Promoting hybrid twins structure to reduce yield asymmetry of rolled AZ31 plates by combining side-rolling and torsion

Bo Song,Meng Wang,Ruolan Shi,Zhiwen Du,Ning Guo,Fang Wang,Shengfeng Guo

School of Materials and Energy,Southwest University,Chongqing,China

Abstract In this work,an as-rolled AZ31 square bar with c-axis//ND (normal direction) texture was used.Side-rolling and reciprocating torsion were performed to treat the bar.Microstructure evolution and tensile-compressive properties were investigated in detail.Initial rolled AZ31 bar exhibits a large yield asymmetry along the rolling direction (RD).Reciprocating torsion can generate extension twins to introduce twin boundaries and twin-texture.The twin structure can reduce yield asymmetry.However,only limited regions in the rolled AZ31 bar can be twinned during torsion.Pre-side-rolling along the transverse direction (TD) can generate two texture components (c-axis//TD texture and c-axis//ND texture) by introducing profuse {10–12} twins.Such dual texture components help increase the regions which are favorable for twinning during torsion.Finally,combining side-rolling and reciprocating torsion generates hybrid {10–12} twins structure on the entire cross-section,resulting in a remarkably low yield asymmetry.The relevant mechanisms were discussed in detail.

Keywords: AZ31;Square section;Torsion;Hybrid twins;Orientation;Yield asymmetry.

1.Introduction

The tension-compression yield asymmetry has been widely reported in wrought Mg alloys [1–8].Typically,the rolled Mg alloys with basal texture exhibit a large yield asymmetry along rolling direction [1,2].This restricts their use as construction parts,especially beams.It has been proved that yield asymmetry in Mg alloys is closely related with activity of {10–12} twinning [4,5].For most Mg alloys,{10–12}twinning are easy to activate owing to its low critical resolved shear stress (CRSS).Under some loading conditions,it can be dominant deformation mode to determine yield strength[9–11].However,twinning activity has a polar nature,which means twins are formed only in one direction in the twin plane [12].When rolled Mg alloys with basal texture are loaded along the RD,compression can easily activate {10–12}twinning,while tension inhibits the twinning and requires prismatic slip with high CRSS to accommodate plastic strain[9,13].Therefore,the compressive yield strength is significantly lower than the tensile yield strength.Research shows that refining grains and randomizing texture can reduce the yield asymmetry.Refining grains generates strong hardening effect to suppress twinning [5].Randomizing texture balances the activity of twinning between tension and compression[14].

It is well known that twinning deformation can generate twin boundaries and twin texture [15–18].Thus,pretwinning has been an effective and economical way to refine grains and re-assign texture.Previous work shows that the {10–12} twin boundaries via pre-side-rolling along the TD can remarkably reduce the yield asymmetry in the RD direction [19].Moreover,activity of hybrid twins structure(i.e.,multiple twin variants and high-order twins) can further refine grains and randomize texture to further reduce yield asymmetry [19–23].For rolled Mg alloy plates,the hybrid twins structure is usually obtained by alternate compression along the RD and TD [20,23].Obviously,this is not applicable to the plates or bar with large aspect ratio.

Recent work has showed that free-end torsion is a suitable method to process the Mg alloy bars with high aspect ratio [24–26].Pre-torsion has been widely used to tailor microstructure and mechanical properties of extruded Mg alloys.A gradient microstructure can be formed in the twisted Mg alloy rods [24].Such torsion deformed microstructure has been applied to enhance the strength/toughness and reduce the yield asymmetry of Mg alloy rods [24.25].In a recent study,reciprocating torsion was also used to process a rolled AZ31 square bar [26].It has been confirmed that reciprocating torsion can also generate {10–12} twins in a rolled AZ31 square bar.And the twins via reciprocating torsion have different orientations with those via side-rolling [19,26].It is expected that combining side-rolling along the TD and reciprocating torsion might also prepare hybrid twins structure.To reveal the possibility of this hybrid twins structure,the effects of side-rolling and reciprocating torsion on twinning behavior of rolled AZ31 square bar were studied in detail.Tensile and compressive properties were also evaluated.The side-rolling along the TD and reciprocating torsion are suitable for plates or rods with high aspect ratio [19,26].Thus,present work is of great significance for the fabrication of rolled Mg alloy bars with high-property.

