Pow er dem and and mixing performance of coaxial mixers in a stirred tank with CMC solution

Yuyun Bao ,Yu Lu ,Qianqin Liang ,Li Li,Zhengm ing Gao ,Xiongbin Huang ,*,Song Qin 2 State Key Laboratory of Chemical Resource Engineering,Beijing University of Chemical Technology,Beijing 00029,China

2 Lanzhou Petrochemical,PetroChina,Lanzhou 730060,China

Keyw ords:Non-New tonian fluids Coaxial mixer Pow er dem and M ixing performance

ABSTRACT Experim entalinvestigationwas carried out in an ellip ticalbased stirred tankwith a diameter of0.48m to explore the power dem and and mixing performance of coaxial mixers.Syrup and CMC solu tion(sodium carboxy methy l cellulose)were used as the New tonian and non-New tonian fluids,respectively.Fou r different coaxial mixers were com bined with either CBY or Pfaud ler im peller as the inner one,and anchor or helical ribbon(HR)as the outer one.Results show that Pfaud ler-HR is the op tim ized com bination am ong four coaxial mixers in th is work,which provides the shortest mixing time given the sam e power consum ption.Com pared with the syrup solution,the increase of power inpu t can make the mixing time decreasing more obviously in the CMC so lution.The quan titative correlations forboth syrup and CMCsolutionswere established to calculate the power d raw and the mixing time of four coaxial mixers.

1.Introduction

M ixing operations involving high ly viscous fluids are comm only encounteredin chemical industry.Coaxial mixers have been designed for hand ling with such difficu lt conditions.Now adays,the vertical coaxial mixing devicehasbeen com prehensively investigated.Intensive studies on th is sub ject have been reported by Tanguy and his co-workers[1-12].The investigated coaxialm ixers consisted ofa dispersing turbine(Maxblend,Rush ton,PBT)com bined with a proxim ity im peller(anchor,helical ribbon).They concluded that the power draw n by the proxim ity im peller was significan tly influenced by the fast-rotating inner im pellers,bu t the power d raw n by inner im peller was not affected by the speed of the outer im peller.Moreover,they gave the im portant conclusion that the co-rotating mode is more efficien t than the coun terrotating one in all investigated configu rations[4,6,10].Liu et al.[13]also made the similar conclusions based on their CFD simulations on coaxial mixers.

After studying a stirred tank with an anchor as outer agitator and pitched b lade tu rbine(PBT),Rush ton tu rbine(RT),2-b lade hyd rofoil(CBY)as inner dispersion im pellers,Bao etal.[14]found that itwasnecessary to include the effect of speed ratio(RN)in the definition of the generalized power number and Reynolds number.Besides,they confi rm ed that the co-rotating mode was more efficien t than the coun terrotatingm ode in term sofpower consum ption andm ixing performance.Moreover,the power consum ption of the com bination of anchor with RTor CBYdecreasedm uchm ore than com bined with PBTin the lam inar regim e.Recently,the investigation of Li et al.[15]show ed that CBY or Pfaud ler as inner im peller has a better mixing performance than Rush ton or PBT as inner im peller in high viscosity New tonian sy rup so lutions.

How ever,there is no report about Pfaud ler and CBY as the inner im pellers in coaxial im pellers with non-New ton ian fluids.In th is study,besides Pfaud ler-HR and CBY-HR,Pfaud ler-anchor and CBY-anchor were also included to com pare both the power dem and and mixing performance as coaxial mixers in non-New ton ian CMC solution with different concentrations.Based on the previous investigation,only the co-rotating mode was tested to com pare with the inner im pelleronly configu rations.Besides,different correlations between mixing time and power inpu t were also ob tainedin bo th sy rup and CMC solutions for different coaxial mixers.

2.Experimental

2.1.Device and procedure

The presentexperiments fo llow the study of Li et al.[15]in the sam e tank with an ellip tical dished bottom with a diameter of 0.48 mand an aspect H/T of1,asschem atically show n in Fig.1.An opticalpowermeter was used to measure the mixing time,as detailedin Section 2.2.An inner im peller and outer im peller were am oun ted respectively on to two coaxial shafts.The rotational speeds of two shafts were controlled separately by twofrequency converters(VLT 5000,Dan foss Com pany,USA)so as to reach different rotational speed ratio.The inner highspeed dispersion im peller(CBY or Pfaud ler im peller)is moun ted 0.144 mabove the bottom,and the outer low-speed anchor or helical ribbon(HR)im peller is installed about0.01m apart from thewall of the tank with close-clearance.The speed ratio between the inner im peller and the outer im peller,RN,was kep t at 8,10,12,or 14.Based on our previous works[14,15],only the op tim al co-rotating mode and the inner im peller-only mode were testedin this work.

