Modified sewage sludge as temporary landfill cover material

Jun He*,Feng Li,Yong Li,Xi-lin Cui

College of Civil and Architectural Engineering,Hubei University of Technology,Wuhan 430068,PR China

Received 20 December 2013;accepted 19 March 2015

Available online 17 August 2015

Modified sewage sludge as temporary landfill cover material

Jun He*,Feng Li,Yong Li,Xi-lin Cui

College of Civil and Architectural Engineering,Hubei University of Technology,Wuhan 430068,PR China

Received 20 December 2013;accepted 19 March 2015

Available online 17 August 2015

Abstract

In order to study the feasibility of modified sewage sludge as landfill cover material and its performance in a complex landfill environment,strength and hydraulic conductivity tests were conducted.The permeability requirements for daily and interim covers were analyzed first.Based on saturated-unsaturated seepage calculations,it is suggested that approximately 1.0×10-4cm/s and 1.0×10-5cm/s are the appropriate values for the hydraulic conductivities of daily and interim covers,respectively.The strength and permeability requirements of the mixtures,when used as an interim cover,can be met at a sludge:lime:cement:silt:tire-derived aggregate(TDA)weight ratio of 100:15:5:70:15.Results also demonstrate that the solid content ratio of modified sewage sludge,which should be greater than 60%when modified sewage sludge is used as a temporary cover material,is crucial to both strength and hydraulic performance.In addition,as the duration of soaking of modified sewage sludge in synthetic leachate increases,the unconfined compressive strength increases,and the hydraulic conductivity decreases slightly or fluctuates between 1.0×10-5cm/s and 1.0×10-6cm/s,still meeting the requirements for an interim cover.The reduction in hydraulic conductivity of modified sewage sludge under the effect of synthetic leachate,as well as the long-term and environmental performance of the modified sewage sludge,should be examined in future studies.

©2015 Hohai University.Production and hosting by Elsevier B.V.This is an open access article under the CC BY-NC-ND license(http:// creativecommons.org/licenses/by-nc-nd/4.0/).

Modified sewage sludge;Temporary cover;Hydraulic conductivity;Unconfined compressive strength;Soaking

1.Introduction

In China,the output of urban sewage sludge has been dramatically increasing year by year.However,sludge treatment and disposal technology has lagged behind.The publication Report on Sludge Treatment and Disposal Market in China(2011),from www.h2o-China.com,pointed out that by 2010 the quantity of dewatered sludge was close to 22 million tons,of which 80%were not disposed of properly.Sludge contains a large quantity of pollutants,which may cause secondary pollution to the environment if handled improperly. On the other hand,in a sanitary landfill,a large amount of cover material is usually needed to cover the garbage,as required in Technical Code for Municipal Solid Waste Sanitary Landfill(CJJ 17-2004).Sludge can be used as an alternative to traditional cover materials such as soil.Furthermore,the pollution caused by sludge can be prevented in a closed landfill system.However,as sludge usually has relatively high water content and low strength,modifications are necessary to improve its mechanical properties if it is used as a cover material in landfills.

Cover systems can be divided into temporary cover(including daily cover and interim cover)and final cover,and,according to CJJ 17-2004,the upper limit of the hydraulic conductivity(k)forafinalcovermustbelessthan 1.0×10-7cm/s.There is no specification of hydraulic conductivity for daily cover,as its main purpose is not to reduce the rain invasion.As for an interim cover,the hydraulicconductivity must be low enough to prevent the waste from being exposed to rain,but the value is not stipulated explicitly in CJJ 17-2004.However,in recent decades,suggestions given for the hydraulic standard of temporary covers have been controversial.Li et al.(2003)suggested that the hydraulic conductivity of a temporary cover in a bioreactor landfill be high enough to facilitate the recirculation of leachate,but not so high as to ensure uniform degradation and waste stability. Therefore,they recommended that the hydraulic conductivity be maintained at the order of 10-4cm/s for a bioreactor landfill,but low enough for a traditional landfill to reduce the output of leachate.Some researchers have pointed out that the hydraulic conductivity of a temporary cover,like that of a final cover,should not exceed 10-7cm/s(Ng and Lo,2007;Chen et al.,2011).Kamon et al.(2002b)suggested that when sludge barrier layers have a hydraulic conductivity of less than 1.0×10-5cm/s,daily cover systems intercept rainwater at a satisfactory level.Meanwhile,other researchers have argued that daily cover and municipal solid waste should be more permeable,or that they should have hydraulic conductivities greater than 1.0×10-4cm/s.That way,standing water on the cover surface can be prevented(Ma et al.,2007;Jiao,2007;Md and Mohamed,2012).Zhang(2007)determined that soils with either high or low hydraulic conductivity are not suitable as interim cover materials,since soils with high hydraulic conductivity fail to control rainfall infiltration,and soils with low hydraulic conductivity might cause perched leachate.However,Zhang(2007)did not consider the effects of permeability of the daily cover and waste.Alternative daily cover materials are suggested in Standard Guide for Evaluation and Selection of Alternative Daily Covers(ADCs)for Sanitary Landfills(ASTM,2005),including foams,spray-on slurries,geosynthetics,and indigenous materials(such as sludge,ash,and shredded tires),which have different levels of permeability.In general,the hydraulic conductivity of solid waste might vary between 3.7×10-5cm/s and 4×10-2cm/s,according to Qian et al.(2010).Therefore,consider the effects of permeability of the daily cover and waste on the leachate migration in landfills should be considered.

