Analysis of the Effect and Influencing Factors of Rural Domestic Sewage Treatment Based on A2O-MBBR Integrated Process

Wangang WU Aiping WU Guixiang YUAN Yuyuan ZHOU Junwei LU

Abstract [Objectives] This study was conducted to solve the prominent problems in the treatment of domestic sewage in southern rural areas of China.

[Methods] An integrated process treatment mode of anaerobic/anoxic/aerobic moving bed biofilm reactor (A2O-MBBR) was proposed to analyze and study its operating effect and influencing factors.

[Results] The A2O-MBBR mode had good COD removal efficiency and nitrogen and phosphorus removal performance, and the water quality index of the effluent met the Class A standard of GB181918-2002. This mode is suitable for treating rural domestic sewage, and has high treatment effects in different operating periods. In spring, the average removal rates of COD, NH+4-N, TN, TP and SS reached (83.53 ± 2.15)%, (89.44 ± 4.97)%, (67.36±18.53)%, (88.22±11.21)% and (91.73±2.25)%, respectively; In the autumn period, the average removal rates of COD, NH+4-N, TN, TP and SS were (83.49±2.64)%, (89.26±9.19)%, (66.05±17.00)%, (87.48±9.68)%, and (91.13±2.35)%.

[Conclusions] This study provides theoretical reference and technical support for the popularization and application of A2O-MBBR integrated process.

Key words A2O-MBBR process; Rural domestic sewage; Nitrogen and phosphorus removal

DOI:10.19759/j.cnki.2164-4993.2024.02.009

With the acceleration of rural revitalization in China, domestic water consumption in rural areas has risen sharply, and domestic sewage output and emissions have increased significantly.In recent years, the CPC Central Committee and the State Council have attached great importance to the treatment of rural domestic sewage in China, and successively promulgated a series of rural environmental protection policies and technical documents, such as Guiding Opinions on Promoting the Treatment of Rural Domestic Sewage (Zhong Nong Fa [2019] No.14), Guiding Opinions on Promoting the Treatment of Black and Odorous Water Bodies in Rural Areas (Huanban Turang Han [2019] No.48) and Five-year Action Plan for Improving and Upgrading Rural Living Environment (2021-2025). It can be seen that seeking more efficient and economical domestic sewage treatment techniques is an important measure to deal with the increasingly severe water environment situation in rural areas of China and an inevitable demand for the revitalization of rural industries.

At present, the treatment methods of rural domestic sewage in China include: constructed wetland[1], biological filter[2], biological contact oxidation tank[3], sequencing batch bioreactor (SBR)[4], membrane bioreactor (MBR)[5], moving bed biofilm reactor (MBBR)[6] and other processes and facilities. Each process treatment technique has its own characteristics and applicability. A municipal sewage treatment plant in Huaian combines A2O (anaerobic-anoxic-oxic) and MBBR (moving bed biofilm reactor) to treat domestic sewage with an improved pollutant removal rate[7]. The A2O process plays a main role in removing organic pollutants, suspended solids and nitrogen and phosphorus, and the treatment effect is good[8]. MBBR is a sewage treatment technique based on biofilm process. It provides a suitable environment for the growth of microorganisms and increases the amount of active microorganisms in the system by adding suspended filler with density similar to that of water into the system, thus making the system more resistant to impact load[9]. The MBBR process can effectively make up for the shortcomings of traditional activated sludge process and fixed bed biofilm technique[10]. It not only has good process flexibility, but also is widely used in the upgrading and efficiency improvement of sewage treatment plants[11-13], so it has good engineering application prospects[14]. Therefore, the development of A2O-MBBR integrated process for domestic sewage treatment has better engineering guiding significance in the practical application of rural domestic sewage treatment.

In this study, the A2O-MBBR integrated process treatment mode was analyzed for its characteristics including effluent stability, stable compliance rate and pollutant removal rate of rural domestic sewage, and its design and operation problems were analyzed, hoping to provide reference and technical support for the popularization and application of A2O-MBBR integrated process treatment.