Fig.1.Schem atic of the experim ental setup.

The h igh-speedinner im peller provides strong shear rate to enhance local dispersion of the fluid,and both CBY and Pfaud ler impellers provide radial and axial flow s respective ly.The low-speed outer im pellers guaran tee full mixing in the tank and reduce the stagnan t zones,w h ich often appear near the wall and bo ttom of the stirred tank,especially with h igh viscosity fluids.HR can provide bo th axial and tangen tial flow s w h ile anchor provides only tangential flow.The experimental im pellers were demonstratedin Fig.2.Besides,geometrical parameters of these experimental im pellers are given in Tab le 1.

2.2.Measurement technique

2.2.1.Power consumption

The agitation speeds for both the outer and the inner im pellers were controlled separately by twofrequency converters and measured by a photoelectric tachometer.The torque of two shafts was measured with two separated torquemeters.The power consum ptions are given by

where M is the torque in N·m;pis the power consum ption in W;ω is the angular speed of the shaft in rad·s-1and N is the agitation speedin s-1.

2.2.2.Mixing time

Differen t methods cou ld be used to evaluate the mixing performance in a stirred tank,based on the change of physical properties or chemical processes.The physical methods,such as the conductivity change,pH variation,and so on,cou ld not be appliedin ou r present work involving the mixing of high viscous fluids because of the refreshing difficulty of the probe.Our present work makes use of decoloration method and an op tical power meter based on the reaction of iodine(I2)with a sodium thiosu lfate solution(Na2S2O3).First,10 ml iodine so lution with a concentration of 1.33 mo l·L-1was pou redin to the tank and the w ell-m ixed fluid appeared brow n.Then,11 ml of sodium thiosulfate solution(2.67 mol·L-1)was added to make the fluid decolorate.In the experiment,the monitoring probe was fixed between the inner and the outer im pellers,about 20 cm from the free surface.The sodium thiosu lfate solution was added to the opposite side of the monitoring position at the sam e distance to the shaft on the surface of liquid.Both feeding and monitoring positions were not changed so as to com pare the mixing time based on the sam e measurement configuration.The variation of the ligh t abso rp tion,caused by the co lorchanging fluid,was detected by an op tical power meter and reco rdedin to a computer[16].

The ligh t intensity variation with the time was monitored and show n in Fig.3 and the mixing time in all experiments was determined based on a 90%rule.Four measurements were taken for each experimental condition un til successive measurements differ by less than 10%,and theaverage mixing timewas calculated.Besides,all the experim ents were perform ed at room temperature.

2.3.Rheological properties of experimental fluids

Fig.2.Im pellers for experim ents.

Tab le 1 Size of experimental im pellers

Fig.3.Signal of mixing time measurement.

Syrup solutions of different concentrations were used as the New tonian fluids,and CMC(hyd roxymethyl cellu lose)so lutions of 2%or 3%concentrations as the non-New tonian fluids.The CMC solutions are typical shear-thinning fluids and their rheological properties cou ld be expressed by the power-law model as Eqs.(2)or(3):

