CFD simulation of high-temperature effect on EHD characteristics in a wire-plate electrostatic precipitator☆

Yan Li,Chenghang Zheng,Kun Luo*,Xiang Gao,Jian ren Fan,Kefa Cen

State Key Laboratory of Clean Energy Utilization,Institute of Thermal Pow er Engineering of Zhejiang University,Hangzhou 310027,China

Keyw ords:Electro-hyd rodynam ic Electrostatic precipitation High temperature Ionic wind

ABSTRACT A com putational fluid dynam ics(CFD)m odel is carried out to describe the wire-plate electrostatic precipitator(ESP)in h igh temperature conditions,aim ing to study the effects of high temperature on the electrohydrodynam ic(EHD)characteristics.In the model,the com plex in teractions at high temperatures between the electric field,fluid dynam ics and the particu late flow are taken in to accoun t.W e apply different numerical methods for different fields,including an electric field model,Eu ler-Lagrange particle-laden flow s model,and particle charging model.The effects of high temperature on ionic wind,EHD characteristics and collection ef ficiency are investigated.The numerical results show high temperature causes more significan t effects of the ionic wind on the gas secondary flow.High viscosity of gas at high temperature makes particles follow the gasflow pattern more closely.High temperature reduces the surface electric strength,so that the mean electric strength w eakens the space charging.On the con trary,there is an increase in the diffusion charging at high temperature com pared with at low temperature.High temperature increases the ratio of mean drag force over mean electrostatic force acting on the particles which may con tribute to a decline of collection efficiency.

1.Introduction

Particle rem oval at high temperatures is a technology adoptedin many processes,such as in tegrated gasification com bined cycle(IGCC)and pressurized fluidized-bed com bustion(PFBC).High-temperature electrostatic precipitator(ESP)is an im portan t industrial techno logy for gas cleaning to meet the requirements of above applications.The electrostatic precipitation involves two major physical processes:particle charging and turbu len t transport of charged particles to the collection plates.The suspended particles are charged by both field charging and diffusion chargingm echanism s,then charged dustparticlesm igrate to the collecting plates due to the Cou lom b force[1].

M any numerical models have been developed to model the particle dynam ics in ESpin the past decades.Lam i et al.[2]developed the coupled system of the Poisson equation and the space charge d rift formula taking into account the charging processes with a finite difference schem e.Afinite volum ediscretization schem e for calculation ofcoupled electric and space charge density fields in ESP was presented by Neim arlija et al.[3].Schm id and Vogel[4,5]developed a numerical model coupling fluid flow and electric field.They show ed that the Lagrangian app roach is superior over the Eu lerian one,and the signi fican t effect of tu rbu lence on the electric field had been demonstrated.The dispersion of particles in turbulentflow under the influenceof electrostatic field was studied using direct numerical simulation by So ldati et al.[6].Choi and Fletcher[7]introduced com putational fluid dynam ics in the descrip tion of ESP operation.Yam am oto and Velkoff[8],Kallio and Stock[9]solved governing equations for fluid flow and electricfield to investigate the particu late-free secondary flowinteraction between those fields.The motion of charged particles suspendedin the gas stream had been studied by W atanabe[10]and Meroth et al.[11].How ever,the effects of particu late space charge were neglectedin their analysis.Cristina and Feliziani[12]in troduced the particle space charge effect in the calculation of the electric field and the curren t density distribution,and show ed that the charge developm en t of particles through their trajectories is much different from the saturation value,especially for sm all particles.Skod ras et al.[13]developed a CFD model for the descrip tion of fully coupled three coexisting fieldincluding the process of particle charging.How ever,in their work,only the space charging was considered due to the large particle size(m ore than 2 μm).Adam iak and Atten[14]estimated the numerical model for simulating precipitation of sub-Micrometer particles,both space charging and diffusion charging mechan ism s were included.Lin and Tsai[15]provided detailed spatial distribution of charged nanoparticles with the consideration ofnon-uniform distribution of flowfield,electricfield strength,andion concentration.They also investigated the partial charging effect.Guo et al.[16]developed a full scale ESP model to describe the wire-plate electrostatic precipitator,while discrete element method(DEM)was used to model the cake form ation process considering detailed particle-wall and particle-particle in teractions.M o reover,several possib le respects were suggested for fu rther study.Nouri et al.[17]studied the effect of the pressure on positive and negative corona discharge behavior in wire-to-plane electrostatic precipitato r.Lancereau et a l.[18]iden tified five dim ension less numbers to analyze wire-cy linder electrostatic precipitator under lam inar flow conditions.A modified fin ite element method(FEM)was developed to investigate the vibrations of co llecting electrodes by Now ak et al.[19].

Classical ESP numerical simulations have been widely investigated at room temperature in the past years as noted above.How ever,there are few data availab le in the literature regarding the simulation of ESPs under high temperature conditions above 573 K.Therefore,the main objective of cu rren t work is to develop a model to describe the effects of operating temperature from 273 K to 673 K on the electro-hyd rodynam ic characteristics in a wire-plate electrostatic precipitator.

2.Numerical Method

In this work,the descrip tion of high-temperature ESP operation is based upon a theoretical analysis focused on the gas flow,electricfield,particle dynam ics and particle charging,and each sub-process is separately described by their respective governing equations.The in tegratedm odel takes in to consideration allthe processes involvedinsidea high-temperature industrial ESP.

