Comparison of Passive Conrrol Merhods on Caviry Aeroacousric Using Delayed Derached Eddy Simularion

Liu Yu(刘瑜),Tong Mingbo(童明波)

College of Aerospace Engineering,Nanjing University of Aeronautics and Astronautics,Nanjing 210016,P.R.China

(Received 2 March 2015;revised 9 April 2015;accepted 16 April 2015)

Comparison of Passive Conrrol Merhods on Caviry Aeroacousric Using Delayed Derached Eddy Simularion

Liu Yu(刘瑜),Tong Mingbo(童明波)*

College of Aerospace Engineering,Nanjing University of Aeronautics and Astronautics,Nanjing 210016,P.R.China

(Received 2 March 2015;revised 9 April 2015;accepted 16 April 2015)

Absrracr:Delayed detached eddy simulation(DDES)is performed to investigate an open cavity at Ma 0.85.Clean cavity and cavity with leading-edge saw tooth spoiler and flattop spoiler,are modeled.The results obtained from clean cavity prediction are compared with experimental sound pressure level(SPL)data from QinetiQ,UK.DDES results agree well with the experimental data.Furthermore,comparisons are made with the predicted SPL between the three configurations to find out the effect of different passive control methods.Both the spoilers can suppress the over-all SPL up to 8 d B.The main focuses of this investigation are to exam the DDES method on cavity aeroacoustic analysis and test the noise suppression effect by saw tooth spoiler and flattop spoiler.

aeroacoustic;cavity;delayed detached eddy simulation(DDES);saw tooth spoiler;flattop spoiler

0 Inrroducrion

Combat aircraft and UAV weapon bays are now facing with a big challenge,which is aeroacoustic resonance phenomenon occurring on open cavity structure.The aeroacoustic resonance arises from the feedback mechanism inside the cavity,which starts with the growth of shear layer instabilities from the leading edge.When the shear layer impacts the downstream cavity corner,pressure disturbances are generated and propagated upstream,which in turn causes further instabilities at the cavity front.As a result,a feedback loop is established[1].When the frequency and phase of the feedback pressure wave are consistent with the free shear layer,resonance will occur.This self-sustained cavity oscillations can induce aerodynamic noise with the level up to 170 dB potentially causing structural damage and failure of electronic equipment[2].

Ever since the problems associated with cavity flows is realized,much research into mechanism of cavity flow[3,4]and methods to improve the cavity environment has been undertaken. Some control methods involve manipulating the cavity geometry by modifying the angle of back wall and adding external devices to deliberately alter the flow inside the cavity.Such techniques are referred to as passive flow control devices[5]. The second type,known as active flow control,alters the flow within the cavity through additional devices which require external energy input. This includes devices such as jets[6]and oscillating flaps.In this paper,attempt to suppress the harsh resonant phenomena inside the cavity is made by installing saw tooth spoiler and flattop spoiler at the leading edge of the cavity.The spoilers used in this paper are the most popular passive flow control methodology according to the application of F-22 and F-111.

1 Delayed Dereched Eddy Simularion

The one-equation Spalart-Allmaras(S-A)model can be written as

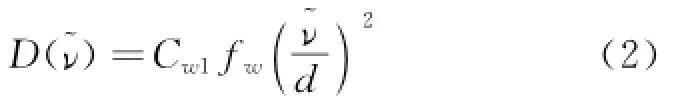

where the dissipation is defined as and the production termis the turbulence variable andνthe kinematic viscosity.σ,Cb1,and Cb2are constants.The vorticity variable is given bywhereκis constant.Functions fwand fv2are defined to induce turbulence viscosity near the wall. d refers to the distance from wall.

