Effects of Different Grinding Methods on the Quality of Soybean Bean Milk

Miao XIAO Xuejiao ZHANG Muwen LIU Xiao LI Tao YE Xiaoping YANG

Abstract [Objectives] This study was conducted to improve the nutritional value of soybean milk, enrich the variety and taste of soybean milk, and find healthy food that is more conducive to peoples nutritional needs.

[Methods] Whole soybean milk was prepared by grinding with a grinding wheel at a low concentration (low-concentration grinding) and a stainless steel mill at a high concentration (high-concentration grinding). The sensory, physical and chemical characteristics and anti-nutritional factors of whole soybean milk produced by different grinding methods were studied.

[Results] Compared with low-concentration grinding, the protein content in soybean milk prepared by high-concentration grinding increased by 24%, and the dietary fiber content increased by 74.7%. Before and after high-pressure homogenization, the particle size D(4, 3) of soybean milk prepared by low-concentration grinding was 212.1 and 93.59 μm, respectively, and the particle size D(4, 3) of soybean milk prepared by high-concentration grinding was 134.0 and 64.64 μm, respectively. The trypsin inhibitor activity and phytic acid content of soybean milk prepared by high-concentration grinding were significantly lower than those of soybean milk prepared by low-concentration grinding.

[Conclusions] This study improves the diet structure of the broad masses of people, strengthens peoples physique, and provides a new idea for the implementation and development of Chinas "Soybean Action Programme".

Key words Whole soybean milk; Grinding method; Low-concentration grinding; High-concentration grinding; Antinutritional factor

DOI:10.19759/j.cnki.2164-4993.2024.02.007

Soybeans are rich in nutrition, and contain many nutrients such as protein, fat, carbohydrate, cellulose and minerals[1], and the products processed from soybeans have high nutritional value. Soybean milk refers to the liquid products processed with soybeans as the main raw material, containing protein of 2% or more, including soybean milk, fermented soybean milk and soybean yogurt[2]. As the most popular and commonly used food, soybean milk is still the main processing form of soybean intake. Meanwhile, it is also the raw material for making many other bean products. It can be further processed into traditional bean products, such as tofu and dried beancurd sticks, and can also be processed into emerging plant-based products, such as soybean yogurt, soybean cheese and soybean ice cream.

Traditional soybean milk will produce a lot of bean dregs in the process of making, which will often be discarded, making the utilization rate of raw materials only 55%[3], but bean dregs contain a lot of nutrients, including protein, fat, dietary fiber, vitamins and minerals, phospholipid compounds and plant compounds[4]. In order to reduce the waste of soybean resources and the loss of nutrients in soybean milk, we developed a kind of whole soybean milk with a small amount of bean dregs by using advanced high-concentration grinding technique. In this study, the sensory quality and nutritional components of whole soybean milk processed by high-concentration grinding using a stainless steel mill (hereinafter referred to as high-concentration grinding) and traditional soybean milk processed by low-concentration grinding using a grinding wheel (hereinafter referred to as low-concentration grinding) were compared, aiming at improving the nutritional value of soybean milk, enriching the varieties and tastes of soybean milk, finding healthy foods that are more conducive to peoples nutritional needs, improving the diet structure of the broad masses of people, enhancing peoples physique, and providing a new way for the implementation and development of Chinas "Soybean Action Programme".

Materials and Methods

Materials and reagents

Soybeans were commercially-available non-GMO northeast soybeans, purchased online.

Reagents such as ethanol, sodium hydroxide and hydrochloric acid were provided by Chengdu Jinshan Chemical Test Co., Ltd. Magnesium sulfate, manganese sulfate, dipotassium hydrogen phosphate and sodium acetate were domestic, all analytically pure, and purchased from China by Tianjin Kemiou Chemical Reagent Co., Ltd. Daidzin, daidzein, genistin, genistein, glycitin and glycitein standards were purchased from Beijing Solarbio Science & Technology Co., Ltd. Methanol and acetonitrile were domestic, chromatographically pure, and purchased from Shanghai Aladdin Biochemical Technology Co., Ltd.

