in Fig.1(a).The two volum es of liquids in Containers III andiV were 1200 ml and 1500 ml respectively,and their temperatures were kep t at room temperature.The two gas flow meters had been regulated to the set locations.N2with an appoin ted pressure(0.5-0.7 MPa)was introducedinto thefive containers.The two stream s from Containers I andiI were first pushedinto Entrances I andiI to create Fe3O4suspension.Subsequently,the two liquid flow meters controlling the two stream s from Container III andiV were turned up to 6.67 ml·s-1and 8.33 ml·s-1,respectively.W hen all the stream s in the PR were stab le,the 2.5 ml·s-1of indicator stream was alternately pushedin to the above two stream s to observe the b ran ch flux distribu tion.The discharged suspension was mon ito red by a pH/temperature meter and continuously collected by a series of beakers.The collecting time for every beaker was 20 s,and every volum e was measured.

2.3.1.Regulation of flux distribution

In order to con tro l the two-step reactive precipitations accurately,the flux distribution in the PR must be controlled exactly.This was realized by regu lating the pressure distribu tion in the PR.

The pressure of Con tainers I andiI can be stab ly con trolled by a gasflow meter and a pressure gauge,as show n in Fig.1(a).Therefore,the constantflux of F0was realized by con trolling the pressureofCon tainers I andiI.In order to make the two stream s from Con tainers I andiI to have equalfluxes,twomethods can beused to balance the two pressure drops:(1)File a rod andinsert it into the channel with higher flux;and(2)elevate the temperature of the stream with low erflux to decrease its viscosity.In reality,only the modu lating temperature method was adopted.Solution I was set at 308 K and Solution II was set at 336 K.

The two pairs of lateral fluxes were regu lated by two liquid flow meters.To confirm F1-11=F2-12and F13-23=F14-24,either pair of bypasseswasm ade to haveequal liquid con ten tsand observed w hether either pair of the lateral entrances turned red at the sam e time.

The branch flux distribu tion was con trolled by the pressure drops of the suspension stream,4 lateral stream s and 24 branch stream s.The pressure drop cu rve of the suspension stream was like a 24 steps of staircase due to the 24 times of collisions.Each step cou ld move up or dow n with the variations of im pinging fluxes.Furtherm ore,w hen a rod was insertedin to a channel,the higher flux through the rod led to the higher pressure drop.Therefore,the rods in the lateral channels generated higher pressure drops,and the rods in the branch channels generated low pressure drops.Correspondingly,the pressure drop curveofevery lateralstream seem ed likea shortstaircase,which shou ld be basically parallel with the long staircase.If the b lack suspension en teredin to a lateral channel by w ay of a branch channel,it suggested that the long and the short staircases hadin tersected.only w hen the redindicator arrived at the outlets of 12 branch stream s of either fish at sam e time,the branch flux distribution had been regu lated w ell.W hen the good flux distribu tion was repeatab le,the first stage wasfin ished.

2.3.2.Preparation of the products

The second stage was very easy.The redindicator was still used to observe the stability of the branch flux distribution before the discharged suspension was collected.Furtherm ore,the series of collected suspensions were selected according to an appointed volum e.The confirm ed suspension was treated by thermal hyd rolysis at 393 K for 24 h,follow ed by filtering,rinsing,and drying at 373 K to obtain nano Fe3O4/M nOOH pow ders.Nine typical sam ples were obtained and com pared,and their preparation conditions are listedin Table 2.

2.4.Product characterization

The morphology and elemental distribu tion of the nanocom posites were examined by a high-resolution transm ission electron microscopy(HRTEM;JEM-2011,JEOL Co.,Japan)together with an Energy Dispersive X-ray Detector system(Oxford,Britain).The particle crystal phase was characterized by a D8 Discover X-ray diffractometer(Bruker,Germ any).The magnetic hysteresis loops for sam ples were measured by a model-7410 Vibrating Sam ple Magnetometer(Lake Shore,Am erica).A specific surface area analyzer(JW-BK,China)was em ployed to characterize BET surface area.

