中国服装行业上市企业数字化转型评价

郑通 张立杰

摘要:为了研究中国服装企业数字化转型的主要影响因素和转型程度,文章以中国服装行业上市企业为研究对象,从技术变革能力、组织变革能力和业务变革能力3个维度建立了服装行业上市企业数字化转型评价指标体系,并运用熵权—TOPSIS评价法对中国24家服装行业上市企业2018—2021年的企业面板数据进行了分析。权重分析结果表明,业务变革能力权重为0.365,对中国服装行业上市企业数字化转型的影响最大。数字化转型指数表明,超过50%的样本企业数字化程度有所提升;2018—2021年的数字化指数平均值分别为0.288、0.292、0.333和0.336,整体取得一定进展,但程度较低。最后基于企业层面,分析了数字化转型程度低的原因并给出相关建议。

关键词:数字化转型;服装企业;熵权—TOPSIS;影响因素;权重;转型指数

中图分类号:TS941.1; F407.86 文献标志码:A 文章编号: 10017003(2023)090001

引用页码:091101 DOI: 10.3969/j.issn.1001-7003.2023.09.001(篇序)

随着数字化浪潮席卷全球,以大数据、互联网、人工智能等新兴数字技术驱动的“数字经济”成为研究热点,传统制造型企业数字化转型成为未来发展趋势[1]。服装行业作为传统制造业之一,在中国经济发展中占有重要地位。2016年G20峰会通过《二十国集团数字经济发展与合作倡议》以来,中国服装企业数字化相关研究迅速增加,研究内容主要集中在对数字技术应用介绍[2-3]、转型路径分析[4]等,缺乏基于企业层面的转型效果评价。

TOPSIS法又称为优劣解距离法,本质上是一种综合排序方法,具有对数据信息利用充分、计算简单、精确反映评价对象与最优目标的接近程度等优点,常被用于解决多层次、多指标的企业转型评价[5]。熵权法是一种指标权重的客观赋权方法,熵值的大小反映了指标数据信息量,权重计算完全按照指标间的数值离散程度来设置,具有极强的客观性和适应性[6]。将熵权法与TOPSIS评价法结合,适用于本文构建的多层次、多指标的服装企业数字化转型指标体系,并且评价结果客观,逻辑清晰。

综上所述,本文采用熵权法对指标進行赋权,分析各个指标在数字化转型过程中的重要程度;将权重值带入TOPSIS评价法,计算各个服装企业数字化转型指数并进行评价。研究结果可为中国服装企业顺利进行数字化转型提供一定参考。

1 熵权—TOPSIS评价法和数据来源

1.1 熵权—TOPSIS评价法

综合运用熵权—TOPSIS评价法,可以克服TOPSIS方法无法反映变量之间相关性和重要程度的缺点,通过无量纲化处理也可以有效避免逆序问题[7]。熵权—TOPSIS评价法的计算原理如下:

1) 正向化数据。本文所采集的指标数据中,组织管理层级需要进行正向化处理,其他指标为正向数据,不需要进行正向化处理。

2) 构建决策矩阵。有n个样本企业,m个可量化评价指标,用极差变换法对指标数据进行无量纲化处理,矩阵中每一个元素x*ij为:

4) 计算概率矩阵P。概率矩阵中每个元素pij计算公式为:

式中:j=1,2,…,m。

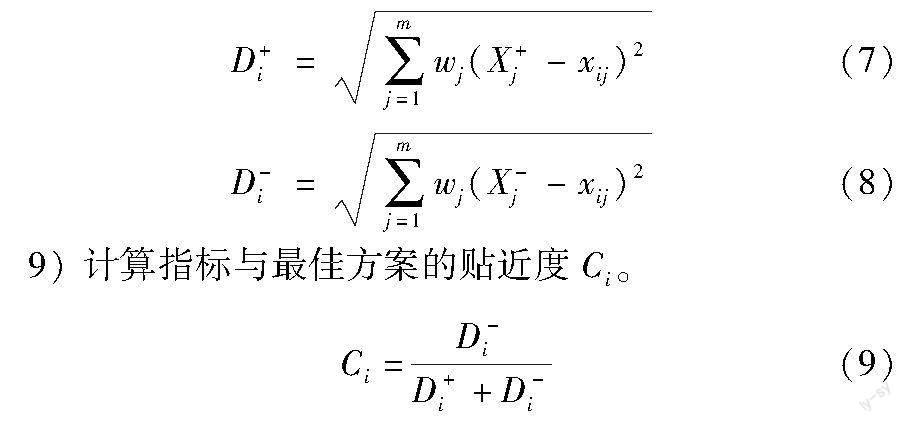

8) 基于欧氏距离,计算各指标与最优解和最劣解向量之间的距离。正理想解为X+0=(x+0(1),x+0(2),…,x+0(n)),负理想解为X-0=(x-0(1),x-0(2),…,x-0(n))。