Instrumentation and equipments

VELOCITY18R high-speed freezing centrifuge (Dynamica, Australia); LS-B50L high-pressure steam sterilizer (Shanghai Huaxian Medical Nuclear Instrument Co., Ltd.); visible spectrophotometer (Xiamen Analytical Instrument Factory); SB25-12DT ultrasonic cleaner (Changsha Kenji Technology Development Co., Ltd.); NDJ-1B-1 digital viscometer (Changsha Kenji Technology Development Co., Ltd.); TG16K-II high-speed centrifuge (Changsha Aidi Biotechnology Co., Ltd.); automatic Kjeldahl azotometer (Beijing Ensoul Technology Ltd.), SX-4-10 muffle furnace (Tianjin Taisite Instrument Co., Ltd.); Sicentz-150 high-pressure homogenizer (Changsha Aidi Biotechnology Co., Ltd.); SX-4-10 muffle furnace (Tianjin Taisite Instrument Co., Ltd.); stainless steel high-concentration mill.

Experimental methods

Preparation of whole soybean milk

Process flow: Soybean→selection→cleaning→soaking→grinding→boiling→soybean milk→high-pressure homogenization→sterilization and bottling.

Key points of grinding wheel low-concentration grinding process: First, 5 kg of soybean was weighed, and soaked in cold water for 8-10 h according to the ratio of 1:4. After draining the water, the soybeans were mixed with water according to the ratio of beans to water of 1:7 (w/w, based on dry beans) and ground in a grinding wheel. The obtained slurry was heated with steam at 102 ℃ for 10 min and filtered with a vibrating screen of 80 meshes to obtain a filtrate, which was homogenized under high pressure. Finally, the obtained soybean milk was sterilized at 120 ℃ for 15 min to acquire sterile bottled whole soybean milk.

Stainless steel mill high-concentration grinding process: First, 5 kg of soybean was weighed, and soaked in cold water for 8-10 h according to the mass ratio of beans to water of 1:4. After draining the water, the soybeans were mixed with water according to the ratio of beans to water of 1:1 (w/w, based on dry beans) and ground in a two-stage series stainless steel grinding disc. The obtained slurry was diluted according to the ratio of beans to water of 1:7 (w/w, based on dry beans). After mixing well, the slurry was heated with steam at 102 ℃ for 10 min and filtered with a vibrating screen of 80 meshes to obtain a filtrate, which was homogenized under high pressure. Finally, the obtained soybean milk was sterilized at 120 ℃ for 15 min to acquire sterile bottled whole soybean milk.