2.Experimental

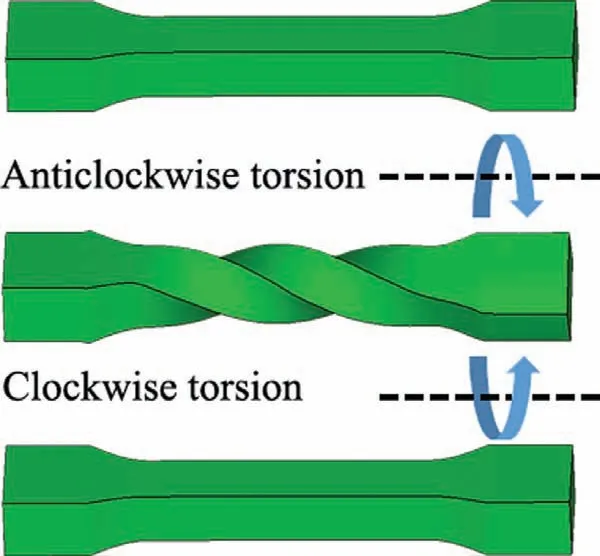

In this work,a commercial rolled AZ31 plate (AR sample) was used.The samples with dimensions of 120 mm(RD) × 11 mm(TD) × 30 mm(ND) were cut to from starting material.In this work,pre-side-rolling along the TD is used to fabricate the AZ31 plate with initial {10–12} twins(PR sample).Based on a previous report [9],as the compressive strain along the thickness increases to 10%,the area fraction of {10–12} twins can reach more than 90%.When the strain exceeds 6%,the number of twin boundaries decreases rapidly due to the growth and merging of twin lamellae.To obtain better hardening effect of twin boundaries,the thickness reduction was set as ∼5.6% for PR sample in this work.The dog-bone-shaped torsion samples with a gauge size of 25 mm(RD) × 5 mm(TD) × 5 mm(ND) were cut.The AR and PR plates were processed by the reciprocating torsion to obtain the torsion deformed samples at a constant rate of 2 rpm,as shown in Fig.1.The rolling direction is parallel to the torsion axis.Twisted AR and PR plates are called as ART and PRT samples,respectively.The detailed torsion way can be found in a previous report [26].Reciprocating torsion(back and forth once at the 108°) was selected to completely restore the shape of sample (see Fig.1).

Fig.1.Schematic diagram of reciprocating torsion.

Mechanical properties along the RD were tested to investigate the yield asymmetry.The dog-bone-shaped torsion samples were employed as tension samples.The rectangular prism samples (5mm × 5mm × 5mm) were cut for the compression test.The Lishi test machine (LD26.105) was used to carry out the mechanical testes at a constant strain rate of 1 × 10-3s-1.Each set of experiments was repeated three times to obtain convincing results.The microstructure,texture and twinning behavior were characterized in detail using electron backscatter diffraction (EBSD,Oxford Instruments NordlysMax3 equipped in a JEOL 7800F FEG-SEM).The EBSD samples were prepared by mechanical polishing to 2000-grit SiC paper,followed by electro-polishing for 60 s at 20 V using the AC-II electrolyte.Based on EBSD data,some figures and maps related with orientation were obtained.The basal pole figure was used to investigate the orientation of parent grains and twins.The IPF (inverse pole figure) map was utilized to observe the features of grains with different orientations.The GB (grain boundaries) map was obtained to analyze the evolution of grain boundaries and twin boundaries.KAM (Kernel average misorientation) value was counted to estimate the distribution of dislocations.KAM cartography represents the mean angle between the lattice orientation of each pixel and those of its eight nearest neighbors(misorientations below 5°are included in the calculation of KAM).Based on EBSD data,the area fraction of twins and the length of twin boundaries pre area can be also calculated by a method described previously [26].