The properties of deeply dewatered sludge and modified sludge used as temporary landfill cover material have been studied by a number of researchers(Wang et al.,1992;Moo-Young and Zimmie,1996;Kamon et al.,2002a;Kim et al.,2005;Jiao,2007;Ma et al.,2007;Chen et al.,2011,2013;Zhou et al.,2011).It has been found that sludge can be used as temporary cover material because of its strength,hydraulic performance,and capability of leaching toxicity.So far,the relevant studies have not given adequate concern to the effects of leachate on the properties of the temporary cover.In fact,during the operation and after the closure of a landfill,the temporary cover is soaked in the leachate.The interaction between cover material and leachate might change the properties of cover material,such as the strength and hydraulic conductivity.The effect of leachate on the hydraulic conductivity of clay liner has received much attention(Frempong and Yanful,2008;Guyonnet et al.,2005).After deeply dewatered sewage sludge was soaked in de-aired water and leachate for one or two months,the strength was found to show a decreasing trend and the permeability an increasing one(Chen et al.,2011,2013).In spite of these findings,there is still a lack of deep understanding of the interaction between leachate and modified sludge.

When used as landfill cover material,sludge is usually modified with cement,lime,slag,mineralized refuse,and construction waste(Kamon et al.,2002a;Kim et al.,2005;Jiao,2007;Ma et al.,2007;Zhou et al.,2011).Silt and fly ash can be used as an additive to construct the skeleton(Li,2006;Yang et al.,2012).As a light-weight material and good adsorbent of organic contaminants,tire-derived aggregate(TDA)has been mixed with paper sludge as a daily cover material to improve the quality of leachate and overall stability,and to reduce settlement of solid waste(Ng and Lo,2007,2010).Nevertheless,the hydraulic conductivities of such modified sludge are usually very low(generally around 1×10-7cm/s)(Ng and Lo,2007),which might make them unsuitable for daily cover.In this study,traditional modification materials(i.e.,quicklime and cement)along with some waste materials(i.e.,abandoned silt and TDA)were used in combination to alter the sludge properties.

One objective of this study was to determine the permeability value appropriate for temporary cover.The effects of hydraulic conductivity of interim and daily covers on the leachate migration were analyzed with unsaturated and saturated seepage software(SEEP/W).Another objective was to examine the strength and hydraulic performance of the modified sludge proposed in this study after soaking it in water and synthetic leachate.Based on the results of the study,the potential effectiveness of the proposed modified sludge as temporary landfill cover material is discussed.

2.Appropriate permeability for temporary covers

The finite element program SEEP/W was used to analyze the leachate migration through a landfill element.The simulation test was run in stages:initially,from a drainage layer,only the first waste discharge and daily cover were simulated,and,afterwards,the first interim cover,the second waste discharge and daily cover,and the second interim cover were added in turn.The thicknesses of the drainage layer,waste and daily cover,and interim cover were 0.4 m,7.6 m,and 0.4 m,respectively.Each layer was deposited for one year before another one was input,and the total simulation time was four years.

