Effect of particle gradation on pore structure and seepage law of solution in weathered crust elution-deposited rare earth ores

Defeng Liu ,Wenxin Yn ,Zhenyue Zhng, *,Run Chi

a School of Resource and Safety Engineering, Wuhan Institute of Technology, Wuhan 430073, China

b Key Laboratory for Green Chemical Process of Ministry of Education, Wuhan Institute of Technology, Wuhan 430073, China

Keywords:Weathered crust elution-deposited rare earth ores Particle gradation Pore structure Seepage law Fractal dimension

ABSTRACT Both CT and Avizo software were used to explore the effect of particle gradation on the evolution characteristics of pore structure and seepage paths in weathered crust elution-deposited rare earth ores during leaching.The results showed that the pore areas in four kinds of ore samples before leaching were mainly concentrated in 104-107 μm2,whose pore quantities accounted for 96.89%,94.94%,90.48%,and 89.45%,respectively,while the corresponding pore volume only accounted for 30.74%,14.55%,7.58%,and 2.84%of the total pore volume.With the decrease of fractal dimension,the average pore throat length increased,but pore throat quantities,the average pore throat radius and coordination number decreased.Compared with that before leaching,the change degree of pore structure during leaching increased with the fractal dimension decreasing.For example,the reduction rate of the average coordination number of ore samples was 14.36%,21.30%,28.00%,and 32.90%,respectively.Seepage simulation results indicated that seepage paths were uniformly distributed before leaching while the streamline density and seepage velocity increased with the fractal dimension decreasing.Besides,the phenomenon of the streamline interruption gradually reduced during leaching while preferential seepage got more obvious with the decrease of the fractal dimension.

1.Introduction

The weathered crust elution-deposited rare earth ores are rich in medium and heavy rare earth elements[1-3].They are adsorbed on the surface of clay minerals in the form of hydrated or hydroxylhydrated ions.Thus,rare earth cations are usually replaced from clay mineral surfaces by ion exchange [4].With the continuous efforts of scientific researchers and field experts,the mining technology of the weathered rare earth ores has gradually developed into three major technologies: pool leaching,heap leaching and in-situ leaching [5-7].Among them,the in-situ leaching technology is regarded as a better-combined mining and beneficiation process,which is widely applied on-site [8].In the leaching process,the factors that affecting the leaching effect of rare earth mainly include the ion exchange reaction and the seepage law of solution [9].The ion exchange reaction time is relatively short,so the leaching effect mainly depends on the permeability characteristics of the ore body whose main influencing factor was particle gradation during leaching[10].This was because good particle gradation was beneficial for rare earth leaching.Poor particle gradation led to low permeability of such deposits,and even formed a large number of seepage blind spots,resulting in low rare earth leaching efficiency and resource recovery rate.Therefore,exploring the intrinsic relationship between particle gradation and solution law of solution has practical guiding significance for improving the leaching efficiency of rare earth.

Scholars have conducted some related research work.Yin et al.[11]found that the poorly-gradated ores showed weak percolation characteristics while well-graded ores exhibited a better seepage effect.The leaching effect of non-ferrous metals can be improved by adjusting the particle size of the ores.The effect of particle gradation on the permeability coefficient was studied by Liu et al.[12].It was found that the rare ores in the humus layer belonging to uniformly graded particles showed the best permeability while that in the completely weathered layer had the worst permeability.Besides,Liu et al.[13] discovered that the leaching velocity of the weathered crust elution-deposited rare earth ores gradually decreased with the burial depth of the ore increasing.This was because the particle gradation changed due to the migration of fine particles during leaching.The above meaningful research results indicated that there was a good relationship between particle gradation and the seepage law of solution,but the reasons have not been revealed from a microscopic perspective.As was well known,the seepage behaviors of the solution were determined by the pore structure characteristics,which were controlled by particle gradation.Accordingly,the evolution characteristics of the pore structure can be studied to explore the effect mechanism of the particle gradation on the seepage of solution.

In the leaching process,the seepage and diffusion movement of solution in ore samples with different particle gradations was completed through the pore channels,but not all pore channels were the migration paths of solution.Some of them were effective and played a positive induction role,controlling the seepage law of the solution.The other part of them was natural or closed or semi-closed due to blockage by fine particles in the leaching process [14].They were ineffective pore channels and played a negative induction role,resulting in the leaching agent solution and the ore surface cannot be fully contacted.It was not conducive to the leaching of weathered rare earth ores.In recent years,experts have carried out relevant research on the pore structure of weathered rare earth ores by using advanced instruments and equipment such as nuclear magnetic resonance (NMR) and computer tomography (CT).Chen et al.[15] studied the change characteristics of pore structure in rare earth ores after leaching by using CT equipment.It was found that leaching increased the porosity of rare earth ore but reduced the number of pores,which made the distribution of pores more uniform.The evolution law of rare earth pores was explored by Zhou et al.using the NMR,who revealed that the porosity of the ore sample remained constant during leaching[16].The pore distribution,pore throat and pore network distribution characteristics of the humic fully-weathered and semi-weathered layers of the rare earth ore in Jiangxi Province were studied by Luo et al.[17].It was found that the pore structure in the semi-weathered layer was dense and the pores were not developed,while the pores in the humus layer and the fullyweathered layer grew along the vertical direction,presenting the characteristics of the slender columnar distribution.Consequently,it was very helpful to explore the mechanism of impact of the particle gradation on the seepage of solution from the perspective of pore structure and seepage path.

Because of this,the weathered rare earth ores with four kinds of particle gradations were taken as the research object in this paper.By using CT and Avizo software,the influence law of particle gradation on the characteristic parameters of the pore structure and solution seepage path of weathered rare earth ores in different leaching periods were analyzed to reveal the mechanism of the effect of particle gradation on the leaching rate.Besides,the optimal particle gradation that could achieve the best leaching effect during leaching was analyzed.The research results can not only help to reveal the influence mechanism of particle gradation on solution seepage,but also provide technical guidance for optimizing injection and collection parameters.

2.Experiments

2.1.Experimental samples

The experimental samples were taken from a weathered crust elution-deposited rare earth ore in Fujian Province,China.X-ray diffraction analysis was conducted on the raw ore samples in the paper,as shown in Fig.1a.It showed that the mineral composition of the ore sample was mainly composed of quartz and clay minerals (illite,halloysite,and kaolinite).In addition,the ion phase rare earth composition of the ore sample was analyzed by inductively coupled plasma mass spectrometry (ICP-MS),as shown in Fig.1b.It demonstrated that the content of light rare earth elements La,Ce,Pr and Nd accounted for 55.79%of the total rare earth elements,while that of medium rare earth elements Sm,Eu,Gd,Tb and Dy accounted for 14.91%.The content of heavy rare earth elements Ho,Er,Tm,Yb,Lu and Y accounted for 29.30%.It indicated that rare earth ore has significant industrial utilization value.

First,the primary raw ore was screened and weighed according to the four particle sizes of-0.15 mm,+0.15 to-0.90 mm,+0.90 to-2.00 mm and +2.00 to -4.75 mm.The grades of rare earth ores with different particle sizes were obtained by using the EDTA titration method,as shown in Table 1.

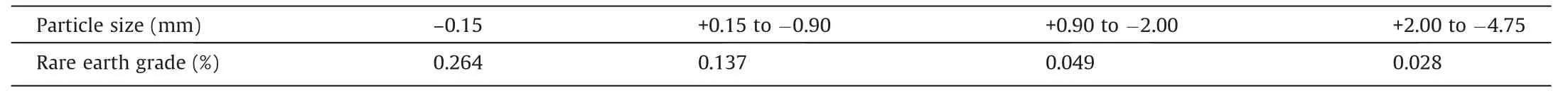

Table 1 Grades of rare earth ores with different particle sizes.

It can be seen from Table 1 that the smaller the particle size,the higher the rare earth grade.Among them,the rare earth content in-0.15 mm ore particles was the highest,accounting for over 55%,which was representative.This showed that rare earth elements mainly occurred in small particle size ores,rather than large particle size ores.It was because rare earth elements were mainly adsorbed on the surface of clay minerals which mainly existed in ores with small particle sizes.While large size ores were mainly composed of quartz,containing a small number of clay minerals[3].

