纳米纤维素基材料在柔性电子器件中的应用

熊鑫,宁洪龙,方志强,苏国平,黎振超,刘贤哲,姚日晖*,彭俊彪

先进材料

纳米纤维素基材料在柔性电子器件中的应用

熊鑫1a,b,宁洪龙1a,b,方志强1c,d,苏国平1a,b,黎振超2,刘贤哲3,姚日晖1a,b*,彭俊彪1a,b

(1.华南理工大学 a.材料科学与工程学院 b.发光材料与器件国家重点实验室 c.轻工科学与工程学院 d.制浆造纸工程国家重点实验室,广州 510641;2.广东风华高新科技股份有限公司 新型电子元器件关键材料与工艺国家重点实验室,广东 肇庆 526060;3.五邑大学应用物理与材料学院 柔性传感材料与器件研究开发中心,广东 江门 529020)

由于纳米纤维素基材料良好的柔韧性、热力学性能和高透明度,近年来在柔性电子产品中引起越来越多的关注。通过综述该领域的研究进展,将有助于研究人员更高效地开展研究。综述3类纳米纤维素的制备方法及将纳米纤维素基材料应用在柔性电子产品中的研究进展。分别阐述纳米纤维素基材料应用于器件柔性衬底及绝缘材料的研究实例,并讨论纳米纤维素在各种应用方向中的优势以及存在的问题,最后对材料的未来应用前景进行展望。纳米纤维素是天然纤维素与纳米技术结合的产物,可主要划分为纤维素纳米纤丝、纤维素纳米晶以及细菌纤维素3类。近年来,纳米纤维素基材料作为电子器件柔性衬底、绝缘材料等研究均有许多成果问世。虽然纳米纤维素基电子器件的开发还主要停留在实验室阶段,但是与传统的石油化工产品相比,纳米纤维素具有原材料丰富、环保可降解等优点。对纳米纤维素基新型材料的开发利用,有助于解决人类社会中日益严重的电子垃圾问题。

纳米纤维素;柔性电子;可再生;绝缘层

高分子材料由于具有绝缘性好、种类多样、易加工等特点,目前应用已经十分广泛,塑料、纤维、橡胶等高分子材料在生活中随处可见。但是,各类高分子材料大量使用的同时,也产生了许多一系列相应的副作用有待解决。比如,某些高分子材料的原材料本身或加工过程中的添加剂存在毒性,可能会危害人体健康;某些高分子材料废弃后难以降解,造成“白色污染”[1]。随着人类社会信息化、电子化的发展,社会中每年产生的电子垃圾急剧增长,对保护生态环境提出了巨大挑战[2]。为了从根本上解决这一问题,开发出可大规模应用于各类电子产品中的环境友好型高分子材料是非常必要的[3]。基于这样的背景下,纳米纤维素基材料逐渐进入了研究人员的视野。

作为世界上储量最丰富的生物聚合物之一,纤维素具有清洁无毒、可生物降解且生物相容性好等优点[4]。天然纤维素基材料于造纸、服装等行业已经应用了数千年,而纳米纤维素是一种传统纤维素材料与纳米技术结合而诞生的新型材料[5-6]。纳米纤维素继承了天然纤维素的基本结构以及良好的生物相容性,同时由于其纳米级的尺寸,纳米纤维素还兼具了纳米粒子的特性,如强度高、比表面积大、稳定性好、光学透明性好且易交织成网状结构等。因此,许多研究人员尝试将纳米纤维素基材料应用于电子器件中,开发出符合环保理念的新型绿色电子产品。

鉴于纳米纤维素良好的应用前景,通过完成本篇论文,可以帮助新入门的研究人员简单、快速地了解有关纳米纤维素的研究进展,并制定研究路线。本文主要分为2部分,第1部分主要综述3类纳米纤维素的制备工艺以及主要性能参数,第2部分综述纳米纤维素基材料应用于器件柔性衬底以及绝缘材料的研究实例,并展望材料未来的应用前景。

1 纳米纤维素的分类及制备方法

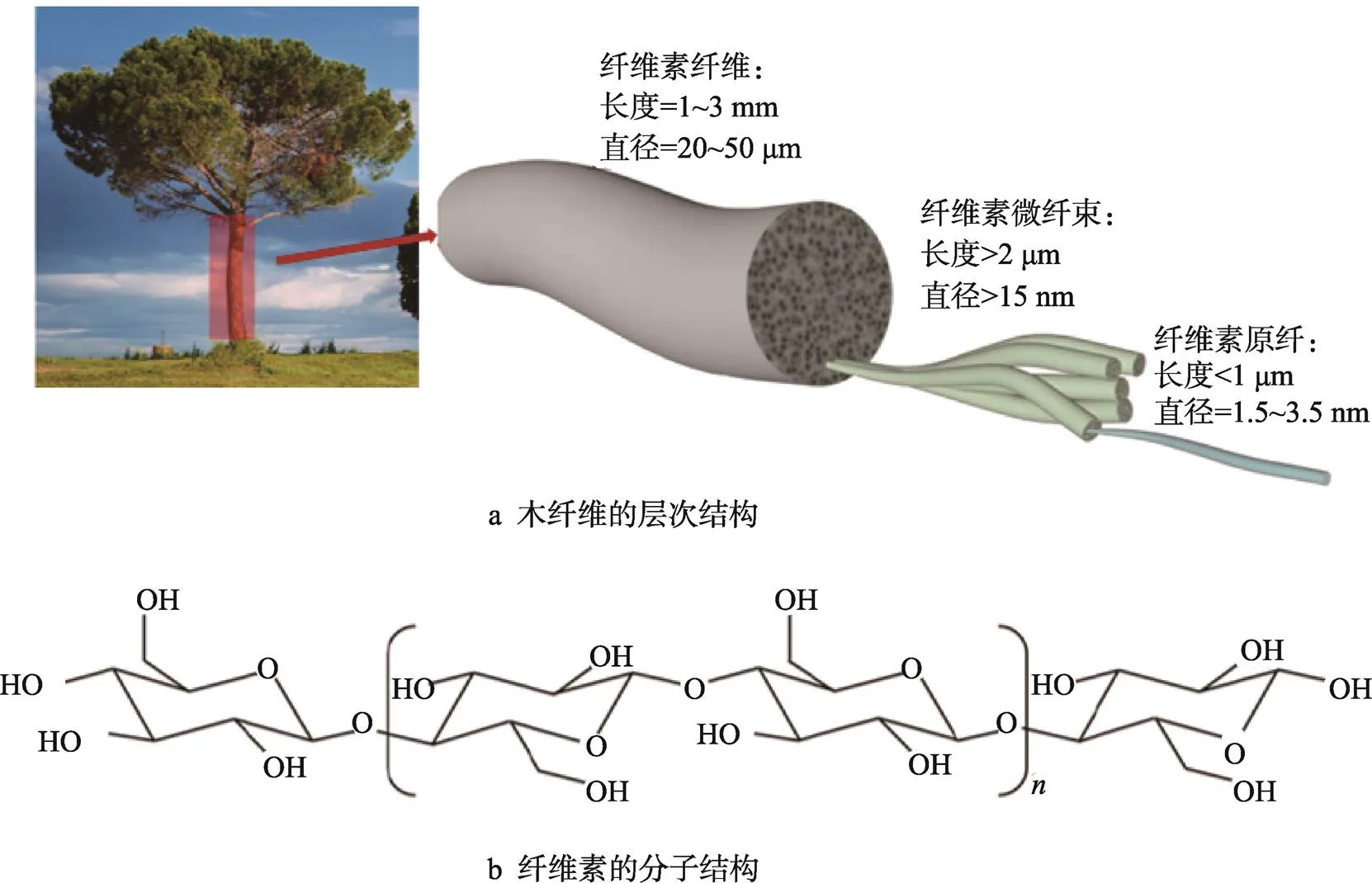

纤维素(C6H10O5)是一种由D-葡萄糖单元由β-(1→4)糖苷键连接而成的高分子量的同聚糖。纤维素分子链通过氢键和范德华力结合构成具有结晶区和无定型区的纤维素原纤丝,进而聚集成纤维素微纤束,并最终形成纤维素纤维,如图1a所示。每个葡萄糖单元在C2、C3和C6上有羟基,能够在纤维素大分子的分子内部和分子间形成氢键,其重复片段的分子结构如图1b所示,这种结构通常被认为是葡萄糖的二聚体,称为纤维二糖[7]。

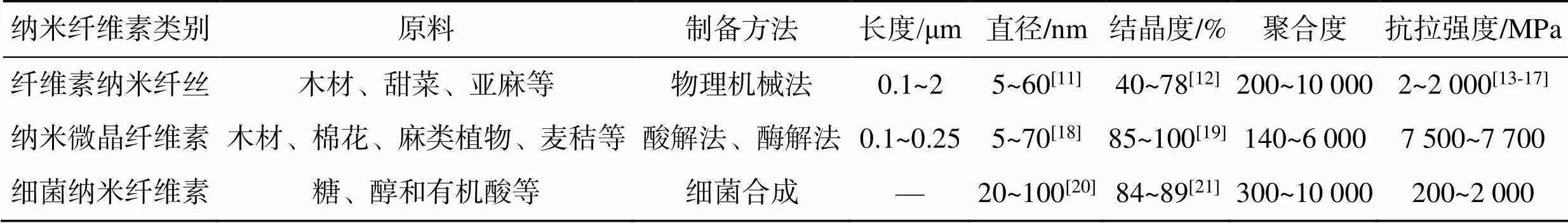

纳米纤维素指至少一个维度为纳米尺度的天然纤维素纳米材料。目前,纳米纤维素可以通过多种方法从植物或细菌等来源进行提取,常用于提取纳米纤维素的方法包括物理方法,化学方法以及生物方法,也可以使用物理化学结合法。根据纤维素来源及形态参数的差异,纳米纤维素可划分为3种类别:纤维素纳米纤丝、纳米微晶纤维素以及细菌纳米纤维素,如表1所示。其中,纤维素纳米纤丝和纳米微晶纤维素来源于植物,可通过不同的工艺从植物纤维中提取得到。细菌纳米纤维素则由细菌产生。

1.1 纤维素纳米纤丝

纤维素纳米纤丝(Cellulose Nanofibril, CNF)的结构由原始纤维素纤维的无定形区和结晶区组成,呈微纤丝状,具有网络或网状结构,极易形成氢键,具有长径比大,比表面积大,强度高,热稳定性好等特点。