2.1.Gas phase hydrodynam ics

Due to the lim it of com puter capacity,the most effective w ay for practical com putation is to use time-averaged Navier-Stokes equations.For a steady-state incom pressib le turbulent flow,the govern equations can be written asConservation of mass:

Conservation of mom en tum:

In the above equations,ukis the gas velocity com ponent in the xkdirection,μtis the tu rbu lent dynam ic viscosity,and fDiis the d rag force per unit volum e.ρionand ρpcare the charge density of ion and particle,respectively,Eiis the electric strength com ponen t.The term(ρion+ ρpc)Eiexpresses the ionic wind effect on the gas flow.

The gas density and viscosity are influenced by temperature.Subm odels are used to implement the variation of densities and viscosities for the gas of different temperatures.

2.2.Electric field

In the wire-plate electrostatic precipitators,the electrostatic field and the ion charge density are high ly nonuniform and calculated by the following equations.

Poisson equation:

Cu rren t con tinuity equation:where φ is the electric poten tial,ε0is the perm ittivity of free space,kionis the mobility of ions,Ekis the electric strength in the xkdirection and Deis the effective diffusivity of ions.

The electric strength,Ei,can be defined by a sim ple relation:

The descrip tion of theelectricfiled and the ion density is implemented by solving scalar transport equations using a CFD code.The convective flux,diffusion coefficient and source term can be respectively sim plified as Tab le 1,where Φkis the scalar of in terest,Fiis the convective flux,Γkis the diffusion coefficient,and SΦkis the source term s.

Tab le 1 Term s of the scalar transport equations

2.3.Particle dynam ics

Since the particu late two-phase flowin industrial electrostatic precipitators is su fficien tly dilu te,the present study em ploys the Lagrangian app roach.Semm ar et al.[20]p roposed that particle-particle,wallparticle in teractions and coalescence phenom ena might be reasonably neglectedin the case of dilute gas flow s under strong electric fields.

For micron or above micron particles,the effects of Brow nian motion,therm ophoretic force and Saffm an lift force are negligible.In this work,the gravity of micron size particles has a very sm all order of magnitude com pared with d rag force and Cou lom b force.It is therefore assum ed that the force balance can be written as

where mpis the particlem ass,vpis particle velocity,FDiis the d rag force,qpEiis the Coulom b force and qpis the particle charge.

2.4.Particle charging

According to W hite[1],there are two distinct mechanism s for the charging of aeroso l particles:space charging and diffusion charging.The space charging occurs w hen the actual particle charge qpis sm aller than the saturation charge,qs,given by

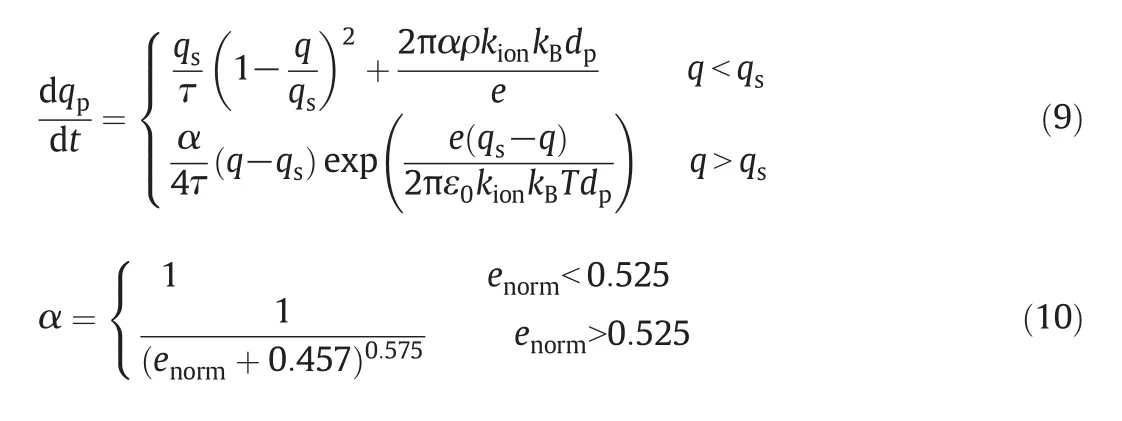

where ε0is the perm ittivity of free space, ε0=8.854 × 10-12C·V-1·m-1,εris the relative perm ittivity and dpis the particle diameter.Diffusion charging can occu r even for qpabove the satu ration level.The overall charging rate is given as[21]

whereτis the time constant(time taken for the particle to reach half the saturation),kBis the Boltzm ann constant and e is the electronic charge,e=1.6×10-19C.

W e can get the particle charge by integrating the charging rate.The particle charge density is calculated as

where Njis the number of particles visiting the con trol volum e,k is the index of particle,Δτ is the particle residence time in the cell,mpkis the mass flow rate and Vcis the cell vo lum e.

3.Com putational Details

3.1.Numerical schem es

In th is work,the wire-plate ESpis sim plified to two-dim ensional since the gravitation of fine particle is not considered due to its very sm all order of magnitude com pared with forces in other directions.The geometry of the 3-wire ESpis show n in Fig.1.The total length of co llection plate is 0.65 m,the diameter of corona wire is 5 mm,the wire-wire spacing is 0.15 mand the wire-plate spacing is 0.1 m.

Fig.1.Schem atic precipitator geometry.

Fig.2.Com putational mesh:(a)Total view,(b)wire close-up view.

