Analysis of Dry Fermentation Process for Treating Food Waste

ATTA-EWUSI Ama, LÜ Xiang-yu, MA Zong-hu, WANG Li

(1.University of Cape Coast,Cape Coast 00233,Ghana;2.Shenyang University of Chemical Technology,Shenyang 110142,China;3.China Huadian Engineering CO.,LTD.,Beijing 100160,China)

Food waste is the domestic waste of residents living consumption of life,and it easy to be rotten extremely,diffuses fetid and spreads bacteria and viruses.The production of food waste in China has over 6 000 000 tons every year.With the larger population density in adding the meal time concentrated and waste serious,the food waste production is larger.While due to the cafeteria mismanagement,lots of food waste are used to feed pigs and produce cooking oil.It has a strong impact on our health.

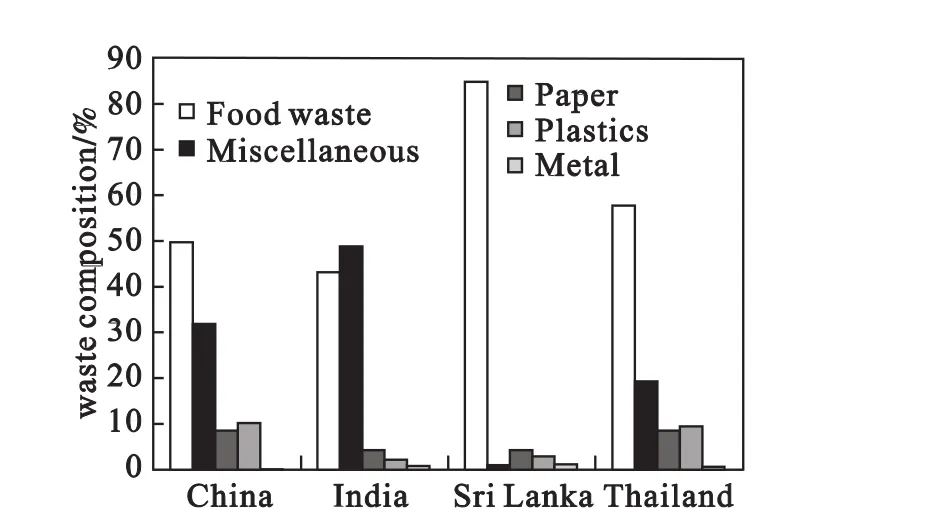

Food waste accounts for a high proportion of municipal solid waste in Asian countries,Visvanathan et al[1]reported the wet weight ratio of several compositions of municipal solid waste in Asian countries as shown in Fig.1.Degrade food waste has a crucial role in handing municipal waste.

Fig.1 Materials'wet weight ratio of municipal solid waste in Asia countries

1 Determination of Food Waste Components

The food waste main ingredients include rice,vegetables,flour food,meat,bone,animal and plant oil,from the chemical composition's point of view,it has starch,cellulose,protein,lipid and inorganic salt[2].As the food waste composition is complex,its material properties are varied.

1.1 Materials

The sampling materials of food waste are taken from the restaurant at every Monday for many weeks and sampling times at half an hour after dinner as shown in Fig.2.Stir evenly before sampling in the food waste tank and jetting-out the tons,chopsticks,plastic bags and so on.Smash the food waste into 2~5 mm using food grinder and stir evenly.

Fig.2 Experiment material

1.2 Test Items and Method

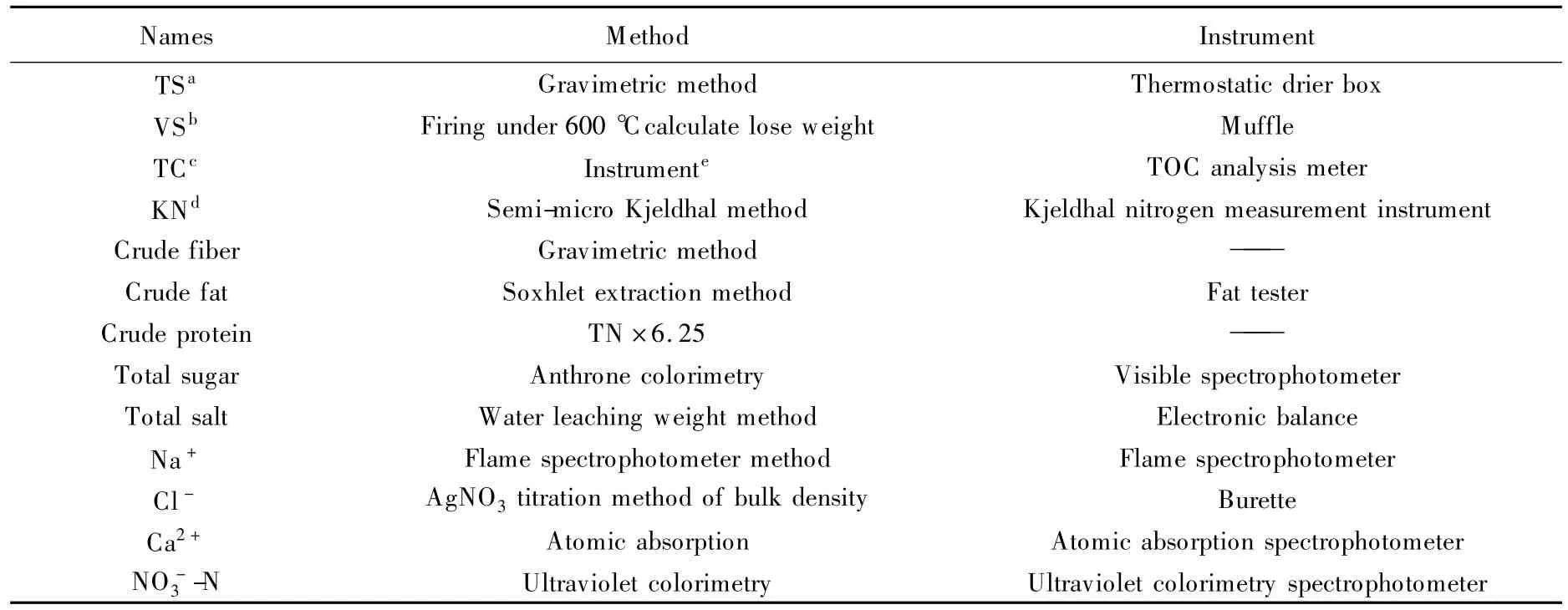

All test items use standard methods,the results as shown in Table 1.

