Preparation and Properties of Spray Polyurea Elastomer for Aquaculture Foam Floating Balls

Guifang HUANG Guanyuan WEI Shengjun WEI Lan DING Wenhong CAI Bolin PAN

Abstract [Objectives] This study was conducted to develop a polyurea elastomer which can be sprayed on the surface of expanded polystyrene (EPS) floating balls, so as to improve the surface strength and service life of the floating balls.

[Methods] The effects of the types and amounts of isocyanate, chain extenders and polyether polyols on the gelation rate, adhesion and wear resistance of polyurea elastomer were investigated, and it was finally determined the preparation process of polyurea elastomer using liquid isophorone diisocyanate (IPDI) and amino-terminated polyether (D2000) as the main raw materials, dimethylthiotoluene diamine (E300) as the chain extender and silica as the wear resistance modifier through two-step solution polymerization of prepolymerization and chain extension.

[Results] The physical properties and chemical resistance tests of spray polyurea elastomer showed that it had good physical properties and acid and alkali resistance, and could meet the requirements of spraying and protection of EPS floating ball surface in marine environment.

[Conclusions] Polyurea elastomer coating can improve the aging resistance, wear resistance and acid and alkali resistance of EPS floating balls, and prevent them from being fragile and floating randomly to form marine floating garbage which results in "white pollution".

Key words EPS floating ball; Spray polyurea elastomer; Gelation rate; Wear resistant; Adhesion; Chemical resistance

DOI:10.19759/j.cnki.2164-4993.2024.02.011

China is a big aquaculture country, where most of existing aquaculture facilities use expanded polystyrene (EPS) floating balls as floating bodies. EPS floating balls have become a global public hazard, and are called "white pollution" because of its shortcomings such as easy aging and easy formation of marine floating garbage after being crushed, dissolving nonyl phenol which feminizes male fish, blocking the digestive system of marine animals eating them by mistake and then causing the death of marine animals, being unable to be decomposed by microorganisms in nature to form garbage for thousands of years, and producing toxic substances after burning[1-2]. In order to improve the aging and breakage of EPS floating balls, a polymer protective layer with excellent aging resistance and wear resistance can be sprayed on its surface.

Polyurea elastomer is prepared by the reaction of an isocyanate component (referred to as component A) and an amino compound component (referred to as component B). It is a new type of green polymer developed abroad in the middle and late 1960s to meet the needs of environmental protection[3]. In 1960s, Soviet expert FEDOTOVA[4] and his team started the research on polyurea synthesis. Early polyurea is difficult to form because of its high reactivity, which restricts its development. The development of spraying equipment has greatly promoted the development and application of polyurea elastomer. In the mid-1980s, Texaco (now Huntsman) Company[5] took the lead in successfully developing spray polyurea elastomer (SPUA) technique, which completely broke through the limitations of traditional environmental protection painting technique and achieved rapid development. North America, Australia, Japan and South Korea introduced this technique in 1991, 1993, 1995 and 1997 respectively, and put it into commercial application one after another[6]. In China, the team of Huang Weibo of Marine Chemical Engineering Institute (Qingdao) took the lead in the research of SPUA technique in 1995, and successfully introduced the first polyurea elastomer formula "SPUA-102 waterproof and wear-resistant material" with independent intellectual property rights in the laboratory in 1998[7-8]. Huang et al.[9] studied the durability of Qtech-412 polyurea anticorrosive coating by natural exposure and ultraviolet-accelerated aging in marine atmospheric environment. The study showed that the actual anticorrosive effect of this coating was far superior to other anticorrosive coatings. Wang et al.[10] developed a polyurea elastomer material suitable for marine instruments, and the newly developed polyurea elastomer had excellent abrasion resistance, impact resistance, aging resistance and corrosion resistance through experiments. ARUNKUMAR T et al.[11] chose low-carbon steel IS2062 and aluminum 5052-H32 as substrates, and studied the influence of polyurea coating on metal corrosion resistance in seawater environment. The results showed that for KOH, H2SO4 and NaCl, the protective efficiency of polyurea coating was higher than 90%, and it had strong adhesion to metal. Lin et al.[12] conducted seawater immersion tests on pure polyurea coatings of QF-163 and QF-165, and the results showed that pure polyurea coatings had good stability in seawater environment.

