单根氮化硅纳米线压阻效应研究

毕精会

(太原科技大学,太原 030024)

单根氮化硅纳米线压阻效应研究

毕精会

(太原科技大学,太原 030024)

为了实现恶劣环境下的精密仪器和精确测量,适应于恶劣环境下的压力传感器的需求大大增加。首次报道单根氮化硅纳米线的横向压电效应。在不同压力负载下,采用导电原子力显微镜(CAFM)对单根氮化硅纳米线进行压阻效应测量。计算得到横向压电效应的系数在1.8~7.5×10-11Pa-1范围内。压电电阻系数和负载压力之间的关系几乎是线性的。稳定和可重复的电流-电压曲线通过多次循环往复测量完成,表明氮化硅纳米线压力传感器是相当可靠的。

氮化硅纳米线;压阻效应;压阻系数;原子力显微镜

线[7-10],碳化硅纳米线[11-13]等纳米材料已被广泛的应用在各种压力传感器制备方面,表明在纳微电机械系统中,一维半导体材料将成为测量nN级压力的一个优异的备选制备器件材料。为了实现恶劣环境下的精密仪器和精确测量,适应于恶劣环境下的压力传感器的需求大大增加。不同形状的Si3N4纳米材料[14-19]已经制备出来,并且被应用在了光学[20-21],晶体管等方面。然而,目前还没有对Si3N4纳米线压阻特性的报道。首次对单根高质量的单晶Si3N4纳米线压阻特性进行报道。采用原子力显微镜导电模式对Si3N4纳米线的压阻效应进行测量,并分析了压阻的产生机理。该工作将开启采用Si3N4纳米材料制备压力传感器的一扇大门。

1 实验过程

采用高温热解聚铝硅氮烷(polyaluminasilazane)有机前驱体的方法制备Si3N4纳米线纳米材料[19]。从基底上刮取少量所制备的Si3N4纳米线,将其放入酒精中,将Si3N4纳米线与酒精混合物放入超声仪中超声5~10 min,可以把Si3N4纳米线分散开。将超声好的混有Si3N4纳米线的酒精滴一滴在金属石墨基底上,采用原子力显微镜导电模式对单根Si3N4纳米线压阻进行测量。

2 结果与讨论

图1(a)和(b)表示在不同倍率下观测到的Si3N4纳米线材料扫描电镜图片。从图中可以看出,Si3N4纳米线生长密度高,并且其长度可达到几毫米,直径均匀;所制备的Si3N4纳米线材料的尺寸分布较均匀,观察同一根纳米带,可以看到沿着整个纳米线的生长方向,纳米线的直径基本没有变化,分布均匀,并且纳米线的表面比较光洁和光滑,没有其他颗粒的存在,没有受到污染。

采用原子力显微镜对所制备的Si3N4纳米线材料进行压阻性质测量。图2(a)为测量单根Si3N4纳米线的示意图。将制备好的样片放在原子力显微镜平台上,由图2(a)可知,Pt/Ir探针针尖、Si3N4纳米线、金属石墨基底经过原子力显微镜组成了一个电流回路,当Pt/Ir针尖对Si3N4纳米线施加不同压力时,在相同电压下流过Si3N4纳米线的电流发生变化,从而可以对其进行压阻性质测量。

图2(b)为原子力显微镜测量的单根Si3N4纳米线形貌图,由图示可以看出,所制备的Si3N4纳米线表面光滑,直径均匀。图2(c)为图2(b)中虚线所示位置对应的高度图,由其可以看出,所制备的纳米材料为纳米线结构,其直径大约为60 nm左右。

图1 1 300℃下合成的Si3N4纳米线不同放大倍数的SEMFig.1 SEM image of the Si3N4nanowires obtained from 1 300℃under different magnifications

图2(a) Si3N4纳米线压阻测量示意图 图2(b) 单根Si3N4SiC纳米线AFM图片Fig.2(a)chematic diagram for measurement Fig.2(b)epresentative AFM image of nanowire