1.2 数据来源

选择中国A股服装行业上市企业,均为中国自主品牌服装企业。通过上海证券交易所和深圳证券交易所,查询到属于纺织服装业的上市企业41家。筛选出以多品种服装服饰产品为主营业务,服装服饰营业收入大于企业总营业收入50%的上市企业,时间跨度为2018—2021年,剔除数据不连贯,没有“数字化”“智能化”等相关内容披露的企业,最终找到符合条件的上市企业24家。数据主要来源于上海证券交易所、深圳证券交易所、企知道专利数据库、国泰安金融数据库等,同一企业不同年份的少数缺失数据采用移动平均法补齐。

2 实证分析

2.1 指标体系

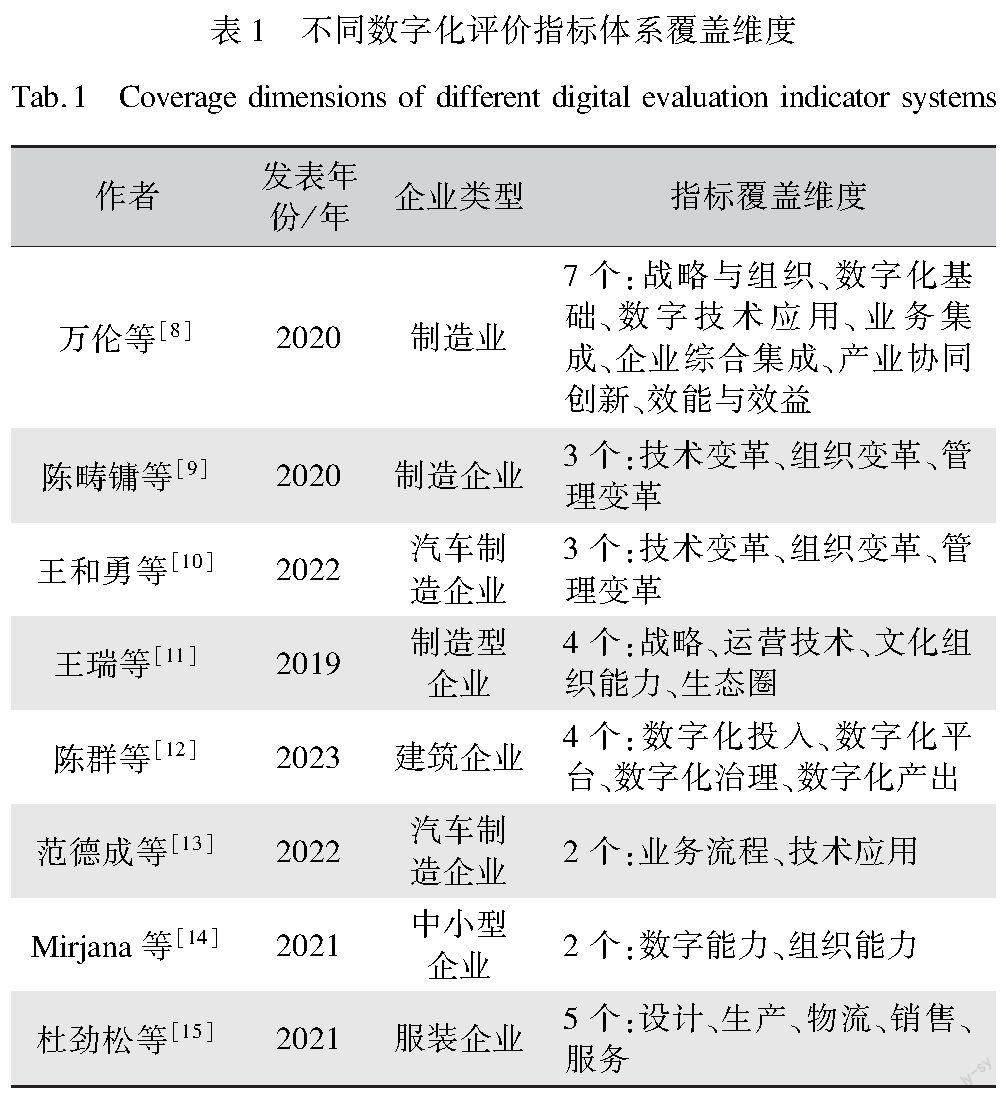

服装企业数字化转型受到多个层次中多种因素的影响,为全面了解服装企业数字化转型中的影响因素,本文对相关的企业数字化评价文献进行梳理。部分具有代表性的文献作者及指标覆盖维度如表1所示。