To sum up, polyurea elastomer coating is mostly used in metal and concrete buildings in marine anticorrosion engineering, but it has not been used in the protection of EPS floating balls.In this study, the effects of isocyanate type and dosage (4,4-diphenylmethane diisocyanate, isophorone diisocyanate), chain extender type and dosage (thymine, N-isopropyl-phenyl-p-phenylenediamine, 1,3-dicyclohexylurea and dimethylthiotoluene diamine E300), polyether polyol and the ratio of soft to hard segments on the gel speed, adhesion and wear resistance of polyurea elastomer were investigated, so as to effectively improve the aging resistance, wear resistance and acid and alkali resistance of EPS floating balls.

Materials and Methods

Main materials

4,4-Diphenylmethane diisocyanate (MDI-50): Yantai Wanhua Polyurethanes Co., Ltd.; isofluorone diisocyanate: COVESTRO, Germany; amino-terminated polyether D2000: Yangzhou Chenhua New Materials Co., Ltd.; dimethylthio-toluenediamine E300: Hangzhou Chongshun Chemical Co., Ltd. All raw materials were industrial grade.

Experimental instruments

The mechanical properties of polyurea elastomer were tested using a CTM2500 tensile machine (Xie Qiang Instrument Manufacturing (Shanghai) Co., Ltd.) with reference to GB/T 16777-1997. The hardness was tested using an LX-A hardness tester (Shanghai Tool Factory Co., Ltd.) according to GB/T 531.1-2008. The viscosity was tested using an NDJ-1 rotary viscometer (Shanghai Youke Instrument Co., Ltd.) according to GB/T 10247-2008. The wear resistance was tested using a DR-2M56 TABER wear tester (Taiwan Dongri Testing Instruments and Equipment Company) with reference to GB/T 1768-197.

Experimental methods

Preparation of spray polyurea elastomer

(1)Preparation of component A

Component A was a quasi-prepolymer. At room temperature (25℃), weighed amino-terminated polyether which had been dehydrated in vacuum was added into a reaction kettle with a stirrer, a heating device and nitrogen protection, and then weighed isocyanate was slowly dropped, and the reaction lasted for 30 min. When NCO% reached the theoretical value, the material could be discharged under nitrogen protection.

(2) Preparation of component B

Component B was amino polyether and amine chain extender. The amino-terminated polyether and amine chain extender which had been dehydrated and metered in vacuum were evenly mixed at room temperature (25 DEG C).

When studying the effect of nano wear-resistant filler on the wear resistance of spray polyurea elastomer, a certain amount of nano wear-resistant filler and silane coupling agent KH550 (the amount of coupling agent was 10% of the filler) should be added to the chain extender first, and then the mixture should be vibrated in ultrasound for 1 h. The remaining process was consistent with the above preparation process.

(3) Experimental formulas

The MDI-50 spray polyurea elastomer of the MDI-50 system was synthesized from liquid 4,4-diphenylmethane diisocyanate (MDI-50) and amino-terminated polyether (D2000) as main raw materials, using dimethylthiotoluene diamine (E300) as chain extender through two-step solution polymerization of prepolymerization and chain extension. The formula was D2000: 100 g, MDI-50: 64.934 g, E-300: 42.237 g, and 1010: 0.207 2 g.

The IPDI spray polyurea elastomer of the IPDI system was synthesized from liquid isophorone diisocyanate (IPDI) and amino-terminated polyether (D2000) as main raw materials, using dimethylthiotoluene diamine (E300) as chain extender through solution polymerization undergone two steps of prepolymerization and chain extension. The formula was D2000: 100 g, IPDI: 57.73 g, E-300: 42.237 g, and 1010: 0.200 0 g.

In order to prepare polyurea elastomer with the same hardness, the formula values of the MDI-50 system and IPDI system were different.

Spraying process

The spraying equipment used in the experiment was Reactor H-XP3 equipment and GX-7 spray gun produced by Graco, America. The components were accurately measured with Reactor H-XP3 and pumped to the spray gun. The two components were mixed in the mixing chamber of the spray gun and then sprayed out. The moving speed of the spray gun was 0.3-0.5 m/s, and the single-layer spraying thickness was 2-4 mm.

Main process parameters: ① The hydraulic pressure was 13.7-17.2 MPa, and the material temperature was in the range of 60-70 ℃. ② The isocyanate index was controlled between 1.05 and 1.1. ③ The volume ratio of component A and component B was controlled at about 1:1.

