Experimental study on instability mechanism and critical intensity of rainfall of high-steep rock slopes under unsaturated conditions

Xiaoshuan Li ,Qihan Li *,Yunmin Wan *,Wei Liu ,Di Hou ,Wenbo Zhen ,Xion Zhan

a School of Urban Construction, Changzhou University, Changzhou 213164, China

b College of Civil Engineering, Qilu Institute of Technology, Jinan 250200, China

c Key Laboratory of Rock Mechanics and Geohazards of Zhejiang Province, Shaoxing 312000, China

d School of Resources and Safety Engineering, Chongqing University, Chongqing 400044, China

e Sinosteel Maanshan General Institute of Mining Research Co.LTD., Maanshan 243000, China

f Guizhou Survey and Design Research Institute for Water Resources and Hydropower, Guiyang 550001, China

g School of Engineering, University of Northern British Columbia, Prince George V2K3V3, Canada

Keywords:Open-pit to underground mining Rock slope Rainfall infiltration Excavation unloading Similar physical model Image recognition

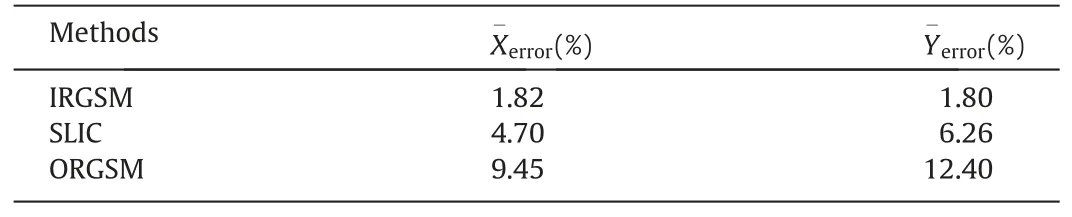

ABSTRACT Two critical factors,namely intense precipitation and intricate excavation,can trigger rock mass disasters in mining operations.In this study,an indoor rainfall system was developed to precisely regulate the flow and intensity of precipitation.A large-scale model experiment was conducted on a self-designed physical simulation experiment platform to investigate the failure and instability of high-steep rock slopes under unsaturated conditions.The real-time reproduction of the progressive failure process in high-steep rock slopes enabled the determination of the critical rainfall intensity and revealed the mechanism underlying slope instability.Experiment results indicated that rainfall may be the primary factor contributing to rock mass instability,while continuous pillar mining exacerbates the extent of rock mass failure.The critical failure stage of high-steep rock slopes occurs at a rainfall intensity of 40 mm/h,whereas a rainfall exceeding 50 mm can induce critical instability and precipitation reaching up to 60 mm will result in slope failure.The improved region growing segmentation method(IRGSM)was subsequently employed for image recognition of rock mass deformation in underground mines.Herein an error comparison with the simple linear iterative cluster (SLIC) superpixel method and the original region growing segmentation method(ORGSM) showed that the average identification error in the X and Y directions by the method was reduced significantly (1.82% and 1.80% in IRGSM;4.70% and 6.26% in SLIC;9.45% and 12.40% in ORGSM).Ultimately,the relationship between rainfall intensity and failure probability was analyzed using the Monte Carlo method.Moreover,the stability assessment criteria of rock slope under unsaturated condition were quantitatively and accurately evaluated.

1.Introduction

Affected by various environmental stresses (e.g.in-situ stress),heavy rainfall infiltration,groundwater seepage,and the transition from open-pit to underground mining,the original joints and fractures have undergone evolution,expansion and penetration processes that ultimately lead to instability of rock mass engineering[1-3].In 1963,the Vaiont landslide in Italy was infiltrated by heavy rainfall,the brittle fractures in the clay layer expanded and eventually led to progressive instability.As a result,it caused the mountain mass of about 240 million m3to slide down at a maximum speed of 30 m/s[4].Between 1998 and 2004,five consecutive large deformations of the Xiangjiapo landslides in China were caused by a combination of rainfall and slope excavation,posing significant threats to the safety of the surrounding areas[5].Deadly landslides caused by heavy rainfall and strip mining were twice reported in Emei County,Sichuan Province,China,from 2011 to 2015.Herein approximately 6.0 million m3of rock detached from the upper slopes at an average velocity of 18 to 36 km/h,impacting the stability of the opposite mountains [6].Furthermore,in September 2022,a series of prolonged heavy rainfall events triggered three significant landslides near Hongya village in Qinghai Province,China,resulting in an estimated landslide volume ranging from 3.2 to 3.8 million m3[7].Currently,with the rapid development of rock engineering technology in China,there are numerous major projects with large scale and extremely complex geological conditions[8].For instance,the open-pit slope of Dexing Copper Mine in Jiangxi Province,China has achieved a maximum vertical depth of 700 m,with an overall slope angle exceeding 40° [9].Therefore,under the environment of heavy rainfall infiltration and complex excavation,the long-term stability and safety of high-steep rock slopes need to be studied urgently.

In recent years,numerous fruitful studies have been conducted by scholars on the evolution characteristics of rock mass fractures under single-rainfall infiltration,single-mining stress,and stress-seepage coupling.Nowadays,the predominant focus of large-scale indoor geomechanics model testing research lies within the realm of deep coal mining [10].Li et al.explored the evolution characteristics of mining cracks by quantitatively analyzing the length,height,width and angle of cracks [11].Wang et al.studied the fractal evolution characteristics of fissures in mining rock mass through fractal geometry theory [12].Under extreme weather conditions,the occurrence of slope instability disasters cannot overlook the significant role played by continuous heavy rainfall [13-15].Di et al.elucidated the mechanism of rainfall-induced failure of sandy slopes and proposed a method to assess slope stability under rainfall conditions [16].Calvillo et al.[17] investigated the triggering mechanism of rainfallinduced landslides,which is attributed to the transformation of pore water pressure caused by infiltration,leading to a reduction in shear strength within unsaturated layers.Wu et al.[18] proposed a landslide safety factor calculation model that effectively evaluates the stability of storm-induced landslides in layered rock formations at a regional scale.Another important factor is external mining stress.Michalowski and Park[19]studied the Hoek-Brown failure criterion and demonstrated the application of plasticity theory in rocks.Geng et al.[20] used the room-and-pillar method for three-stage mining,and revealed the deformation characteristics of the surrounding rock in the slope.With the rapid advancement of rock mass engineering technology,the stability of rock masses under stress-seepage coupling has become increasingly prominent.Yang et al.[21] employed the discrete fracture network (DFN)model to conduct an in-depth investigation into the equivalent permeability and damage tensor of fractured rock mass.Zhao et al.[22]discussed the deformation mechanism and permeability characteristics of fractured rock masses under high water pressure-stress coupling conditions.Landslide monitoring are crucial steps in providing early warning of fracture rock masses deformation.Particularly,identification of landslide deformation areas has been widely used for slope failure monitoring and evaluation.Xie et al.[23] proposed a synthetic aperture radar (SAR) image superpixel generation method based on significant difference and spatial distance to accurately reflect the boundary of the texture details of uneven areas.Yang et al.[24] realized the identification of small-scale landslide deformation areas by the changes of image superpixel roughness during the landslide deformation process.To identify small-scale landslides,by using the superpixel simple linear iterative cluster zero (SLICO) method to check the appropriate area size,Hashiba and Sonobe [25] extracted the landslide area with high accuracy.

Most of the aforementioned methods are applicable to rock masses of small to medium size,as well as single rainfall infiltration or mining environment with coupled loading stress and groundwater seepage.However,(1)limited research has been conducted on the evolution mechanisms underlying large-scale highsteep rock slope rupture and instability;(2)regarding the stability of rock slopes,multi-factor coupling conundrum needs to be solved urgently;and (3) the seepage-stress coupling is primarily employed in the context of deep and ultra-deep rock masses,whereas excavation unloading is predominantly utilized during surface-to-underground mining operations.Hence,in the coupled environment of rainfall-excavation,these factors bring great challenges to the safe production of mines.

The main motivation of this paper is to reveal the fracture and instability evolution of high-steep rock slopes under the coupling of variable rainfall and excavation.To overcome these challenges,a large-scale similar physical model experiment is carried out based on the self-developed indoor rainfall system equipment.Combined with pore water pressure,water content,stress,displacement and other data,the progressive failure mechanism of fractured rock mass is deeply analyzed.By comparing different image recognition methods(IRGSM,SLIC,and ORGSM),the advantages of IRGSM in the recognition of fractured rock mass deformation regions are verified.Furthermore,the stability evaluation criterion of rock slope under unsaturated condition is given.

2.Experimental design

2.1.Mine overview

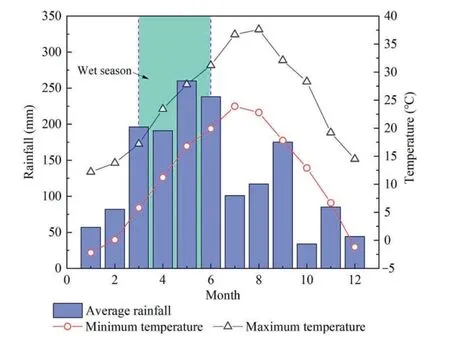

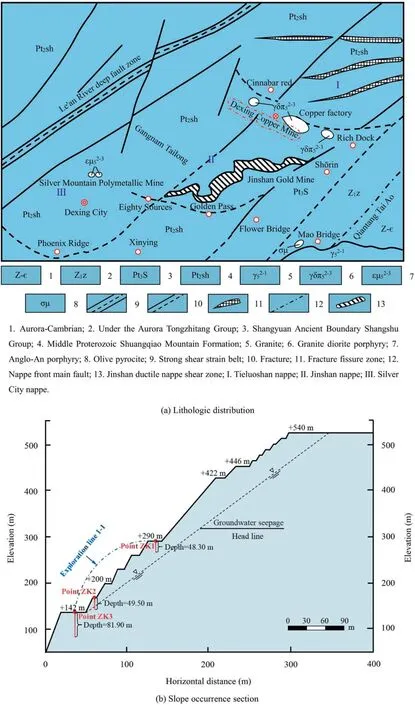

The Dexing Copper Mine is located in Sizhou Town,Dexing City,Jiangxi Province,China,which is approximately 20 km away from the city center.The Huangniuqian slope is situated to east of the copper factory mining area,in close proximity to the construction machinery maintenance section (Fig.1).In our investigation,the study area exhibits warm climatic conditions,abundant precipitation,and distinct seasonal variations.Moreover,the slope structure induces erosion in the foothills of the low mountain,thereby fostering a profusion of montane vegetation.In Dexing city,mountain,hill and plain account for 44%,33%,and 23%,respectively.Therefore,the predominant landform are primarily mountains and hills.The occurrence of the slope is 144°-152° in strike,234°-242° in tendency,as well as 41°-42° in inclination.Fig.2 illustrates the mean monthly precipitation and minimum-maximum temperature over the last decade(2012-2021).The rainy season is concentrated in March-June,with increased intensity observed from early May until late June,which is commonly referred to as the plum rain season [26,27].Fig.3 depicts the regional lithologic distribution of Dexing Copper Mine(Fig.3a)and the slope occurrence section of Huangniuqian (Fig.3b).