Sensory evaluation

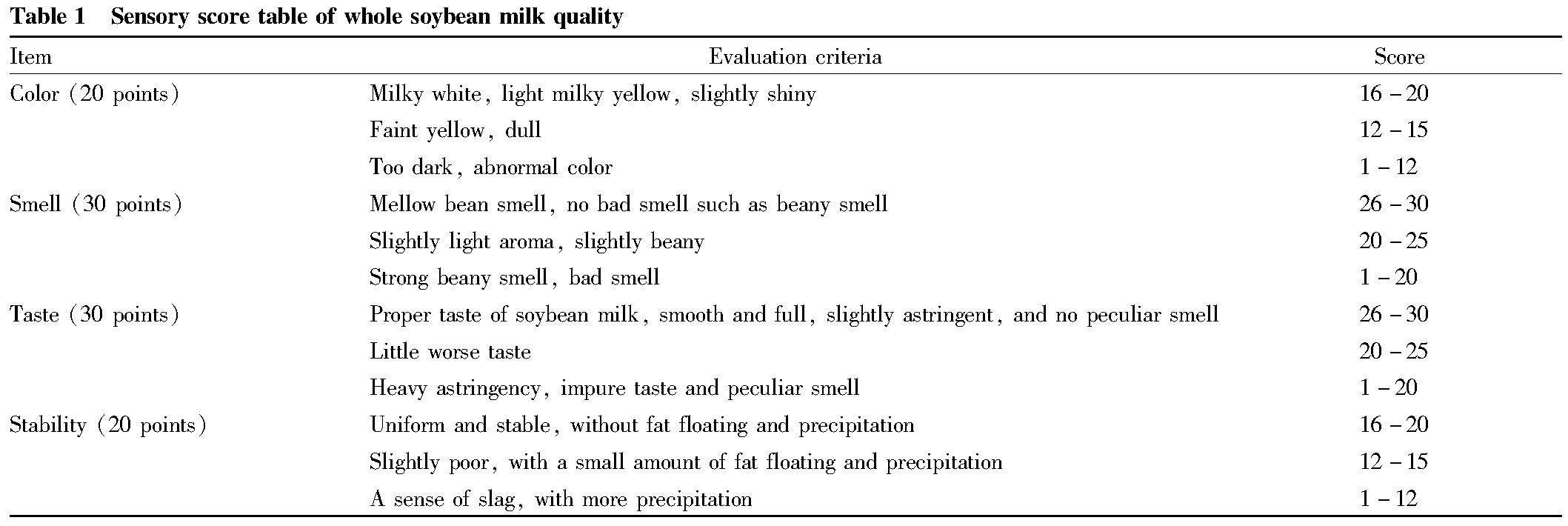

Ten trained graduate students were selected to form a sensory evaluation group, and the soybean milk produced by two different grinding methods was evaluated independently. According to the evaluation criteria in Table 1, each product was cored from four aspects: color, smell, taste and stability, and the total scores were recorded as the sensory scores, and then the average value was taken as the final sensory evaluation result.

Determination method of physical and chemical indexes

(1) Determination of protein

The content of protein was determined according to GB 5009.5-2016 National Food Safety Standard: Determination of Protein in Foods[5].

(2) Determination of dietary fiber

The determination of dietary fiber referred to national standard GB 5009.88-2014.

(3) Determination of viscosity

The viscosity of soybean milk was measured using an NDJ-5S viscometer. The calibration medium of the instrument was distilled water, and the viscometer used a No. 0 rotor. The measurement was carried out at a temperature of 25 ℃ and a rotational speed of 60 r/min[6].

(4) Determination of particle size

The particle size distribution range of soybean milk before and after high-pressure homogenization was measured using a WJL-628 laser particle size analyzer. Parameter control: The dispersion medium was distilled water; the refractive index was 1.76 for the real part and0.05 for the imaginary part; the ideal shading ratio was 1-2; and the refractive index of the medium was 1.33[6].

(5) Determination of stability[6]

A proper amount of whole soybean milk was diluted 40 times, and centrifuged at 4 000 r/min for 5 min. The absorbance of the sample before and after centrifugation was determined at the wavelength of 785 nm, and the stability coefficient was calculated according to formula (1):

R=A2/A1(1).

In the formula, R is stability coefficient; A2 is the absorbance of supernatant after centrifugation; and A1 is the absorbance before centrifugation. Under the premise of R≤1.00, a greater R value indicates a more stable whole soybean milk system.

(6) Determination of centrifugal sedimentation rate[6]

A sample was added into a 10 ml centrifuge tube, and centrifuged at 5 000 r/min for 10 min. The upper liquid was discarded, and the test tube was inverted for drainage. It was measured in parallel for 3 times, and the centrifugal sedimentation rate was calculated according to formula (2):

w1(%)=(m2-m1)/m0×100(2)

In the formula, w1 is centrifugal sedimentation rate, %; m0 is the mass of sample, mg; m1 is the mass of the centrifuge tube, mg; and m2 is mass of the centrifuge tube after discarding the supernatant, mg.

Determination of anti-nutritional factors

Determination of trypsin inhibitor activity

The trypsin inhibitor activity was determined according to the method of Yan et al.[7] with some modifications. ① Extraction: Into a 250 ml conical flask was added 1 ml of whole soybean milk, and 50 ml of 0.006 mol/L NaOH solution was then added. The mixture was shaken at room temperature for 30 min, and then taken out. After adjusting the pH value to 9.5-9.8, shaking was continued for 2.5 h, and the final mixture was taken out for later use. ② Determination: The concentration of enzyme solution used in the experiment was 0.15 mg/ml. A blank tube and a reaction tube were set. The reaction in the blank reaction tube was progressed according to following steps of adding 1 ml of distilled water and 2.5 ml of BAPA solution, heating in a water bath at 37 ℃ for 10 min, taking out, adding 0.5 ml of acetic acid solution to terminate the reaction, and adding 1 ml of trypsin solution and mixing well. Subsequently, for the enzyme reaction tube, 1 ml of distilled water and 1 ml of trypsin solution were added in sequence, and the mixture was mixed well, added with 2.5 ml of BAPNA solution, and heated in a water bath at a temperature of 37 ℃ for 10 min; the tube was then taken out, and added with 1 ml of acetic acid solution and shaken well to terminate the reaction; and finally, its absorbance was measured at 410 nm. The concentration of trypsin solution was adjusted to make the absorbance in the range of 0.380-0.420.