3.Results and discussion

3.1. Twinning behavior during reciprocating torsion

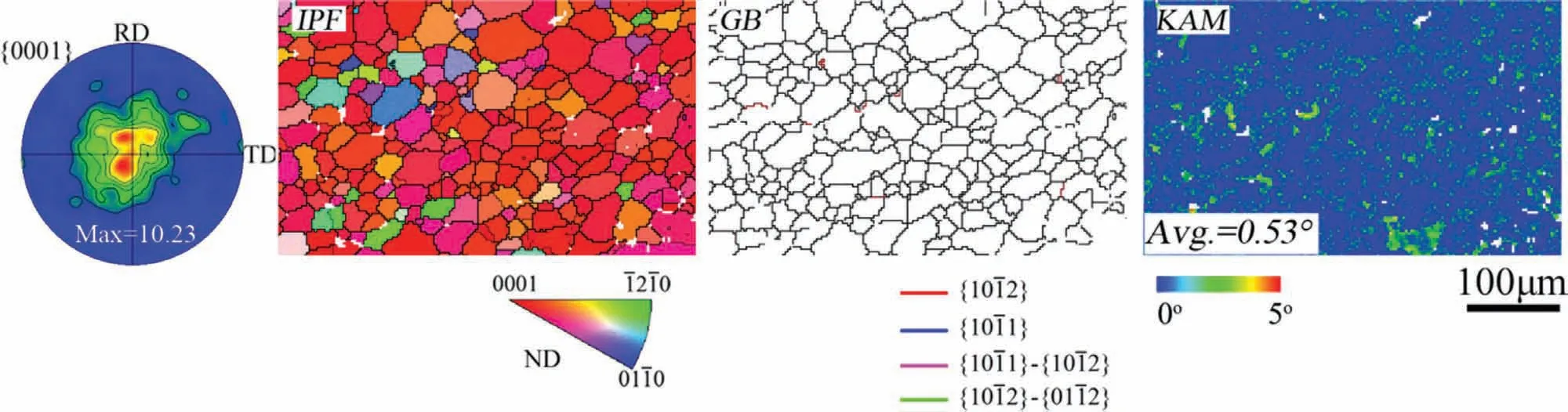

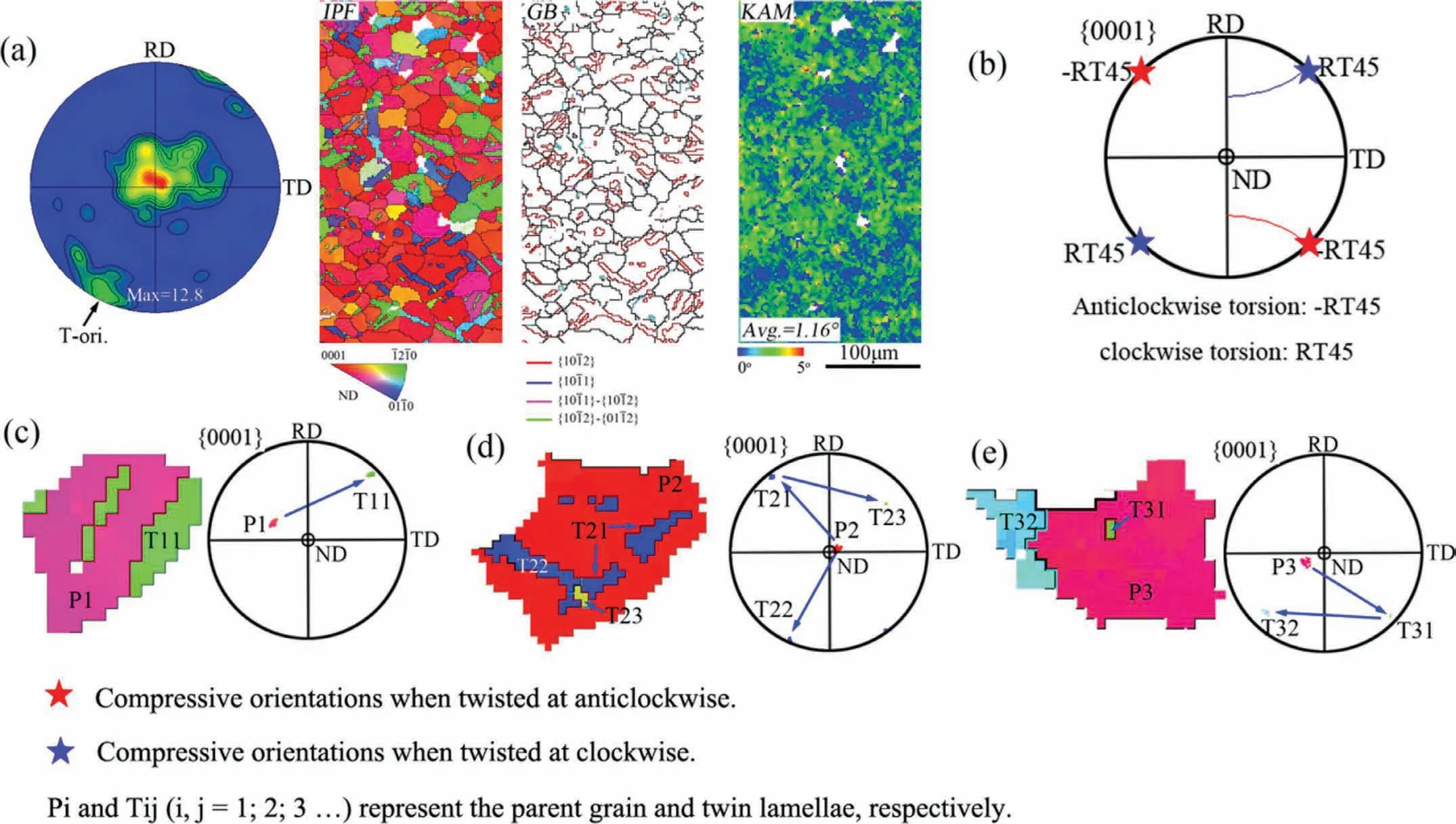

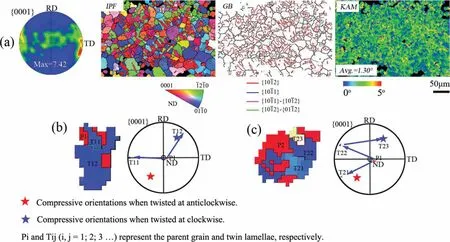

Fig.2 exhibits the basal pole figure and EBSD maps of AR sample.It exhibits a recrystallized microstructure and basal texture (c-axis//ND texture).The average grain size was measured as ∼30 μm for AR sample.Moreover,AR sample contains little twins and a low KAM value (0.53°).

Fig.2.EBSD maps and {0001} pole figure of AR samples.

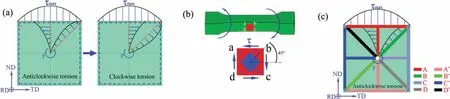

Reciprocating torsion is carried out to process the AZ31 bar with square section.Based on the report from Ref.[27],Fig.3 draws the state of shear stress on the TD-ND plane of twisted sample (i.e.cross-section) during reciprocating torsion.The direction and amplitude of shear stress exhibit uneven distribution in the TD-ND plane of twisted sample (see Fig.3a).The direction of torsional shear stress exhibits a continuous change on the cross-section.Fig.3b shows the simple shear and its equivalent normal stress state.The equivalent normal stress is a biaxial stress which has a compressive stress (σ1) at 45° to the shear and a tensile stress (σ3) normal to the compressive stress.It indicates that the angle betweenσ1(orσ3) and TD (or ND) direction shows a continuous change from 45° to 90° in the cross section [26].Based on this,Fig.3c marks some typical regions in the TD-ND plane of the twisted bar.Reciprocating torsion reverses the shear direction,while cannot change the angle between equivalent normal stress and the TD (or ND) [26].It is reported that twinning behavior during deformation largely relies on the angle between c-axis and normal stress.It infers that different regions might exhibit various twinning behavior.

Fig.3.(a) Distribution of shear stress in the TD-ND plane of rolled square bar subjected to reciprocating torsion along the RD,(b) simple shear and its equivalent normal stresses,(c) representative regions with various stress directions in the TD-ND plane of twisted samples.