目前,CNF主要采用物理机械法进行制备,即对纤维素原料进行物理作用,减小其尺寸到纳米尺度。物理机械法主要包括高压均质法[22],高速搅拌法、热压法、研磨[23]、冷冻粉碎[24]、超声波处理[25]等。其中高压均质法由于效率高、易控制且工艺中不涉及有机溶剂,是CNF制备中最常用的一种物理机械法。其工作过程中,首先将纤维素原料导入高压均质阀中,使物料在高压环境下反复与碰撞环发生高速碰撞,利用由此产生的剪切作用力实现纤维素的细化和均质。物理机械法制备的CNF在纤维高度微细化后比表面积增大,表面裸露出大量的羟基,因此表现出较好的吸水性和黏结力。

图1 纤维素结构示意图[8-10]

表1 纳米纤维素的分类

Tab.1 Classification of nanocellulose

然而,通过以高压均质法为代表的物理机械法制备CNF,存在制备时间长、能耗高、设备易受损害等缺点。因此,实际制备过程中,往往需要先对纤维素原料进行预处理,以大大降低制备所需时长及能耗。常见的预处理方法包括酶解法[26]、羧甲基化法[27-28]、TEMPO氧化法[29-30]、磷酸化法等[31-32]。在一些研究中,通过预处理手段可将纤维素表面的醇羟基转化为带负电的羧基或羧甲基,使得纤维素原纤之间产生静电斥力,氢键作用点减少,氢键更难形成,纤维素原纤直接的结合力减弱,更容易分解细化。

1.2 纳米微晶纤维素

纳米微晶纤维素(Cellulose Nanocrystal, CNC)由纤维素原料经过化学处理后剩下的高结晶度刚性棒状颗粒组成,其力学性能优异,具有高结晶度、高弹性模量、高拉伸强度等特点。从纤维素纤维中分离CNC的主流方法是基于无机酸水解法的化学处理,这是由于纤维素的非晶区抗酸性较差,而纤维素的结晶区具有更致密的物理化学结构,具有较好的抗酸性。通过酸处理过程可将纤维素的非晶区水解除去,而结晶区能抵抗酸溶液侵蚀,则会被保留下来。包括硫酸[33]、盐酸[34]、磷酸[35]和氢溴酸[36]在内的多种酸均可用于提取CNC,其中硫酸水解目前应用最为广泛。硫酸可将纤维素表面的羟基置换为带负电的硫酸根基团,硫酸根基团之间产生的静电排斥力使CNC的分散稳定性更好[37],然而硫酸的使用存在一些缺点,如CNC的热稳定性低、设备易腐蚀、用水量大以及环境不友好等[38]。因此,一些研究人员着眼于探索硫酸的替代品,如离子液体[39-40]、马来酸、草酸[41]、甲苯磺酸、富马酸和柠檬酸水解[42]等。

1.3 细菌纳米纤维素

细菌纳米纤维素(Bacterial Nanocellulose, BNC)是由细菌(如木醋杆菌)在含有糖源的水培养基中合成的一种由带状纳米纤维组成的网状纳米纤维素。一般来说,BNC的结构随培养条件和菌株种类的差异而有所不同[43-46]。BNC的化学结构单元与前文所述的2种植物纳米纤维素相同,但BNC更薄,且具有纯度高(约100%)、结晶度高、热稳定性强等优势。木材或植物纤维素在纯化过程中通常会引入多种官能团,如羧基或羰基,而BNC中不含除醇以外的其他官能团,同时也不含其他聚合物,如木质素、半纤维素或果胶等,这有助于BNC在生物医学中的应用。BNC合成的生化过程包括3个主要步骤:葡萄糖残基聚合成β-1,4葡聚糖、细胞外分泌线状链、葡聚糖链通过氢键和范德华力在细胞外空间排列而结晶[47]。目前,主要有2种方法用于培养菌株生产BNC:静态培养法[48]和搅拌培养法[49],培养时间一般从几天到2周不等[50]。

2 纳米纤维素在电子产品中的应用

近年来,越来越多研发人员将目光投向柔性电子器件的开发,如太阳能电池、有机发光二极管、薄膜晶体管[51]、超级电容器等。基于纳米纤维素制备的薄膜具有优异的柔韧性、纳米级的表面粗糙度、超高的透明度及优异的力学性能和热性能,可以直接作为衬底材料应用于透明柔性电子器件中,也可以通过与其他功能材料复合的方式改善其性能。同时,纳米纤维素薄膜也被证明具有优异的介电性能,可以作为一种绿色绝缘材料应用于下一代环保电子产品中。

2.1 柔性电子器件的衬底材料

衬底是电子器件的重要组成部分,它独立支撑电子器件的运行与工作,衬底薄膜的光学、机械和热性能是决定电子器件性能的关键因素[52]。目前常见的衬底材料多为玻璃或塑料。玻璃衬底高密度及高刚性的特点使其不适用于柔性电子器件中。塑料衬底(PET、PEN、PI、PC等)具有高透明度、高柔韧性及轻便的优势[53-54],可应用于柔性电子器件。但是塑料衬底普遍存在低热耐久性和高热膨胀系数(CTE)的缺点,衬底与器件其他层之间热膨胀系数的巨大差异会在界面处造成不良应力,从而导致整个器件在制造过程中弯曲或变形[55],这一定程度上限制了塑料衬底在柔性电子器件中的应用。

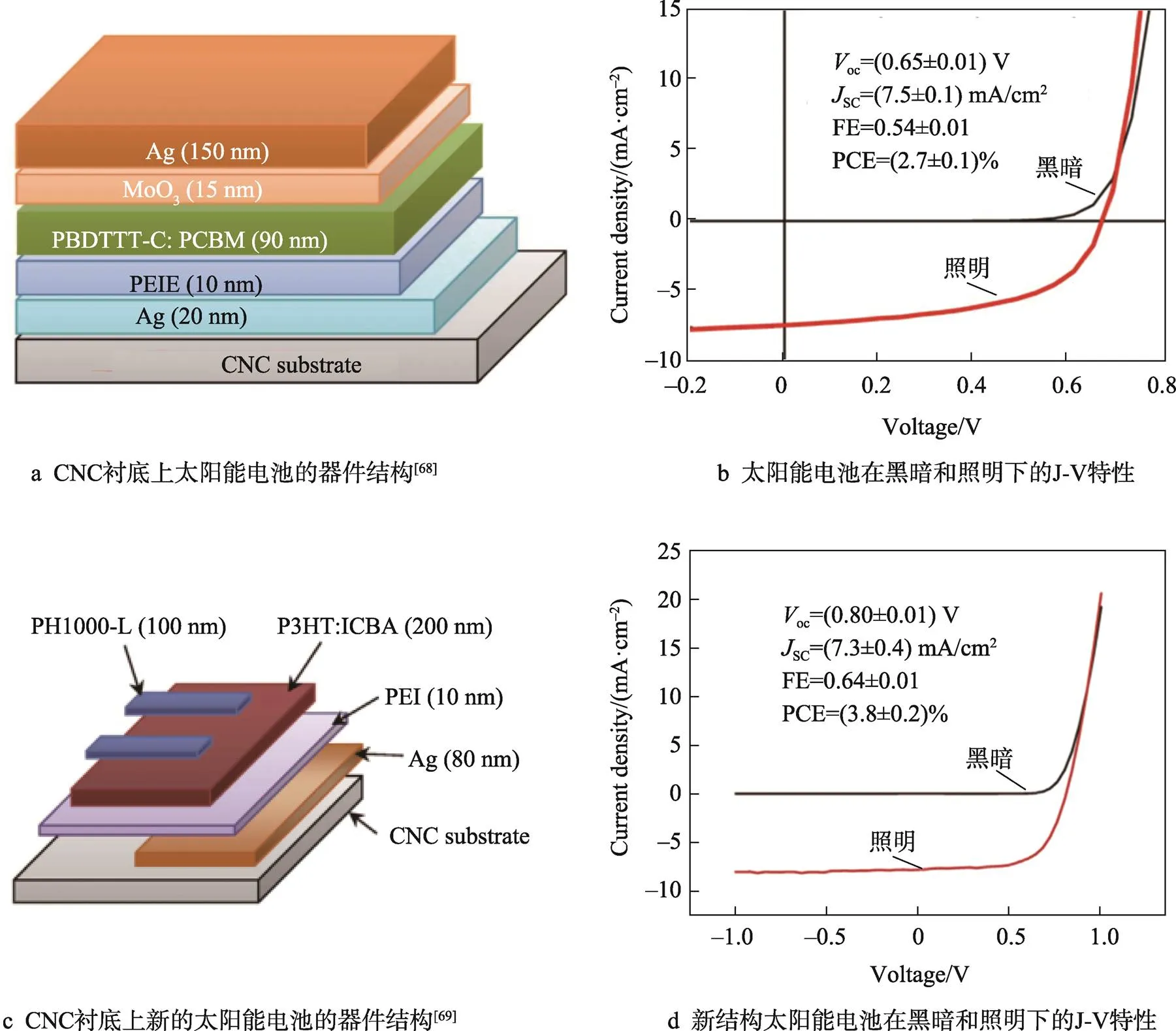

以CNF制成的纳米纸具有优异的热稳定性(>180 ℃)、化学耐久性,以及较低的热膨胀系数(CTE:5×10−6~10×10−6K),是一种很有前途的柔性衬底,有望广泛应用于柔性电子器件中[56-66]。2012年,Hu等[67]展示了一种由CNF制成的新型柔性透明纳米纸,并作为光电器件的衬底制备了太阳能电池。然而,器件表现出较差的性能(最大光能转化效率(PCE)为0.4%)和较差的整流,主要是因为CNF衬底的表面相对粗糙(表面高度变化为 40 nm)。2013年,Zhou等[68]在相对CNF衬底表面粗糙度低得多的独立透明CNC衬底上制造了聚合物太阳能电池,具有以下结构:CNC/Ag(20 nm)/聚乙烯亚胺乙氧基化(PEIE)/活性层/MoO3/Ag,如图2a所示。图2b显示了太阳能电池在黑暗和95 mW/cm2的AM1.5照明下的J-V特性曲线。太阳能电池的PCE(2.7%)高于其他可再生衬底上制造的聚合物太阳能电池,但相较于玻璃/氧化铟锡(ITO)衬底上制造的类似结构器件的(PCE值约为6%)低,这归因于半透明Ag(20 nm)底部电极的低透射率。同年,Zhou等[69]又在CNC衬底上报告了新的太阳能电池器件结构,使用半透明PEDOT:PSS作为顶部空穴收集电极,同时使用反射性Ag/聚乙烯亚胺(PEI)作为底部电子收集电极,器件结构如图4c所示,新的器件显示出(0.64±0.02)的高填充因子(FF)和(3.8±0.2)%的高平均PCE。