Determination of tannin

The pH of whole soybean milk was adjusted to 4.5, and centrifugation was performed for 10 min at 1 500 r/min to collect supernatant. The determination method adopted the F-D reagent method. In specific, 1 ml of sample solution, 0.85 ml of 75% ethanol, 0.05 ml of metaphosphoric acid, 12.5 ml of deionized water, 1.25 ml of F-D reagent and 5 ml of anhydrous sodium carbonate solution were added in sequence into a 25 ml colorimetric tube, which was shaken to mix evenly, and the obtained reaction system was diluted to constant volume. Subsequently, it was placed in an environment at 30 ℃ to react for 1.5 h, and taken out after the reaction, and the absorbance was measured at 680 nm. Based on tannic acid, the regression equation was obtained as y=0.967 6x+0.022 8, R2=0.995 2.

Determination of phytic acid

Phytic acid was determined according to the method of Gao et al.[7] with some modifications.In specific, 0.5 g of soybean milk sample was added in a 250 ml conical flask, and then added with 10 ml of 2.4% diluted hydrochloric acid. After shaking for 2 h at 220 r/min, the conical flask was taken out and centrifuged for 20 min at 3 000 r/min to obtain a supernatant. Next, 1 g of NaCl was added and dissolved in the supernatant, which was then stood at 4 ℃ for 1 h and centrifuged (3 000 r/min, 20 min), and the supernatant was collected for later use. During the determination, 5 ml of diluted supernatant was mixed with 4 ml of Wade reagent (0.03% FeCl3·6H2O, 0.3% sulfosalicylic acid), centrifuged (3 000 r/min, 20 min), and stood for 10 min, and the absorbance was determined at 500 nm. In this method, phytic acid was used as the standard, and the regression equation was y=0.556 04-22.123 1x, R2=0.990 5.

Data processing

The experimental data were processed and statistically analyzed by Excel 2017 and SPSS Statistics 22.0, with P<0.05 indicating that there was a statistically significant difference. Origin 2018 was employed to plot the experimental data.

Agricultural Biotechnology2024

Results and Analysis

Analysis on sensory evaluation results of whole soybean milk

Sensory evaluation of whole soybean milk prepared by the two kinds of grinding methods showed that the total sensory score of soybean milk prepared by high-concentration grinding was 86, which was significantly higher than that of soybean milk prepared by low-concentration grinding (78) (P<0.05). As can be seen from Fig. 1, the scores of coloration, smell, taste and stability of whole soybean milk with high-concentration grinding were higher than those with low-concentration grinding. Different grinding methods will lead to different particle sizes and distributions in soybean milk. The soybean milk obtained by low-concentration grinding had larger bean dregs and rough taste. The kneading technique of high-concentration grinding could more effectively grind soybean fiber, greatly reduce the particle size of soybean dregs and produce finer uniform soybean milk.