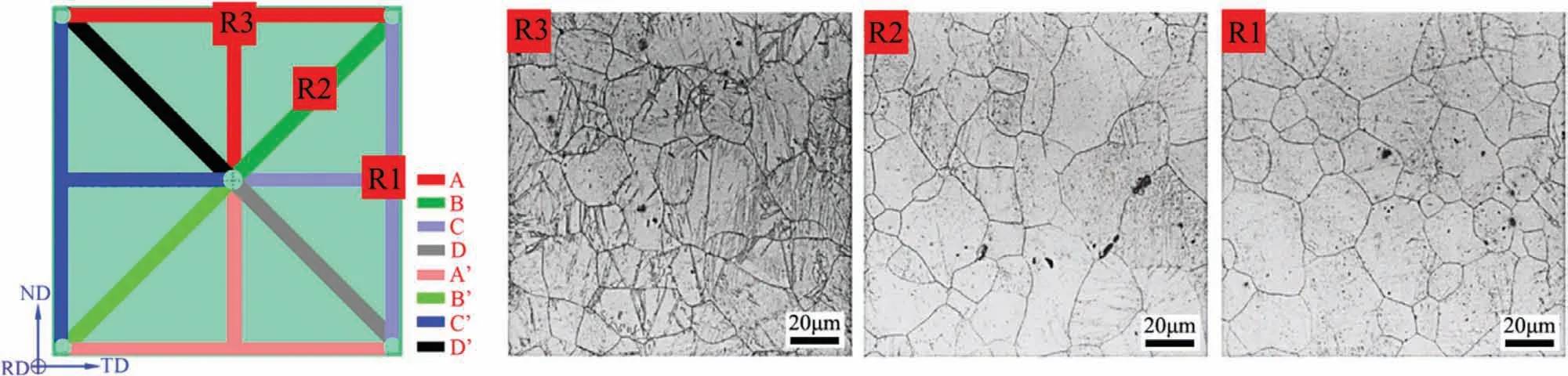

The position with maximum shear stress in each typical region (R1 in region C,R2 in region B and R3 in region A)was selected to investigate the microstructure of ART sample.The optical metallographic (OM) of typical positions are shown in Fig.4.For ART sample,the position R3 in region A contains profuse twins,but the position R2 in region B and R1 in region C have a very low amount of twins.The position R3 in ART sample was further analyzed by EBSD to reveal the twinning behavior during reciprocating torsion,as shown in Fig.5a.The twins via reciprocating torsion are characterized as {10–12} twins,which generate twin-texture(see T-ori.in pole figure).In fact,the effect of reciprocating torsion on twinning behavior of AZ31 bar with c-axis//ND texture has been revealed [26].The twin variants selection under torsion follows the Schmid factor (SF) law.It results in that the c-axis of most {10–12} twins generated during torsion favorably gathers at the orientation of the equivalent compressive stress.Fig.5b marks the orientations of compressive axial in basal pole figures for the region A under torsion.The compressive orientations during first-pass torsion and second-pass torsion were marked as red pentagram and blue pentagram,respectively.It is found that the orientation of twin-texture is close to the c-axis//RT45 orientation,i.e.,that c-axis of most twins in the position R3 of ART sample concentrates in the compressive orientation of second-pass torsion.This is consistent with the results reported earlier [26].In EBSD map,primary {10–12} twins with the close orientation with c-axis//RT45 can be seen everywhere (e.g.T11 and T22 in Fig.5c).According to SF law,they are generated during second-pass torsion.A small amount of twins whose c-axes are close to the-RT45 orientation are also detected(see Fig.5d,e).They are usually thin primary twins (e.g.T21 and T31) or have been re-twinned.And the orientation of{10–12}-{10–12} twins with them (T21–T23 and T31–T32)is close to the c-axis//RT45 texture.It is considered that the twins with c-axis//-RT45 are from the first-pass torsion and are easily de-twinned or re-twinned during second-pass torsion due to the reversal of the stress direction [26,28–30].Therefore,the twin-texture with c-axis//RT45 mainly comes from the primary twins and {10–12}-{10–12} twins which are generated during second-pass torsion.

Fig.4.Typical positions in the cross-section and corresponding OM images in ART sample.

Fig.5.(a) EBSD maps and {0001} pole figure of the position R3 in ART sample;(b) the orientation of equivalent normal stress in basal pole figure in this region during reciprocating torsion.(c)-(e) Some typical grains in the region and corresponding orientations.