图2 2种基于CNC衬底的太阳能电池结构

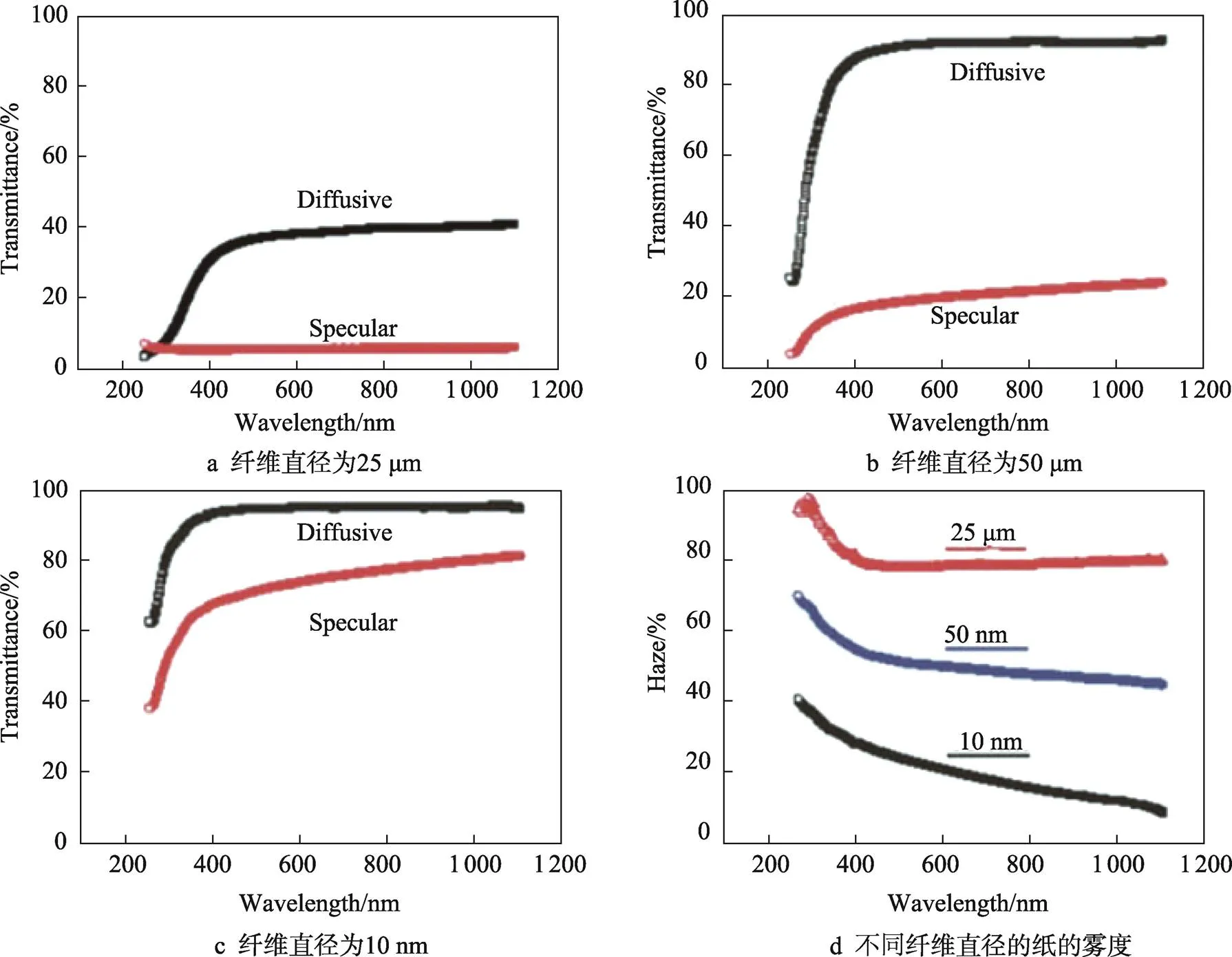

2013年,Hu等[70]制备了TEMPO氧化CNF纳米纸,发现CNF直径与纳米纸的光学性能存在联系。如图3所示,直径越大,成纸透明度越低,而雾度越高。实际应用中,高雾度高透明度的纸比较适用于太阳能电池等户外电子设备[31, 71-73],而高透明度低雾度的纸更适用于显示器等领域。研究团队通过调整纸张内纤维素微米纤维与纳米纤维素的比例可制备光学性能可调的纳米纸。基于纳米纤维素纸的优异光学性能与力学性能,制备了一系列透明纳米纸基电子器件,如透明发光二极管[58]、透明晶体管[74]、触摸屏[62]、太阳能电池[75]。

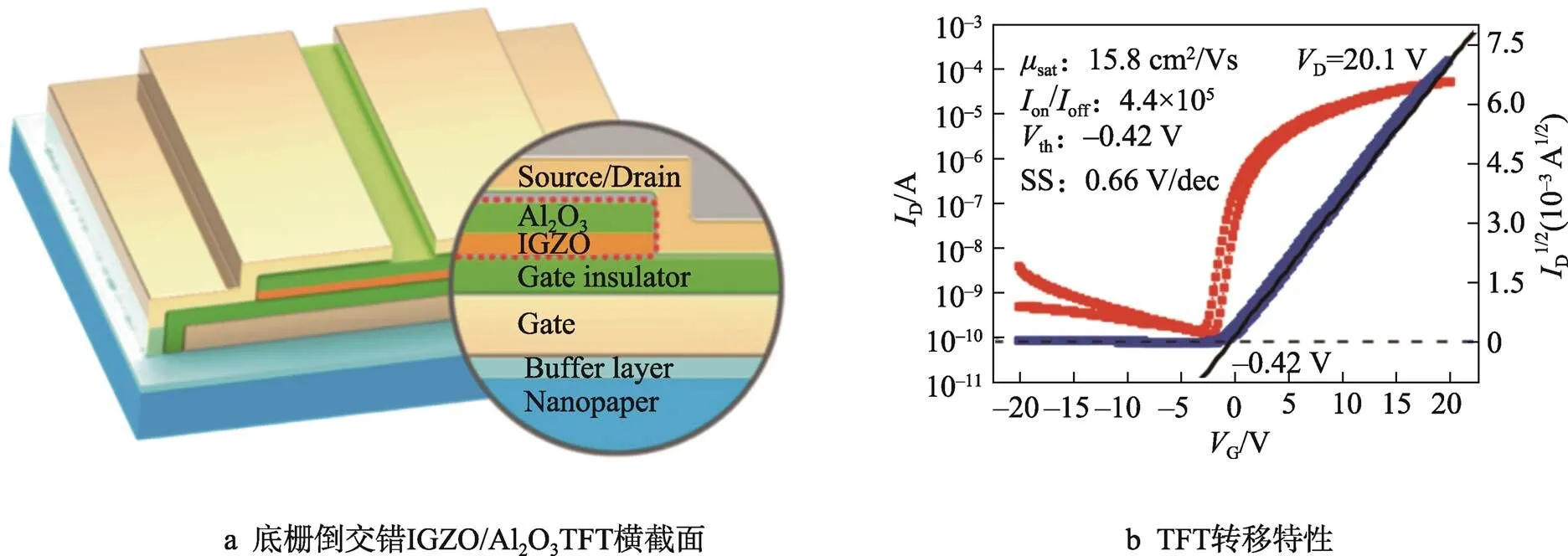

在以往的研究中,基于薄透明CNF纳米纸衬底制备的OTFT具有良好的柔韧性[55]。但是由于纳米纸衬底无法耐受较高的退火温度,器件性能和热退火之间的矛盾然是实现高性能纳米纸TFT应用的障碍。2017年,Ning等[77]使用IGZO/Al2O3双层薄膜作为沟道有源层,通过传统的物理气相沉积方法在光学性能优异(92%透明度,0.85%透射雾度)和超光滑(在5×5 μm扫描区域中面粗糙度为1.8 nm)的CNF纳米纸基板上制造了高性能TFT,器件结构如图4a所示,制备过程无需进一步热退火处理。如图4b所示,器件表现出优异的工作特性:饱和迁移率为15.8 cm2/(V·s),开关比为4.4×105,阈值电压为−0.42 V,亚阈值摆幅为0.66 V/dec。室温下,纳米纸基高性能IGZO/Al2O3TFT的成功制备,有助于研发廉价绿色、柔性轻质的显示器件。