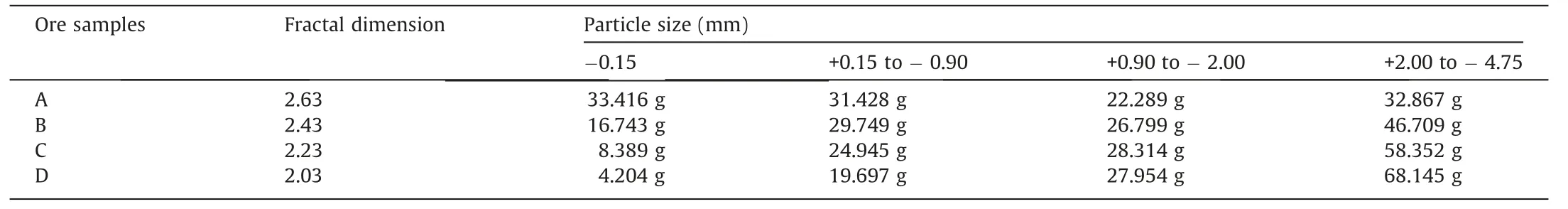

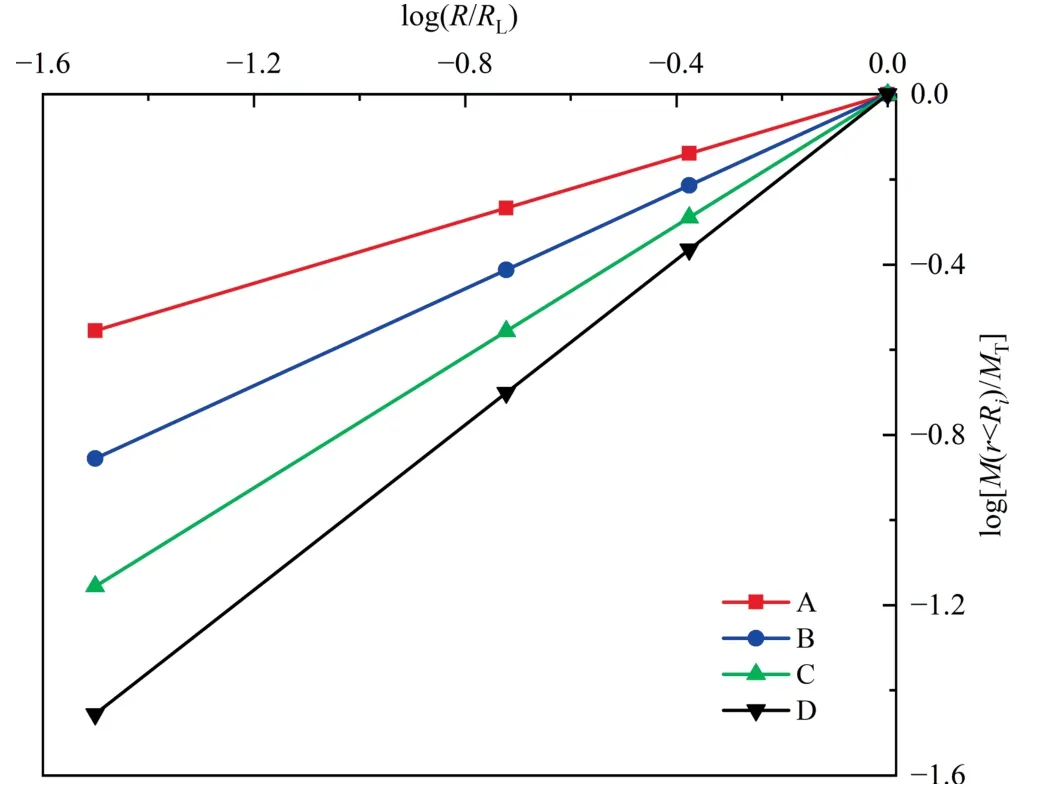

Rare earth ores with different particle sizes were reconstituted into 120 g of ore samples with four kinds of particle gradation,named A,B,C and D respectively,as shown in Table 2.In addition,the fractal theory was initially applied to the kinetics of uranium heap leaching,mainly used to describe the particle distribution characteristics of uranium ore [18].Later,it was introduced into the weathered crust elution-deposited rare earth ores by Liu et al.[19].It was found that the particle distribution characteristics of the ores could be described quantitatively and could also quantitatively represent a certain type of weathered rare earth ores.Therefore,the fractal theory was adopted to analyze the effect of particle gradation on pore structure and seepage law of solution in weathered crust elution-deposited rare earth ores.According to the fractal theory [20],the fractal dimension of particle gradation in the ores can be expressed by Eq.(1).The fractal dimensions of ore samples A,B,C and D can be obtained,as shown in Fig.2 and Table 2.

Table 2 Mass distribution of each particle size in four rare earth ore samples.

Fig.2.Double logarithmic curve of particle gradation of ore samples.

whereM(r<Ri) represented the mass of the samples with particle size less thanR;MTthe total mass of the samples;RLthe maximum particle size of the samples;andDthe fractal dimension.

Table 2 showed that ore samples with more fine particles and less coarse particles have larger fractal dimensions.The fractal dimension of four groups of ore samples with different particle sizes was A>B>C>D.Among them,the proportion of+2 mm particle weight in sample D was the most,reaching 56.8%,while the proportion of -0.15 mm particle weight was the least,only 3.5%.

2.2.Leaching experiment and CT scanning

First,four kinds of ore samples before leaching were scanned by using the Geoscan 200 CT scanner.Then they were evenly loaded into the leaching test device,as shown in Fig.3.Second,based on the leaching optimization experimental results of weathered crust elution-deposited rare earth ores [21],the 0.2 mol/L ammonium sulfate solution was used as leaching agent.It was slowly injected into the leaching test device through the peristaltic pump to keep the liquid-solid ratio of 1:1.At the same time,the leaching solution was collected during leaching.The concentration of rare earth ions was obtained by the EDTA titration method [22].When the concentration of rare earth ions reached its peak,ore samples were scanned by CT.After the scanning was completed,the liquid injection was continued until the concentration of the rare earth ions approached zero.Then ore samples after leaching were scanned again.To ensure the accuracy and comparability of the experiments,the parameters set for the CT scan were consistent with the orientation of ore samples.The CT scan setting parameters were 170 kV,current 130 μA,and scan spatial resolution of 56.05 μm.Through scanning,500 images of four kinds of ore samples at different leaching periods were obtained.Among them,the two-dimensional CT tomographic images of the 100th layer of ore samples before leaching were extracted,as shown in Fig.4,where black and gray were the pore and the ore particle respectively.

Fig.3.Leaching experimental device.

Fig.4.Two-dimensional CT tomographic images of four samples before leaching.

It can be seen from Fig.4 that sample D has the largest proportion of black area,indicating that there were large pores inside it.The structural compactness of the four kinds of ore samples was A>B>C>D,while the order of pore size between particles was A<B<C<D.This was because there were differences in particle gradation for each type of ore sample.

2.3.Image processing and 3D reconstruction

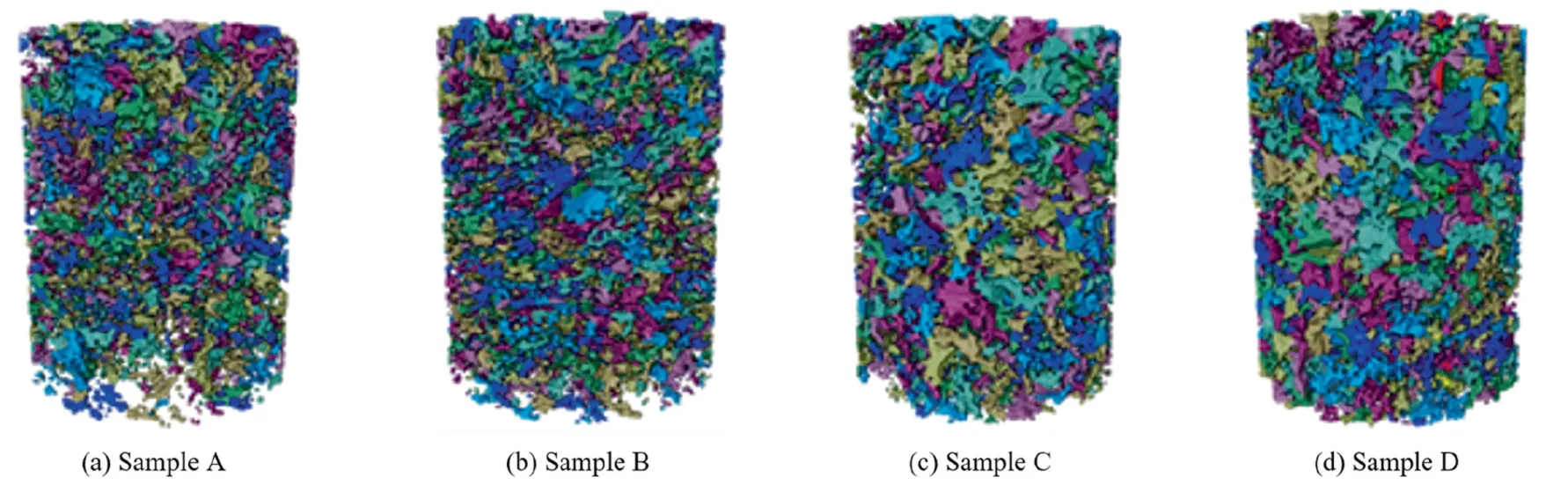

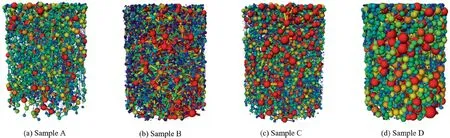

In this paper,Avizo processing software was used to cut and service thresholding CT images.First,to avoid the irregular boundary of the original images,all the original CT images of ore samples were cut into circular images with a diameter of 400 pixels.Second,the interactive threshold was used to segment the ore particles and pores.Finally,based on the threshold segmentation,the images were reconstructed into three-dimensional pore structure models of the four kinds of ore samples with different particle gradations,as shown in Fig.5,where different colors represented different pore sizes.