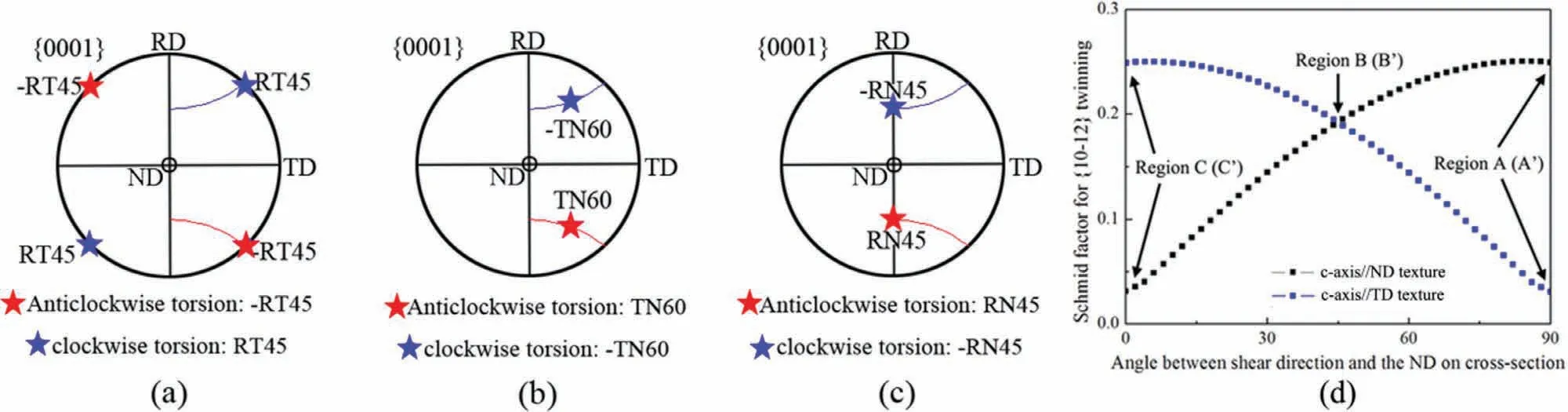

It is confirmed that {10–12} twins can be introduced in rolled AZ31 bar by reciprocating torsion.However,only limited regions are favorable for {10–12} twinning.It might be ascribed to the continuous change in the direction of normal stress on the TD-ND plane.Fig.6a–c shows the orientation of normal stress in three typical regions under torsion.According to a previous report [26],the SF of {10–12} twinning under simple shear is calculated and is plotted as the function of the angle between shear direction and the ND (see Fig.6d).It shows that,for c-axis//ND texture,from region A(or A’) to region C (or C’),the SF tends to decrease.It may be the reason why only limited regions in ART sample can generate profuse twins during torsion.

Fig.6.The orientation of equivalent compression stress in the representative regions under reciprocating torsion.(a) Region A;(b) region B,(c) region C.(d) SF of {10–12} twinning in various regions under reciprocating torsion.

3.2. Twinning behavior during pre-side rolling and subsequent reciprocating torsion

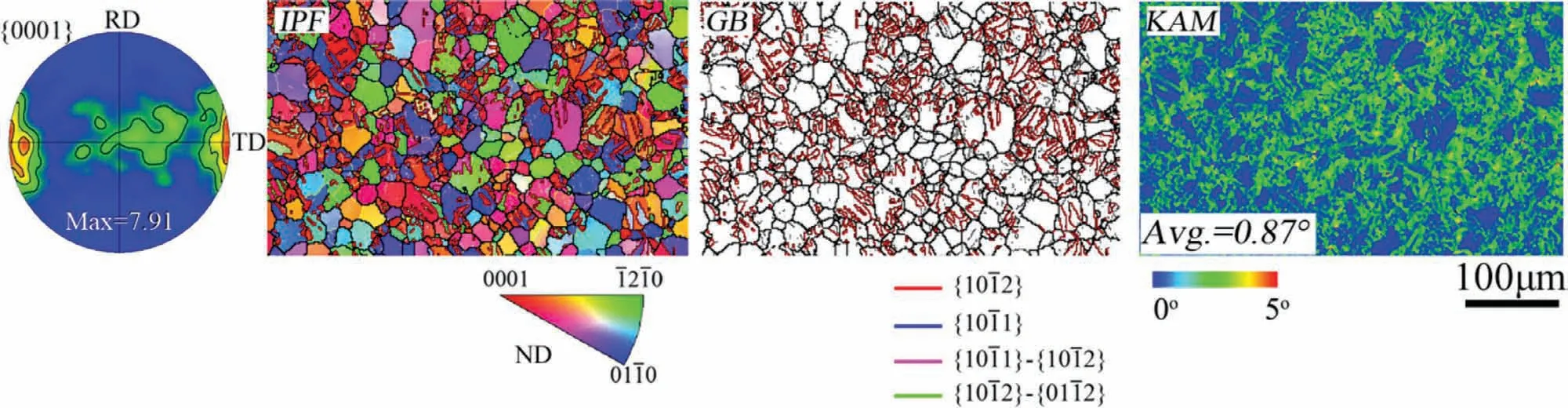

Fig.6 indicates that the twinning behavior largely depends on the angle between shear direction and c-axis of texture.Fig.3a shows that shear direction exhibits a continuous change in the TD-ND plane.Thus,if multiple texture components exit in the rolled bar,it is expected that more regions might be favorable for {10–12} twinning.Pre-side rolling along the TD can be an effective way to fabricate the rolled bar with dual texture components [19].Fig.7 shows the EBSD data of a pre-side-rolled AZ31 bar (PR sample).It indicates that two texture components can be observed,i.e.,c-axis//ND texture and c-axis//TD texture.In EBSD maps,mass {10–12} twins can be found and the area fraction of twins is ∼56%.The new c-axis//TD texture component can be ascribed to the lattice rotation of ∼86.3° in the twinned regions [31].Formation of mass twins leads to a remarkable reduction in the intensity of basal texture in PR sample.The SF of {10–12} twinning under torsion is also been calculated for initial c-axis//TD texture and shown in Fig.6d.It indicates that single orientation leads to a large difference in SF of {10–12} twinning among various regions.However,if the sample contains both c-axis//TD and c-axis//ND orientations at the same time,the SF of twinning are relatively high across the cross-section.It indicates that pre-siderolling may help increase the activation of {10–12} twins in AZ31 bar during torsion.Moreover,the interaction between initial twins via pre-side rolling and new twins via torsion may further increase the hardening effect of twin-boundaries.The microstructure evolutions in the typical positions (position R1 of region C,position R2 of region B and position R3 of region A) of PRT sample are further analyzed by EBSD.