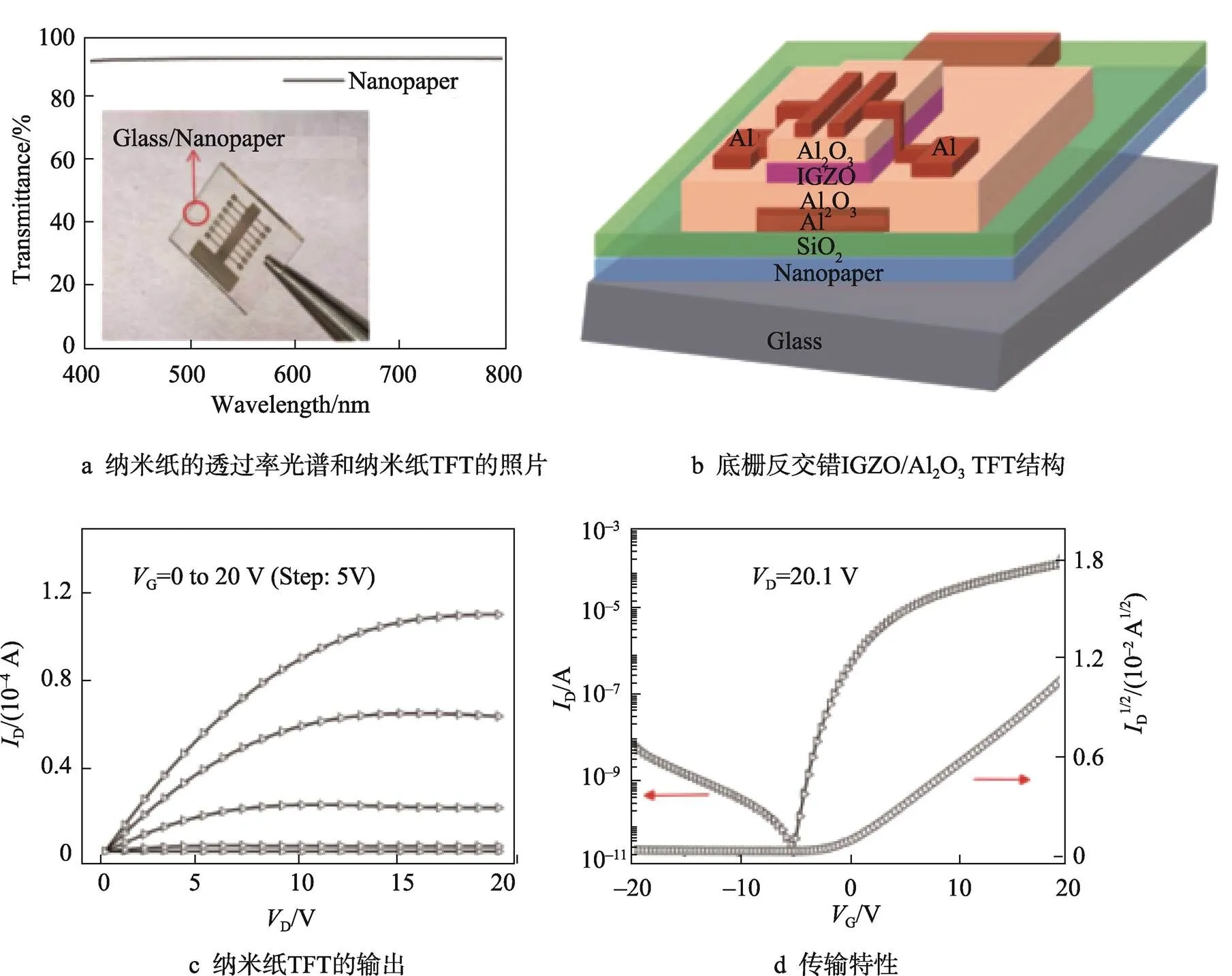

2023年,Zhong等[78]以宽度为3~5 nm的CNF为原料,通过旋涂法在玻璃基板上制备了表面粗糙度为3.49 nm的纳米纸作为器件衬底,并在透明纳米纸上通过室温物理气相沉积制备了具有底栅结构的双层沟道(IGZO/Al2O3)TFT,如图5所示。旋涂制备的纳米纸具有超光滑表面,且室温制备工艺可以防止TFT沉积过程中纳米纸发生分解或形变。因此,纳米纸TFT的每个功能层截面都没有观察到明显的皱纹,平坦的IGZO/Al2O3层可以减少TFT的内部缺陷,同时提高器件的稳定性。所制备的纳米纸TFT不仅表现出高达21.98 cm2/(V·s)的饱和迁移率、5.07×106的on/Ioff开关比和0.75 V/dec的亚阈值摆幅,而且表现出良好的偏置稳定性。这项研究对开发绿色、可持续且廉价的透明纸电子产品具有重要意义。

图3 CNF直径对纳米纸光学性能的影响[76]

图4 基于CNF基板的TFT结构及器件特性[77]

图5 基于CNF纳米纸衬底的TFT[78]

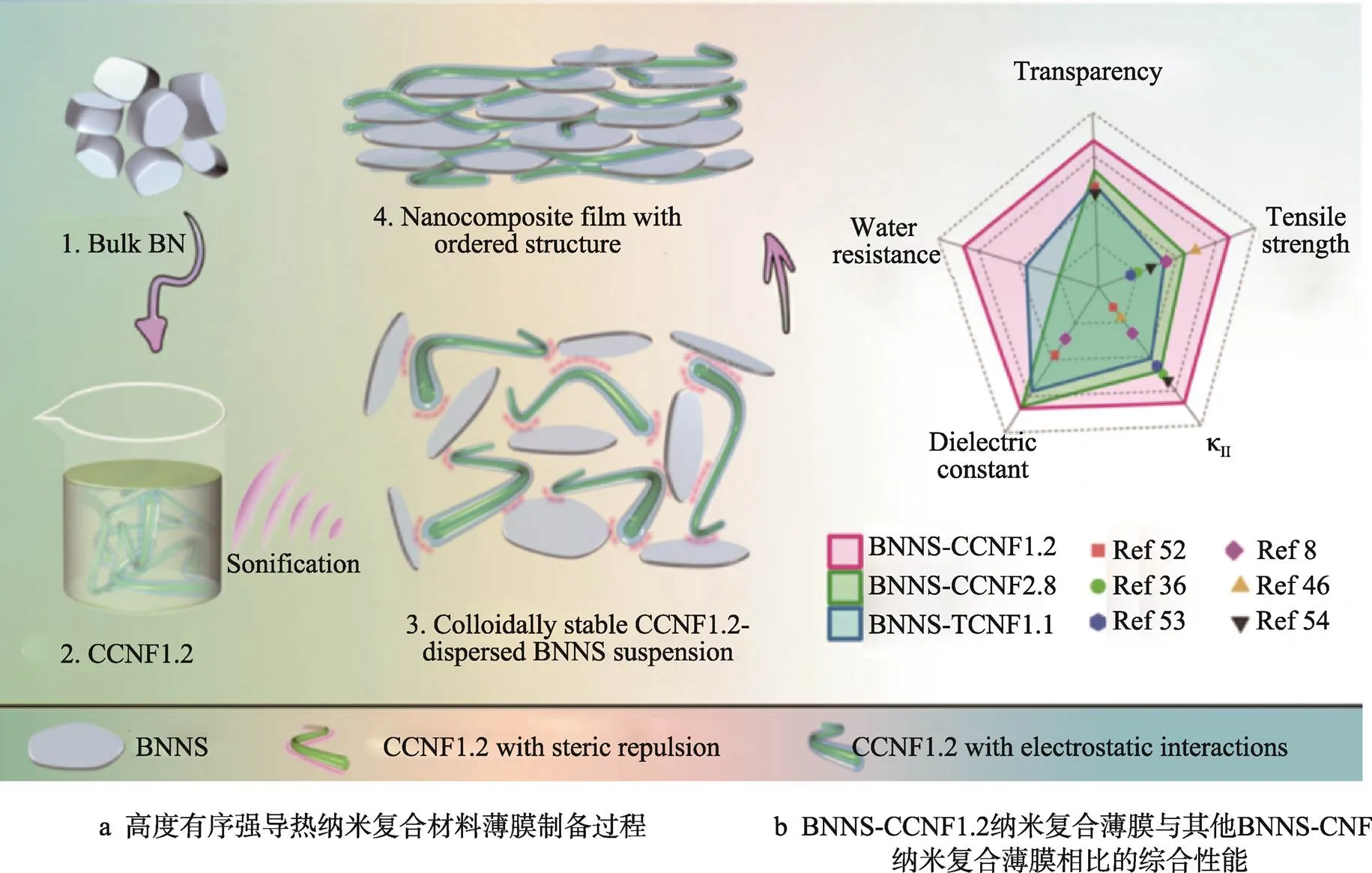

不同于直接将纳米纤维素纸作为器件衬底,部分研究人员尝试将CNF与其他功能材料进行复合以获得性能优势[79-83]。迄今为止报道的纳米复合材料薄膜的整体性能还有较大的提升空间,特别是导热性和拉伸强度。2023年,Chen等[84]通过使用CCNF1.2(羧基含量为1.2 mmol/g的羧甲基化CNF)同时作为BNNS(氮化硼纳米片)的有效分散剂和增强基质,制备了具有优异综合性能的BNNS-CNF纳米复合薄膜,制备过程如图6a所示。CCNF1.2的高长径比使其对BNNS具有优异的分散能力,提供强大的空间位阻排斥力。同时,CCNF1.2与BNNS表现出最强的疏水-疏水相互作用,其羧基与BNNS的−OH完全通过氢键相互作用。因此,如图6b所示,BNNS-CCNF1.2薄膜(BNNS质量分数为50%)表现出致密的排列结构和优异的综合性能(拉伸强度为125.0 MPa、面内导热率为17.3 W/(m·K)和改善的耐水性),BNNS-CCNF1.2薄膜在1 kHz时的介电常数为1.06,介电常数在高频(10 kHz至1 MHz)下的漂移可以忽略不计。这项工作证明了CCNF在提高BNNS-CNF薄膜整体性能方面的有效性,并为其在下一代电子设备的先进热管理中的实际应用铺平了道路。

图6 BNNS-CCNF1.2复合薄膜[84]

目前距纳米纸诞生已经过了10年时间,研究人员对纳米纸的制备、性能研究以及各种纳米纸衬底在柔性电子器件的应用已经初步取得了一系列的突破和成果。纳米纸作为一种天然可再生的新型衬底,同时兼具优异的力学性能、光学性能和热稳定性,被认为在柔性电子器件领域具有光明的应用前景,目前已成功应用于薄膜晶体管、太阳能电池、有机发光二极管[85]等多种电子器件中。但是,目前有关纳米纸及纳米纸基衬底材料应用于电子器件领域的研究多处于实验室阶段,实现大规模商业化应用的过程还面临一些科学技术问题和挑战[86]。在纳米纸制备方面,目前通过真空过滤法或铸涂法制备纳米纸的工艺时间成本太高,未来需研发新的生产工艺和设备实现纳米纸的高效率制备;在器件构建方面,基于纳米纸基衬底的器件性能与玻璃或塑料基器件还存在差距,未来需进一步优化纳米纸的光、电、热稳定性及力学性能,深入研究纳米纸衬底的结构与各项性能参数对器件性能的影响,进一步提升纳米纸电子器件的性能。

2.2 电子器件的绝缘材料

绝缘材料是各种电子器件的重要组成部分之一,目前电子行业中常用的无机绝缘材料大多不可降解,废弃后会对环境造成破坏。由于具有稳定的化学结构与致密的物理堆积,纳米纤维素薄膜有被用作绝缘材料的潜力。同时,纳米纤维素还具有柔韧性好、表面光滑、质量轻盈、高透明度、低热膨胀和生物相容性好等优点,基于纳米纤维素的绝缘材料有望用于高性能环保电子器件中。目前,已有一些基于纳米纤维素薄膜作绝缘层的晶体管等电子器件的报道[87-94]。

