施氮量对甘薯块根膨大过程中淀粉含量及特性的影响

吴世雨 陈匡稷 吕尊富 徐锡明 庞林江 陆国权,*

施氮量对甘薯块根膨大过程中淀粉含量及特性的影响

吴世雨1,2陈匡稷1,3吕尊富1,2徐锡明1,2庞林江2,4陆国权1,2,*

1浙江农林大学现代农学院/浙江省农产品品质改良重点实验室, 浙江杭州 311300;2浙江农林大学薯类作物研究所, 浙江杭州 311300;3仪征市农业技术综合服务中心, 江苏扬州 211400;4浙江农林大学食品与健康学院, 浙江杭州 311300

为探究施氮量对甘薯块根膨大过程中淀粉含量及特性的影响, 以‘心香’和‘商薯19’为试验材料, 设置0 kg hm–2(CK)、57.5 kg hm–2(N1)、115 kg hm–2(N2) 3个氮肥(N)处理在栽插当日施用。在栽插后60、80、100、120和140 d取样, 研究了施加氮肥后甘薯块根膨大过程中淀粉的含量、糊化特性、流变特性、凝胶质构特性及淀粉酶活性的变化规律。结果表明, (1) 在块根膨大过程中, 施用氮肥可显著提高2个甘薯品种淀粉含量。块根膨大前期施氮显著降低‘心香’淀粉糊化特性的最低黏度、最终黏度和消减值, 后期显著降低‘商薯19’淀粉糊化特性的最低黏度、最终黏度和消减值, 显著提高‘心香’淀粉糊化特性的最低黏度、最终黏度和消减值; (2) 3个处理下, 淀粉凝胶硬度和咀嚼性随块根的膨大逐渐降低。在块根膨大后期, N2处理可显著提升2个品种的淀粉凝胶硬度; (3) 2个品种淀粉凝胶呈现弹性性质, N1、N2处理可提高‘心香’的储能模量和损耗模量, 降低‘商薯19’的储能模量和损耗模量; (4)块根膨大前期, 施氮降低2个品种α-淀粉酶和β-淀粉酶活性, 但是块根膨大后期提高。因此, 施氮量会对甘薯块根膨大过程中淀粉含量及特性产生显著影响。‘商薯19’在115 kg hm–2施氮量下, 栽插后120 d时进行收获, 有利于甘薯淀粉加工。合理施氮、适时收获有利于甘薯淀粉的积累及其品质提升。

甘薯; 氮肥; 块根膨大期; 淀粉; 理化特性

甘薯((L.) Lam.)是重要的粮食、饲料、工业原料等, 在世界粮食生产中总产列第7位, 在中国粮食与能源安全中具有重要作用[1]。甘薯因其光合能力强, 单位面积的淀粉产量高于一般谷类作物, 已成为生产淀粉的主要原料作物[2]。淀粉是甘薯块根的主要成分之一, 占块根干物质含量的50%~80%[3-4]。甘薯可用作鲜食、淀粉加工、食品加工等, 其中甘薯淀粉广泛用于面条、粉条、焙烤食品、糖果产品等方面[5-6]。

甘薯淀粉的理化特性主要受遗传因素控制, 环境也会对其产生影响[7]。氮是甘薯生长发育期间所必需的大量营养元素[8]。适量施氮可有效提高甘薯块根产量[9]。王良平等[10]研究结果表明土壤中氮含量对甘薯块根的淀粉率产生极显著影响。陈晓光等[7]研究表明施氮使‘徐薯22’和‘徐薯28’品种块根的淀粉最高黏度、最低黏度、最终黏度和消减值等特征值升高, 且施氮量对淀粉RVA谱特征值的影响因品种的不同而有差异。黄华宏等[11]研究了不同生育期甘薯块根淀粉糊化特性的差异, 发现‘徐薯18’、‘浙大9201’和‘浙3449’ 3个甘薯品种在生育期内, 淀粉率都呈下降趋势, 随生育期延长, RVA的最高黏度呈现递增趋势。李臣等[12]以鲜食甘薯代表性品种‘心香’为试验材料, 对其进行生育期内的营养成分及加工特性指标变化规律和相关性分析, 发现生育期119 d的淀粉率最高, 适合淀粉加工。

氮肥对作物淀粉品质的影响在小麦[13]、水稻[14]等主要作物上已有了大量的研究, 同时在与甘薯相似的作物马铃薯[15]上也有了大量研究, 目前对甘薯的研究大多集中收获时产量、淀粉含量及其特性方面, 对于甘薯块根膨大期淀粉特性的影响涉及较少。本研究以鲜食型品种‘心香’和淀粉型品种‘商薯19’为试验材料, 设置3个氮肥(N)处理, 从甘薯块根膨大期的淀粉含量、糊化特性、动态流变特性、质构特性及淀粉酶活性方面探讨施氮量对不同品种甘薯块根淀粉含量及特性影响, 以期为甘薯淀粉食品加工生产提供优质原料, 为氮肥科学施用提供理论基础。

1 材料与方法

1.1 试验材料与设计

本试验于2020年在浙江农林大学农作园基地进行, 甘薯选用淀粉型品种‘商薯19’ (河南省商丘市农林科学院选育, 淀粉率21%以上)和鲜食型品种‘心香’ (浙江省农林科学院培育, 淀粉率22.1%), 氮肥采用尿素(N含量46%)、磷肥采用过磷酸钙(P2O5含量16%)、钾肥采用硫酸钾(K2O含量51%)。供试土壤类型为红壤土, 0~20 cm土层土壤含全氮0.82 g kg–1、全磷0.61 g kg–1、全钾25.8 g kg–1、速效氮55.42 mg kg–1、速效磷6.70 mg kg–1、速效钾218.97 mg kg–1。

设置0 kg hm–2(CK)、57.5 kg hm–2(N1)、115 kg hm–2(N2) 3个氮肥(N)处理, 各处理的磷肥(P2O5)用量均为120 kg hm–2, 钾肥(K2O)用量均为300 kg hm–2, 种植前统一施肥。小区面积36 m2(6 m×6 m), 每个小区6垄, 重复3次, 垄宽85 cm, 高25 cm, 垄间距1 m, 株距20 cm, 于2020年5月28日栽插, 于2020年10月17日收获, 在栽插后60、80、100、120和140 d进行取样。对所有的小区进行覆盖地膜处理, 水源为雨水自然灌溉。统一种植, 保证甘薯的种植周期、光照及管理措施等条件一致。

1.2 测定项目与方法

1.2.1 淀粉提取 淀粉提取参照唐忠厚等[16]的方法并稍做修改。淀粉制备: 薯块去皮, 切成细块状,放入高速打浆机, 加适量水, 粉碎30 s, 倒入100目纱袋, 加0.5 L水洗提, 另0.5 L水再洗提一次, 将洗提液合并, 过100目筛, 静置12 h, 置40℃空气干燥机中干燥24 h, 研磨成粉末, 过100目筛, 密封, 干燥避光条件保存。