Technological Process

Process overview

In this study, the A2O-MBBR integrated process treatment facilities, with a scale of 200 m3/d, included four tanks in each reaction zone, namely anaerobic tank, anoxic tank, aerobic tank and sedimentation tank, and the effective volumes in various zones were 19.5, 18.5, 25.5 and 13.5 m3 respectively. In the experimental study, the anaerobic tank, anoxic tank and aerobic tank of the A2O unit were all filled with elastic filler, and the filling rate was about 55%-70%. The filler was a flat cylindrical polyethylene suspended carrier with a diameter of 25 mm, a height of 10 mm, a density of 0.96-0.98 g/cm3 and a specific surface area of 600-700 m2/m3, which met the industry standard requirements of High Density Polyethylene Suspended Carrier for Water Treatment (CJ/T461-2014)[15]. Interception screens were arranged at the junction of anoxic tank and aerobic tank, and at the junction of aerobic tank and sedimentation tank. A secondary sedimentation tank was arranged behind the aerobic tank, and the sludge liquid in the secondary sedimentation tank flew back to the anaerobic tank through an air lift mud pump to reduce sludge discharge.

Process flow

The main flow diagram of A2O-MBBR integrated process is shown in Fig. 1.

Materials and Methods

Research object

In this study, the domestic sewage facilities in Heping Village, Ansha Town, Changsha County, Hunan Province were taken as the object, and the domestic sewage of the A2O-MBBR integrated process treatment facilities was sampled on the spot, and divided into two phases: winter and summer. The sampling date in winter is from November to December, 2022, and there was continuous rainfall during the sampling period. The sampling time in summer was from June to August, 2023, and there was no rain in the first 3 d before sampling.

Sample collection

The number of samples taken at each station in the experimental area was three, and no parallel samples were set, but quality control samples were set. For each treatment facility, 3-5 bottles of water samples were collected from the water collecting well, the A2O secondary sedimentation tank and the water discharging well in turn. Each bottle of water sample was 550 ml, and the collected samples served as the influent and effluent of A2O, respectively. The water sample collection process was strictly in accordance with the requirements. The collected samples were packed in sterile plastic bags and immediately stored at 4 ℃. The test indexes included COD, NH3-N, TN, TP and SS, and the reagents were analytically pure according to the national standard method[16]. The analysis and test time was: NH3-N and TN<24 h, TP<48 h, COD and SS<72 h.

Discharge standards

The water quality indexes of COD, NH3-N, TN, TP and SS in the influent of the reactor and the effluent of the sedimentation tank were measured in spring and autumn in various stages of the experimental area. The quality indexes of effluent reached the Class A standard of Discharge Standard of Pollutants for Municipal Wastewater Treatment Plant (GB181918-2002). An A2O influent and effluent quality standard table was designed for the process (Table 1).

Statistical analysis of data

According to the measured data, the software Origin (2022) and SPSS were used for clustering analysis.

