Carbon Fiber Breakage Mechanism in Aluminum (Al)/Carbon Fibers (CFs) Composite Sheet during Accumulative Roll Bonding (ARB) Process

HU Shufen, SUN Zhenzhong, SHEN Fanghua, DENG Jun,YANG Weiping*, YANG Haokun

(1.School of Engineering, Jiangxi Agricultural University, Nanchang 330045, China; 2.School of Mechanical Engineering, Dongguan University of Technology, Dongguan 510730, China; 3.Guangdong-Hong Kong-Macao Joint Laboratory for Neutron Scattering Science and Technology, Dongguan 510730, China; 4.Smart Manufacturing Division, Hong Kong Productivity Council, 78 Tat Chee Avenue, Hong Kong 5999075, China)

Abstract: We put forward a method of fabricating Aluminum (Al)/carbon fibers (CFs) composite sheets by the accumulative roll bonding (ARB) method.The finished Al/CFs composite sheet has CFs and pure Al sheets as sandwich and surface layers.After cross-section observation of the Al/CFs composite sheet, we found that the CFs discretely distributed within the sandwich layer.Besides, the tensile test showed that the contribution of the sandwich CFs layer to tensile strength was less than 11% compared with annealed pure Al sheet.With ex-situ observation of the CFs breakage evolution with -16%, -32%, and -45% rolling reduction during the ARB process, the plastic instability of the Al layer was found to bring shear damages to the CFs.At last, the bridging strengthening mechanism introduced by CFs was sacrificed.We provide new insight into and instruction on Al/CFs composite sheet preparation method and processing parameters.

Key words: Al/CFs composite sheet; accumulative roll bonding; tensile strength; plastic instability;carbon fiber breakage

1 Introduction

The composite sheet with lightweight and/or high strength properties, is proposed to achieve fuel-saving and safety purposes[1,2].Therefore, the composite materials shall have board applications in electric vehicle industries if the mass production and shaping problems are solved.Stamping process has high production volume and low production cost characteristics, which are commonly adopted by vehicle component manufacturers for product manufacturing.To fulfill the targets of lightweight and high strength for the stamping products, ultrahigh strength steel[3], high strength aluminum (Al) and its composites[4,5], as well as the carbon fibers (CFs) composites[6-7]are developed.

However, the above-mentioned ultrahigh strength steel with tensile strength > 1 GPa is difficult to be cold stamped due to the large spring back characteristic, while hot stamping needs additional energy consumption for dies heating, and the oxidation damages on the steel sheet surface cannot be avoided[8].The stamping process for high strength Al sheet is also considered, for example the rapid blank heating process is developed at 300 ℃ heating temperature to obtain higher local ductility and maintain high strength.Nevertheless, the controlling of temperature needs to be sensitive and accurate to avoid ductility reduction[9].It thus appears that the high strength metallic sheet forming needs more expensive equipment and accessories, as well as stricter processing requirements,which are not acceptable for mass production applications.Recently, Yanget al[10]proposed the sandwich Al/carbon fiber reinforcement plastic (CFRP)composite sheet with high strength (>175 MPa) and lower density (2.27 g/cm3) compared with pure Al sheet, and the hot stamping process only required 130℃ with limited damages to stamping dies and samples.The composite preparation of the Al/CFRP sandwich sheet needs hot melting glue to combine the metal and CFRP sheets together as one finished product.However, the hot melting glue is expensive and composite process is not environmentally friendly.

Previous studies[10,11]pointed out that the combination of low alloying Al with continuous carbon fibers (CFs) embedded exhibits a bridging strengthening mechanism and lightweight characteristics at the same time.In the meanwhile, the composite sheet shall be stamped directly to form desirable engineering products.To extend the preparation methods of continuous CFs-reinforced Al sheet, the accumulative roll bonding (ARB) technology is proposed to fabricate the Al/CFs composite sheet without gluing or other chemical treatment to avoid environmental protection issues.Tiwariet al[12]pointed out that the hot ARB process, with temperatures between 200 and 480 ℃,significantly improved the tensile strength and hardness of Al/Graphene composite sheet up to 25% and 20%,respectively.Meanwhile, Morovvatiet al[13]adopted ARB method and subsequent annealing treatment to prepare the carbon nanotube (CNT)-reinforced Al composite sheet.The punch test reveals that the proper formability with high strength of Al/CNT composite sheet can be designed by appropriate heat treatment.Learning from these previous studies, the ARB method for Al/CFs composite sheet fabrication and the underlying mechanism will be further discussed.In the present study, theex-situobservation of the ARB process will be adopted, and the analysis of the CFs damages mechanism will be evaluated for further Al/CFs composite sheet industrial production.