图2(c) 图2(b)中Si3N4纳米线所示虚线对应的高度图Fig.2(c)eight data provided 2(b)

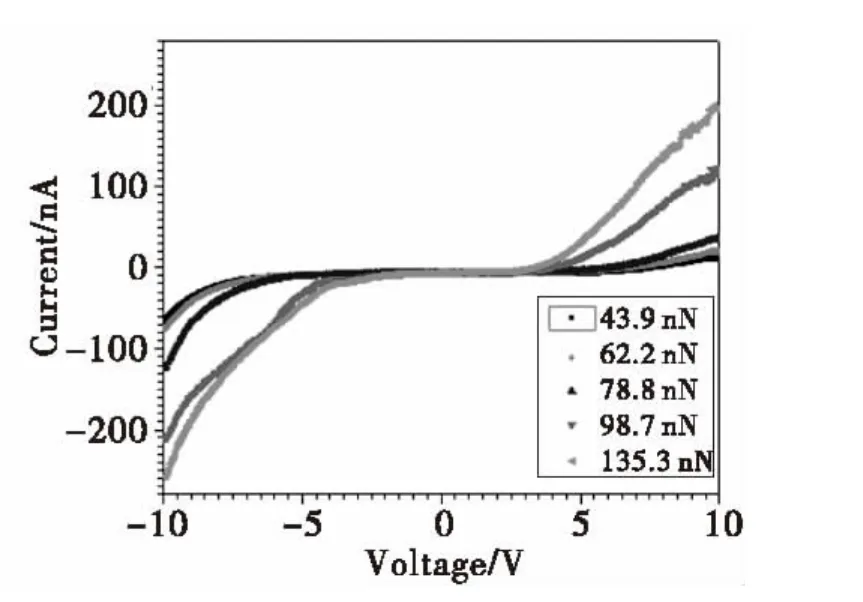

图2(d)不同压力下,流过Si3N4纳米线的电压-电流图Fig.2(d)Ⅰ-Ⅴ curves recorded at different forces

图2(d)为原子力显微镜测试的流过氮化硅(Si3N4)纳米线材料的电压-电流图。由图中可以看出,不同压力采用了不同形状区分,测试了从43.9 nN~135.3 nN不同压力下的电压电流。压力比较小的情况下,电压电流图比较平缓,随着压力的增大,电压-电流图变的陡峭。

根据压阻的定义,Si3N4纳米线的压阻计算公式如下:

其中R0表示未施加压力时的氮化硅(Si3N4)纳米线电阻,当对氮化硅(Si3N4)纳米带施加压力时,其电阻会发生变化,其变化可记为△R,σ是氮化硅(Si3N4)纳米线单位面积上所受到的压力(σ = F/S,F为 Pt/Ir探针针尖施加压力,S为氮化硅(Si3N4)纳米线受力面积)[22]。

受力面积为Pt/Ir探针针尖与氮化硅(Si3N4)纳米带纳米材料之间的接触面积,由于Pt/Ir探针针尖可看作半径大约为20 nm球形,由图2(c)可知,氮化硅(Si3N4)纳米线是直径约为60 nm的圆柱体,因而接触面积可近似看作为椭球形,长轴沿氮化硅(Si3N4)纳米线纵向方向,可记为2ɑ,短轴沿氮化硅(Si3N4)纳米线径行方向,记为2b;他们大小可由以下公式计算得出:

其中,rtip表示Pt/Ir探针针尖的半径(探针针尖可看为球面),大小约为20 nm;rnanowire表示氮化硅(Si3N4)纳米线半径(其中平面可看作半径为无限大的球面),大小约为30 nm;Δh是氮化硅(Si3N4)纳米线沿横向方向的形变量,由赫兹(Hertz)模型可知,形变可为:

其中,Yeff为氮化硅(Si3N4)纳米线杨氏模量,大小为570 GPa,Q为几何因子。

根据式(1)~式(4),压阻系数计算公式表示为:

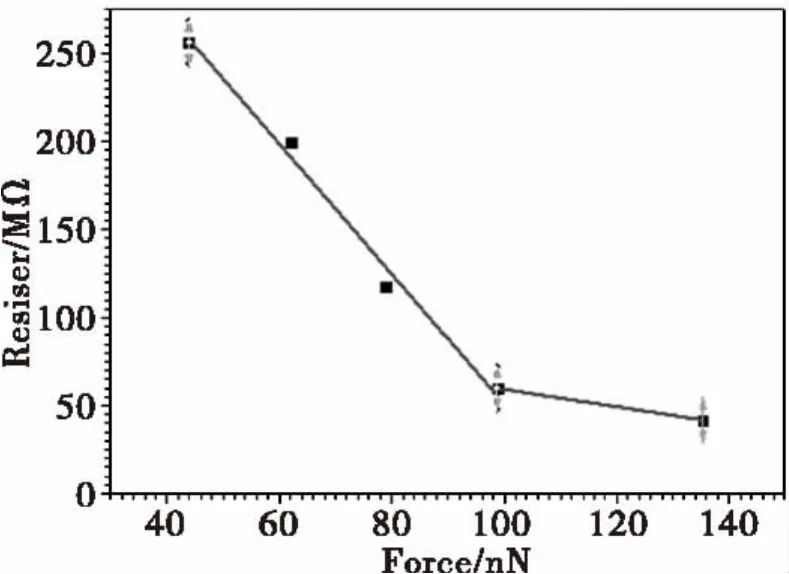

根据公式(5),计算得到,当所制备的氮化硅(Si3N4)纳米线受到压力大小为43.9~135.3 nN,氮化硅(Si3N4)纳米线的压阻系数大小为1.8~7.5× 10-11Pa-1,如图3所示。

图3 氮化硅(Si3N4)纳米线压阻系数图Fig.3 The relationship between the piezoresistance coefficients and the applied forces

由图4可知,随着压力的增加,单根氮化硅(Si3N4)纳米线的电阻在减小,这个现象说明压力可以改变氮化硅(Si3N4)纳米线的电子浓度和传导性。氮化硅(Si3N4)纳米线电阻变化与压力关系基本呈线性关系,可分为两部分,一部分为0~98.7 nN,一部分为98.7~135.3 Nn.并且前半部分变化的速率基本上是后半部分的5倍左右,这表明该氮化硅(Si3N4)纳米线在压力0~98.7 nN之间在压力传感器方面有很好的应用前景。

图4 压力-氮化硅(Si3N4)纳米线电阻关系图Fig.4 The relationship between the resistances of thenanowrie and the applied forces

根据图2(b)可知,所制备的氮化硅(Si3N4)纳米线材料直径在60 nm附近,远大于波尔半径(<10 nm),因而量子效应对于氮化硅(Si3N4)纳米线压阻效应的产生可忽略。因此推测该氮化硅(Si3N4)纳米线压阻主要还是由压力引起的表面态和能带变化引起的。当纳米材料收到外力作用形变时,其表层和内部会有相反的反应[23]。当Pt/Ir探针针尖压到氮化硅(Si3N4)纳米线表面时,随着压力的增加,氮化硅(Si3N4)纳米线表面在Pt/Ir探针针尖位置发生形变,由于表面发生形变,引起内部结构的变化,内部结构为了应对这种变化,故和表层变化有了相反的趋势,这种相反的变化会引起氮化硅(Si3N4)纳米线表面态的变化,从而引起其电阻的变化;另一方面是压力的施加会引其纳米材料的能带的变化[24],Pt/Ir探针针尖、氮化硅(Si3N4)纳米线、金属石墨之间形成了金属-半导体-金属的接触模式,随着 Pt/Ir探针针尖对氮化硅(Si3N4)纳米线施加压力时,氮化硅(Si3N4)纳米线发生形变,使得其电阻会发生变化,并且Pt/Ir探针针尖、氮化硅(Si3N4)纳米线之间的肖特基势也会发生变化。根据传统的热辐射电子理论,轻微的肖特基势的减小,由于他们之间指数关系的存在,使得反向偏压的电流大大增加,相同的理论也可以解释在正向偏压下,随着压力的增大,流过化硅(Si3N4)纳米线的电流也随之增大;另外,考虑到氮化硅(Si3N4)纳米带表面存在着大量的空缺和吸附氧原子,使得流过肖特基势的隧道电流不可忽视。

