各向异性对IC10高温合金磨削表面完整性的影响

朱志成,杨昭,潘博,张帅奇,杨忠学,王赛,张长春,郭江

精密与超精密加工

各向异性对IC10高温合金磨削表面完整性的影响

朱志成1,杨昭2,潘博1,张帅奇3a,杨忠学3a,王赛3a,张长春3b,郭江1

(1.大连理工大学 高性能精密制造全国重点实验室,辽宁 大连 116024;2.陆军装备部驻北京地区航空军代室,北京 100037;3.北京航空材料研究院 a.先进高温结构材料国防科技重点实验室 b.高温材料研究所,北京 100095;)

探究IC10单晶高温合金缓进磨削表面完整性的影响因素,提高关键零件的使用性能。通过制备不同晶面、同一晶面不同晶向试块,采用刚玉砂轮在同一工艺参数下开展缓进磨削实验,研究各向异性对工件表面粗糙度、表面形貌、显微硬度和塑性变形层的影响。在s= 20 m/s,w= 150 mm/min,p= 0.2 mm条件下,不同晶面磨削后的平均表面粗糙度为0.3~0.4 μm,其中(001)晶面加工后的平均表面粗糙度为0.32 μm,加工纹理均匀且轮廓起伏变化程度最小,(011)晶面的平均表面粗糙度为0.35 μm,(111)晶面的平均表面粗糙度为0.39 μm,其表面出现了深的犁沟及凹坑等现象;不同晶面加工后工件表面均发生了硬化,硬化程度由强到弱依次为(001)、(011)、(111)晶面;不同晶面磨削后表面存在微米级厚度的塑性变形层,其中(111)晶面塑性变形层最厚,厚度为3.6 μm,(011)和(001)晶面的厚度分别为2.8、2 μm。(001)晶面在不同晶向磨削后工件的表面粗糙度、表面形貌、显微硬度和塑性变形层则无明显的规律性变化。IC10单晶高温合金各向异性对磨削后工件表面完整性具有一定影响,不同晶面由于塑性变形难度存在差异,导致磨削后其表面完整性存在规律性变化,其中(001)晶面加工后的表面粗糙度最低,加工纹理最平整,显微硬度最大,塑性变形层厚度最小。由于显微组织呈现随机分布的圆形、方形、三角形等形态,且不规则,导致同一晶面不同晶向对磨削后工件表面完整性的影响无明显规律。

IC10单晶高温合金;缓进磨削;各向异性;表面粗糙度;表面形貌;显微硬度;塑性变形层

作为“现代工业皇冠上的明珠”,航空发动机的发展水平是一个国家国防和科技实力的重要体现。随着国家对自主研发的新一代战机和民航客机性能要求的不断提高,航空领域对大推重比和大涵道比航空发动机的需求日益迫切[1-2]。高温合金因其优异的高温性能被广泛用于航空发动机、燃气轮机的关键零部件材料,其用量占据发动机总质量的40%~60%[3]。其中,IC10高温合金具有密度小、高温强度大、抗蠕变等优异性能,已被应用于制造高推重比航空发动机涡轮叶片[4-5]。目前,IC10高温合金的研究主要集中在材料制备、组织性能表征和疲劳性能测试等方面[6-9],对于机械加工工艺研究较少。Yue等[10]通过在中间层添加B和Hf作为降低熔点的元素,开展了IC10高温合金瞬态液相结合实验,探究了温度对焊接接头组织演变的影响。Yang等[11]研究了电子束的轮廓和冷却条件对IC10高温合金激光镀层几何形貌和显微组织的影响,并通过激光沉积热过程数值模拟揭示了影响机理。高奇等[12-13]通过正交实验,研究了IC10单晶高温合金微铣削加工工艺参数对表面质量的影响,并通过优化获得了理想的工艺参数组合。

涡轮叶片在铸造成型后需要去除一定的余量,以保证缘板、榫齿等装配部位的尺寸精度和形位精度,然而高温合金在切削时刀具容易发生黏附,磨损严重,致使生产成本过高。缓进磨削具有高效率、高精度的优势,广泛应用于航空领域的精密加工[14-16]。杨忠学等[17]研究了IC10高温合金在缓进给磨削过程中工艺参数对磨削表面完整性的影响,并获得了较好表面质量的参数域。Zhang等[18]研究了缓进磨削工艺参数对IC10定向凝固高温合金磨削力、磨削温度、表面粗糙度及表面硬化层的影响,进一步揭示了表面粗糙度和表面硬化层对疲劳寿命的影响。实验结果表明,表面粗糙度是疲劳寿命的主要影响因素,且表面粗糙度越高,疲劳寿命越低,而表面硬化有利于疲劳寿命的提高。Zhu等[19]研究了磨削工艺参数对IC10定向凝固高温合金表面完整性的影响,实验结果表明,高的进给速度或者大的切削深度会导致工件表面出现沟槽、分层或其他缺陷,并通过正交试验建立了工艺参数与磨削力、磨削温度关系的经验公式,验证了单因素实验的准确性。

