防水透湿膜在纺织上的应用及研究进展

仇慧丽 杨群 崔进 裴刘军 胡庚昊

摘要:防水透湿膜是一种兼具耐水渗透性和水汽透过性的功能膜材料,其与纤维面料复合,可制备具有独特防护性和兼顾透气、透湿于一体的舒适型功能性纺织品。目前,用于可穿戴纺织品的人体-环境交互领域的湿热传输膜材料主要有聚四氟乙烯疏水膜、聚氨酯亲水膜和静电纺丝纤维膜。本文对这3种防水透湿膜的结构、制备方法、防水透湿机理及应用性等进行综述,总结防水透湿膜的研究进展及其在纺织上的应用趋势,并对未来智能防水透湿薄膜的研发重点做出展望。

关键词:防水透湿性;功能膜材料;智能织物;静电纺丝纤维膜;防护性

中图分类号:TB34,TQ028

文献标志码:A

文章编号:1009-265X(2023)02-0244-12

防水透湿织物,是全球纺织业多年以来一直追求的兼顾防水、透气、透湿于一体的纺织品。虽然防水性、透湿性这两个看似矛盾的性能起初难以兼具于一块织物上,但随着研究的深入及技术的发展,具有独特防护性和兼顾透气、透湿于一体的功能性纺织品问世,并取得突破进展,而随环境温湿度变化而自动调节人体微气候的智能防水透湿材料也正处于全面发展阶段[1-2],应运而生的防水透湿膜材料也引起了广泛关注。

防水透湿膜是一种兼具耐水渗透性和湿气透过性的功能膜材料,其与纤维面料复合,可制造具有独特防护性和舒适性的功能纺织品。目前,用于可穿戴纺织品的人体-环境交互领域的湿热传输膜材料,主要有聚四氟乙烯(PTFE)疏水性微孔膜、聚氨酯親水性无孔膜和静电纺丝纤维膜[3-4]。由于水分子在固体中的传输比在孔道中要慢,因此,PTFE疏水性微孔膜的防水透湿性主要源于其孔径的调控。当孔径小于雨滴尺寸但大于水蒸气分子时,具有较好的防水透湿性,但由于膜材料疏水,会导致水滴在孔道中聚集堵塞。聚氨酯亲水性膜则是通过吸湿-转移-释放过程将水汽分子排到外部的,因其无孔结构而具有较高的耐水压,但透气性和透湿性相对较差,使穿着者产生不适感[5]。静电纺丝纤维膜因纤维直径小、孔隙率高,从而可有效提高其透气透湿性,但其防水性、机械性能与透气透湿性的兼顾需统筹考虑,且目前离大规模产业化应用还有一段距离[6-7]。因此,本文主要从目前用于纺织品防水透湿功能的角度出发,介绍几种膜材料的结构、制备方法、防水透湿机理及应用,并对未来智能防水透湿薄膜的研发重点进行展望。

1聚四氟乙烯防水透湿膜

1.1聚四氟乙烯分子结构

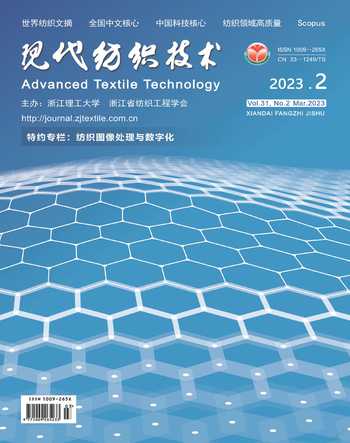

聚四氟乙烯(PTFE)是一种高结晶的聚合物,其分子链是由氟和碳两种元素通过共价键结合而成。由于负电荷的作用,相邻氟原子之间相互排斥,从而分子链在空间上呈螺旋构象,并形成一个紧密“氟代”保护层[8],如图1所示。由于PTFE分子间的堆砌密度大,各种试剂难以深入分子链中间,外加氟原子本身极高的化学惰性,PTFE几乎能够抵抗所有的强酸、强碱及有机溶剂,呈现出无可比拟的化学稳定性[9]。此外,由于PTFE分子结构为四个氟原子包覆着一个碳原子,氟原子的化学惰性使PTFE呈现出较好的疏水性以及较小的吸水率和渗透性[10]。因此,可制备具有防水、防污性的功能型防护服,一度在纺织工业领域有着广泛的应用[11]。

1.2聚四氟乙烯防水透湿膜的在纺织上应用进展

美国人Gore于1962年研制出了一种具有微孔结构的PTFE防水透湿性薄膜,采用层压复合技术将其与纺织面料相结合,制备出具有优良的防水透湿性纺织品,并将其商业命名为Gore-Tex,于1976年推向市场[12]。此阶段的制备工艺主要是将PTFE的细粉加热熔融后形成薄膜,再进行快速拉伸,随后冷却形成厚度约25 μm、孔隙率为82%的网状微细多孔结构,其孔径大小大约是水滴(平均直径约为100 μm)的两万分之一,但又比水蒸气分子(平均直径约为0.4 nm)大700倍[13]。因此,其防水透湿便是基于膜的孔径小于雨滴尺寸但大于水蒸气分子尺寸,水滴不通过而防水,水汽分子能通过而透湿[14],如图2所示。采用黏合剂将所得PTFE微孔薄膜与织物复合,可得到透湿量约5 kg/(m2·d),耐静水压力大于9.8 kPa的防水透湿织物,并且此防水透湿织物兼具耐化学试剂腐蚀、耐热、拒水、拒油、抗静电性等性能[15]。

此外,以PTFE为原料,经纺丝或制成薄膜后切割或原纤化等方式制得PTFE纤维。其强度高,延伸性好,化学稳定、耐腐蚀等性能优于其他合成纤维[16]。由于PTFE微纳米纤维因直径较细,尺度效应十分显著,展现出优异的性能。而且,纤维的细化增加了纤维膜表面的粗糙度,疏水性进一步提高[17]。虽然PFTE膜材料具有如此优异的防水性能,但其制备工艺复杂,生产条件严苛,需要特殊的制膜设备和原料,且工艺技术要求非常高[18],从而极大地制约了它的进一步的应用。此外,在制造过程通常会涉及全氟辛磺酸(PFOA)和全氟辛磺酸盐(PFOS)两种具有高生物积累、环境持久性和长距离迁移的物质[19-21],近年来,这些具有长全氟烷基链(-CnF2n+1,n≥8)的含氟聚合物许多国家已禁止其广泛应用。