Results and Analysis

Analysis on operation effect of A2O-MBBR

Analysis on COD removal performance

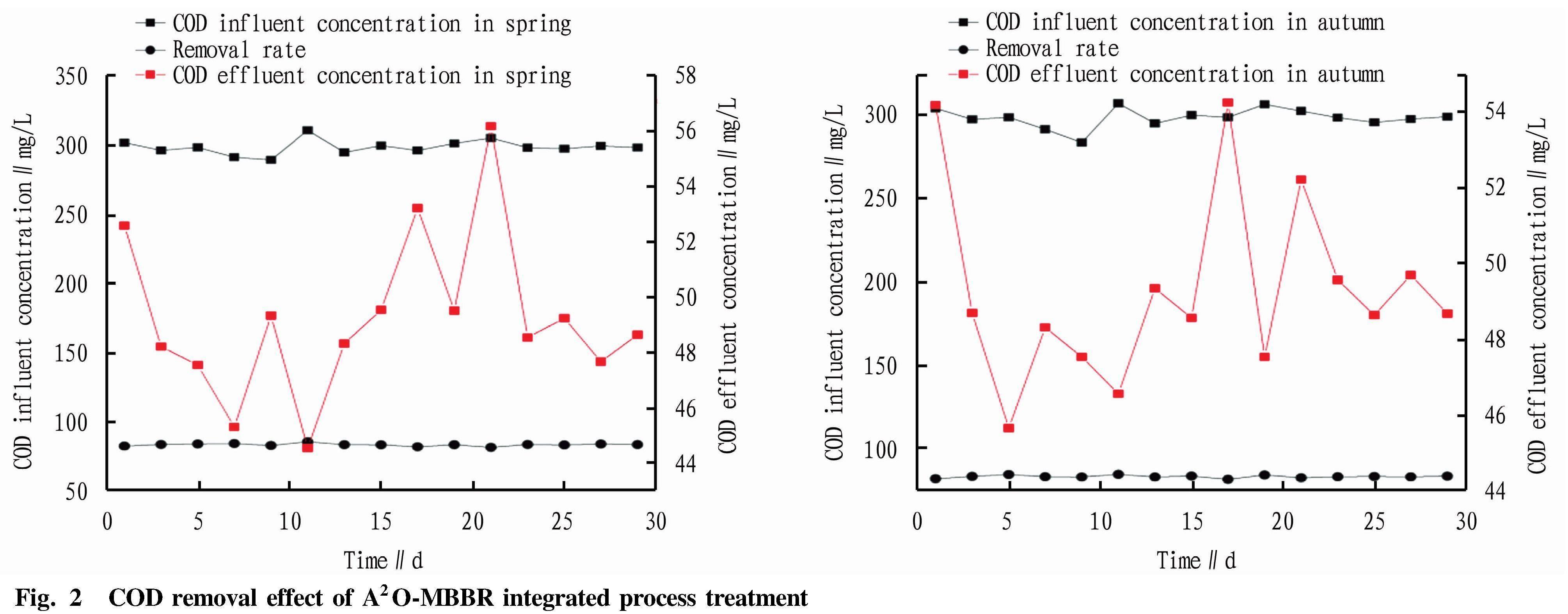

During the experiment, the COD concentrations in the influent and effluent of A2O-MBBR integrated process reactor at various stages and its removal effect are shown in Fig. 2.

It could be seen that in spring, the COD concentrations in the influent of reactor and effluent of sedimentation tank were (298.99±12.22) and (49.24±6.97) mg/L, respectively, and the average COD removal rate reached (83.53±2.15)%. In autumn, the COD concentrations in the influent of reactor and effluent of sedimentation tank were (298.60±15.58) and (49.29±8.59) mg/L, respectively, and the average COD removal rate reached (83.49±2.64)%. The A2O-MBBR integrated process had strong COD removal performance.

Analysis on NH3-N removal performance

During the experiment, the NH3-N concentrations in the influent and effluent at various stages of A2O-MBBR integrated process and its removal effect are shown in Fig. 3.

Wangang WU et al. Analysis of the Effect and Influencing Factors of Rural Domestic Sewage Treatment Based on A2O-MBBR Integrated Process

It could be seen that in spring, the NH3-N concentrations in the influent of reactor and effluent of sedimentation tank were (47.54±9.13) and (4.98±3.23) mg/L, respectively, and the average NH3-N removal rate reached (89.44±4.97)%. In autumn, the NH3-N concentrations in the influent of reactor and effluent of sedimentation tank were (49.49±17.62) and (5.28±3.43) mg/L, respectively, and the average NH3-N removal rate reached (89.26±9.19)%. The A2O-MBBR integrated process had strong NH3-N removal performance.

Analysis on TN removal performance

During the experiment, the TN concentrations in the influent and effluent at various stages of A2O-MBBR integrated process and its removal effect are shown in Fig. 4.

It could be seen that in spring, the concentrations of TN in the influent of reactor and effluent of sedimentation tank were (54.22±24.46) and (17.25±4.11) mg/L, respectively, and the average TN removal rate reached (67.36±18.53)%. In autumn, the concentrations of TN in the influent of reactor and effluent of sedimentation tank were (54.23±21.26) and (17.86±3.43) mg/L, respectively, and the average TN removal rate reached (66.05±17.00)%. The removal effect of TN by A2O-MBBR integrated process was remarkable.

Analysis on TP removal performance

During the experiment, the TP concentrations in the influent and effluent at various stages of A2O-MBBR integrated process and its removal effect are shown in Fig. 5.

It could be seen that in spring, the TP concentrations in the influent of reactor and effluent of sedimentation tank were (5.38±3.2) and (0.61±0.28) mg/L, respectively, and the average TP removal rate reached (88.22±11.21)%. In autumn, the concentrations of TP in the influent of reactor and effluent of sedimentation tank were (6.37±3.83) and (0.88±0.38) mg/L, respectively, and the average TP removal rate reached (87.48±9.68)%. The integrated A2O-MBBR process had a good TP removal effect.