1.2.2 甘薯全粉制备 选取3~5个大小一致、无病虫害、无破损的薯块, 洗净晾干, 用切片机切成0.2 cm的薄片, 液氮迅速浸泡20 min后, 转移至冷冻干燥机中, 进行–80℃冷冻干燥72 h, 干燥后用锤式旋风磨磨成粉状, 过100目筛, 密封, 低温干燥避光条件保存。

1.2.3 淀粉含量测定 采用盐酸水解DNS法[17]。

1.2.4 淀粉的糊化特性测定 参照包劲松[18]的方法测定淀粉的糊化特性, 参照美国谷物协会(AACC)76-21方法[19], 采用升温-降温循环程序。

1.2.5 淀粉凝胶的质构特性测定 参照Bao等[20]的方法。

1.2.6 淀粉凝胶的动态流变特性测定 参照Sandhu等[21]的方法。

1.2.7 淀粉酶活性测定 参照曹建康[22]试验方法。

1.3 数据处理与分析

采用Microsoft Excel 2016软件进行试验数据的录入和整理, 采用SPSS 23和Origin 8.6软件进行数据分析, 采用Duncan’s多重比较法进行方差分析, 采用spearman相关性分析法进行相关性分析, 采用Microsoft Excel 2016和Origin 8.6软件绘图。

2 结果与分析

2.1 施氮对甘薯块根膨大过程中淀粉含量的影响

由图1可知, 施氮可显著提高2个品种的淀粉含量, N2处理提高淀粉含量效果更显著。‘心香’薯块淀粉含量在块根膨大期呈现出先升高后降低的整体趋势, 在栽插后100 d达到最大值, 分别为79.54%、81.54%、84.19%。N1处理下, 薯块淀粉含量在栽插后60、100、120 d显著高于CK组, 在栽插后80、140 d显著低于CK组; N2处理下, 薯块淀粉含量在块根膨大期间显著高于CK组。‘商薯19’块根淀粉含量在块根膨大期呈现上下波动的变化, 这与周志林等[23]的研究结果相一致。CK、N1处理下, 栽插后100 d出现淀粉含量最大值, 分别是67.56%、69.39%; N2处理下, 栽插后60 d淀粉含量最高, 为73.33%。

2.2 施氮对甘薯块根膨大过程中淀粉糊化特性的影响

由表1和表2可知, 施氮对2个品种的淀粉糊化特性具有显著影响, 其中对最低黏度、崩解值、最终黏度、消减值的影响最大。由表1可知, 与CK处理相比较, 栽插后60~100 d, N1、N2处理显著降低最低黏度; 栽插后120 d, N1、N2处理下最低黏度大于CK处理但无显著差异; 栽插后140 d, N1、N2处理显著提升最低黏度; 在块根膨大过程中, N1、N2处理间最低黏度无显著差异。崩解值用于测量淀粉糊的耐热性, 栽插后60~80 d, N1、N2处理显著提升淀粉的崩解值; 栽插后100~140 d, CK、N2处理间崩解值差异显著。N1、N2处理下最终黏度在栽插后60~100 d显著低于CK处理, 在栽插后100 d, 显著高于CK处理。消减值等于最终黏度减最高黏度, 栽插后60~120 d, N1、N2处理消减值显著低于CK, 栽插后140 d, 显著高于CK处理。栽插后60~80 d, N2处理显著降低峰值时间, 峰值时间在块根膨大后期差异不显著。糊化温度仅在栽插后140 d时, N1、N2处理显著高于CK其余时期, 差异不显著。

由表2可知, 栽插后60 d, 3个处理间淀粉糊化特性指标无显著差异。与CK处理相比较, 栽插后80 d, N2处理显著提高淀粉糊化温度; 栽插后100 d, N1处理显著提高最高黏度和崩解值, 显著降低消减值, N2处理显著降低最低黏度; 栽插后120 d, N2处理显著提高最高黏度和崩解值; 栽插后140 d, N1处理显著降低最高黏度、最低黏度、最终黏度、消减值、峰值时间和糊化温度, N2处理显著提升最高黏度和崩解值, 显著降低最低黏度、最终黏度、消减值、峰值时间及糊化温度。

图1 不同施氮量对甘薯块根膨大过程中淀粉含量的影响

A: 心香; B: 商薯19。CK: 0 kg hm–2氮肥施用量; N1: 57.5 kg hm–2氮肥施用量; N2: 115 kg hm–2氮肥施用量。不同小写字母标识代表不同处理在同一时期差异显著(< 0.05)。

A: Xinxiang; B: Shangshu 19. CK: 0 kg hm–2of nitrogen fertilizer application rate; N1: 57.5 kg hm–2of nitrogen fertilizer application rate; N2: 115 kg hm–2of nitrogen fertilizer application rate. Different lowercase letters indicate that the different treatment is significant differences in the same periods at< 0.05.

表1 不同施氮量对‘心香’块根膨大过程中淀粉糊化特性的影响

处理同图1。不同小写字母标识代表不同处理在同一时期差异显著(< 0.05)。

Treatments are the same as those given in Fig. 1. PKV: peak viscosity; HPV: hot paste viscosity; BDV: breakdown viscosity; CPV: cold paste viscosity; SBV: setback viscosity; T: peak time; PT: pasting temperature. Different lowercase letters indicate that the different treatment is significant differences in the same periods at< 0.05.

表2 不同施氮量对‘商薯19’块根膨大过程中淀粉糊化特性的影响

处理同图1。不同小写字母标识代表不同处理在同一时期差异显著(< 0.05)。

Treatments are the same as those given in Fig. 1. PKV: peak viscosity; HPV: hot paste viscosity; BDV: breakdown viscosity; CPV: cold paste viscosity; SBV: setback viscosity; T: peak time; PT: pasting temperature. Different lowercase letters indicate that the different treatment is significant differences in same periods at< 0.05.