Waste and daily cover was assumed to be a single homogeneous medium and buried instantaneously.According to the summary by Qian et al.(2010),the saturated hydraulic conductivity of the waste and daily cover layer were set to a minimum value(i.e.,3.7×10-5cm/s),an average value(i.e.,1× 10-3cm/s),and a maximum value(i.e.,0.04 cm/s),respectively.A drainage layer with a saturated hydraulic conductivity of 1×10-2cm/s was assumed to be located at the base of the waste.Saturated hydraulic conductivities of two interim covers were set to 1×10-5and 1×10-6cm/s for two simulations.

In the simulations,both the waste and daily cover and the interim cover were assumed to be composed of unsaturated materials.The soil-water characteristic curves of the shallow waste and silty clay reported by Zhang(2007)were used,and the unsaturated hydraulic conductivity was calculated using the van Genuchten(1980)model.Initial pressure was set to -5 kPa.Zero pressure head was applied to the bottom boundary in order to simulate the free discharge,and the top was a flux boundary.When the rainfall intensity was greater than the hydraulic conductivity,the flux boundary was set to zero pressure head to simulate the surface runoff.The value of the rainfall intensity was selected according to the average meteorological data of Wuhan,in Hubei Province,China,neglecting the effect of evapotranspiration.

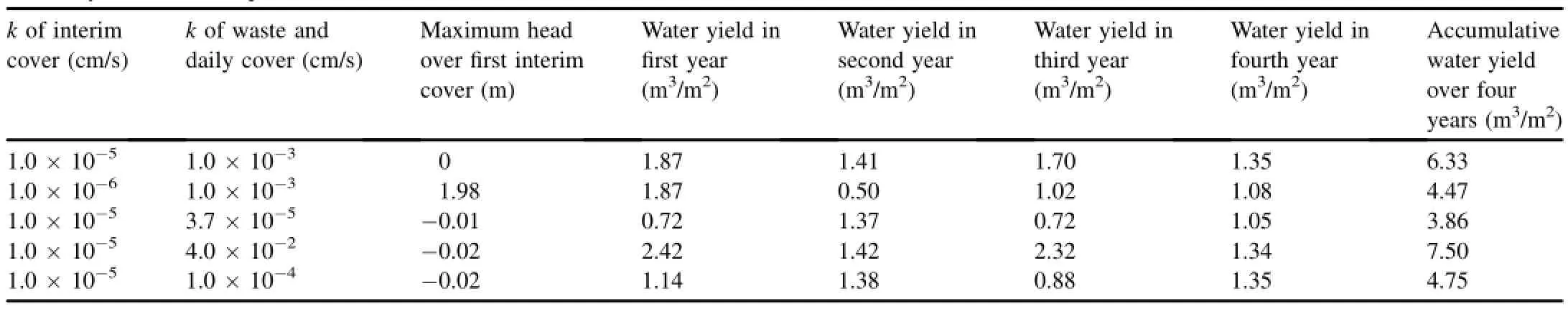

Simulation results are presented in Fig.1 and Table 1.On the premise of k=1.0×10-3cm/s for the waste and daily cover,when k=1.0×10-6cm/s is used for the interim cover,the water yield in the second year(i.e.,0.5 m3/m2)is much less than in the first year(i.e.,1.87 m3/m2)or in the second year when k=1.0×10-5cm/s(i.e.,1.41 m3/m2),which indicates that an interim cover with a lower permeability can reduce the leachate quantity effectively.On the other hand,the k value of the interim cover has a significant impact on the head over the first interim cover.The highest head reaches 1.98 m when k=1.0×10-6cm/s for the interim cover,while there is no saturated zone when k=1.0×10-5cm/s.The reduction in hydraulic performance of the interim cover results in leachate perched over the interim cover,which might have negative effects on the stability of landfill.

Fig.1.Head distribution in third year with different k values.

When the saturated hydraulic conductivity of the waste and dailycoverisatitsminimum,average,andmaximumvalues,the accumulative water yield over four years is 3.86,6.33,and 7.50 m3/m2,respectively.This indicates that the leachate quantity increases with the k value of the waste and daily cover,and the treatment intensity of the leachate might increase correspondingly.The decreasing k value of the waste and daily cover helps to reduce the leachate treatment load,but might increase thewater content of thewaste.When thewater content of the waste is equal to the field capacity,the corresponding matric suction is10 kPa(or,alternatively,a headof-1 m).Meanwhile,asshowninFig.1,theheadinthewasteanddailycoverismostly intherangeof-0.4mto-0.2mwhenkisatitsminimumvalue(i.e.,3.7×10-5cm/s),whichisconsiderablygreaterthan-1m,indicating a poorly drained condition.From this perspective,the permeability of daily cover material cannot be too low.