通过仔细阅读企业数字化评价相关文献发现,指标覆盖维度以3~4个居多,其中数字技术和组织环境是指标体系的研究重点,其他维度由于研究对象不同而各有侧重。不同行业之间的数字化转型具有异质性,本文研究对象为中国服装行业上市企业,参考杜劲松等[15]、舒伟[16]、陈雁[17]等学者对服装企业数字化的相关研究,认为业务流程数字化是服装企业数字化转型的重点之一。因此,从技术变革能力、组织变革能力和业务变革能力3个方面构建数字化转型评价指标体系。为最大程度保证评价的客观性,本文所选具体指标均可量化。

2.1.1 技术变革能力

数字技术是企业数字化转型的关键驱动因素,越来越多的学者认可其在企业数字化转型中的重要地位[18]。数字技术变革离不开数字化软硬件基础设施,数字化基础设施对企业转型升级的积极效应得到了学术界的广泛认可[19]。数字化基础设施带来的积极效应推动企业研发创新,主要体现在研发投入强度和创新成果产出[20]。因此,技术变革能力包括数字化基础设施建设和数字化研发2个二级指标。

2.1.2 组织变革能力

数字技术帮助服装企业员工更加有效地进行沟通和获取信息,提高数字化技能与管理能力,拉动企业对数字化人才的需求,迫使服装企业在数字化转型过程中利用数字技术进行组织结构变革。数字技术的应用帮助企业转型成为高新技术企业、减少人员冗余,促使企业管理层级扁平化;数字化背景高管可以明确转型方向、合理分配资源等。数字化人才是企业数字化转型不可或缺的因素,体现在人才的培养、高学历员工和研发人员占比。企业通过优化组织结构、引进和培养数字化人才促进企业数字化转型,从而提高企业的运营效率和效益。因此,组织变革能力包括组织结构转型和数字化人才建设2个二级指标。

2.1.3 业务变革能力

服装行业既属于制造业,又属于零售行业,服装产品容易受到人和市场的影响,数字系统应贯穿服装设计、生产、物流、营销、服务等环节,满足消费者对服装越来越偏向个性化、多样化的需求[21]。业务核心环节之间系统集成可以提高企业对数据处理的效率和数据的自动流动水平。因此,业务变革能力包括设计、生产、物流、营销、服务和端到端集成6个二级指标。