Table 1 The main project measuring method and evidence of food waste

1.3 Food Waste Properties Analysis

From outside,the food waste of breakfast main include egg shells,pickles,porridge,steamed stuffed buns,deep-fried dough sticks,deep-fried dough cakes and so on,the lunch and the dinner almost similar,which also include rice,noodle,vegetables,meat and so on.By contrast,the breakfast,lunch and dinner contain more oil and salt.

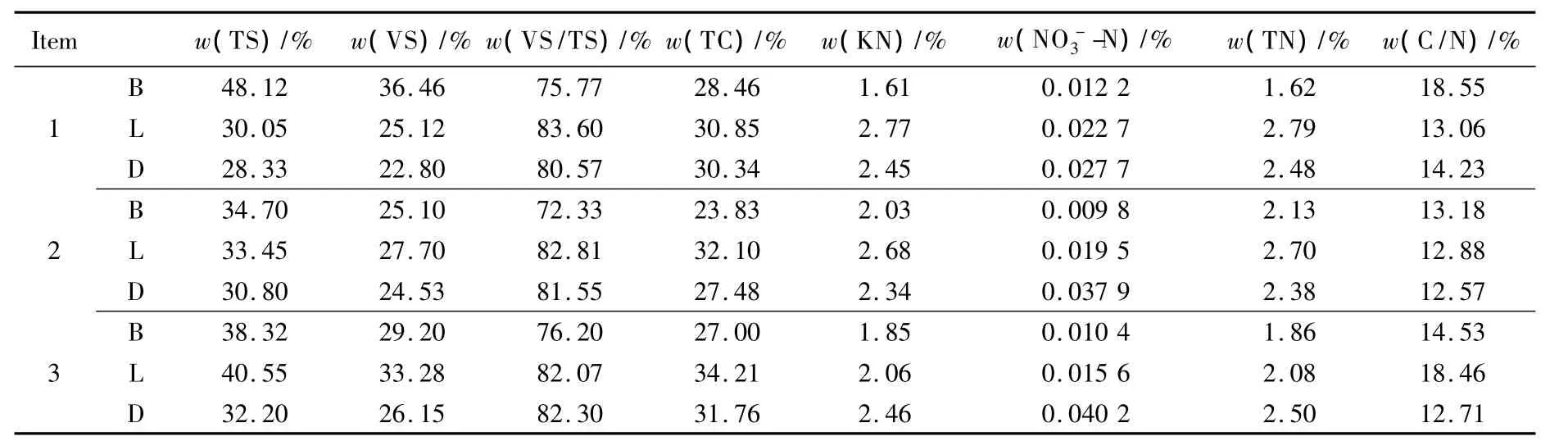

1.3.1 Changes of TS,VS,TC,TN and C/N

Carbon source and nitrogen source are necessary for microbial growth and development,and TS,VS,TC,TN and C/N play an important role in fermentation.

Cho et al[3]reported that a text about methane yields of cooked meat,cellulose,boiled rice,fresh cabbage and mixed food waste,with the same TS from 15%to 30%,were 482,356,294,277 and 472 mL/g VS added respectively,and anaerobic biodegradability based on the stoichiometric methane yield were 82% ,92% ,72% ,73%and 86%,respectively.

Hashimoto[4]reported at both mesophilic(35℃)and thermophilic(55℃).The batch tests could smoothly start-up with 0.49 m3/g VS fed.While thermophilic operation was not stable at an effluent substrate concentration of 62.5 m3/kg VS.Chea Eliyan[5]found that as the VS increased,the bio-gas production decreased.The methane bio-gas production rate of 140.35 L/kg VS when reactor loading rate at 2 kg/m3d.However,when loading was increased to 2.5 kg/m3d,the significant deterioration of biogas composition as well as production was only 62.55 L/kg VS.