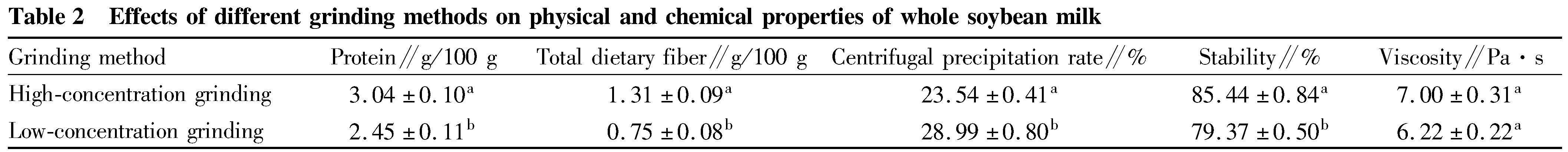

Analysis on physical and chemical properties of whole soybean milk

As can be seen from Table 2, compared with the whole soybean milk prepared by low-concentration grinding, the whole soybean milk prepared by high-concentration grinding showed a protein content of (3.04±0.1) g/100 g and a total dietary fiber content of (1.31±0.09) g/100 g, which were significantly higher than those of the whole soybean milk prepared by low-concentration grinding (P>0.05). The viscosity of whole soybean milk is the main factor affecting the concentration, and it also affects the stability of whole soybean milk. The results showed that the viscosity and stability of soybean milk from high-concentration grinding were the best without adding any stabilizer or emulsifier. Preparing soybean milk by high-concentration grinding can not only reduce particle size and avoid precipitation, but also play an important role in the emulsification of whole soybean milk. Soybean protein is called a natural emulsifier because of its amphipathic properties, and protein in whole soybean milk can be effectively adsorbed to the interface between oil and water under the treatment of high-concentration grinding, which can hinder the aggregation of oil droplets, thus improving the emulsion stability of whole soybean milk[9].

It can be seen from the table 2 that the contents of protein and total dietary fiber in whole soybean milk made by the grinding wheel low-concentration grinding process were lower than those in whole soybean milk made by the stainless steel mill high-concentration grinding process, which might be due to the fact that the nutritional components in soybean were not completely immersed in whole soybean milk after grinding and the grinding was not sufficient, resulting in the nutritional components in whole soybean milk being lower than those in whole soybean milk made by high-concentration grinding using a stainless steel mill. The high-concentration grinding using a stainless steel mill adopted grinding with hot water for the second time, which greatly reduced the content of nutrients lost in whole soybean milk, improved the dissolution rate of nutrients in soybeans, and made more nutrients such as protein and total dietary fiber dissolve into whole soybean milk, so the whole soybean milk made by high-concentration grinding using a stainless steel mill had highest nutritional contents. Generally speaking, the nutrient contents of soybean milk made by high-concentration grinding using a stainless steel mill were protein 3.04 g/100 g and total dietary fiber 1.31 g/100 g, and those by low-concentration grinding using a grinding wheel were protein 2.45 g/100 g and total dietary fiber 0.75 g/100 g.

Particle size analysis of whole soybean milk

Particle size distribution is one of the performance indicators of particle aggregation. Particle size and its distribution determine the state and stability of a solution. Small particle size with uniform distribution leads to high stability, while large particle size with uneven distribution leads to low stability[10]. The particle size distribution of soybean milk prepared by two different grinding methods before and after high-pressure homogenization is shown in Fig. 2a and Fig. 2b, respectively. Before high-pressure homogenization, the particle sizes D(4, 3) of soybean milk obtained by low-concentration grinding and high-concentration grinding were 212.1 and 134.0 μm, respectively. After high-pressure homogenization, the particle sizes D(4, 3) of soybean milk obtained by low-concentration grinding and high-concentration grinding were 64.64 and 93.59 μm, respectively. It showed that high-concentration grinding had a significant effect on crushing large particles.

Analysis on the results of anti-nutritional factors of whole soybean milk

The existence of anti-nutritional factors will reduce the digestibility and utilization rate of protein, thus delaying the growth of animals, reducing the feed conversion rate, causing pancreatic hypertrophy and proliferation, and leading to digestive dysfunction, and even serious diarrhea and tumors[11]. Therefore, we determined the content of anti-nutritional factors to evaluate the nutritional status of whole soybean milk. Fig. 3 shows the changes of trypsin inhibitor activity (TIA) and tannin and phytic acid contents in whole soybean milk prepared by different grinding methods. From Fig. 3A, it can be seen that different grinding methods affected the nutritional components of whole soybean milk, and could induce, by physical changes and chemical actions, disulfide bond and other structural changes of protein, which could inactivate TIA[12]. The TIA activity of whole soybean milk ground by high-concentration grinding was lower, showing that the high-concentration grinding technique had an ideal effect on TIA inactivation. Moreover, the TIA activity (1.87 mg/g) of whole soybean milk obtained by high-concentration grinding after cooking was significantly lower than that of raw whole soybean milk (3.69 mg/g), which might be because the grinding and heating process changed the TIA structure, leading to TIA inactivation. It can be seen from Fig. 3B that the whole soybean milk prepared by high-concentration grinding led to an increase in tannin content (low-concentration grinding 1.09 mg/100 ml, high-concentration grinding 1.21 mg/100 ml). The reason might be that the extraction rate of tannin increased due to sufficient grinding, and the content of dissolved tannin was far greater than the loss during soybean soaking[13]. From the phytic acid content in Fig. 3C, it can be seen that the phytic acid content in soybean could be reduced by 24%-46% through high-concentration grinding, which might be due to the fact that the blade of the mill for high-concentration grinding allowed soybeans to be fully ground, and the phytase originally existing in dry soybeans was activated, so that phytic acid was hydrolyzed into inositol and phosphoric acid[14].