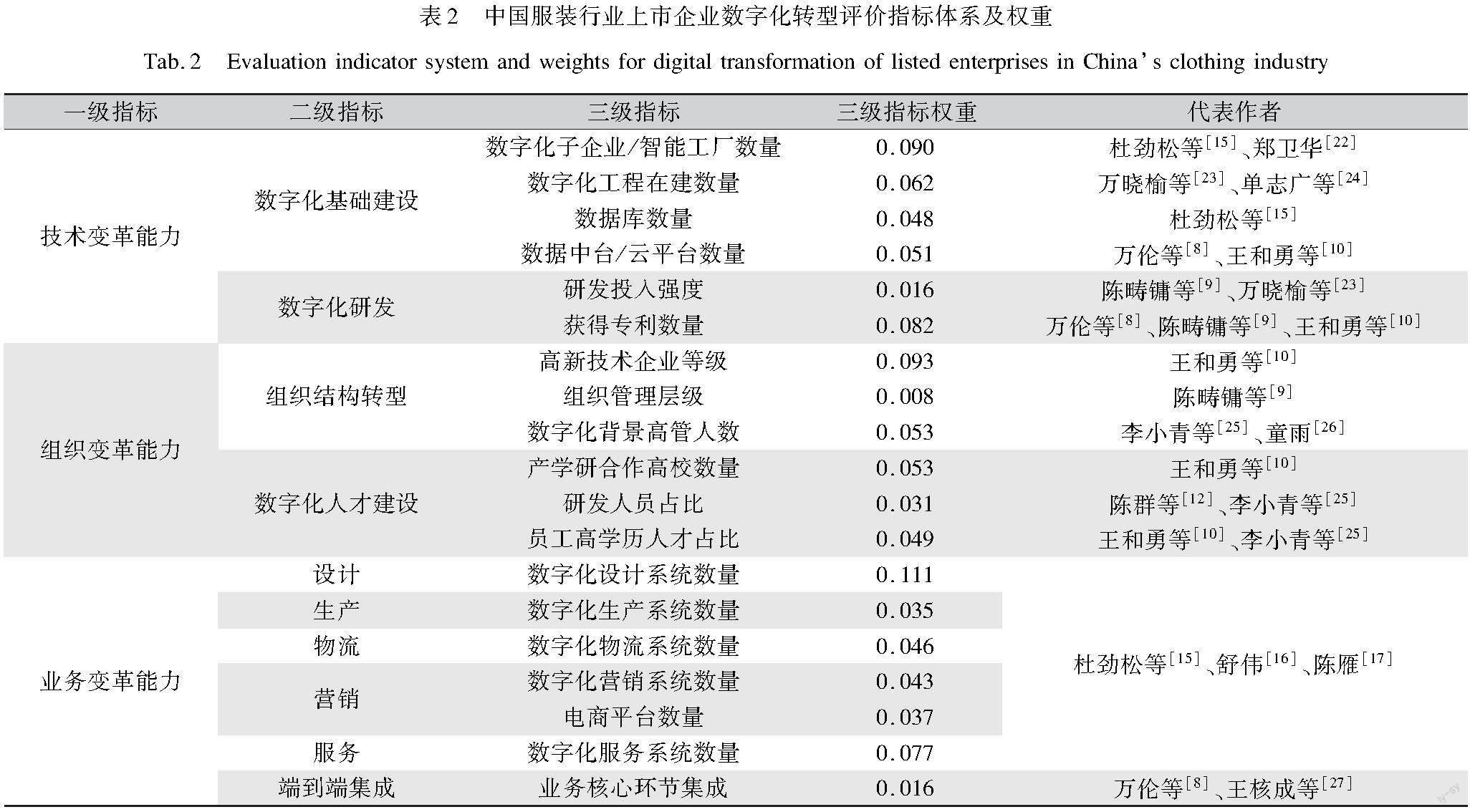

本文借鉴现有学者的数字化转型研究,遵循科学性、客观性、层次性等原则,构建中国服装行业上市企业数字化转型评价指标体系,并使用熵权法对三级指标进行赋权,如表2所示。

2.2 指标权重分析

一级指标和二级指标的权重由三级指标的权重加和得到。业务变革能力在一级指标中权重占比最大,为0.365。服装企业需要研发和引进新的数字系统,促使各个业务环节之间有机连接,提高企业的运营效率,从而应对快速变化的市场需求。

在二级指标中,权重在前3位的是数字化基础建设、组织结构转型和数字化人才建设,分别为0.251、0.154和0.133。这3个二级指标所包含的三级指标较多,企业应均衡发展每一个具体的影响因素。业务变革能力的6个二级指标中,数字化设計系统数量所占权重为0.111,在二级指标中排第4位,其他5个二级指标权重均没有达到0.100,端到端集成所占权重为0.016,说明不同环节之间数字化发展不平衡,数据共享和系统集成程度低,没有完全打破“信息孤岛”,服装企业更应该关注业务流程总体的提升。

三级指标中,服装数字化设计系统数量在业务流程5个核心环节中权重占比最高,也是三级指标中所占权重最大的项。可以看出当下中国服装企业在数字化转型过程中对服装设计更为重视,服装设计所用到的数字化技术,如服装颜色自动搭配、风格迁移、3D测量、新的工艺设计等成为当下中国服装企业数字化转型的研究重点。数字化生产系统数量所占权

重较小,为0.035,这与服装的特点相关,服装种类和样式繁多,大型服装企业在服装制作过程中都采用“自主生产+劳务外包”的模式,企业自身生产系统和设备的数字化程度较低,服装制造过程仍然严重依赖传统手工作业。数字化物流系统数量所占权重为0.046,中国服装企业的物流环节主要使用RFID、自动识别等系统实现仓储智能化,而运输业务会外包给物流企业,造成该环节数字化系统数量相对较少。营销阶段有2个三级指标,数字化营销系统数量和电商平台数量。大多数服装行业上市企业都有成熟的精准营销,部分企业与京东合作,开发无界营销系统等。企业在天猫、京东等电商平台上有自己的店铺,并通过抖音、小红书等流量平台进行品牌营销。数字化服务系统数量的权重为0.077,高于生产和物流2个环节所占比重,多数服装企业意识到企业数字化转型是以消费者需求为核心,为提高服务质量,从传统服务转向数字化服务,开始布局智慧店铺、3D虚拟试衣、个性化定制系统、智能会员管理系统等新型数字化服务系统,数字化服务为服装企业与消费者之间增添了互动,提升了消费者的购物体验。

2.3 转型指数分析

将权重值代入TOPSIS评价法,计算2018—2021年样本企业数字化转型指数,如表3所示。表3按照各企业在2018—2021年数字化转型指数平均值进行降序排序。