3 结论

利用原子力显微镜对氮化硅纳米线压阻效应进行测量。在压力43.9 nN~135.3 nN范围内,其压阻系数位于1.8~7.5×10-11Pa-1范围内,压阻系数与压力之间基本呈线性关系。随着压力的增大,氮化硅纳米线的电阻在减小,并且在nN级的压力下有MΩ级别的电阻变化,表明采用氮化硅纳米线所制备的压力传感器具有优异的灵敏性。对碳化硅纳米材料压阻效应的测量分析,为其在后续的制备适用于恶劣环境下的压力传感器件做出了准备。

[1]HE R,YANG P.Giant piezoresistance effect in silicon nanowires[J].Nature nanotechnology,2006,1(1):42-46.

[2]TIAN H,SHU Y,CUI Y L,et al.Scalable fabrication of high-performance and flexible graphene strain sensors[J].Nanoscale,2014(6):699-705.

[3]STAMPFE C,HELBLING T,OBERGFELLD,et al.Fabrication of single-walled carbon-nanotube-based pressure sensors[J].Nano Letters,2006(6):233-237.

[4]STAMPFER C,JUNGEN A,LINDERMAP R,et al.Nano electromechanical displacement sensing based on single-walledcarbon nanotubes[J].Nano Lett,2006(6):1449-1453.

[5]HU N,KARUBE Y,YAN C,et al.Tunneling effect in a polymer/carbon nanotube nano-composite strain sensor[J].Acta-Mater.,2008(56):2929-2936.

[6]NEUZIL P,WONG C C,REBOUD J.Piezoresistance in Silicon Nanowires[J].Nano Letters.,2010(10):1248-1252.

[7]WANG X,ZHOU J,SONG J,et al.Piezoelectric field effect transistor and nanoforce sensor based on a single ZnO nanowire[J].Nano Letters,2006(6):2768-2772.

[8]YANG Y,QI J,ZHANG Y,et al.Controllable fabrication and electromechanical characterization of single crystalline Sb-doped ZnO nanobelts[J].Applied Physics Letters,2008(92):117-123.

[9]YANG Y,QI J,GUO W,et al.Mechanical and longitudinal electromechanical properties of Sb-doped ZnO nanobelts[J].CrystEngComm,2010(12):2005-2007.

[10]YANG Y,GUO W,QI J,et al.Flexible piezoresistive strain sensor based on single Sb-doped ZnO nanobelts[J].Applied Physics Letters,2010(97):107-109.

[11]GAO F,ZHENG J,WANG M,G.et al.Piezoresistance behaviors of p-type 6H-SiC nanowires[J].Chemical Communications,2011(47):11993-11995.

[12]SHAO R.,ZHENG K,ZHANG Y,et al.Piezoresistance behaviors of ultra-strained SiC nanowires[J].Applied Physics Letters,2012,101(23):233109-233109-4.

[13]BI JH,WEI GD,WANG L,et al.B.Tang and W.Yang.Highly sensitive piezoresistance behaviors of n-type 3C-SiC nanowires[J].Journal of Materials Chemistry C,2013(1):4514-4517.