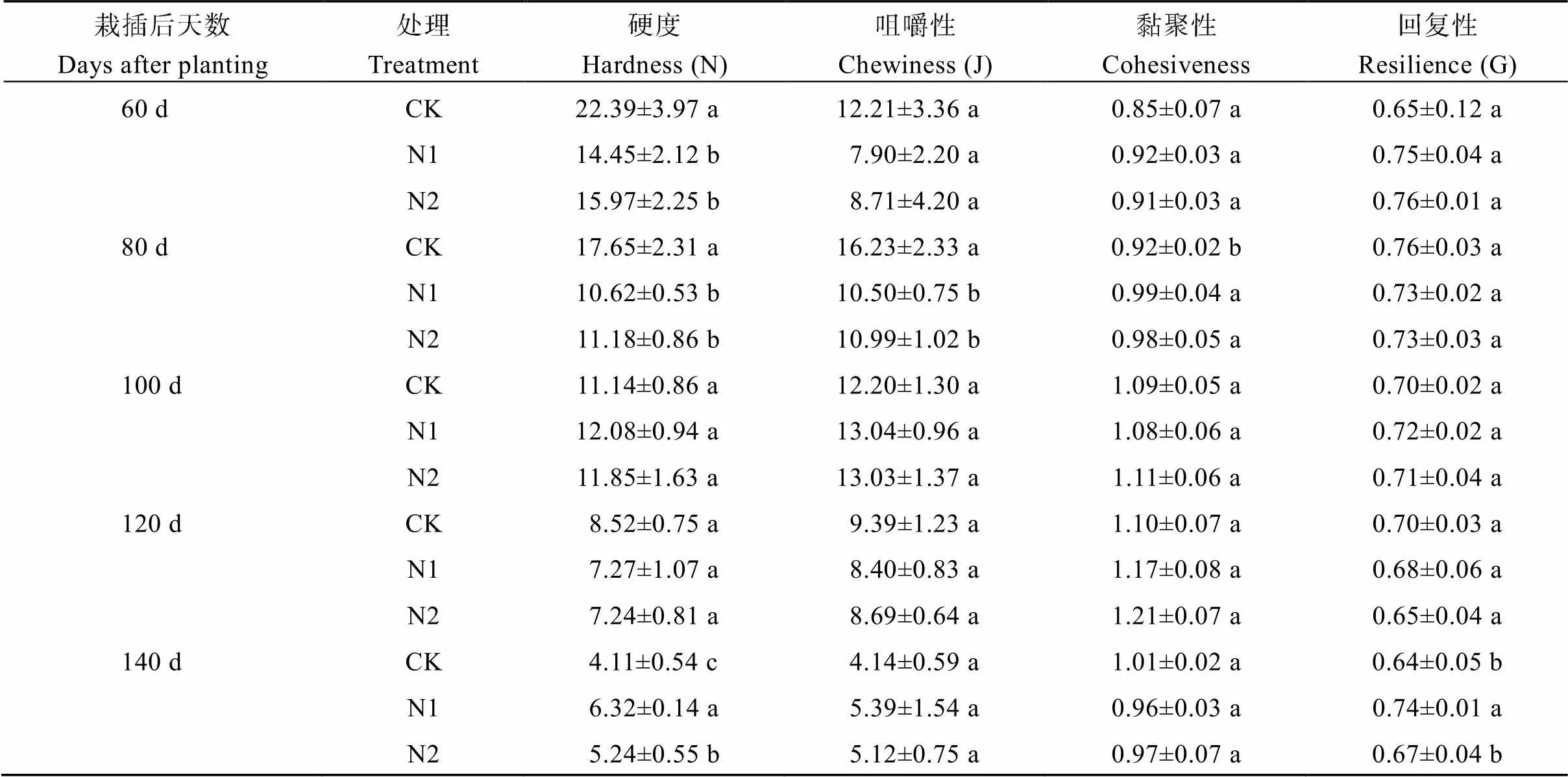

2.3 施氮对甘薯块根膨大过程中淀粉凝胶质构的影响

表3和表4为甘薯块根膨大过程中, 不同施氮量下淀粉凝胶的质构参数变化。块根膨大过程中, 2个品种淀粉凝胶硬度和咀嚼性呈逐渐降低的趋势, 黏聚性和回复性则呈现波动的趋势。不同施氮量对‘心香’块根膨大过程中淀粉凝胶的硬度影响最大, 对‘商薯19’块根膨大过程中淀粉凝胶的硬度和咀嚼性影响最大。由表3可知, 与CK处理相比较, 栽插后60~80 d, N1、N2显著降低‘心香’淀粉凝胶硬度; 栽插后100~120 d, 各处理间无显著差异; 栽插后140 d, N1、N2处理显著提高硬度。由表4可知, N2处理在栽插后80、120和140 d显著提升‘商薯19’淀粉凝胶硬度和咀嚼性, N1处理在栽插后100 d显著提升淀粉凝胶硬度和咀嚼性, 其他时期3个处理间无显著差异。

表3 不同施氮量对‘心香’块根膨大过程中淀粉凝胶质构特性的影响

处理同图1。不同小写字母标识代表不同处理在同一时期差异显著(< 0.05)。

Treatments are the same as those given in Fig. 1. Different lowercase letters indicate that the different treatment is significant differences in the same periods at< 0.05.

表4 不同施氮量对‘商薯19’块根膨大过程中淀粉凝胶质构特性的影响

(续表4)

处理同图1。不同小写字母标识代表不同处理在同一时期差异显著(< 0.05)。

Treatments are the same as those given in Fig. 1. Different lowercase letters indicate that the different treatment is significant differences in the same periods at< 0.05.