Considering fourfinite volum e grids:33098 cells,62879 cells,91645 cells and 209811 cells,each model is developed as the gas flow rate is 0.03615 kg·s-1(linear velocity of 0.3 m·s-1)carrying the particles of 5 μm diameter at 673 K.The collection efficiencies represented by the ratio of the number of trapped particles and the total particles are 31.9%,35.0%,35.1%,34.8%,respectively.Since the variation of collection efficiencies for the particles of different cell numbers from 62879 to 209811 is sm all,the grid has little effect on the results which means that it is independent of the com putational results.So w e choose 62879 cells and the gridin form ation is show n in Fig.2.

3.2.Computational conditions

In order to assess the influence of the various parameters,a reference case is devised.The operating parameters are as fo llow s:the in let velocity of the gas is 1.0 m·s-1or the gas mass flow rate is 0.1205 kg·s-1w hen the Reynolds number based on the gas velocity Re=11050.The operating temperature is 293 K and electric poten tial at wire is 69514 V.In jected dust particles are assum ed to be spherical in shape with diameter of 5 μm and density of 1500 kg·m-3.They are in jected with the sam e velocity as the gas flow(1.0 m·s-1)from the in let boundary while the particle mass flow rate is 0.0001 kg·s-1.

The geometry and operating parameters of cases at norm al and high temperatures are show n in Table 2.

The Peek Law for a circular wire reads:

with

In above equations,Esis the electric strength at wire surface,δ is the relative density of gas with respect to the norm al conditions,R is the wire radius,T0=273.15 K,P0=101325 Pa.

The electric strength at the surfaces of all wire electrodes has the sam e value satisfying Peek's formula.Ion charge density at the wire is ad justed by the iterative process until the calculated electric strength agrees with the value calculated from Peek's formula.A user defined function is needed here.

Tab le 2 Applied boundary conditions

Yam am oto et al.[22]investigated the three-dim ensional flowin teraction for point corona industrial electrostatic precipitators using both lam inar and turbu len t flow models.He proposed that turbu len t model appears to be more app rop riate for predicting the wire-plate ESP based on experimental investigation.In this work,the RNG k-epsilon model and standard wall functions are em ployed to so lve the flowfield.The DPM perform s trajectory calculations for dispersed phases whereas the user defined functions are em ployed for body force(electrostatic force),scalar update(particle charge)and source(particle charge density).The comm ercial CFD code ANSYS FLUENT is used for the solution with the softw are capability of User Defined Functions(UDFs).

4.Results and Discussion

4.1.Model validation

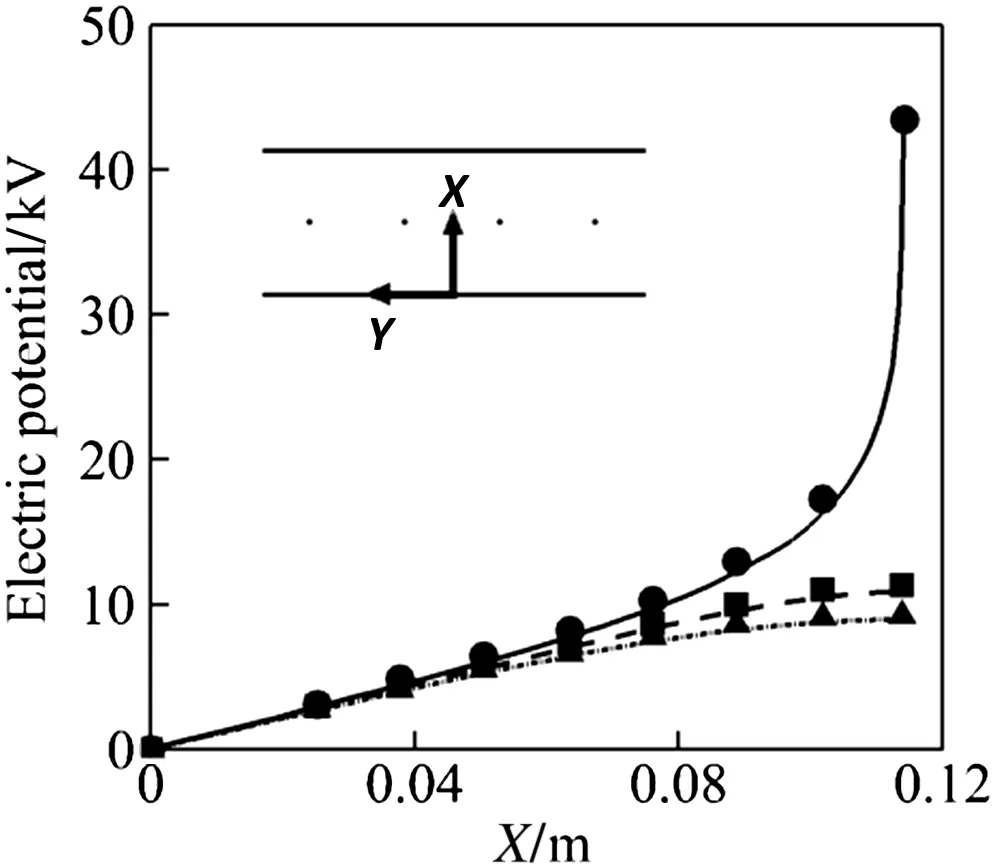

Though many relevan t experimental data in norm al temperature conditions are availab le,the experimental data at room temperature of Penny and M atick[23]is a classic,which is used to validate the numerical prediction using the presentm odel.The electric potentialis calculated for the precipitator geometry of Penney and Matick with the wire diameter of 0.3 mm and the applied voltage of 43.5 kV.The wireplate distance is 0.1143 mand the wire-wire distance is 0.1524 m.The electric poten tial distribu tions at different Y values along X direction are plotted respective in Fig.3.Obviously,the results are in good agreement with experim ental data,and the model seem s to be able to give better prediction.