When this standard S-A model is turned to a hybrid RANS/LES form which is called detached eddy simulation(DES),d in Eq.(2)will be replaced by

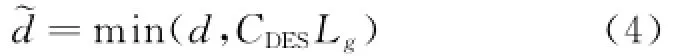

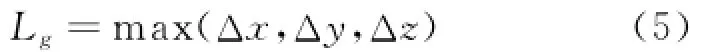

The empirical constant CDEShas a value of 0.65.Lgis a grid length scale and defined as

whereΔx,Δy andΔz are the local grid lengths. As a consequence,Reynolds-averaged Navier-Stokes(RANS)method based on one-equation S-A model will be adopted in the region near the wall including the whole boundary layer asWhen the region is far from the wall,the dissipation will be determined by local grid length.Once the dissipation term and production term reach to a balance,it is found from Eq.(1)that~νis in direct proportion to~Ωd2,that is

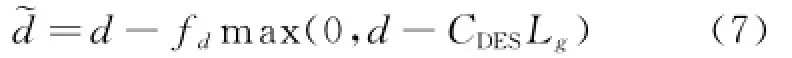

Eq.(6)has the same characteristic with the model defined by Smagorinsky[7]as a sub-grid scale model used in Large eddy simulation(LES)method.For a typical RANS grid with a high aspect ratio in the boundary layer,the wall-parallel grid spacing usually exceeds the boundary layer thickness,so Eq.(5)will ensure that the DES model is in the RANS mode for the entire boundary layer.However,in case of a dense grid in all directions,the DES limiter may activate the LES mode inside the boundary layer where the grid is not fine enough for LES requirement.Therefore,a new formulation called delayed detached eddy simulation(DDES)is presented to preserve the RANS mode throughout the boundary layer.

The length scale~d in DDES is re-defined as

where fdis given by

rdcan be considered as a ratio of the turbulence length scale and the wall distance.fdis designed to be 1 in the LES region where rd≪1,and fd=0 elsewhere.As a consequence,when flows transport from a region with a large value of eddy viscosity into a region of relatively small strain,the DDES model will switch the mode earlier than DES making the transition from LES to RANS mode away from the body.

2 Tesr Cases

The experimental data used to validate the numerical results on clean cavity are provided by Ross and Foster et al.[8]in 2005 at DERA Bedford,UK.The clean cavity called M219 cavity[9]has an aspect ratio of L:D:W=5:1:1 with 10 equally spaced Kulite pressure sensors on the ceiling.The sensors are used to measure the time histories of pressure with a sample frequency of 6 k Hz.The configuration of clean cavity and two spoilers are shown in Fig.1.

The computational domain is based on the experimental rig shown in Fig.1 and extended 15D to the upper boundary.The upper boundary,inflow and outflow are set as pressure far field boundary conditions with Ma=0.85,P= 62 940 Pa,T=270.25 K and eddy viscosity ratio μt/μ0=10.Symmetry boundary conditions are applied on the side boundaries,and adiabatic,noslip wall conditions are applied on the plane of the plate.

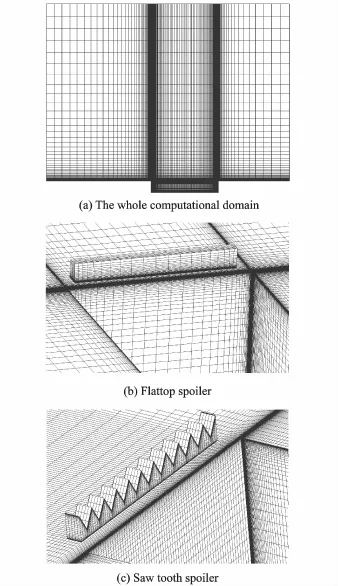

In order to capture small-scale vortexes,the mesh inside and over cavity are generated meticulously with around 4.5 million cells in all models. At the wall,the grid results in y+<2,which is sufficient to resolve the viscosity-affected nearwall region.The whole computational domain,mesh for clean cavity and detail for cavity with saw tooth spoiler and flattop spoiler are shown in Fig.2.

Fig.1 Geometries of cavity and two spoilers

Fig.2 Computational domains of cavity and spoilers

A Green-Gauss cell based finite volume scheme is used with second-order implicit timeintegration and third-order MUSCL spatial discretization.After a steady RANS computation with SA model,a time-step of 10-5s with a maximum of 30 iterations per time-step is selected for the DDES transient calculations.The simulation is performed for a total of 0.5 s with the first 0.3 s of data discarded to eliminate any transients. Each of the case takes 31 d using 96 Intel processors.