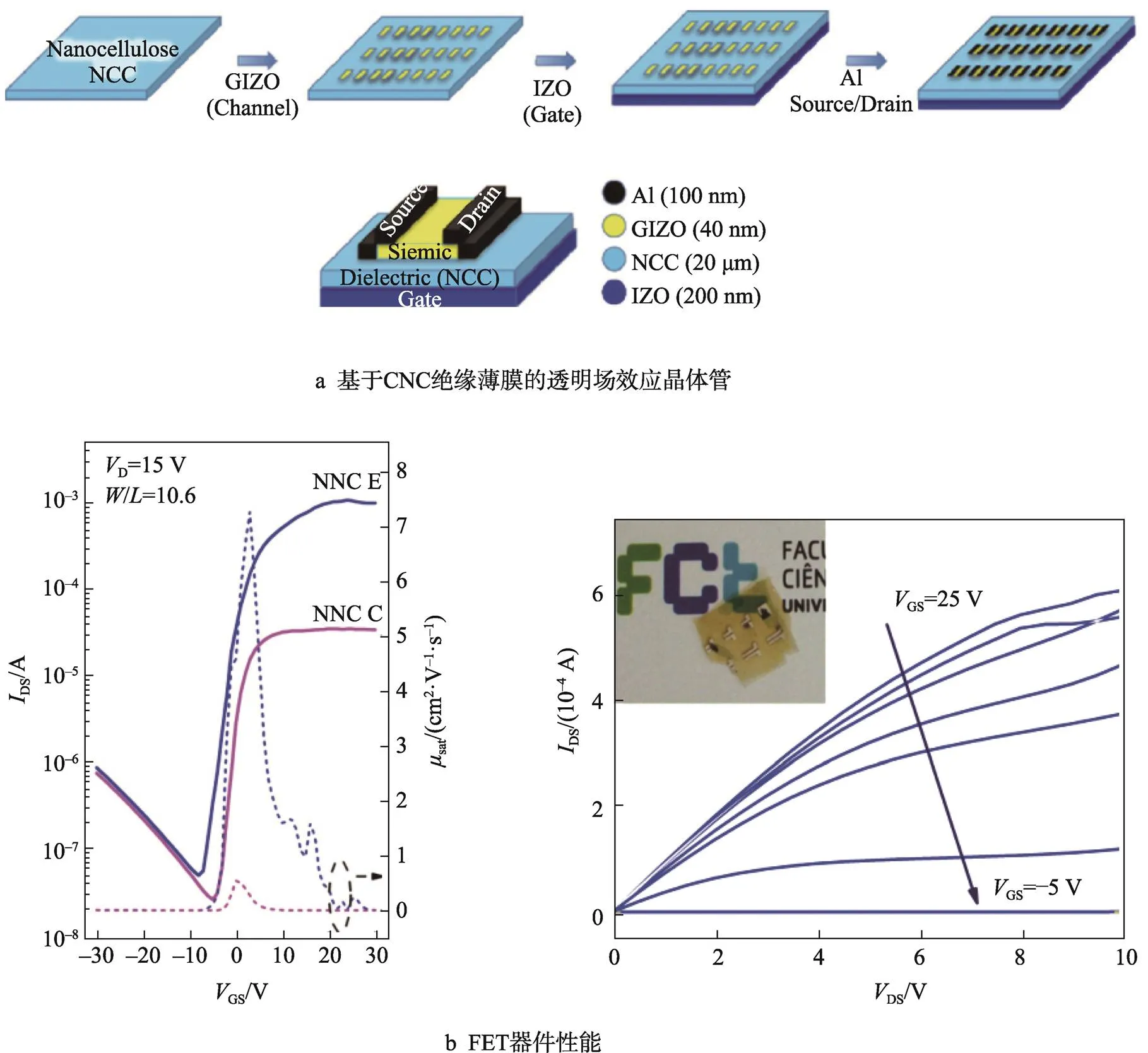

2014年,Gaspar等[93]首次报道了一种基于CNC绝缘薄膜的透明场效应晶体管,制备过程首先采用铸涂法制备厚度为20 µm的CNC薄膜,随后将其他器件结构构建在CNC两侧,该器件的制备过程及器件结构如图7a所示。在该结构中,CNC薄膜同时充当FET器件的基板和绝缘层。FET器件性能如图7b所示,其沟道饱和迁移率高于7 cm2/(V·s),源漏电流开关比高于105,亚阈值摆幅为2.11 V/dec。Fortunato等[95-99]的一系列研究结果表明基于纳米纤维素薄膜绝缘材料制备高性能场效应电子器件具有可行性。

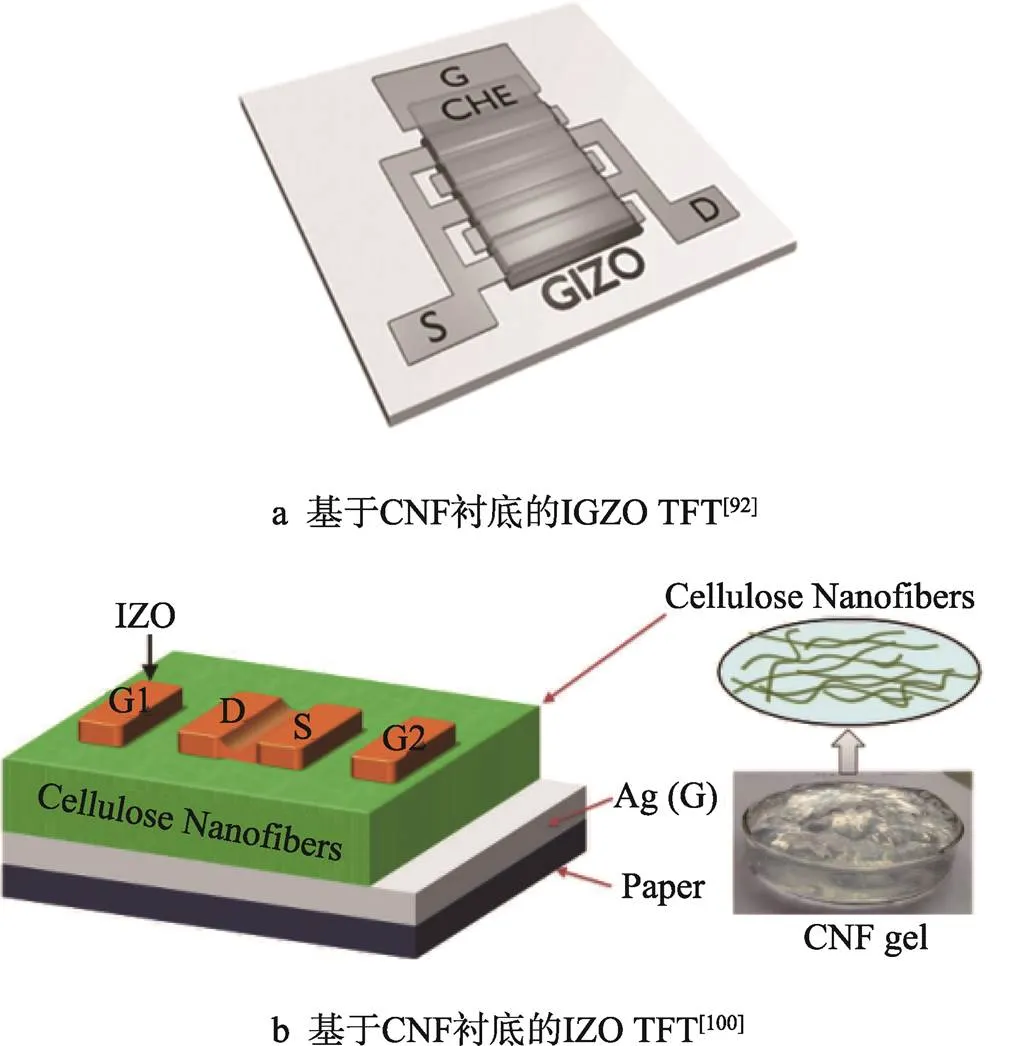

2017年,Cunha等[92]以CNF薄膜单独作为绝缘层,并以IGZO薄膜作为半导体层制备了TFT器件,器件结构如图8a所示。CNF薄膜由羧甲基化CNF制备,由于羧甲基化过程会在纳米纤维素溶液中引入可移动的离子,因此所得CNF薄膜具有离子胶介电特性。在低频(~200 Hz)下可获得较高的有效电容密度(2~6 µF/cm2),IGZO TFT工作电压小于2 V,开/关电流比高于106,关态电流约为10–8A,表明CNF绝缘层具有良好的绝缘特性。同年,Shao等[100]在纸衬底/银电极复合材料上依次沉积CNF薄膜和氧化铟锌(IZO)薄膜制备了晶体管器件,其结构如图8b所示。经测试,当测试电场设为−3.0~3.0 kV/cm时,CNF薄膜的最大漏电流密度约为10−6A/cm2,与常规氧化物绝缘材料接近。同时,得益于CNF绝缘薄膜的低漏电流和高电容,所得薄膜晶体管的开启电压小于1.5 V,开关比高于107,关态电流低于10−10A。

图7 兼具衬底和绝缘层功能的CNC薄膜[93]

图8 基于CNF绝缘层的电子器件

目前,用作绝缘材料的纳米纤维素主要采用铸涂法制备,先制得大片的薄膜后再进行切割。这样的工艺不能精确控制薄膜的厚度、尺寸等,不利于器件的小型化以及集成化。喷墨印刷是一种绿色环保的溶液法薄膜沉积工艺,具有节约材料、生产速率快、无需光刻以及成本低廉等优势,有望克服传统铸涂、过滤工艺的不足,从而促进CNF绝缘薄膜在大规模集成电路的应用。2020年,Zhou等[101]报道了通过喷墨打印制备均匀的CNF薄膜的研究,并基于CNF绝缘层构建了IGZO TFT,器件结构及性能如图11所示。该研究中,选用TEMPO氧化处理的CNF作为原材料,加入合适浓度的PVA、EG及FSO作为添加剂调控墨水的黏度、表面张力及墨水挥发速率,得到了适用于印刷系统的、具有快速自凝胶特性的CNF墨水。印刷后的CNF薄膜表现出良好的均匀性,同时还兼具高透明度、低漏电流密度和高效率电容等优异性能。以喷墨打印CNF薄膜为绝缘层的高性能薄膜晶体管,其迁移率大于10 cm2/(V·s),电流开关比超过5×104。该项研究证明了CNF绝缘薄膜具有大规模应用于电子元器件的潜力。

图9 基于喷墨打印CNF绝缘薄膜的IGZO TFT[101]