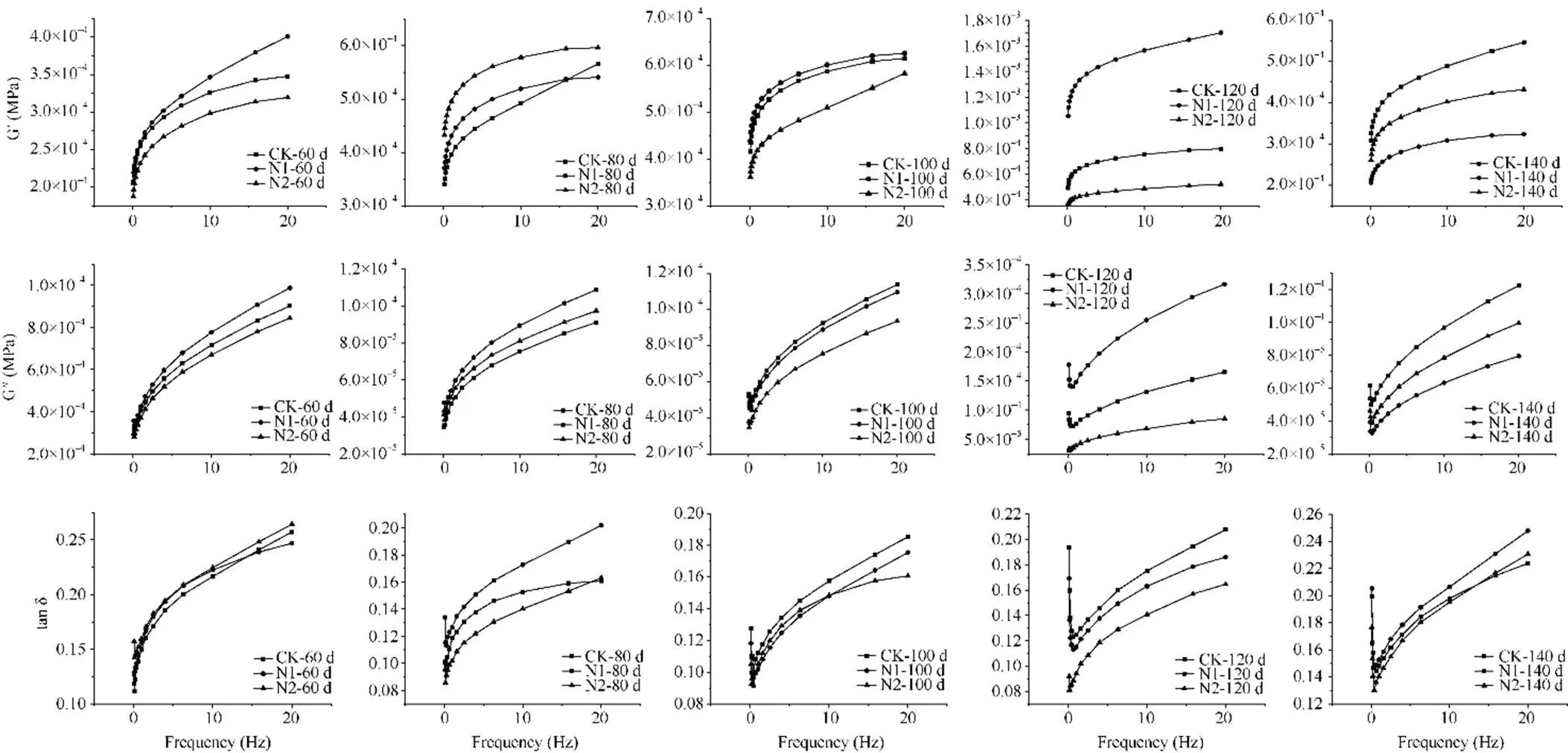

2.4 施氮对甘薯块根膨大过程中淀粉凝胶动态流变特性的影响

不同施氮量处理对‘心香’与‘商薯19’块根膨大期的淀粉凝胶动态流变特性如图2和图3所示。储能模量(G′)代表样品的弹性特性, 损耗模量(G″)代表样品的黏性特性。G″/G′定义为损耗角正切值(tan δ)。由下图可知, 随频率增大, ‘心香’和‘商薯19’淀粉凝胶的储能模量和损耗模量值均呈现逐渐增加的整体趋势; 损耗角正切值整体上呈现先降低后升高的趋势, 且所有样品损耗角正切值(tan δ)均小于1, 即G′始终大于G″。甘薯块根的膨大过程中, N1、N2处理提升了‘心香’淀粉凝胶的储能模量和损耗模量, 且提升强度N2>N1, 同时降低损耗角正切值。对于‘商薯19’, N1、N2处理降低其储能模量和损耗模量, 对损耗角正切值影响不明显。

2.5 施氮对甘薯块根膨大过程中淀粉酶活性的影响

不同施氮量处理下, ‘心香’和‘商薯19’块根膨大过程中α-淀粉酶活性值如图4所示。在各处理下, 2个品种的α-淀粉酶活性呈整体上升的趋势, 在栽插后100 d具有显著上升变化。栽插后60~80 d, N1、N2处理可显著降低2个品种的α-淀粉酶活性。栽插后100~140 d, N1、N2处理可提升2个品种的α-淀粉酶活性, 对于‘心香’ N1处理效果更显著, 对于‘商薯19’ N2处理效果更显著。

图2 不同施氮量对‘心香’块根膨大过程中动态流变特性的影响

CK: 0 kg hm–2氮肥施用量; N1: 57.5 kg hm–2氮肥施用量; N2: 115 kg hm–2氮肥施用量。60、80、100、120和140 d分别代表栽插后60、80、100、120和140 d。

CK: 0 kg hm–2of nitrogen fertilizer application rate; N1: 57.5 kg hm–2of nitrogen fertilizer application rate; N2: 115 kg hm–2of nitrogen fertilizer application rate. 60, 80, 100, 120, and 140 d represent 60, 80, 100, 120, and 140 days after planting, respectively.

图3 不同施氮量对‘商薯19’块根膨大过程中动态流变特性的影响

处理同图2。Treatments are the same as those given in Fig. 2.

图4 不同施氮量对甘薯块根膨大过程中a-淀粉酶活性的影响

A: 心香; B: 商薯19。不同小写字母标识代表不同处理在同一时期差异显著(< 0.05)。处理同图1。

A: Xinxiang; B: Shangshu 19. Different lowercase letters indicate that the different treatment is significant differences in the same periods at< 0.05. Treatments are the same as those given in Fig. 1.

不同施氮量处理下, ‘心香’和‘商薯19’块根膨大过程中β-淀粉酶活性值如图5所示。在各处理下, 2个品种β-淀粉酶活性呈现逐渐升高的趋势, 在栽插后120 d有显著性增强。栽插后140 d 2个品种β-淀粉酶活性达到最大值, 且N2处理的β-淀粉酶活性显著高于CK组。栽插后60~80 d, 施氮可降低2个品种的β-淀粉酶活性, 但与CK处理比较差异不显著。栽插后100~140 d, N1、N2处理可显著提高2个品种的β-淀粉酶活性。