Analysis on SS removal performance

During the experiment, the SS concentrations in the influent and effluent at various stages of A2O-MBBR integrated process and its removal effect are shown in Fig. 6.

It could be seen that in spring, the SS concentrations in the influent of the reactor and the effluent of the sedimentation tank were (207.62±11.21) and (17.17±5.01) mg/L, respectively, and the average SS removal rate reached (91.73±3.75)%. In autumn, the concentrations of SS in the influent of reactor and effluent of sedimentation tank were (206.63±13.20) and (18.31±4.00) mg/L, respectively, and the average removal rate of SS reached (91.13±2.35)%. The removal effect of SS by A2O-MBBR integrated process was significantly improved.

Analysis on influencing factors of A2O-MBBR operation

Influencing factors of COD removal

As shown in Fig. 2, there was no significant difference in COD removal rate between various operation stages of A2O-MBBR integrated process reactor (P=0.445). Main influencing factors: First, the removal rate of COD was related to the concentration of DO in the aerobic tank, and the COD removal effect did not changed significantly in each operation stage of the integrated process reactor when the concentration of DO changed slightly. Second, the removal rate of COD had little correlation with the influent quality concentration. When the water quality concentration fluctuated greatly, the integrated process reactor still maintained a stable COD removal effect at each operation stage, showing excellent tolerance. Third, the removal rate of COD was not related to the influent COD/N ratio, and the removal effect of COD in each operation stage of the integrated process reactor was not significantly influenced. It is consistent with the research results of Machat et al.[17]. It could be seen that the removal of COD in domestic sewage must be carried out by anaerobic reaction, and under the disturbance of DO, influent COD/N ratio and volume loading, the integrated process reactor could maintain a stable COD removal effect in each operation stage.

Influencing factors of NH3-N removal

As can be seen from Fig. 3, the NH3-N removal effect of A2O-MBBR integrated process reactor in various operation stages was significantly improved (P=0.292). Main influencing factors: the removal rate of NH3-N was related to DO concentration in the aerobic tank. When DO≤2.0 mg/L, the demand for nitrification reaction was slow; when 2.5≤DO≤3.5 mg/L, the removal rate of NH3-N reached (89.44±4.97)%; and when DO≥3.5 mg/L, no significant improvement was shown in the removal effect of NH3-N. The conclusion is similar to that of Zheng et al.[18] and Wang et al.[19]. It could be seen that DO formed aerobic zones and anaerobic zones in different thickness periods of biofilm, which promoted nitrification and anaerobic ammoxidation and improved NH3-N removal efficiency.

Influencing factors of TN removal

As can be seen from Fig. 4, the TN removal rate of A2O-MBBR integrated process reactor was improved significantly in various operation stages (P<0.023). Main influencing factors: First, the removal rate of TN was closely related to influent water quality C/N. If the influent water quality C/N was low, the removal rate of TN would be low. Second, the removal rate of TN was related to DO concentration. Because of the difference of DO concentration inside and outside the biofilm, aerobic bacteria such as nitrifying bacteria grew on the surface of the biofilm, anaerobic bacteria such as denitrifying bacteria grew inside the biofilm, and the difference of bacteria inside and outside the biofilm affected the removal effect of TN. Third, the removal rate of TN was affected by diversified factors such as reflux ratio and biomass. It is similar to the research results of Wang et al.[20] and Yang et al.[21]. It could be seen that the removal rate of TN was affected by many factors, such as influent water quality C/N, DO, reflux ratio and biomass. In actual operation, the reflux ratio of nitration liquid in A2O-MBBR integrated process should not be too high, and the influent C/N should not be too low.

Influencing factors of TP removal

As shown in Fig. 5, the effluent TP concentration in various operation stages of A2O-MBBR integrated process reactor were relatively high (P=0.112). Main influencing factors: First, the volume space of various compartments in the equipment was limited, and there was a backmixing phenomenon between nitrate nitrogen and dissolved oxygen carried by reflux and adjacent aerobic compartments, which affected the anaerobic environmental conditions in the equipment and led to insufficient biological phosphorus removal conditions. Second, the phosphorus removal function of A2O was mainly realized by discharging sludge. If the C/N of rural domestic sewage was low and the output of activated sludge was low, the biological phosphorus removal capacity of MBBR would be limited. Third, the biological removal of phosphorus of MBBR was related to microbial biomass, that is, the material exchange between biofilm and substrate was related to microbial assimilation. It is consistent with the research results of Zhang[22]. Therefore, in the actual operation, the space in various compartments of the equipment of the A2O-MBBR integrated process reactor is appropriate, and it is suggested to add an appropriate amount of microorganisms and replace the packing matrix in the equipment regularly during the process treatment to improve the removal rate of TP.