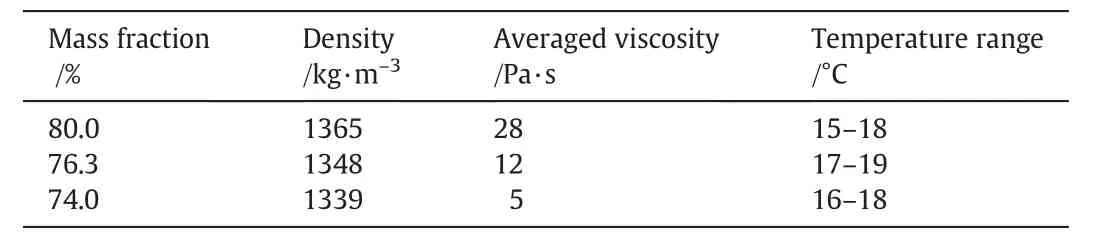

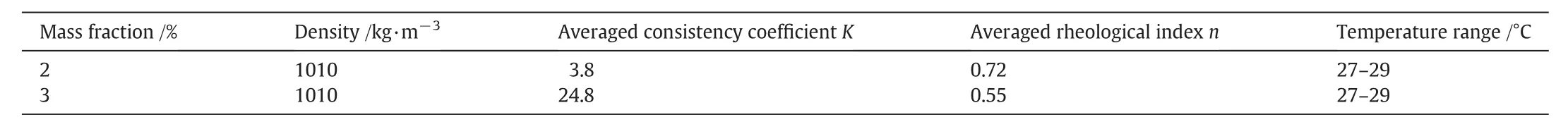

During each experiment,the actual temperature was recorded because it increased gradually due to agitation energy dissipated,and the rheological properties of fluids were measured every half an hou r by a rotational rheometer(RS150,Haake,Germ any)with a cone-plate sensor system of C60/1°Ti.All data related to the power consum ption orm ixing performancewere calculated based on the specific rheological properties of syrup or CMC solu tions measured every half an hour.The averaged rheo logical properties of the New ton ian and non-New ton ian flu ids usedin the experiments are show n in Tab les 2 and 3,respectively.

Tab le 2 Physical and rheological properties of syrup solutions

3.Results and Discussion

3.1.Pow er consump tion

3.1.1.Metzner-Otto constants for different impellers

In such non-New tonian fluids,the apparen t viscosity must be determinedin order to evaluate the power consum ption of the im pellers[17].M etzner and Otto[18]firstly reported that the average shear rate around the im peller was proportional to agitation speed and the proportionality parameter kswas know n as the Metzner constant in subsequen t pub lications.W e used the app roach of Reiger and Navok[19]to determine ksfor four im pellers including CBY,Pfaud ler,anchor and HR to obtain values of 11,11.8,25.9 and 56,respectively.These values of ksconstants are in good agreement with those reported by M etzner and Otto[18]and Nagata[20].

3.1.2.Power draw for individual impellers

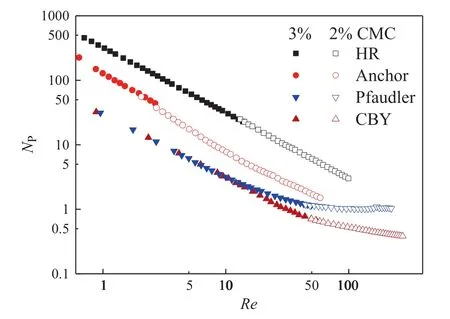

The characteristic power cu rveswith two differentCMCsolutions for four different im pellers as a single im peller are presentedin Fig.4.while measuring the power dem and of two inner im pellers,theanchor was installed and played the role of two baffles with the agitation speed of 0.The inner im peller was installed but not rotated w hen measuring the power dem and of each outer im peller.

Fig.4 show s that the slope of each cu rve is app roxim ately equal to-1 in the lam inar regim e,and the specific correlations between power numbers NPand Reynolds number Re are show n in Tab le 4.The lam inar regim e corresponds to Re values of 10 for two inner im pellers with sm all D/T of 0.70 and around 100 for anchor and HR with large D/T of 0.95 rotating at relatively sm all agitation speed,which is in good agreement with the results of Foucau lt et al.[4].

Com pared the power number cu rve for CBY with that for Pfaud ler im peller,w e can see that NPofCBY isalm ost the sam e as thatofPfaud ler in lam inar region with Re less than 10,corresponding to the sam e factor of about 2.8 for both CBY and Pfaud ler im pellers,as show n in Tab le 4.How ever,the decreasing tendency of the power number for Pfaud ler im peller becom es slow er after Re>50 than CBY.As for the outer im pellers,NPfor HR im peller is more than two times larger than that for anchor im peller.

3.1.3.Effect of outer impeller on inner impeller at different speed ratios

W e define the speed ratio as RN=Ni/No,where Niis the speed of inner im pellers and Nois that of outer ones.Fig.5(a)to(d)show s the characteristic power curves for the inner im pellers in two differentCMC solutions at different speed ratios RN.The values of NPand Re of inner im pellers were calculated based on Eqs.(4)and(5)with the Metzner constan t of 11:

Tab le 3 Physical and rheological properties of CMC so lutions

Fig.4.Pow er curves of each im peller in non-New tonian system s.