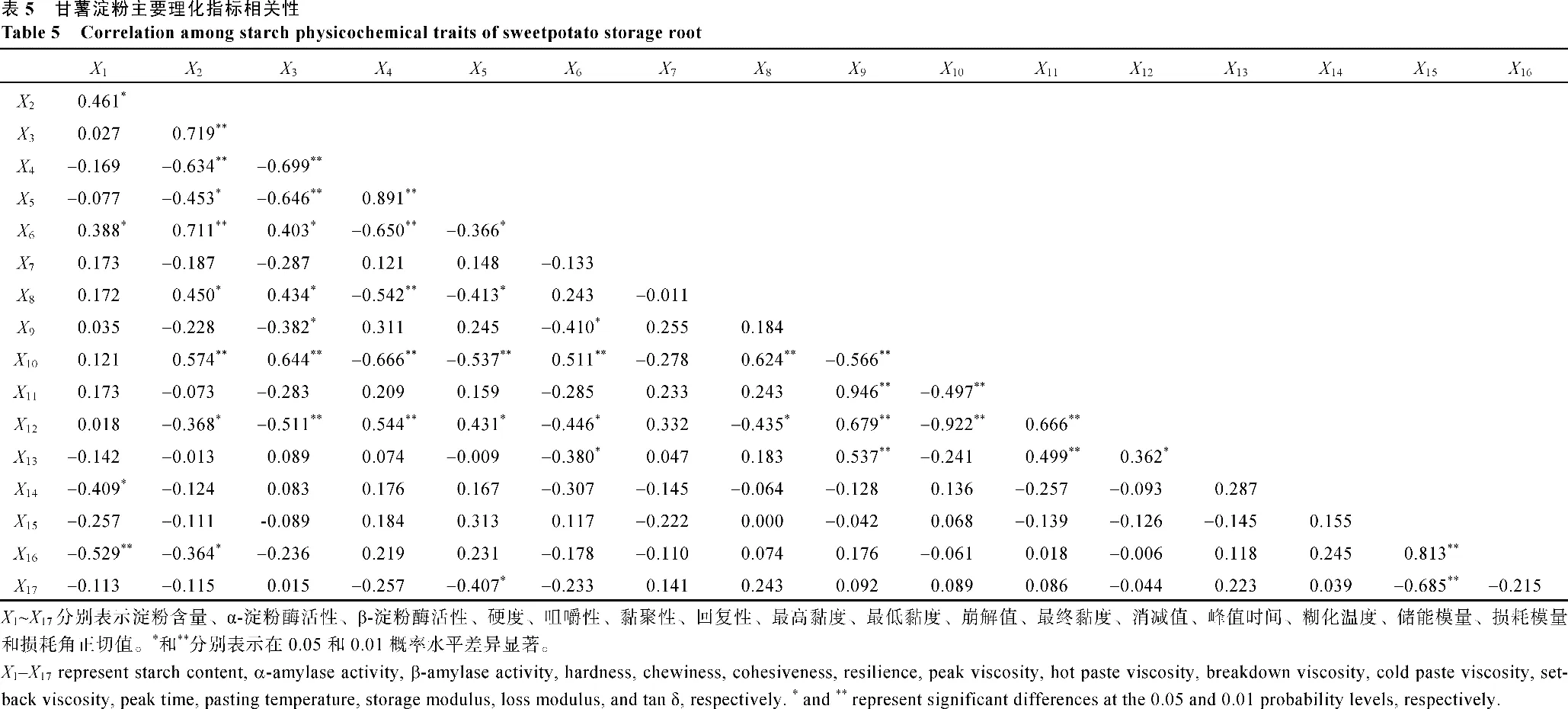

2.6 甘薯块根淀粉主要理化指标相关性分析

相关分析结果显示(表5), 淀粉含量与α-淀粉酶活性、淀粉质构黏聚性呈显著正相关, 与RVA糊化温度呈显著负相关, 与淀粉凝胶损耗模量呈极显著负相关。α-淀粉酶活性与淀粉凝胶质构的硬度呈极显著负相关, 与RVA最低黏度呈极显著正相关, 与咀嚼性、RVA最终黏度、淀粉损耗模量呈显著负相关, 与黏聚性、RVA最高黏度呈显著正相关, α-淀粉酶活性与b-淀粉酶活性呈极显著正相关关系。硬度与RVA最高黏度、崩解值呈极显著负相关, 与消减值呈极显著正相关。因此, 甘薯块根淀粉含量及淀粉酶活性与淀粉的糊化特性、流变特性、质构特性等理化特性密切相关。

图5 不同施氮量对甘薯块根膨大过程中β-淀粉酶活性的影响

Fig. 5 Effects of different nitrogen fertilizer application rates on the β-amylase activity during storage root expansion in sweetpotato

A: 心香; B: 商薯19。不同小写字母标识代表不同处理在同一时期差异显著(< 0.05)。处理同图1。

A: Xinxiang; B: Shangshu 19.Different lowercase letters indicate that the different treatment is significant differences in the same periods at< 0.05.Treatments are the same as those given in Fig. 1.

3 讨论

淀粉作为甘薯块根干物质的主要成分之一, 其含量及理化性质对薯块的产后加工有重要影响, 淀粉含量主要受品种的影响, 同时也受环境的影响[24]。柳强娟等[25]研究表明随着施氮量的增加, 马铃薯总淀粉含量呈现先上升后下降的趋势。张友良等[26]研究结果表明, 在相同滴灌湿润比条件下, 淀粉含量随着施氮量增加而先增加后减小, 180 kg hm-2处理获得最高的淀粉含量, 适量施加氮肥对甘薯的生长有促进的效果, 能提高甘薯块根的干物质率。本研究中, N1、N2处理均使2个品种淀粉含量显著增大, 和前人研究结果不一致可能是因为品种的原因, 导致施氮效果不一样。对于鲜食型品种来说, 淀粉含量较低, 块根蒸煮食味较好, 因此施加氮肥更有利于甘薯品种‘商薯19’。a-淀粉酶和b-淀粉酶是参与甘薯块根中淀粉酶水解最主要的酶, 其活性变化对甘薯品质有着重要的影响[27]。本研究中, α-淀粉酶活性与β-淀粉酶活性呈极显著正相关关系, 施氮可在块根膨大前期降低2个品种淀粉酶活性, 后期增强2个品种淀粉酶的活性。

糊化特性是反应淀粉品质的重要指标, 是评价甘薯淀粉物理品质的重要参数, 对薯块食味和加工品质有着重要的影响[28]。前人研究认为崩解值大、消减值小的稻米食味品质优[29-30], 本研究中, 施氮处理使‘心香’在块根膨大后期的淀粉崩解值变小、消减值变大, 使‘商薯19’淀粉崩解值变大、消减值变小, 这说明施用氮肥可能会降低鲜食型品种的食用品质,提升淀粉型甘薯的食用品质。RVA参数(保持强度、最终黏度、峰黏度、回生值和衰减度) 与粉丝品质有显著的相关性[31]。俞树玺等[32]研究结果表明, 峰值时间、糊化温度与甘薯粉条品质呈正相关, 最终黏度与之呈负相关。本研究中, 施氮处理对2个品种的峰值时间和糊化温度影响较小, 在块根膨大前期显著降低‘心香’最终黏度, 在块根膨大后期显著降低‘商薯19’最终黏度, 这说明施用氮肥可能会提升2个品种的粉条加工品质。

淀粉凝胶的质构特性可以反映出食品的品质特性, 对于研发新食品、改善食品的感官性质、控制食品品质等有重要作用[33]。已有研究表明淀粉浓度和直链淀粉含量是影响淀粉凝胶特性的关键参数, 直链淀粉含量与淀粉凝胶强度呈正比[34]。本研究中, 淀粉凝胶的硬度随块根膨大期的延长呈现逐渐降低的趋势, 淀粉酶活性呈现逐渐升高的趋势, 同时相关性分析显示, 淀粉凝胶的硬度与淀粉酶活性呈极显著负相关的关系。施氮处理使2个品种淀粉凝胶的硬度降低, 这可能与直链淀粉分子间的相互交联程度减弱有关, 进而形成了质地较柔软的淀粉凝胶。