2 Experimental

2.1 Al/CFs composite sheet fabrication

Before the roll bonding process, 0.5 mm thickness and 30 mm width industrial pure Al sheets wereannealedat 300 ℃for60min to have recovery microstructureas ourpreviousstudy did[10].The 3 and 6 K CFs were provided by Sunwell Carbon Fiber Composite Co., Ltd.The 3 and 6 K carbon fibers mean that one bundle of carbon fiber contains 3 000 and 6 000 carbon filaments.

Before ARB process, the pure Al sheets were polished by angle grinder to have rough surface condition, and then the pure Al sheets and CFs were washed with ethanol and dried in atmosphere.The ARB method was adopted to fabricate the composite sheet with the sequence of Al/(3 K or 6 K) CFs/Al as shown in Fig.1(a).The rolling reductions (ε) were arranged as -15%, -28% and -36%, respectively,forex-situobservation of the breakage mechanism of carbon fibers after rolling process.To have one finished composite sheet, the samples were rolled with -50%reduction.Subsequently, the cross-section observation and mechanical properties tests of the one finished Al/CFs composite were carried out.

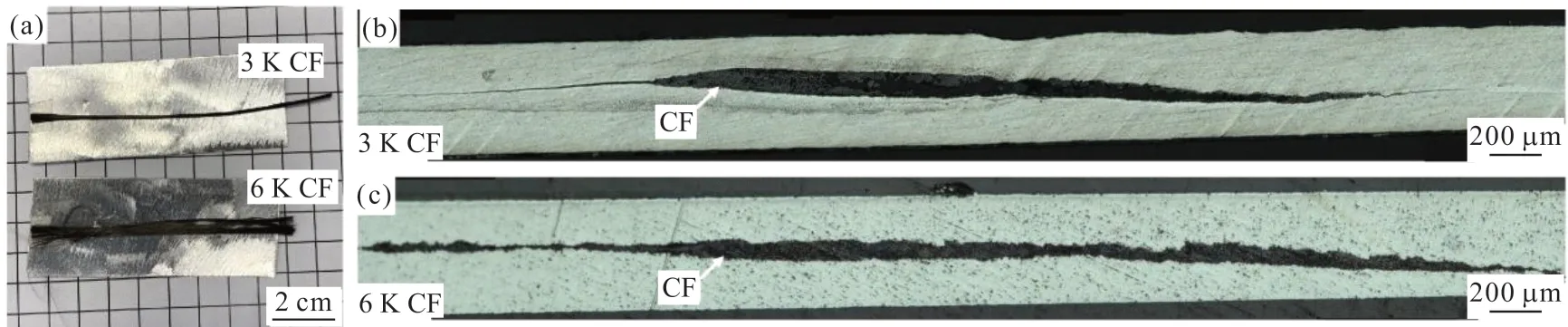

Fig.1 (a) The illustration of the sample preparation, and the cross-section observation of composite Al/CF composite sheet with (b) 3 K and (c)6 K CF under -50% rolling reduction

2.2 Mechanical test and microstructure observation

The tensile tests of the Al/CFs composite sheet with -50% rolling reduction were carried out by Zwick/Roell Z250 with strain rate of 2 mm/min, and the dimension of tensile sample was 0.48 (thickness)×30.4 (width) × 25 (length) mm.

The cross-section of the Al/CFs composite sheet was prepared by sample mounting.The samples were cut by vertical band saw and then polished with 2 000#SiC particles to have mirror surface.All the observation of the Al/CFs composite sheet were carried out under Keyence VHX-7000 stereo optical microscope (OM).

