GO-QAS/棉复合纱线的构建及其性能

齐庆欢 廖焕如 张庆 师晓含 周玉嫚

摘要:针对现有抗菌纺织品加工方法存在问题,利用静电纺喷技术,将接枝有机硅季铵盐的氧化石墨烯(GO-QAS)均匀喷射在棉网表面,经后序集聚加捻,构建GO-QAS/棉复合纱线。结果表明:当纺丝电压为35 kV、棉网厚度为3 mm、GO-QAS质量浓度为4 mg/mL时,GO-QAS在静电力作用下能够稳定喷射在棉网表面,同时GO-QAS包裹卷绕在棉纤维表面;进一步集聚加捻获得的GO-QAS/棉复合纱线也显示了优异的力学性能,并对大肠杆菌和金黄葡萄球菌具有大于99.99%的抗菌性。基于静电纺喷工艺路线,通过对氧化石墨烯不同的功能改性,还可制备多重功能因子组合的复合纱线,从而实现纱线的多功能改性。

关键词:功能纱线;静电纺喷;氧化石墨烯;有机硅季铵盐;复合纱线;抗菌

中图分类号:TS195.644

文獻标志码:A

文章编号:1009-265X(2023)02-0139-07

由于服装等纺织品是抵御外界细菌侵害的第一道屏障,可有效免交叉感染、预防疾病传播、保证人体健康,因此抗菌纺织品相比其他功能纺织品表现出更多的需求,且抗菌纺织品在医用、服用、日用、产业用等领域均显示广泛的应用前景[1]。

目前,广泛使用的抗菌纺织品制备方法为原纤法和后整理法。原纤法是在纺丝过程中,将功能因子添加到聚合物中,经不同纺丝工艺制得功能纤维后,再进行纺织品织造[2-4];后整理加工法即在后整理过程中采用功能整理剂处理织物,从而赋予其功能,主要包括表面涂层法、浸轧法、微胶囊法和接枝法[5-8]。然而,采用这两种方法加工抗菌纺织品时,会存在抗菌性能或耐久性差、工艺复杂、环境污染、成本高、易脱落等问题。

除此之外,抗菌剂的选择也至关重要。现有抗菌剂主要分为金属离子型、光触媒型和有机阳离子型3种体系。金属离子型通过金属离子与细菌蛋白质中的巯基结合,引起蛋白变性,从而抑制细菌生长,如纳米银、纳米铜等[9-11];光触媒型通过光激发产生具有强氧化性的活性氧自由基,破坏细菌细胞的分子结构,达到抗菌抑菌作用,如纳米金属氧化物Ti2O、ZnO等[12];有机阳离子型通过静电作用和疏水作用与细菌的细胞膜结合,破坏细胞膜正常运转系统,达到抗菌抑菌效果,如季铵盐、吡啶盐、抗菌肽等[13]。虽然上述三类抗菌剂均展示了优异的抗菌效果,但是存在制备工艺复杂、生物安全性、易溶出等问题。

氧化石墨烯(GO)因呈现薄的片层结构且表面包含大量的含氧基团,能够为功能化修饰材料提供活性位点,而成为优良的药物载体被广泛应用于生物、药物传输等领域[14-16]。如果将GO作为载物平台,在其表面负载季铵盐类抗菌剂,构建一种具有抗菌功能的氧化石墨烯,可有效解决现有有机阳离子型抗菌剂存在问题。因此,本文基于静电喷射原理,采用接枝有机硅季铵盐的GO作为抗菌剂,提出一种嵌入功能氧化石墨烯的复合纱线制备方法,获得具有抗菌性能的纱线。

1实验

1.1实验材料

氧化石墨烯分散液(GO,2 mg/mL,溶剂乙醇),苏州碳丰科技有限公司;有机硅季铵盐(二甲基十八烷基[3-三甲氧基硅丙基]氯化铵,简称QAS,液体,纯度60%)、无水乙醇(分析纯),上海阿拉丁化学试剂有限公司;金黄色葡萄球菌(S.aureus)和大肠杆菌(E.coli),由河南汇博医疗股份有限公司免费提供。

1.2GO-QAS分散液的制备

首先将QAS加入GO分散液中(GO和QAS质量比1∶1),在75℃下磁力搅拌4 h;然后离心洗涤3次(转速4000 r/min);最后将无水乙醇加入洗涤后的GO-QAS抗菌剂中,超声分散5 min,得到浓度为4 mg/mL的GO-QAS分散液。