Fig.5.Three-dimensional pore structure of ore samples.

It can be seen from Fig.5 that the reconstructed threedimensional pore model could well describe the distribution characteristics of the pore space in ore samples.The pore size gradually increased with the decrease of the fractal dimension,which was consistent with the mass distribution law of each particle size of the four kinds of ore samples.

3.Results and discussion

3.1.Change law of extraction rate of the rare earth

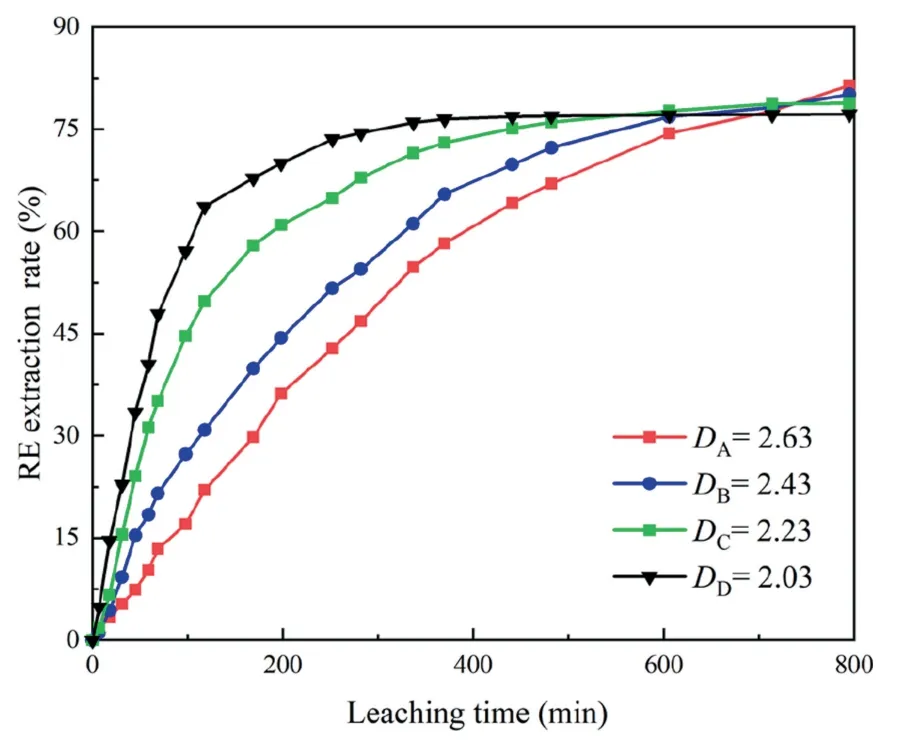

Change curves of the cumulative extraction rate of the rare earth of four types of ore samples were obtained through statistical analysis,as shown in Fig.6.

Fig.6.Change curves of the cumulative extraction rate of the rare earth.

Fig.6 demonstrated that the cumulative extraction rate of the four groups of ore samples continuously increase with time until the maximum extraction rate was reached.Although they were basically the same,the time to reach the maximum extraction rate was different.It increased with the decrease of fractal dimension.For example,ore sample D had reached the maximum extraction rate at 370 min while ore sample A had not reached the leaching balance within 800 min.This was because the larger the fractal dimension,the poorer the permeability of the ore sample.It prolonged the time for chemical reactions between ore samples and the leaching agent solution to fully come into contact [17].

3.2.Effect of particle gradation on pore structure characteristics

3.2.1.Pore characteristic parameters

Pores were usually used to store liquids,which directly controlled the leaching rate of the solution.In order to reveal the mechanism of the effect of particle gradation on the leaching rate,it was significant to explore the variation law of pore characteristic parameters in different leaching periods.The evolution law of pore characteristic parameters (pore size,pore distribution and pore shape) of weathered rare earth ore during leaching was investigated by Liu et al.[23].Therefore,this paper mainly analyzed the influence of particle gradation on other pore characteristic parameters such as pore area,pore volume and porosity.

3.2.1.1.Pore area

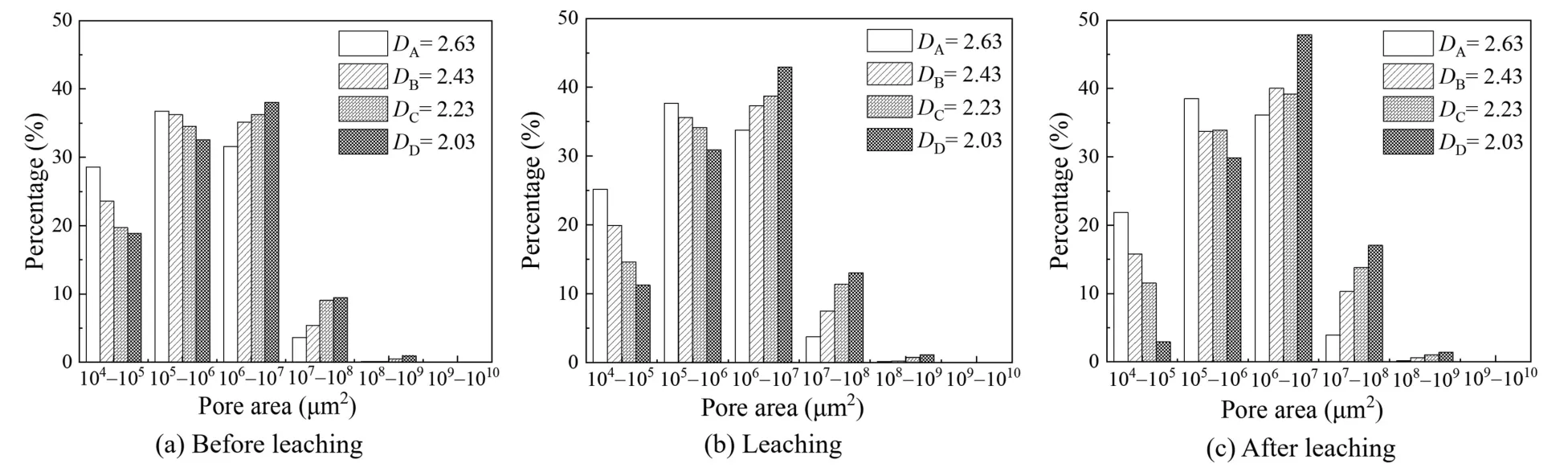

The pore areas of four kinds of ore samples before,during and after leaching were statistically analyzed,as shown in Fig.7.

Fig.7.Pore area distribution of ore samples in different leaching periods.

Fig.7 presented that the pore areas of ore samples before leaching were mainly concentrated in 104-107μm2.For samples A,B,C and D,the number of pores whose pore areas were less than 107μm2accounted for 96.89%,94.94%,90.48%,and 89.45%,respectively.It indicated that when the pore area was less than 107μm2,the proportion of pore number decreased with the fractal dimension of particle gradation decreasing.In addition,there were pores in ore sample D with a pore area larger than 1010μm2,whose maximum pore area reached 8.705×1010μm2,but the maximum pore area in ore sample A was only 6.979×109μm2.This was due to the development of pore structure and a large number of pores in the ore sample with a large content of coarse particles,increasing pore area and the permeability of the ores.