Fig.1.Geographical location of the study area.

Fig.2.Average monthly rainfall and minimum-maximum temperature from 2012 to 2021.

Fig.3.Lithologic distribution and slope profile of Huangniuqian in Dexing Copper Mine.

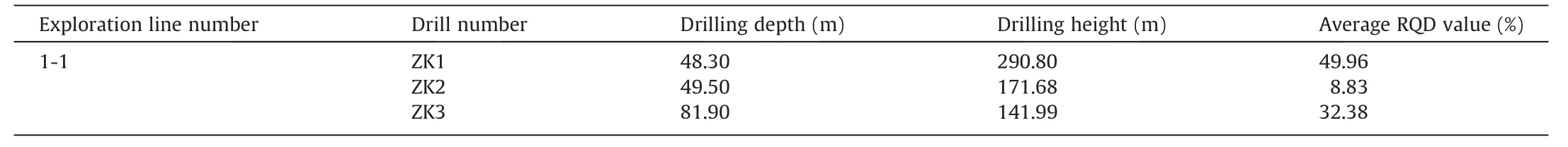

Rock quality designation(RQD)is an important parameter usually considered in engineering rock mass classification.In this study,according to the results of drilling core cataloging,three drilling cores are measured and enumerated.The RQD value for each drilling hole is determined as indicated in Table 1.In addition,the variation of RQD with depth in each borehole at different depths is illustrated in Fig.4.In our statistical results,the highest RQD is 49.96% (ZK1) and the lowest is 8.83% (ZK2).Based on the RQD classification table proposed by Deere[28],the quality grades of the slope rock masses represented by exploration line 1-1 is‘‘poor” and locally ‘‘very poor”.

Table 1 RQD statistics.

Fig.4.Variation of RQD value with depth at different boreholes.

2.2.Obtaining rock mechanical parameters

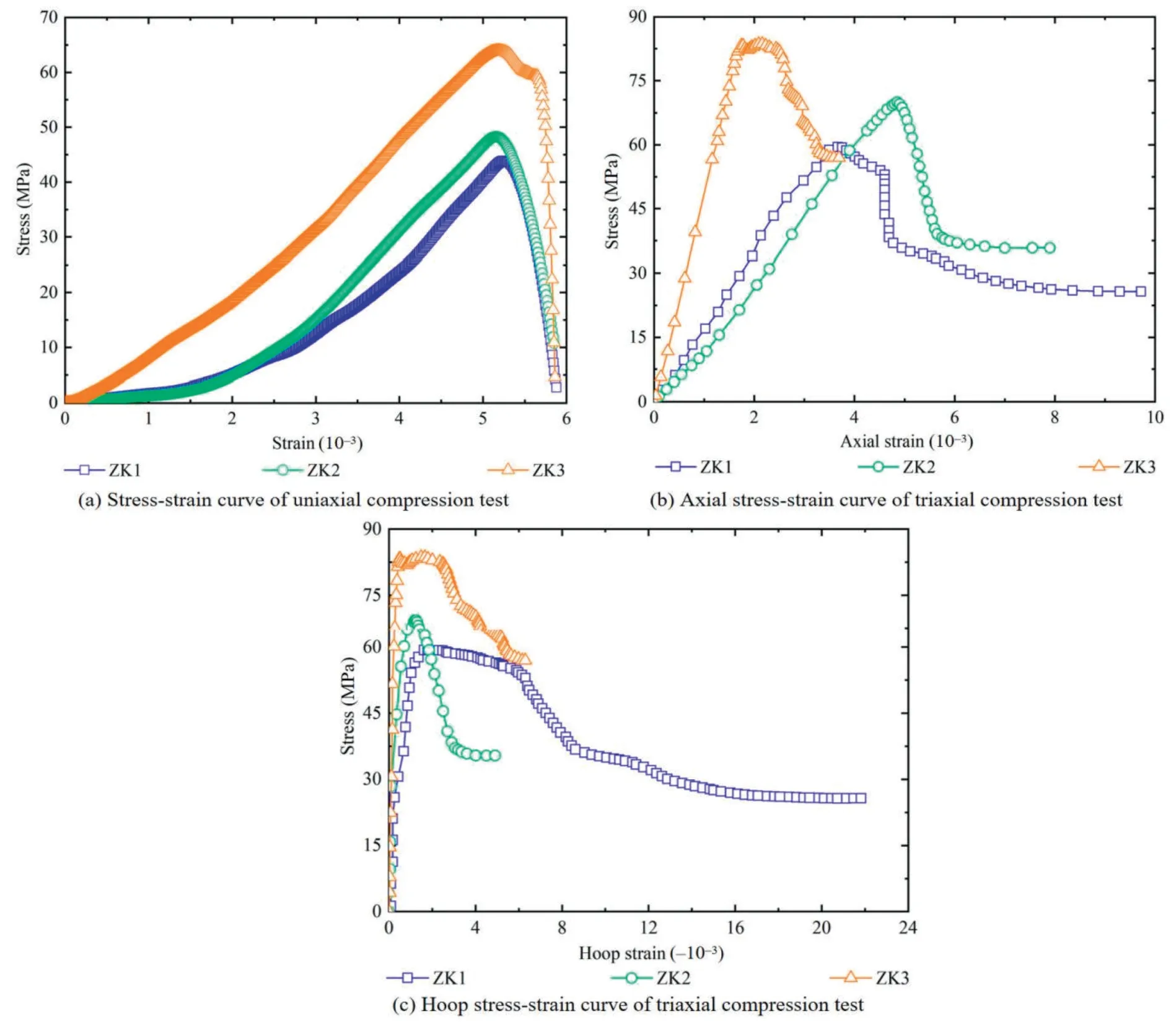

Based on the results of engineering geological investigation,the predominant lithology comprising the eastern slope of Huangniuqian is phyllite,with tuffaceous phyllite being a secondary component.A sufficient number of representative phyllite blocks at depths ZK1-ZK3 are selected for indoor sample processing.Considering both the actual engineering conditions and test requirements comprehensively,the height error of our experimental rock samples is controlled to be within 1-3 mm,while ensuring that their plane flatness error is no more than 0.3 mm.Subsequently,uniaxial and triaxial compression tests are conducted under a confining pressure of 10 MPa.Fig.5 illustrates the results of laboratory rock mechanics tests,which are conducted to measure the mechanical properties of both the ore body and its surrounding rock,including elastic modulus,Poisson’s ratio,tensile strength,uniaxial compressive strength,internal friction angle,and cohesion [29,30].

Fig.5.Laboratory rock mechanics tests.

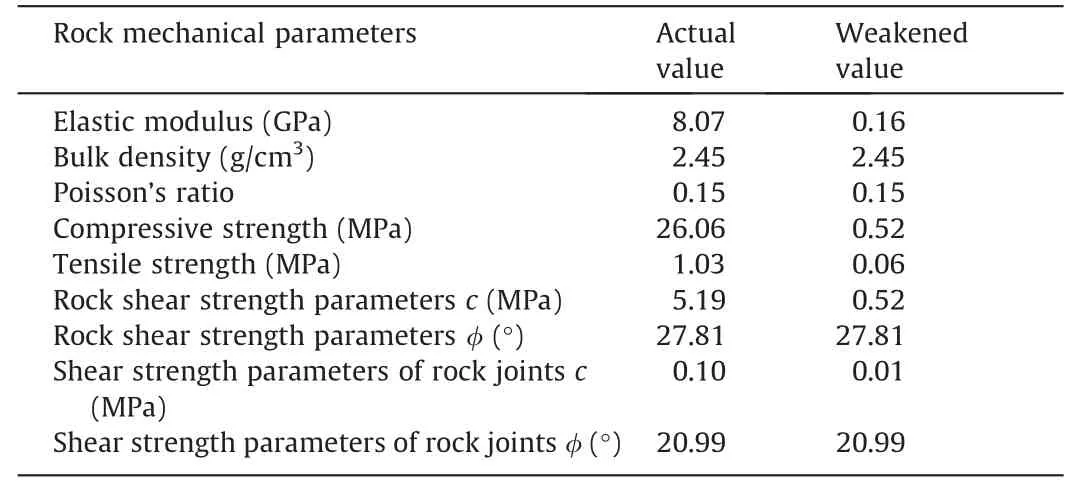

Due to prolonged geological activities,excavation and rain erosion,various faults,joints and other structural planes have been formed on the surface and its interior of the fractured rock mass.Based on the field investigation and calculation analysis,the joint plane of the rock mass in the study area can be divided into: (1)245°∠65°;(2) 330°∠60°;(3) 154°∠40°-60°;(4) 50°-70°∠65°,corresponding joint densities are 0.735%,1.193%,3.462%,and 2.918%,as well as GSI values are 42.0,58.5,74.3,and 67.0,respectively.Because of this,the measured mechanical parameters cannot be close to the actual rock mass.Thus,the measured rock mechanical parameters are weakened by the Hoek-Brown equation,and the weakened results are as shown in Table 2.

Table 2 Rock mechanics parameters.

where σmaxand σminare the maximum and minimum principal stress of rock failure strength,respectively;σadthe uniaxial tensile strength (UTS) of intact rock;GSI the geological strength index whose value is between 0 and 100;Dthe stress disturbance factor whose value is between 0 and 1;andmithe rock mass parameter.