3 Results

3.1 Al/CFs composite sheet observation

The cross-section observation of the Al/CFs composite sheet with -50% rolling reduction is illustrated in Fig.1(b).The cross-section observation of Al/CFs composite sheet with 3 and 6 K CFs shows that the CFs are embedded between two Al layers, and no obvious delamination or voids are found under macro-OM observation.

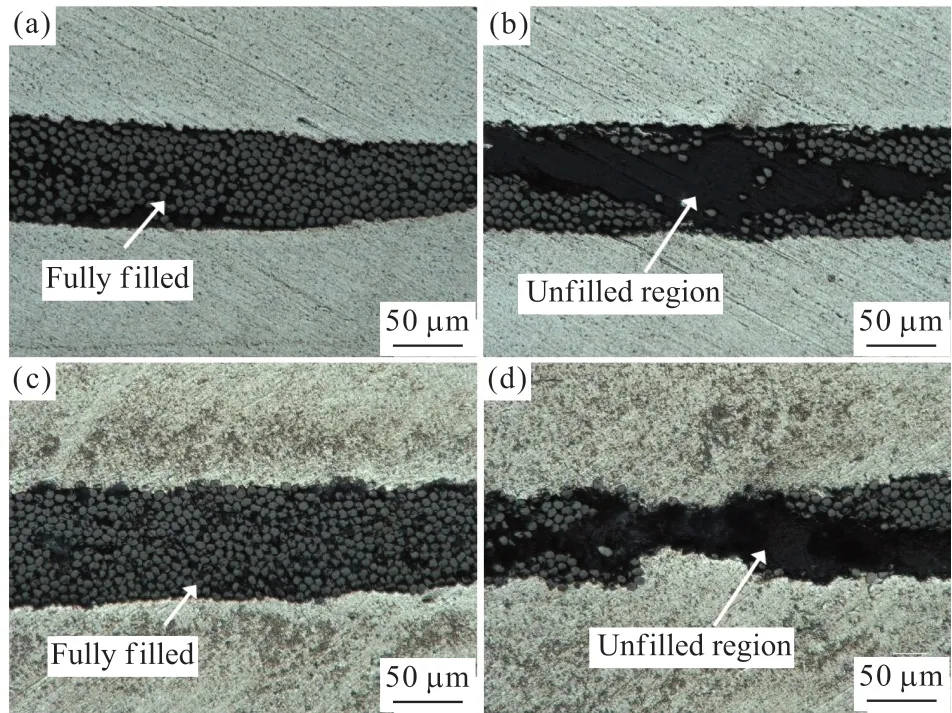

However, with detailed OM observation of CFs embedded between Al layers, the CFs are not continuously distributing within the CFs sandwich layer.In details, it is found that there are two parts of the CFs distribution modes.As shown in Figs.2(a)and 2(c)), the CFs are fully filled along with the sandwich layers of Al/(3 K & 6 K) CFs samples.In the meanwhile, the CFs break in the other areas, exhibiting unfilled regions as shown in Figs.2(b) and 2(d)).This breakage behavior of the CFs within Al/CFs composite sheet, during/after the ARB process, shall have a nonnegligible effect on the mechanical properties.Therefore, the tensile test is needed to evaluate the mechanical properties of Al/CFs composite sheet.

Fig.2 Cross-section observation of composite Al/CF sheet with (a, b)3 K and (c, d) 6 K CF