从表3可以看到,2018—2021年数字化转型指数在波动中上升的企业有11家,森马服饰的转型指数连续4年最高,均在0.460以上,2020年开始迅速增加,2021年转型指数达到0.683。样本企业在2018—2021年平均转型指数中,排名在前3位的为森马服饰、红豆实业和安正时尚,平均值均大于0.400,这3家企业的研发投入强度、研发人员占比、员工高学历人才占比等处于领先地位,业务流程中数字系统使用更为全面。2018—2021年,数字化转型指数持续上升的有6家企业,占比25.00%;数字化转型进程较为稳定的有3家企业,占比1250%;转型指数在波动中处于下降的有4家企业,占比1667%。由此看出,中国大多数服装行业上市企业数字化转型都取得了进步。

2.4 数字化转型管理启示

样本企业2018—2021年当年的数字化转型平均指数由0.288逐渐升高至0.336,可以看出中国服装企业数字化转型整体正在稳步进行中,但是当年的数字化转型平均指数低于0.400,整体数字化水平较低,结合指标体系分析,得出以下原因和相关建议。

1) 数字化投入有限。数字技术和设备投入花费资金较大,新的数字技术更新迭代迅速,加上企业受到近几年疫情、国际贸易摩擦等影响,企业面临转型失败的风险,对数字化建设投入有限。随着数字化技术日渐成熟,企业应增加投入资金来引进和研发数字技术和设备,必要时向政府数字化相关部门寻求帮助,政府的财政科技支持可以显著提高服装企业数字化转型效率[28]。

2) 组织结构转型能力弱。中国服装企业已经开始注重数字化人才建设,但是员工高学历人才比重较低,24家上市企业均没有超过10%;与高校产学研合作强度不够;对数字化背景高管的重视有待加强,24家上市企业中只有红豆实业一家设有信息化部门。数字化背景高管在企业数字化资源分配、数字化战略制定等方面起到关键作用。人才是企业数字化转型的基石,企业应完善引进和培养数字化人才的相关制度,增设数字化相关部门和数字化高管职位,制定数字化转型路径,最大程度利用企业资源,为数字化转型提速。

3) 业务流程变革困难。中国服装企业已经开始在设计、生产、营销等环节使用新的数字系统,新系统与传统信息系统之间集成困难,数据传输不便,不能很好解决“信息孤岛”问题,数据及新旧系统接口之间缺乏统一标准。企业应重视数据治理,制定数据传输标准;运用人工智能、大数据等相关技术,充分挖掘线上线下数据,完善数据收集、清洗、分析等流程,充分发挥数据的价值。完善数据中台的建设,利用数据中台连接业务流程各个环节,解决数据传输过程中新旧系统难以集成的问题,打破“信息孤岛”,实现信息在消费者和企业之间快速、无障碍传递。

3 结 语

服装企业数字化转型关系到中国服装企业未来发展,本文以中国24家服装行业上市企业2018—2021年面板数据为依据,综合运用熵权—TOPSIS评价法对指标数据进行分析和评价。熵权法计算得出技术变革能力、组织变革能力和业务变革能力3个维度(一级指标)的19个影响因素在数字化转型过程中所占权重;TOPSIS评价法计算得出24家上市企业的数字化转型指数。结果表明,业务变革能力所占权重最高;2018—2021年超过半数的样本企业数字化转型指数得到了提升,但总体水平不高;最后根据指标体系分析其原因并给出了合理建议。

本文主要聚焦于中国服装行业上市企业,囿于数据可得性,未关注中小型服装企业数字化转型。在条件允许的情况下,今后的研究可以将中国中小型服装企业纳入研究范围,在更大范围内收集服装企业的数字化转型数据,以更准确地反映中国服装企业的整体水平。本文构建的指标体系完全客观,未考虑定性指标,之后可以根据服装企业的实际情况,对指标体系进行修改,加入定性指标,从定性和定量两个方面共同衡量企业的数字化水平。

参考文献:

[1]郑琼洁, 姜卫民. 数字经济视域下制造业企业数字化转型研究: 基于企业问卷调查的实证分析[J]. 江苏社会科学, 2022, 320(1): 137-149.

ZHENG Qiongjie, JIANG Weimin. Research on the digital transformation of manufacturing enterprises from the perspective of digital economy: An empirical analysis based on an enterprise questionnaire survey[J]. Jiangsu Social Sciences, 2022, 320(1): 137-149.

[2]张辉, 信晓瑜, 康晓静, 等. 基于服装数字化技术的尼雅“万世如意”锦袍复原[J]. 丝绸, 2021, 58(9): 73-79.

ZHANG Hui, XIN Xiaoyu, KANG Xiaojing, et al. Restoration of “Wan Shi Ru Yi”brocade robe unearthed from Niya relics[J]. Journal of Silk, 2021, 58(9): 73-79.

[3]雷鸽, 李小辉. 数字化服装结构设计技术的研究进展[J]. 纺织学报, 2022, 43(4): 203-209.