通过开发兼具高防护性和舒适性的环保型防水透湿膜材料是扩大其应用需解决的主要问题。虽然一些长全氟烷基链的含氟聚合物具有极低的表面能,展示出出色的防水和防油性[22-25],但随着其禁止广泛使用,开发兼具高防护性和舒适性的环保型含氟类防水透湿膜材料是扩大含氟类材料应用的主要途径,因此,设计具有短氟化的环保防水透湿材料已成为不可抗拒的趋势[26-28]。研究发现,聚偏氟乙烯(PVDF)的拒水性略低于PTFE,但其在制备工艺和成膜性能优于PTFE,且不存在释放PFOA、PFOS的风险。因此,刘延波等[29]以PVDF和聚偏氟乙烯六氟丙烯(PVDF-HFP)为原料制备了PVDF/PVDF-HFP复合纳米纤维薄膜,并对其防水透湿性进行研究,发现该复合薄膜具有良好的防水和透湿性。周颖等[30]以聚氨酯(PU)和PVDF进行复合,制备PU/PVDF复合防水膜,并通过层压工艺将其应用于织物,对比了复合膜和整理织物的防水透湿性能,结果表明,PU/PVDF复合防水膜具有较高的防水透湿性能,但是通过层压工艺与织物复合后,防水性能有所下降。

随着研究的进一步深入,以及绿色环保型功能助剂的开发,不少无氟防水整理剂和纤维膜由于价格优势和工艺优势,逐渐受到重视。Gu等[6]将聚氨酯-聚(ε-己内酯)纤维浸渍到聚二甲基硅氧烷溶液中,所得膜具有中等防水透气性能(耐水压为73.6 kPa,水蒸气透过率为9.03 kg/(m2·d)。Sheng等[5]采用氨基-硅油和SiO2纳米粒子对聚丙烯腈纤维膜进行改性以制备防水透湿膜,所得纤维膜表现出相似的防水性(耐水压为74.3 kPa)和良好的透湿性(11.4 kg/(m2·d)。Zhao等[7]通过逐步的浸镀和热固化技术来制造无氟、高效和可生物降解的防水透湿膜,含有长烃链的超支化聚合物涂层提供了具有高疏水性的电纺丝醋酸纤维素(CA)纤维基质,封闭的异氰酸酯交联剂涂层确保了碳氢化合物段在CA表面的强附着,所得到的膜的耐渗水压为102.9 kPa,透气性为12.3 kg/(m2·d),抗拉强度为16.0 MPa。

可持续发展刺激着生态环保产品的持续开发,防水透湿面料的风格也在不断变化。在纺织服装的应用中,无氟类产品在慢慢取代含氟性产品,聚氨酯、三羧酸等亲水性产品也被证明是普遍且有效地适用于的纺织产品的,不仅突出了材料的设计和制备,而且提供了环保和高性能的防水透湿膜。

2聚氨酯防水透湿膜

2.1聚氨酯分子结构

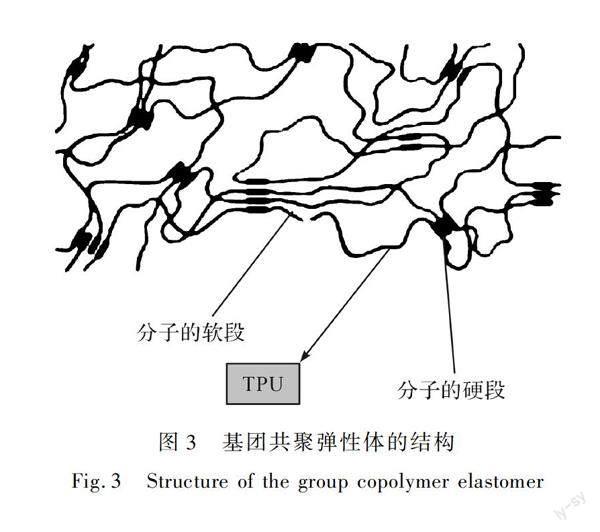

聚氨酯是一种在预定温度范围内感知和响应外部热刺激的功能材料,其具有相分离的为分段式结构,即热可逆相(软段)和固定相(硬段),如圖3所示。主要是聚氨酯分子在制备时,大分子二元醇(或二元胺)和异氰酸酯连接形成长链结构,因分子链长,表现出柔性,所以形成整个大分子链中的软段结构;小分子多元醇和异氰酸酯连接形成短链结构,因分子链短,从而呈现刚性,形成大分子链结构中的硬段结构。软段部分通常与刚性的硬段交替存在于聚氨酯分子链中,以共价键“尾—尾”连接[31]。由于聚氨酯硬段间的相互作用,所以它具有良好的机械性能。聚氨酯良好的回弹性得益于分子链的相对运动,分子链的运动性能很大程度取决于软段的化学性质和链段长度,软段越是呈无定形状态,其柔顺性就越好。

2.2聚氨酯防水透湿膜在纺织上的应用进展

根据自由体积理论,膜材料中可用的自由体积孔的大小和形状控制着气体扩散的速度和其渗透性[32]。在材料内部有大量的亲水性自由体积分子,这种亲水性分子可以吸收人体散发的水蒸气分子,水分子形式的水蒸气再与聚氨酯材料中的亲水性软段以氢键结合,在纺织品内外部温湿压力差下,通过吸湿-转移-释放过程将水分子排到外部,如图4所示。