Tab le 4 Pow er number correlations for different im pellers in lam inar flow

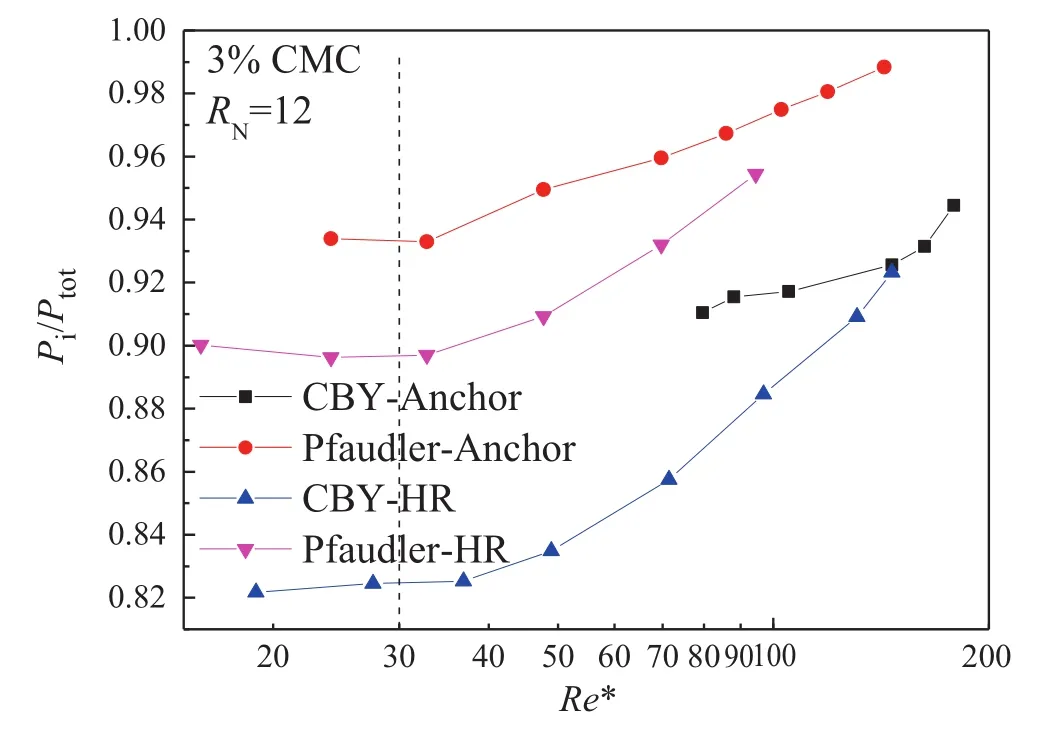

Fig.5 show s that the power draw of the inner im peller CBY is independen t of the anchor speed for the w ho le range of Re,as show n in Fig.5(d).How ever,Fig.5(a)to(c)show s that NPof either CBY or Pfaud ler in three coaxial im pellers is more or less influenced by the outer im peller w hen Re is less than 10.NPof HR is much larger than that of anchor,so that the power d raw ratio of the inner im peller to the total power d raw of the coaxial im pellers with HR as outer im peller Pi/Ptotis less than that in coaxial im pellers with anchor as the outer one.Fig.6 show s the relationship between Pi/Ptotand Reiwith the sam e scale of coordinate,based on the inner im peller.Pi/Ptotgrow s rapid ly to more than 90%for high RNand Re.This helps to explain w hy NPfor the inner im pellers is alm ost independent of the speed of the out im peller w hen Re is larger than 80.

3.1.4.Effect of inner impeller on outer impeller at different speed ratios

Fig.5.Pow er curves of inner im pellers at different speed ratios.