Conclusions and Discussion

We studied the effects of low-concentration grinding with a grinding wheel and high-concentration grinding with a stainless steel mill on the physical and chemical properties and anti-nutritional factors of whole soybean milk. It was found that compared with low-concentration grinding, high-concentration grinding significantly increased the contents of protein and dietary fiber in soybean milk, and simultaneously significantly reduced the particle size of cellulose, decreased the activity of trypsin inhibitor and phytic acid content, improved the stability and taste of products, and greatly improved the utilization rate of soybeans. The high-concentration grinding method using a stainless steel mill is expected to be a good grinding method for producing whole bean products.

References

[1] CAI JS. Study on flavor, stability and antioxidant activity of nutritive soybean milk[D]. Hefei: Hefei University of Technology, 2021. (in Chinese).

[2] Consensus on nutrition, health and consumption of soymilk[J]. China Food, 2022(15): 76-83. (in Chinese).

[3] SHI YG, CHENG CL. Study on technological of bean curd without residue[J]. Cereals and Oils Processing, 2004(1): 64-65, 67. (in Chinese).

[4] RAN CX, KAN JQ. Effect of process condition on the quality of white whole-soybean Sufu Pehtze[J]. Food Science, 2012, 33(24): 160-164. (in Chinese).

[5] GB 5009.5-2016 National food safety standard: Determination of protein in Foods. (in Chinese).

[6] FAN L, LIU HY, ZHAO LZ, et al. Effects of different pulping processes on the quality of soybean milk[J]. Food and Fermentation Industries, 2020, 46(7): 148-154. (in Chinese).

[7] YAN FL, HUA L. Determination of trypsin inhibitor activity of soya products[J]. Physical Testing and Chemical Analysis (Part B: Chemical Analysis), 2007(3): 226-228. (in Chinese).

[8] GAO Y, SHANG C, MAROOF M, et al. A modified colorimetric method for phytic acid analysis in soybean[J]. Crop Science, 2007, 47(5).

[9] LI Y, CHEN M, DENG L, et al. Whole soybean milk produced by a novel industry-scale micofluidizer system without soaking and filtering[J]. Journal of Food Engineering, 2021(291): 110228.

[10] CUI LL, LI YY, LUAN GZ, et al. Relationship between particle size and quality of soymilk[J]. Soybean Science, 2012, 31(1): 103-107. (in Chinese).

[11] MA M, ZHANG H, XIE Y, et al. Response of nutritional and functional composition, anti-nutritional factors and antioxidant activity in germinated soybean under UV-B radiation[J]. Lwt, 2020(118): 108709.

[12] HUANG H, KWOK KC, LIANG HH. Inhibitory activity and conformation changes of soybean trypsin inhibitors induced by ultrasound[J]. Ultrasonics Sonochemistry, 2008, 15(5): 724-730.

[13] GU CM, JIANG L, YU HS, et al. Effect of soybean pretreatment on soybean milk quality[J]. Food Science and Technology, 2020, 45(2): 68-73. (in Chinese).

[14] ZUO F, ZHAO ZL, SHI XD, et al. Effects of micro-pressure boiling process on formation of protein particles in soybean milk and its processing characteristics[J]. Transactions of the Chinese Society of Agricultural Machinery, 2016, 47(1): 247-251. (in Chinese).

- 农业生物技术(英文版)的其它文章

- Research Progress on Effects of Continuous Cropping on Soil Microbial Florae and Its Restoration

- Slaughter Performance, Muscle Quality and Nutritional Composition of Duoluo Goats in Sichuan Province

- Analyses of Chicken Tenderness Traits Based on Transcriptome Sequencing

- A method for Improving the Efficiency of Pear Tree Crossbreeding

- Analysis of the Effect and Influencing Factors of Rural Domestic Sewage Treatment Based on A2O-MBBR Integrated Process

- Study on Detection of Antibiotic Contents in Water around Landfill Sites