3.Results and Discussion

3.1.Macro-distributions of operating parameters

3.1.1.Branch flux distribution

W hen every lateral stream sim u ltaneously arrives at the six exits of the branch channels,the branch flux distribution is related to the structure parameters of the PR including the lateral channel lengths(Ln),branch channel lengths(ln),as show n in Fig.2.Their relationships can be expressedin the following equations:

F2-12,F13-23and F14-24also can be expressed as the above two equations.Since the volum es of those inserted rods are not includedin Eq.(2),there exist sm all deviations of the fluxes.These sm all deviations are system atic deviations,because the rod distribution is unknow n w hen the PR is designed.Therefore,the designed flux distribution needs to be ad justed.M oreover,artificial deviations are also inevitab le w hen the flux distribu tion is observed.W hen F1-12=2 F1-11=6.67 ml·s-1and F13-24=2 F13-23=8.33 ml·s-1,the designed and ad justed b ranch flux distribu tions are show n in Fig.3.The maxim um positive and negative deviation ratios between them are+5.5%and-3.8%,respectively.

3.1.2.Other distributions

In term sof thead justed branchflux distribu tion,their outletvelocity distribution was between 1.0 ml·s-1and 1.8 ml·s-1assum ing that every outletwidth was0.1mm,and thesuspension velocity distribution can be calculated by the following equation:

Fig.4 indicates the distribu tion of the h igh-gravity level and the reversing frequencies with reversing times for the nine sam ples.The high-gravity levels are calculated by the following equation:

The reversion frequency means the recip rocal of time in terval for keeping a high-gravity direction,which is basically equalto the im pinging frequencies between the suspension stream and 24 branch stream s.The im pinging frequencym eans the recip rocalof time in terval between two ad jacent im pingements.The reversing frequencies and the roughfilm-coating time are calculated by the following equations:

Tab le 2 Preparation conditions of the nine sam ples

The rough film-coating time is 0.153 s for Sam ple 5,was 0.175 s for Sam ple 6 or 9,and 0.256 s for others.

If them ixing timesbetween every branch stream and the suspension stream are less than the induction time for nucleation,the precursor concentrations(cn)at 24 im pinging points can be calculatedin term s of the following equation:

Fig.3.Designed and ad justedflux distributionsof24 branch channelsin the PR.(Conditions:F1-24=15.0 ml·s-1;F1-12=6.67 ml·s-1;F13-24=8.33 ml·s-1).

where Knand c are the dilu tion ratio and the M n2+concentration in Container III or IV,respectively.

It is apparent that every parameter distribu tion is con tro lled by theflux distribu tion(F0-F24).As every branch flux is one order of magnitude low er than F0,the changes of F0have markedinfluences on these parameter distribu tions.

3.2.Form ation of nano Fe3O4 cores

Du ring the experimental processes the initial Fe3O4suspension was alw ayskep tat the concentration of0.15m o l·L-1and had been sam pled to characterize pure nano Fe3O4pow ders.The surface areas of the samples were between 70 m2·g-1and 100 m2·g-1and the magnetization intensities were between 50 em u·g-1and 75 em u·g-1.Fig.5(a)and Fig.8 indicate the TEM im ages and XRD patterns,respectively.It can be seen from Fig.5(a)that the nanoparticles agglom erate severely and their shapes are ellipsoid or similar to cube.

M oreover,the conversion time(t0)between the hom ogeneous nucleation of Fe3O4and the heterogeneous nucleation of M nOOH is an im portan t parameter.If t0is too short,the nano Fe3O4cores are still growing up.Contrarily,these nano cores agglom erate together.In the experiments,the t0is 0.0207 s for Sam ple 5,0.0259 s for Sam ples 6 and 9,and 0.0517 s for others.

Fig.4.Distributions of the high-gravity level(a)and the reversion frequency(b)with reversion times for the nine sam ples.

Fig.5.TEM photograph of pure nano Fe3O4(a)and pure M nOOH particles(b).

3.3.Film-coating process

The film-coating process in HFIS reactor is typical of heterogeneous nucleation process.The key for the form ation of uniform film is low and uniform supersatu ration degree of M nOOH precu rsor,which depends on the in tensifiedinitial dispersion,m eso-and micro-m ixings.The w hole reaction model can be expressed below:

(1)The w hite M n(OH)2sols were form ed and more easily oxidized than the nano Fe3O4cores.

II TheMn(OH)2solswere suddenly oxidized by hydrogen peroxide to precipitateMnOOH precursorson to the surfacesofnano Fe3O4cores.

In order to preven t nano Fe3O4cores being oxidized by hyd rogen peroxide,M n(OH)2so l shou ld be in excess.Therefore,Con tainer I alw ays con tained 0.013 mol·L-1of MnSO4,but the total molar ratio of MnSO4and H2O2in Con tainers I,III andiV was kep t at 2.0.