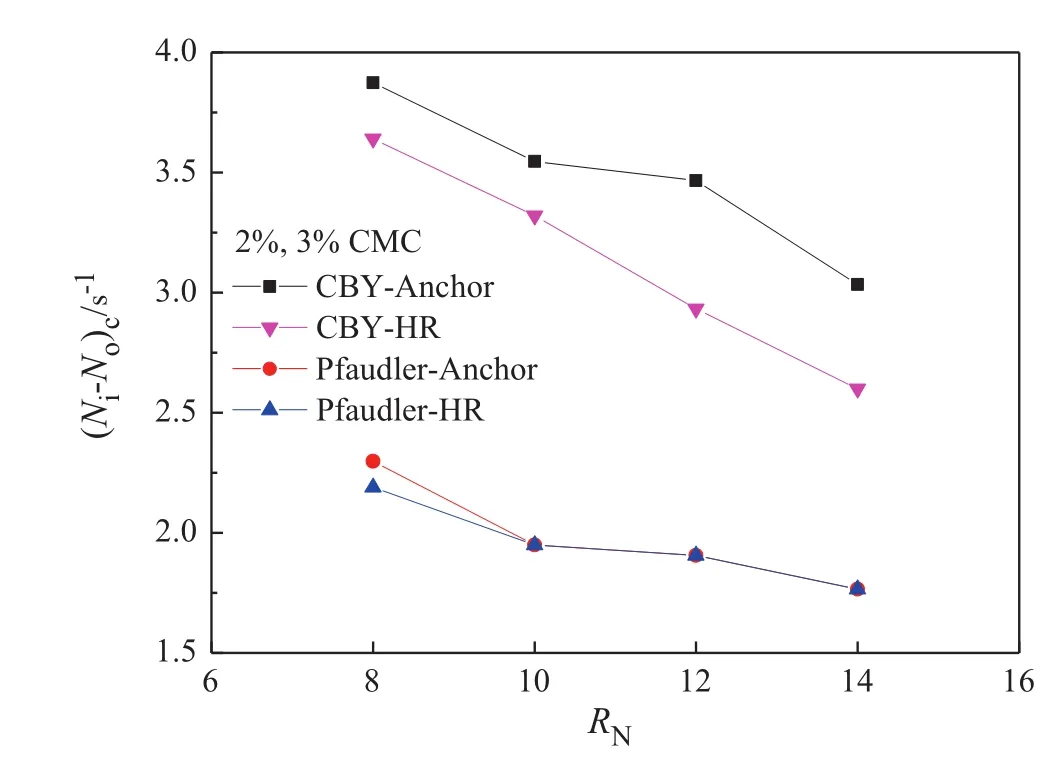

Fig.7 show s the relationship between NPof the outer im peller and Re′(based on the corresponding M etzner constant foreach outer im peller)for different speed ratios.NP(HR)or NP(anchor)was calculated based on the diameter and agitation speed of the specific outer im peller.The results for four coaxialm ixersshow that the power dem and of theouter im peller con tinuously decreases w hen RNincreases in the co-rotating mode.It can be explained by the positive force of the co-rotating inner im peller acting on them oving outer im peller.with the increasing agitation speed of the inner im peller,the power consum ption or measured torque of the outer im peller cou ld decrease to nearly zero.In order to explain this phenom enon,w e define(Ni-No)Cas the critical agitation speed difference between the inner im peller speed and the outer one while the power dem and of the outer im peller decreases to 10%of that for the outer im peller stirred-only.

Fig.8 show s the relationship between RNand(Ni-No)Cfor four different coaxial mixers.Com pared with CBY as the inner im peller,Pfaud ler has more im pact on the outer im peller,as indicated as the low er(Ni-No)Cin Fig.8.This shou ld be consideredin the design of the industrial coaxial mixers,otherwise the outer im peller will becom e the obstacle in the flow field agitated dom inan tly by the inner one,which should be avoidedin the industrial application.

3.1.5.Generalized power curves for coaxial mixers

The determination ofpower input isoneof them ost im portant tasks in the design of coaxial mixers.Although the mutual influence between inner and outer im pellers is com plicated,the inner im peller plays a more im portan t ro le in the coaxial mixers than the outer one.In our previous work[16],the speed ratio RNwas includedin the definitions of the generalized power number and Reynolds number,as expressedin Eqs.(6)and(7).How ever,the viscosity is not constan t for non-New ton ian fluids in this work,so that Eq.(6)was changedin to Eq.(8),with theMetzner constant11 for the inner im pellers.Itshould be noticed thatEq.(8)introduced them odified agitation speed(Ni-No/RN)into the calculation of the shear rates,not directly including the agitation speed of the inner im peller.

In the above equations,the negative sign rep resen ts the co-rotating mode usedin our present work.Eq.(8)degenerates to Eq.(6)w hen n equals to 1 for New tonian fluids.

Fig.6.Relationship between P i/P to t and Re i.