[14]GAO F,YANG W.Aligned ultra-long single-crystalline α-Si3N4nanowires[J].Nanotechnology,2008(19):105602.

[15]YANG W,XIE Z.Coalescence of nanobranches:A new growth mechanism for single crystal nanobelts[J].The Journal of Physical Chemistry B,2006(110):3969-3972.

[16]YANG W,WANG H.Controlled Al-doped single-crystalline silicon nitride nanowires synthesized via pyrolysis of polymer precursors[J].The Journal of Physical Chemistry B,2007(111):4156-4160.

[17]YANG W,CHENG X.Bundled silicon nitride nanorings[J].Crystal Growth and Design,2008(8):3921-3923.

[18]YANG W,GAO F.Ostwald ripening growth of silicon nitride nanoplates[J].Crystal Growth&Design,2009(10):29-31.

[19]YANG W,GAO F.Asymmetric silicon nitride nanodendrites[J].Crystal Growth and Design,2008(8):2606-2608.

[20]ZHANG L,JIN H.Optical properties of single-crystalline α-Si 3 N 4 nanobelts[J].Applied physics letters,2005(86): 061908-061908-3.

[21]MAIRE G,VIVIEN L.High efficiency silicon nitride surface grating couplers[J].Optics Express,2008(16):328-333.

[22]ANGELIDIS N,WEI C,IRVING P.The electrical resistance response of continuous carbon fibre composite laminates to mechanical strain[J].Composites Part A:applied science and manufacturing,2004(35):1135-1147.

[23]CAO J,GONG X,WU R.Giant piezoresistance and its origin in Si(111)nanowires:First-principles calculations[J].Physical Review B,2007(75):233-302.

[24]YANG Y,LIAO Q.Synthesis and transverse electromechanical characterization of single crystalline ZnO nanoleaves[J].Physical Chemistry Chemical Physics,2010(12):552-555.

Abstract:To achieve precision instrumentation and accurate measurement,there is increasing need for pressure sensors to be well serviced in harsh environments.We report,for the first time,piezoresistance in single-crystalline Si3N4nanowire by conductive atomic force microscopy(C-AFM).The transverse electromechanical properties of Si3N4nanowire were investigated under various loading forces applied by the C-AFM tip.The calculated transverse piezoresistance coefficient of the nanowire was in the range of 1.8 to 7.5×10-11Pa-1.The relationship between the piezoresistance coefficients and the applied forces was almost linear.Stable and repeatableⅠ-Ⅴ curves through multiple voltage sweepings were accomplished,suggesting that the Si3N4nanowires pressure sensors are quite reliable.

Key words:Si3N4nanowire,piezoresistance behavior,piezoresistance coefficient,C-AFM

Study on Vortex-induced Vibration of Reinforced Concrete Chimneys

CHENG Hong

(Shanxi Architectural Technical College,Taiyuan 030024,China)

A numerical model is presented to evaluate the response of cylindrical structure subjected to vortex excitation.The model can assess displacement amplitude for wind velocities lower than or greater than the critical wind speed.Finally,the numerical simulation on a 100 m reinforced concrete chimney is given to show the good agreement between experimental and simulated responses.

numerical model,vibration,reinforced concrete chimney,vortex

Piezoresistance Properties of Single Si3N4Nanowire

BI Jing-hui

(College of Applied Science,Taiyuan University of Science and Technology,Taiyuan030024,china)

O59

A

10.3969/j.issn.1673-2057.2015.04.017

1673-2057(2015)04-0318-05

2015-03-27

太原科技大学博士启动基金(20152016)

毕精会(1979-),女,讲师,主要研究方向为微纳米制备与器件。

近期发现,纳米结构材料随着尺度的减小表现出更为优异的压阻性能[1-2],因而基于一维纳米材料制备的压力传感器成为热点,受到各方面的关注。目前,碳纳米管[3-5],硅纳米线[6],氧化锌纳米