Fig.3.comparison ofelectric potentialcharacteristicscurvesbetween com putationalresults and experim entaldata in the ESP.Exp.:●Ref.[23]Y=0.0762 m;■ Ref.[23]Y=0.0381 m;▲Ref.[23]Y=0 m.Cal.:Y=0.0762 m;=0.0381 m;=0 m.

The simulated mean transverse particle velocities at different norm alized positions X′(X′=X/S,S means the wire-to-wire distance)at a Y distance of 5 mm from the co llecting plate are com pared with the measurements at 293 K of Parasram[24]in Fig.4.In this case the bu lk gas-phase velocity is 3.0 m·s-1and the discharge wire diameter is 100 μm.The Al2O3seeding particles were used for the 20.0 kV discharge with diameters in the range 4 to 9 μm,density of 3970 kg·m-3and relative perm ittivity of 13.3.The com putational results are in good agreement with the experim ental results in the in let,outlet and the regions close to the wire.Though the simulated results generally give higher transverse velocities in the regions between two wires,the agreement between the calculated results of the particle mean migration velocity and the experimental data is satisfactory in the sense of engineering application.

Fig.4.comparison of transverse particle velocities between computational results and experimental data of Parasram[24].

The calculated collection efficiencies are com pared with the experimental data at 293 K of Kihmet al.[25]in Fig.5.They measured particle collection efficiencies foran 8-wirewire-plate ESPseeded with particles of diameter 4 μm at a bu lk flow velocity of 2.0 m·s-1with discharge wires of 0.1 mm diameter.The calculation results of this study are in good agreement with the experimental results.

Fig.5.comparison of collection efficiencies between com putational results and experim ental data of Kihm[25].