Kim等[33]发现,以异佛尔酮二异氰酸酯(IPDI)和聚酯型多元醇(PTAd)/聚醚多元醇(PPG)制备聚氨酯,其中PTAd含量越高,聚氨酯的力学性能越好,分子链的运动性越强。Yen等[34]研究了聚己内酯(PCL)、聚乙二醇(PEG)、PCL/PEG等不同软链段共混和三嵌段PCL-PEG-PCL对聚氨酯性能的影响。由于构象和分子间氢键的作用[35],单酯型聚氨酯的性能最好,其次是PCL-PEG-PCL型聚氨酯。在这些体系中,聚醚聚氨酯的水蒸气渗透率最高。由于聚氨酯软硬链段之间的相分离,聚乙二醇含量越高,水蒸气渗透率也越高。Yen等[36]提出了通过修改PCL-PEG-PCL三嵌段聚氨酯多元醇的软段组成,增加软链段中的乙二醇的比例,可以获得更高的水蒸气渗透率、更低的机械性能和更明显的宏观相分离。此外,随着2, 2-双(羟基甲基)丙酸(DMPA)和NCO-to-OH比例的增加,水蒸气渗透率也增加[37]。Jeong等[38]发现PEG和DMPA形成的聚氨酯具有较低的机械性能,并且可以从较低的玻璃化温度值(Tg)中获得较高的水蒸气渗透率。Cho等[39]则发现随着聚氨酯硬段百分比的增加,或使用浓缩的聚氨酯溶液,水蒸气渗透率降低。

基于以上研究,Lin等[40]利用聚乙二醇/聚酯多元醇PBA体系制备的聚氨酯薄膜比采用单纯的PBA体系制备的聚氨酯薄膜具有更好的水蒸气渗透性能。且当温度低于18 ℃时,聚氨酯膜的水蒸气渗透率较低,直到温度高于18 ℃,水蒸气渗透率开始明显上升。聚氨酯膜的水蒸气渗透率会随着硬段比、温度及异氰酸酯指数的增加而增加,但随着温度下降到Tg以下而降低。为了更好地监测水蒸气透过率,Zhou等[41]制备了一种具有功能门的分段聚氨酯膜,并将其应用于水蒸气渗透。当温度从-10 ℃变化到10 ℃时,该聚合物中自由体积孔的平均半径从0.23 nm变化到0.467 nm。因此,随着对此膜的感知和回应外部热刺激功能的改进,聚氨酯膜的自由体积孔洞尺寸增大,对热刺激的敏感性增强,其水蒸气渗透率显著增加。因此,聚氨酯无孔膜因无孔结构而具有较高的耐水压,但其透气性和透湿性相对较差,使穿着者产生不适感。

为提高纺织服装的舒适性,许多研究致力于智能湿热管理材料,即:纺织服装更加强调对周围复杂多变环境的全天候适应能力,随着环境温度、湿度的变化自动调整自身水分、热量的传导,使人体表面始终保持最佳状态,达到全天候舒适的状态。随环境温度和湿度的变化能动态调节湿热的材料中,美国Baughman团队[42-43]曾提出对纤维加捻可以发热,解捻可获得一定程度的降温,这种“扭热制冷”是基于螺旋收缩过程中螺旋内部捻度降低导致能量的变化,但该变化在于温度的改变,且属于高温形变,不适用于纺织服装对湿热的智能调控。东华大学王宏志教授团队和佐治亚理工大学Elsa Reichmanis教授团队[44]提出了基于纳米通道机理的全氟磺酸树脂的气体响应致动材料,在体表湿热发生变化时,利用水分蒸发可向外卷曲打开孔道,进而对体表湿热进行调节,提高人体体表舒适感,这为智能湿热管理材料的设计和制备提供了新的思路,但全氟磺酸钠与纤维和织物的结合仍是一个问题。

由于在大多数情况下,热可逆相的相变温度(结晶熔融转变温度或玻璃转变温度)可作为可控水蒸气渗透性的开关温度[45]。当人体体温上升时,它不存在微孔,所以该膜材料的防水及其排汗透湿性能比常规的防水透湿膜更好。一类研究较为深入的智能透湿材料是形状记忆聚氨酯(温敏性聚氨酯)防水透湿膜。在转变温度范围内,形状记忆聚氨酯具有相应的相态转变过程和温度。当温度高于临界转变温度时,聚合物的自由体积孔隙尺寸会明显增大,使水蒸气通过聚合物薄膜的通道增大,提高水蒸气的透过率[45]。

由于形状记忆聚氨酯的温敏透湿机理和水分子的传输分别基于分子链运动引起的相变过程和溶解-扩散机制[40]。基于此理论,对聚氨酯软、硬段分子结构、分子量进行设计,使其自由体积和孔隙尺寸在一定的温度变化范围内发生急剧的改变,从而可智能化地控制聚氨酯膜的透气性和透湿性,如图5所示[46]。但有研究发现,虽然其透湿量在12~45 ℃内随温度的升高,可从455 g/(m2·d)增加到2625 g/(m2·d)(增加4.77倍),但由于过膜阻力大,该过程经历了近33 ℃的升温变化,在环境温度和湿度快速变化时难以满足实际使用要求[47]。课题组在前期研究中也遇到类似问题,使用传统膜结构不能有效解决。在智能防水透湿膜研究领域中,高过膜阻力导致的低通量和响应灵敏度不足的问题仍是研究者需面对的挑战。

为降低温敏性聚氨酯膜的水蒸气过膜阻力,提高透湿通量,课题组[48]以不同浓度的N, N-二甲基甲酰胺(DMF)和水为凝固浴,采用湿法成膜的方法制备了多级孔聚氨酯膜,并重点研究了在凝固浴中加入氯化钠(NaCl)对多级聚氨酯膜结构和性能的影响。研究发现,NaCl的含量对大孔的影响比较大,随着凝固浴中NaCl的含量加大,大孔孔径逐渐减小,且位置从皮膜向底膜过渡;而DMF用量的增加,会减缓铸膜液中的DMF向凝固浴中扩散的速度,影响DMF与凝固浴中H2O的双向扩散速度,从而影响膜中小孔的分布状态。而透湿性数据与膜结构表明孔的结构和尺度不同,湿热过膜阻力不一样,最终影响湿热过膜通量。Zhou等[41]在通过原位纳米混合工艺将纳米TiO2颗粒引入形状记忆聚氨酯基体,制备了一种新型温敏性聚氨酯/TiO2纳米复合膜,并用于可控水蒸气渗透。与纯温敏性聚氨酯膜相比,温敏性聚氨酯/TiO2纳米复合膜具有良好的组织结构和相变温度(Ts),且能有效提高膜的水蒸气透过率。特别是当温度高于Ts时,如在50~60 ℃范围内,温敏性聚氨酯/TiO2纳米复合膜的水蒸气透过率值提高了114%。而当TiO2质量分数为5.0%时,纳米复合膜的水蒸气透过率能提高145%,且表现出更高的水蒸气透过率变化和对热刺激更敏感的性能。