LEI Ge, LI Xiaohui. Review of digital pattern-making technology in garment production[J]. Journal of Textile Research, 2022, 43(4): 203-209.

[4]任若安, 陈涵. “十四五”规划下服装企业数字化转型升级路径研究[J]. 毛纺科技, 2022, 50(4): 104-111.

REN Ruo’an, CHEN Han. Research on digital transformation and upgrading path of garment enterprises under the 14th Five-Year Plan[J]. Wool Textile Journal, 2022, 50(4): 104-111.

[5]楊瑾, 王忠伟, 庞燕. 基于熵权TOPSIS法的油茶产业发展绩效评价[J]. 中南林业科技大学学报, 2021, 41(12): 168-177.

YANG Jin, WANG Zhongwei, PANG Yan. Performance evaluation of camellia industry development based on entropy TOPSIS method[J]. Journal of Central South University of Forestry & Technology, 2021, 41(12): 168-177.

[6]张莉, 许君, 马大力, 等. 基于主观评价和熵权—TOPSIS的虚拟试衣软件评价[J]. 毛纺科技, 2022, 50(11): 80-87.

ZHANG Li, XU Jun, MA Dali, et al. Evaluation of virtual fitting software based on subjective evaluation and entropy-TOPSIS[J]. Wool Textile Journal, 2022, 50(11): 80-87.

[7]傅为忠, 储刘平. 长三角一体化视角下制造业高质量发展评价研究: 基于改进的CRITIC-熵权法组合权重的TOPSIS评价模型[J]. 工业技术经济, 2020, 39(9): 145-152.

FU Weizhong, CHU Liuping. Research on the evaluation of high quality development of manufacturing industry from the perspective of integration of the Yangtze River Delta: TOPSIS evaluation model based on improved CRITICAL-Entropy wight method[J]. Journal of Industrial Technological Economics, 2020, 39(9): 145-152.

[8]万伦, 王顺强, 陈希, 等. 制造业数字化转型评价指标体系构建与应用研究[J]. 科技管理研究, 2020, 40(13): 142-148.

WAN Lun, WANG Shunqiang, CHEN Xi, et al. Research on construction and application of evaluation index system for digital transformation of manufacturing[J]. Science and Technology Management Research, 2020, 40(13): 142-148.

[9]陈畴镛, 许敬涵. 制造企业数字化转型能力评价体系及应用[J]. 科技管理研究, 2020, 40(11): 46-51.

CHEN Chouyong, XU Jinghan. Manufacturing enterprise digital transformation ability evaluation system and application[J]. Science and Technology Management Research, 2020, 40(11): 46-51.

[10]王和勇, 何泓漫. 制造企业数字化转型评价及影响机制研究: 以汽车制造企业为例[J]. 工业技术经济, 2022, 41(8): 3-11.

WANG Heyong, HE Hongman. Research on evaluation and influence mechanism of digital transformation of manufacturing enterprises: Take automobile manufacturing enterprises as an example[J]. Journal of Industrial Technological Economics, 2022, 41(8): 3-11.

[11]王瑞, 董明, 侯文皓. 制造型企业数字化成熟度评价模型及方法研究[J]. 科技管理研究, 2019, 39(19): 57-64.

WANG Rui, DONG Ming, HOU Wenhao. Evaluation model and method of digital maturity of manufacturing enterprises[J]. Science and Technology Management Research, 2019, 39(19): 57-64.

[12]陈群, 李佳昕, 陈哲. 我国建筑企业数字化发展水平测度研究[J]. 建筑经济, 2023, 44(1): 21-28.

CHEN Qun, LI Jiaxin, CHEN Zhe. Research on measurement of digital development level of construction enterprises in China[J]. Construction Economy, 2023, 44(1): 21-28.

[13]范德成, 王婭. 传统企业数字化转型对其创新的影响研究: 以汽车制造企业为例[J]. 软科学, 2022, 36(6): 63-70.

FAN Decheng, WANG Ya. Research on the impact of traditional enterprise digital transformation on its innovation: Taking automobile manufacturing companies as an example[J]. Soft Science, 2022, 36(6): 63-70.

[14]MIRJANA K B, ANDREJA P. Multi-attribute assessment of digital maturity of SMEs[J]. Electronics, 2021, 10(8): 1-15.

[15]杜劲松, 余雅芸, 赵妮, 等. 不同类型服装企业智能制造能力成熟度评价模型[J]. 纺织学报, 2021, 42(5): 162-167.

DU Jinsong, YU Yayun, ZHAO Ni, et al. Evaluation modelling for maturity in intelligent manufacturing for multi-type clothing factories[J]. Journal of Textile Research, 2021, 42(5): 162-167.