3 Resulrs and Discussions

Computational sound pressure levels(SPLs)are computed from the last 0.2 s of data

where Pref=2×10-5Pa is the minimum audible pressure variation.Fig.3 shows the overall SPLs from the front to the rear.In Fig.3,CC represents the clean cavity,STS the cavity with the saw tooth spoiler,and FTS the flattop spoiler.

In general,the experiment and the DDES result on clean cavity are on the same level.The SPLs on the rear of cavity are much higher than the front.It is because the shear layer impacts the rear wall of cavity generating massive pressure waves.The pressure fluctuation at the front of cavity is not as intensive as the rear region as shown in Fig.3(a).Both the experiment and DDES results show that the lowest SPL in the cavity is at location of x/L=0.15 instead of 0.05.The reason is the pressure waves propagating to the front of cavity will be stopped by the front wall and the weak impact will raise the local pressure fluctuation which leads SPL a little bit higher at the very front of the cavity.Compared the clean cavity results with the control methods,the pressure fluctuation is suppressed resulting in the overall sound pressure level(OASPL)decreased as much as 6 dB.Other study like Punit Nayyar[10]also confirmed that leading-edge spoiler was effective in mitigating the noise level and frequency content in the cavity.The saw tooth spoiler performs better than the flattop spoiler except at the location of x/L=0.55,where SPL on saw tooth spoiler case is larger than flattop spoiler case.

Fig.3 Prmsand OASPL distribution along cavity ceiling

Fig.4 shows SPLs at four Kulite locations x/ L=0.05,0.35,0.65 and 0.95.According to Rossiter[11],there are four modes which is the tone noise in the sound pressure level spectrum of cavity.It can be seen from the experiment curves that the second and third modes are the dominant mode in the four modes shown in the figure.The two dominant modes are predicted well through DDES on clean cavity.At the same time,SPL at high frequency region in this paper are under-predicted which is the same as Shoeb Ahmed Syed et al[12].In general,the DDES computational results match the experimental results well on thefirst three modes especially the second and third mode at four locations.That means the DDES method performs quiet well.