随着对纳米纤维素基材料的研究和认识不断深入,其用途不局限于作为电子器件的衬底材料,还有望作为电子器件的功能组件,提升电子器件的性能。纳米纤维素薄膜具有极高的光学透过率、良好的电学绝缘性以及独特的离子胶电容特性,有望作为绝缘层广泛应用于透明电子器件、低功耗电子器件以及环保电子器件中,从而减缓电子废弃物带来的环境问题。然而,目前纳米纤维素绝缘薄膜的应用仍存在不少问题。纳米纤维素薄膜主要采用铸涂工艺制备,往往只能先得到大片的薄膜,之后再根据需求进行切割,制备流程需要额外的剥离、转移以及切割过程,难以兼容大规模的工业生产。进一步地,通过铸涂法不能精确控制薄膜的厚度、尺寸等,所得薄膜的厚度、尺寸过大,不利于器件的小型化以及集成化。此外,由于薄膜不能精细图形化,多个器件集成时需要共用一片薄膜作为绝缘层,因此相互之间存在耦合串扰现象,不利于集成电路的稳定工作。喷墨印刷技术具有定位准确、尺寸可控以及图形化精度高等优点,基于喷墨印刷技术开发纳米纤维素薄膜制备工艺,有望克服传统铸涂、过滤工艺的不足,从而促进CNF绝缘薄膜在大规模集成电路的应用。

3 结语

纳米纤维素基材料拥有柔韧性好、透明度高、质量轻盈以及环境友好等优点。近年来,许多关于纳米纤维素基材料应用于电子器件中作为柔性衬底或其他功能材料的研究被报道。本文介绍了纳米纤维素的制备工艺以及纳米纤维素基材料在电子器件中的应用。虽然已经取得了许多成果和突破,但目前对纳米纤维素基电子器件的开发还主要停留在实验室阶段,目前常用的纳米纸制备方法,如真空过滤法或铸涂法,制备流程较为复杂,且所制备的薄膜厚度往往较大,无法实现薄膜尺寸的精确控制,纳米纤维素想要在未来柔性电子产品中取得大范围应用,还需要解决纳米纸低成本、大面积制备的问题,未来需研发新的生产工艺和设备实现纳米纸的高效率制备。在器件构建方面,基于纳米纸基衬底的器件性能与玻璃或塑料基器件还存在差距,纳米纸基材料无法耐受较高的工艺温度,一定程度上限制了其在高性能电子器件中的应用,未来需进一步优化纳米纸的光、电、热稳定性及力学性能,深入研究纳米纸衬底的结构与各项性能参数对器件性能的影响,进一步提升纳米纸电子器件的性能。为了实现商业化应用,必须加强与其他学科之间的交叉融合,找到纳米纤维素材料及器件制备的新理论与新工艺,在高效率制备及优异器件性能等方向寻求突破。纳米纤维素可从自然界中储量丰富的植物纤维素中获取,同时具有环保无毒且可生物降解等优点,符合当今世界对环境保护的理念,未来与传统的石油化工产品进行竞争将是大势所趋。可以相信,纳米纸衬底将会成为主流的新型绿色柔性衬底,推动下一代电子器件朝着柔性、质轻、低成本、可降解的方向发展,促进人类社会的可持续发展。

[1] QIN M, CHEN C Y, SONG B, et al. A Review of Biodegradable Plastics to Biodegradable Microplastics: Another Ecological Threat to Soil Environments?[J]. Journal of Cleaner Production, 2021, 312: 127816.

[2] LIU Q, CAO J, LI K Q, et al. Chromosomal Aberrations and DNA Damage in Human Populations Exposed to the Processing of Electronics Waste[J]. Environmental Science and Pollution Research, 2009, 16(3): 329-338.

[3] ZHANG T M, ZHANG Y, WANG X Y, et al. Characterization of the Nano-Cellulose Aerogel from Mixing CNF and CNC with Different Ratio[J]. Materials Letters, 2018, 229: 329-338.

[4] KUMAR R, SHARMA R K, SINGH A P. Grafted Cellulose: A Bio-Based Polymer for Durable Applications[J]. Polymer Bulletin, 2018, 75(5): 2213-2242.

[5] FANG Z Q, ZHANG H L, QIU S Y, et al. Versatile Wood Cellulose for Biodegradable Electronics[J]. Advanced Materials Technologies, 2021, 6(2): 2000928.

[6] FANG Z Q, HOU G Y, CHEN C J, et al. Nanocellulose-Based Films and Their Emerging Applications[J]. Current Opinion in Solid State and Materials Science, 2019, 23(4): 100764.

[7] EICHHORN S J. Cellulose Nanowhiskers: Promising Materials for Advanced Applications[J]. Soft Matter, 2011, 7(2): 303-315.

[8] ZHU H L, JIA Z, CHEN Y C, et al. Tin Anode for Sodium-Ion Batteries Using Natural Wood Fiber as a Mechanical Buffer and Electrolyte Reservoir[J]. Nano Letters, 2013, 13(7): 3093-3100.

[9] KLEMM D, KRAMER F, MORITZ S, et al. Nanocelluloses: A New Family of Nature-Based Materials[J]. Angewandte Chemie (International Ed in English), 2011, 50(24): 5438-5466.

[10] HABIBI Y, LUCIA L A, ROJAS O J. Cellulose Nanocrystals: Chemistry, Self-Assembly, and Applications[J]. Chemical Reviews, 2010, 110(6): 3479-3500.

[11] IFUKU S, YANO H. Effect of a Silane Coupling Agent on the Mechanical Properties of a Microfibrillated Cellulose Composite[J]. International Journal of Biological Macromolecules, 2015, 74: 428-432.

[12] LAVOINE N, DESLOGES I, DUFRESNE A, et al. Microfibrillated Cellulose - Its Barrier Properties and Applications in Cellulosic Materials: A Review[J]. Carbohydrate Polymers, 2012, 90(2): 735-764.

[13] WEI P, LI G H, GAO S, et al. Effectively Reinforcing Rolled Reconstituted Tobacco with Carboxymethylated Cellulose Fibers[J]. Cellulose, 2023, 30(11): 7129-7140.

[14] ZHOU J, FANG Z Q, CHEN K H, et al. Improving the Degree of Polymerization of Cellulose Nanofibers by Largely Preserving Native Structure of Wood Fibers[J]. Carbohydrate Polymers, 2022, 296: 119919.

[15] CHEN K H, QIN F M, FANG Z Q, et al. Mechanically Stable Core-Shell Cellulose Nanofibril/Sodium Alginate Hydrogel Beads with Superior Cu(II) Removal Capacity[J]. International Journal of Biological Macromolecules, 2022, 222: 1353-1363.

[16] ZHANG D J, LI G H, LIU Y, et al. Favorable Combination of Foldability and Toughness of Transparent Cellulose Nanofibril Films by a PET Fiber-Reinforced Strategy[J]. International Journal of Biological Macromolecules, 2020, 164: 3268-3274.

[17] ZHOU J, FANG Z Q, CUI J Y, et al. Wood-Inspired Strategy to Toughen Transparent Cellulose Nanofibril Films[J]. Carbohydrate Polymers, 2021, 259: 117759.

[18] TRACHE D, HUSSIN M H, MOHAMAD HAAFIZ M K, et al. Recent Progress in Cellulose Nanocrystals: Sources and Production[J]. Nanoscale, 2017, 9(5): 1763-1786.

[19] MOON R J, MARTINI A, NAIRN J, et al. Cellulose Nanomaterials Review: Structure, Properties and Nanocomposites[J]. Chemical Society Reviews, 2011, 40(7): 3941-3994.

[20] SANI A, DAHMAN Y. Improvements in the Production of Bacterial Synthesized Biocellulose Nanofibres Using Different Culture Methods[J]. Journal of Chemical Technology & Biotechnology, 2009, 85(2): 151-164.

[21] HUANG Y, ZHU C L, YANG J Z, et al. Recent Advances in Bacterial Cellulose[J]. Cellulose, 2014, 21(1): 1-30.

[22] ZIMMERMANN T, BORDEANU N, STRUB E. Properties of Nanofibrillated Cellulose from Different Raw Materials and Its Reinforcement Potential[J]. Carbohydrate Polymers, 2010, 79(4): 1086-1093.

[23] 顾俐慧, 金永灿. 木质纤维素纳米纤丝的制备与表征[J]. 纤维素科学与技术, 2018, 26(2): 31-37.

GU L H, JIN Y C. Preparation and Characterization of Lignocellulose Nanofibril (LCNF)[J]. Journal of Cellulose Science and Technology, 2018, 26(2): 31-37.

[24] ALEMDAR A, SAIN M. Biocomposites from Wheat Straw Nanofibers: Morphology, Thermal and Mechanical Properties[J]. Composites Science and Technology, 2008, 68(2): 557-565.

[25] CHENG Q, WANG S, RIALS T G J C P A A S, et al. Poly(Vinyl Alcohol) Nanocomposites Reinforced with Cellulose Fibrils Isolated by High Intensity Ultrasonication[J]. Composites Part A Applied Science & Manufacturing, 2009, 40(2): 218-224.

[26] CARVALHO A F, DE OLIVA NETO P, SILVA D, et al. Xylo-Oligosaccharides from Lignocellulosic Materials: Chemical Structure, Health Benefits and Production by Chemical and Enzymatic Hydrolysis[J]. Food Research International, 2013, 51(1): 75-85.

[27] WÅGBERG L, DECHER G, NORGREN M, et al. The Build-up of Polyelectrolyte Multilayers of Microfibrillated Cellulose and Cationic Polyelectrolytes[J]. Langmuir, 2008, 24(3): 784-795.

[28] EYHOLZER C, BORDEANU N, LOPEZ-SUEVOS F, et al. Preparation and Characterization of Water-Redispersible Nanofibrillated Cellulose in Powder Form[J]. Cellulose, 2010, 17(1): 19-30.

[29] ISOGAI A, SAITO T, FUKUZUMI H. TEMPO-Oxidized Cellulose Nanofibers[J]. Nanoscale, 2011, 3(1): 71-85.

[30] SAITO T, NISHIYAMA Y, PUTAUX J L, et al. Homogeneous Suspensions of Individualized Microfibrils from TEMPO-Catalyzed Oxidation of Native Cellulose[J]. Biomacromolecules, 2006, 7(6): 1687-1691.