2.3.Experimental device

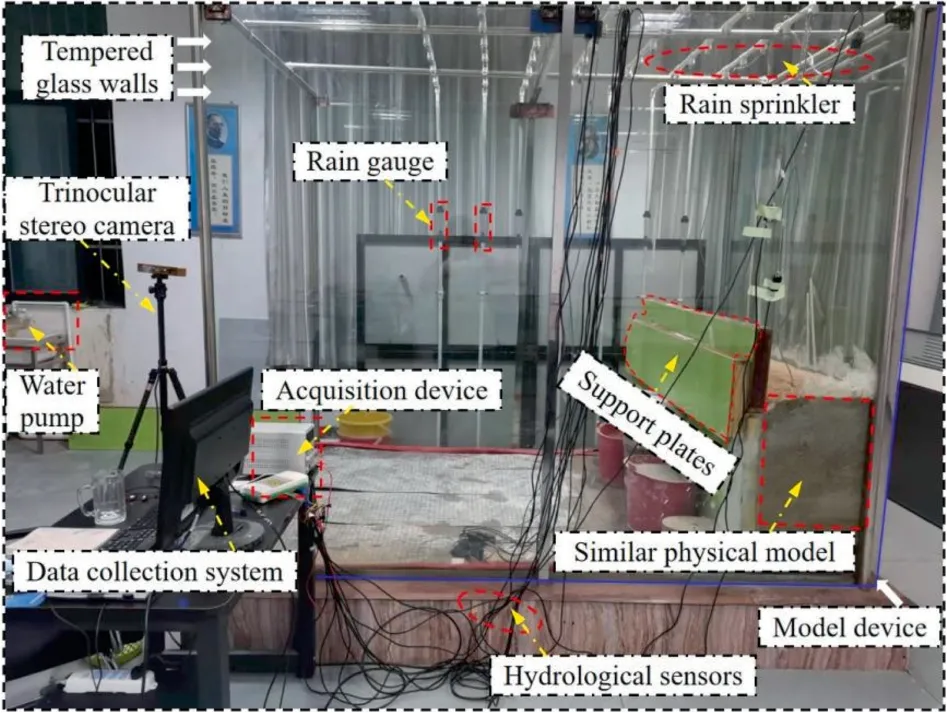

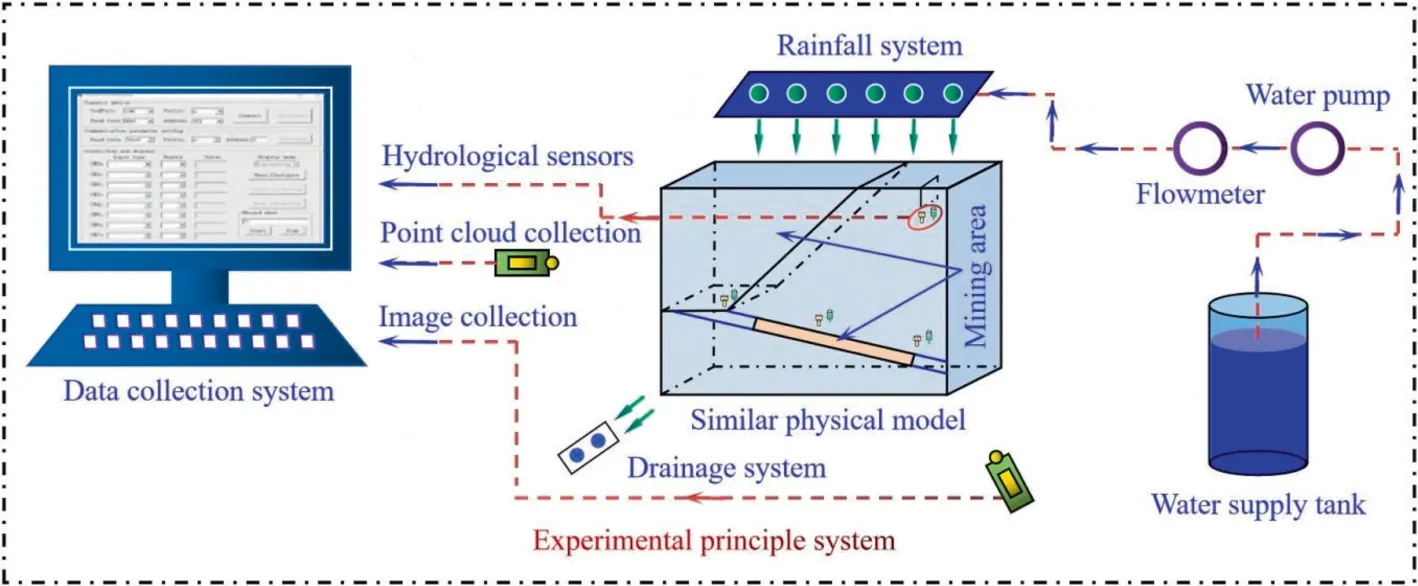

The self-developed rainfall experiment device of a similar physical model is depicted in Fig.6,comprising primarily a model box,a rainfall system,a monitoring system,and a collection system.Among them,the length of the model box is 2.2 m,the width is 1.6 m and the height is 1.8 m.In detail,the model box consists of a base plate and three tempered glass walls.Herein,the glass wall served as a support for the similar model during the experiment.Besides,a screen in the base plate prevents similar materials from clogging the drain with the flow of water.The rainfall system mainly includes a water storage tank,a rain gauge,a rainfall sprinkler,and a drainage pipe.Rain gauge with a manual adjustment feature is capable of measuring precipitation rates ranging from 0 to 100 mm/h.The rain sprinkler has a hole diameter of 1.6 mm,corresponding to a flow rate of 2.8 W,and there are a total of 30 rain sprinklers.The model box has a total of seven rows of rain pipes (each row spacing 0.25 m).According to the thickness(0.3 m)of the physical model,two rows of rain pipes near the tempered glass wall at the back of the model box are utilized to implement the rainfall process.In the experiment,we use a trinocular stereo camera to collect point clouds and RGB images to monitor the whole process of similar physical model instability.The principle of the independently developed rainfall experiment device is illustrated in Fig.7.To ensure the synchronization of rainfall infiltration and excavation unloading,we employ pore water pressure and water content sensors for data collection,which is subsequently stored on the computer.

Fig.6.The self-developed rainfall experiment device.

Fig.7.Experimental schematic.

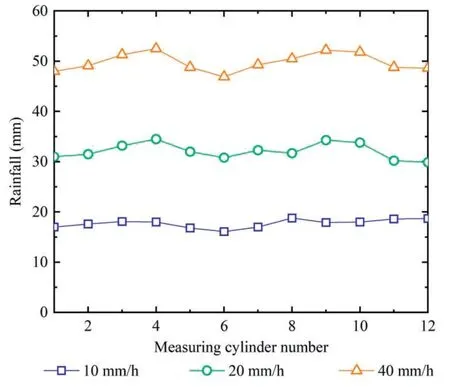

To effectively reflect the similar simulation experiment,the physical model is equally affected by rainfall erosion.Therefore,we calculate the deviation value of rainfall intensity across different regions [31].The performance of rainfall uniformity depends on the spray characteristics and nozzle layout.In this experiment,multiple rows of rain gauges are arranged to detect rainfall at different rainfall intensities.Rainfall uniformity is calculated by the following equation [32]:wherekis coefficient of rainfall uniformity;nthe measuring cylinder number;Hithe rainfall value of each cylinder,mm;andHthe mean rainfall of each cylinder,mm.

In order to investigate the deformation and failure of the rock slope caused by the variable rainfall intensity,the similar simulation experiments are carried out under the rainfall intensity of 10,20,and 40 mm/h,respectively.Based on Eq.(2),thekvalues of 10,20,and 40 mm/h are 96.14%,96.05%,and 96.92%,respectively (Fig.8).Additionally,the effect is enhanced with a rainfall intensity of 40 mm/h.Nevertheless,based on the previous literature [33],whenkvalue is greater than 80%,it can be considered that rainfall spraying effect is uniform.As a result,the spraying effect of our developed rainfall equipment is uniform and can maintain the effect of atomization.

Fig.8.Results of rainfall uniformity detection.