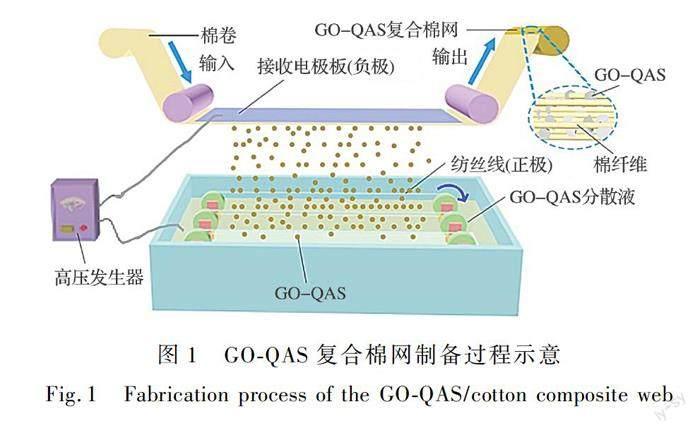

1.3负载GO-QAS抗菌剂的复合棉网的制备

利用自制静电纺喷装置制备负载GO-QAS抗菌剂的复合棉网,如图1所示。首先,退绕的棉网经过接收电极板下方卷绕在卷绕装置上;然后,GO-QAS分散液在电场力的作用下喷覆在棉网表面;最后,卷绕成卷,形成负载GO-QAS抗菌剂的复合棉网。静电纺喷工艺参数为:纺丝电压35 kV,纺丝间距20 cm,纺丝线运动速度20 cm/min,棉网卷绕速度20 cm/min,棉网厚度3 mm。

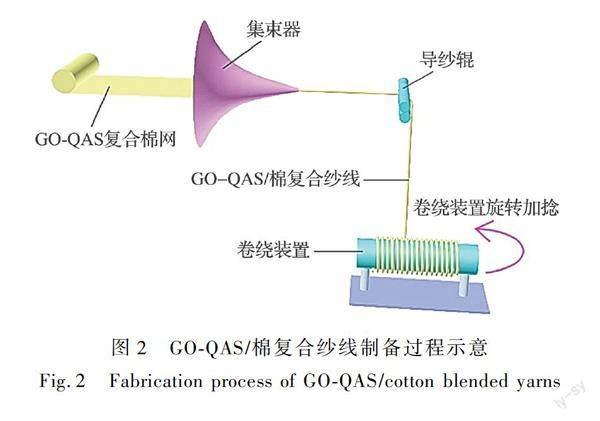

1.4GO-QAS/棉复合纱线的制备

负载GO-QAS抗菌剂的复合棉网经喇叭集束器集聚成束,进而卷绕加捻成GO-QAS/棉复合纱线,如图2所示。其中,卷绕装置的旋转速度为50 r/min,棉卷退绕速度与纱线卷绕速度相同。

1.5测试与表征

利用扫描电子显微镜(SEM,复纳科学仪器(上海)有限公司)观察样品的形貌结构。利用傅里叶红外光谱(FT-IR,美国Thermo Fisher Scientific公司)和X射线光电子能谱(XPS,岛津kratos公司)表征GO、QAS和GO-QAS的化学结构组成。利用强度测试仪(INSTRON,美国英斯特朗公司)表征纱线的力学性能,样品长度50 mm,测试速度20 mm/min。采用金黄色葡萄球菌(S.aureus)和大肠杆菌(E.coli)作为指示菌,进行抗菌性能测试[17];通过固体培养基中的菌落数计算抑菌率。