当形状记忆聚氨酯被用于户外服装时,需要考虑一些重要因素,如可控的水蒸气渗透性、高机械性能和高热、化学稳定性等。在过去的几年里,为了改善高分子材料的机械和热性能,国内外学者不断地通过各种途径对聚氨酯进行改性,以达到既有防水又有透湿功能的目的,也采用不同的工艺改变聚氨酯膜的结构,以适应环境温度和湿度的变化,以快速调控体表微气候。

3静电纺丝防水透湿膜

静电纺丝技术是一种方便、有效的制备微/纳米纤维的途径,其制备的纤维膜易于功能化改性,可用于制备防护性高、舒适性好的高性能防水透湿膜,近年来发展迅速。它的技术关键是在高压静电力的作用下,聚合物溶液或熔体会带电并变形,在喷嘴的末端形成一个锥形的悬浮液滴,当液滴表面的静电斥力超过它的表面张力时,液滴的表面会产生一个高速的射流,然后通过电场力拉伸、溶剂挥发,聚合物会固化形成纤维[49]。

3.1静电纺丝防水透湿膜的结构

静电纺丝制成的纳米纤维膜,纤维直径小,孔隙率高,孔道连通性好、多孔结构可控、易于表面改性、轻且柔等特点,适合于制造具有优异防水透湿性能的微孔膜,在功能性纺织服装面料、屏蔽材料等领域展现出巨大的市场潜力[50-51]。目前,已经有各种防水透湿纤维膜被开发,如聚氨酯纤维膜[52]、聚丙烯腈纤维膜[24]、聚丙烯纤维膜[53-54]等。辛东坡等[55]采用静电纺丝技术,将聚丙烯腈(PAN)聚合物制成纳米纤维薄膜,并对其防水透湿性进行了研究,实验结果表明PAN纤维膜具有较好的透湿性。Miao等[56]采用简单、可控的静电纺丝技术和碱处理,展示了一种基于聚氨酯/聚氨酯-聚丙烯腈/聚丙烯腈的三层纤维膜的功能性吸湿排汗织物,如图6所示,其具有优越的防水渗透性和定向吸濕排汗特性。在转移层诱导的递进润湿性下,所制备的纤维膜表现出优越的抗静水压和较高的单向迁移指数R,均远高于双层的聚氨酯/聚丙烯腈纤维膜。该研究表明,以聚氨酯膜作为内层,可使水渗透,同时不沿表面扩散,而聚氨酯-聚丙烯腈纤维膜作为中间转移层,可促使水汽从内层渗透到外层,并能阻止其反向渗透,从而促进了水的运输和蒸发。

3.2静电防水透湿膜在纺织上的应用进展

2007年,韩国首尔国立大学的Kang等[57]首次将静电纺丝技术引入到纺织服装领域,其将聚氨酯(PU)直接电纺在衬底织物上制成多功能织物,并与涂布聚氨酯树脂的织物进行比较,发现,在PU纺丝溶液在质量分数为12%、电压为13 kV、接收距离为10 cm的制备条件下,所得到的静电纺丝纤维能够有效地覆盖面料,在相同厚度下,静电纺丝纤维织物的重量比树脂涂层织物轻,透气性能好,透湿率高,可达9.1 kg/(m2·d),但其耐水压极低(3.6 kPa),必须进行改进,才能适应市场需求。东华大学的Ge等[58]通过引入含有全氟烷烃段(—C8F17)的合成氟化聚氨酯掺杂改性方法制备出聚氨酯/含氟聚氨酯(PU/FPU)静电防水透湿膜,氟聚氨酯的引入大幅度地提高了纤维膜的耐水性,其耐水压增加到39.3 kPa,提高了约10倍,同时该材料具有较好的透湿性,水蒸气透过率仍高达9.2 kg/(m2·d)。随后,Zhang等[59]通过将氯化锂引入聚氨酯氟化聚氨酯溶液,降低纤维膜的孔径,制备的纤维膜具有良好的防水性和透湿性,静水压力达到82.1 kPa,水蒸气透过率为10.9 kg/(m2·d)。然而,此类防水透湿纤维膜材料所使用的是长链氟碳聚合物(Rfn,n≥8),因此,开发环保的氟化聚合物来取代传统的氟化物是材料科学家的重点。

目前,防水性能优异且环保的氟化聚合物是含有4个全氟原子(Rfn,n=4)的水性含氟化学品,可通过整理使织物或膜材料具有优异的防水性。然而,该产品的缺点是疏水涂层的不均匀性和耐久性差,以及处理工艺复杂[27]。于是,在纤维中掺入环保的氟化聚合物(Rfn,n=4)制备防水透气膜具有重要意义,但也极具挑战性。Zhao等[60]通过静电纺丝技术合成了一种具有双端短链全氟丁基(—C4F9)链的新型氟化聚氨酯弹性体,并将其掺杂进聚氨酯纤维基体中,通过静电纺丝制得复合纤维膜,该纤维膜具有强大而持久的疏水性。此外,加入硝酸银可大大降低其最大孔径,从而显著提高了其防水性,静水压力高达102.8 kPa,水蒸气透过率为12.9 kg/(m2·d),且具有较高的力学性能(9.8 MPa)。

受自然界的啟发,在结构或性质进行的仿生制备超疏水人工表面的仿生技术取得了很大的进展。Muthiah等[61]和Lin等[62]通过引入环境友好型的有机硅疏水剂和疏水性的二氧化硅(SiO2)纳米颗粒,通过静电纺丝制备了仿生超疏水纤维膜,其表现出纳米突起和众多凹槽组合的结构,达到类似荷叶的超疏水结构,大大提升了其防水性和耐水压。通过静电纺丝制备出具有多孔微球和纳米纤维的复合结构的荷叶状超疏水表面,多孔微球在其超疏水性中起着主导作用,与此同时纳米纤维将单个的微球连接在一起,增强了复合材料薄膜的防水性能[63]。同样,根据Murray定律可知,自然界中的动植物体所具有的网络状等级结构,例如叶子的叶脉、植物的根茎系统、人体的血管系统等,可以确保生命体在新陈代谢与物质能量传递过程中所受阻力最小、运输效率最高[64]。Wang等[65]通过静电纺丝技术构筑了仿生树状多级分叉网络结构,并利用纤维的毛细管效应成功制备了单向导湿性纤维薄膜,如图7所示。这种仿生树状多级分叉网络结构由大孔-微米孔-亚微米孔的多级连通孔道组成,具有类似于植物蒸腾作用的多级网络状结构,遵循Murray定律最大化物质输运原则,具有快速定向导湿性,水分蒸发速率高达0.67 g/h。