[31] HOU G Y, ZHAO S S, LI Y J, et al. Mechanically Robust, Flame-Retardant Phosphorylated Cellulose Films with Tunable Optical Properties for Light Management in LEDs[J]. Carbohydrate Polymers, 2022, 298: 120129.

[32] HOU G Y, ZHAO S S, PENG L Y, et al. A Systematic Study for the Structures and Properties of Phosphorylated Pulp Fibers Prepared under Various Conditions[J]. Cellulose, 2022, 29(13): 7365-7376.

[33] BONDESON D, MATHEW A, OKSMAN K. Optimization of the Isolation of Nanocrystals from Microcrystalline Celluloseby Acid Hydrolysis[J]. Cellulose, 2006, 13(2): 171-180.

[34] YU H Y, QIN Z Y, LIANG B L, et al. Facile Extraction of Thermally Stable Cellulose Nanocrystals with a High Yield of 93% through Hydrochloric Acidhydrolysis under Hydrothermal Conditions[J]. Journal of Materials Chemistry A, 2013, 1(12): 3938-3944.

[35] CAMARERO E S, KUHNT T, FOSTER E J, et al. Isolation of Thermally Stable Cellulose Nanocrystals by Phosphoric Acid Hydrolysis[J]. Biomacromolecules, 2013, 14(4): 1223-1230.

[36] SADEGHIFAR H, FILPPONEN I, CLARKE S P, et al. Production of Cellulose Nanocrystals Using Hydrobromic Acid and Click Reactions on Their Surface[J]. Journal of Materials Science, 2011, 46(22): 7344-7355.

[37] 唐丽荣, 黄彪, 戴达松, 等. 纳米纤维素晶体的制备及表征[J]. 林业科学, 2011, 47(9): 119-122.

[38] LIU Y F, WANG H S, YU G, et al. A Novel Approach for the Preparation of Nanocrystalline Cellulose by Using Phosphotungstic Acid[J]. Carbohydrate Polymers, 2014, 110: 415-422.

[39] TAN X, ABD HAMID S B, LAI C W. Preparation of High Crystallinity Cellulose Nanocrystals (CNCS) by Ionic Liquid Solvolysis[J]. Biomass and Bioenergy, 2015, 81: 584-591.

[40] MAO J, OSORIO-MADRAZO A, LABORIE M P. Preparation of Cellulose I Nanowhiskers with a Mildly Acidic Aqueous Ionic Liquid: Reaction Efficiency and Whiskers Attributes[J]. Cellulose, 2013, 20(4): 1829-1840.

[41] CHEN L H, ZHU J Y, BAEZ C, et al. Highly Thermal-Stable and Functional Cellulose Nanocrystals and Nanofibrils Produced Using Fully Recyclable Organic Acids[J]. Green Chemistry, 2016, 18(13): 3835-3843.

[42] NAGARAJAN K J, BALAJI A N, KASI RAJAN S T, et al. Preparation of Bio-Eco Based Cellulose Nanomaterials from Used Disposal Paper Cups through Citric Acid Hydrolysis[J]. Carbohydrate Polymers, 2020, 235: 115997.

[43] LI S H, HUANG D K, YANG J C, et al. Freestanding Bacterial Cellulose-Polypyrrole Nanofibres Paper Electrodes for Advanced Energy Storage Devices[J]. Nano Energy, 2014, 9: 309-317.

[44] YANO H, SUGIYAMA J, NAKAGAITO A, et al. Optically Transparent Composites Reinforced with Networks of Bacterial Nanofibers[J]. Advanced Materials, 2005, 17(2): 153-155.

[45] KONDO T, RYTCZAK P, BIELECKI S. Chapter 4 - Bacterial NanoCellulose Characterization[M]. Bacterial Nanocellulose. Amsterdam; Elsevier. 2016: 59-71.

[46] SHI Z J, PHILLIPS G O, YANG G. Nanocellulose Electroconductive Composites[J]. Nanoscale, 2013, 5(8): 3194-3201.

[47] JR R. Cellulose Structure and Biosynthesis: What is in Store for the 21st Century?[J]. Journal of Polymer Science Part A Polymer Chemistry, 2004, 42(3): 487-495.

[48] BROWN R M, WILLISON J H, RICHARDSON C L. Cellulose Biosynthesis in Acetobacter Xylinum: Visualization of the Site of Synthesis and Direct Measurement of the in Vivo Process[J]. Proceedings of the National Academy of Sciences of the United States of America, 1976, 73(12): 4565-4569.

[49] CAMPANO C, BALEA A, BLANCO A, et al. Enhancement of the Fermentation Process and Properties of Bacterial Cellulose: A Review[J]. Cellulose, 2016, 23(1): 57-91.

[50] GATENHOLM P, KLEMM D. Bacterial Nanocellulose as a Renewable Material for Biomedical Applications[J]. MRS Bulletin, 2010, 35(3): 208-213.

[51] LIANG Z H, WU W J, FU X, et al. Flexible High-Entropy Poly(vinyl alcohol) Dielectric Films were Prepared at a Low Temperature and Applied to an Indium Gallium Zinc Oxide Thin-Film Transistor[J]. The Journal of Physical Chemistry Letters, 2023, 14(41): 9245-9249.

[52] 杨曌, 李保昌, 王烨, 等. 基板表面粗糙度对电阻薄膜微观形貌及电学性能的影响[J]. 材料研究与应用, 2022, 16(4): 505-510.

YANG Z, LI B C, WANG Y, et al. Effect of Substrate Surface Roughness on the Morphology and Electrical Properties of Resistance Films[J]. Materials Research and Application, 2022, 16(4): 505-510.

[53] PARK J S, KIM T W, STRYAKHILEV D, et al. Flexible Full Color Organic Light-Emitting Diode Display on Polyimide Plastic Substrate Driven by Amorphous Indium Gallium Zinc Oxide Thin-Film Transistors[J]. Applied Physics Letters, 2009, 95(1): 013503.

[54] 周廷亮, 朱伟刚, 胡凤鸣, 等. 基于碳纤维浆料的柔性薄膜弯曲传感器制备与研究[J]. 材料研究与应用, 2023, 17(2): 323-328.

ZHOU T L, ZHU W G, HU F M, et al. Preparation and Study of Flexible Thin Film Bending Sensors Based on Carbon Fiber Slurry[J]. Materials Research and Application, 2023, 17(2): 323-328.

[55] FUJISAKI Y, KOGA H, NAKAJIMA Y, et al. Transparent Nanopaper-Based Flexible Organic Thin-Film Transistor Array[J]. Advanced Functional Materials, 2014, 24(12): 323-328.

[56] HENRIKSSON M, BERGLUND L. Structure and Properties of Cellulose Nanocomposite Films Containing Melamine Formaldehyde[J]. Journal of Applied Polymer Science, 2007, 106(4): 2817-2824.

[57] FUKUZUMI H, SAITO T, IWATA T, et al. Transparent and High Gas Barrier Films of Cellulose Nanofibers Prepared by TEMPO-Mediated Oxidation[J]. Biomacromolecules, 2009, 10(1): 162-165.

[58] ZHU H L, XIAO Z G, LIU D T, et al. Biodegradable Transparent Substrates for Flexible Organic-Light-Emitting Diodes[J]. Energy & Environmental Science, 2013, 6(7): 2105-2111.

[59] YAO R H, LI X Q, LI Z H, et al. Fabrication and Properties of Silver Nanowire Flexible Transparent Electrode; Proceedings of the 19th International Conference on Electronic Packaging Technology (ICEPT)[C]// Inst Microelectron Chinese Acad Sci, Shanghai, Ieee: New York, 2018: 454-456.

[60] MING S Y, CHEN G, HE J H, et al. Highly Transparent and Self-Extinguishing Nanofibrillated Cellulose-Monolayer Clay Nanoplatelet Hybrid Films[J]. Langmuir, 2017, 33(34): 8455-8462.

[61] TAO J S, FANG Z Q, ZHANG Q, et al. Super-Clear Nanopaper from Agro-Industrial Waste for Green Electronics[J]. Advanced Electronic Materials, 2017, 3(5): 1600539.

[62] FANG Z Q, ZHU H L, PRESTON C, et al. Highly Transparent and Writable Wood All-Cellulose Hybrid Nanostructured Paper[J]. Journal of Materials Chemistry C, 2013, 1(39): 6191-6197.

[63] GUO Y C, FANG Z Q, DU M D, et al. Flexible and Biocompatible Nanopaper-Based Electrode Arrays for Neural Activity Recording[J]. Nano Research, 2018, 11(10): 5604-5614.

[64] LI Y Y, ZHU H L, GU H B, et al. Strong Transparent Magnetic Nanopaper Prepared by Immobilization of Fe3O4Nanoparticles in a Nanofibrillated Cellulose Network[J]. Journal of Materials Chemistry A, 2013, 1(48): 15278-15283.

[65] FANG Z Q, LI B, LIU Y, et al. Critical Role of Degree of Polymerization of Cellulose in Super-Strong Nanocellulose Films[J]. Matter, 2020, 2(4): 1000-1014.

[66] SHUOYANG Q, HUILONG Z, QIANGU Y, et al. Flexible Lumped Microwave Passive Components and Filters on Cellulose Nanofibril Substrates[J]. IEEE Journal of Microwaves, 2023: 96-101.

[67] HU L B, ZHENG G Y, YAO J, et al. Transparent and Conductive Paper from Nanocellulose Fibers[J]. Energy & Environmental Science, 2013, 6(2): 513-518.

[68] ZHOU Y H, FUENTES-HERNANDEZ C, KHAN T M, et al. Recyclable Organic Solar Cells on Cellulose Nanocrystal Substrates[J]. Scientific Reports, 2013, 3: 1536.

[69] ZHOU Y H, KHAN T, LIU J C, et al. Efficient Recyclable Organic Solar Cells on Cellulose Nanocrystal Substrates with a Conducting Polymer Top Electrode Deposited by Film-Transfer Lamination[J]. Organic Electronics, 2014, 15(3): 661-666.

[70] 胡招湘, 侯高远, 李冠辉, 等. 单根木质纤维尺寸对高透光率纤维素复合薄膜雾度的影响[J]. 中国造纸, 2022, 41(10): 16-23.

HU Z X, HOU G Y, LI G H, et al. Effect of Individual Wood Fiber Dimension on Haze for High Transmittance Cellulose Composite Film[J]. China Pulp & Paper, 2022, 41(10): 16-23.