4.2.High-temperature effect on ionic wind

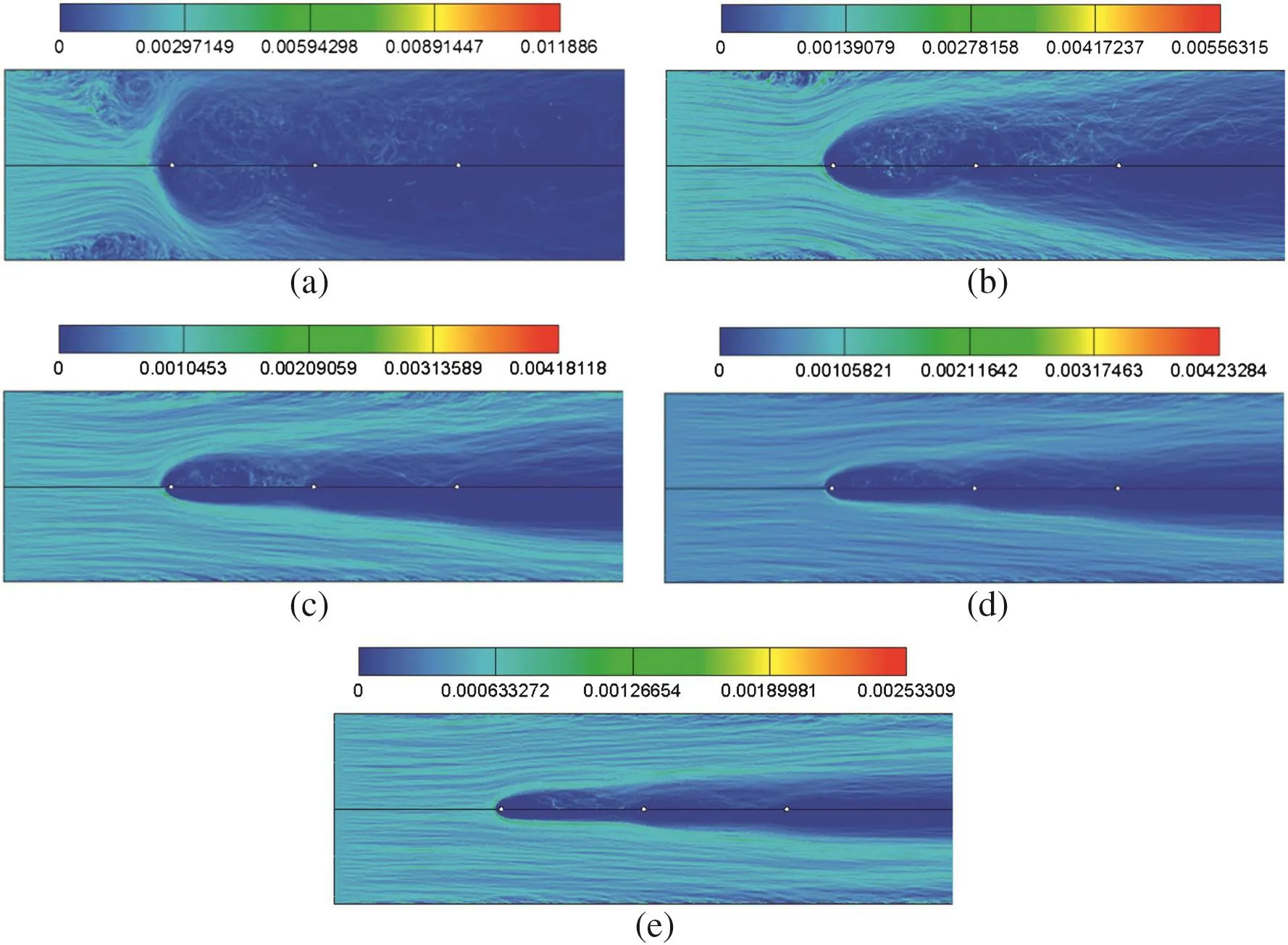

Figs.6 and 7 show the distribu tions of particle mass concentration for the particles of different temperatures and gas mass flow rates w hen dp=5 μm,respectively.High temperature causes more signi fican t effects of the ionic wind on the gas secondary flow by two possib le mechanism s:(1)The ion charge density increases with the rising temperature as show n in Fig.8,(2)the particles follow the gas flow pattern more closely due to an increase in gasviscosity athigh temperature.The influence of the secondary flowis not negligib le for low mass flow rate or lowin let velocity in Fig.7 according to the conservation of mom entum of gas.The effect of the particle diameter on the distribu tions is presentedin Fig.9.It show s that the ionic wind effect becom es more significant as the particle size decreases.It should be pointed out that the top half plots in Figs.6,7,9 rep resent the com putational results including the secondary flow caused by the ionic wind while the bottom not.

Fig.7.Particle concentration distribu tions for different gas mass flow rates:(a)0.0241 kg·s-1,(b)0.0482 kg·s-1,(c)0.0723 kg·s-1,(d)0.0964 kg·s-1,(e)0.1205 kg·s-1(T=573 K,d p=2 μm).

Fig.8.Variation of mean ion charge densities with different temperatures.m =0.0241 kg·s-1;m =0.0482 kg·s-1;=0.0723 kg·s-1; =0.0964 kg·s-1;m =0.1205 kg·s-1.

According to Eq.(2),the term(ρion+ρpc)Eirep resen ts the effects of the ionic wind on the flow field.Figs.6,7,9 show that the maxim um effects are foundin the region between the first and second wires for the probable reason that the ion charge densityρionhasam axim um close to the electrode.Besides,since the particle charge density ρpcreaches a maxim um close to the collection plate,there may be vortices in that region which causes collection efficiency loss.

Therefore,it seem s clear that the ionic wind effects cannot be ignored,particularly for sm all particles,low mass flow rate(lowin let velocity)and high temperature.

4.3.High-temperature effect on EHD and collection efficiency

The temperature has an influence on fluid properties,such as the density and viscosity of gas.The gas density becom es low er as the temperature increases,while the viscosity becom eshigher.Theelectrostatic and particle fields are also affected by temperature in several respects:(a)the ion charge density;(b)the electric strength at the surface of wire electrodes;(c)particle charging;and(d)operating voltage that can be used though it rem ains constant in this paper.