Results and Analysis

Effects of isocyanate on synthesis of spray polyurea elastomer

As the protective material on the surface of EPS floating balls, spray polyurea elastomer needs to be synthesized without solvent, so that the solid content should reach 100%. Therefore, in this study, the effects of MDI-50 system and IPDI system on the synthesis of spray polyurea elastomer were studied by selecting different solid contents for synthesis experiments. Table 1 shows the viscosity of polyurea synthesized using MDI-50 and IPDI with different solid contents.

Through experiments, it was found that the sample with a solid content of 80% in the MDI-50 system had a viscosity of 9 470 cps, and it could not be sprayed from the spray gun, so this viscosity was the highest limit for spraying polyurea elastomer. The viscosity of the sample with a solid content of 70% was 4 180 cps, and it could be sprayed from the spray gun, without sagging and gel phenomenon in the spray gun, and the spraying effect was better than samples with other solid contents. Among the samples in the IPDI system, the sample with a solid content of 100% showed a viscosity of 4 800 cps, and could be sprayed from a spray gun, and its spraying effect was similar to that of the sample in the MDI-50 system with 80% solid content.

The experimental results showed that the IPDI system could reach a solid content of 100% when synthesizing spray polyurea elastomer, while MDI-50 couldnt reach a 100% solid content, and the former was more in line with the requirements of spray polyurea.

Effects of chain extender types on polyurea synthesis

Effects of chain extender types on gel time of polyurea

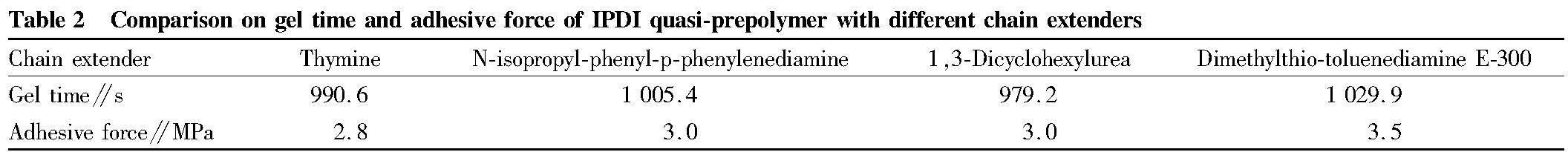

Spray polyurea elastomer for EPS floating balls needs proper gel time to form a complete and continuous coating on the surface of EPS floating balls. Therefore, after confirming that the IPDI system was more suitable for spray polyurea elastomer, quasi-prepolymer synthesized by IPDI was used to synthesize polyurea elastomer synthesized with different chain extenders, and the gel time was observed, as shown in Table 2.

Agricultural Biotechnology2024

It can be seen from Table 2 that the gel time of polyurea elastomer synthesized by four chain extenders, thymine, N-isopropyl-phenyl-p-phenylenediamine, 1,3-dicyclohexylurea and dimethylthiotoluene diamine (E-300), was slightly different, but all of them could reach the reaction time required for spray polyurea elastomer. Among them, the polyurea elastomer synthesized with dimethylthiotoluene diamine (E-300) as the chain extender required the longest gel time. IPDI, with the full name of isophorone diisocyanate, has high weather resistance and chemical corrosion resistance, mainly due to its molecular structure characteristics. Firstly, IPDI contains a large number of benzene rings and nitrogen element, which makes it highly stable under the influence of external environment such as light and heat. Secondly, the molecule of IPDI also contains two isocyanate groups, which enable IPDI to form stable chemical bonds with many materials, thus endowing it with good chemical corrosion resistance. Therefore, IPDI can maintain its excellent performance no matter under extreme weather conditions or under the erosion of various chemicals, which is also an important reason why it is widely used in various high-performance coatings, adhesives and other products.

Effects of chain extender types on adhesive force of polyurea elastomer

EPS is a substrate with weak polarity, which contains no polar functional groups and has low surface energy. It is difficult for polyurea coatings to completely infiltrate its surface, resulting in poor adhesion, so it is necessary to choose a suitable chain extender. Polyurea elastomer was synthesized with quasi-prepolymer synthesized by IPDI and the four different chain extenders, and its adhesive force was tested. The test results are shown in Table 2. It could be known from the comparison on the adhesive force among the four diamine chain extenders that the adhesive force of primary amine E-300 was better than that of secondary amine, and thymine was the worst. Finally, E-300 was selected as the chain extender.