Pure M nOOH precipitate had been obtained at the pH value higher than 10.0,following thermal hyd rolysis at 393 K for 24 h.The TEM im ages and XRD patterns of the pure M nOOH pow ders are show n in Figs.5(b)and 8,respectively.

3.3.1.Effects of coating ratio

The value of coating ratio is equal to the molar ratio of Mn and Fe in the product.The ratio can not only be detected by TEM/EDS microscopy but also has im portan t influences on the product performances.Therefore,the ratios were firstly investigated by com paring the nine sam ples,w hose aim coating ratios ranged from 1.0 to 0.10.These aim ing coating ratios are realized by modu lating F0and the concentrations of Solutions III andiV,as show n in Table 2.

Table 3 show s the aim coating ratios,the EDS results,the means of the EDS results and the two deviation indexes for the nine sam ples.The two deviation indexes are the maxim um positive and negative deviation indexes from the average value am ong the EDS results.Every EDS result is marked with the corresponding scale of TEM photograph.The values of the two deviation indexes can distinctly reflect the meso-m ixing degrees of the nine sam ples.It can be seen from Tab le 3 that w hen the aim coating ratio is between 1.0 and 0.5,the deviation indexesare very high.How ever,with theaim coating ratio con tinuously being lowered from 0.5 to 0.125,the deviation indexes are sharply lowered from(+109%,-76%)to(+13%,-10%).This suggested that with the fall of the ratio,the induction period of nucleation is prolonged step by step.Thus,a longer dispersion time was provided for the initial dispersion,m eso-and micro-m ixings.

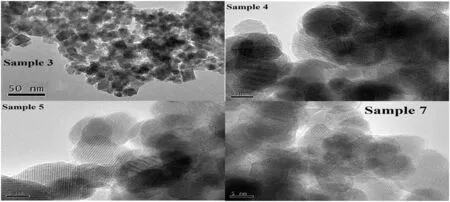

Moreover,the particle morphologies of Sam ples 1-3 are very different from Sam ples 4-9.The typical differences between them can be detected from Fig.6(Sam ples 3 and 4).Firstly the form er particles have edges and corners,whereas the latter shape is ellipsoid.Second ly,m any little chips and cloud substances cling to the particles of the form er,whereas the surfaces of the latter particles are clean.Third ly,the form er particle agglom erate is more severe than the latter particles.Clearly,the latter is form ed by heterogeneous nucleation bu t not the form er.The critical coating ratiofor the heterogeneous precipitation is around 0.23.

Fig.7 displays the Fe and Mn distribution maps of Sam ple 4 from a selected area electron microscope EDS.Upon comparison of the twofigures,it is found that the distribution of the Mn element on the surfaces of nano Fe3O4cores is basically w ell-p roportioned.This proves that the micro-m ixing is rough ly uniform in the area with a scale of 20 nm.

W hen the scale of microphotographs is shortened,m ore details em erged.For exam ple,Fig.6(Sam ple 4)displays the crystal lattices of partially naked core as w ell as the surface lattices of the shell.This im age not only verifies the existence of heterogeneous nucleation,but also explains w hy the particle surfaces are clean.Fu rtherm ore,this photograph also indicates thatm any nanoparticlesagglom erate together.This is due to defective coverage,which results from insu fficient micro-m ixing.The agg lom eration phenom enon is also observedin Sam ples5,7,8 and 9.Fig.6 also exhibits the TEM im ages of the Sam ples 5 and 7.

The XRD patterns of the nine sam ples disclose that excep t Sam ple 1,other sam ples only have the crystal phase of nano Fe3O4.Fig.8 show s the XRD patterns of four sam ples,pure nano Fe3O4and M nOOH powders.The XRD patterns im ply that with the decrease of coating ratio,the nucleation modes of M nOOH precu rsor experience crystalline precipitation,am orphous precipitation,and heterogeneous precipitation.