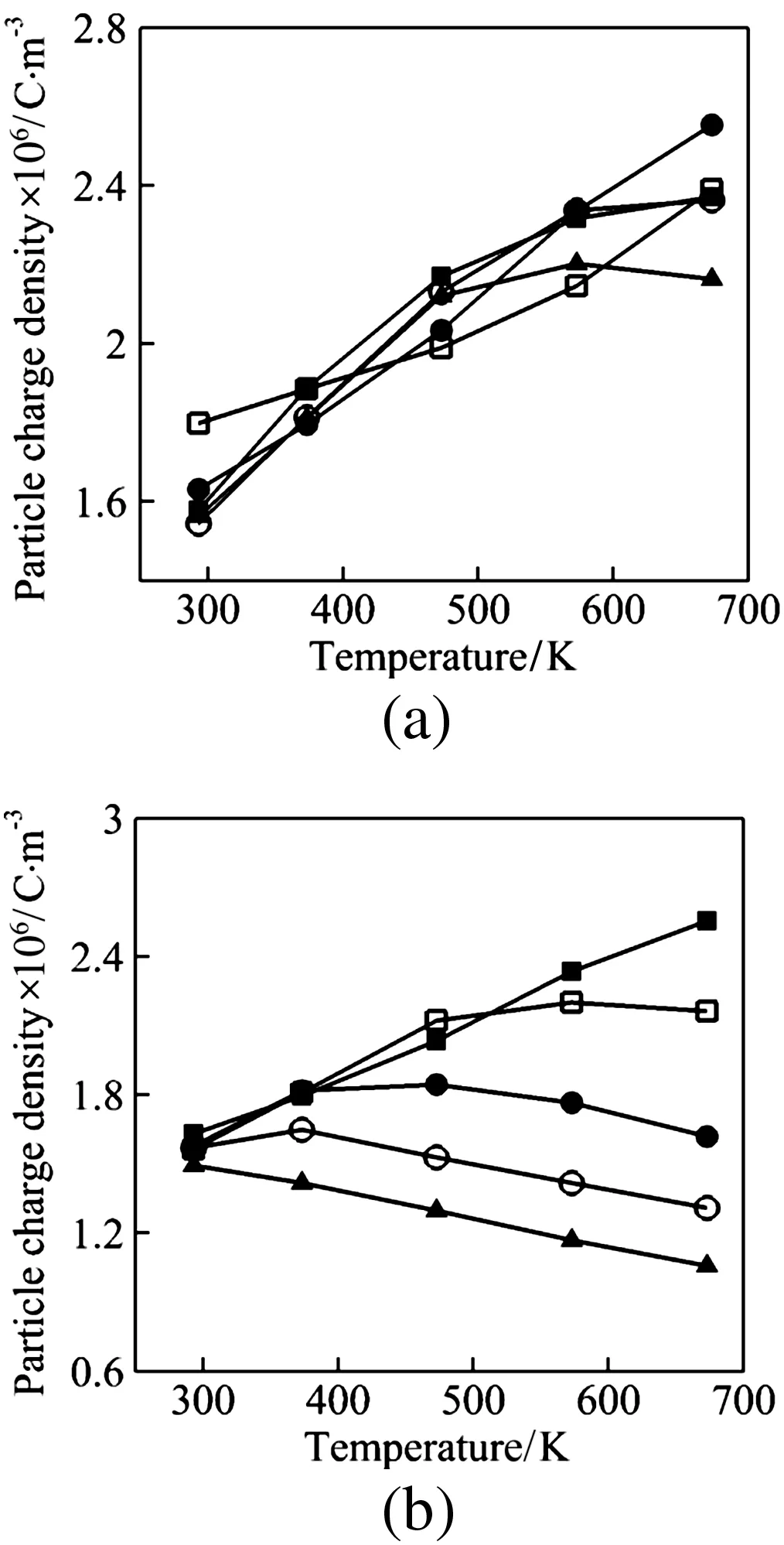

The mean charge densities for ion of different temperatures and gas mass flow rates(or velocities)are com paredin Fig.8.It is clear that the mean ion charge density increases with an increase in temperature,while the effect of gas mass flow rate is sm all.Note that the mean particle charge density is affected by both temperature andin let gas massflow rate seriously as show n in Fig.10(a)and(b).temperature affects the particle charge density by influencing the ion charge density and the residence time.The particle charging becom es easy due to the high value of ion charge density in high temperature conditions.High velocity causes short residence time,offering less opportun ity for a charged particle to travel the necessary distance before be collected at the electrode wires.Low velocity makes particles easily trapped which results short elapsed time.In summ ary,the calculated residence time has a low value in both low(being trapped easily)and high velocity regions(easily escaping).In other w ords,the residence time increases as the velocity increases initially and decreases afterw ards.Under the sam e mass flow rate conditions,the velocity has an increase with the temperature increases.Therefore,the residence time trends are different in different mass flow rates because of the different ranges of velocity as the temperature increases.

The particle charge density isdependen ton both the ion charge density and the residence time.As a result,the particle charge density has different trends as show n in Fig.10(b).It maybe alw ays increases,alw ays decreases,or increases first and then decreases.

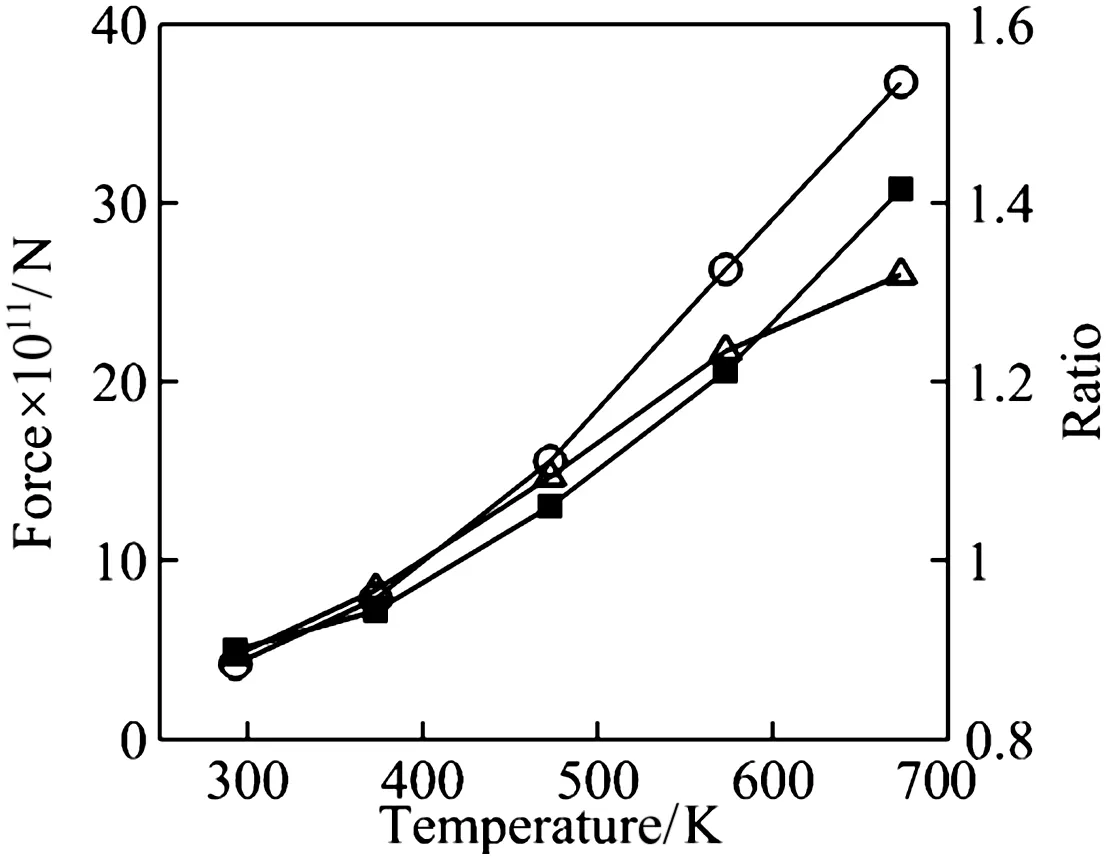

Theoretically,temperature affects the electric strength at the surface of all wire electrodes calculated from Peek's formula in Eqs.(14)and(15).The surface electric strength reduces as the temperature increases,so does the mean electric strength.According to the charging Eqs.(8)and(9),there is a reduction of the space charging and an increase in diffusion charging as the temperature rises.To sum up,the variation of electrostatic forces is show n in Fig.11.