3.2 Mechanical properties of Al/CFs composite sheet

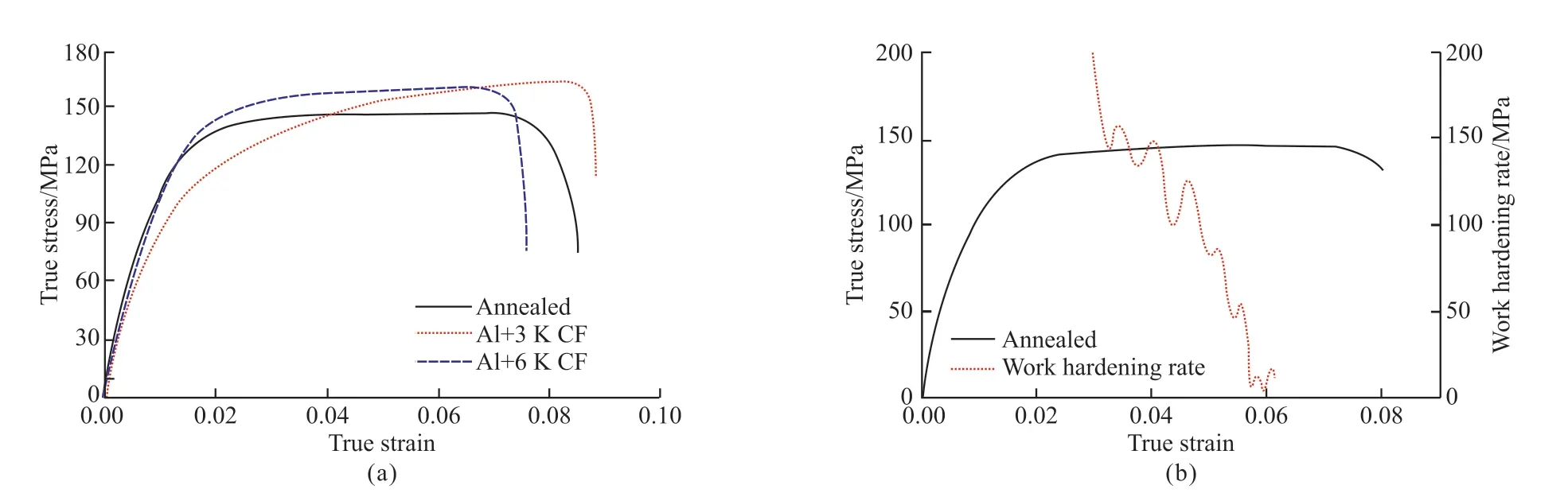

Fig.3(a) illustrates that the Al/ (3 K and 6 K) CFs composite sheets have slight higher ultimate tensile strength (UTS) of 162 and 159 MPa, compared with UTS of annealed pure Al sheet (146 MPa).The testing result shows that the addition of CFs into Al composite sheet does not exhibit an obvious strengthening effect.

Fig.3 (a) The tensile curves of annealed Al and Al/CF sheet with 3 K and 6 K CF, and (b) the work hardening rate of annealed Al sheet

To further study the work hardening behavior, the true stress-strain and work hardening rate curves are plotted in Fig.3(b).According to the Considere criterion[14], it is found that the necking behavior,i e, plastic instability, of annealed pure Al sheet appears at the true strain of 0.03 (where the dash curve of work hardening rate reaches the solid curve of true stress).This calculation result supports that the plastic instability of annealed pure Al sheet shall arise during ARB process,which introduces serve plastic deformation to the rolled metallic materials[15-16].

3.3 Carbon fiber breakage phenomenon

To explore the breakage mechanism of CFs, theex-situobservation method is adopted.As illustrated in Fig.4, the rolled Al/CFs (3 K & 6 K) composite sheets with -16% (Figs.4 (a1 & b1), -32% (Figs.4(a2)& 4(b2)) and -45% (Figs.4(a3) & 4(b3)) rolling reduction are prepared.Due to the limited rolling reduction, the two surface Al layers cannot be rolled as one finished product.Thus, the direct OM observation of the interface between Al and CFs can be shown and the CFs breakage mechanism will be discussed later.

Fig.4 The illustration of the composite Al/CF sheet: (a1-a3) 3 K CF, and (b1-b3) 6 K CF with rolling reduction of -16%, -32% and -45%,respectively

4 CFs breakage mechanism under ARB process

4.1 The ex-situ microstructure observation of annealed pure Al sheet after ARB

The detailed observations of the Al sheet surface with 0%, -16%, -32% and -45% rolling reduction are displayed in Fig.5, and the observation area is randomly picked up away from CFs region for study.The polishing curves are observed in 0%rolling reduction Al sheet (Fig.5(a)), and the ridges,i e, polishing curves, continuously distribute on the polished surface.With further rolling reduction to-16%, the polishing curves are still being observed in Fig.5(b), while some of the ridges become flat due to the contact plastic deformation and minor slip bands are observed after rolling.