动态流变性用来描述样品的黏弹性, 对加工品质和质量具有很大意义[35]。当tan δ>1时, 样品总体呈现黏性性质; 反之, 当tan δ<1时, 则呈现弹性性质[36]。tan δ越大, 凝胶流动性强, tan δ越小, 固体特性越强。本研究中, 施氮提升了‘心香’淀粉凝胶的流动性, 可能与改变淀粉颗粒大小影响了甘薯淀粉的流变性能有关[37]。本研究中甘薯淀粉凝胶以弹性性质为主, 呈现典型的弱凝胶动态流变学图谱, 这一结果与谭洪卓等[38]对甘薯淀粉凝胶研究结果相一致。本研究中, 施氮处理提高‘心香’淀粉凝胶的黏弹性, 降低‘商薯19’的黏弹性, 黏弹性更高的淀粉糊, 更适合作为食品加工的辅料和添加剂。

4 结论

施加氮肥会对甘薯块根膨大过程中淀粉含量、淀粉酶活性、糊化特性、流变特性、质构特性产生不同程度影响。‘商薯19’在115 kg hm-2施氮量下, 栽插后120 d进行收获, 此时淀粉含量最高, 淀粉最终黏度低有利于甘薯粉丝加工。合理施氮、适时收获有利于甘薯淀粉的积累及其品质提升。

[1] 刘庆昌. 甘薯在我国粮食和能源安全中的重要作用. 科技导报, 2004, (9): 21–22.

Liu Q C. Importance of sweet potato in the security of food and energy in China., 2004, (9): 21–22 (in Chinese with English abstract).

[2] 马剑凤, 程金花, 汪洁, 戴红君, 戴起伟. 国内外甘薯产业发展概况. 江苏农业科学, 2012, 40(12): 1–5.

Ma J F, Cheng J H, Wang J, Dai H J, Dai Q W. Overview of sweet potato industry development at home and abroad., 2012, 40(12): 1–5(in Chinese with English abstract).

[3] Aina A J, Falade K O, Akingbala J O, Titus P. Physicochemical properties of twenty-one Caribbean sweet potato cultivars., 2009, 44: 1696–1704.

[4] Antonio G C, Takeiti C Y, Oliveira R A D, Park K J. Sweet potato: production, morphological and physicochemical characteristics, and technological process., 2011, 5: 914035.

[5] 张令文, 琚星, 李欣欣, 胡新月, 计红芳, 毕继才, 马汉军. 8个品种甘薯淀粉的理化性质及其相关性分析. 食品工业科技, 2021, 42(4): 26–32.

Zhang L W, Ju X, Li X X, Hu X Y, Ji H F, Bi J C, Ma H J. Physicochemical properties and their correlation of starches from eight sweet potato cultivars., 2021, 42(4): 26–32(in Chinese with English abstract).

[6] 王欣, 李强, 曹清河, 马代夫. 中国甘薯产业和种业发展现状与未来展望. 中国农业科学, 2021, 54: 483–492.

Wang X, Li Q, Cao Q H, Ma D F. Current status and future prospective of sweet potato production and seed industry in China., 2021, 54: 483–492(in Chinese with English abstract).

[7] 陈晓光, 丁艳锋, 唐忠厚, 魏猛, 史新敏, 张爱君, 李洪民. 氮肥施用量对甘薯产量和品质性状的影响. 植物营养与肥料学报, 2015, 21: 979–986.

Chen X G, Ding Y F, Tang Z H, Wei M, Shi X M, Zhang A J, Li H M. Suitable nitrogen rate for storage root yield and quality of sweet potato., 2015, 21: 979–986(in Chinese with English abstract).

[8] Duan W, Zhang H, Xie B, Wang B, Zhang L. Impacts of nitrogen fertilization rate on the root yield, starch yield and starch physicochemical properties of the sweet potato cultivar Jishu 25., 2019, 14: e0221351.

[9] 刘兆辉, 薄录吉, 李彦, 孙明, 仲子文, 张英鹏, 井永苹. 氮肥减量施用技术及其对作物产量和生态环境的影响综述. 中国土壤与肥料, 2016, (4): 1–8.

Liu Z H, Bo L J, Li Y, Sun M, Zhong Z W, Zhang Y P, Jing Y P. Effect of nitrogen fertilizer reduction on crop yield and ecological environment: a review., 2016, (4): 1–8(in Chinese with English abstract).

[10] 王良平, 张菡, 乐正碧, 黎华, 王季春. 密度和施肥对甘薯品种‘万薯5号’淀粉含量的影响. 作物杂志, 2012, (1): 108–110.

Wang L P, Zhang H, Le Z B, Li H, Wang J C. The effect of planting density and Fertilization on the starch content of high-starch sweet potato Wanshu 5., 2012, (1): 108–110(in Chinese with English abstract).

[11] 黄华宏, 陆国权, 郑遗凡. 不同生育期甘薯块根淀粉糊化特性的差异. 中国农业科学, 2005, 38: 462–467.

Huang H H, Lu G Q, Zheng Y F. Variation in root starch gelatinization characteristics during the growth and development of sweet potato., 2005, 38: 462–467(in Chinese with English abstract).

[12] 李臣, 薛冠炜, 黄静艳, 王宁东, 陆国权. 生育期对鲜食甘薯品种‘心香’营养成分及产品加工特性的影响. 浙江农业学报, 2017, 29: 1957–1962.

Li C, Xue G W, Huang J Y, Wang N D, Lu G Q. Effects of different growth stages on nutritional components and processing characteristics of sweet potato cultivar Xinxiang., 2017, 29: 1957–1962(in Chinese with English abstract).

[13] 严美玲, 殷岩, 姜鸿明, 丁晓仪, 于经川, 王江春. 氮肥用量对小麦籽粒粒重及淀粉含量的影响. 麦类作物学报, 2008, 28: 1011–1015.

Yan M L, Yin Y, Jiang H M, Ding X Y, Yu J C, Wang J C. Effects of nitrogen amount on grains weight and amylose, amylopectin content of wheat., 2008, 28: 1011–1015(in Chinese with English abstract).

[14] 孙涛, 同拉嘎, 赵书宇, 王海微, 韩云飞, 张忠臣, 金正勋. 氮肥对水稻胚乳淀粉品质、相关酶活性及基因表达量的影响. 中国水稻科学, 2018, 32: 475–484.

Sun T, Tong L G, Zhao S Y, Wang H W, Han Y F, Zhang Z C, Jin Z X. Effects of nitrogen fertilizer application on starch quality, activities and gene expression levels of related enzymes in rice endosperm., 2018, 32: 475–484(in Chinese with English abstract).