The proportion of pores with small pore areas during leaching was decreasing while the proportion of pores with large pore areas was gradually increasing.And the change rate increased with the decrease of fractal dimension.Compared with that before leaching,the number of pores whose pore area was 104-107μm2in ore samples A,B,C and D decreased by 9.79%,6.46%,5.65%,and 0.38%,respectively.This was mainly because under the action of solution seepage movement,the migration amount of fine particles with small fractal dimensions was larger,resulting in larger pores.Accordingly,a decrease in pore area could weaken the seepage law of the solution.

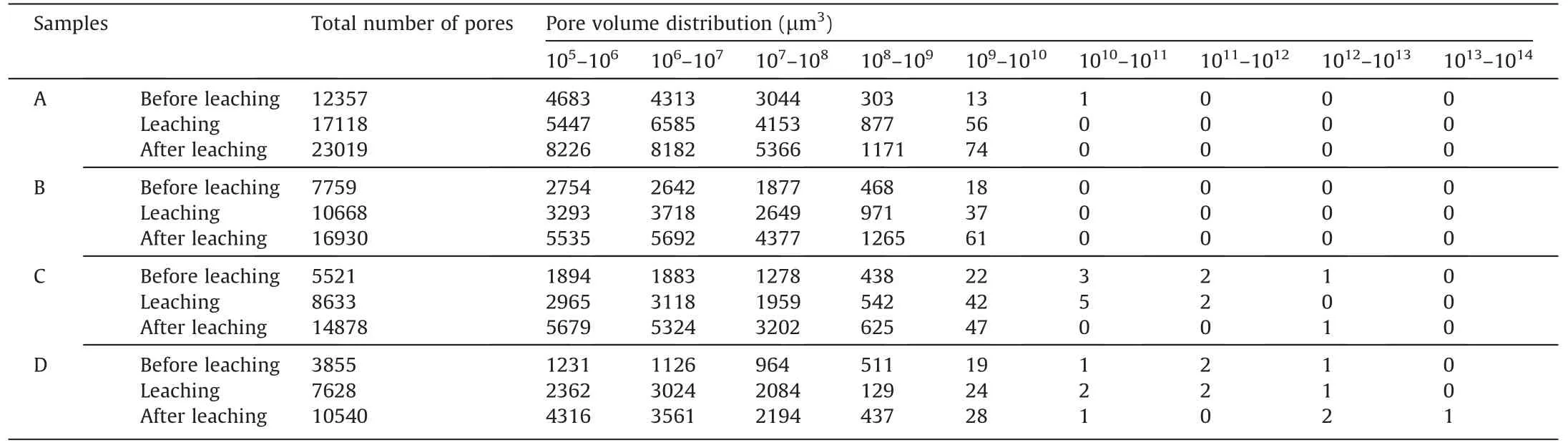

3.2.1.2.Pore volume

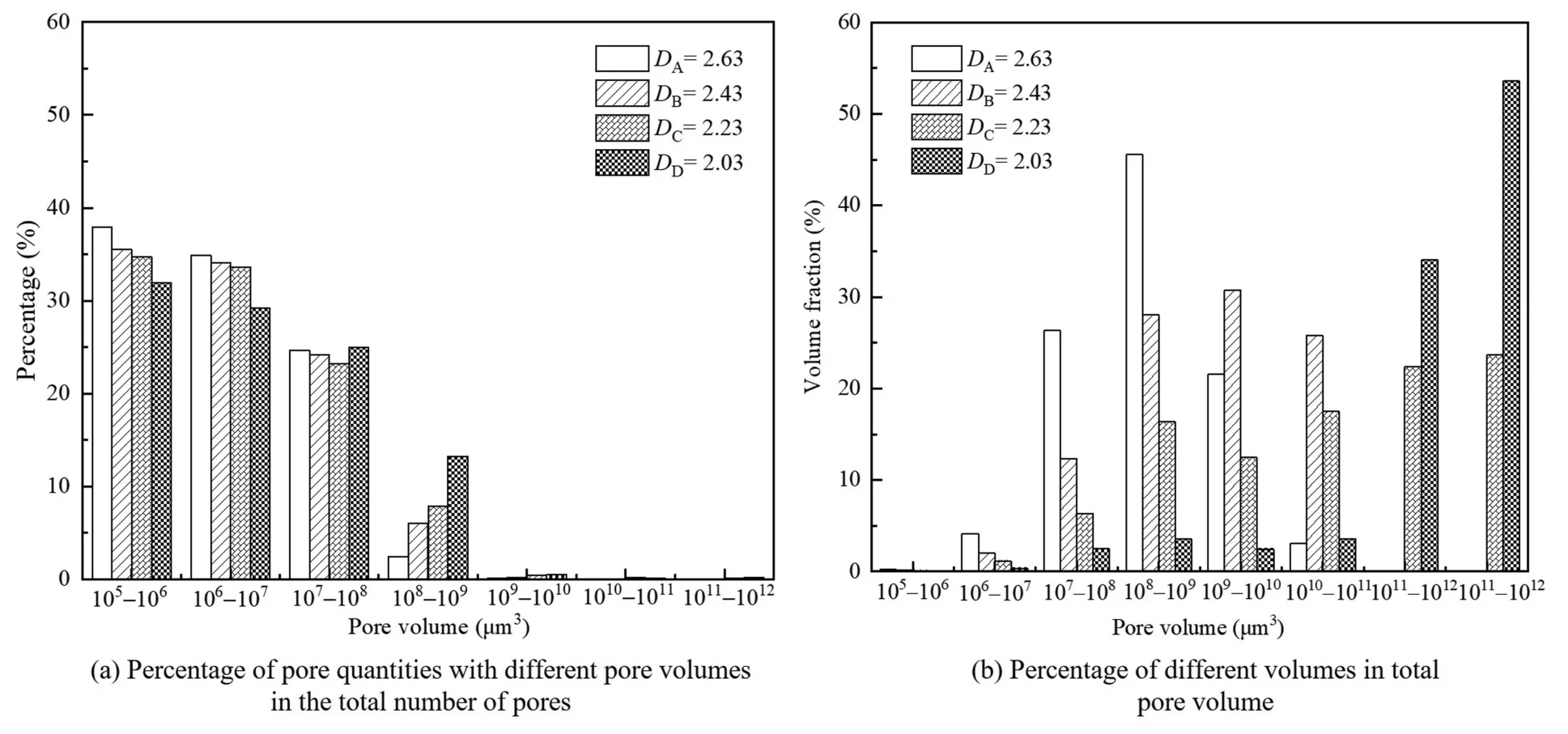

The pore volume distribution and volume fraction in four kinds of ore samples were shown in Fig.8 and Table 3 respectively.

Table 3 The pore volume distribution and its quantity of four groups of ore samples.

Fig.8.Distribution of pore volumes of samples before leaching.

It can be seen from Fig.8a that pore quantities gradually decreased with the increase of pore volume of ore samples before leaching.The number of small pores whose pore volumes were less than 108μm3accounted for a large proportion such as 97.44%,93.74%,91.61%,and 86.23%.It indicated that the larger the content of fine particles in the samples,the greater the percentage of micropores.As can be seen from Fig.8b,micropores quantities in ore samples accounted for a large proportion,but its volume only accounted for a small proportion of the total pore volume.The pores with a volume less than 108μm3only accounted for 30.74%,14.55%,7.58% and 2.84% of the total pore volume.This illustrated that the pore volume of rare earth ore was determined by the large pore volume.It was because the pore volume between coarse particles increased with the increase of the content of coarse particles in ore samples.For example,the order of pore volume greater than 108μm3in four samples was A<B<C<D.

Table 3 showed that the total number of pores in ore samples increased after leaching.The proportion of the increase in the number of pores in samples A,B,C and D were 86.28%,118.20%,169.48%,and 173.41%,respectively,which showed that new pores were generated under the coupling action of solution seepage and particle migration [24].But its pore quantities increased with the decrease of fractal dimension.The pores with pore volume greater than 1010μm3in ore sample A disappeared,which may be due to the pore blockages caused by the migration of fine particles,making the large pore volume reduce or disappear.In addition,four kinds of samples also generated larger pores during leaching,especially C and D ore samples generated pores with pore volumes larger than 1013μm3.It was because of the particle migration or the increase of the surface tension of the bound water film on the particle surface,resulting in the aggregation of small particles.It eventually led to the penetration of macropores or the formation of larger pores,which could accelerate the seepage rate of the solution.