[16]舒伟. 纺织智能制造任重而道远: 第11期纺织科技新见解学术沙龙后记[J]. 纺织学报, 2017, 38(10): 184-186.

SHU Wei. Textile intelligent manufacturing has a long way to go: Postscript of the 11th issue of the academic salon on new insights in textile technology[J]. Journal of Textile Research, 2017, 38(10): 184-186.

[17]陈雁. 服装设计与工程学科发展趋势与关键议题[J]. 纺织学报, 2019, 40(1): 182-188.

CHEN Yan. Trends and key subjects of apparel design and engineering[J]. Journal of Textile Research, 2019, 40(1): 182-188.

[18]胡元林, 莊永耀. 企业数字化转型的影响因素及其绩效研究进展[J]. 昆明理工大学学报(自然科学版), 2023, 48(1): 160-169.

HU Yuanlin, ZHUANG Yongyao. Research progress on influencing factors and performance of enterprise digital transformation[J]. Journal of Kunming University of Science and Technology (Natural Science), 2023, 48(1): 160-169.

[19]赵宸宇, 王文春, 李雪松. 数字化转型如何影响企业全要素生产率[J]. 财贸经济, 2021, 42(7): 114-129.

ZHAO Chenyu, WANG Wenchun, LI Xuesong. How does digital transformation affect the total factor productivity of enterprises[J]. Finance & Trade Economics, 2021, 42(7): 114-129.

[20]白雪洁, 李琳, 宋培. 数字化改造能否推动中国行业技术升级[J]. 上海经济研究, 2021, 397(10): 62-76.

BAI Xuejie, LI Lin, SONG Pei. Can digital transformation promote the technological upgrading of China’s industry[J]. Shanghai Journal of Economics, 2021, 397(10): 62-76.

[21]毛雅菲. TOC理论在零售行业的应用研究[J]. 商业经济研究, 2018, 763(24): 97-100.

MAO Yafei. Research on the application of TOC theory in the retail industry[J]. Journal of Commercial Economics, 2018, 763(24): 97-100.

[22]郑卫华. 制造企业数字化转型路径研究: 基于acatech工业4.0成熟度指数[J]. 科技与经济, 2018, 31(4): 51-55.

ZHENG Weihua. Research on digital transformation path of manufacturing enterprises: Based on acatech industry 4.0 maturity index[J]. Science & Technology and Economy, 2018, 31(4): 51-55.

[23]万晓榆, 赵寒, 张炎. 我国智能化发展评价指标体系构建与测度[J]. 重庆社会科学, 2020, 306(5): 84-97.

WAN Xiaoyu, ZHAO Han, ZHANG Yan. Construction and measurement of intelligent development evaluation index system in China[J]. Chongqing Social Sciences, 2020, 306(5): 84-97.

[24]单志广, 徐清源, 马潮江, 等. 基于三元空间理论的数字经济发展评价体系及展望[J]. 宏观经济管理, 2020, 436(2): 42-49.

SHAN Zhiguang, XU Qingyuan, MA Chaojiang, et al. Evaluation system and prospect of digital economy development based on the theory of ternary space[J]. Macroeconomic Management, 2020, 436(2): 42-49.

[25]李小青, 何玮萱, 李子彪, 等. 制造企业数字化创新能力影响因素识别及评价[J]. 科技管理研究, 2022, 42(16): 1-10.

LI Xiaoqing, HE Weixuan, LI Zibiao, et al. Identification and evaluation of influencing factors of digital innovation capability of manufacturing enterprises[J]. Science and Technology Management Research, 2022, 42(16): 1-10.

[26]童雨. 中国制造业数字化转型的影响因素研究[J]. 技术经济与管理研究, 2022, 308(3): 124-128.

TONG Yu. Research on the influencing factors of manufacturing digital transformation[J]. Journal of Technical Economics & Management, 2022, 308(3): 124-128.

[27]王核成, 王思惟, 劉人怀. 企业数字化成熟度模型研究[J]. 管理评论, 2021, 33(12): 152-162.

WANG Hecheng, WANG Siwei, LIU Renhuai. Research on enterprise digital maturity model[J]. Management Review, 2021, 33(12): 152-162.

[28]王浩然, 李欣华. 数字化时尚策展在服装品牌文化构建及传播中的探索[J]. 丝绸, 2022, 59(6): 95-102.

WANG Haoran, LI Xinhua. Exploration of digital fashion curation in constructing and communication of fashion brand culture[J]. Journal of Silk, 2022, 59(6): 95-102.