[15] 李勇, 吕文河, 吕典秋, 宿飞飞, 李辉, 胡林双, 杨焕春, 刘振宇, 王绍鹏, 刘尚武. 施氮水平对不同淀粉型马铃薯块茎产量和淀粉品质的影响. 中国农业大学学报, 2019, 24(3): 27–38.

Li Y, Lyu W H, Lyu D Q, Su F F, Li H, Hu L S, Yang H C, Liu Z Y, Wang S P, Liu S W. Effects of nitrogen fertilizer application rote on the tuber yield and starch quality of potato varieties with different starch contents., 2019, 24(3): 27–38(in Chinese with English abstract).

[16] 唐忠厚, 张爱君, 陈晓光, 靳容, 刘明, 李洪民, 丁艳锋. 低钾胁迫对甘薯块根淀粉理化特性的影响及其基因型差异. 中国农业科学, 2017, 50: 513–525.

Tang Z H, Zhang A J, Chen X G, Jin R, Liu M, Li H M, Ding Y F. Starch physicochemical properties and their difference in three sweet potato genotypes under low potassium stress., 2017, 50: 513–525(in Chinese with English abstract).

[17] 陆国权, 李秀玲, 丁守仁. 盐酸水解DNS比色法快速测定甘薯淀粉含量的标准方法研究. 中国粮油学报, 2002, (1): 25–28.

Lu G Q, Li X L, Ding S R. Quick analysis of starch content of sweet potato by HCL hydrolysis–DNS method., 2002, (1): 25–28 (in Chinese with English abstract).

[18] 包劲松. 应用RVA测定米粉淀粉成糊温度. 中国水稻科学, 2007, 21: 543–546.

Bao J S. Accurate measurement of pasting temperature of rice flour by a Rapid Visco Analyzer., 2007, 21: 543–546(in Chinese with English abstract).

[19] Qiao D L, Tu W Y, Liao A P, Li N N, Zhang B J, Jiang F T, Zhong L, Zhao S M, Zhang L, Lin Q L. Multiscale structure and pasting digestion features of yam bean tuber starches., 2019, 213: 199–207.

[20] Bao J S, Shen S Q, Sun M, Corke H. Analysis of genotypic diversity in the starch physicochemical properties of nonwaxy rice: apparent amylose content, pasting viscosity and gel texture., 2006, 58: 259–267.

[21] Sandhu K S, Siroha A K. Relationships between physicochemical, thermal, rheological anddigestibility properties of starches from pearl millet cultivars., 2017, 83: 213–244.

[22] 曹健康. 果蔬采后生理生化实验指导. 北京: 中国轻工业出版社, 2017. pp 81–84.

Cao J K. Guidance for Postharvest Physiological and Biochemical Experiments of Fruits and Vegetables. Beijing: China Light Industry Press, 2017. pp 81–84 (in Chinese).

[23] 周志林, 唐君, 曹清河, 赵冬兰, 张安. 淀粉专用型甘薯品质形成规律及其与主要农艺性状的相关性. 江苏农业学报, 2020, 36: 277–283.

Zhou Z L, Tang J, Cao Q H, Zhao D L, Zhang A. Formation laws of quality characters in starch sweet potato cultivars and its correlation with main agronomic characters., 2020, 36: 277–283 (in Chinese with English abstract).

[24] 侯夫云, 陈桂玲, 董顺旭, 解备涛, 秦桢, 李爱贤, 张立明, 王庆美. 不同品种甘薯淀粉组分、物化及粉条品质的比较研究. 核农学报, 2022, 36: 392–401.

Hou F Y, Chen G L, Dong S X, Xie B T, Qin Z, Li A X, Zhang L M, Wang Q M. Comparative study on starch components, physicochemical properties and noodle quality of different sweet potato varieties., 2022, 36: 392–401 (in Chinese with English abstract).

[25] 柳强娟, 康建宏, 吴佳瑞, 孙建波, 马雪莹, 王星强, 坚天才. 施氮量对宁夏旱区马铃薯块茎淀粉形成和产量的影响. 核农学报, 2021, 35: 1196–1208.

Liu Q J, Kang J H, Wu J R, Sun J B, Ma X Y, Wang X Q, Jian T C. Effects of nitrogen application amount on formation and yield of potato tuber starch in Ningxia arid region., 2021, 35: 1196–1208 (in Chinese with English abstract).

[26] 张友良, 汪兆辉, 冯绍元, 王凤新. 覆膜滴灌条件下滴灌湿润比和施氮量对甘薯生长的影响. 农业机械学报, 2021, 52(7): 261–270.

Zhang Y L, Wang Z H, Feng S Y, Wang F X. Effects of soil wetted percentages and nitrogen fertilizations on sweet potato growth under drip irrigation with film mulching., 2021, 52(7): 261–270 (in Chinese with English abstract).

[27] 项超, 沈升法, 吴列洪, 李兵, 罗志高. 甘薯块根淀粉酶特性及糖化效应研究. 中国粮油学报, 2021, 36(5): 56–61.

Xiang C, Shen S F, Wu L H, Li B, Luo Z G. The characteristics of amylase and sweetening effect of sweet potato root., 2021, 36(5): 56–61 (in Chinese with English abstract).

[28] 朱红, 钮福祥, 徐飞, 孙健, 岳瑞雪, 张毅. 钾肥对甘薯产量、品质及淀粉RVA特性的影响. 江苏农业科学, 2016, 44(5): 138–139, 195.

Zhu H, Niu F X, Xu F, Sun J, Yue R X, Zhang Y. Effects of potassium fertilizer on yield, quality and RVA characteristics of sweet potato., 2016, 44(5): 138–139, 195 (in Chinese with English abstract).

[29] 周治宝, 王晓玲, 余传元, 雷建国, 胡培松, 王智权, 李马忠, 朱昌兰. 籼稻米饭食味与品质性状的相关性分析.中国粮油学报, 2012, 27(1): 1–5.

Zhou Z B, Wang X L, Yu C Y, Lei J G, Hu P S, Wang Z Q, Li M Z, Zhu C L. Correlation analysis of eating quality with quality characters of indica rice., 2012, 27(1): 1–5 (in Chinese with English abstract).

[30] 胡雅杰, 薛建涛, 吴培, 李娈, 丛舒敏, 余恩唯, 倪嘉颢, 张洪程. 施氮量和直播密度对稻米食味品质和淀粉结构的影响. 中国粮油学报, 2022, 37(2): 7–13.

Hu Y J, Xue J T, Wu P, Li L, Cong S M, Yu E W, Ni J H, Zhang H C. Effects of nitrogen application and sowing density on eating quality and starch structure of direct-seeding rice., 2022, 37(2): 7–13 (in Chinese with English abstract).