Fig.9 presents thegeneralized power curves in term sof Eqs.(8)and(7)for four coaxial mixers in co-rotating mixing mode.Reasonab le unifi ed power curve is resulted for each coaxial mixer with different speed ratios,which cou ld be used for the design of the industrial application.The generalized power numbers are main ly determined by the inner im pellers with similar power cu rves for CBY-HR and CBY-anchor with different outer im pellers and the sam e ru le cou ld be obtained for Pfaud ler-HR and Pfaud ler-anchor,too.In general,the inner im peller plays a dom inan t role in the power consum ption of the coaxial mixer.How ever,the op tim ization of the outer im peller relies also on the mixing performance of the coaxialm ixerswith different inner im pellers.

3.2.M ixing performance

3.2.1.Mixing time

The mixing times for four coaxial mixers in co-rotating mode were measured using the chemical deco loration method.Fig.10 show s the relationship between the dim ension lessm ixing time NTmand the generalized Reynolds number Re*,calculated by Eq.(8)for different coaxial mixers.

Fig.10 show s that NTmdecreases unsurp risingly with an increase of Re*,quite similar to that of single shaft mixers.How ever,the decreasing tendency of NTmwith Re*is obviously different for the coaxial mixers with different outer im pellers.Table 5 show s the quantitative correlation in the form of

The abso lu te value of the exponen t for both coaxial mixers with anchor as the outer im peller is about twice of that for coaxial mixers with HRas theouterone.The lastcolum n in Tab le5 lists the correlations with constan texponen t for the sam e outer im peller,suggesting that the factor A isdetermined by the inner im peller.A low er A for Pfaud lerand a higher A for CBY can be obtained with the sam e outer im peller.

Generally,the inner im peller plays a dom inan t ro le in the mixing performance of the coaxial mixers because of the large ratio of the power inpu t of the inner im peller,as show n in Fig.11.Given the sam e Re*larger than 40,Fig.10 show s that NTmfor Pfaud ler im peller is much sm aller than those with CBY as the inner one.How ever,the curves for Pfaudler-anchor and CBY-HR in tersect at Re*equaling to 30,w h ich cou ld be explained by Fig.11.The con tribu tion of the outer impeller HR for CBY-HR at low er Re*is about 18%,two times higher than that for Pfaud ler-anchor(about 6%),so that the in tersection of cu rves is caused by the con tribu tion of HR.

Fig.7.Pow er curves of outer im pellers at different speed ratios.

Fig.8.Relationship between R N and(N i-N o)C for four coaxial mixers.

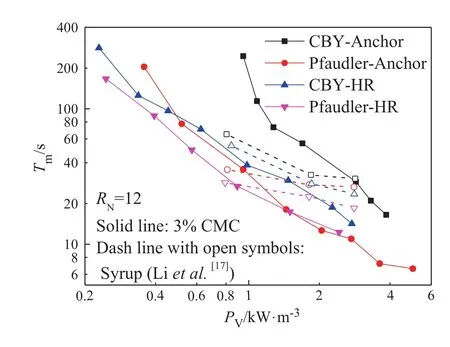

Since the power numbers for different coaxial mixers are quite different,it is necessary to evaluate the mixing performance of different coaxial mixers based on the specific power consum ption(PV).Fig.12 show s the relationship between the mixing time(Tm)and the specific power consum ption for four different coaxial mixers in co-rotating mode w hen RNis 12.with the increasing PV,Tmdecreases con tinuously.How ever,Tmfor Pfaud ler-HR and Pfaud ler-anchor are very close w hen PVis higher than 1 kW·m-3.It cou ld be explained by the dom inan t ro le of the inner im peller Pfaud ler with Pi/Ptothigher than 93%,as show n in Fig.13.Pfaud ler-HR cou ld be recomm ended for the future industrial application am ong four coaxial mixers because of its shortest mixing time for the given power consum ption,especially for the low er range of PV.

Thequantitative correlationsbetween Tmand PVfor differentcoaxial mixers are presentedin Tab le 6.The exponen ts for CBY-HR and Pfaud ler-HR are around-1.50,so a unified correlation with the comm on exponent of-1.50 is listed for Pfaud ler-HR,too.The mixing time cou ld be reduced about 31%w h ile changing the inner im peller from CBY to Pfaudler for the given power consum ption.It should be noticed that the correlations cou ld only be used for the comparison of the coaxial mixers under the similar experimental conditions.