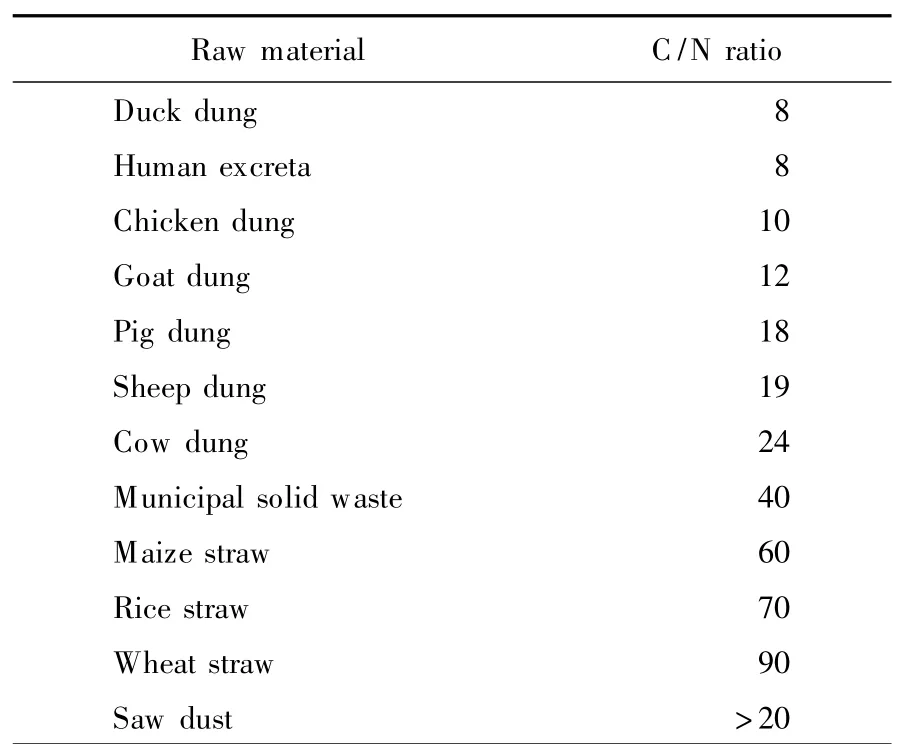

C/N make a very important effect on anaerobic digestion.The most suitable C/N proportion(molar ratio)for anaerobic digestion is(10~20)∶1,Polprasert[6]also gave an optimum(C/N)ratio(molar ratio)about(25 ~30)∶1,which is considered suitable for an anaerobic digester.If the C/N proportion too high might be due to acid accumulation and ammonia inhibition when proportion low.If the C/N of material is not suitable,we can mix food waste with other materials,and there are some materials C/N ratio as follows Table 2.

Table 2 C/N ratio of some materials

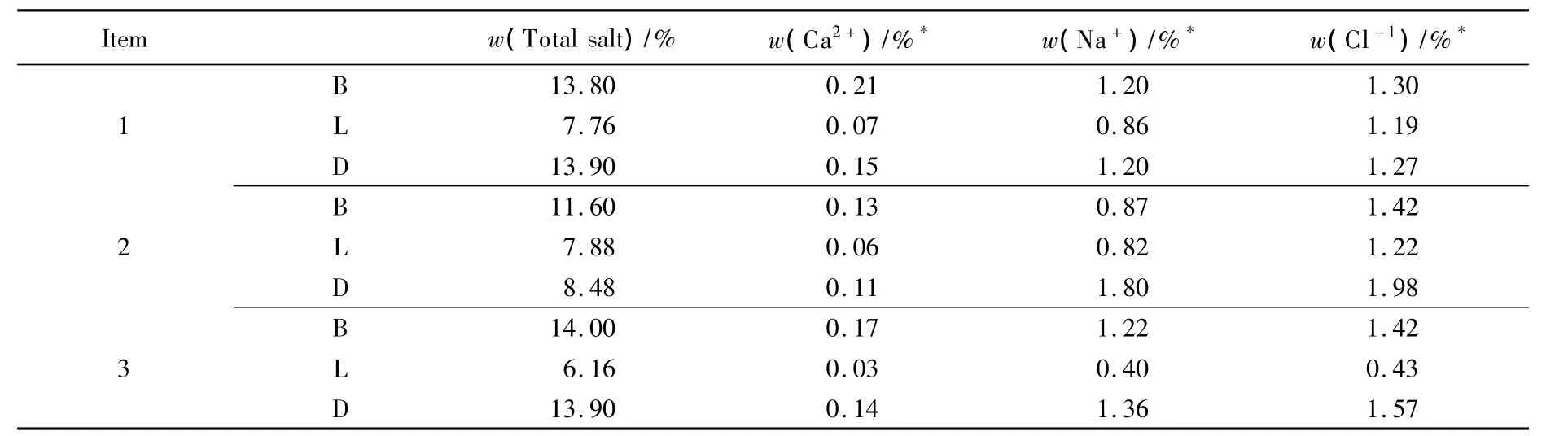

1.3.2 Inorganic Salt Ions

Food waste contains many complicated nutrients,there is more amount of salt.While the amount of salt might affect performance of anaerobic digestion,so we determine the water-solubility salt.Some studies indicated that it made no difference for methane bacteria under low Na+、Ca2+、C1-concentration.The salt content of food waste of breakfast,lunch and dinner was shown in Table 3.High concentration has clear evidence to restrain the growing of methane bacterial.The inoculation sludge was taken from process maturity anaerobic reaction tank,bacterial domestication as well,so it's feasible for food waste digestion.

From the result of the analysis about food waste in Table 4 shown,there are abundant nutriments in food waste and C/N、VS/TS rate are all in the appropriate rang,and inorganic salt concentration also haven't reached the degree of inhibition.Comprehensive analysis of the food waste has enormous potential for anaerobic digestion.

Table 3 The salt content of the food waste

Table 4 The TS、VS、TC、kjeldahl nitrogen-N、TN of the food waste and the C/N、TS/VS

Table 4 The TS、VS、TC、kjeldahl nitrogen-N、TN of the food waste and the C/N、TS/VS

Notes:B—breakfast;L—lunch;D—dinner.

Item w(TS)/% w(VS)/%w(VS/TS)/%w(TC)/% w(KN)/% w(NO-3-N)/% w(TN)/% w(C/N)/%1 2 3 55 L 30.05 25.12 83.60 30.85 2.77 0.022 7 2.79 13.06 D 28.33 22.80 80.57 30.34 2.45 0.027 7 2.48 14.23 B 34.70 25.10 72.33 23.83 2.03 0.009 8 2.13 13.B 48.12 36.46 75.77 28.46 1.61 0.012 2 1.62 18.18 L 33.45 27.70 82.81 32.10 2.68 0.019 5 2.70 12.88 D 30.80 24.53 81.55 27.48 2.34 0.037 9 2.38 12.57 B 38.32 29.20 76.20 27.00 1.85 0.010 4 1.86 14.71 53 L 40.55 33.28 82.07 34.21 2.06 0.015 6 2.08 18.46 D 32.20 26.15 82.30 31.76 2.46 0.040 2 2.50 12.

2 Dry Fermentation and Factors

Dry fermentation,one of the most efficient and productive treatment technologies has received significant attention from researchers.Dry fermentation means organic solid concentration between 20%to 30%,and methane fermentation under no or little flow water condition.Contrast with the wet anaerobic digestion there are no or little fresh water by dry anaerobic digestion,it is only saving water but also save cost for digestive residue dehydration.Therefore dry anaerobic digestion has more high organic loading and bio-gas production efficiency.