Effects of nano wear-resistant filler on wear resistance of spray polyurea elastomer

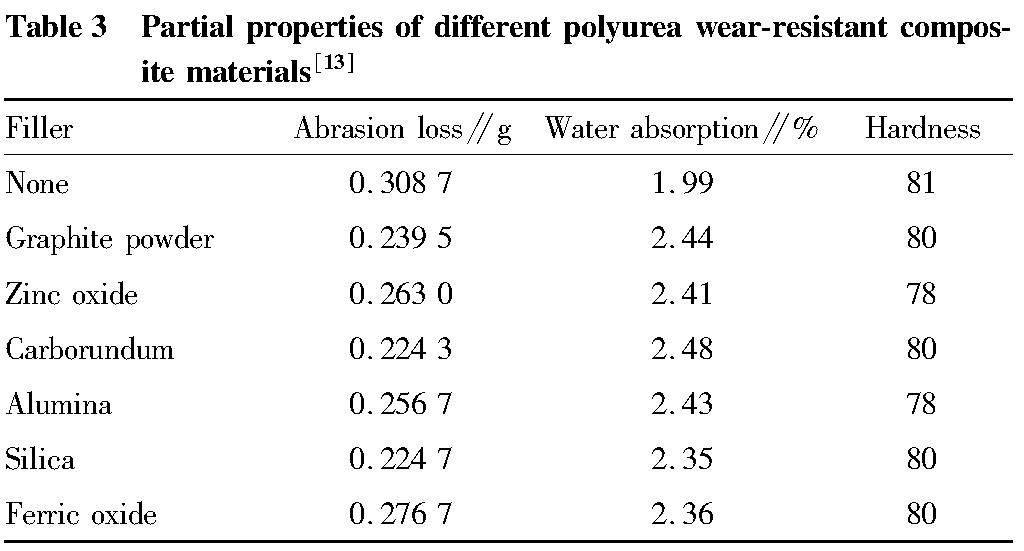

In order to improve the wear resistance of polyurea elastomer, Li[13] studied the influence of wear-resistant fillers on the wear resistance of polyurea elastomer by adding different nano wear-resistant fillers into chain extender E-300 and changing the amount of used wear-resistant agent. Relevant results are shown in Table 3. As shown in Table 3, after adding several different fillers, the wear resistance of polyurea elastomer was improved to varying degrees compared with pure polyurea elastomer without any fillers, but the water resistance and hardness decreased.

After comprehensively comparing the abrasion loss, water absorption and hardness of various wear-resistant materials in Table 3, alumina and silica were selected for performance comparison with different addition amounts, and the comparison results are shown in Table 4. As shown in Table 4, when the amount of alumina filler was 1%, the abrasion loss was the smallest. Whensilica filler was at a certain amount between 0% and 0.5%, the wear resistance was the best. After comprehensive consideration, the addition of silica at a small amount was selected to modify the wear resistance of the polyurea elastomer for EPS floating balls.

Performance test of polyurea elastomer for EPS floating balls

According to the application environment of EPS floating balls, on the basis of using liquid isophorone diisocyanate (IPDI) and amino-terminated polyether (D2000) as the main raw materials, dimethylthiotoluene diamine (E-300) as the chain extender and silica as the wear-resistant modifier, the ratio of soft to hard segment in the formula was adjusted to prepare a soft material 84A (D2000: 100 g, IPDI: 53.99 g, 1010: 0.192 8 g, nano SiO2: 0.964 1 g) and a hard material 88A (D2000: 100 g, IPDI: 57.73 g, E-300: 42.237 g, 1010: 0.200 0 g, nano SiO2: 1 g). A performance test was carried out for comparison, and the test results of the two samples are shown in Table 5.

From Table 5, it can be seen that both soft material 84A and hard material 88A met the requirements of various performance indexes. In terms of gel time and surface drying time, hard material 88A was shorter than soft material 84A, but it did not affect the construction. In terms of physical properties, hard material 88A was superior to soft material 84A except for the bonding strength and wear resistance. After alkali treatment and acid treatment, hard material 88A was still superior to soft material 84A in tensile strength retention rate and breakage elongation rate. After comprehensive consideration, the spray polyurea elastomer made of hard material 88A was more in line with the requirements of EPS floating balls for aquaculture.