2结果与分析

2.1GO-QAS抗菌剂形貌结构分析

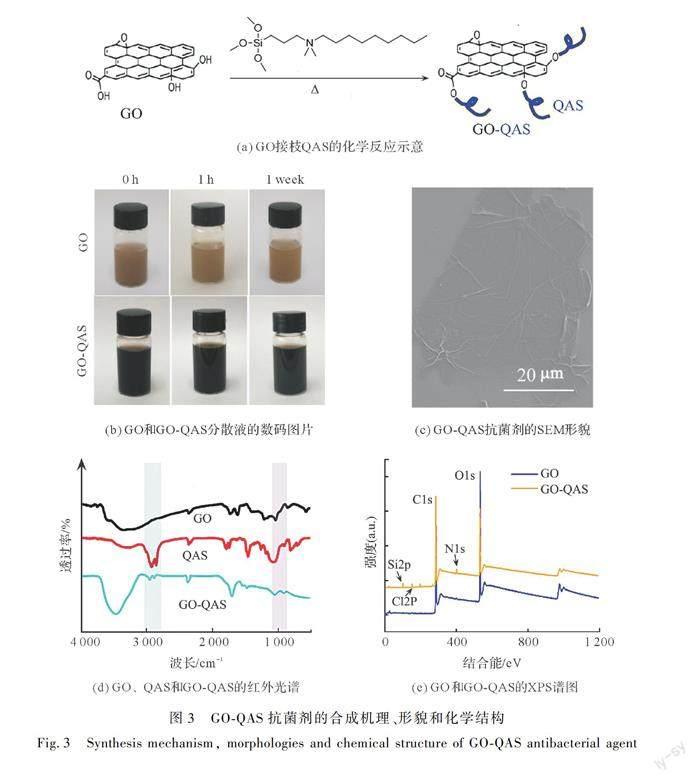

片状GO表面含有大量羟基,能够为功能化修饰材料提供活性位点。本文选用有机硅季铵盐(QAS)作为发挥抗菌性能的主要物质,通过QAS的硅氧烷与GO表面羟基之间发生偶联反应[18],将QAS共价接枝在GO表面,形成GO-QAS抗菌剂,其化学反应过程如图3(a)所示。接枝改性后的GO-QAS依然维持了GO较好的分散性和褶皱形态结构,如图3(b)―(c)所示,为后续均匀地静电喷覆在棉网表面奠定基础。与GO相比,GO-QAS在2800~3000 cm-1之间出现了明显的QAS的CH3和CH2的伸缩振动峰,且在1100~900 cm-1处出现了Si—O的伸缩振动峰;同时,GO-QAS的XPS谱图上也出现了除283.08 eV处的C1s和533.08 eV处的O1s之外的N1s、Si2p和Cl2p;GO-QAS的红外光谱和XPS谱图综合表明QAS成功接枝在GO表面,如图3(d)—(e)所示。

2.2負载GO-QAS的复合棉网形貌分析

负载GO-QAS抗菌剂之前,单纯的棉网呈白色,单根棉纤维沿纤维长度方向呈不规则天然转曲,纤维与纤维之间独立存在,如图4(a)所示。当通过自制静电防喷装置将GO-QAS抗菌剂自下而上喷覆在纯棉网表面时,棉网表面由白色转变成褐黑色。由于纺丝电压、棉网厚度和GO-QAS抗菌剂浓度会影响电场强度分布和溶液性质,因此上述3个参数对GO-QAS抗菌剂喷射过程影响较大。当纺丝电压为35 kV、棉网厚度为3 mm、GO-QAS抗菌剂浓度为4 mg/mL时,GO-QAS抗菌剂在棉网表面覆盖均匀,没有出现块状团聚的GO-QAS抗菌剂。进一步通过扫描电子显微镜观察负载GO-QAS的复合棉网可以发现,大片GO-QAS抗菌剂较好地包裹在棉纤维表面,从而形成了核壳纤维结构,如图4(b)所示。由于GO-QAS抗菌剂尺寸较大,少部分GO-QAS抗菌剂在包裹完纤维后还连接或嵌入在棉纤维中间。GO-QAS抗菌剂能够卷曲包裹在棉纤维表面的原因主要是:棉纤维属于纤维素纤维,表面含有较多羟基,能够与GO-QAS抗菌剂产生氢键作用[19]。当GO-QAS抗菌剂在电场力作用下喷覆到棉网表面时,GO-QAS抗菌剂首先静电力的作用直接吸附到棉纤维表面,然后受GO-QAS抗菌剂与棉纤维之间的氢键作用,诱导GO-QAS抗菌剂发生卷曲,随着溶剂的逐渐挥发最终牢固包裹在棉纤维表面。

2.3GO-QAS/棉复合纱线形貌

采用相同的集聚加捻工艺制备纯棉纱和GO-QAS/棉复合纱线。负载GO-QAS抗菌剂之前,自制纯棉纱呈现典型的棉纱结构特征,纱中纤维取向排列,单根纤维天然扭转,如图5(a)所示。而在GO-QAS/棉复合纱线中,GO-QAS抗菌剂一部分包裹在棉纤维表面,另一部分均匀嵌入在棉纤维之间,如图5(b)所示。进一步通过GO-QAS/棉复合纱线的截面电镜也可发现,GO-QAS抗菌剂由纱线内部向外部均匀分布,且是由包裹的和嵌入的两部分组成,如图5(c)所示。GO-QAS抗菌剂在纱线内部的均匀分布对纱线抗菌性能的影响至关重要,因为较少的GO-QAS抗菌剂不利于抗菌性能的发挥,处于纤维内部的GO-QAS抗菌剂也不利于抗菌性能的立即作用。