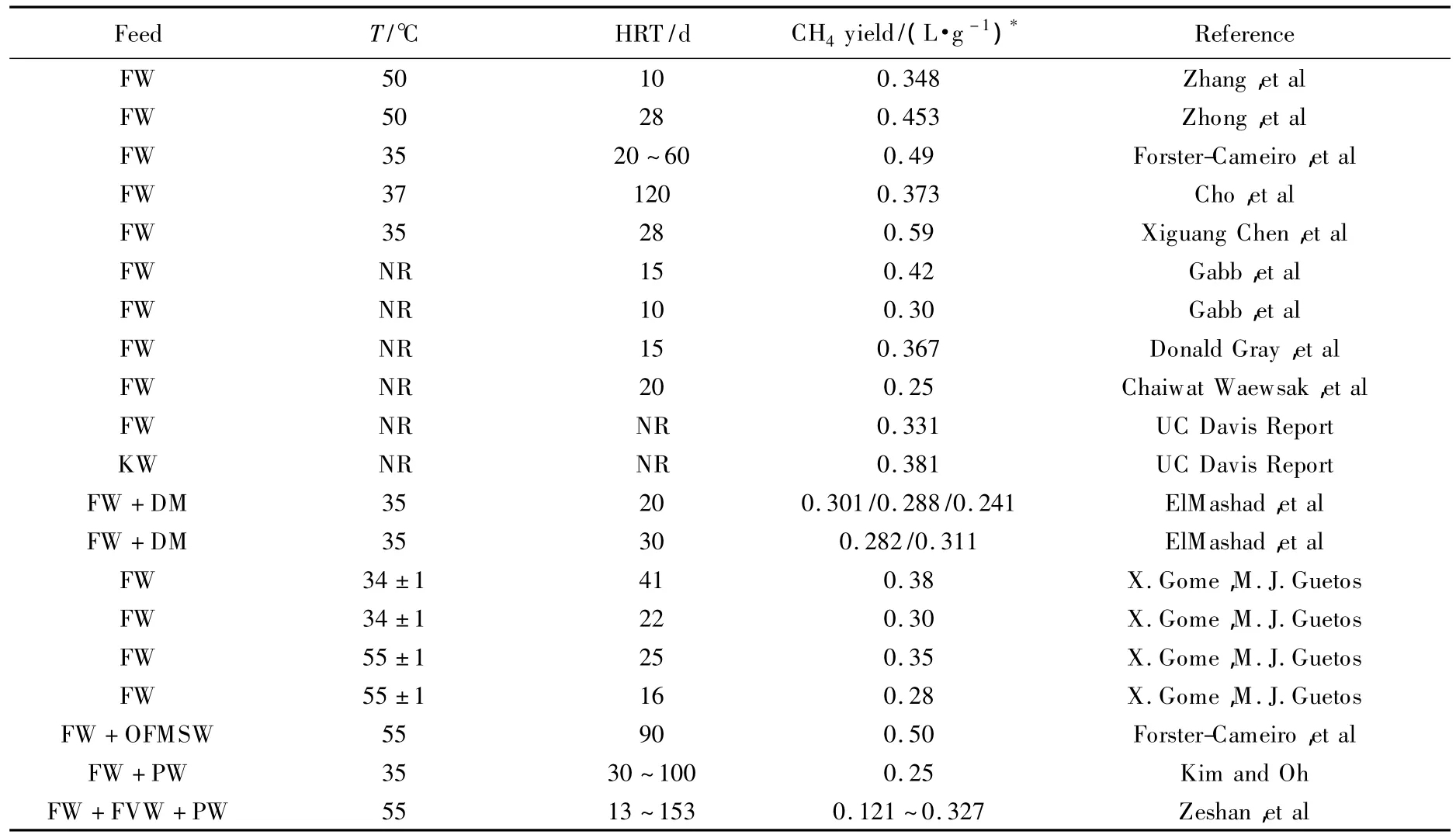

Food waste has abundant organic materials and water,using food waste as matrix for anaerobic digestion not only reduce waste emission but also provide cleaner energy.Zhang et al[7]sampled 500 food waste point location for investigation and bio-gas production study,find food waste is suitable matrix for anaerobic digestion,it has high biodegradability and methanogenesis performance.As shown in Table 5.

Table 5 Several performance data of digestion for food waste and other solid[8]

2.1 Temperature

The optimum temperature is important for microorganism growth and metabolism,it's also important factor for enzyme activity.Generally,thermophilic fermentation and mesophilic fermentation are used for degradation waste.Though thermophilic fermentation have some advantages such as quick response,short digest time,high biogas production and so on.Baere[9]claimed that when thermophilic dry fermentation occurred and became attractive due to higher gas production and pathogen killed-off.A report shown that at a temperature of 35℃,the methane yield was increased by 43%compared to 25 ℃ .Chae et al[10].reported that the bio-gas composition differed according to digestion temperature.Methane contents in the biogas were 65.3%,64.0%and 62.0%at 35℃,30℃ and 25℃,respectively.In view of the geographical environment and climate conditions in northern China,thermophilic fermentation might increase fermentation costs.While mesophilic fer-mentation digests process stability,need less energy consumption,higher treatment ability and more mature technology.It's more suitable for northern Chinese food waste digestion.

2.2 Hydrogen Concentration(pH)

The activity of microorganisms is affected by pH value,so pH value affects the whole process of anaerobic digestion.In single-phase anaerobic process,as acid production and methane production in the same reactor,general pH range between 6.4~7.2 is most suitable for the anaerobic digestion process.Mace et al[11]reported at the range of 7.0 to 7.2 bacteria shows the highest performance.When the pH is too low,can make the acid producers occur irreversible inhibition,thus affect the entire digestive process.Lay et al reported that a pH less than 6.1 or more than 8.3 will cause bad performance,even failure of a digester.In two-phase anaerobic digestion process,acidification reactor can regulate the pH value for choosing particular acid producer microbial populations,thus to control acid producing approach and the subsequent methanogenesis process.The growths of methanogens have influenced by the pH value,too high or too low pH value will reduce the active of methanogens,and even kill them.