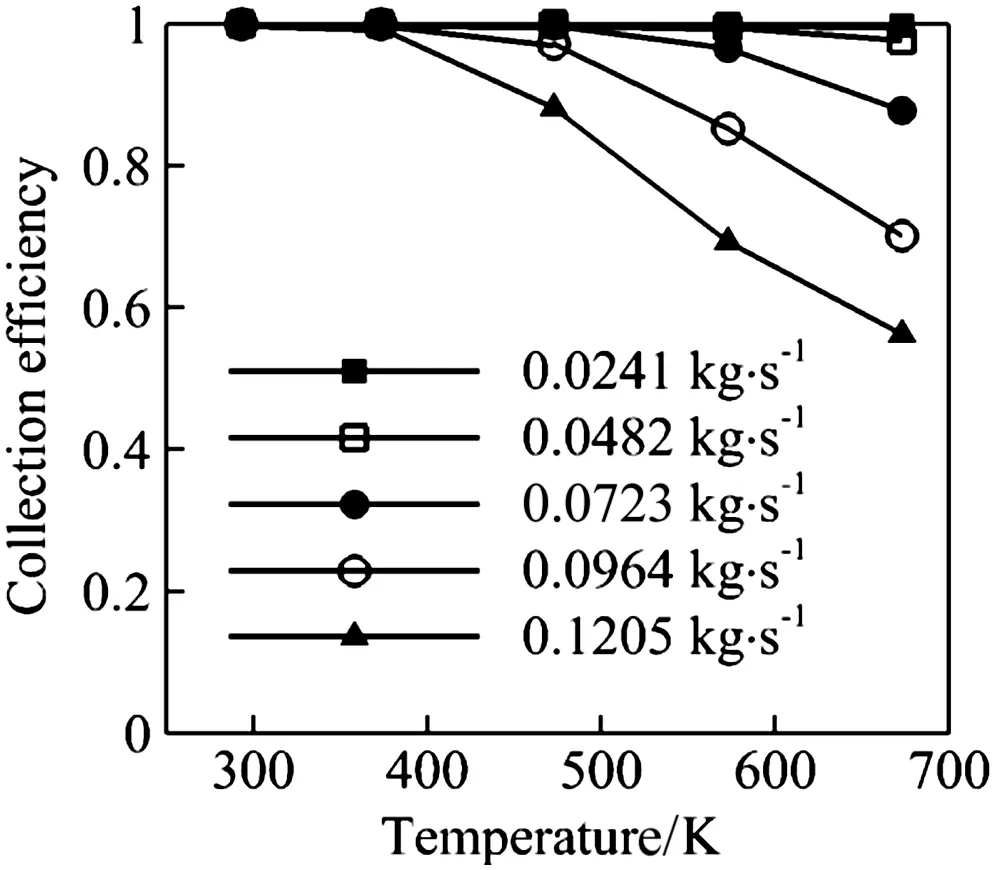

High temperature means high viscosity of gas,which may lead to a larger d rag force and particles fo llowing the gas flow pattern more closely.Fig.11 show s the ratio of mean d rag forces and mean electrostatic forces acting on the particles.It indicates that the percentage of d rag force has a slowincrease as the temperature goes up,which may con tribu te to the reduced collection efficiency.

Fig.12 show s the effects for particle diameter and temperature on the co llection efficiencies.It is w ell know n that large particle is easily to be trapped.Fig.13 presents the effects of temperature on collection efficiency with differentgasm ass flow rates,showing thathigh temperature decreases the collection efficiency under these circum stances.

Fig.10.Variation of mean particle charge densities with different temperatures.(a)= 0.0241 kg·s-1; = 0.0482 kg·s-1;=0.0723 kg·s-1; = 0.0964 kg·s-1; = 0.1205 kg·s-1;(b)=0.0723 kg·s-1;=0.1205 kg·s-1;m=0.1808 kg·s-1; =0.2410 kg·s-1;m =0.3012 kg·s-1.

Fig.11.Variation of mean electrostatic forces and d rag forces acting on the particles with different temperatures(m =0.0482 kg·s-1,d p=5 μm).Drag force;Electrostatic force;Drag force/Electrostatic force.

Fig.12.Variation of collection efficiencies for the particles of different temperatures and diameters(m =0.1205 kg·s-1).

Fig.13.Variation of collection efficiencies for the particles of different temperatures and mass flow rates(d p=5 μm).

Note that though theoperating vo ltage in thispaper is constant,high temperature causes lowincep tion voltage and low breakdow n voltage,so that theupper lim it decreases.Thatm eansahigher operating voltage can be usedin low temperature conditions than in high temperature ones.Many researches illustrated that the collection efficiency increases as theoperating voltage increases.So the collection efficiencym aybe reduced more in practical applications with low operating voltage.