In addition,the accumulative water yield over four years was determined to be 4.75 m3/m2with k=1.0×10-5cm/s for the interim cover and k=1.0×10-4cm/s for the waste and daily cover.After calculation,the head is mostly in the range of -0.35 m to-0.4 m,and there is no saturated zone.These results suggest that it is appropriate to maintain the hydraulic conductivities of the interim cover and daily cover at around 1.0×10-5cm/s and 1.0×10-4cm/s,respectively,as this controls the leachate quantity and reduces the water content as well as the head over the interim cover to some degree.

3.Modified sludge as temporary cover material

In this study,digested sewage sludge was taken from a sewage plant in Hubei Province,in China.Traditional modification materials,i.e.,building quicklime and Portland blastfurnace slag cement,were used to modify the sludge.Pond silt from a landfill site in Hubei Province was used to form the skeleton in the modified sludge.The geotechnical properties of the pond silt and sludge are listed in Table 2.The sludge has a relatively high water content,high liquid and plastic limits,and low permeability.In addition,the sludge usually exhibits low strength,which cannot be measured in an unconfined compressive test.Hence,the sludge is not suitable for direct use as temporary cover material.

Samples were prepared by mixing sludge with the modification materials at various weight ratios.Preliminary tests suggest that the curing condition has an important effect on the water content and strength of the mixture.When the mixture is cured in indoor natural conditions,the water content decreases and the strength increases significantly.Moreover,the natural curing method might simulate the actual landfill environment well.Hence,in this study,a certain amount of sludge was first weighed and placed in a mixer for rapid mixing for one minute. Then,the modification materials were added for another rapid mixing for five minutes.Finally,the mixed sample was spread out in a tray and cured for three days in indoor conditions. Afterwards,water content,strength,and hydraulic conductivity tests were conducted.The water content was obtained by drying the samples in an oven at a temperature of 105°C for 24 h. The unconfined compressive strength was measured with a calcareous soil pressure tester.A displacement rate of 1%per minute and a total displacement of 15%were adopted.The saturated hydraulic conductivity was measured with a falling head permeability test using a QY1-2 piezometer,with anormal stress of 50 kPa.All tests were carried out according to Specification of Soil Test(SL 237-1999).

Table 1Summary of calculation parameters and results.

Table 2Geotechnical properties of modification materials.

Orthogonal experiments were conducted first,in order to examine the strength and hydraulic performance of the sludge modified using lime,cement,and siltwith a sludge:lime:cement:silt weight ratio of 100:15:5:70.It was determined that the strength of the modified sludge was improved rapidly and significantly.After three days of curing,the unconfined compressive strength was 150.6 kPa,which was greater than 50 kPa and met the strength requirement for temporary cover according to GB/T 23485-2009.The hydraulic conductivity of the modified sludge was 3.1× 10-7cm/s,which failed to meet the permeability requirement for temporary cover,as mentioned in section 2.

Fig.2.Relationships between water content*,unconfined compressive strength,and hydraulic conductivity.(*means the weight ratio of water to the total.)

In an effort to increase the hydraulic conductivity of the modifiedsludge,TDAwasusedaswell.TDAwasobtainedfrom acompanyinHubeiProvince.Nometalpieceswerefoundinthe TDA and its specific gravity was 1.2.The particle size ranged from 4 mm to 8 mm,which meant it was fine and medium gravel.The adopted tire content was in the range of 10%-30% of the sludge weight.The test results for the sludge modified with lime,cement,silt,and TDA are shown in Figs.2 and 3.

Fig.3.Relationships between tire content,unconfined compressive strength,and hydraulic conductivity.

As shown in Fig.2,both the unconfined compressive strength and the hydraulic conductivity demonstrate a generally decreasing trend with the increase in water content.At a relatively low water content(less than 40%),the unconfined compressive strength is relatively high(greater than 100 kPa)and the hydraulic conductivity is greater than 1.0×10-6cm/s(ranging from 1.6×10-6cm/s to 2.7×10-5cm/s).When the water content increases to around 40%,the unconfined compressive strength decreases remarkably,and the hydraulic conductivity reaches the order of 10-7cm/s and no longer meets the permeability requirement for temporary cover. Hence,it is very important to control the water content when using modified sludge as temporary cover.In other words,it is essential to maintain the solid content at a level greater than 60%,an amount also in agreement with Chen et al.(2013).