2.4.Experimental procedure

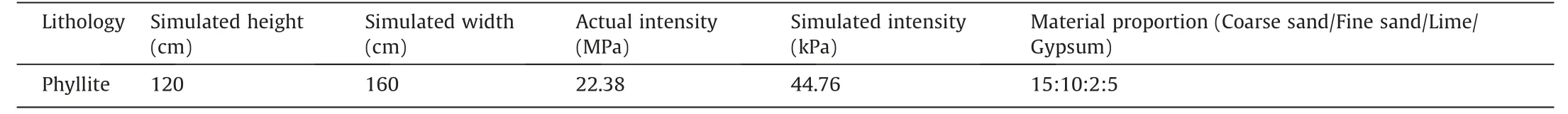

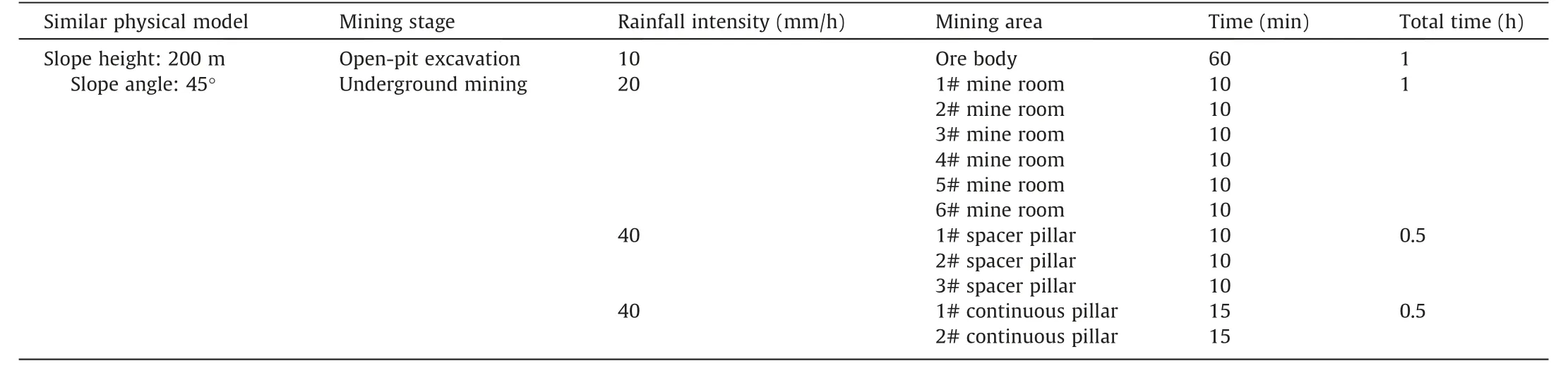

When cracks are strongly developed,the interaction between the crack and rainfall infiltration accelerates the formation of the critical sliding surface of the rock slope.The material strength and the degree of fragility of the fault layer might be the main factors affecting the stability of fractured high and steep rocky slopes.In the similar physical experiment,the cementing materials are 60-mesh coarse river sand,120-mesh fine river sand,600-mesh lime,and 800-mesh gypsum.Based on the measured actual rock mechanical parameters,we finally selected the proportioning scheme and the smallest error in the material parameters and theoretical value (Table 3).In previous study,we separately studied the influence of open-pit to underground excavation on ore body(the model with the slope height is 200 m and the slope angle is 45°),and the results showed that the mining of underground continuous pillar was the key cause of rock mass instability.To more accurately simulate the impact of rainfall and excavation on rock mass stability,the method of simultaneous incremental continuous rainfall and excavation is adopted.A two-phase trial protocol:The initial stage involves a singular open-pit mining of the entire model,accompanied by an hour-long simulation of rainfall.The other stage is underground room-and-pillar mining,and the rainfall duration is 2 h.Thus,the total duration of the similar simulation experiment amounts to three hours.Moreover,we adopt the mode of increasing rainfall,and the rainfall per hour is 10,20,and 40 mm,respectively.As shown in Fig.9,the mine rooms and pillars are successively divided into three stages.In this similar model,the dimensions of the mine rooms,spacer pillars,continuous pillars and mining area heights are 10,7,14,and 7 cm,respectively (Fig.9a).In this paper,the underground mining method of first mine rooms,then spaced pillars,and finally continuous pillars is adopted.Among them,mine room 1#-6# excavation time is 10 min in sequence.At this time,the rainfall intensity is 20 mm/h.On the other hand,the mining time of spacer pillar 1#-3# is 10 min,and the mining time of continuous pillar 1# and 2# is 15 min.The rainfall intensity of spacer pillar and continuous pillar mining is 40 mm/h (Fig.9b).As shown in Table 4,the scheme is designed in two stages.

Table 3 Proportioning scheme.

Table 4 Experimental scheme.

Fig.9.Experimental design in the underground mining stage.

Based on the actual height of rock slope and the width of slope excavation area in the study area,the simulated height and width in similar model tests are 300 and 400 m,respectively.In our study,the ratio of geometric similarity constant between the model and prototype is adopted as 1:250(FH1 crack is used to simulate faults in actual engineering),and the bulk density similarity constant is intended to be 1:1.The making procedure of the large scale model is as follows (Fig.6):

(1) mark the model size and sensor location on the glass wall of the model box;

(2) weigh the different materials and pour into the blender to mix thoroughly;

(3) install the baffle(length×width×height=160 cm×3 cm×30 c m),inject the mixed material from bottom to top and compacted;

(4) when the mixture is filled with each layer of baffle height,sprinkle a layer of mica powder and let dry for 1 to 2 d;

(5) continue installing the baffle and inject the mixture,embedding the water content and pore water pressure sensors;

(6) as the model is stacked to the fourth layer of baffle,the initial crack FH1 is prefabricated;

(7) after drying the model for 20 d,remove the baffle and drying it for another 3 to 5 d;

(8) install and debug the trinocular stereo camera and data acquisition device to carry out experiments.

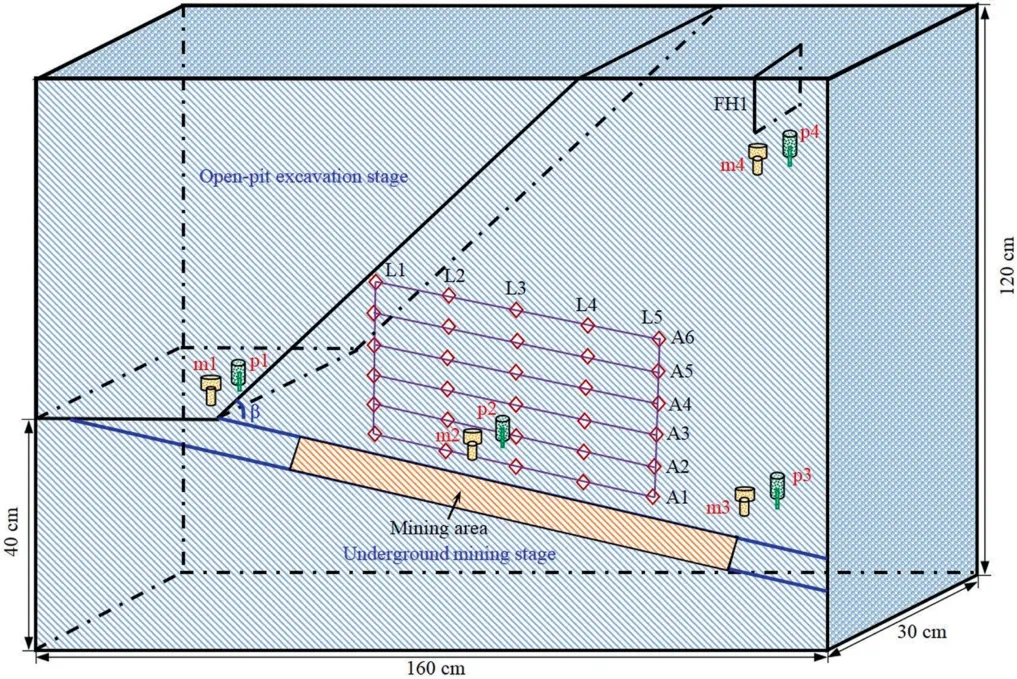

Fig.10 represents the size of the model built in the similar simulation experiment,where the length,width and height are 160,30,and 120 cm,respectively.In this experiment,the displacement,water content and pore water pressure measuring points are mainly arranged.As shown in Fig.10,a total of five displacement lines (L1,L2,L3,L4,and L5) are arranged above each stope andinter-column respectively.In addition,six displacement measuring points (A1,A2,A3,A4,A5,and A6) are arranged on each displacement measuring line,for a total of 30 displacement measuring points.The vertical interval of the measuring points is 6.7 cm,and the horizontal interval is 10 cm.Specifically,the water content measuring points m1,m2,m3,and m4 are located above the mining area.The embedded width is 10 cm.Among them,m1 is distributed at the boundary pillar 1#.The purpose is to monitor the change of water content of the ore body at the 200 m location.The water content sensors at m2 and m3 are buried at the upper middle and right side of the mining area,respectively.Besides,m4 is buried under the prefabricated initial fracture FH1(length×width×height=10 cm×0.4 cm×10 cm),to monitor the transform of water content of the initial fracture.Likewise,the distribution of monitoring sites from p1 to p4 is the same as that from m1 to m4,but the buried depth is 15 cm.

Fig.10.Layout of hydrological sensor monitoring points.

3.Experimental results and analysis

3.1.Rock mass displacement and deformation characteristic

Before underground mining,rock masses are subjected to various constraints in different directions.It is especially manifested in the joint force of open-pit excavation and heavy rainfall infiltration[34].Additionally,the rock mass will experience deformation and failure due to ground stress and gravity,resulting in an increase in elastic potential energy within the rock mass [35].As the ore body is mined from open-pit to underground,a new balance of stress fields is formed.Due to the irregular movement of rock mass,cracks gradually appear in the surrounding rock of stope,and eventually lead to the rock mass sliding or depression failure [36].On the other hand,rainfall infiltration will increase the water content of rock mass,resulting in the increase of rock mass capacity and the decrease of shear strength,and eventually lead to the occurrence of deformation.Therefore,studying the instability mechanism of variation rainfall and mining of high-steep rock slopes under unsaturated conditions helps to clarify the stability of mine slopes under complex conditions.

3.1.1.Open-pit slope excavation stage

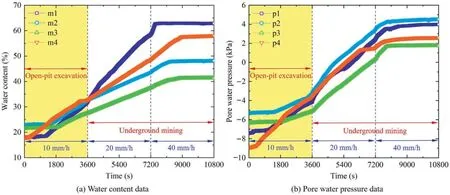

For a similar physical model with a slope height of 200 m and a slope angle of 45°,while simulating excavation,the rainfall duration is 1 h (rainfall intensity is 10 mm/h).As depicted in Fig.11,the water content at m4 and pore water pressure at p4 exhibit an initial increase.In other words,rainfall infiltration follows a top-down mechanism whereby rainwater permeates gradually through the FH1 fissure,consequently leading to an elevation in hydrologic sensor readings.The continuous increase of rainfall duration caused the gradual increase of water content and pore water pressure in m1.Subsequently,the values of water content and pore water pressure at m2 and m3 also increase gradually[37].After the open-pit slope excavation is completed,the maximum water content of the model is 32.7% (m4) (Fig.11a),and the maximum pore water pressure is -3.2 kPa (p2) (Fig.11b).

Fig.11.Hydrological data for a model with a slope height of 200 m and a slope angle of 45°.

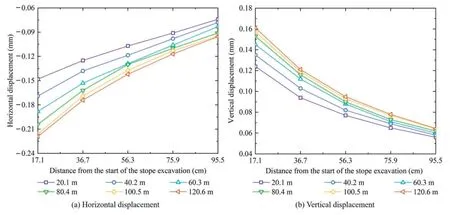

According to the effective monitoring of the similar physical model by the trinocular stereo camera,we obtain the displacement value changes of each measuring point in the slope cutting process,as shown in Fig.12.This calculation method is based on the conversion relationship between object distance and pixel focal length[38].By establishing the correlation between object distance and pixel focal length,the trinocular stereo camera is capable of computing the variation of pixel point in the monitoring images,thereby determining the actual displacement change value of monitoring points.Upon completion of the excavation,all displacement measuring points exhibited a tendency to move in an upward and leftward direction.In our study,the maximum horizontal displacement and vertical displacement of the model are -0.219 and 0.161 mm respectively,which correspond to the displacement of-54.79 and 40.25 mm in actual engineering (Fig.12a and b).Evidently,the similar physical model may be deformed in a small range under open-pit excavation.However,when the open-pit excavation reaches the toe of the slope,the water content and pore water pressure values showed a steady upward trend,which may be the result of rainwater accumulation here [39].Thus,it can be concluded that the toe of the slope is the largest deformation point in open-pit excavation stage.

Fig.12.Displacement change of measuring point in open-pit mining stage.

3.1.2.Underground mining stage

When the rainfall intensity increases to 20 mm/h,the water content values of m1,m2,m3,and m4 in the model all increase sharply.Notably,the water content of m1 is the largest(Fig.11a).The reason is that the rainwater from the infiltration of precipitation and the flow of the slope at the 200 m location accumulate together,causing the water absorption capacity of the mixed material at m1 to be greater than that at m2,m3,and m4.Meanwhile,the pore water pressure values at p1,p2,p3,and p4 also increased rapidly compared to the open-pit excavation stage(Fig.11b).Continuing to increase up to 40 mm/h,m1(located at the toe of the slope)attains its saturation state for the first time.Then,m2,m3,and m4 sequentially reach the state of saturation.The maximum water content reaches 62.92%(m1),while the maximum pore water pressure is 4.38 kPa (p2).