3.2.1.3.Porosity

(1) 2D porosity

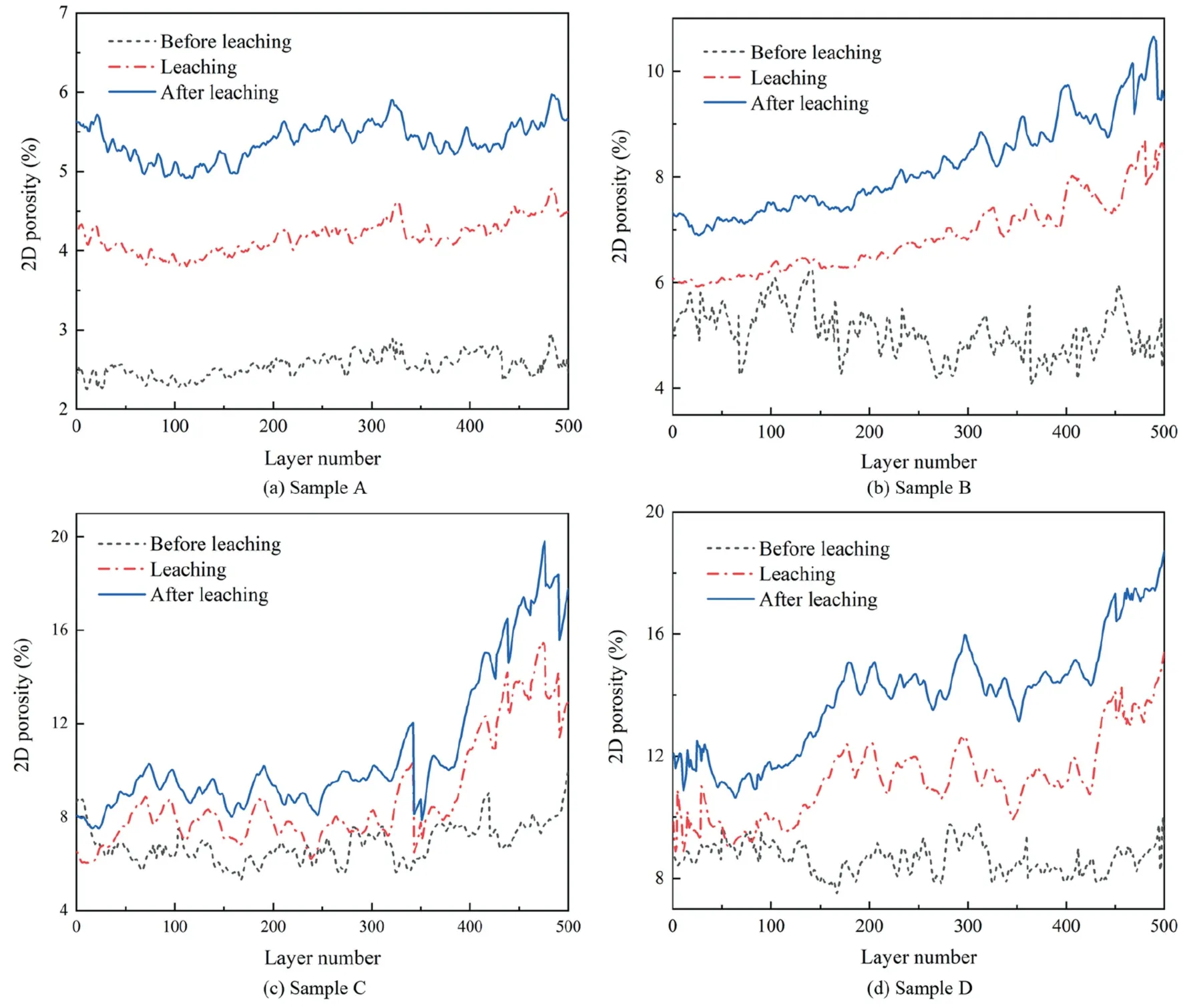

The ore sample was divided into 500 layers along the vertical direction.Through statistical analysis of the cross-sectional of four kinds of samples,the change curves of the two-dimensional porosity in different leaching periods were obtained,as shown in Fig.9.

Fig.9.Two-dimensional porosity in the vertical direction of ore samples.

Fig.9 showed that the range of two-dimensional (2D) porosity for ore samples A,B,C and D before leaching was 2.225%-2.950%,4.072%-6.249%,5.297%-9.937%,and 7.265%-10.134%,respectively.The obvious difference in the 2D porosity of ore samples was caused by particle gradation.The higher the coarse particle content,the greater the 2D porosity.The 2D porosity of samples at different burial depths fluctuated to different degrees,which was caused by the uneven distribution of ore at different burial depths.

In addition,it could also be seen from Fig.9 that the 2D porosity of ore samples with different burial depths after leaching was significantly different from that before leaching.For example,the maximum pore growth rates of ore samples A,B,C and D were 3.442%,6.061%,10.959%and 12.249%respectively.This was consistent with previous research findings [25].It explained the reason why the permeability characteristics of the ores gradually changed strongly with the depth of the ore body.This was because in the process of leaching,fine particles migrated downward under the combined action of water pressure of leaching agent solution,pore water pressure and gravity of fine particles,resulting in an increase in the upper pore volume and the porosity of the ore sample.Moreover,the larger the content of coarse particles,the greater the overall skeleton support role,the larger the migration of fine particles,and the more significant the change amplitude of porosity.It also explained the largest increase of porosity in the cross-section of the ore sample D.

(2) Volume porosity

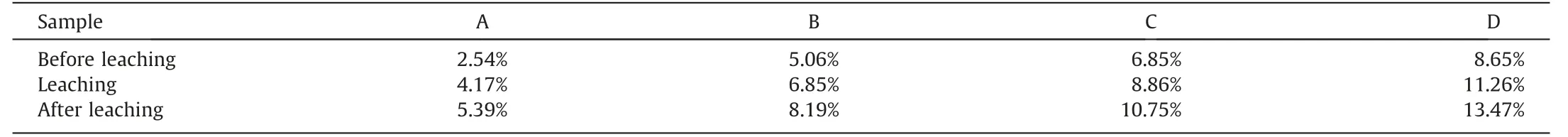

The volume porosity of the four samples in different leaching periods was obtained by comparing the pore voxel values with the overall voxel values,as shown in Table 4.

Table 4 The volume porosity of the four kinds of samples in different leaching periods.

As can be seen from Table 4,the volume porosity of four kinds of samples was in the order of A<B<C<D,which was caused by different particle gradations.This was because ore samples with more coarse particles and less fine particles have larger volume porosity.It consisted of the variation law of the 2D porosity.Besides,the volume porosity of samples A,B,C and D increased with the leaching time increasing.Whose volume porosity increased by 2.85%,3.13%,3.9% and 4.82%,which was due to the increase in the number of macropores and the pore volume under the effect of solution seepage.Especially for ore samples with more coarse particles,macropores quantities increased more,increasing the leaching rate.

3.2.2.Pore throat characteristic parameters

The pore throat was the main connecting channel between pores,which directly affected the leaching rate and the leaching effect of the rare earth.In order to reveal the mechanism of the effect of particle gradation on the leaching rate,it was necessary to analyze the change law of characteristic parameters of the pore throat (such as pore throats quantities,pore throat radius,pore throat length and coordination number)in different leaching periods by reconstructing the three-dimensional pore network model using Avizo software,as shown in Fig.10.Where the ball and stick represented the pore and pore throat respectively.The larger the ball,the greater the pore size.

Fig.10.Three-dimensional pore network model of ore samples.

(1) Pore throat quantities

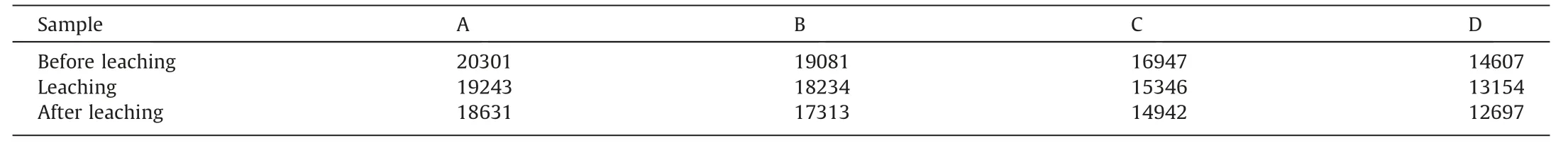

The pore throat quantities of ore samples in different leaching periods were shown in Table 5.

Table 5 The pore throat quantities of the samples in different leaching periods.