The relationships between the tire content,unconfined compressive strength,and hydraulic performance of the modified sludge are shown in Fig.3.It can be seen that the unconfined compressive strength decreases with the increase in the tire content,which corresponds with the findings of Xin et al.(2010).This is because TDA is an inert matter and consists of coarse particles.Therefore,it cannot react with cement to form a skeleton in the same way as silt.In addition,with the increase in the tire content,the ratio of lime and cement to the total decreases relatively.Hence,the hydration cementation decreases accordingly.In spite of the factors mentioned above,the strength of the modified sludge sample using TDA is still greater than 50 kPa even if the tire content reaches 30%.As for the modified sludge at a relatively low watercontent,the hydraulic conductivity is close to 1.0×10-5cm/s when the tire content is between 15%and 20%,meeting the permeability requirement of an interim cover as well.Considering both strength and hydraulic performance,it is appropriate to adopt a tire content of 15%-20%,and 15%was chosen for the subsequent tests.

4.Modified sludge soaking in water and synthetic leachate

After three days of curing,the water content of the modified sludge with 15%tire content by weight was measured. The samples with water contents of less than 40%were compacted,and the unsaturated and vacuum-saturated samples were subjected to unconfined strength tests.Other compacted samples were soaked in water for 30 days and in synthetic leachate for 60 days.Ca2+and Cl-are the common pollutant ions in landfill leachate,and phenol is the top-priority controlled pollutant in China and in the world,as it is commonly detected in the leachate of municipal and industrial landfills(Varank et al.,2011).Therefore,solutions with a CaCl2concentration of 0.05 mol/L and phenol concentration of 1 g/L,representing the organic and inorganic pollutants,respectively,were selected as synthetic leachates.The results are shown in Figs.4 and 5.

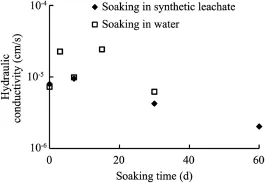

The relationship between the unconfined compressive strength and soaking time is described in Fig.4.The unconfined compressive strength of vacuum-saturated samples is less than that of the unsaturated ones when the time is zero,but still meets the strength requirement of 50 kPa(GB/T 23485-2009).As soaking time goes on,the unconfined compressive strength of groups of samples in water(Fig.4(a))and synthetic leachate(Fig.4(b))have a tendency to generally increase.The increase is more remarkable at early soaking time.The relationship between the hydraulic conductivity and soaking time is shown in Fig.5.The effect of soaking in water and synthetic leachate on the hydraulic conductivity is not significant.As soaking time goes on,the hydraulic conductivity fluctuates around 1.0×10-5cm/s.In the case of synthetic leachate,although the hydraulic conductivity decreases slightly,it is still greater than 1.0×10-6cm/s.

Fig.4.Relationships between unconfined compressive strength and soaking time in water and synthetic leachate.

Fig.5.Relationships between hydraulic conductivity and soaking time in water and synthetic leachate.

These results are different from those reported on deeply dewatered sludge by Chen et al.(2013),who stated that the strength decreased slightly and the hydraulic conductivity increased slightly when deeply dewatered sludgewas soaking in waterandleachate.Thisdifferenceismainlyduetotheexistence of lime and cement in the modified sludge in this study.The hydration reaction of lime and cement takes time,which results inanincreaseinstrengthwithsoakingtime.Whensoakinginthe synthetic leachage,the components in the modified sludge canadsorb the phenol and Ca2+(Chen et al.,2009),which might slightly decrease the pore size and the hydraulic conductivity.