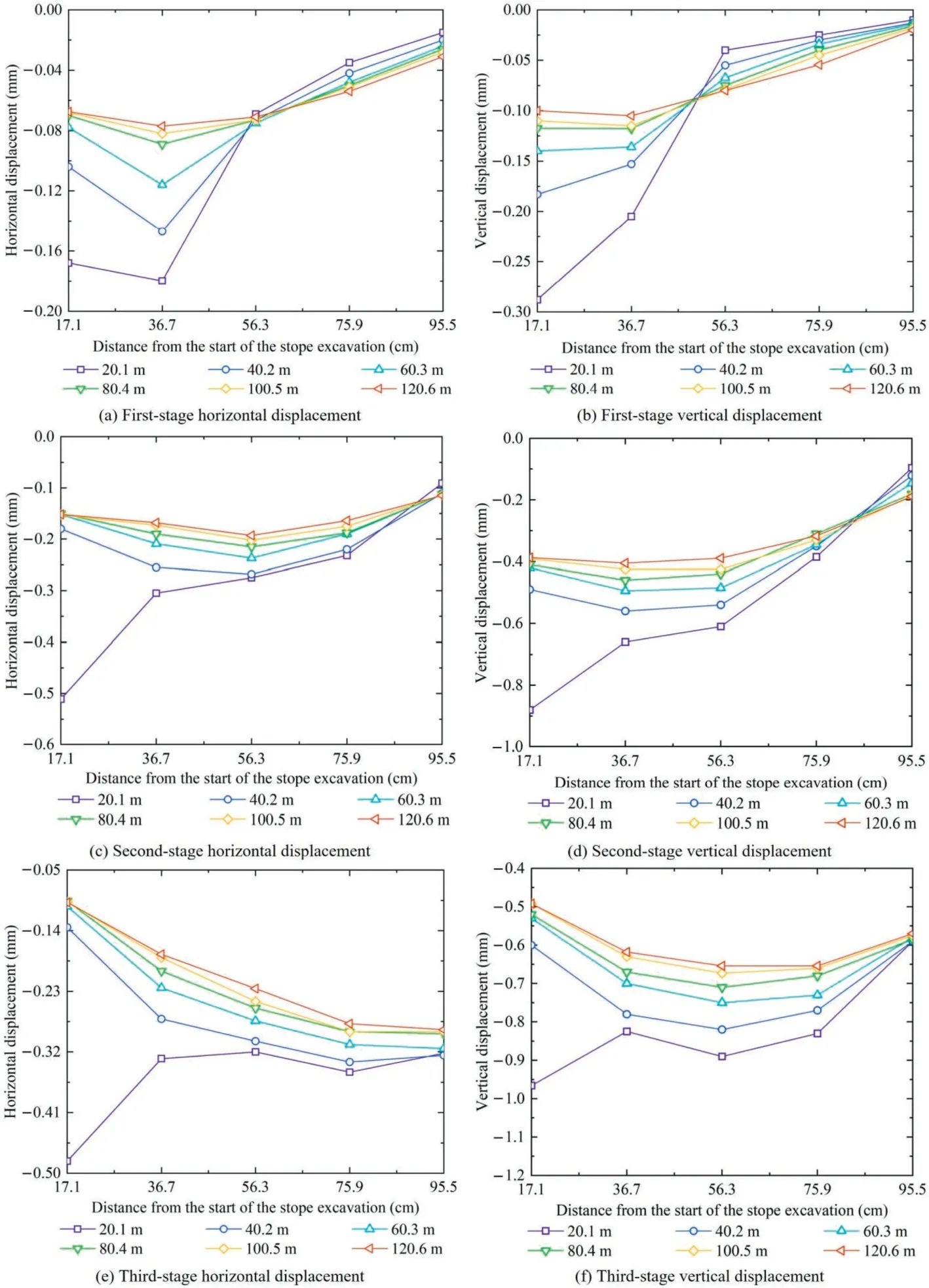

Fig.13 illustrates the variation in displacement during threestage underground mining.Mining 27 cm from the toe of the slope along the direction of the goaf (67.5 m in the actual project),the maximum horizontal displacement and vertical displacement of underground mining exist in adjacent roof.In detail,microarched fissures appear in the roofs of mine rooms 1# and 2#.The maximum horizontal and vertical displacements are -0.18(-45) and -0.288 mm (-72 mm),respectively (Fig.13a and b).Continuing to advance 73 cm (182.5 m),3# and 4# mine rooms become new stopes.Under the action of heavy rainfall infiltration,external mining and gravity stress of ore body,the surrounding rock of the stope appears initial movement and deformation.Specifically,the layer separation fissures above the mine room begin to extend from the immediate roof to the main roof.Herein the maximum horizontal and vertical displacements are -0.511 and -0.88 mm,respectively,and the corresponding engineering displacements are -127.75 and -220 mm,respectively (Fig.13c and d).After advancing to 119 cm (297.5 m),the overlying rock bend and subside along the direction of the goaf.In this case,the displacement change rate of each measuring point is larger than that of the horizontal displacement,indicating that the similar physical model will slide failure.In our study,both horizontal and vertical displacement lead to the weakening of overlying strata due to mining effects after a certain degree of excavation.This process is further exacerbated by rainfall infiltration.At the same time,the maximum horizontal displacement and vertical displacement reach -0.482 and -0.966 mm,respectively,which may lead to large-scale collapse failure of similar physical model (Fig.13e and f).In the stage of open-pit slope excavation and underground mining,FH1 fissure is located at the right upper end of similar physical model,far from the toe of slope and mining area,while deformation occurs first at the toe of slope under the combined action of rainfall and excavation.Combined with the experimental process,we believe that the deformation at FH1 is small.Thus,we do not consider the deformation evolution analysis of FH1 fissure in this paper.

Fig.13.Three-stage displacement curve of underground mining.

3.2.Fracture evolution characteristics of rock masses

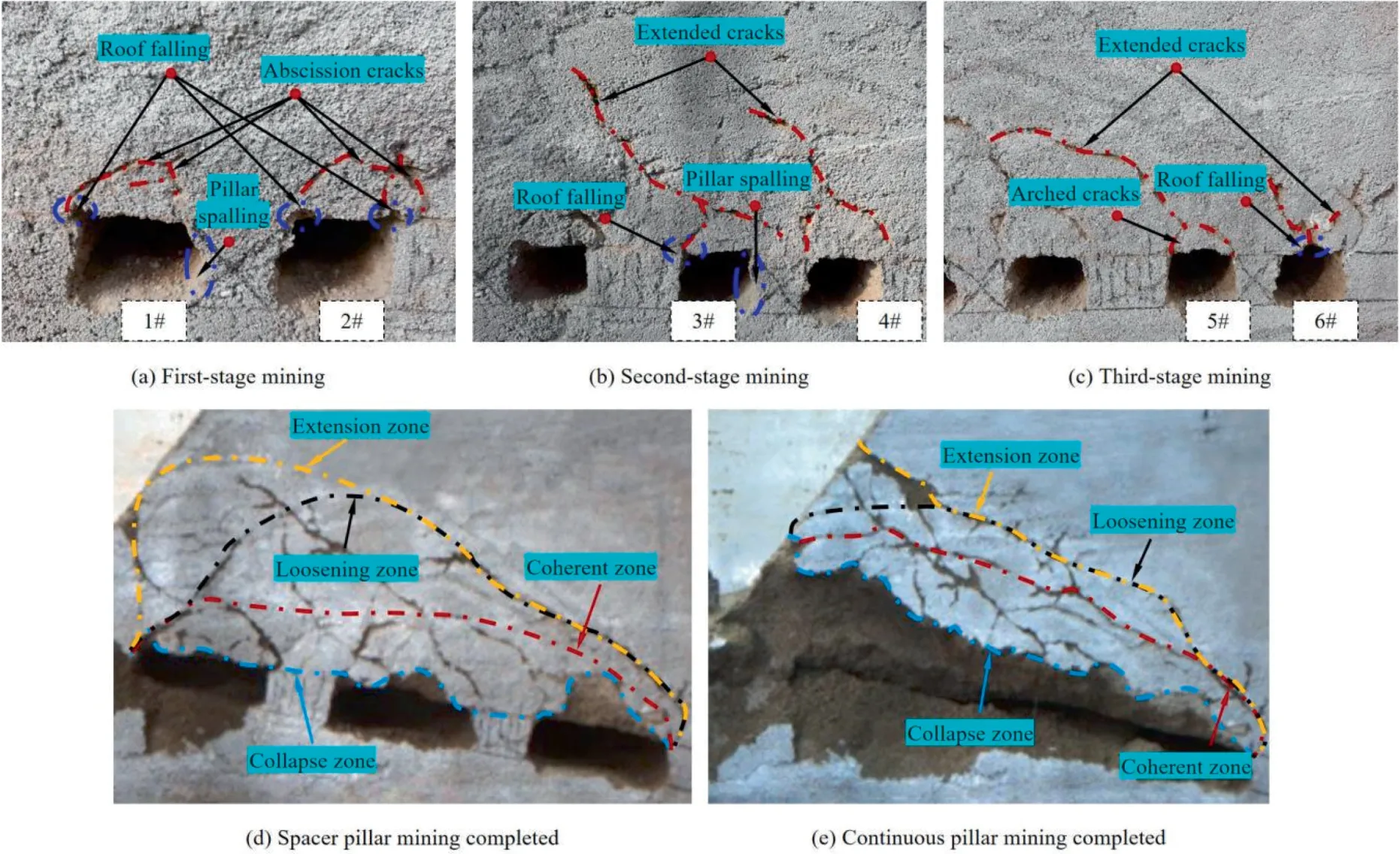

Fig.14 represents the fracture evolution characteristics of the underground stope at different mining stages.After the mining of the first stage of the mine room,the roof fell off in multiple ranges.Furthermore,a large number of abscission cracks are generated(Fig.14a).In the second stage,under the combined action of rainfall infiltration,mining stress and the gravity of the overlying rock,extended fractures are generated above the mining area.At this stage,the extensional fissures tends to develop towards the open-pit slope (Fig.14b).After the completion of mining of 1#-6# mine rooms,the development trend of the extended fracture above the 5# mine room remains consistent with the observed during the second stage,but the extension angle is lower(Fig.14c).With the excavation of mine room 6#,the microcracks have developed into arch-shaped continuous cracks,however,the model remains in a stable state.