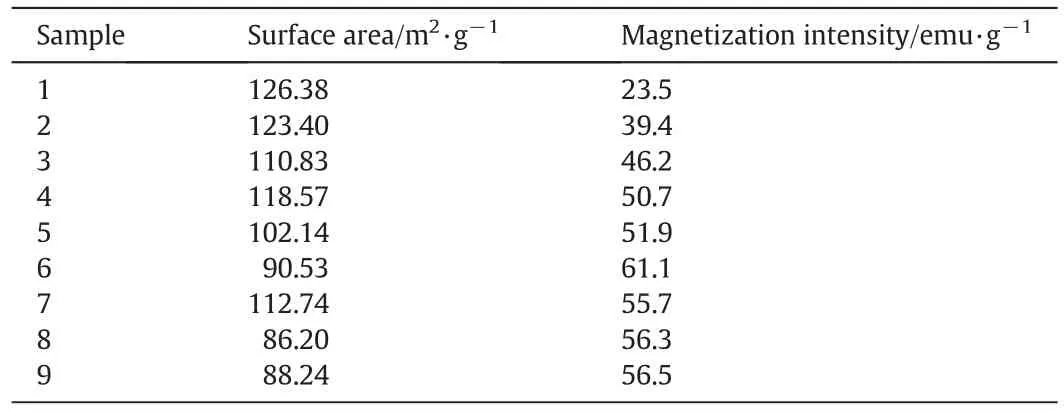

On the productp roperties,the surfaceareaandm agnetization in tensity were paid atten tion.Tab le 4 indicates the surface areas and the magnetization in tensities of the nine sam ples.As show n in Table 4,w hen the coating ratio reduced from 1.0 to 0.1,their surface areas decline from 126 m2·g-1to 86.2 m2·g-1but the magnetization intensitiesgradually riseup from 23.5 em u·g-1to 61.1 em u·g-1.The surface area of Sam ple 6 is low er than other sam ples excep t Sam ples 8 and 9.Meanwhile the magnetization intensity of Sam ple 6 was the highest am ong the nine sam ples.

Over all,the variationsof coating ratio main ly change the nucleation modeandinduction period,and thereforehave im portan teffectson the product performances.

3.3.2.Effects of initial suspension flux

For Sam ple 5,as its coating ratio is0.208 andits F0is2.5 times thatof Sam ple 4,its M n2+concentration in all branch stream s reaches to the value of Sam ple 2.How ever,the experimental results indicate that its M nOOH precu rsor is deposited by heterogeneous nucleation,andits deviation indexes are much low er than those of Sam ple 4.These mean that w hen the coating ratio is fixed,the increase of F0will not affect the dispersion process of M nOOH precursor.The reason is that theim pingements between the suspension stream and branch stream s realize rapid mixings,which can preven t hom ogeneous nucleation.This is an im portant performance of HFIS reactor.

Tab le 3 Aim coating ratios,EDS results,m eans and deviations for the nine sam ples

Fig.6.TEM photographs of the Sam ples 3,4,5 and 7.

Fig.7.Fe and M n distribution maps from a selected area electron microscope of Sam ple 4.

Fig.8.XRD patterns of four sam ples as w ell as the pure M nOOH and nano Fe3O4.

Tab le 4 Surface area and magnetization intensity values of the nine sam ples

Am ong thenine sam ples,only Sam ple8 and 9 take deionized wateras Solution IV.So the deviation indexes of Sam ples 8 and 9 only reflect the meso-m ixing degree in the baby fish.Furtherm ore,although Sam ples 4 and 8 have similar preparation conditions excep t Solution IV,the deviation indexes of Sam ple 8 are much higher than those of Sam ple 4.This im plies that the meso-m ixing degree in the baby fish is in ferior to that in the mother fish.Tab le 3 also indicates that although the coating ratio of Sam ples 8 and 9 is very close,the deviation indexes of Sam ple 9 are much low er than those of Sam ple 8.As the F0of Sam ple 9 is 2.0 times the figure of Sam ple 8,high F0can reinforce the meso-m ixing in the baby fish.

Am ong the six sam ples from 4 to 9,it is found thatSam ple6 is thebest product.Fig.9 gives the TEM im ages of the Sam ple 6.Fig.9(a)indicates that only several nanoparticles adhere together,even mono-dispersed particles can be observed.The agglom eration degree of Sam ple 6 is slightly.This phenom enon discloses that the coverage degree of Sam ple 6 was the highest am ong the six sam ples.Fig.9(b)show s that a core is perfectly covered by latticed film.Obviously,the film-coating process for the Sam ple 6 is con trolled by the in trinsic kinetics without the disturbance of micro-m ixing.Such a good micro-m ixing com es from not only the low precursor concentration butalso thehigh F0.This can be validated by Sam ple 7.The Sam ples 6 and 7 have similar precursor concentrations in the suspension stream,but the F0of Sam ple 6 is two times higher than that of Sam ple 7.Hence,the higher F0in tensifies the micro-m ixing of suspension stream.

In summ ary,the increase of F0can in tensify the meso and micro mixings of suspension stream,but not affect the nucleation mode w hen the coating ratio is fixed.