5.Conclusions

In this study,the effect of permeability of temporary landfill covers on the leachate migration in a landfill was analyzed,and the mechanical properties of the modified sludge were evaluated with a series of experimental studies for determination of the strength and hydraulic conductivity of the material.For the purposes of controlling the leachate quantity and reducing the water content as well as the head over the interim cover,approximately 1.0×10-4cm/s and 1.0×10-5cm/s were found to be appropriate values for the hydraulic conductivities of daily cover and interim cover,respectively,under these conditions.The sludge is characterized by high water content and low hydraulic conductivity and strength.Therefore,modification is necessary.When the water content increases to 40%,the unconfined compressive strength decreases significantly and the hydraulic conductivity is close to 1.0×10-7cm/s.Hence,it is important to reduce the water content of modified sludge to less than 40% (or increase the solid content to greater than 60%)when it is used as temporary landfill cover material.In addition,with the increase in tire content,the unconfined compressive strength of modified sludge decreases slightly,but is still greater than 50 kPa. Modified sludge with a sludge:lime:cement:silt:TDA weight ratioof100:15:5:70:15canbeusedasaninterimcoverfromthe perspectives of strength and hydraulic performance.When the modified sludge was soaking in water for 30 days and synthetic leachate for 60 days,the unconfined compressive strength was found to increase.The hydraulic conductivity fluctuated around 1.0×10-5cm/s when the modified sludge was soaking in water,and decreased slightly when the modified sludge was soaking in synthetic leachate.These results suggest that the proposed modified sludge has desirable mechanical and hydraulic characteristics as an interim landfill cover material. However,more detailed studies are expected in the future,so that special attention can be paid to the reduction in the hydraulic conductivity of the interim cover under the effect of synthetic leachate.Moreover,more field observations are needed on the long-term and environmental performance of the modified sludge,and these will be carried out in the future.

References

American Society for Testing and Materials(ASTM),2005.Evaluation and Selection of Alternative Daily Covers(ADCs)for Sanitary Landfills(D6523).ASTM International,West Conshohocken.

Chen,A.C.,Cu,Y.H.,Zheng,X.J.,Yang,J.,Chen,P.,2011.Research on advanced dewatered sewage sludge as intermediate cover soil at refuse landfill site.China Water Wastewater 27(19),85-87,91(in Chinese).

Chen,P.,Lin,W.A.,Zhan,X.J.,Jiang,Y.Y.,2013.Influence of leachate soaking on strength and permeability of deeply dewatered sewage sludge. Rock Soil Mech.34(2),337-341(in Chinese).

Chen,Y.G.,Zhang,K.N.,Deng,F.Y.,Ye,W.M.,2009.Adsorption of phenol in leachate on clay-solidified grouting curtain.J.Central South Univ.Sci. Technol.40(1),243-247(in Chinese).

Frempong,E.M.,Yanful,E.K.,2008.Interaction between three tropical soils and municipal solid waste landfill leachate.J.Geotechnical Geoenvironmental Eng.134(3),379-396.http://dx.doi.org/10.1061/(ASCE)1090-0241(2008)134:3(379).

Guyonnet,D.,Gaucher,E.,Gaboriau,H.,Pons,C.H.,Clinard,C.,Norotte,V.,Didier,G.,2005.Geosynthetic clay liner interaction with leachate:Correlation between permeability,microstructure,and surface chemistry.J. Geotechnical Geoenvironmental Eng.131(6),740-748.http://dx.doi.org/ 10.1061/(ASCE)1090-0241(2005)131:6(740).

Jiao,Y.J.,2007.Study of Sewage Sludge of Chongqing Used as Daily Cover Material in MSW Landfill.M.S.Dissertation.Chongqing University,Chongqing(in Chinese).

Kamon,M.,Inazumi,S.,Katsumi,T.,2002a.Performance evaluations of landfill cover systems with sludge barriers.Geotech.Eng.33(3),113-132.

Kamon,M.,Inazumai,S.,Rajasekaran,G.,Katsumi,T.,2002b.Evaluation of waste sludge compatibility for landfill cover application.Soils Found. 42(4),13-27.

Kim,E.H.,Cho,J.K.,Yim,S.,2005.Digested sewage sludge solidification by converter slag for landfill cover.Chemosphere 59(3),387-395.http:// dx.doi.org/10.1016/j.chemosphere.2004.10.038.

Li,L.,2006.Study on Sludge Solidification Technology and Heavy Metal Pollution Control.Ph.D.Dissertation.Hohai University,Nanjing(in Chinese).

Li,Q.B.,Liu,D.,Yang,L.Z.,2003.Selection of temporary cover materials for bioreactor landfills.Environ.Sci.Technol.26(4),29-30(in Chinese).

Ma,P.D.,Wang,L.A.,Huang,C.,Chen,M.,Ren,J.K.,Jiao,Y.J.,2007.Test on daily cover material of landfill site based on modified sludge from municipal sewage treatment plant.China Water Wastewater 23(23),38-41(in Chinese).