2.3 Solid Holdup

Dry anaerobic fermentation solid content rate can be raised to 20% ~40%,studies had shown that the initial use higher Total Solid(TS)concentration of food waste as anaerobic fermentation raw materials,in the early reaction the solid-phase hydrolysis acidification rapidly,a large number of Volatile Fatty Acids(VFA)can be produced and inhibit hydrolysis-acidification phase and subsequent methane-producing,even affected the speed and stability of the anaerobic fermentation seriously.Forster-Carneiro et al[12],using food waste as raw materials for dry fermentation experiments found that the TS was 20%,and the sludge was 30%,the yield of methane gas rate is 0.49 L·g-1VS.

2.4 Ratio of Inocula

The acidification phenomenon of food waste anaerobic digestion might due to the rate of hydrolysis acidification and methane-producing phase mismatch;anaerobic fermentation inocula not only provide a microbial but also plays an important role in regulating acid-base balance.Angelidaki[13]reported it is very important to find appropriate inocula containing the necessary bacteria for the degradation process to proceed,and another important factor is the amount of inocula.Studies had found that mesophilic fermentation under the condition of inoculation proportion between 10∶90 to 15∶85(volume ratio)could be starting and running normally,while when inoculation proportion over 50∶50(volume ratio)the volatile solid(VS)degradation rate and the methane production rate high-efficiency.Mesophilic fermentation in a ratio inocula of 90∶10(volume ratio),volatile solid degradation rate was 99%,the volatile solid methane-producing rate up to 519.3 mL/g,methane production rate can reach 94.5%.

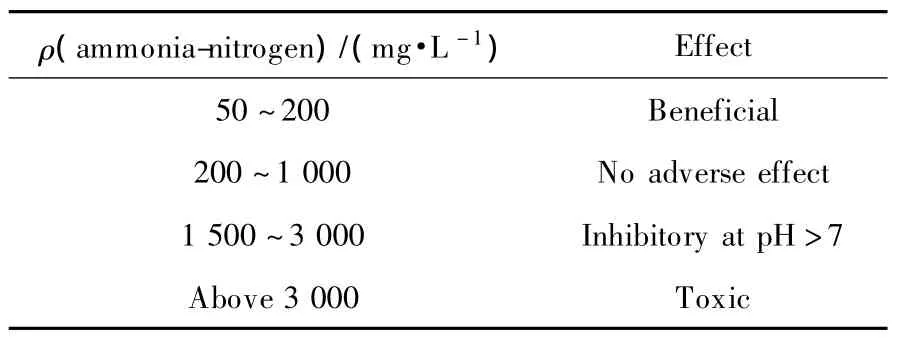

2.5 Ammonia Nitrogen

Generally believes that mass concentration below 200 mg/L of ammonia nitrogen is good for anaerobic process,because nitrogen is one of the important nutrients in anaerobic microorganisms.And Gerardi[14]reported that ammonia concentration more than 1 500 mg·L-1at high pH may result into digester failure.Chynoweth and Pullammanappali[15]reported that the concentration of NH4-N between 200 to 1 000 mg·L-1had no adverse effect on digestion,while the concentration above 3 000 mg·L-1,it had toxic for bacteria.Ammonia inhibition concentration range is wide,cause methane production fell into 50%(half inhibition)of mass concentration range is 1.7~14 g·L-1.The effect of ammonia-nitrogen/ammonia in anaerobic digester was summarized in Table 6.Much higher concentrations could be accepted through acclimation.Ammonia inhibition concentration of significant differences can be attributed to the matrix,the inoculation sludge,environmental conditions,and the domestication time difference.

Table 6 Effect of ammonia-nitrogen/ammonia in an anaerobic digester

3 Dry Fermentation Kinetics Analysis

In the 1970s,Bryant discovered originally referred to as“the methane-producing bacteria bacterium”is composed by two kinds of bacteria,one bacterial oxidation acetic acid into ethanol and H2,and another kind of bacteria use H2,CO2and acetic acid generate CH4.Thus he puts forward the theory of anaerobic digestion for three stages,namely hydrolysis-fermentation stage,producing hydrogen-production acetate stage and methaneproducing phase.First of all,through the fermentation of bacteria produce ethanol,propionic acid,butyric acid,lactic acid and so on.Schieder et al[16]found that hydrolysis is often the slowest and limiting-step in anaerobic degradation process for solid substrate.Mata-Alvarez claimed that the hydrolysis is considered to be the key step in the biodegradation of complex wastes.Then through the production of acetic,acid bacteria degradation functions to generate acetic acid,H2and CO2.Schink found that the accumulation of product such as lactate,ethanol,propionate,butyrate and higher volatile fatty acids(VFAs)is the bacteria's response to increased hydrogen concentration.Last by methane bacteria use materials converted to CH4and CO2eventually.

3.1 Anaerobic Microbe Growth Dynamics

Microbial growth of six typical periods for:delay phase, acceleration phase, logarithmic phase,deceleration phase,stagnation and death phase.

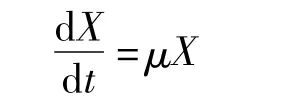

In the logarithmic phase of growth rate dX/dt,growth rate μ and the biomass X has relationship as follows:

μ is restricted production such as carbon source,nitrogen source.

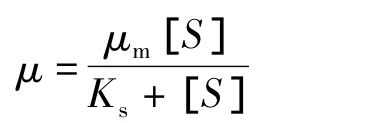

This is the Monod equation,[S]is the concentration of free organic substrate in reactor,the maximum growth rate of microbesm μmand the difference constant Kshas relationships as follows:the research has shown that the hydrolysis acidification phase and the degradation of propionic acid,butyric acid and the acetic acid reaction of methane bacteria ofpseudo-first-order kinetic model(Monod equation).