It can be seen from Table 5 that the pore throat quantities of the four samples were in the order of A>B>C>D.This was because the coarse particle content in ore sample A was the least while that in ore sample D was the most.The micropore structure between the particles became simple with the decrease of the fractal dimension,which was the reason why the number of pore throatsdecreased.Moreover,the number of pore throats in ore samples gradually decreased during leaching.The reduction rates of pore throats of ore samples A,B,C and D were 8.23%,9.27%,11.93%,and 14.17%,respectively.It was because the migration of fine particles blocked the pore throats during leaching,resulting in the reduction of pore throat quantities.The higher the coarse particles and the lower the fine particles,the more significant the particle migration phenomenon.Therefore,the pore throats quantities in sample D with the most obvious change of particle gradation during leaching decreased most significantly.This was consistent with the most obvious phenomenon of preferential seepage in ores rich in coarse particles [13].

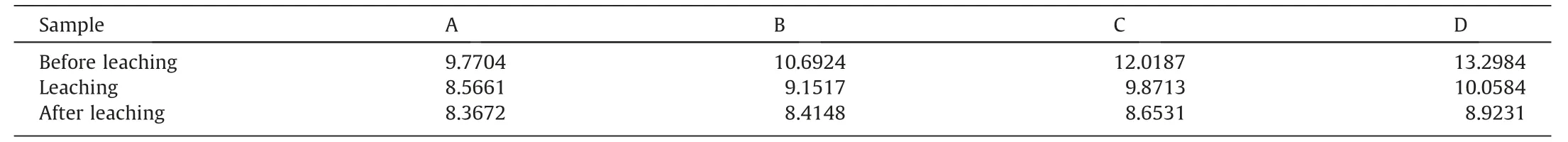

(2) Pore throat radius

The distribution law of the pore throat radius of ore samples in different leaching periods was statistically analyzed,as shown in Fig.11.

Fig.11.Distribution curves of the pore throat radius.

Fig.11 illustrated that the proportion of pore throat increased rapidly at first and then decreased slowly with the increase of pore throat radius.Besides,the number of pore throats whose pore throat radius was less than 0.05 mm before leaching accounted for only 0.355%-0.536% of the total number of pore throats.The throat radius was mainly 0.05-0.8 mm.Whose pore throat quantities were 80.905%,68.072%,66.937%,and 65.398%,respectively.However,the number of pore throats with a throat radius greater than 0.12 mm accounted for 2.12%,2.32%,5.54%,and 5.94%,respectively.This was because with the decrease of fractal dimension,the number of large-scale pores and the size of communication channels between pores increased while the number of small and medium pore throats decreased.

The average pore throat radius of the four kinds of ore samples showed a decreasing trend during leaching.For example,the average pore throat radius of the ore sample A decreased from 0.547 to 0.526 mm.The average pore throat radius of ore sample B lessened from 0.634 to 0.604 mm.The average pore throat radius of the ore sample C reduced from 0.753 to 0.708 mm.The average pore throat radius of the ore sample D dropped from 0.803 to 0.743 mm.This was because in the process of leaching,the migration of fine particles caused some pore throats to be blocked,resulting in the reduction of the average pore throat radius.Compared with the permeability coefficient of the ores,it could be seen that the pore throat radius was positively correlated with the penetration effect of the solution.

(3) Pore throat length

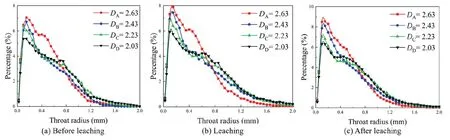

The pore throat lengths of ore samples in different leaching periods were statistically analyzed,as shown in Fig.12.

Fig.12.Distribution curves of the pore throat length.

Fig.12 showed that the percentage of pore throat quantities of four kinds of samples increased first and then decreased with the increase of pore throat length.The throat length of four kinds of samples before leaching was mainly less than 4 mm,accounting for 96.402%,92.951%,90.876%,and 90.623%,respectively.The average pore throat length was 2.12,2.44,2.54 and 2.58 mm respectively.This was mainly because the number of small and medium-sized pores increased with the fractal dimension increasing,resulting in more complex and short communication channels between pores in ore samples with larger fractal dimensions.In addition,it could also be seen from Fig.12 that the number of short pore throats decreased and the percentage of long pore throats increased during leaching.For example,the proportion of pore throats with lengths less than 1.8 mm in ore samples A,B,C and D decreased by 27.87%,48.17%,49.98%,and 57.85%,respectively.The percentage of pore throats with lengths greater than 2.8 mm increased by 23.68%,64.21%,65.66%,and 116.03%,respectively.This was because some pore throats in ore samples with smaller fractal dimensions were blocked during leaching and small pores were connected,which made the channels between pores longer and the permeability coefficient of the ores higher.Especially for ore samples with greater fractal dimension,the pore structure became simpler and the pore throat length changed more obviously.

(4) Average coordination number

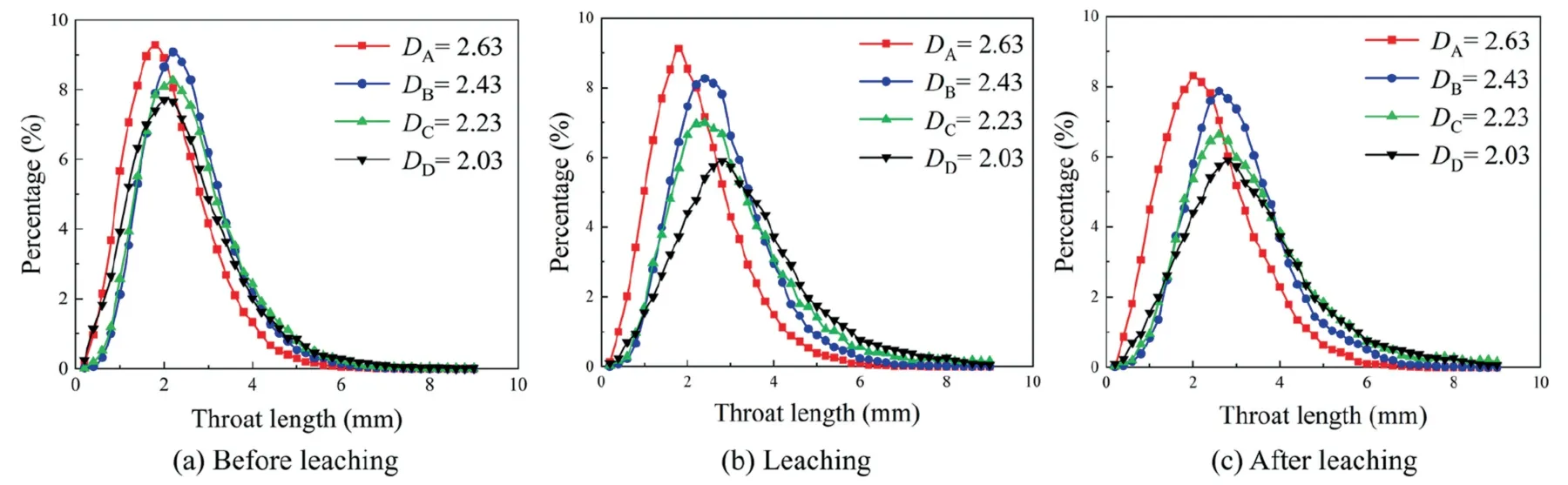

The coordination number referred to the number of independent throats connected by a pore,which can effectively reflect the connectivity of the pores between particles.The larger the coordination number,the stronger the connectivity [26].And the average coordination number was the average value of the number of channels connected by each pore in samples by using the maximum ball algorithm,as shown in Table 6.

Table 6 Average coordination number of ore samples in different leaching periods.

Table 6 showed the order of the average coordination number of four kinds of ore samples before leaching was A<B<C<D.It was because the content of -0.075 mm particles in ore sample A was the largest,where there were many isolated pores,resulting in some pore throats becoming invalid pore channels.The average coordination number of ore sample A was the smallest,whose pore connectivity was the weakest.For ore sample D with the largest content of coarse particles,its internal pore development degree was the highest,and the coordination number of the ore sample was the largest,leading to the strongest pore connectivity [27].Moreover,the coordination number of four kinds of ore samples decreased during leaching.The average coordination number reduction rates of ore samples A,B,C and D were 14.36%,21.3%,28%,and 32.9%,respectively.This was because of the particle migration phenomenon of fine particles during leaching.It caused some pore gaps to be blocked,resulting in some pore throats becoming invalid pore channels.It ultimately led to a decrease in pore connectivity and leaching rate.There was an inverseproportional linear relationship between the fractal dimension of particle gradation and the coordination number.Especially for ore samples A with the largest fractal dimension,the change degree of particle gradation was the most obvious,resulting in the largest reduction of pore connectivity and the largest reduction rate of pore coordination number.