Fig.14.Evolution characteristics of cracks in different stages of underground stope.

As depicted in Fig.14d and e,the excavation of spacer pillars and continuous pillars results in large-scale sliding failure of the overlying rocks.According to the degree of crack development,it is mainly divided into four deformation zones,which are roof subsidence zone,crack coherent zone,crack loosening zone and crack extension zone.When water content and pore water pressure reach a maximum (material saturation),the overburden caving area is expanded [40].In other words,due to rainfall infiltration and excavation unloading,the material strength is reduced,resulting in extensive deformation and failure.

3.3.Instability failure mechanism of high-steep rock slope

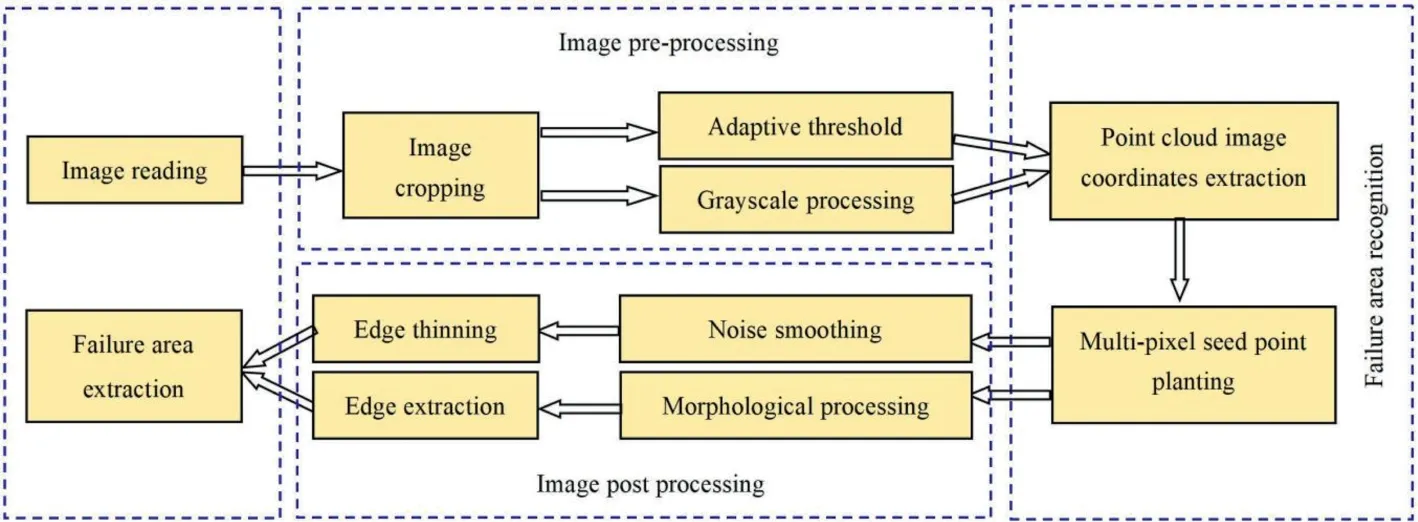

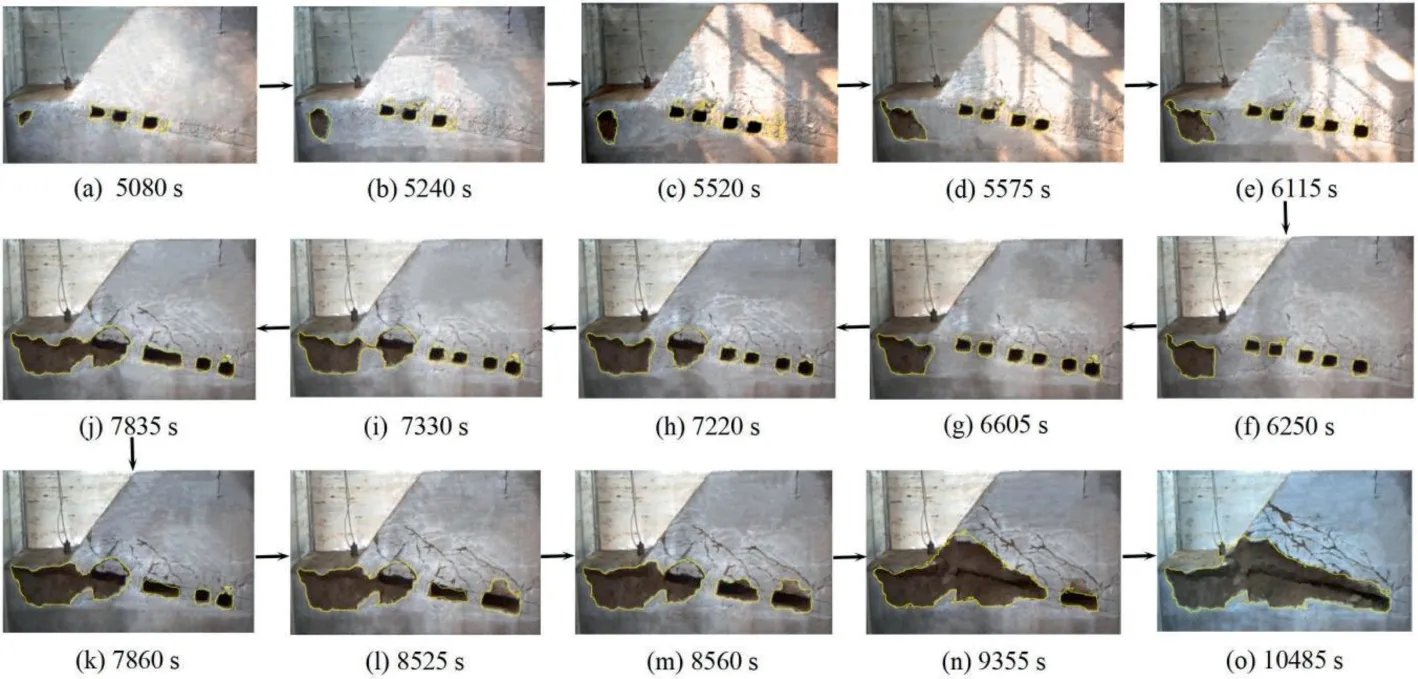

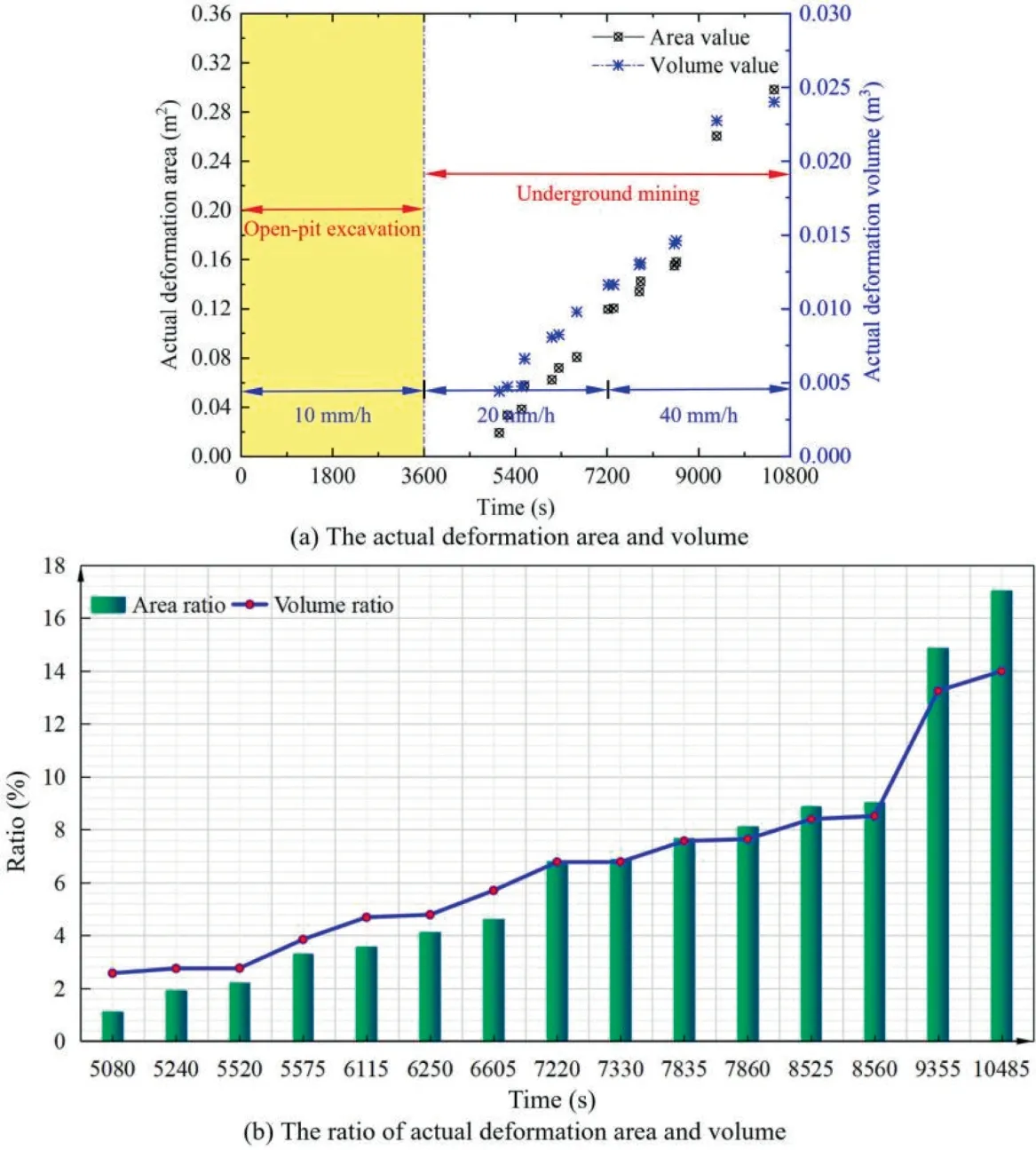

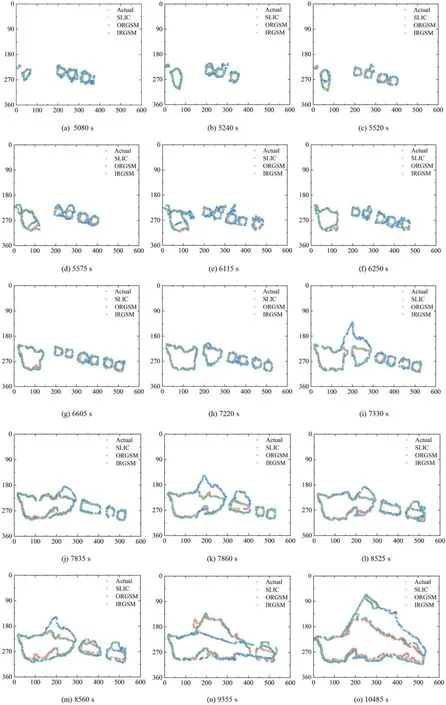

To analyze the failure mechanism of high-steep rock slope,the IRGSM is applied to automatically identify the deformation characteristics of rock mass.Fig.15 shows the flow chart of IRGSM identifying the deformation area of fractured rock masses.Fig.16 represents the contours of the damaged areas identified by IRGSM at different times (yellow curve).In our study,the image recognition thresholds at different times are:T5080s=9.5,T5240s=9.4,T5520s=9.5,T5575s=9.0,T6115s=9.3,T6250s=9.6,T6605s=9.4,T7220s=9.8,T7330s=9.6,T7835s=9.4,T7860s=10.0,T8525s=9.7,T8560s=9.5,T9355s=9.5,T10485s=10.0.Fig.17 shows the actual deformation areavolume and its proportion of rock mass identified by IRGSM under the time series.In the stage of open-pit excavation,there is no substantial failure to the similar physical model.This may be mainly due to the low rainfall intensity and weak excavation disturbance ability [41,42].However,the accumulation of rainwater at the toe of the slope resulted in significant increases in water content at m1 and pore water pressure at p1 (Fig.11).

Fig.15.The flow chart of IRGSM identifying the deformation area of fractured rock masses.

Fig.16.Deformation and failure evolution characteristics of rock mass under time series.

Fig.17.IRGSM identificaiton of the actual deformation area-volume and its proportion at different times.

The fracturing of the rock mass primarily occurs during the underground mining phase.The water content and pore water pressure of the high-steep rock slope increase continuously when the rainfall intensity reaches 20 mm/h.After the excavation of 1#-3#mine rooms,the rock mass at 200 m platform begin to caving (Fig.16a).This indicates that rainfall is the dominant factor of rock mass instability failure.When the rainfall increases to 30 mm,the gravity of the material at the slope height of 200 m increases,and has a tendency to extend to the toe of the slope (Fig.16c-g).Continuing to increase the intensity of rainfall (from 20 to 40 mm/h),the water content at m1 and pore water pressure at p1 gradually reaches the maximum,and some rock mass reaches saturation state.The maximum values are 63.21% and 3.7 kPa,respectively.At this time,deformation occurs at the toe of the slope.This is mainly due to the lack of effective drainage at the slope toe,which resulted in a large amount of rainwater accumulation at this location (Fig.11a and b,and 16h).Subsequently,the developed fracture (Fig.16i) evolved into a coherent fracture zone (Fig.16j).When the rainfall increased to 50 mm,the spacer pillar stage is completed (Fig.16m).The values of water content at m2 and pore water pressure at p2 are close to the maximum,and their values are 46.88% and 4.6 kPa,respectively (Fig.11).Moreover,compared with the excavation deformation regions of spacer pillars 1# and 2# (Fig.16k and l),the changes are small.The results show that excavation is not the main factor of rock slope instability.However,when the rainfall increased to 60 mm,large-scale sliding and sunken deformation occurred in the highsteep rock slope (Fig.16n).From the critical instability stage to the instability stage,the deformation area of rock mass increases from 0.15804 to 0.26047 m2with a growth rate of 64.8%,and the deformation volume increases from 0.01462 to 0.02274 m3with a growth rate of 55.5% (Fig.17).Under the synchronous action of rainfall,continuous pillar mining intensifies the deformation scale of rock slope.Finally,the full completion of the underground mining stage causes the slope deformation to develop to the slope waist (Fig.16o).

In summary,the similar physical model almost does not fail at the rainfall intensity of 10 mm/h.Moreover,the rock mass at the toe of the slope falls off when the rainfall intensity is 20 mm/h.As the rainfall intensity reaches 40 mm/h,the large-scale sliding and sunken deformation of the rock slope is caused,such as sliding deformation (Fig.16k-n),sunken deformation (Fig.16o).Herein the sliding deformation occurs first.On the other hand,open-pit excavation,the mining of mine rooms and spacer pillars lead to the displacement changes of rock mass and aggravate the falling range of rock mass.Nevertheless,the mining of continuous pillars intensifies the failure scale of the rock slope.Therefore,rainfall is the main factor causing the instability of rock slopes.

3.4.Fracture evolution with SLIC, ORGSM