[31] 谭洪卓, 谭斌, 刘明, 田晓红, 谷文英. 甘薯淀粉性质与其粉丝品质的关系. 农业工程学报, 2009, 25(4): 286–292.

Tan H Z, Tan B, Liu M, Tian X H, Gu W Y. Relationship between properties of sweet potato starch and qualities of sweet potato starch noodles., 2009, 25(4): 286–292 (in Chinese with English abstract).

[32] 余树玺, 邢丽君, 木泰华, 张苗, 孙红男, 陈井旺. 4种不同甘薯淀粉成分、物化特性及其粉条品质的相关性研究. 核农学报, 2015, 29: 734–742.

Yu S X, Xing L J, Mu T H, Zhang M, Sun H N, Chen J W. The study of correlation between the physicochemical properties of starch from different sweet potato varieties and the quality of its starch noodle., 2015, 29: 734–742 (in Chinese with English abstract).

[33] 江帆, 杜春微, 任妍婧, 梁鸡保, 杜双奎. 不同藜麦品种淀粉的理化性质与消化特性. 中国粮油学报, 2021, 36(7): 77–83.

Jiang F, Du C W, Ren Y J, Liang J B, Du S K. Physicochemical properties and digestibility of starches of different quinoa varieties., 2021, 36(7): 77–83 (in Chinese with English abstract).

[34] Zheng M J, Ye A, Singh H, Zhang Y. The in vitro digestion of differently structured starch gels with different amylose contents., 2021, 116: 106647.

[35] 唐敏敏, 洪雁, 顾正彪, 刘月. 黄原胶对绿豆淀粉糊化和流变特性的影响. 食品科学, 2013, 34(21): 42–46.

Tang M M, Hong Y, Gu Z B, Liu Y. Effects of xanthan on pasting and rheological properties of mung bean starch., 2013, 34(21): 42–46 (in Chinese with English abstract).

[36] Khatkar B S, Bell A E, Schofield J D. The dynamic rheological properties of glutens and gluten subfractions from wheats of good and poor bread making quality., 1995, 22: 29–44.

[37] Ye F, Li J, Zhao G. Physicochemical properties of different-sized fractions of sweet potato starch and their contributions to the quality of sweet potato starch., 2020, 108: 106023.

[38] 谭洪卓, 谷文英, 刘敦华, 陆建安. 甘薯淀粉糊的流变特性. 食品科学, 2007, 28(1): 58–63.

Tan H Z, Gu W Y, Liu D H, Lu J A. Rheological properties of sweet potato starch paste., 2007, 28(1): 58–63 (in Chinese with English abstract).

Effects of nitrogen fertilizer application rate on starch contents and properties during storage root expansion in sweetpotato

WU Shi-Yu1,2, CHEN Kuang-Ji1,3, LYU Zun-Fu1,2, XU Xi-Ming1,2, PANG Lin-Jiang2,4, and LU Guo-Quan1,2,*

1College of Advanced Agricultural Sciences, Zhejiang A&F University / Key Laboratory for Quality Improvement of Agricultural Products of Zhejiang Province, Hangzhou 311300, Zhejiang, China;2Institute of Root & Tuber Crops, Zhejiang A&F University, Hangzhou 311300, Zhejiang, China;3Yizheng Agricultural Technology Comprehensive Service Center, Yangzhou 211400, Jiangsu, China;4College of Food and Health, Zhejiang A&F University, Hangzhou 311300, Zhejiang, China

In order to explore the effect of nitrogen fertilizer application rate on starch contents and properties during storage root expansion of sweetpotato ((L.) Lam.), two sweetpotato cultivars (‘Xinxiang’ and ‘Shangshu 19’) were taken as the experimental materials, and three nitrogen fertilizer application rates (0 kg hm–2(CK), 57.5 kg hm–2(N1), and 115 kg hm–2(N2)) were designed and conducted on the day of planting. To investigate the changes of starch content, starch gelatinization properties, starch dynamic rheological properties, gel texture properties, and amylase activity in sweetpotato storage roots during storage root expansion, the storage root samples were collected at the 60th, 80th, 100th, 120th, and 140th days after planting. Results were as follows: (1) Nitrogen fertilizer application could significantly increase the starch content of two cultivars during storage root expansion, but significantly reduce the hot paste viscosity (HPV), cold paste viscosity (CPV), and setback viscosity (SBV) of starch gelatinization properties of ‘Xinxiang’ at the initial stage of storage root expansion (IES), and significantly decrease the HPV, CPV, and SBV of ‘Shangshu 19’, while remarkably increase the HPV, CPV, and SBV of ‘Xinxiang’ at the late-expanding stage of storage root expansion (LES). (2) The hardness and chewiness of starch gel under three nitrogen fertilizer application treatments gradually decreased during storage root expansion. Among them, N2 treatment could significantly improve the hardness of gel of sweetpotatoes at LES. (3) The starch gel of two cultivars exhibit elastic properties. N1 and N2 treatments could increase the storage modulus and loss modulus of ‘Xinxiang’ whereas reduce the storage modulus and loss modulus of ‘Shangshu 19’. (4) Nitrogen fertilizer application rates reduced the amylase activity at IES, but increased the amylase activity at LES of the two cultivars. Therefore, nitrogen fertilizer application rate obviously affected the starch contents and properties of sweetpotatoes during storage root expansion. Moreover, ‘Shangshu 19’ with 115 kg hm–2of nitrogen fertilizer application rate harvesting on 120 days after planting, which was conducive to the processing properties of sweetpotato starch. In conclusion, reasonable nitrogen application and timely harvest were beneficial to the accumulation and quality improvement of sweetpotato starch.

sweetpotato; nitrogen fertilizer; storage root expansion stage; starch; physicochemical properties

10.3724/SP.J.1006.2023.24087

本研究由财政部和农业农村部国家现代农业产业技术体系建设专项(CARS-10), 浙江省重点研发计划项目(2021C02057, 2022C02041- 2), 浙江省三农九方科技协作项目(2022SNJF008)和浙江省教育厅科研资助项目(Y202147184)资助。

This study was supported by the China Agriculture Research System of MOF and MARA (CARS-10), the Zhejiang Key Research and Development Program (2021C02057, 2022C02041-2), the Zhejiang Sannong Jiufang Science and Technology Cooperation Project (2022SNJF008), and the General Research Program for the Education Department of Zhejiang Province (Y202147184).

陆国权, E-mail: lugq10@zju.edu.cn

E-mail: wsyu@stu.zafu.edu.cn

2022-04-07;

2022-09-05;

2022-09-15.

URL: https://kns.cnki.net/kcms/detail/11.1809.S.20220914.1708.002.html

This is an open access article under the CC BY-NC-ND license (http://creativecommons.org/licenses/by-nc-nd/4.0/).