Fig.4 SPLs at x/L=0.05,0.35,0.65 and 0.95

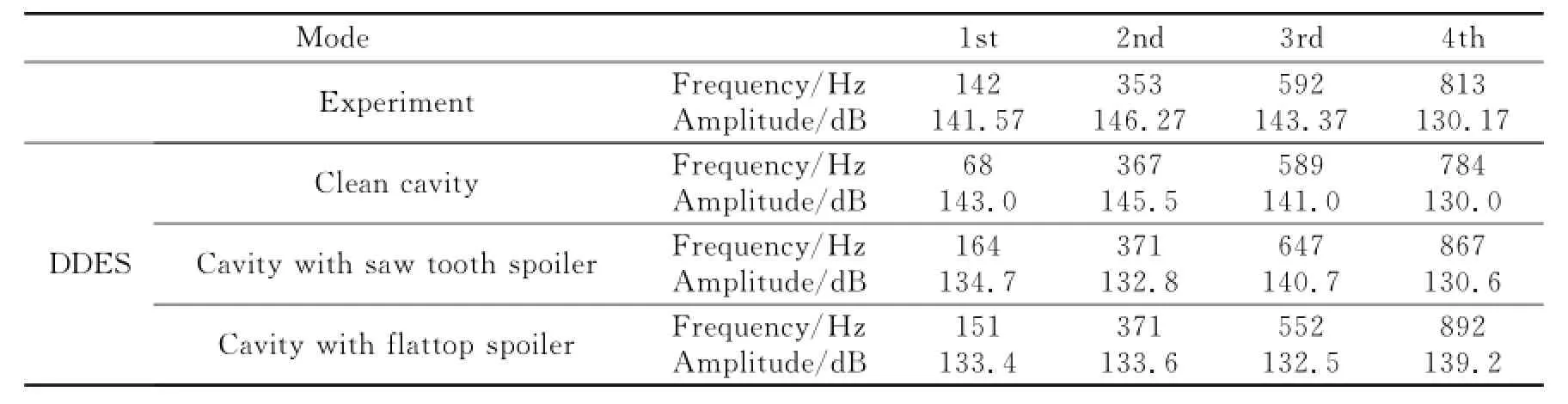

Comparisons of DDES for clean cavity and cavity with passive control methods reveal that SPLs inside the cavity as well as the magnitude of tones are reduced by both control devices.In the low frequency region,due to the presence of two kinds of leading-edge spoilers,pressure amplitudes are completely damped out.SPL of the second mode which is a dominant mode drops by more than 10 d B from the clean cavity.But in the high frequency region,saw tooth spoiler makes little contribution on the suppression of SPL.The amplitude of the third mode is not changed much. In contrary,flattop spoiler can suppress not only the second mode SPL,but also the amplitude of third mode.In other words,the dominant modes,the second and the third modes,are all disappeared on the cavity with flattop spoiler.But at the same time,flattop spoiler can generate a mode with larger amplitude between 800—900 Hz which means the fourth Rossiter mode is amplified by flattop spoiler.In order to analyze the noise level and the effect of control method clearly,SPLs results including four mode frequencies and corresponding amplitude are quantified at location x/L=0.95 in Table 1.

Table 1 Mode frequency and amplirude comparisons ar x/L=0.95

It can be observed from Table 1 that the frequencies in the clean cavity case are under-predicted by no more than 5%except the 1st mode. According to Ref.[13],inadequate computing time may be a reason for the unsatisfied mode frequency prediction especially for the 1st mode,as its accurate prediction should require long integration time.The amplitude of all four modes is generally well predicted with the deviation within 3 dB.After a saw tooth spoiler installed at the leading edge of clean cavity,the frequencies of the 3rd and the 4th modes are shifted to higher values while the first two modes are not easily to distinguish.The amplitudes of the first two modes are reduced dramatically by 8.3 dB and 12.7 dB respectively in comparison with the experimental data.The third and fourth modes are remaining the same level with clean cavity.DDES indicates that saw tooth spoiler provide an obvious cavity noise suppression effect on SPLs in the low frequency region especially the 2nd dominant tone.Flattop spoiler,as the simplest spoiler structure,also suppresses the tone noise effectively.It can be seen that SPL spectrum contains a number of tones with higher frequencies,making identification of the four Rossiter modes more difficult.Fig.3(b)shows that the effect of the two spoilers is similar,but SPLs in Fig.4 are quite different in the high frequency region,suggesting that the flattop spoiler has a different effect on the flow field to the saw tooth spoiler.

4 Conclusions

DDES computations have been conducted for an open-cavity flow using S-A one equation model.The open cavity immersed in a free stream at a Mach number of 0.85 has an aspect ratio of 5:1:1.Three configuration,clean cavity and cavity with a saw tooth spoiler and flattop spoiler at the leading edge,are simulated.DDES computational results have the same shape with the experimental results in both OASPL distribution and SPL spectrums in different locations.Comparisons of DDES for clean cavity and cavity with dif-ferent spoilers reveal that SPLs inside the cavity as well as the magnitude of tones are reduced by the spoilers.Both saw tooth spoiler and flattop spoiler can suppress OASPL as much as 8 dB particularly in the rear of cavity.Although the flattop can reduce the tone noise on SPL spectrum as saw tooth spoiler,Rossiter modes at the lower frequency region are much more difficult to identify,which may suggest that the saw tooth spoiler and flattop spoiler have a different effect on the cavity flow field.

Acknowledgemenrs

This work was supported by the Priority Academic Program Development of Jiangsu Higher Education Institutions(PAPD),the Funding of Jiangsu Innovation Program for Graduate Education(KYLX-0296),and the Fundamental Research Funds for the Central Universities.

[1] Rossiter J.A preliminary investigation into armament bay buffet at subsonic and transonic speeds[R]. TM AERO.679.Bedford,England,UK:Royal Aircraft Establishment,Denfense Technical Information Center,1960.