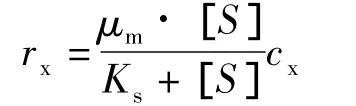

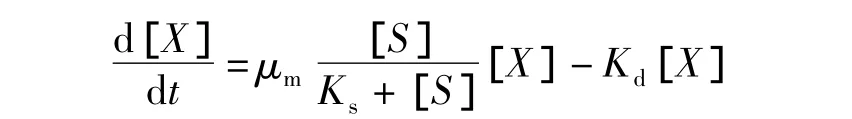

The growth rate of cells equation as follows:

rxis the absolute rate of cell growth;cxis the cell concentration.

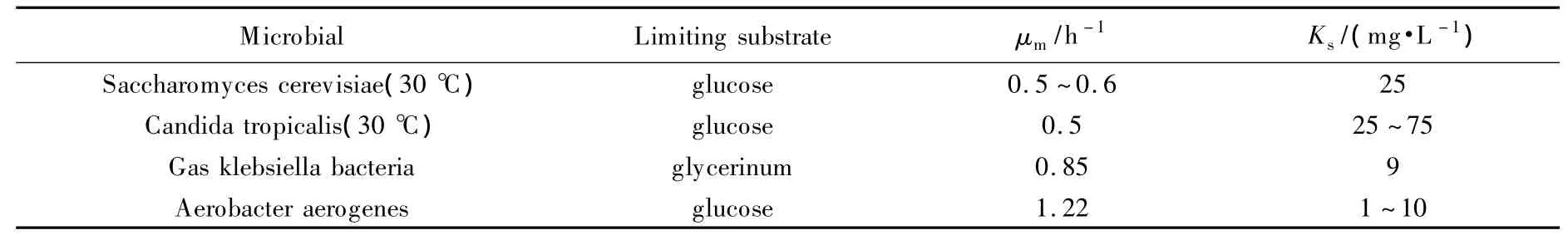

Two parameters of Monod equation are Ksand μm,respectively.Several kinds of common microorganisms'Ksand μm.were shown in Table 7.

Table 7 Several kinds of common microorganisms'Ksand μm

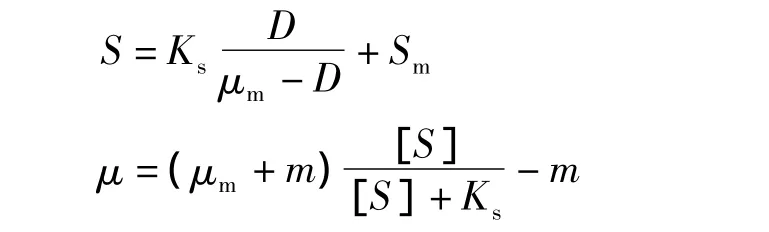

Later,people consider some of the specific problems of facts,such as matrix lack.So some deformation equation occur as follows[17-18]:

Smis the threshold concentration;D is the actual growth rate;m is maintenance rate.

The dynamics of death is represented mathematically as a decay of the population Kd[X].Incorporating Monod's concept and the kinetics of death into equation follows.

[X]is total concentration of organisms in reactor.

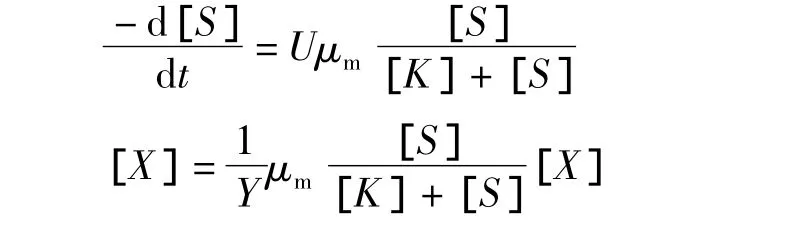

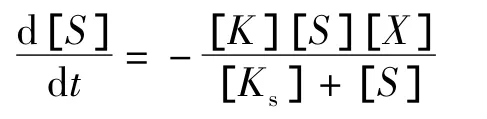

The rate of decrease of the concentration of the substrate is proportional to the rate of increase of the concentration of the organisms.The rate of decrease of the substrate is the equation.

[K]is rate constant;U is the reciprocal of Y.

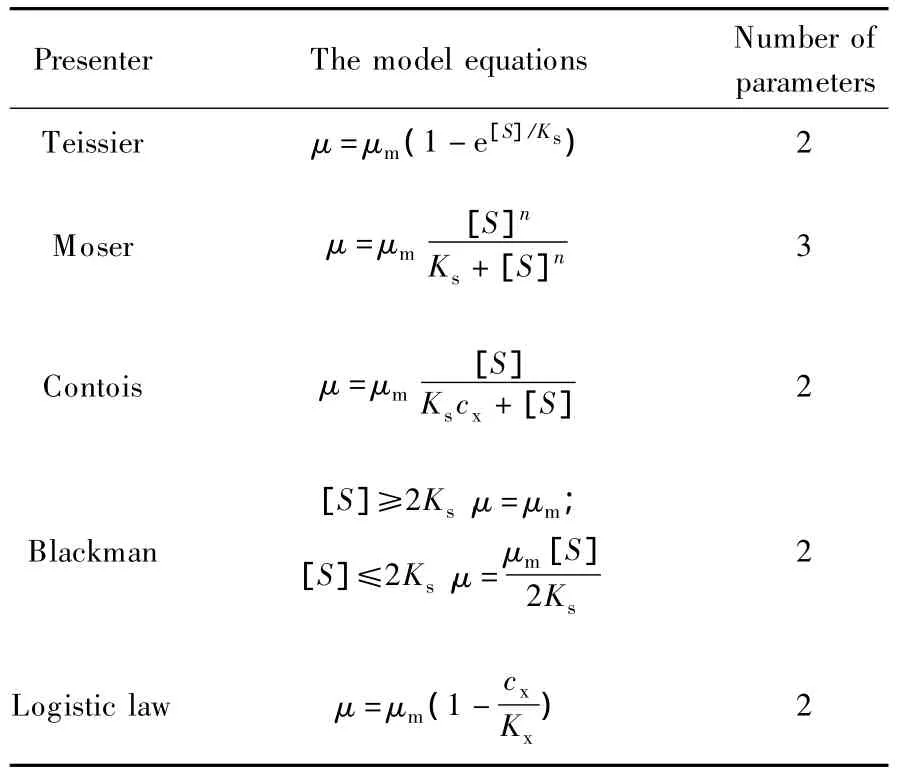

In some cases,Monod equations become no longer applicable,such as high cell density.As a result,people have otherunstructured model(Table 8)is put forward.