Fig.7.EBSD maps and {0001} pole figure of PR samples.

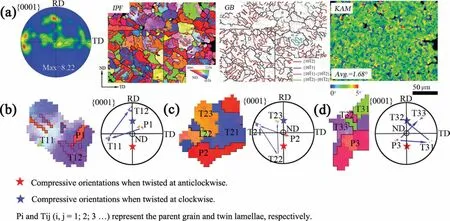

Fig.8 shows EBSD data of the position R3 in PRT sample.It is found that profuse cross twins can be found in parent grains.Basal pole figure in Fig.8a indicates that there are two main texture components in the position R3,i.e.,caxis//TD texture and c-axis//RT45° texture.Like ART sample(see Fig.5),the c-axis//RT45 texture is the orientation of new twins generated during reciprocating torsion.Three typical grains are shown in Fig.8b–d.Most grains contain coarse primary {10–12} twins with c-axis//RT45 texture (see T12 and T22).Moreover,{10–12}-{10–12} twins with c-axis//RT45 texture(see T23)are also observed in ART sample.The twinning behavior in parent grains in the PR sample is similar to that in the AR sample.The initial twins with c-axis//TD texture might also be re-twinned to form secondary extension twins(see T13 and T32).However,their amount is very small,so the secondary twins have little effect on the main texture components.Therefore,for region A,reciprocating torsion mainly introduces new {10–12} twins and {10–12}-{10–12}twins with c-axis//RT45 in parent grains.According to the Fig.6d,for region A,parent grains have a high SF for {10–12}twinning under torsion,but the twins with c-axis//TD texture are not conducive to the activation of {10–12} twinning during torsion.Thus,after reciprocating torsion,c-axis//TD texture was retained and a new c-axis//RT45 texture was generated in the position R3 of PRT sample.For region R3,new twins via reciprocating torsion mainly consume parent grains with c-axis//ND.Thus,after reciprocating torsion,the intensity of basal texture is weakened in the position R3 of PRT sample.

Fig.8.(a) EBSD maps and {0001} pole figure of the position R3 in region A of PRT sample and (b)-(d) some typical grains in the region and corresponding orientations.

Fig.9 shows EBSD data of the position R1 in PRT sample.It is found that a new texture component whose c-axis is close to the-RN45 orientation which is the compressive direction during second-pass torsion (see Fig.6c).It is hard to find the primary twins with c-axis//–RN45 texture in parent grains.The typical grains (in Fig.9b–d) indicate that the new texture is mainly from{10–12}-{10–12}secondary twins(see T12 and T32) or {10–12}-{10–12}-{10–12} tertiary twins(see T23) in the primary twins with c-axis//TD texture.It confirms that the orientation with c-axis//TD texture is beneficial for {10–12} twinning under torsion in this region.It is consistent with the results of SF in Fig.6d.Moreover,the parent grains with tilt basal texture (e.g.grain P3),{10–12}twinning might be activated under such stress state (e.g.twin T33).However,the number of the twins is relatively low.Retwinning of initial twins will be responsible for the formation of the new texture in the position R1 of PRT sample.Finally,c-axis//ND,c-axis//TD and c-axis//-RN45 can be found in the position R1 in PRT sample.

Fig.9.(a) EBSD maps and {0001} pole figure of the position R1 in region C of PRT sample and (b)-(d) some typical grains in the region and corresponding orientations.

Fig.10 shows EBSD data of the position R2 in PRT sample.Reciprocating torsion does not produce new texture components and remains the initial twin-texture in this region.Two typical grains are shown in Fig.10b and c.According to orientation,it can infer that T11 in grain P1,T22 and T21 in grain P2 are the initial twins via pre-side rolling [9].It indicates that both parent grains and initial twins may also be twinned to form new twins (e.g.T12 and 23).The c-axes of new twins have a close orientation with compressive direction during second-pass torsion.According to Fig.6d,c-axis//ND and c-axis//TD have a close SF value for {10–12} twinning in the position R2 under torsion.However,the relative low SF value may limits activation of twins in this region.Thus,the area fraction of twins in the position R2 of PRT sample (∼62%) is only slightly higher than that in PR sample(∼56%).

Fig.10.(a) EBSD maps and {0001} pole figure of the position R2 in region B of PRT sample and (b) and (c) some typical grains in the region and corresponding orientations.

3.3. Distribution of torsion deformed microstructure

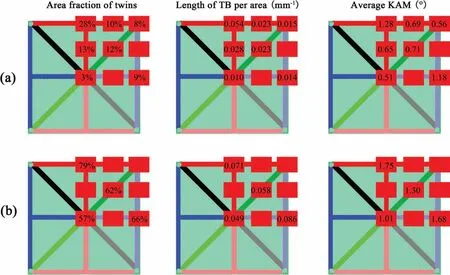

It has been reported that reciprocating torsion has little effect on orientation of parent grains [26,32].But it can introduce {10–12} twins in the matrix to generate twin-texture.The c-axis of twin-texture via reciprocating torsion mainly locates at an angle of 45° to the RD.Moreover,profuse twin boundaries (TBs) and dislocations can also be generated during torsion.In order to investigate the distribution of deformed microstructure,the length of TBs per area (Ltwin),area fraction of twins (ftwin) and average KAM value can be calculated.Average KAM value is usually used to evaluate dislocation density.Their distributions in the TD-ND plane of bar are shown in Fig.11.It is interesting to compare the microstructure features of ART and PRT samples in Fig.11.The data of ART sample is from the Ref.[26].According to the results in Figs.2 and 7,the average KAM values are 0.53° and 0.87° for AR and PR samples,respectively,and theLtwinare 0.002 mm-1and 0.052 mm-1for AR and PR samples,respectively.Fig.11 indicates that reciprocating torsion increases the KAM value and theLtwinacross the entire cross section.And combined use of pre-side rolling and reciprocating torsion can further increase these values.Moreover,Fig.11 also indicates that theftwintheLtwinare related to both the strain and the direction of stress.