[71] HOU G Y, LIU Y, ZHANG D J, et al. Approaching Theoretical Haze of Highly Transparent All-Cellulose Composite Films[J]. ACS Applied Materials & Interfaces, 2020, 12(28): 31998-32005.

[72] HOU G Y, LI G H, CHEN H, et al. Rapid Preparation of Highly Transparent Paper with High Built-in Haze by an Ion Exchange Approach[J]. SSRN Electronic Journal, 2022, 439: 135776.

[73] HU W, FANG Z Q, LIU Y, et al. A Protonation Process to Enhance the Water Resistance of Transparent and Hazy Paper[J]. ACS Sustainable Chemistry & Engineering, 2018, 6(9): 12385-12392.

[74] HUANG J, ZHU H L, CHEN Y C, et al. Highly Transparent and Flexible Nanopaper Transistors[J]. ACS Nano, 2013, 7(3): 2106-2113.

[75] FANG Z Q, ZHU H L, YUAN Y B, et al. Novel Nanostructured Paper with Ultrahigh Transparency and Ultrahigh Haze for Solar Cells[J]. Nano Letters, 2014, 14(2): 765-773.

[76] ZHU H L, PARVINIAN S, PRESTON C, et al. Transparent Nanopaper with Tailored Optical Properties[J]. Nanoscale, 2013, 5(9): 3787-3792.

[77] NING H L, ZENG Y, KUANG Y D, et al. Room-Temperature Fabrication of High-Performance Amorphous In-Ga-Zn-O/Al(2)O(3)Thin-Film Transistors on Ultrasmooth and Clear Nanopaper[J]. ACS Applied Materials & Interfaces, 2017, 9(33): 27792-27800.

[78] ZHONG J Y, LI G H, GUO R P, et al. Bilayer Metal Oxide Channel Thin Film Transistor with Flat Interface Based on Smooth Transparent Nanopaper Substrate[J]. IEEE Electron Device Letters, 2022, 43(12): 2113-2116.

[79] TANG S W, WU Z G, FENG G X, et al. Multifunctional Sandwich-Like Composite Film Based on Superhydrophobic MXene for Self-Cleaning, Photodynamic and Antimicrobial Applications[J]. Chemical Engineering Journal, 2022, 454(9): 140457.

[80] WEI L S, WU Z G, TANG S W, et al. Tracheid-Inspired Nanoarchitectured Carbon-Based Aerogels with Ultra-Compressibility for Wearable Piezoresistive Sensors[J]. Carbon, 2022, 203(12): 386-396.

[81] TANG S W, WU Z G, LI X Y, et al. Nacre-Inspired Biodegradable Nanocellulose/MXene/AgNPs Films with High Strength and Superior Gas Barrier Properties[J]. Carbohydrate Polymers, 2023, 299: 120204.

[82] ZHOU W, FANG J W, TANG S W, et al. 3D-Printed Nanocellulose-Based Cushioning-Antibacterial Dual- Function Food Packaging Aerogel[J]. Molecules, 2021, 26(12): 3543.

[83] ZHOU W, WU Z G, XIE F W, et al. 3D Printed Nanocellulose-Based Label for Fruit Freshness Keeping and Visual Monitoring[J]. Carbohydrate Polymers, 2021, 273: 118545.

[84] CHEN K H, PENG L Y, FANG Z Q, et al. Dispersing Boron Nitride Nanosheets with Carboxymethylated Cellulose Nanofibrils for Strong and Thermally Conductive Nanocomposite Films with Improved Water-Resistance[J]. Carbohydrate Polymers, 2023, 321: 121250.

[85] NAJAFABADI E, ZHOU Y H, KNAUER K A, et al. Efficient Organic Light-Emitting Diodes Fabricated on Cellulose Nanocrystal Substrates[J]. Applied Physics Letters, 2014, 105(6): 1-4.

[86] 陈港, 彭从星, 况宇迪, 等. 纳米纸衬底的制备、性能及其在柔性电子器件中的应用[J]. 材料工程, 2018, 46(6): 1-10.

CHEN G, PENG C X, KUANG Y D, et al. Preparation, Properties and Applications of Nanopaper Substrates for Flexible Electronics[J]. Journal of Materials Engineering, 2018, 46(6): 1-10.

[87] LIU Z H, NIE S, LUO J, et al. Flexible Indium- Tin-Oxide Homojunction Thin-Film Transistors with Two In-Plane Gates on Cellulose-Nanofiber-Soaked Papers[J]. Advanced Electronic Materials, 2019, 5(7): 1900235.

[88] DAI S L, WANG Y, ZHANG J Y, et al. Wood-Derived Nanopaper Dielectrics for Organic Synaptic Transistors[J]. ACS Applied Materials & Interfaces, 2018, 10(46): 39983-39991.

[89] DAI S L, CHU Y L, LIU D P, et al. Intrinsically Ionic Conductive Cellulose Nanopapers Applied as all Solid Dielectrics for Low Voltage Organic Transistors[J]. Nature Communications, 2018, 9: 2737.

[90] HUANG J W, ZHOU Y X, ZHANG L, et al. Study on the Electrical Properties of Nanopaper Made from Nanofibrillated Cellulose for Application in Power Equipment[J]. Cellulose, 2018, 25(6): 3449-3458.

[91] TAO J, CAO S N. Flexible High Dielectric Thin Films Based on Cellulose Nanofibrils and Acid Oxidized Multi-Walled Carbon Nanotubes[J]. RSC Advances, 2020, 10(18): 10799-10805.

[92] CUNHA I, BARRAS R, GREY P, et al. Reusable Cellulose-Based Hydrogel Sticker Film Applied as Gate Dielectric in Paper Electrolyte-Gated Transistors[J]. Advanced Functional Materials, 2017, 27(16): 1606755.

[93] GASPAR D, FERNANDES S N, DE OLIVEIRA A G, et al. Nanocrystalline Cellulose Applied Simultaneously as the Gate Dielectric and the Substrate in Flexible Field Effect Transistors[J]. Nanotechnology, 2014, 25(9): 094008.

[94] GASPAR D, PEREIRA L, DELATTRE A, et al. Engineered cellulose fibers as dielectric for oxide field effect transistors; proceedings of the E-MRS Spring Meeting/Symposium H/Symposium I/Symposium BB/Symposium FF/Symosium D, Lille, FRANCE, F May 11-15, 2015[C]// Wiley-V C H Verlag Gmbh: Weinheim, 2015: 1421-1426.

[95] FORTUNATO E, CORREIA N, BARQUINHA P, et al. High-Performance Flexible Hybrid Field-Effect Transistors Based on Cellulose Fiber Paper[J]. IEEE Electron Device Letters, 2008, 29(9): 988-990.

[96] MARTINS R, BARQUINHA P, PEREIRA L, et al. Write-Erase and Read Paper Memory Transistor[J]. Applied Physics Letters, 2008, 93(20): 203501.

[97] MARTINS R, NATHAN A, BARROS R, et al. Complementary Metal Oxide Semiconductor Technology with and on Paper[J]. Advanced Materials, 2011, 23(39): 4491-4496.

[98] MARTINS R F P, AHNOOD A, CORREIA N, et al. Recyclable, Flexible, Low-Power Oxide Electronics[J]. Advanced Functional Materials, 2013, 23(17): 2153-2161.

[99] MARTINS R, FERREIRA I, FORTUNATO E. Electronics with and on Paper[J]. Physica Status Solidi (RRL) - Rapid Research Letters, 2011, 5(9): 332-335.

[100]SHAO F, FENG P, WAN C J, et al. Multifunctional Logic Demonstrated in a Flexible Multigate Oxide- Based Electric-Double-Layer Transistor on Paper Substrate[J]. Advanced Electronic Materials, 2017, 3(3): 1600509.

[101]ZHOU S X, XU Z H, FANG Z Q, et al. Invited Paper: Inkjet Printing of Homogeneous and Green Cellulose Nanofibrils Dielectric for High Performance IGZO TFTS[J]. SID Symposium Digest of Technical Papers, 2021, 52(S2): 580-581.

Application of Nanocellulose-based Materials in Flexible Electronic Devices

XIONG Xin1a,b, NING Honglong1a,b, FANG Zhiqiang1c,d, SU Guoping1a,b, LI Zhenchao2, LIU Xianzhe3, YAO Rihui1a,b*, PENG Junbiao1a,b

(1. a. School of Materials Science and Engineering, b. State Key Laboratory of Luminescent Materials and Devices, c. School of Light Industry and Engineering, d. State Key Laboratory of Pulp and Paper Engineering, South China University of Technology, Guangzhou 510640, China; 2. State Key Laboratory of Advanced Materials and Electronic Components, Guangdong Fenghua Advanced Technology Holding Co., Ltd., Guangdong Zhaoqing 526060, China; 3. Research Center of Flexible Sensing Materials and Devices, School of Applied Physics and Materials, Wuyi University, Guangdong Jiangmen 529020, China)

Nanocellulose-based materials have attracted more and more attention in flexible electronic products in recent years due to their good flexibility, thermodynamic properties and high transparency. The review of the research progress in this field will help researchers to carry out research more efficiently. Three types of nanocellulose preparation methods and the research progress of applying nanocellulose-based materials in flexible electronic products were reviewed. The research examples of nanocellulose-based materials applied to flexible substrates of devices and insulating materials were described, and the advantages of nanocellulose in various directions of application as well as the existing problems were discussed, and finally, the future prospects of the material application were proposed. Nanocellulose is a product of the combination of natural cellulose and nanotechnology, which can be mainly divided into cellulose nanofibrils, cellulose nanocrystal and bacterial nanocellulose. In recent years, many achievements have been made in the research of nanocellulose-based materials as flexible substrates and insulating materials for electronic devices. Although the development of nanocellulose-based electronic devices is still mainly in the laboratory stage, compared with traditional petrochemical products, nanocellulose has the advantages of abundant raw materials and environmental degradation. The development and utilization of new nanocellulose-based materials can help to solve the increasingly serious problem of electronic waste in human society.

nanocellulose; flexible; renewable; insulating layer

TS206.4

A

1001-3563(2024)01-0040-14

10.19554/j.cnki.1001-3563.2024.01.006

2023-09-16

国家重点研发计划资助(2021YFB3600604);国家自然科学基金(62174057,62074059,22090024,21978103);广东省自然科学基金(2023A1515011026);广东省教育厅广东省普通高校重点领域专项(新一代电子信息)(2022ZDZX1002);广东省基础与应用基础研究基金(2020B1515020021,2023B1515040013);季华实验室自主立项项目(X190221TF191)