Table 8 Some unstructured model

Teissier equation was considered as pure empirical formula;Moser equation described the high series reaction substrate consumption;Contois equation described in the high densityofcell growth;Blackman equation reflected in addition to the bottom store there may be other limiting factors;Logistic law belonged to the logic equations,it integrated said because of the lack of nutrients and toxic metabolite accumulation and cell concentration on the negative effectsofcell growth rate.

3.2 Substrate Consumption Dynamics

The substrate utilization rate or substrate decrease rate can be modeled with the following expression.

d[S]/dt is the rate of formation.

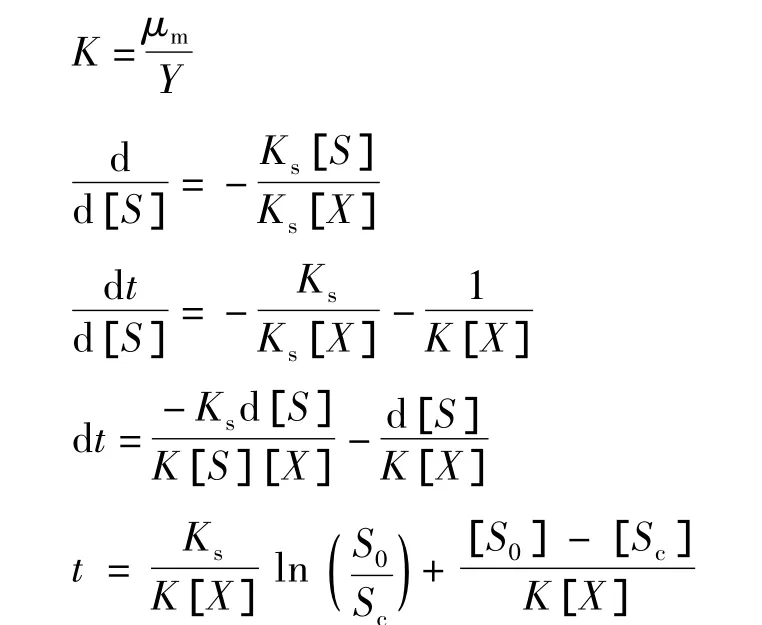

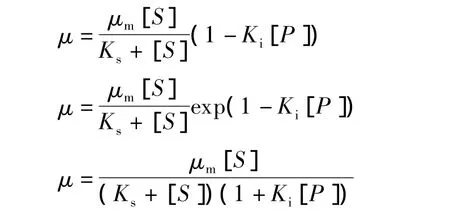

When matrix inhibited by its own bio-degradation,the Monod model above becomes unsatisfactory.In this case,someone made the following equation after their research.

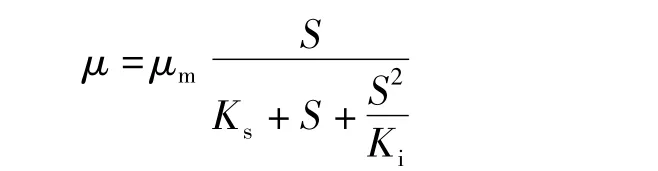

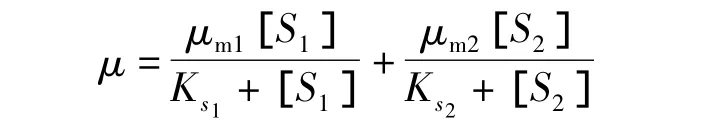

In some case,the effect of the cell growth is by a variety of substrates at the same time,its means the influence is also different.If there are two limiting substrate influence cellspecific growth rate at the same time,expressed by the following equation.

μmis the maximum specific growth rate when the two substrates also enough;Ks1、Ks2is the two substrates saturated coefficient.

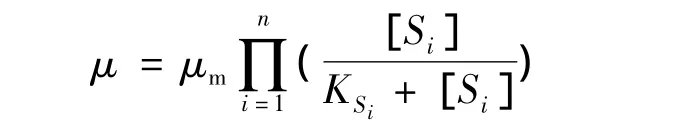

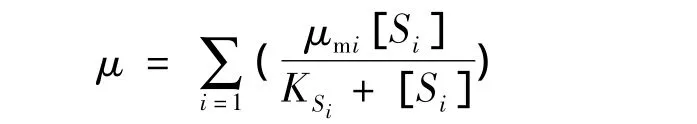

If there are n kinds of restrictive substrates.

If the two substrates can be used at the same time,and also can be substituted.

μm1、μm2is the maximum specific growth rate at the two substrates,respectively.

For n kinds of restrictive substrates.

For more complex cases,the substrates can be divided into two kinds:one kind is necessary to cell growth,if lack of them,a cell cannot grow;another kind is promote cell growth,it can improve the specific growth rate of cells.

[SI]is the promote cell growth substrate concentration;[SE]is the substrate concentration necessary to cell growth;μm0is the maximum specific growth rate when the promote growth substrates does not exist.

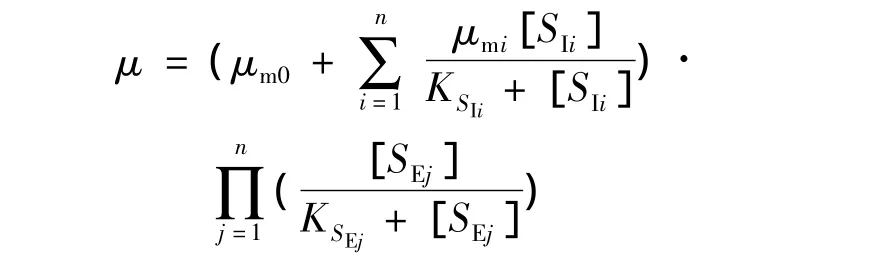

3.3 Product Inhibition Growth Dynamics

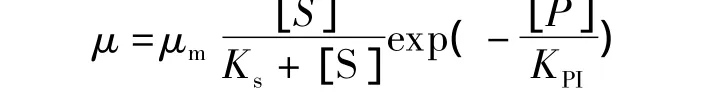

When microbial growth inhibited by its metabolites,expressed by the dynamics equations as follows:

Kifor response inhibition constant,[P] is product concentration.