Influencing factors of SS removal

It could be seen from Fig. 6 that under the conditions of anaerobic, anoxic and aerobic alternate operation, the phosphorus content in SS was relatively high, and the SVI value was generally less than 100 (P=0.068). Main influencing factors: First, the removal rate of SS was related to the P content in the influent. When the P/BOD value was high, the filamentous microorganisms in the reaction tank failed to proliferate in large quantities, making it difficult for the filamentous expansion of sludge to occur, and there was a certain limit to the growth of SS, which made it difficult to improve the SS removal rate. Second, the removal rate of SS was related to DO concentration. When the DO concentration of the treated water entering the sedimentation tank was low, it would lead to an anaerobic state and phosphorus release from sludge, and the SS removal rate would decrease. It could be seen that in actual operation, the influent tank of A2O-MBBR integrated process must maintain a certain concentration of DO and the concentration should not be too high, and the residence time should be reduced, so as to avoid the phenomena such as anaerobic state, phosphorus release from sludge and interference of circulating mixed liquid with the anoxic reactor.

Conclusions and Discussion

(1) The A2O-MBBR integrated process was adopted to treat rural domestic sewage. The pollutant removal effect was stable, and the water quality indexes of the effluent reached the Class A standard of GB181918-2002. In spring, the average removal rates of COD, NH+4-N, TN, TP and SS were (83.53±2.15)%, (89.44±4.97)%, (67.36±18.53)%, (88.22±11.21)% and (91.73±2.25)%, respectively. In autumn, the average removal rates of COD, NH+4-N, TN, TP and SS were (83.49±2.64)%, (89.26±9.19)%, (66.05±17.00)%, (87.48±9.68)% and (91.13±2.35)%, respectively.

(2) In the mode of A2O-MBBR integrated process for treating rural domestic sewage, the removal effect of pollutants was related to the designed hydraulic load of A2O-MBBR, outlet position, influent carbon-nitrogen ratio and less sludge discharge.

(3) There is room for improvement in the mode of A2O-MBBR integrated process for treating rural domestic sewage. Suggestions: The first is to optimize the sewage reflux ratio of each reaction tank. During the process, there will be a phenomenon of large instantaneous quantity and small instantaneous quantity in each reaction tank, which will affect the duration of microbial residence reaction. The second is to optimize the control of dissolved oxygen, because it is difficult to control dissolved oxygen in the anaerobic tank and anoxic tank, which affects the effect of nitrogen and phosphorus removal in the whole process. The third is to optimize the space of the equipment, such as increasing the unit volume of the reaction tank and optimizing the reactor structure, so as to improve the removal effect of various pollutants and give full play to the functions of A2O-MBBR integrated process treatment facilities.

References

[1] LI HF, LIU F, LI HJ, et al. Combined process of biofilter, constructed wetland and stabilization pond for treatment of rural decentralized sewage[J]. China Water & Wastewater, 2015, 31(2): 84-87. (in Chinese).

[2] WANG YQ, YANG LZ, FENG YF, et al. Experimental study on treatment of rural domestic sewage with serial vertical-flow filters[J]. Ecology and Environment, 2011, 20(2): 332-336. (in Chinese).

[3] HU JF, ZHOU SM, LIU DF, et al. Application of two-stage A/O biological contact oxidation process in rural domestic sewage treatment[J]. Technology of Water Treatment, 2021, 47(12): 95-98. (in Chinese).

[4] PENG J, HUANG TY, CAO Q, et al. Design of integrated SBR facility for rural domestic sewage treatment[J]. Technology of Water Treatment, 2015, 41(1): 132-134. (in Chinese).

[5] JIANG LL, LIU J, QIAN CY, et al. Treatment of rural domestic sewage by MBR/constructed wetland process[J]. China Water & Wastewater, 2010, 26(4): 29-34, 41. (in Chinese).