We compared the IRGSM with the SLIC superpixel method and the ORGSM under the complex rainfall-excavation scenario.Based on the previous definition,the initial region growing segmentation algorithm relies on pixels or sub-regions to finish the evolution of the growth range,and realizes the segmentation of a larger region based on the set growth criteria [43].In this study,we adopt the growth criterion of automatic selection of a single seed point in the 8-neighborhood.The result show that the segmentation quality is the best when the thresholds are set asT5080s=6.0,T5240s=6.4,T5520s=5.5,T5575s=6.8,T6115s=6.3,T6250s=6.6,T6605s=6.4,T7220s=5.8,T7330s=6.6,T7835s=6.4,T7860s=7.0,T8525s=6.7,T8560s=6.5,T9355s=5.5,andT10485s=6.0,respectively.Furthermore,a superpixel SLIC method,by selecting the V channel,the number of superpixels is 350,and the brightness of the superpixel block is used as the fusion index [44].When the brightness value is less than 0.02,the mask is set to black,as well as the mask is set to white when the brightness value is greater than 0.02.

IRGSM can basically coincide with the contour of the actual deformation region,showing a high identification accuracy in rock mass instability deformation (Fig.18c,i and o).Nevertheless,SLIC can segment the target regions well by using the superpixel block principle,but it cannot accurately locate the contour boundaries(Fig.18l and m).In addition,for some images with relatively complex pixels,there is a phenomenon of recognition error (Fig.18o).In the face of complex images (depth of color of model materials,difference of illumination pixels,distribution pattern of cracks,interference of glass walls and sensors,etc.),ORGSM can only recognize two-dimensional information and cannot achieve relatively perfect segmentation.Therefore,in the comparison of these three methods,segmentation quality performs the worst (Fig.18k,m and n).On the contrary,by using three-dimensional point cloud information,IRGSM can effectively solve this problem.Furthermore,error analysis is carried out using the deformed regions from one set of images of 45° slope angle identified by real data,SLIC,ORGSM and IRGSM.By extracting the coordinates of the deformation region contours identified by different methods,Xcoordinates andYcoordinates are used to make difference respectively,and finally the relative error value is obtained (Fig.18).In our study,20 corresponding coordinate points are selected from each contour region,thus the total number of test samples is 1320.

Fig.18.Comparation of IRGSM,ORGSM,SLIC and actual deformation area profiles at a slope angle of 45°.

Based on Eqs.(3) and (4),the average segmentation errors of different methods are calculated.Table 5 represents the total average segmentation errors inXandYdirections of IRGSM,SLIC and ORGSM,and Table 6 shows the average segmentation errors inXandYdirections of IRGSM,SLIC and ORGSM at different times of the model.

Table 5 Average segmentation errors in X and Y directions under different methods.

Table 6 Average segmentation errors in X and Y directions of IRGSM,SLIC and ORGSM at different times of the model.

In the past,we have applied this technology to the rainfall infiltration failure of rock dumps and tailings ponds,and achieved good results in the segmentation of deformation regions.At present,IRGSM is preparing to be applied in the mining monitoring process of Dexing Copper Mine.The multi-factor conditions on the engineering field may cause certain deviations to the segmentation results,which is impossible for us to predict.In the future plans,we will further improve the algorithm according to the field application condition and dig the available information in depth.Combined with the existing machine learning technologies,different parameters in landslide,such as rainfall time,rainfall intensity,deformation area,volume,etc.are trained to further advance the accuracy of IRGSM.Moreover,the equipment system based on IRGSM will be developed and promoted around different types of landslide disaster regions in the country.

4.Discussions

In this case,the overall height of the slope is 540 m,which is ultra-high slope [45].Chen et al.[46] determined the reliability by computing the standard deviation and coefficient of variation of rock and soil mass parameters.The concept of instability probability is introduced to enhance the statistical reliability of unsaturated rock mass parameter probabilities,thereby ensuring the validity of the calculated results[47].Thus,the calculation process of failure probability is as follows:

The standard deviation of unsaturated rock mass parameters can be calculated by Eq.(5):

The safety factor of slope adopts the limit equilibrium method,such as the generalized limit equilibrium method (GLE)and Spencer method [48].The mean safety factor and standard deviation can be calculated by Eqs.(6) and (7):

The variation coefficient of mean safety factor can be calculated by Eq.(8):

where vkis the variation coefficient of the mean safety factor.

When the safety factor is normally distributed,the reliability index can be calculated by Eq.(9):

As the safety factor is lognormal distribution,the calculation equation of the reliability index can be written as follows:

where βkis a reliable index of mean safety factor.