2.4GO-QAS/棉复合纱线力学性能

纱线的力学性能影响其实际使用性能,力学性能较差,无法满足其实际应用。GO-QAS/棉复合纱线的力学性能如图6所示。混合GO-QAS抗菌剂后,该混合纱线断裂伸长和断裂强度增强,其原因主要是GO自身具有较好的力学性能,GO-QAS抗菌剂包裹在纤维表面有利于提高纤维力学性能;同时GO-QAS抗菌剂混合在纤维之间,增加了纤维与纤维之间的摩擦力,二者共同作用提高善了纱线的力学性能。

2.5GO-QAS/棉复合纱线抗菌性能

图7为对照组(Control)、GO/棉复合纱线、QAS/棉复合纱线和GO-QAS/棉复合纱线对S.aureus和E.coli的抗菌效果和抗菌率。其中,GO/棉复合纱线和QAS/棉复合纱线采用与GO-QAS/棉复合纱线相同的制备工艺,GO分散液和QAS分散液的浓度均为2 mg/mL,溶剂为无水乙醇。结果表明,GO/棉复合纱线对S.aureus和E.coli不具有抑制作用,QAS/棉复合纱线对S.aureus和E. col具有一定的抗菌性,但明显低于GO-QAS/棉复合纱对S.aureus和E.coli的抑制作用,如图7所示;GO-QAS/棉复合纱对S.aureus和E.coli的抑菌率高达99.99%以上,如图8所示。GO-QAS/棉复合纱线优异的抗菌性主要来自纱中均匀分布的GO-QAS对细菌的抑制作用。由于片状GO比表面积大,且一片GO同时可以接枝多个QAS分子,使得QAS与细菌均匀接触的概率增加;当GO-QAS与细菌接触后,QAS能够破坏细菌的细胞壁,造成菌体内酶、代谢物等溢出,进而导致细菌死亡,实现杀菌、抑菌作用[20]。而QAS/棉复合纱线对S.aureus和E. col的抗菌性低于GO-QAS/棉复合纱的原因主要是:本文的抗菌纱线是采用由下而上静电纺喷技术实现的,当没有GO作为载体时,在喷射过程中小分子QAS可能会沉积在纤维之间的空隙,导致无法完全附着在棉纤维表面;或者QAS液滴直接喷射在纤维表面,导致干燥后QAS团聚在纤维表面,无法均匀分布在棉纱中,不利于QAS均匀发挥抗菌性能,最终导致较低的抗菌性能。

3结论

本文采用接枝QAS的GO作为抗菌剂,利用静电纺喷技术,将GO-QAS由下而上喷覆在棉网表面,经后续集聚加捻成纱,制备了GO-QAS/棉复合纱线;表征了GO-QAS抗菌剂的形貌和化学结构,分析了GO-QAS/棉复合棉网和纱线的形貌特征,测试了GO-QAS/棉复合纱线的力学性能,探讨了GO-QAS/棉复合纱线的抗菌机理,结论如下:

a)QAS能够接枝在GO表面,且维持了GO较好的分散性和褶皱形态结构。

b)当纺丝电压为35 kV、棉网厚度在3 mm、GO-QAS抗菌剂浓度为4 mg/mL时,GO-QAS抗菌剂能够均匀地喷覆在棉网表面;进一步集聚加捻获得的GO-QAS/棉复合纱线显示规整的纱线结构,且GO-QAS抗菌剂包裹卷绕在棉纤维表面或嵌入在纤维中间;同时,GO-QAS/棉复合纱线的力学性能显著优于纯棉纱。

c)GO-QAS/棉复合纱线显示了优异的抗菌性能,对S.aureus和E.coli的抗菌率大于99.99%。

参考文献:

[1]翟丽莎,王宗垒,周敬伊,等.纺织用抗菌材料及其应用研究进展[J].纺织学报,2021,42(9):170-179.

ZHAI Lisha, WANG Zonglei, ZHOU Jingyi, et al. Research progress of antibacterial materials for textiles and their applications[J]. Journal of Textile Research, 2021, 42(9): 170-179.