5.Conclusions

A high-temperature ESP process model is em ployed by the application of numerical techniques.In this model,the electric field,gas-particleflow,particle charging,and the com plex in teractions am ong them can be simulated.The numerical observations on effects of hightemperature on the electro-hyd rodynam ic characteristics lead to the following conclusions:

(1)High temperature presents more significan t effects of the ionic wind on the gas secondary flow while the maxim um effects are foundin the region between thefirstand second wires.It isp robab ly attributed to the increase in ion charge density.

(2)High temperature means low gas density and high velocity for the sam e gas mass flow rate,w h ich leads to short residence time of the particles.Also high viscosity of gas makes particles follow the gas flow more closely.This maybe decreases the collection efficiency.

(3)High temperature reduces the surface electric strength,and as a result it reduces the mean electric strength and w eakens the space charging.On the con trary,there is an increase on the diffusion charging athigh temperature com pared with at low temperature.Taken together,the mean ion charge density increases with an increase in temperature,while the changing trend of the mean particle charge density depends on conditions.

(4)High temperature increases the ratio of mean d rag force and mean electrostatic force acting on the particles which maybe con tribu tes to a decline of collection efficiency.

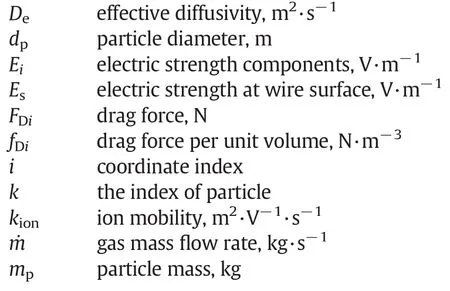

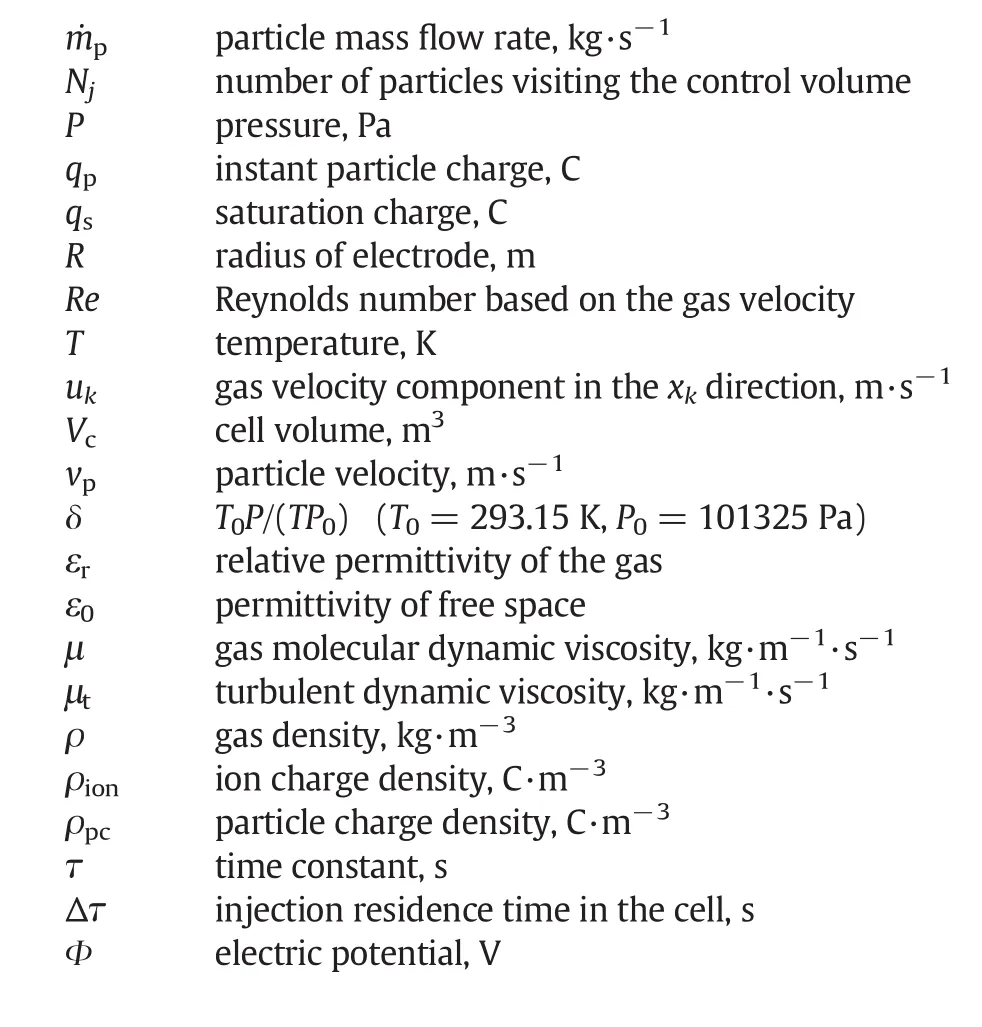

Nomenclature

Chinese Journal of Chemical Engineering2015年4期

Chinese Journal of Chemical Engineering2015年4期

- Chinese Journal of Chemical Engineering的其它文章

- Accurate level set method for simulations of liquid atom ization☆

- Heat transfer augmentation in a circular tube with winglet vortex generators☆

- Influence of im peller diameter on local gas dispersion properties in a sparged mu lti-im peller stirred tank☆

- Pow er dem and and mixing performance of coaxial mixers in a stirred tank with CMC solution

- Em u lsion liquid mem brane for selective extraction of Bi(III)

- Adsorption of zinc onto anionic ion-exchange resin from cyanide barren solution☆