Further, an aging resistance test was carried out on the hard material 88A to compare the change of physical properties. The results showed that the properties of hard material 88A declined after accelerated aging, especially in tear strength, but it was still stronger than soft material 84A and standard indexes. The test results are shown in Table 6.

Conclusions and Discussion

(1) Of the two different curing systems, MDI-50 and IPDI, the IPDI system was more suitable for spray polyurea for EPS foam floating balls.

(2) Through the screening of chain extenders, it was determined that polyurea synthesized from IPDI quasi-prepolymer and E-300 chain extender could meet the gel time of forming a complete and continuous coating on the surface of EPS floating balls during spraying, and the polyurea coating had good adhesion.

(3) Adding different nano wear-resistant fillers into chain extender E-300 could improve the wear resistance of spray polyurea to varying degrees, and among them, the wear resistance of carborundum and silica polyurea composites was the best.

(4) The formula of hard spray polyurea material for EPS floating balls obtained by adjusting the ratio of soft to hard segment was more in line with the requirements of aquacultural floating balls.

(5) The physical properties and chemical resistance of the spray polyurea sample obtained with the hard material formula were tested. The results showed that it had good physical properties and acid and alkali resistance, and its performance was still excellent after accelerated aging, and could meet the requirements of spraying and protection of EPS floating ball surface in marine environment.

References

[1] GUO XY, XU G, SONG Y, et al. Study of recycle of wasted PS foam[J]. China Plastics Industry, 2007, 35(5): 68-70. (in Chinese).

[2] LI Z, GUO L. Summary of polystyrene foam (EPS)[J]. Sichuan Building Materials, 2012, 38(5): 10-11. (in Chinese).

[3] PRIMEAUX DJ. A study of polyurea spray elastomer system[J]. High Solid Coatings, 1994(15): 2-6.

[4] FEDOTOVA OY, GROZDOV AG, YELIN IO. Synthesis of polyurea copolymers[J]. Polymer Science USSR, 1965, 7(10): 2011 -2015.

[5] PRIMEAUX D. Polyurea spray technology in commercial applications[J]. Polyurea Development Association, 1997(60): 60-66.

[6] GUO GJ, CHEN CY, WANG XM, et al. Research progress of polyurea elastomer protective materials[J]. China Surface Engineering, 2021, 34(6): 1-20. (in Chinese).

[7] HUANG WB, WANG BZ, CHEN JJ. Progress and prospect of the spray polyurea elastomer technolog y in China[J]. Polyurethane Industry, 2002, 17(3): 6-9. (in Chinese).

[8] HUANG WB. A single spark can start a prairie fire: Commemorating the 10th anniversary of polyurea technology in China[J]. Shanghai Coatings, 2008, 46(7): 42-45. (in Chinese).

[9] HUANG WB, XIE YW, HU X, et al. Durability study of pure polyurea heavy anti-corrosion coating in marine atmosphere environment[J]. Materials Reports, 2013, 27(6): 23-26. (in Chinese).

[10] WANG F, YIN C, ZHANG XB. Demonstration study on spray polyurea technology in anticorrosion of marine instruments[J]. Ocean Development and Management, 2014(5): 48-50. (in Chinese).

[11] ARUNKUMAR T, SUNITHA S, THEERTHAGIRI J, et al. Effect of polyurea coating on corrosion resistance over mild steel and aluminium substrates for liquid storage applications[J]. Molecular Crystals and Liquid Crystals, 2018, 670(1): 60-73.

[12] LIN J, LYU P, HUANG WB, et al. Study on seawater corrosion resistance of pure polyurea protective coatings [J]. Journal of Functional Materials, 2018, 49(10): 10071-10074. (in Chinese).

[13] LI GD. Synthesis and improving abrasion resistance of polyurea elastomer[D]. Dalian: Dalian Maritime University, 2015. (in Chinese).

- 农业生物技术(英文版)的其它文章

- Research Progress on Effects of Continuous Cropping on Soil Microbial Florae and Its Restoration

- Slaughter Performance, Muscle Quality and Nutritional Composition of Duoluo Goats in Sichuan Province

- Analyses of Chicken Tenderness Traits Based on Transcriptome Sequencing

- Effects of Different Grinding Methods on the Quality of Soybean Bean Milk

- A method for Improving the Efficiency of Pear Tree Crossbreeding

- Analysis of the Effect and Influencing Factors of Rural Domestic Sewage Treatment Based on A2O-MBBR Integrated Process