3.4.Analysis of engineering principles of HFIS reactor

The fundamental engineering principles of the HFIS reactor are the intensification of the mu lti-scale mixings between the suspension stream and the two stream s from the Con tainers III andiV.

3.4.1.High-frequency im pingements of thin liquid sheets

On the macro level,the h igh-frequency im pingements of the 24 branch stream s greatly in tensified the macro-m ixing.For Sam ple 6,the total time of the macro-m ixing(t1-24)is 0.175 s.Such a short time of macro-m ixing not only avoids the agglom eration of nano Fe3O4cores,but also im proves the productivity of the HFIS reactor.

On the micro level,in order to be close to inelastic im pingements,the im pact angle between the suspension stream and every branch stream is designed at 30°,the outlet width of every branch stream is less than 0.1 mm,and the im pact velocity of every branch stream is higher than 1 m·s-1.Thanks to the app roxim ate inelastic im pingements,the im pingements between the suspension stream and branch stream s realized rapid mixings.

3.4.2.High-frequency reversing high-gravity fields

Secondary flow(Dean Vortices)is d riven by the high-gravity fields and occurs in the planes perpendicu lar to the curved central axis of the channel[28].The Reynolds and Dean numbers can distinguish the secondary flow s and their intensities.The two numbers can be calculated as the following equations:

It is measured that w hen the suspension stream flow s through the reaction channel,its apparen t viscosity and density vary sligh tly.For Sam ples 6 and 7,its apparent viscosity varies between 2.51 mPa·s and 2.35 mPa·s,andits density low ers from 1.09 g·m l-1to 1.02 g·m l-1.Therefore,the Reynolds and Dean numbers of the suspension stream rise up main ly with the increase of flux.Fig.10 indicates the cu rves of the two numbers with the serial number of sem i-circle channels for Sam ples6 and 7.As the curvatures(d/2rn)of these sem i-circle channels are low er than 0.3,the criticalReynoldsand Dean numbersofsecondaryflow are less than 200 and 60 respectively[29].From Fig.10,it can be seen that the Reynolds and Dean numbers of the two sam ples are much higher than the two critical values and the two numbers of Sam ple 6 are much higher than those of Sam ple 7.As the meso and micro mixings of Sam ple 6 are much better than those of Sam ple 7,it can be deduced that the strong secondary flowin the 1.1 mm-width of reaction channel can greatly in tensify the meso and micro mixings.The influences of high-frequency reversing high-gravity direction on the film-coating process rem ain to be found.

Fig.9.TEM photographs of the Sam ple 6.

Fig.10.Cu rves of the two numbers with the serial number of sem i-circle channels for Sam ples 6 and 7.

In the long run,w hen the HFIS reactor scales up along the length direction of reaction channel,F0will be fu rther increased,and then the meso-and micro-m ixings will be further in tensified.Thus,HFIS reactor is more suitab le for large-scale production than the laboratory level.

4.Conclusions

Fe3O4/M nOOH nanocom posites have been successfully syn thesized by acoupling process in the HFISreactor.The followingm ajor conclusions can be d raw n from the study.

(1)The HFISreactorwas a static high-gravity reactor but can generate dynam ic high-gravity fields.

(2)The designed flux distribution was realized by regu lation of the pressure distribution.The initial suspension flux(F0)had markedinfluences on other im portant parameter distributions.

(3)with the fall of the coating ratio,the longer induction period was provided to the initial dispersion,m eso-and micro-m ixings.

(4)The high-frequency im pingements of thin liquid sheets and the high-frequency reversing high-gravity fields intensified liquidliquid mu lti-scale mixings,which were realized by increasing F0.

(5)The HFIS reactor was more suitable for large-scale production than the laboratory level.It will be used for the large-scaled and low-cost production of various core-shell nanocom posites.

Nom enclature

Chinese Journal of Chemical Engineering2015年4期

Chinese Journal of Chemical Engineering2015年4期

- Chinese Journal of Chemical Engineering的其它文章

- Accurate level set method for simulations of liquid atom ization☆

- Heat transfer augmentation in a circular tube with winglet vortex generators☆

- Influence of im peller diameter on local gas dispersion properties in a sparged mu lti-im peller stirred tank☆

- Pow er dem and and mixing performance of coaxial mixers in a stirred tank with CMC solution

- CFD simulation of high-temperature effect on EHD characteristics in a wire-plate electrostatic precipitator☆

- Em u lsion liquid mem brane for selective extraction of Bi(III)