Md,S.H.,Mohamed,A.H.,2012.Effects of intermixed soils and decomposition on hydraulic conductivity of municipal solid waste in bioreactor landfills.J.Mater.Civ.Eng.24(10),1337-1342.http://dx.doi.org/10.1061/(ASCE)MT.1943-5533.0000451.

Moo-Young,H.K.,Zimmie,T.F.,1996.Geotechnical properties of paper mill sludge for use in landfill covers.J.Geotechnical Eng.122(9),768-775. http://dx.doi.org/10.1061/(ASCE)0733-9410(1996)122:9(768).

Ng,K.T.W.,Lo,I.M.C.,2007.Mechanical behaviors of a synthetic paste of tire chips and paper sludge in MSW landfill daily cover.Can.Geotechnical J.44(8),928-941.http://dx.doi.org/10.1139/T07-041.

Ng,K.T.W.,Lo,I.M.C.,2010.Effects of design mix and porosity of wastederived paste as landfill daily covers on lead retardation.Pract.Periodical Hazard.Toxic,Radioact.Waste Manag.14(3),195-204.http:// dx.doi.org/10.1061/(ASCE)HZ.1944-8376.0000033.

Qian,X.D.,Shi,J.Y.,Liu,X.D.,2010.Modern Sanitary Landfill Design and Construction.China Construction Industry Press,Beijing(in Chinese).

van Genuchten,M.Th,1980.A closed-form equation for predicting the hydraulic conductivity of unsaturated soils.Soil Sci.Soc.Am.J.44(5),892-898.

Varank,G.,Demir,A.,Yetilmezsoy,K.,Bilqili,M.S.,Top,S.,Sekman,E.,2011.Estimation of transport parameters of phenolic compounds and inorganic contaminants through composite landfill liners using onedimensional mass transport model.Waste Manag.31(11),2263-2274. http://dx.doi.org/10.1016/j.wasman.2011.06.005.

Wang,M.C.,Hull,J.Q.,Jao,M.,Dempsey,B.A.,Cornwell,D.A.,1992.Engineering behavior of water treatment sludge.J.Environ.Eng.118(6),848-864.http://dx.doi.org/10.1061/(ASCE)0733-9372(1992)118:6(848).

Xin,L.,Liu,H.L.,Shen,Y.,He,J.,2010.Unconfined compressive test of lightweight soil mixed with rubber chips of scrap tires.J.PLA Univ.Sci. Technol.Nat.Sci.Ed.11(1),79-83(in Chinese).

Yang,J.K.,Yang,X.,Li,Y.L.,Zhang,M.,Li,Y.,He,S.,2012.Dewatering of sewage sludge with skeleton builder and engineering properties of dewatered sludge.J.Wuhan Univ.Sci.Technol.35(2),133-136(in Chinese).

Zhang,C.J.,2007.Experimental and Numerical Study on Water/Leachate Transport in Landfill of Municipal Solid Waste.Ph.D.Dissertation. Zhejiang University,Hangzhou(in Chinese).

Zhou,L.Q.,Wu,C.L.,Wu,J.J.,2011.Study of modified sludge as landfill cover soil.Chin.J.Environ.Eng.5(12),2864-2868(in Chinese).

This work was supported by the National Natural Science Foundation of China(Grant No.51008120),the Youth Science and Technology Morning Program of Wuhan(Grant No.201271031418),and the Natural Science Foundation of Hubei Province(Grant No.2014CFB606).

*Corresponding author.

E-mail address:hjunas@126.com(Jun He).

Peer review under responsibility of Hohai University.

http://dx.doi.org/10.1016/j.wse.2015.03.003

1674-2370/©2015 Hohai University.Production and hosting by Elsevier B.V.This is an open access article under the CC BY-NC-ND license(http:// creativecommons.org/licenses/by-nc-nd/4.0/).

Water Science and Engineering2015年3期

Water Science and Engineering2015年3期

- Water Science and Engineering的其它文章

- Uniqueness,scale,and resolution issues in groundwater model parameter identification

- Flash flood hazard mapping:A pilot case study in Xiapu River Basin,China

- Variable fuzzy assessment of water use efficiency and benefits in irrigation district

- Effects of thermodynamics parameters on mass transfer of volatile pollutants at air-water interface

- Analysis of soluble chemical transfer from soil to surface runoff and incomplete mixing parameter identification

- Adsorption of Cr(VI)in wastewater using magnetic multi-wall carbon nanotubes