The plastic instability,i e, the observed slip bands, obviously appears on the Al sheet surface after-32% and -45% rolling reduction, as shown in Figs.5(c)-5(d)).These uneven slip bands act as microinterlockings[17]to connect two Al sheets tightly to form one finished composite sheet, but the microinterlockings shall also bring damages to CFs during ARB process.

4.2 The ex-situ microstructure observation of sandwich CFs layer after ARB

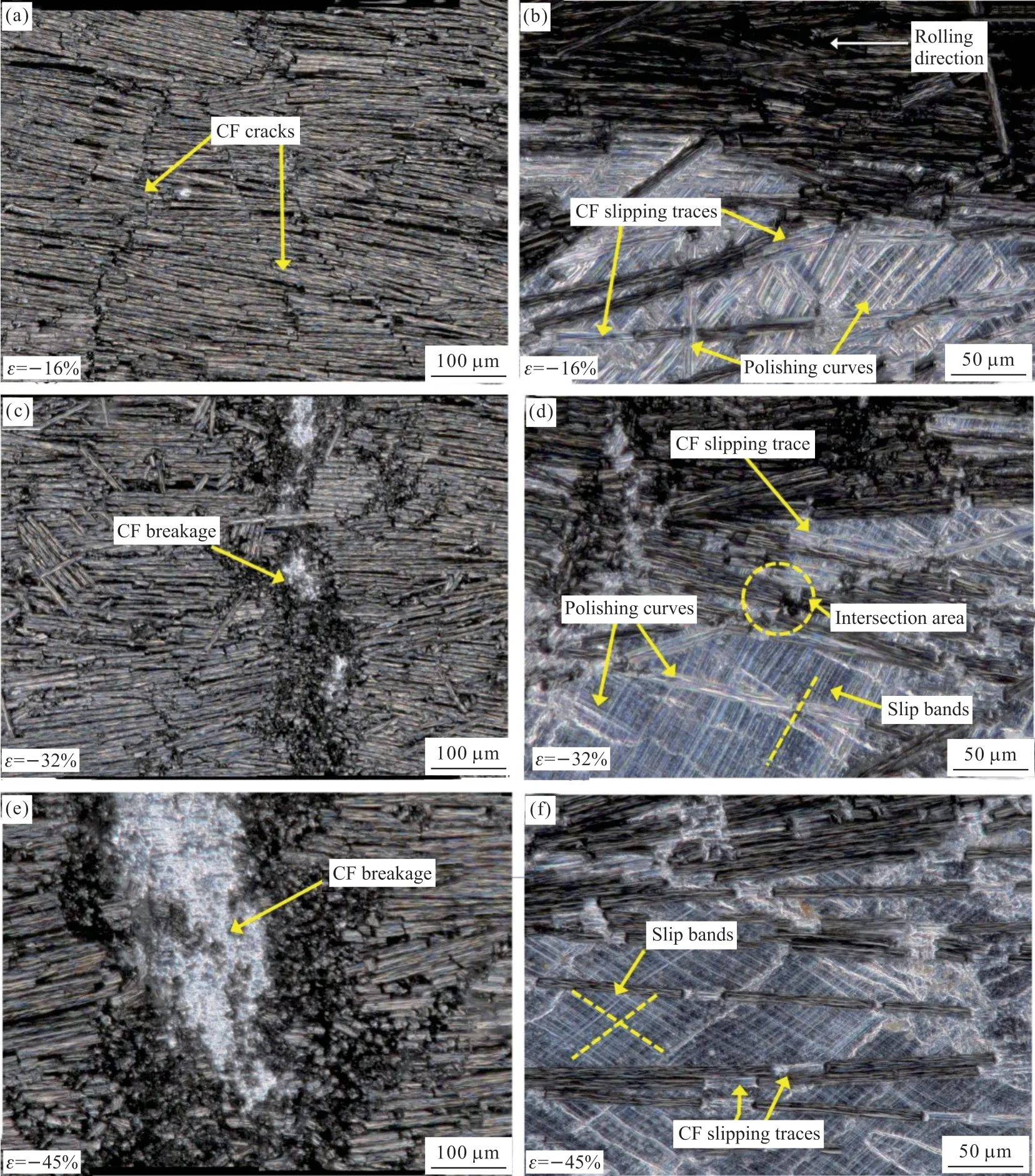

The Al/(3 K & 6 K) CFs composite sheets exhibit similar microstructural evolution and mechanical properties.The detailed observations of the rolled surface of Al/6 K CFs composite sheet, with -16%,-32% and -45% rolling reduction (illustrated in Fig.6) are chosen for further study.The detailed observation of CFs breakage evolution is discussed as below:

Fig.6 The detailed observation of the deformed Al/6 K CF sheet surface with rolling reduction of (a, b) ε= -16%, (c, d) ε= -32% and (e, f)ε= -45%

Rolling reduction of -16%: Based on the macroobservation, the CFs are continuously distributing on the Al sheet layer, while minor cracks are observed as shown in Fig.6(a).It shall be noted that rolling reduction of -16% (equals to be -17.4% true plastic strain) is much higher than the necking strain as shown in Fig.3(b).Therefore, the plastic instability of pure Al sheet shall appear with rolling reduction of -16%, but not being obviously observed as illustrated in Fig.5(b).

With further detailed observation at the edge of CFs (in Fig.6(b)), it is found that the slipping traces of CFs cover the previous polishing curves.According to the previous studies[18,19], the elastic modulus of single CFs is higher than 190 GPa, while the pure Al is only around 69 GPa, indicating that CFs has much higher hardness than that of pure Al does.Therefore, CFs slipping traces originate from the indentation of CFs on pure Al sheet.This existence of CFs slipping trace also proves that the breakage of CFs shall not be resulted from the compression force from Al sheet, which is much softer than that of CFs.

Rolling reduction of -32%: With rolling reduction increasing to -23%, the cracks within CFs connect with each other, becoming more obvious as shown in Fig.6(c).At the same time, the slip bands appear in Al sheet and cover the previous polishing bands, resulting from the plastic instability (in Fig.6(d)).With the detailed observation, the breakage of CFs starts from the CFs and slip bands intersection area.It thus appears that the intersection between slip bands and CFs should cause the critical CFs cracking and breakage.

Rolling reduction of -45%: The gap between the breakage CFs becomes more obvious with rolling reduction increasing, as well as the secondary slip bands are observed with detailed observation near the edge of CFs as displayed in Figs.6(e) & 6(f).

As the rolling plastic deformation makes the sheet elongated, the gap of the through-wall crack gets larger.Besides, due to the severe plastic deformation, the two systems of slip bands are active to trigger much more fluctuant surface compared with the rolled sheet surface at rolling reduction of -16% to -32%.As a result, the broken CFs are much shorter, as well as more cracks are observed in Al/CFs composite sheet with -45%rolling reduction.