[2]南清清,曾慶红,袁竟轩,等.抗菌功能纺织品的研究进展[J].纺织学报,2022,43(6):197-205.

NAN Qingqing, ZENG Qinghong, YUAN Jingxuan, et al. Advances on antibacterial textiles[J]. Journal of Textile Research, 2022, 43(6): 197-205.

[3]SHEILA S, RASHIDIAN M, DORRANIAN D. Preparation of antibacterial textile using laser ablation method[J]. Optics & Laser Technology, 2018, 99: 145-153.

[4]NORTJIE E, BASITERE M, MOYO D, et al. Extraction methods, quantitative and qualitative phytochemical screening of medicinal plants for antimicrobial textiles: A review[J]. Plants, 2022, 11(15): 2011.

[5]李艳艳,赵立环,杨玉洁.MXene及其复合材料的抗菌纺织品研究进展[J/OL].复合材料学报,2022:1-15[2022-08-14].DOI:10.13801/j.cnki.fhclxb.20220627.002.

LI Yanyan, ZHAO Lihuan, YANG Yujie. Research progress on antibacterial textiles of MXene and its composite materials[J/OL]. Acta Materiae Compositae Sinica, 2022:1-15[2022-08-14].DOI:10.13801/j.cnki.fhclxb.20220627.002.

[6]MARKOVIC D, ZILLE A, RIBEIRO A I, et al. Antibacterial Bio-nanocomposite textile material produced from natural resources[J]. Nanomaterials, 2022, 12(15): 2539.

[7]RIAN S, NAZ S, YOUNUS A, et al. Layer by layer deposition of PEDOT, silver and copper to develop durable, flexible, and EMI shielding and antibacterial textiles[J]. Colloids and Surfaces a: Physicochemical and Engineering Aspects, 2022, 650: 129486.

[8]王荣国,王进美.纺织品抗菌剂及其整理方法[J].合成纤维,2021,50(8):24-26,37.

WANG Rongguo, WANG Jinmei. Antimicrobial finishing of textiles and its finishing method[J]. Synthetic Fiber in China, 2021, 50(8): 24-26, 37.

[9]NGUYEN N T, VO T L. Fabrication of silver nanoparticles using Cordyline fruticosa L. leave extract endowing silk fibroin modified viscose fabric with durable antibacterial property[J]. Polymers, 2022, 14(12): 2409.

[10]CHEN N F, LIAO Y H, LIN P Y, et al. Investigation of the characteristics and antibacterial activity of polymer-modified copper oxide nanoparticles[J]. International Journal of Molecular Sciences, 2021, 22(23): 12913.

[11]QIU Q H, CHEN S, LI Y, et al. Functional nanofibers embedded into textiles for durable antibacterial properties[J]. Chemical Engineering Journal, 2020, 384: 123241.

[12]ALI S S, MOAWAD M S, HUSSEIN M A, et al. Efficacy of metal oxide nanoparticles as novel antimicrobial agents against multi-drug and multi-virulent Staphylococcus aureus isolates from retail raw chicken meat and giblets[J]. Inter-national Journal of Food Microbiology, 2021, 344: 109116.

[13]Rodrigues A G, de Oliveira Gonalves P J R, Ottoni C A, et al. Functional textiles impregnated with biogenic silver nanoparticles from Bionectria ochroleuca and its antimicrobial activity[J]. Biomedical Microdevices, 2019, 21(3): 56.

[14]HU W B, PENG C, LUO W, et al. Graphene-based anti-bacterial paper[J]. Acs Nano, 2010, 4(7): 4317-4323.

[15]Akhavan O, Ghaderi E. Toxicity of graphene and graphene oxide nanowalls against bacteria[J]. ACS Nano, 2010, 4(10): 5731-5736.

[16]KIM T I, KWON B, YOON J, et al. Antibacterial activities of graphene oxide-molybdenum disulfide nanocomposite films[J]. ACS Applied Materials & Interfaces, 2017, 9(9): 7908-7917.

[17]YU W, LI X, HE J, et al. Graphene oxide-silver nanocomposites embedded nanofiber core-spun yarns for durable antibacterial textiles[J]. Journal of Colloid and Interface Science, 2021, 584: 164-173.

[18]LIU C H, LIAO X, SHAO W L, et al. Hot-melt adhesive bonding of polyurethane/fluorinated polyurethane/alkylsilane-functionalized graphene nanofibrous fabrics with enhanced waterproofness, breathability, and mechanical properties[J]. Polymers, 2020, 12(4): 836.