Based on the data of Li et al.[15],similar correlations for the sam e coaxial mixers in New tonian syrup solutions are also listedin Tab le 6.W e included the Tmand PVcurves in syrup solutions as the dashed lines in Fig.12.Sam e as in CMC solutions,for a given PV,the mixing time for Pfaud ler-HR in syrupis shorter than that for the other three coaxial mixers.How ever,the abso lu te value of the exponen t for PVobtainedin sy rup solutions reduces to 1/8-1/5 of that ob tainedin non-New tonian CMC solutions.The sm aller exponen ts in syrup solutions im ply that the increase of PVcannot reduce the mixing time as effectively as in CMC solu tions.CMC solu tion is a typical shear-thinning non-New tonian fluid.Higher PVcorresponds to higher agitation speed and low er fluid apparen t viscosity,so that the fluid can be w ell mixed more easily.3.2.2.M ixing efficiency

Fig.9.Generalized power curves of each coaxial mixer.

Fig.10.Relationship between NT m and Re*for different coaxial mixers.

Since the mixing time has close relationsh ip with the power consum ption for the coaxial mixer,it is necessary to evaluate the mixing performance considering both the power d raw and mixing time.Zlokarnik[21]p roposed the mixing energy(π3)and the mixing time Reynolds numbers(Rem)to evaluate the mixing characteristics of im pellers:

Tab le 5 Correlations between NT m and Re*for different coaxial mixers

Fig.11.Relationship between P i/P tot and Re*for different coaxial mixers.

Fig.12.Relationship between T m and P V for different coaxial mixers in different fluids.

Fig.13.Relationship between P i/P tot and P V for different coaxial mixers.

where Tmis the mixing time;μais the apparent viscosity of the non-New ton ian fluid defined by Eq.(3);and T is the tank diameter.Them ixing energy π3is proportional to the product of power inpu t and the square of the mixing time,so that the sm aller π3refers to the higher efficiency of the im peller.

Table 6 Correlations between T m and P V for different coaxial mixers

Fig.14 show s the relationship between the mixing energy(π3)and the mixing time Reynolds numbers(Rem)for all four coaxial mixers in co-rotating mode at RNof 12.

Fig.14.Relationship between mixing energy and mixing Reynolds number.

with the increaseof Rem,them ixingenergy decreasesevidently forall four coaxial mixers.Am ong them,Pfaud ler-HR in co-rotating mode is the most effective one to mix the CMC solutions usedin our experim ents.

4.Conclusions

In high viscosity New tonian and non-New tonian fluids(corn syrup and CMC solutions),the power consum ption and mixing time for four coaxial mixers with HR and anchor as the outer im peller and CBY and Pfaud ler as the inner dispersion im pellers were investigated.

The power curves of the inner im peller(Pfaud ler or CBY)are alm ost independen t of the outer im peller in a coaxial mixer system.How ever,the power dem and of the outer im peller(HR or anchor)decreases constan tly with the increase of the im peller speed ratio RNin a co-rotating coaxial mixer system.The definitions of generalized NP*and Re*were modified to suit the CMC fluids with a reasonab le agreement am ong all different im peller speed ratios.The generalized power number NP*of the coaxial mixers is determined only by the inner im peller and NP*with CBY as inner im peller is only about 40%of that with Pfaud ler as inner one w hen Re*is larger than 100.

The quan titative relationships between Tmand PVfor four coaxial mixers in both syrup and CMC so lutions were correlated as the reference for industrial design.In both types of solution,the mixing time for Pfaud ler-HR is shorter than other three coaxial mixers for the given PV.M oreover,the mixing time Tmdecreases faster with the increase of PVin shear-thinning CMC solution than that in syrup solution.The mixing performance can be im proved more effectively by increasing PVin the shear-thinning fluids than in New tonian fluids.

Nomenclature

Chinese Journal of Chemical Engineering2015年4期

Chinese Journal of Chemical Engineering2015年4期

- Chinese Journal of Chemical Engineering的其它文章

- Accurate level set method for simulations of liquid atom ization☆

- Heat transfer augmentation in a circular tube with winglet vortex generators☆

- Influence of im peller diameter on local gas dispersion properties in a sparged mu lti-im peller stirred tank☆

- CFD simulation of high-temperature effect on EHD characteristics in a wire-plate electrostatic precipitator☆

- Em u lsion liquid mem brane for selective extraction of Bi(III)

- Adsorption of zinc onto anionic ion-exchange resin from cyanide barren solution☆