除此之外,静电纺丝可以开发具有润湿性好、孔径小、比表面积大等特点的纤维膜。可通过设计制备多层梯度孔结构的纤维膜,实现渐润性,这就是Janus润湿性和润湿性梯度的结合[66-68]。只不过,早期关于通过电纺纤维膜定向输送水汽的研究主要在控制每一层厚度和润湿性的双层结构上[69],导致在提高输水能力和防止反向渗透的协同作用下取得的成效有限,阻碍了水分从体表向环境转移过程中的实际应用。

通过对静电纺丝纤维膜的表面和内部的改性,以提高防水透湿膜的相关性能。Xu等[70]采用静电纺丝法和二步刮刀涂层方法结合制备PAN/PU/TiO2薄膜,该复合薄膜具有94.3°的前进接触角,不能满足防水要求。然后,采用2-羟基-4-正辛氧基二苯甲酮与氟化丙烯酸共聚物进行改性,可获得了多功能超疏水膜。Sheng等[28]利用后处理技术,采用聚二甲基硅氧烷和疏水性的二氧化硅(SiO2)纳米颗粒对聚丙烯腈(PAN)纳米纤维膜进行涂层改性,聚二甲基硅氧烷在PAN纤维膜表面形成疏水功能层的同时还构筑了黏合结构,从而有效地改善了纤维的机械性能和透湿性,整理后的纤维膜具有较好的防水性(耐水压为74.3 kPa)和透湿性(透湿量为11.4 kg/(m2·d))。但随着改性剂用量的继续增加,纤维膜的透湿量出现降低的趋势,可能是因为改性剂用量的增加,纤维膜的孔隙率下降所致。通过后整理想进一步提升纤维膜材料的透湿性仍存在一定的局限性。

因此,可以通过功能性吸湿纺织品的结构设计,获得防水透湿维膜能够自发地将汗液从皮肤表面带走,为人体提供一个极其干燥和舒适的体表环境。

4结语

防水透湿膜是一种兼具耐水渗透性和湿气透过性的功能膜材料,其是制造具有独特防护性和兼顾防水、透气、透湿于一体的功能性纺织品的关键材料之一。在全球公共安全应急产业被广泛关注的大背景下,安全防护用纺织材料在快速发展,也面临着良好的市场机遇,但同时,日益复杂的社会生产、生活环境也对其提出了更高要求。用于可穿戴纺织品的人体-环境交互领域的含氟性疏水性膜、聚氨酯亲水膜和静电纺丝纤维膜的结构、制备方法、防水透湿机理及其应用性各不相同,也有着各自的优缺点。如何将防护阻隔性与透气透湿性这一矛盾性能有机统一,提升安全防护纺织材料的舒适性问题是势必要攻克的难关。通过对防水透湿纤维膜结构设计与水蒸气传递的机理相结合,使防水透湿织物越来越趋向于智能化、舒适化和环保化,从而以高性能纤维,产业用纺织品,智能化织物能够在各种环境中时刻调节体表最佳温度和湿度,这必将使人们的未来生活更加健康、美好。

参考文献:

[1]HOSSEIN F, AMIR R G. Developing breathable double-layered fibrous membranes equipped with water pulling mechanism toward clothing with enhanced comfort[J]. Advanced Engineering Materials, 2017, 19(7): 1600863.

[2]CHEN H W, ZHANG P F, ZHANG L W, et al. Continuous directional water transport on the peristome surface of Nepenthes alata[J]. Nature, 2016, 532 (7597): 85-89.

[3]ZHAO Y, WANG H, ZHOU H, et al. Directional fluid transport in thin porous materials and its functional applications[J]. Small, 2017, 13 (4): 1601070.

[4]SRIDHAR R, LAKSHMINARAYANAN R, MADHAIYAN K, et al. Electrosprayed nanoparticles and electrospun nanofibers based on natural materials: Applications in tissue regeneration, drug delivery and pharmaceuticals[J]. Chemical Society Reviews, 2015, 44(3): 790-814.

[5]SHENG J L, XU Y, YU J Y, et al. Robust fluorine-free superhydrophobic amino-silicone oil/SiO2 modification of electrospun polyacrylonitrile membranes for waterproof-breathable application[J]. ACS Applied Materials & Interfaces, 2017, 9(17): 15139-15147.

[6]GU X Y, LI N, GU H H, et al. Polydimethylsiloxane-modified polyurethane-poly (ε-caprolactone) nanofibrous membranes for waterproof, breathable applications[J]. Journal of Applied Polymer Science, 2018, 135(23): 46360.

[7]ZHAO J, ZHU W X, WANG X F, et al. Fluorine-free waterborne coating for environmentally friendly, robustly water-resistant, and highly breathable fibrous textiles[J]. ACS Nano, 2020, 14 (1): 1045-1054.

[8]陳慕荣,刘雪强,张华鹏,等.离心纺丝法制备PTFE/PVA复合微/纳米纤维膜[J].浙江理工大学学报(自然科学版),2020,43(5):625-631.

CHEN Murong, LIU Xueqiang, ZHANG Huapeng, et al. Preparation of PTFE/PVA composite micro/nano fiber membrane by centrifugal spinning[J]. Journal of Zhejiang Sci-Tech University(Natural Sciences Edition), 2020, 43(5): 625-631.

[9]张天,胡祖明,于俊荣,等.PTFE纤维制备技术的研究进展[J].合成纤维工业,2012,35(3):36-39,43.

ZHANG Tian, HU Zuming, YU Junrong, et al. Research progress in PTFE fiber manufacturing technology[J]. China Synthetic Fiber Industry, 2012, 35(3): 36-39,43.

[10]HUANG Y, HUANG Q L, LIU H, et al. Preparation, characterization, and applications of electrospun ultrafine fibrous PTFE porous membranes[J]. Journal of Membrane Science, 2017, 523: 317-326.