The reliabilityPscan be expressed by Eq.(11):

The instability probabilityPfwith mean safety coefficient less than 1 can be calculated by Eq.(12):

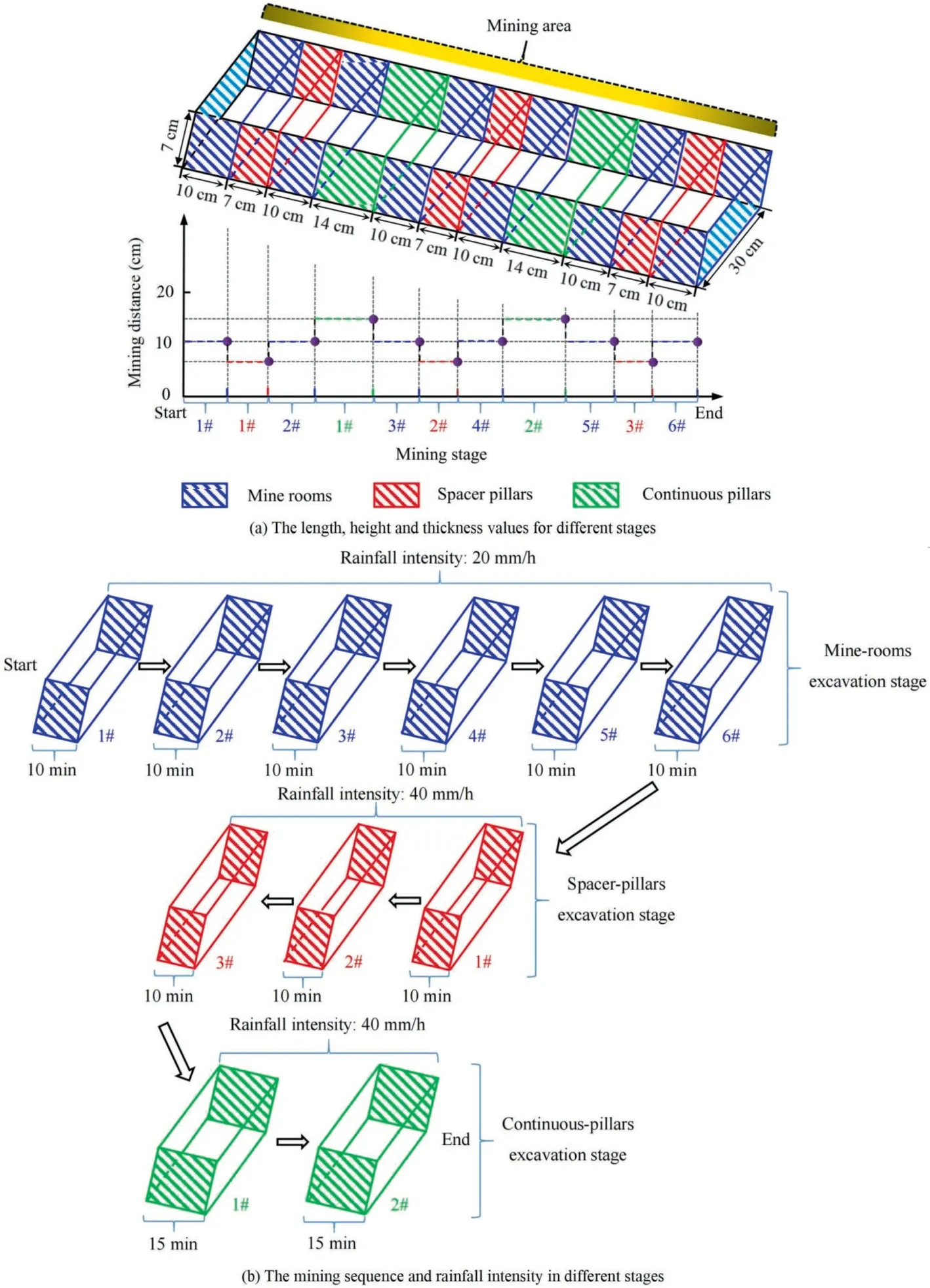

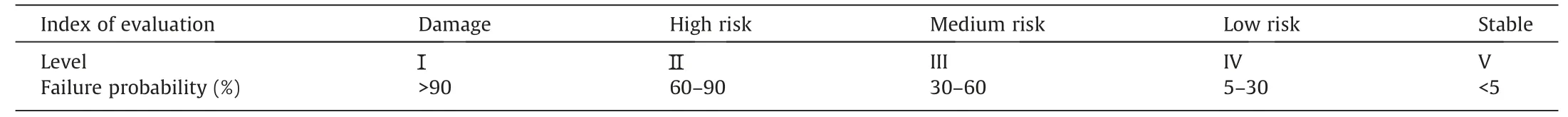

Monte Carlo method is used to analyze the impact of different rainfall intensities on slope reliability[49].The cohesion and internal friction angle of phyllite are taken as random variables,and the parameters are normally distributed.In the experiment,the number of trials is set to 1000.According to combined Eqs.(6)-(8),the standard deviation of the cohesion and internal friction angle of phyllite is 1 and 1.5,and the coefficient of variation is 0.079 and 0.110,respectively.Therefore,the failure probability and variation law of unsaturated rock mass under different rainfall intensities are as shown in Fig.19.Herein the duration under different rainfall intensities is one hour respectively.The evaluation index of the stability grade of unsaturated rock slope is shown in Table 7.

Table 7 The evaluation index of stability grade of unsaturated rock slope.

Fig.19.The relationship between failure probability of unsaturated rock slope and rainfall intensity.

As can be seen from Fig.19,the instability probability of unsaturated rock slope changes with rainfall intensity,showing a positive correlation.After the finish of open-pit excavation,the failure probability increases to 4.37% (Level V).With the adjustment of rainfall intensity from 10 to 20 mm/h,there is a gradual increase in the failure probability,which reaches 6.06%with an incremental rate of 1.69%.In the mining stage of mine rooms,the slope failure level rises from grade IV to grade III,and no instability failure occurs.With the continuous increase of rainfall intensity (40 mm/h),the failure probability of slope continued to increase.The probability of failure for spacer pillars has increased from 72.34% to 89.86%,indicating that the rock slope is currently in a state of critical instability.Thus,it is necessary to strengthen the slope under this condition [50].As the continuous pillar is mined,the failure probability is 94.22%(Level I) and the instability failure occurs.In other words,during the excavation of 1# continuous pillar,the rock slope suddenly changes,causing widespread damage.Herein the rainfall intensity is 40 mm/h,and the rainfall is between 50 and 60 mm.As the underground mining is complete,the instability probability reaches the maximum 97.09%.As a result,the rock mass failure is further aggravated.

Overall,the instability probability of unsaturated rock slope increases with the augment of rainfall intensity and the acceleration of excavation process.When rainfall intensity increases from 20 to 40 mm/h,the instability probability increases sharply.However,failure occurred at the toe of the slope while no deformation occurred around the mining area,indicating that the increase of rainfall intensity may be the main reason for the rapid growth of the instability probability.On the other hand,when the rainfall intensity is maintained at 40 mm/h,the failure probability of continuous pillar mining exceeds 90% and the unsaturated rock slope becomes unstable.This indicates that the mining of continuous pillar is the main factor that aggravates the large-scale failure of rock mass.Thus,rainfall up to 50 mm will cause critical slope instability and up to 60 mm will cause slope failure.This is consistent with the results of similar physical simulation.

5.Conclusions

In this paper,we have independently developed a highprecision rainfall simulator,which enables effective implementation of the rainfall-excavation coupling experiment.Combined with engineering investigation,conventional rock mechanics experiment,similar simulation experiment,theoretical analysis and image recognition,the failure mechanism of high-steep rock slope under complex stress conditions is comprehensively analyzed.Moreover,the evaluation criterion of rock slope stability under unsaturated condition is quantified for the first time.The main conclusions are as follows:

(1) The rainfall will weaken the weak interlayer of the rock slope and cause deformation.The continuous underground mining has caused the overlying strata to bend and produce separation cracks.Accompanied by some rock masses caving,the rock layer above the mining region appears collapse deformation after the underground mining is completed.Thus,the degree of crack development,it is mainly divided into four deformation zones,which are roof subsidence zone,crack coherent zone,crack loosening zone and crack extension zone.Furthermore,the outermost fracture extension zone always develops upward along the slope.As a result,the sliding failure extends to the slope waist.

(2) In the temporal dimension,the continuous increase in rainfall intensity significantly enhances the rainwater absorption capacity of unsaturated rock masses.Moreover,the rapid accumulation of rainwater at the toe of the slope is a crucial factor contributing to rock mass instability,thus effective drainage measures are imperative in practical engineering.Finally,due to the gravitational forces acting on the rock mass,a large-scale collapse failure occurs,accompanied by sliding and subsidence deformation extending from the waist of the slope to its toe.Additionally,we conclude that rainfall intensity of 40 mm/h is the critical failure stage of high-steep rock slope.Rainfall of up to 50 mm/h will induce critical instability of the slope,and rainfall of up to 60 mm/h will result in slope failure.Hence,under the coupled effect of rainfall and excavation,rainfall may be the most critical factor causing rock mass instability.The maintenance of slope toe should be emphasized in practical engineering.

(3) We apply IRGSM effectively in the automatic identification of rock mass deformation area under complex scenes.Compared with SLIC and ORGSM,the average identification error of IRGSM inXandYdirections is significantly reduced.Herein the average identification error values of IRGSM,SLIC and ORGSM in theXdirection are 1.82%,4.70%,and 9.45%,respectively,and 1.80%,6.26%,and 12.40%,respectively,in theYdirection.In the future plans,we will further improve the algorithm according to the field application situation and dig the available information in depth.Furthermore,the equipment system based on IRGSM will be developed and promoted around different types of landslide disaster regions in the country.

(4) Based on Monte Carlo method,an analysis is conducted to examine the impact of variable rainfall intensity on slope reliability.Furthermore,this study establishes evaluation criteria for assessing the stability of unsaturated highsteep rock slopes.The failure probability increased by 49.08% as the rainfall intensity increased from 20 to 40 mm/h.In other words,the increase of rainfall intensity may be the main reason of slope failure probability increasing sharply.The mining of continuous pillar intensifies the scale of rock mass failure.In the mining process from spacer pillar 3# to continuous pillar 2#,the probability of slope instability increases by 11.06%,rising from 83.06% (LevelⅡ) to 94.12% (Level Ⅰ).After the completion of underground mining,the probability of slope instability increases to 97.11%,rendering slope failure an inevitable outcome.

Acknowledgements

The research work was funded by the Research Fund of National Natural Science Foundation of China (NSFC) (No.42277154),the project supported by graduate research and innovation foundation of Chongqing,China (No.CYB22023),Guizhou Province Science and Technology Planning Project (No.Guizhou science and technology cooperation support[2022]common 229),National Natural Science Foundation of Shandong Province of China (NSFC) (No.ZR2022ME188),the State Key Laboratory of Coal Resources and Safe Mining,CUMT (No.SKLCRSM22KF009),and Open Fund of National Engineering and Technology Research Center for Development and Utilization of Phosphate Resources of China (No.NECP 2022-04).

- 矿业科学技术学报的其它文章

- Shear behaviours and roughness degeneration based on a quantified rock joint surface description

- Selective flotation of chalcopyrite from pyrite via seawater oxidation pretreatment

- Numerical modeling on strain energy evolution in rock system interaction with energy-absorbing prop and rock bolt

- Effect of particle gradation on pore structure and seepage law of solution in weathered crust elution-deposited rare earth ores

- Polysaccharides-based pyrite depressants for green flotation separation:An overview

- Mechanical properties and damage characteristics of solidified body-coal combination in continuous driving and gangue backfilling