3.3.Effect of particle gradation on the seepage law of solution

3.3.1.Effect of particle gradation on the seepage streamline of solution

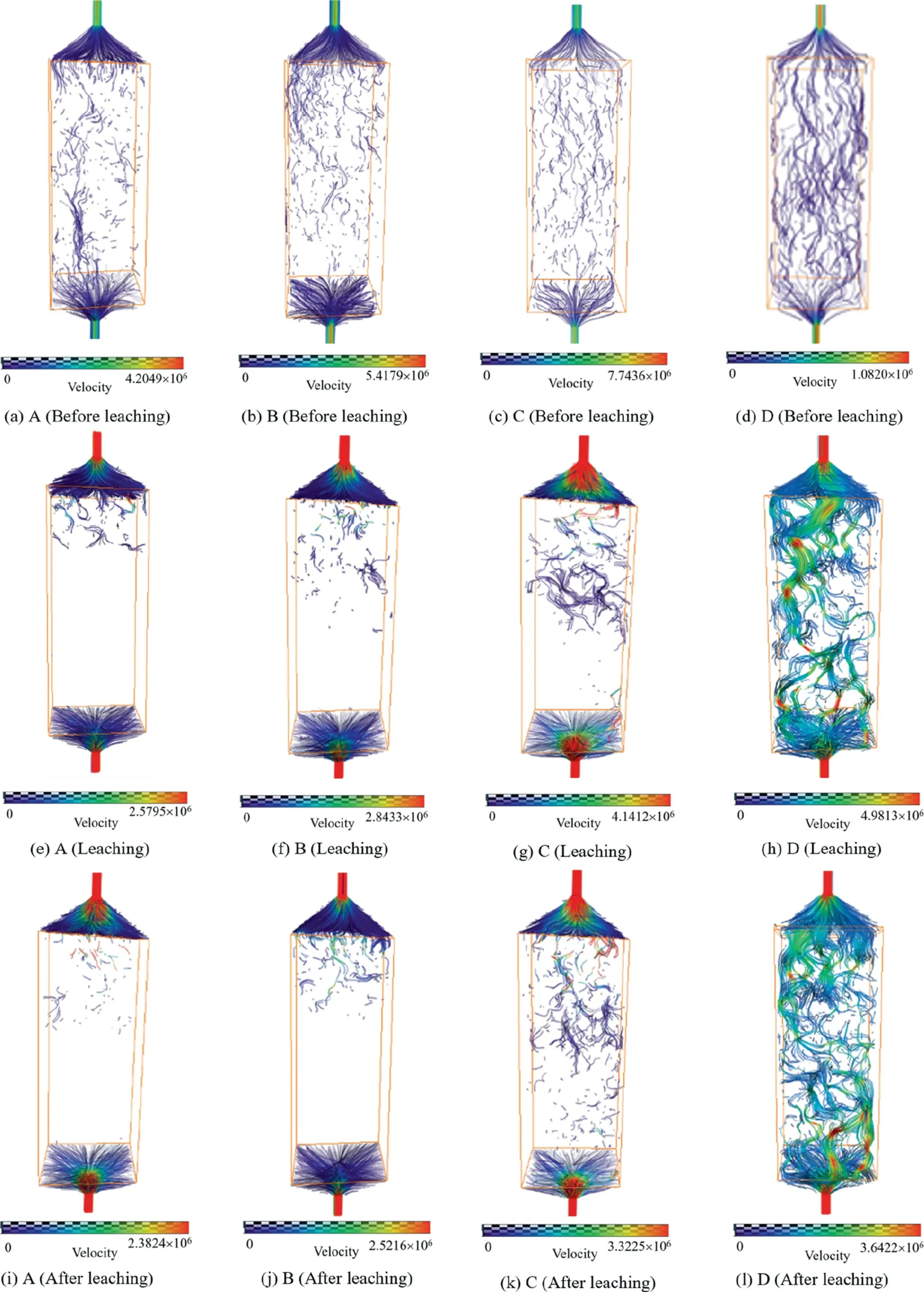

To reveal the influence of particle gradation on the seepage law of the solution in the weathered rare earth ores,Avizo was used to simulate and calculate the seepage path of the solution in different leaching periods based on the CT test results.First,established three-dimensional pore structure models of four kinds of ore samples before,during and after leaching was selected as the research objects.Second,the inlet pressure,outlet pressure and fluid viscosity were set to 10000 Pa,0 Pa,and 0.8 Pa·s,respectively.Finally,Avizo was used to simulate and calculate to obtain the distribution diagrams of the seepage streamline in four kinds of ore samples in the leaching process,as shown in Fig.13,where the streamline and color represented the solution seepage path and seepage velocity respectively.

Fig.13.Distribution diagrams of seepage streamline of ore samples in the leaching process.

It could be seen from Fig.13 that the streamlines in four groups of ore samples before leaching were evenly distributed,but the density and flow velocity of streamlines increased with the decrease of the fractal dimension of the particle gradation.The average flow velocity of ore samples A,B,C and D was 2.1×10-6,2.71×10-6,3.87×10-6and 5.41×10-6m/s,respectively.It implied that with the increase of coarse particle content and the decrease of fine particle content,the pore structure in ore samples got simple,the pore connectivity became stronger,and the solution seepage speed grew larger.

Fig.13 also showed that the streamlines of the four kinds of ore samples during leaching were partially interrupted and preferentially seepage occurred,which led to the continuous reduction of the seepage velocity of the solution.The average seepage velocities of ore samples A,B,C and D after leaching reduced to 1.19×10-6,1.26×10-6,1.65×10-6,and 1.82×10-6m/s,respectively.It indicated that the pore structure characteristics of the samples changed during leaching under the coupling effect of solution seepage and particle migration,resulting in the reduction of the effective pore channels and leaching rate.Besides,streamlined interruption became stronger and preferential seepage got more obvious with the fractal dimension decreasing.This was because of the pores size and pore quantities and pore volume in ore sample A with the finest particles content,where a small amount of particle migration could seriously affect the solution seepage,resulting in the interruption of most streamlines and a small quantity of preferential seepage.This was because the size of pores and pore throats in sample A before leaching was the smallest.The migration of fine particles led to the fewest effective pore channels,resulting in the interruption phenomenon of the larger seepage streamline of the solution.Capillary action was mainly relied on for solution seepage and diffusion movement,which also explained why the permeability coefficient of ores with a high content of fine particles was smaller.In contrast,for the ore sample D with the least fine particle,the pores size and pore volume were large though the number of the pores was small.This was because some pores in the leaching process were connected into large pores,leading to more preferential seepage phenomena.It affected the seepage law of the solution,reducing the velocity of solution seepage and easily producing the solution seepage ‘‘blind zone”which was not conducive to the leaching of the rare earth.This could be reduced by optimizing the particle gradation parameters.

3.3.2.Relationship between particle gradation and leaching effect of the rare earth

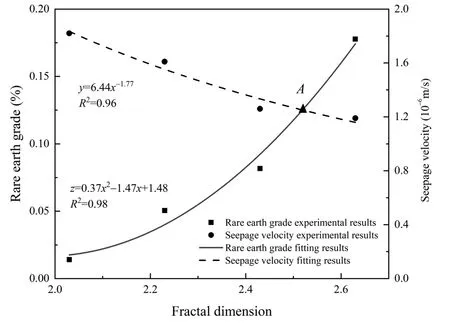

Based on the above analysis,it could be concluded that the change degree of pore structure characteristics and solution seepage law of ore samples with more fine particles and less coarse particles during leaching were smaller than those with more coarse particles and less fine particles.It illustrated that the leaching rate of the solution was closely related to the distribution characteristics of the particle size.Therefore,in the process of heap leaching,the particle gradation could be optimized by finding the internal relationship between it and the seepage velocity to achieve high leaching efficiency of the rare earth ores.Besides,it was found that there were differences in the content of rare earth elements in different rare earth ores [10].Consequently,the relationship models between the fractal dimension and both the seepage velocity and the rare earth grade were established to explore the balance point between them and determine the optimal particle gradation(Fig.14).It was helpful to improve the leaching effect of the weathered rare earth ores.

Fig.14.Relationship between the fractal dimension and both the seepage velocity and rare earth grade.

As shown in Fig.14,the rare earth grade increased with the increase of fractal dimension,whose relationship could be expressed by a quadratic polynomial,such as Eq.(2).This was because the content of fine particles in ore samples with large fractal dimension was more than that in ore samples with small fractal dimension.Rare earth elements were mainly distributed on the surface of clay minerals which mainly occurred in weathered rare earth ores with fine grain size [28].In addition,it could be seen from Fig.14 that the seepage velocity of the solution decreased with the increase of the fractal dimension.There was a negative power exponent relationship between them (Eq.(3)),which was consistent with the aforementioned relationship between both pore structure characteristics and solution seepage law and fractal dimension.It also indirectly confirmed the rationality of revealing the weakening mechanism of seepage velocity from a microscopic perspective.Besides,the intersection point of the two relationship models was the leaching equilibrium point of the rare earth.That is,pointA(around 2.52) was the best particle grading point.This was because the leaching effect of the rare earth ore samples under this condition was the best,which could not only better meet the seepage velocity of the solution,but also get more rare earth ions.

wherexis the fractal dimension of the particle gradation;ythe seepage velocity;andzthe rare earth grade.