[11]YEERKEN T, YU W D, FENG J H, et al. Durable superamphiphobic aramid fabrics modified by PTFE and FAS for chemical protective clothing[J]. Progress in Organic Coatings, 2019, 135: 41-50.

[12]张慢乐,胡进,刘林,等.浅析防水透湿面料[J].中国纤检,2022(6):109-111.

ZHANG Manle, HU Jin, LIU Lin, et al. Analysis of waterproof and moisture permeable fabric[J]. China Fiber Inspection, 2022(6): 109-111.

[13]邵改芹.防水透湿织物研究新进展[J].产业用纺织品,2004,22(6):42-45.

SHAO Gaiqin. Development of waterproof and moisture permeable fabric[J]. Technical Textiles, 2004, 22(6): 42-45.

[14]GUGLIUZZA A, DRIOLI E. A review on membrane engineering for innovation in wearable fabrics and protective textiles[J]. Journal of Membrane Science, 2013, 446: 350-375.

[15]丁子寒,初曦,邹婷婷,等.防水透湿织物的研究进展[J].服装学报,2019,4(5):383-387,419.

DING Zihan, CHU Xi, ZOU Tingting, et al. Research progress on waterproof and moisture permeable fabric[J]. Journal of Clothing Research, 2019, 44 (5): 383-387, 419.

[16]乔春梅,康卫民,鞠敬鸽,等.聚四氟乙烯纤维的制备技术及应用进展[J].产业用纺织品,2015,33(1):1-4,37.

QIAO Chunmei, KANG Weimin, JU Jingge, et al. Preparation and application progress of polytetrafluoroe-thylene fibers[J]. Technical Textiles, 2015,33(1):1-4, 37.

[17]WU J D, DING Y J, WANG J Q, et al. Facile fabrication of nanofiber-and micro/nanosphere-coordinated PVDF membrane with ultrahigh permeability of viscous water-in-oil emulsions [J]. Journal of Materials Chemistry A, 2018, 6(16): 7014-7020.

[18]FENG S S, ZHONG Z X, WANG Y, et al. Progress and perspectives in PTFE membrane: preparation, modifica-tion, and applications [J]. Journal of Membrane Science, 2018, 549: 332-349.

[19]STUCKI M, KELLENBERGER C R, LOEPFE M, et al. Internal polymer pore functionalization through coated particle templating affords fluorine-free green functional textiles [J]. Journal of Materials Chemistry A, 2016, 4(39): 15197-15206.

[20]SOTO D, UGUR A, FARNHAM T A, et al. Short-fluorinated iCVD coatings for nonwetting fabrics[J]. Advanced Functional Materials, 2018, 28(33):1707355.

[21]DICHIARANTE V, MILANI R, METRANGOLO P. Natural surfactants towards a more sustainable fluorine chemistry [J]. Green Chemistry, 2018, 20(1): 13-27.

[22]ZHAO J, LI Y, SHENG J L, et al. Environmentally friendly and breathable fluorinated polyurethane fibrous membranes exhibiting robust waterproof performance[J]. ACS Applied Materials & Interfaces, 2017, 9(34): 29302-29310.

[23]YANG, Y, SHEN J, ZHANG L ,et al. Preparation of a novel water and oil-repellent fabric finishing agent containing a short perfluoroalkyl chain and its application in textiles[J]. Materials Research Innovations, 2015, 19(S8): 401-404.

[24]SHENG J L, LI Y, WANG X F, et al. Thermal inter-fiber adhesion of the polyacrylonitrile/fluorinated polyure-thane nanofibrous membranes with enhanced waterproof-breathable performance[J]. Separation & Purification Technology, 2016, 158: 53-61.

[25]LI Y, YANG F F, YU J Y, et al. Hydrophobic fibrous membranes with tunable porous structure for equilibrium of breathable and waterproof performance[J]. Advanced Materials Interfaces, 2016, 3(19): 201600516.

[26]ZHAO J, ZHU W X, YAN W A, et al. Tailoring waterproof and breathable properties of environmentally friendly electrospun fibrous membranes by optimizing porous structure and surface wettability[J]. Composites Communications, 2019, 15: 40-45.

[27]JIANG J X, ZHANG G F, WANG Q Y, et al. Novel fluorinated polymers containing short perfluorobutyl side chains and their super wetting performance on diverse substrates[J]. ACS Applied Materials & Interfaces, 2016, 8(16): 10513-10523.

[28]SHENG J L, ZHANG M, XU Y, et al. Tailoring water resistant and breathable performance of polyacrylonitrile nanofibrous membranes modified by polydimethylsiloxane[J]. ACS Applied Materials & Interfaces, 2016, 8: 27218-27226.

[29]劉延波,马营,孙健,等.电纺PVDF/PVDF-HFP复合纳米纤维膜及其防水透湿性能评价[J].天津工业大学学报,2014,33(6):6-10.

LIU Yanbo, MA Ying, SUN Jian, et al. Composite nanofiber membrane based on electrospun PVDF/PVDF-HFP and evaluation for waterproof & breathable properties[J]. Journal of Tiangong University, 2014,33(6):6-10.

[30]周穎,姚理荣,高强.聚氨酯/聚偏氟乙烯共混膜防水透气织物的制备及其性能[J].纺织学报,2014,35(5):23-29.

ZHOU Ying, YAO Lirong, GAO Qiang. Preparation and characterization of polyurethane /polyvinylidene fluoride waterproof permeable composite fabric[J]. Journal of Textile Research, 2014, 35(5): 23-29.

[31]XIU Y Y, WANG D N, HU C P, et al. Morphology-property relationship of segmented polyurethaneurea: Influences of soft-segment structure and molecular weight[J]. Journal of Applied Polymer Science, 1993, 48(5): 867-869.

[32]DING X M, HU J L, TAO X M, et al. Free volume and water vapor transport properties of temperature-sensitive polyurethanes [J]. Journal of Polymer Science Part B: Polymer Physics, 2005, 43(14): 1865-1872.

[33]KIM C K, KIM B K. IPDI-based polyurethane ionomer dispersions: Effects of ionic, nonionic hydrophilic segments, and extender on particle size and physical properties of emulsion cast film[J]. Journal of Applied Polymer Science, 1991, 43(12): 2295-2301.