Bryant is indicted that produce hydrogen-acetic-acid bacteria generate hydrogen increase hydrogen partial pressure suppresses the production of acetic-acid bacteria metabolic activity,if a large number of hydrolysis acid accumulation will lead to methane-producing bacteria activity decrease and even kill the bacteria.So build a new reactor online monitoring system to realize the real-time control of the reaction,ensure the anaerobic digestion progress smoothly.

Some of the main empirical formulas is as follows.

Aiba et al:

KPIis the product inhibition constant.

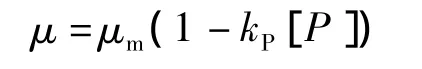

Hinshelwood:

kPis the product inhibition rate constant.

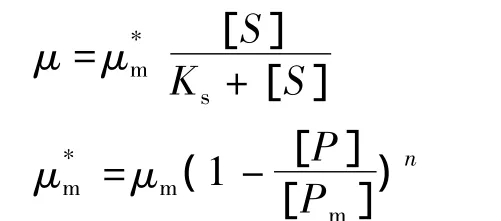

Levenspeil:

[Pm]is the product concentration when the cells stop growing;n is the product toxicity indexis the apparent maximum specific growth rate.

From Levenspiel equation,when [P] =[Pm]=0,cell stop growth,and when[P]=0,μm=

4 Conclusions

Food waste output increased dramatically in recent years.Its proportion of household waste becomes more and vaster,and organic matter content in the food waste is higher and the composition is more and more complex.Food waste dry anaerobic fermentation for waste reduction,harmless and recycling is great significance.Focus on the colder winter in northern China and low rate of gas,this article first analyzes the using probability of the food waste,and then sets about experimental study,optimizes the fermentation equipment and heating preservation method as the reference of the northern city life on the dry fermentation of the food waste.

[1] Visvanathan C,Trankler J,Joseph K,et al.Municipal Solid Waste Management in Asia:Asian Regional Research Program on Environmental Technology(ARRPET)[M].Pathum Thani:Asian Institute of Technology Publication,2004:34-36.

[2] You Y,Ren N Q,Wang A J,et al.Use of Waste Fermenting Liquor to Produce Bioflocculants with I-solated Strains[J].International Journal of Hydrogen Energy,2008,33(13):3295-3301.

[3] Cho J K,Park S C.Biochemical Methane Potential and Solid State Anaerobic Digestion of Korean Food Wastes[J].Bioresource Technology,1995,52(3):245-253.

[4] Hashimoto A G.Thermophilic and Mesophilic Anaerobic Fermentation of Swine Manure[J].Agric Wastes,1983,6(3):175-191.

[5] Chea Eliyan.Anaerobic Digestion of Municipal Solid Waste in Thermophilic Continuous Operation[J/OL].(2007-04-27).http://www.faculty.ait.ac.th/visu/Data/AIT-Thesis/Master%20Thesis%20final/chea%20combined.pdf.

[6] Polprasert C.Organic Waste Recycling Technology and Management[M].America:John Wiley &sons,1996:78-80.

[7] Zhang R H,EI-Mashad H M,Hartman K,et a1.Characterization of Food Waste as Feedstock for Anaerobic Digestion[J].Bioresource Technology,2007,98(4):929-935.

[8] Jay Chand Shiv.Techno-economic Feasibility Evaluation of Conversion of Food Waste toEnergy Through Anaerobic Digestion and Gasification[EB/OL].(2009-08-10).http://www.uea.ac.uk/env/all/teaching/eiaams/pdf_dissertations/2009/Shiv_Jay.pdf.

[9] De Baere L.Anaerobic Digestion of Solid Waste:State-of-the-art[J].Water Science and Technology,2000,41(3):283-290.

[10] Chae K J,Jang A,Yim S K,et al.The Effect of Digestion Temperature and Temperature Shock on the Biogas Yields from the Mesophilic Anaerobic-digestion of Swine Manure[J].Bioresour Technol,2008,99(1):1-6.

[11] Mace S,Bolzonella D,Cecchi F,et al.Comparison of the Biodegradability of the Grey Fraction of Municipal Solid Waste of Barcelona in Mesophilic and Thermophilic Conditions[J].Water Science and Technology,2000,48(4):21-28.

[12] Forste-Carneiro T,Pérez M,Remero L I.Influence of Total Solid and Inoculum Concents on Performance of Anaerobic Reactors Treating Food Waste[J].Bioresource Technology,2008,99(15):6994-7002.

[13] Jantsch T G,Angelidaki I,Schmidt J E,et al.Anaerobic Biodegradation of Spent Sulphite Liquor in a UASB Reactor[J].Bioresource Technology,2002,84(1):15-20.

[14] Gerardi M.The Microbiology of Anaerobic Digesters[M].New Jersey:John Wiley and sons,Inc.,2003:186-189.

[15] Chynoweth D P,Pullammanappallil P.Microbiology of Solid Waste[M].New york:Anaerobic Digestion of Solid Waste,1996:71-77.

[16] Schieder D,Schneider R,Bischof F.Thermal Hydrolysis(TDH)as a Pretreatment Method for the Digestion of Organic Waste[J].Water Science and Technology,2000,41(3):181-187.

[17] Goudar C,Strevett K,Grego J.Competitive Substrate Biodegradation During Surfactant-enhanced Remediation[J].Journal of Environmental Engineering,1999,125(12):1142-1148.

[18] Goudar C T,Ganji S H,Pujar B G,et al.Substrate Inhibition Kinetics of Phenol Biodegradation[J].Water Environment Research,2000,72(1):50-55.