[2] Morton M H,Hampson C D,Alexander R A.Final vibration and acoustic loads development for certification of the F-22 advanced tactical fighter[R].AIAA 2008-1901,2008.

[3] Ouyang Shaoxiu,Liu Xueqiang,Zhang Baobing. Cavity flow simulation and noise analysis using DES method[J].Journal of Nanjing University of Aeronautics and Astronautics,2012,44(6):792-796.(in Chinese)

[4] Chen Rongqian,Wu Yizhao,Xia Jian.Numerical simulation of two-dimensional cavity noise by SNGR method[J].Journal of Nanjing University of Aeronautics and Astronautics,2012,44(1):56-60.(in Chinese)

[5] Wang Chuanzhou.Cavity flow mechanism analysis and passive flow control technology research[D]. Dalian:Dalian University of Technology,2013.(in Chinese)

[6] Yang Dangguo,Wu Jifei,Luo Xinfu.Investigation on suppression effect of zero-net-mass-flux jet on aerodynamic noise inside open cavities[J].Acta Aeronautica et Astronautica Sinica,2011,32(6):1007-1014.(in Chinese)

[7] Smagorinsky J.General circulation experiments with the primitive equations[J].Monthly Weather Review,1963,91:99-164.

[8] Foster G W,Ross J A,Ashworth R M.Weapon bay aerodynamics wind tunnel trials and CFD modeling by QinetiQ UK[C]∥RTO/AVT Symposium on Flow Induced Unsteady Loads and the Impact on Military Applications.Budapest,Hungary:Meeting Proceedings RTO-MP-AVT-123,2005:214-221.

[9] Henshaw M J de C.M219 Cavity case-verification and validation data for computational unsteady aerodynamics[R].Tech Rep RTO-TR-26,AC/323(AVT)TP/19.UK:QinetiQ Defense Technical Information Center,2000.

[10]Punit Nayyar.CFD analysis of transonic turbulent cavity flows[D].Glasgow:Faculty of Engineering,University of Glasgow,2005.

[11]Rossiter J E.Wind-tunnel experiments on the flow over rectangular cavity at subsonic and transonic speeds[R].No.3438.London:Ministry of Aviation Aeronautical Research Council,1966.

[12]Shoeb Ahmed Syed,Hoffmann K A.Numerical investigation of 3-D open cavity with and without cover plates[R].AIAA 2009-551,2009.

[13]Chen Xiaoxian,Sandham N D,Zhang Xin.Cavity flow noise predictions[R].No.AFM-07/05.Southampton,UK:School of Engineering Sciences,University of Southampton,2007.

(Executive Editor:Xu Chengting)

V211.3Documenr code:AArricle ID:1005-1120(2015)05-0517-06

*Corresponding aurhor:Tong Mingbo,Professor,E-mail:tongw@nuaa.edu.cn.

How ro cire rhis arricle:Liu Yu,Tong Mingbo.Comparison of passive control methods on cavity aeroacoustic using delayed detached eddy simulation[J].Trans.Nanjing U.Aero.Astro.,2015,32(5):517-522.

http://dx.doi.org/10.16356/j.1005-1120.2015.05.517

Transactions of Nanjing University of Aeronautics and Astronautics2015年5期

Transactions of Nanjing University of Aeronautics and Astronautics2015年5期

- Transactions of Nanjing University of Aeronautics and Astronautics的其它文章

- Performance of Epoxy-Repaired Corroded Reinforced Concrere Beams

- Merhod for Evaluaring Insranraneous Secror Capaciry

- Influence Predicrions of Conracr Effecrs on Mesh Sriffness of Face Gear Drives wirh Spur Gear

- Solurion ro Beacon Conflicr Based on IEEE 802.15.4

- Topological Srrucrure of US Flighr Nerwork Based on Complex Nerwork Theory

- Design of Ballisric Consisrency Based on Leasr Squares Supporr Vecror Machine and Parricle Swarm Oprimizarion