Evaluation on the digital transformation of listed enterprises in China’s clothing industry

ZHENG Tong, ZHANG Lijie

(College of Textiles and Clothing, Xinjiang University, Urumqi 830046, China)

Abstract:

With the rapid development of related technologies such as the Internet, big data, and artificial intelligence, the digital economy has gradually become an important factor to drive economic development. After several years’ continuous growth, the scale of China’s digital economy reached about 39. 2 trillion yuan by 2020, accounting for 38.6% of GDP. The rapid development of the digital economy promotes the digital transformation of China’s traditional manufacturing enterprises. As one of the traditional manufacturing industries in China, the clothing industry should follow the trend of digitalization and utilize digital technology to comprehensively reform the organizational structure and business processes of enterprises, so as to eliminate issues such as personnel redundancy and low production efficiency, improve operational efficiency and market competitiveness, and better meet the growing personalized needs of consumers. Therefore, the digital transformation of garment enterprises has become a hot topic at present. It is found through literature related to the digitalization of garment enterprises that relevant studies on digitalization of garment enterprises mainly focus on the application aspect of digital technology, lacking analysis of influencing factors and evaluation of transformation degree from the perspective of enterprise.

To promote the digital transformation of China’s garment enterprises, listed enterprises in China’s clothing industry were selected as the sample enterprises, the main influencing factors of transformation were analyzed at the enterprise level, the degree of digital transformation was measured, and digital transformation evaluation was carried out. The research time interval is from 2018 to 2021. By analyzing the annual reports of listed enterprises in the China’s clothing industry, the enterprises mainly engaged in clothing and accessory product business were selected, and the enterprises with inconsistent data and no digital related information disclosure were excluded. Finally, 24 sample enterprises were obtained. To cover as many aspects as possible of the digital transformation of sample enterprises, the relevant literature on digital transformation evaluation and the annual reports of listed clothing companies were sorted out, and the results show that the main changes of garment enterprises of digital transformation are reflected in three dimensions: digital technology, organizational environment and business processes. By comparing relevant evaluation methods, it was found that the entropy-TOPSIS evaluation method has the advantages of objective results and strong logic in dealing with multilevel and multi-index digital transformation indicator systems, which meets the research needs. Therefore, this paper constructed an evaluation indicator system for the digital transformation of listed enterprises in China’s clothing industry, which contains 19 specific indicators in three dimensions: technological transformation capability, organizational transformation capability and business transformation capability. Based on the panel data of 24 listed enterprises in the clothing industry in China from 2018 to 2021, the entropy weight method was employed to assign weights to quantitative indicators, with the weight value representing the influence degree of indicators in the digital transformation process; the weight value was substituted into the TOPSIS evaluation method to calculate and evaluate the digital transformation indicator of each sample enterprise. The weight analysis results show that: among the three primary indicators, the weight of business transformation capability is 0365, indicating the greatest impact on the digital transformation of listed enterprises in China’s clothing industry. Among the 10 secondary indicators, the top three weights are digital infrastructure construction, organizational structure transformation, and digital personnel training, with values of 0.251, 0.154, and 0.133, respectively. These three secondary indicators contain many tertiary indicators, and enterprises should balance the development of each specific influencing factor. Among the tertiary indicators, digital design system has the highest weight of 0.111, which indicates that design is an important part of garment enterprises’ digital transformation in the context of consumers’ pursuit for personalization. The digital transformation index shows that more than 50% of sample enterprises have improved their digital degree; the average digital indexes of full samples from 2018 to 2021 are 0.288, 0.292, 0.333 and 0.336, respectively, showing an upward trend, and indicating that China’s listed garment enterprises have made some progress in digital transformation overall, but the degree of digitalization is low. The sample enterprises could do better in the future. Finally, based on the enterprise level, we summarized three main reasons for the low degree of digital transformation: (i) limited digital investment; (ii) weak ability to transform organizational structure; (iii) difficulties in business process transformation. In view of the three main reasons for the low degree of digital transformation, three suggestions were proposed: (i) increasing investment in digital technology and equipment; (ii) creating a digital environment, cultivating, and introducing relevant people; (iii) emphasizing standardized data transmission and promoting business process transformation.

The evaluation indicator system for digital transformation of garment enterprises constructed in this paper is objective, scientific and hierarchical, which can provide reference for the digital transformation of China’s garment enterprises. In the future, the indicator system could be modified and improved on the basis of the indicator system built in this paper; the small and medium-sized garment enterprises could be included in the research scope, and then the number of sample enterprises could be expanded. In this way, the influencing factors and transformation effects of digital transformation in China’s garment enterprises could be analyzed more comprehensively. We could also compare domestic and foreign garment enterprises, to analyze the advantages and disadvantages of China’s garment enterprises in the process of digital transformation, so as to accelerate the digital transformation.

Key words: digital transformation; garment enterprises; entropy-TOPSIS; influence factor; weight; transformation index