[19]RAMALINGAM P K H, K R. FTIR studies of hydrogen bonding interaction between the hydroxyl and carbonyl liquids[J]. Advances in Applied Science Research, 2016, 6(12): 44-52.

[20]殷珊珊.長链季铵盐的合成及其对聚酰胺6纤维的抗菌改性[D].杭州:浙江理工大学,2020:5-6.

YIN Shanshan. Antibacterial Modification of Polyamide 6 Fiber by Synthetic Long Chain Quaternary Ammonium Salt[D]. Hangzhou: Zhejiang Sci-Tech University, 2020: 5-6.

Construction and performance of GO-QAS/cotton blended yarn

QI Qinghuan, LIAO Huanru, ZHANG Qing, SHI Xiaohan, ZHOU Yuman

(Research Institute of Textile and Clothing Industries, Zhongyuan University of Technology, Zhengzhou 450007, China)

Abstract:

Antibacterial textiles are the first barrier for human body to resist external bacteria and play an important role in improving personal hygiene environment and ensuring human health. Especially after the outbreak of COVID-19 in 2020, antibacterial textiles are favored by more and more people because they can inhibit the propagation of microorganisms, avoid cross infection of bacteria, and prevent the spread of diseases, thus resulting in a substantial increase in demand. As the yarn is the basic component of textiles, it is a simple and effective way to directly construct antibacterial textiles through antibacterial yarns. However, the processing methods of antibacterial yarns widely used in industry have many problems, such as heavy pollution, high energy consumption and unstable antibacterial performance. Therefore, it is of great research value to further develop the green processing method of antibacterial yarns and improve the yarns' antibacterial property.

In view of the existing problems of antibacterial yarns and their processing methods, a new method for fabricating antibacterial blended yarns embedded in graphene is proposed in this paper from the perspective of physical modification based on the principle of electro-spraying. Namely, an organic silicon quaternary ammonium salt (QAS) is first grafted onto graphene oxide by coupling reaction to synthesize nano-composite antimicrobial agents (GO-QAS), in which QAS and GO are respectively used as main antibacterial substance and functional modification carrier. Then, GO-QASs are uniformly sprayed onto the cotton web by electrostatic action to form a GO-QAS/cotton hybrid web. Finally, the GO-QAS/cotton hybrid web is aggregated and twisted into a GO-QAS/cotton blended yarn with antibacterial function. The morphology and chemical structure of GO-QAS antibacterial agent are characterized by scanning electron microscope, Fourier transform infrared spectroscopy and X-ray photoelectron spectroscopy. The distribution rule and existing form of GO-QAS antibacterial agent in yarn are analyzed by morphology observation. The mechanical property of GO-QAS/cotton blended yarn is tested through a strength tester. The antibacterial properties of GO-QAS/cotton blended yarns are researched by antibacterial experiments. The results show that the GO-QAS antibacterial agent has good dispersibility and can be sprayed evenly on the surface of the cotton web. Moreover, the GO-QAS/cotton blended yarn obtained by further agglomerating and twisting the composite web shows excellent yarn structure and mechanical property. In the GO-QAS/cotton blended yarn, the GO-QAS antibacterial agent is wrapped on the surface of cotton fibers or embedded in the middle of the fibers. In addition, the GO-QAS antibacterial agent is evenly distributed from the inside to the outside of the yarn. Benefited by the distribution of GO-QAS antibacterial agents in the yarn, the GO-QAS/cotton blended yarn shows high antibacterial activity against E.coli and S.aureus, which is greater than 99.99%.

Compared with the reported processing methods of antibacterial yarns, using electrostatically spraying functional graphene to prepare antibacterial yarn is a physical modification method. This method is simple in process, less pollution and low energy consumption. In addition, through the different functional modification of graphene oxide, the blended yarn with multiple functions can be prepared in one step, which can easily realize the multi-functional modification of yarns. The research results have important guiding significance for the innovation and upgrading of functional textiles and their green processing technologies.

Keywords:

functional yarn; electro-spraying; graphene oxide; organic silicon quaternary ammonium salt; blended yarn; antibacterial property

收稿日期:20220815

網络出版日期:20221213

基金项目:河南省科技攻关项目(202102210060);中原工学院学科实力提升计划“学科青年硕导培育计划

作者简介:齐庆欢(1999—),女,河南驻马店人,硕士研究生,主要从事功能纺织品性能方面的研究。

通信作者:周玉嫚, E-mail: ymzhou@zut.edu.cn