[34]YEN M S, KUO S C. Effects of mixing procedure on the structure and physical properties of ester-ether-type soft segment waterborne polyurethane [J]. Journal of Applied Polymer Science, 1996, 61(10): 1639-1647.

[35]PENG C C, ABETZ V. A simple pathway toward quanti-tative modification of polybutadiene: A new approach to thermoreversible cross-Linking rubber comprising supramo-lecular hydrogen-bonding networks[J]. Macromolecules, 2005, 38(13): 5575-5580.

[36]YEN M S, KUO S C. PCL-PEG-PCL triblock copolydiol-based waterborne polyurethane. I. Effects of the soft-segment composition on the structure and physical proper-ties[J]. Journal of Applied Polymer Science, 1997, 65(5): 883-892.

[37]CHATTOPADHYAY D K, SREEDHAR B, RAJU K. Thermal stability of chemically crosslinked moisture-cured polyurethane coatings [J]. Journal of Applied Polymer Science, 2005, 95(6): 1509-1518.

[38]JEONG H M, AHN B K, CHO S M, et al. Water vapor permeability of shape memory polyurethane with amorphous reversible phase [J]. Journal of Polymer Science Part B Polymer Physics, 2000, 38(23): 3009-3017.

[39]CHO J W, JUNG Y C, CHUN B C, et al. Water vapor permeability and mechanical properties of fabrics coated with shape-memory polyurethane [J]. Journal of Applied Polymer Science, 2004, 92(5): 2812-2816.

[40]LIN C Y, LIAO K H, SU C F, et al. Smart temperature-controlled water vapor permeable polyurethane film [J]. Journal of Membrane Science, 2007, 299(1/2): 91-96.

[41]ZHOU H, CHEN Y, FAN H, et al. Water vapor permeability of the polyurethane/TiO2 nanohybrid membrane with temperature sensitivity [J]. Journal of Applied Polymer Science, 2008, 109(5): 3002-3007.

[42]KIM T H, KWON C H, LEE C, et al. Bio-inspired hybrid carbon nanotube muscles[J]. Scientific Reports. 2016, 6(1): 1-8.

[43]WANG R, FANG S L, XIAO Y C, et al. Torsional refrigeration by twisted, coiled, and supercoiled fibers [J]. Science, 2019. 366(6462): 216-221.

[44]MU J K, WANG G, YAN H P, et al. Molecular-channel driven actuator with considerations for multiple configura-tions and color switching [J]. Nature Communications, 2018, 9(1): 1-10.

[45]HO K S, HSIEH K H, HUANG S K, et al. Polyurethane-based conducting polymer blends: I. Effect of chain extender [J]. Synthetic Metals, 1999, 107(1): 65-73.

[46]王宜春,薛元,代正偉,等.SMPU/PNIPAM半互穿温敏聚合物的合成与表征[J].聚氨酯工业,2012,27(2):9-11,34.

WANG Yichun, XUE Yuan, DAI Zhengwei. Synthesis and characterization of temperature-sensitive TSPU/PNIPAAm semi-IPN polymer[J]. Polyurethane Industry, 2012, 27(2): 9-11, 34.

[47]SU B, TIAN Y, JIANG L. Bioinspired interfaces with superwettability: From materials to chemistry [J]. Journal of the American Chemical Society, 2016, 138 (6): 1727-1748.

[48]杨群,梁琦,王黎明,等.聚N-异丙基丙烯酰胺/聚氨酯梯度复合膜的温敏亲-疏水性及透湿性[J].纺织学报,2021,42(9):17-23,38.

YANG Qun, LIANG Qi, WANG Liming, et al. Thermo-sensitive hydrophilic-hydrophobic transition and moisture

permeability of poly-N-isopropylacrylamide /polyurethane gradient composite membrane[J]. Journal of Textile Research, 2021, 42 (9): 17-23.

[49]PARK H S, PARK Y O. Filtration properties of elec-trospun ultrafine fiber webs[J]. Korean Journal of Chemical Engineering, 2005, 22(1): 165-172.

[50]SAWHNEY A P S, CONDON B, SINGH K V, et al. Modern applications of nanotechnology in textiles [J]. Textile Research Journal, 2008, 78(8): 731-739.

[51]HOU L L, WANG N, WU J, et al. Bioinspired superwettability electrospun micro/nanofibers and their applications [J]. Advanced Functional Materials, 2018, 28(49): 1801114.

[52]LI Y, ZHU Z G, YU J Y, et al. Carbon nanotubes enhanced fluorinated polyurethane macroporous membranes for waterproof and breathable application [J]. ACS Applied Materials & Interfaces, 2015, 7(24): 13538-13546.

[53]ZHANG M, SHENG J L, YIN X, et al. Polyvinyl butyral modified polyvinylidene fluoride breathable-waterproof nanofibrous membranes with enhanced mechanical perfor-mance [J]. Macromolecular Materials and Engineering, 2017, 302(8): 201600272.

[54]LEE S, OBENDORF K. Developing protective textile materials as barriers to liquid penetration using melt-electrospinning [J]. Journal of Applied Polymer Science, 2006, 102(4): 3430-3437.

[55]辛東坡,覃小红,王善元.静电纺纳米纤维非织造布的热湿传递性能[J].东华大学学报(自然科学版),2009,35(2):148-152.

XIN Dongpo, QIN Xiaohong, WANG Shanyuan. Thermal and moisture transport properties of electrospun nanofiber non-woven fabric[J]. Jouranl of Donghua University (Natural Science), 2009, 35(2):148-152.

[56]MIAO D Y, HUANG Z, WANG X F, et al. Continuous, spontaneous, and directional water transport in the trilayered fibrous membranes for functional moisture wicking textiles[J]. Small, 2018, 14 (32): 1801527.

[57]KANG Y K., PACK C H, KIM J, et al. Application of electrospun polyurethane web to breathable water-proof fabrics [J]. Fibers and Polymers, 2007, 8(5): 564-570.

[58]GE J F, SI Y, FU F, et al. Amphiphobic fluorinated polyurethane composite microfibrous membranes with robust waterproof and breathable performances [J]. RSC Advances, 2013, 3(7): 2248-2255.

[59]ZHANG L W, LI Y, YU J Y, et al. Fluorinated polyurethane macroporous membranes with waterproof, breathable and mechanical performance improved by lithium chloride [J]. RSC Advances, 2015, 5(97): 79807-79814.