Fig.11.Distribution of {10–12} twins and average KAM on the TD-ND plane of (a) ART sample [26] and (b) PRT sample.

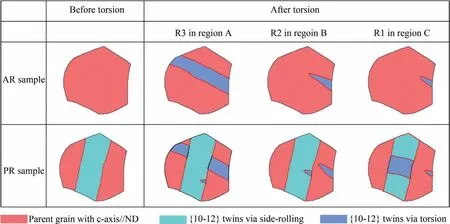

Fig.3a shows that the positions R3 and R1 bear the same shear stress.However,for ART sample,bothftwinandLtwinin the position R3 are far higher than those in the position R1 (see Fig.11a).The distribution offtwinin PRT sample is similar to that in ART sample,but the distribution ofLtwinin PRT sample is completely different to that in ART sample.For PRT sample,both the position R1 and position R3 contain highLtwin.Based on the results of EBSD,schematic diagram of twinning behavior during torsion deformation is drawn and shown in Fig.12.It indicates that pre-side-rolling promotes formation of new twin boundaries during reciprocating torsion.For region A,new-twins in parent grains with caxis//ND texture can be easily activated during torsion.Thus,torsion deformation can cause the increase inftwinandLtwinin region A.For region C,re-twinning in initial twins with c-axis//TD texture dominates the twinning process during torsion.Thus,torsion deformation exhibits little influence on theftwin,but remarkably increases theLtwin.Finally,combined use of pre-side-rolling and reciprocating torsion generates hybrid twins structure (multiple twin variants or high-order twins) to largely increase theLtwin.

Fig.12.Schematic diagram of twinning behavior during torsional deformation in AR sample and PR sample.The red line represents {10–12} twin boundary.

3.4. Mechanical properties

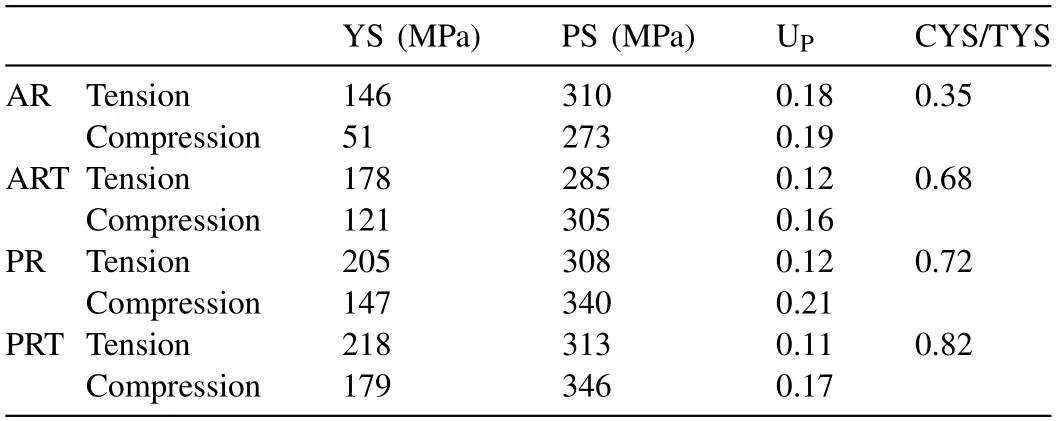

Fig.13 shows the true stress and true strain curves when loading along the RD.The yield stress (YS),peak stress (PS)and the tensile/compressive plasticity (Up) are obtained from the curves and listed in Table 1.The Upis the plastic strain corresponding to peak stress.The extent of yield asymmetry is expressed by the ratio of compressive yield strength to tensile yield strength (CYS/TYS).For AR sample,tensile yield strength (146 MPa) is much higher than compressive yield strength (51 MPa).Clearly,AR sample exhibits severe yield asymmetry(CYS/TYS=0.35).Compression deformation exhibits a low yield strength and s-shaped flow curve,which is a typical deformation characterization dominated by {10–12}twinning [9].Both side-rolling and torsion can increase yield strength and reduce yield asymmetry.The CYS/TYS ratio is raised to 0.72 for the PR sample and to 0.68 for the ART sample,respectively,as shown in Table 1.Moreover,combining pre-side rolling and torsion can further enhance the yield strength and reduce yield asymmetry.For PRT sample,yield strength is enhanced to 218 MPa for tension and 179 MPa for compression,respectively,and the CYS/TYS is raised to 0.82.Moreover,it is also found that PRT sample has a comparable plasticity with ART sample and PR sample.

Table 1Tensile and compressive properties along RD of samples with different states.

Fig.13.Typical true stress-strain curve of samples with different states: (a) tensile curves and (b) compressive curves.