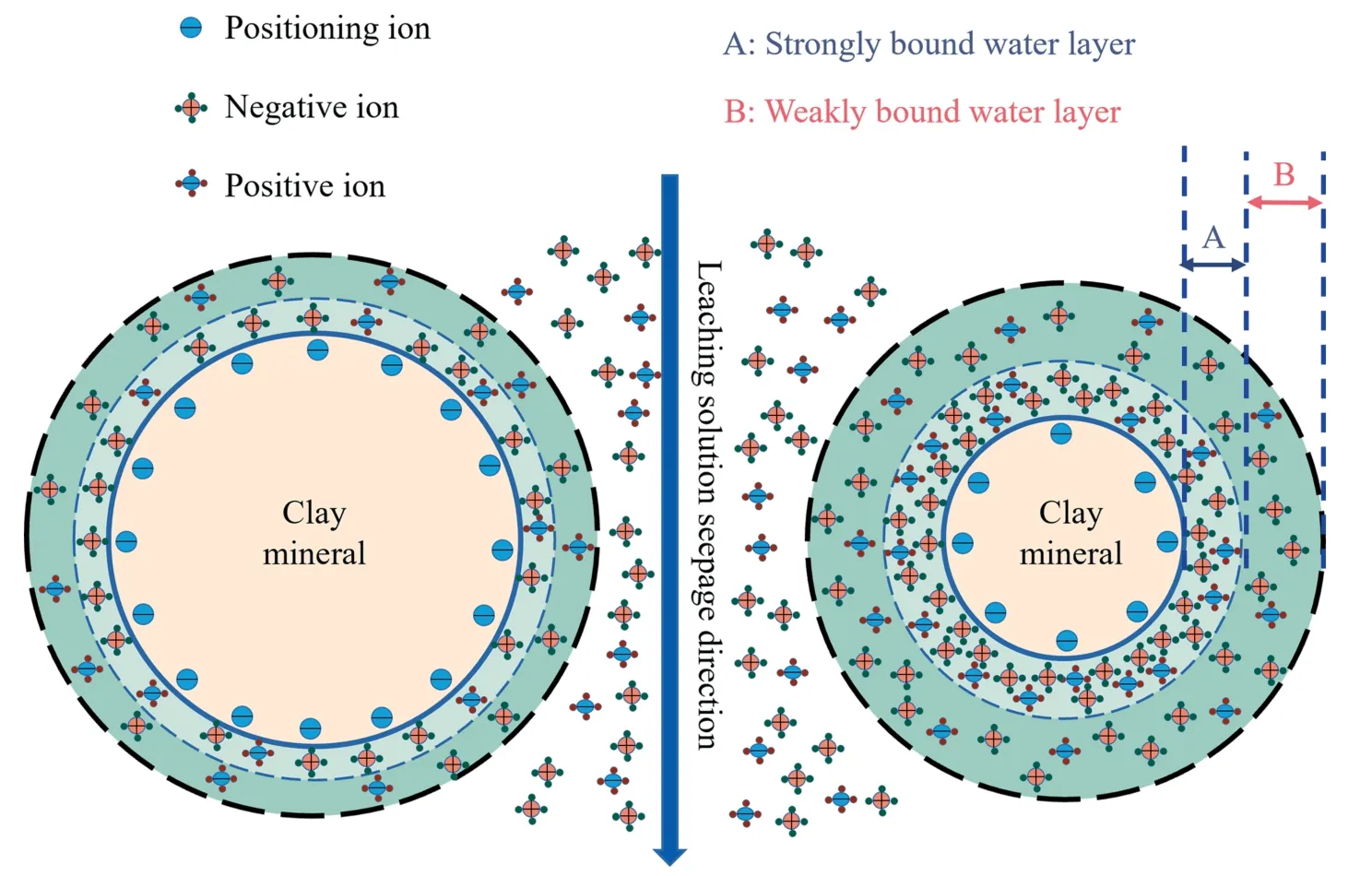

3.4.Discussion

The weathered crust elution-deposited rare earth ores belong to a special clay mineral,which is characterized by small mineral particles and large specific surface area[2].Besides,the surface of ore particles carries negative charges and generates an electric field around them.When it comes into contact with the solution,the surface of the ore particles adsorbs cations and water molecules,which forms a hydration film due to hydration [28].It mainly includes a strongly bound water layer and a weakly bound water layer,as shown in Fig.15.Its thickness is determined by the particle gradation when the leaching agent solution is under certain conditions.For ore samples with smaller fractal dimensions and more fine particles,their specific surface area is larger,which causes stronger capillarity of ores and greater thickness of hydration film formed.This leads to a larger pore area occupied by the hydration film,increasing the content of an immovable solution in the ore particles.It causes more invalid pore channels between ore particles,resulting in poor connectivity of pores,which makes the pore structure more complex and prolongs or interrupts the seepage path of the solution.Thus,the seepage effect of the solution is poor for ore samples with poor particle gradation.However,the content of coarse and fine particles is moderate for well-graded ores.The thickness of the hydration film formed by the capillary action on the surface of ore particles is relatively small.It occupies a smaller pore area,which indicates that the content of an immovable solution in the pores of the ore is relatively low.This indirectly leads to a smaller number of ineffective pore channels,resulting in better pore connectivity between ore particles.Ultimately,it simplifies the pore structure and shortens the seepage path of the solution,leading to a better overall seepage effect of the solution.Therefore,in order to improve the seepage effect of the solution and the leaching efficiency of rare earth,it is necessary to clarify the particle gradation of the weathered crust elution-deposited rare earth ores before leaching.This can be used to help adjust the injection and collection parameters to optimize the pore structure characteristics and seepage behaviors of the solution path in rare earth ores during leaching.

Fig.15.Bound water layer of rare earth ores with different particle sizes during leaching.

4.Conclusions

The evolution law of both pore structure and solution seepage in weathered elution-deposited rare earth ores with four kinds of particle gradations in different leaching periods was investigated to reveal the mechanism of the effect of particle gradation on the leaching rate.The following conclusions were drawn:

(1) There were great differences in pore structure characteristics in weathered rare earth ores due to different particle gradations.With the fractal dimension of the particle gradation increasing before leaching,pore quantities,the average pore throat radius and coordination number increased while the number of pore throats and average pore throat length and large pore volume exceeding 108μm3decreased.

(2) The characteristic parameters of the pore structure in ore samples during leaching have undergone significant changes.Whose influence was gradually increasing with the decrease of fractal dimension.For example,the growth rate of the total number of pores was 86.28%,118.20%,169.48%,and 173.41%,respectively.The volume porosity increased by 2.85%,3.13%,3.90%,and 4.82%,respectively.The percentage of pore throats with lengths greater than 2.8 mm increased by 23.68%,64.21%,65.66%,and 116.03%,respectively.

(3) The evolution law of the solution seepage path could directly express the effect of particle gradation on the extraction rate.The density and flow velocity of the streamlines increased with the decrease of the fractal dimension of particle gradation.In addition,the seepage path interruption and preferential seepage in ore samples appeared during leaching.The streamline interruption got weaker with the fractal dimension decreasing while the preferential seepage became more obvious.

(4) According to the relationship models between the fractal dimension and both the seepage velocity and the rare earth grade,it was known that the optimal fractal dimension of particle gradation was around 2.52.The research results can provide a theoretical reference for optimizing injection and collection parameters of weathered rare earth ores.

Acknowledgments

All sources of funding for the study were supported by the National Natural Science Foundation of China (Nos.52174258,92162109,52222405 and 52004184).

- 矿业科学技术学报的其它文章

- Shear behaviours and roughness degeneration based on a quantified rock joint surface description

- Selective flotation of chalcopyrite from pyrite via seawater oxidation pretreatment

- Numerical modeling on strain energy evolution in rock system interaction with energy-absorbing prop and rock bolt

- Experimental study on instability mechanism and critical intensity of rainfall of high-steep rock slopes under unsaturated conditions

- Polysaccharides-based pyrite depressants for green flotation separation:An overview

- Mechanical properties and damage characteristics of solidified body-coal combination in continuous driving and gangue backfilling