[6] PAN WL, WU QY, WANG QY, et al. Pilot study on treatment of rural sewage by moving bed biofilm reactor[J]. Technology of Water Treatment, 2020, 46(10): 103-107. (in Chinese).

[7] LING R, HUANG C, HUANG DH, et al. Application of A2O-MBBR process in upgrading and reconstruction project of municipal sewage treatment plant[J]. Water & Wastewater Engineering, 2020, 56(S1): 473-475. (in Chinese).

[8] XIA B, SHENG XL, XU F, et al. Performance of A2O combined with constructed wetland on treating rural domestic sewage in plain areas of Yangtze River delta region, China[J]. Chinese Journal of Environmental Engineering, 2021, 15(1): 181-192. (in Chinese).

[9] YANG XF, L凱EZ-GRIMAU V, VILASECA M, et al. Treatment of textile wastewater by CAS, MBR, and MBBR: A comparative study from technical, economic, and environmental perspectives[J]. Water, 2020, 12(5): 1306.

[10] DI BIASE A, KOWALSKI MS, DEVLIN TR, et al. Moving bed biofilm reactor technology in municipal wastewater treatment: A review[J]. Journal of Environmental Management, 2019(247): 849-866.

[11] LU H, XIN T, WU D, et al. Application of MBBR in increasing capacity and improving efficiency of a wastewater treatment plant[J]. China Water & Wastewater, 2019, 35(4): 100-105. (in Chinese).

[12] WU D, ZHOU JZ, ZHENG ZJ, et al. Application of MBBR process to upgrading and reconstruction of WWTP in Shanxi Province[J]. China Water & Wastewater, 2018, 34(15): 6-11. (in Chinese).

[13] LUAN ZX, WU D, HAN WJ, et al. Effect of high efficiency nitrogen and phosphorus removal in a wastewater treatment plant in north China[J]. Chinese Journal of Environmental Engineering, 2020, 14(2): 333-341. (in Chinese).

[14] WU D. Application and development prospect of MBBR in China[J]. China Water & Wastewater, 2018, 34(16): 22-31. (in Chinese).

[15] WU D. Interpretation of high density polyethylene suspended carrier for water treatment and calculation of added amount of suspended carrier[J]. China Water & Wastewater, 2017, 33(16): 13-17. (in Chinese).

[16] State Environmental Protection Administration. Monitoring and analysis methods of water and wastewater[M]. Beijing: China Environmental Science Press, 2002. (in Chinese).

[17] MACHAT H, BOUDOKHANE C, ROCHE N, et al. Effects of C/N ratio and DO concentration on carbon and nitrogen removals in a hybrid biological reactor[J]. Biochemical Engineering Journal, 2019(151): 107313.

[18] ZHENG M, YANG B, WANG CW, et al. Enhanced ammonia removal rate in a pilot-scale MBBR[J]. Chinese Journal of Environmental Engineering, 2012, 32(10): 1778-1783. (in Chinese).

[19] WANG XJ, XIA SQ, CHEN L, et al. Effect of DO on simultaneous nitrification and denitrification in MBBR[J]. Journal of Tongji University (Natural Science), 2006, 34(4): 514-517, 538. (in Chinese).

[20] WANG ZX, CHEN DY, SUN L, et al. Application effect and operating energy consumption of Engelbart SST process integrated rural domestic sewage treatment equipment[J]. Chinese Journal of Environmental Engineering, 2020, 14(9): 2346-2352. (in Chinese).

[21] YANG WH, TANG RK, XIAO ZY, et al. Comparative analysis of multi-level MBBR process and A2/O process treating low C/N ratio domestic wastewater[J]. Environmental Science & Technology, 2017, 40(9): 131-135. (in Chinese).

[22] ZHANG ZJ. Drainage engineering (volume II, 5th edition)[M]. Beijing: China Architecture & Building Press, 2015: 371-372. (in Chinese).

- 农业生物技术(英文版)的其它文章

- Research Progress on Effects of Continuous Cropping on Soil Microbial Florae and Its Restoration

- Slaughter Performance, Muscle Quality and Nutritional Composition of Duoluo Goats in Sichuan Province

- Analyses of Chicken Tenderness Traits Based on Transcriptome Sequencing

- Effects of Different Grinding Methods on the Quality of Soybean Bean Milk

- A method for Improving the Efficiency of Pear Tree Crossbreeding

- Study on Detection of Antibiotic Contents in Water around Landfill Sites