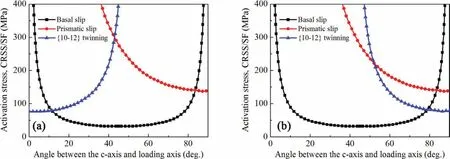

The large plastic anisotropy in wrought Mg alloys can be attributed to the large difference in CRSSs among various deformation modes [13].In order to visually analyze the effects of texture on dominant deformation mode and yield strength,the activation stresses (CRSS/SF) of various deformation modes as the functions of loading direction are plotted in Fig.14.In this calculation,the CRSS values of slips and twinning are from the Ref.[33,34].For AR sample and PT sample,the c-axis of texture is located at ∼90° from the RD.Thus,the dominant deformation mode is {10–12} twinning and prismatic slip for compression and tension along the RD,respectively.The large yield asymmetry in AR sample can be attributed to the fact that CRSS of prismatic slip is far higher than that of {10–12} twinning [35].Previous work found that initial TBs can generate refinement hardening effect [36].Barnett et al.[37] have reported that refining grains can harden twinning more than slip.Thus,the twins generated during pre-side-rolling increase the yield strength and reduce the yield asymmetry.

Fig.14.Activation stress of various deformation modes under: (a) tension and (b) compression.

Reciprocating torsion can also introduce TBs and generate a twin-texture whose c-axis is usually located at the∼45° from the RD,as shown in Fig.5.Such texture is favorable for basal slip when loading along the RD,as shown in Fig.14.Thus,both the TBs and the twin-texture via torsion can contribute to the reduction of yield asymmetry.It is similar the effect of torsion on yield asymmetry of extruded AZ31 bar [24].However,during torsion,the region that can be twinned in AR sample is very limited,as shown in Fig.12.Thus,for ART sample,the degree of improvement in strength and yield asymmetry is limited.As discussed above,side-rolling can promote more regions to be twinned during reciprocating torsion.Moreover,combining side-rolling and torsion generates hybrid twins on entire cross-section of bar,as shown in Fig.12.Hybrid twins can largely increase theLtwin(see Fig.12).Thus,combining side-rolling and torsion further reduces yield asymmetry.It has been reported that multi-directional compression can also generate hybrid twin structures,resulting in the reduction in yield asymmetry.Therefore,it is also interesting to compare the present result with the previous reports.Xin et al.[23] reported that alternate compression along the TD (2.5%) and the RD (2.5%)enhanced compressive yield strength,but largely reduced the tensile yield strength along the RD due to activity of detwinning.Thus,it cannot largely improve the yield asymmetry along the RD.Xu et al.[4] reported that multidirectional precompression along the RD,TD and ND greatly increased the CYS/TYS along the RD from 0.4 to 0.81.Clearly,combined use of side-rolling and torsion can generate similar CYS/TYS value.However,combined use of side-rolling and torsion is more suitable for plates or rods with high aspect ratio than multi-directional compression.

Both side-rolling and reciprocating torsion exhibit little influence on compressive plasticity,but slightly reduce the tensile ductility (by ∼6%),as listed in Table 1.However,further reciprocating torsion cannot reduce the plasticity of PT sample.Finally,PRT sample exhibits higher strength and considerable plasticity comparing with ART sample and PR sample.The highLtwincan contribute to high refinement hardening effect in PRT sample.Moreover,some dislocations can also be introduced during cold deformation to generate dislocation hardening on slip and twinning,as shown in Fig.11.Thus,the increase in yield strength in PRT sample can be ascribed to dislocation hardening and hardening of TBs.Figs.8–10 indicate that the c-axis of twin-texture via torsion is usually located at ∼45° from the RD.Such twin-orientation will enhance the contribution of basal slip to plastic deformation along the RD.It might the reason why PRT sample remains good plasticity [13,38].

4.Conclusions

(1) For AR sample with basal texture,only limited regions is favorable for {10–12} twinning during torsion.Siderolling can split the basal texture to form dual texture components,i.e.c-axis//ND texture and c-axis//TD texture.Such dual texture components increase the regions which are favorable for twinning during torsion.

(2) Combining side-rolling and reciprocating torsion generates hybrid twins structure (multiple twin variants and high-order twins),resulting in a remarkably increase in the length of TBs per area.The c-axes of new {10-12}twins via torsion are mainly located at 45° from the RD.

(3) Both side-rolling and reciprocating torsion can reduce yield asymmetry.Combined use of side-rolling and reciprocating torsion can further reduce yield asymmetry.Moreover,PRT sample exhibits higher yield strength and comparable plasticity compared with ART and PR samples.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

This work was supported by the National Natural Science Foundation of China,No.51601154.

Journal of Magnesium and Alloys2023年6期

Journal of Magnesium and Alloys2023年6期

- Journal of Magnesium and Alloys的其它文章

- Ameliorating the re/dehydrogenation behaviour of MgH2 by zinc titanate addition

- Inhibiting effect of I-phase formation on the plastic instability of the duplex structured Mg-8Li-6Zn-1.2Y (in wt.%) alloy

- PEO coating on Mg-Ag alloy: The incorporation and release of Ag species

- Underlying mechanisms of variation in yield asymmetry and strain hardening behavior of extruded pure Mg with Gd addition

- Edge crack damage analysis of AZ31 magnesium alloy hot-rolled plate improved by vertical roll pre-rolling

- High sintering and dielectric performance: The improved (Mg,Zn)3B2O6 ceramics with the help of the DFT calculation