4.3 CFs breakage mechanism

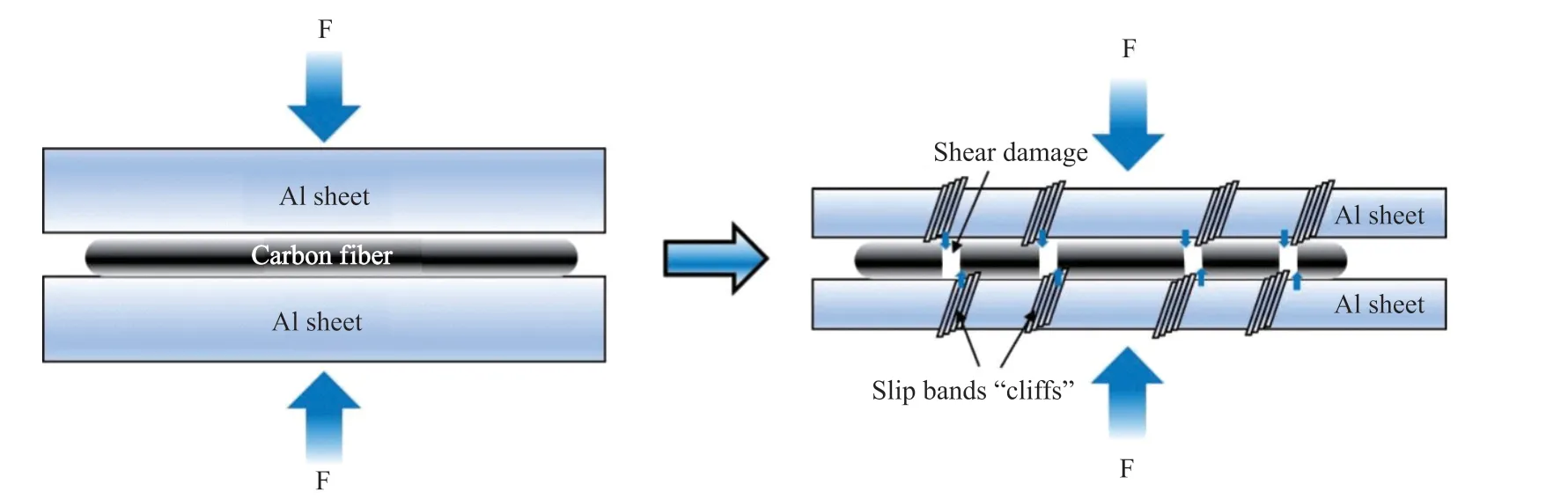

According to theex-situobservation of the breakage phenomenon of CFs after ARB process,it is found that the slip bands, resulting from the plastic instability during ARB process, act as microinterlockings to cut the CFs into discrete fibers.With the rolling reduction increasing, the secondary slipping system emerges to intersect with each other, forming higher density of “cliffs” with stepper morphology.Therefore, the breakage mechanism of CFs results from the plastic instability during ARB process, as shown in Fig.7.As a result, the contribution of CFs to Al/CFs composite sheet mechanical improvement shall be evaluated as little as compared to that with bridging fibers with delaying fracture effect[10,11].

Fig.7 The illustration of carbon fibers breakage mechanism

To minimize the damage of plastic instability to carbon fibers, we propose two methods for consideration:

Softening the Al sheet by annealing heat treatment before the ARB process.The purpose is to lower the yield and flow stress of the Al sheet to delay the onset of plastic instability.Therefore, the occurrence of slip band intersection is postponed and damages to CFs subsequently will be suppressed.

Adopting of hot ARB process, with temperature range between 200 and 480 ℃, shall improve the metallurgical bonding between CFs and Al sheets[12].The underlying mechanism is the utilization of dynamic recrystallization to weaken the damages from plastic instability to CFs.

5 Conclusions

In this study, the ARB process was carried out to prepare the Al/ (3 K & 6 K) CFs composite sheet, and the mechanical properties test andex-situmicrostructure observations were carried out and studied.The summaries can be drawn as below:

a) The Al/ (3 K & 6 K) CFs composite sheet exhibit 11% and 8.9% UTS improvement compared with annealed pure Al sheet.

b) The breakage phenomenon of CFs is resulted from the plastic instability of Al layers during ARB process, resulting in little contribution of CFs to mechanical properties improvement of Al/ (3 K & 6 K)CFs composite sheet.

c) The present study reveals that ARB method can prepare one finished Al/ (3 K & 6 K) CFs composite sheet directly.However, how to reduce the damages of plastic instability of Al sheet to CFs needs to be further studied.

Conflict of interest

All authors declare that there are no competing interests.

Journal of Wuhan University of Technology(Materials Science Edition)2024年1期

Journal of Wuhan University of Technology(Materials Science Edition)2024年1期

- Journal of Wuhan University of Technology(Materials Science Edition)的其它文章

- One-pot Synthesis of Hierarchical Flower-like WS2 Microspheres as Anode Materials for Lithium-ion Batteries

- Controllable Synthesis of Au NRs and Its Flexible SERS Optical Fiber Probe with High Sensitivity

- Effciient Direct Decomposition of NO over La0.8A0.2NiO3(A=K, Ba, Y) Catalysts under Microwave Irradiation

- Appreciable Enhancement of Photocatalytic Performance for N-doped SrMoO4via the Vapor-thermal Method

- Infulence of Current Density on the Photocatalytic Activity of Nd:TiO2Coatings

- The Negative Thermal Expansion Property of NdMnO3 Based on Pores Effect and Phase Transition