[60]ZHAO J, WANG X F, LIU L F, et al. Human skin-Like, robust waterproof, and highly breathable fibrous membranes with short perfluorobutyl chains for eco-friendly protective textiles [J]. ACS Applied Materials & Interfaces, 2018, 10(36):30887-30894.

[61]MUTHIAH P, HOPPE S M, BOYLE T J, et al. Thermally tunable surface wettability of electrospun fiber mats:polystyrene/poly(N-isopropylacrylamide) blende dversus crosslinked poly[(N-isopropylacrylanmide)-co-(metacrylic acid)][J]. Macromolecular Rapid Communications, 2011, 32(21):1716-1721.

[62]LIN J Y, CAI Y, WANG X F, et al. Fabrication of biomimetic superhydrophobic surfaces inspired by lotus leaf and silver ragwort leaf [J]. Nanoscale, 2011, 3(3): 1258-1262.

[63]JIANG L, ZHAO Y, ZHAI J, A lotus-leaf-like superhy-drophobic surface: A porous microsphere/nanofiber composite film prepared by electrohydrodynamics [J]. Angewandte Chemie (International Ed in English), 2004, 43(33): 4338-4341.

[64]SHERMAN T F. On connecting large vessels to small: The meaning of Murray's law [J]. The Journal of General Physiology, 1981, 78(4): 431-453.

[65]WANG X F, HUANG Z, MIAO D Y, et al. Biomimetic fibrous Murray membranes with ultrafast water transport and evaporation for smart moisture wicking fabrics [J]. ACS Nano, 2019, 13(2): 1060-1070.

[66]YONG J L,HUO J L,CHEN F,et al. Oil/water separation based on natural materials with super-wettability: Recent advances [J]. Physical Chemistry Chemical Physics, 2018, 20(39): 25140-25163.

[67]AN Y P, YANG J, YANG H C, et al. Janus membranes with charged carbon nanotube coatings for deemulsification and separation of oil-in-water emulsions[J]. ACS Applied Materials & Interfaces, 2018, 10(11): 9832-9840.

[68]ZHOU H, GUO Z G. Superwetting Janus membranes: Focusing on unidirectional transport behaviors and multiple applications [J]. Journal of Materials Chemistry A, 2019, 7(21): 12921-12950.

[69]ZHU Z, ZHING L, CHEN X, et al. Monolithic and self-roughened Janus fibrous membrane with superhydrophilic/omniphobic surface for robust antifouling and antiwetting membrane distillation[J]. Journal of Membrane Science, 2020, 615: 1-10.

[70]XU Y, SHENG J, YIN X, et al. Functional modification of breathable polyacrylonitrile/polyurethane/TiO2 nanofi-brous membranes with robust ultraviolet resistant and waterproof performance[J]. Journal of Colloid & Interface Science, 2017, 508: 508-516.

Research progress and application of waterproof and moisture permeable membranes on textiles

QIU Huili1a,YANG Qun1a,1b, CUI Jin2, PEI Liujun1a,1b, HU Genghao1a

(1a.School of Textiles and Fashion; 1b.Shanghai Engineering Research Center for Clean Production of Textile Chemistry, Shanghai

University of Engineering Science, Shanghai 201620, China; 2. Shanghai Evershine Co., Ltd, Shanghai 201600, China)

Abstract:

Waterproof and moisture permeable membranes are a kind of functional membrane material with both water permeability and water vapor permeability. Combined with fiber fabric, they can prepare functional textiles with unique protective properties, waterproofness, breathabilityand moisture permeability. Currently, the moisture and heat transfer membranes used in human-environment interaction of wearable textiles mainly include polytetrafluoroethylene (PTFE) hydrophobic membranes, polyurethane hydrophilic membranes and electrospun fiber membranes. At present, protective materials have become an urgent need to improve the comfort and wearability of long-term use while improving the barrier property. Functional and intelligently breathable and moisture permeable materials have also been studied, accelerating their application in medical, garment and military protective materials.

Since water molecules transport more slowly in solids than in pores, the waterproof and moisture permeability of the PTFE hydrophobic microporous membrane mainly comes from the regulation of its pore size. When the pore size is smaller than the raindrop but larger than the water vapor molecule, it has better waterproof and moisture permeability, but because the PTFE is hydrophobic, it will lead to the accumulation of water droplets in the pore channel blockage. The polyurethane hydrophilic membrane discharge water vapor molecules to the outside via the absorption-transfer-release process, which has high water pressure resistance due to its non-porous structure, so the permeability and moisture permeability are relatively poor, and the wearers will feel uncomfortable. Electrospinning, as a convenient and effective route to prepare micro/nanofiber membranes, has been developed rapidly in recent years. The electrospun fiber membrane is considered to be an effective material to prepare waterproof and breathable membranes because of its small pore size, high porosity, controllable porous structure and ease of surface modification. Until now, a variety of strategies such as biaxial stretching, formwork methods, and melt blowing have been used to produce microporous, waterproof and breathable membranes. However, due to the limitations of raw materials and processes, these methods are still difficult to industrialize in large quantities.

Although the research on the physical, chemical preparation and processing of waterproof and moisture permeable membranes has accumulated a lot of valuable results, the actual daily wearing environment is very complex, especially when switching between indoor and outdoor scenes, such as entering and exiting air-conditioned rooms in summer. The waterproof and moisture permeable fabric with undiversified "winter warmness" or "summer coolness" cannot adapt to the complex scene and even cause the medical staff to get cold and sick. Its poor adaptability greatly limits the practical application. Consequently, it is urgent to design and develop a smart textile with thermal/moisture dissipation in hot weather while offer a warm and humid microclimate in cold weather, which may accelerate the development and research on medical protective clothing and other related medical textiles.

Keywords:

waterproofing and moisture permeability; functional membranes; intelligent fabric; electrospun fiber membrane; protective property

收稿日期:20220805

網络出版日期:20221104

基金项目:上海工程技术大学产学研项目((19)FZ-015);浙江省纱线材料成形与复合加工技术研究重点实验室项目(MTC-2020-23)

作者简介:仇慧丽(1998—),女,河南安阳人,硕士研究生,主要从事功能与智能材料设计与应用方面的研究。

通信作者:杨群,E-mail:yangqun@sues.edu.cn