针对IC10单晶高温合金各向异性对缓进磨削表面完整性方面的相关研究还未见报道。磨削作为涡轮叶片机加工的最后一道工序,其表面完整性对零件的疲劳寿命和服役性能有着重要影响[23-26],为了进一步拓宽此种材料的工程应用,文中针对IC10单晶高温合金特有的各向异性开展了(001)、(001)和(111)等3个典型晶面的缓进磨削实验,在此基础上选取(001)晶面探究了不同晶向对磨削表面完整性的影响,系统性地揭示了IC10单晶高温合金各向异性对表面完整性的影响规律,并阐述了表面粗糙度、表面形貌、显微硬度和显微组织的演化机制。

1 实验

1.1 材料

实验材料采用IC10单晶高温合金,元素组成如表1所示。通过螺旋选晶法和定向凝固工艺浇注试棒原材料,采用晶向测量仪检测试棒的生长方向偏差,实验选取的试棒生长方向与[001]晶向的偏差为4.9°(一般认为在8°内合格),然后进行固溶时效处理。

表1 IC10高温合金化学成分组成

1.2 方案

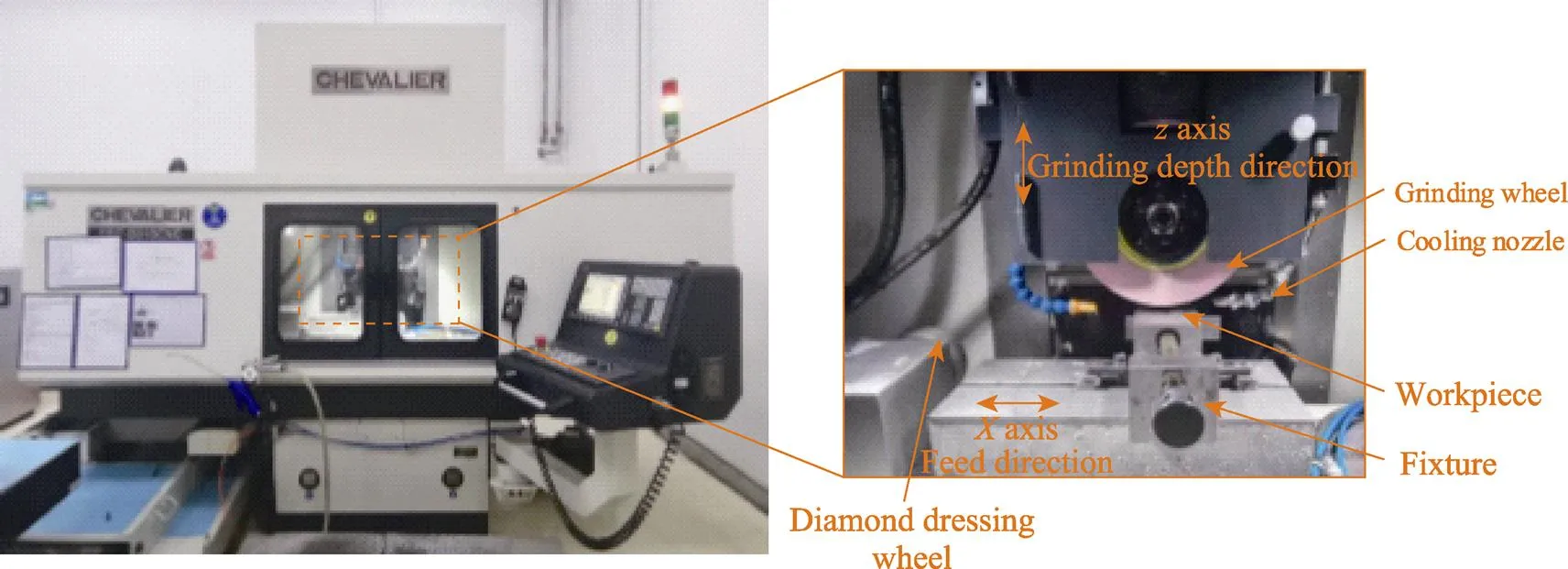

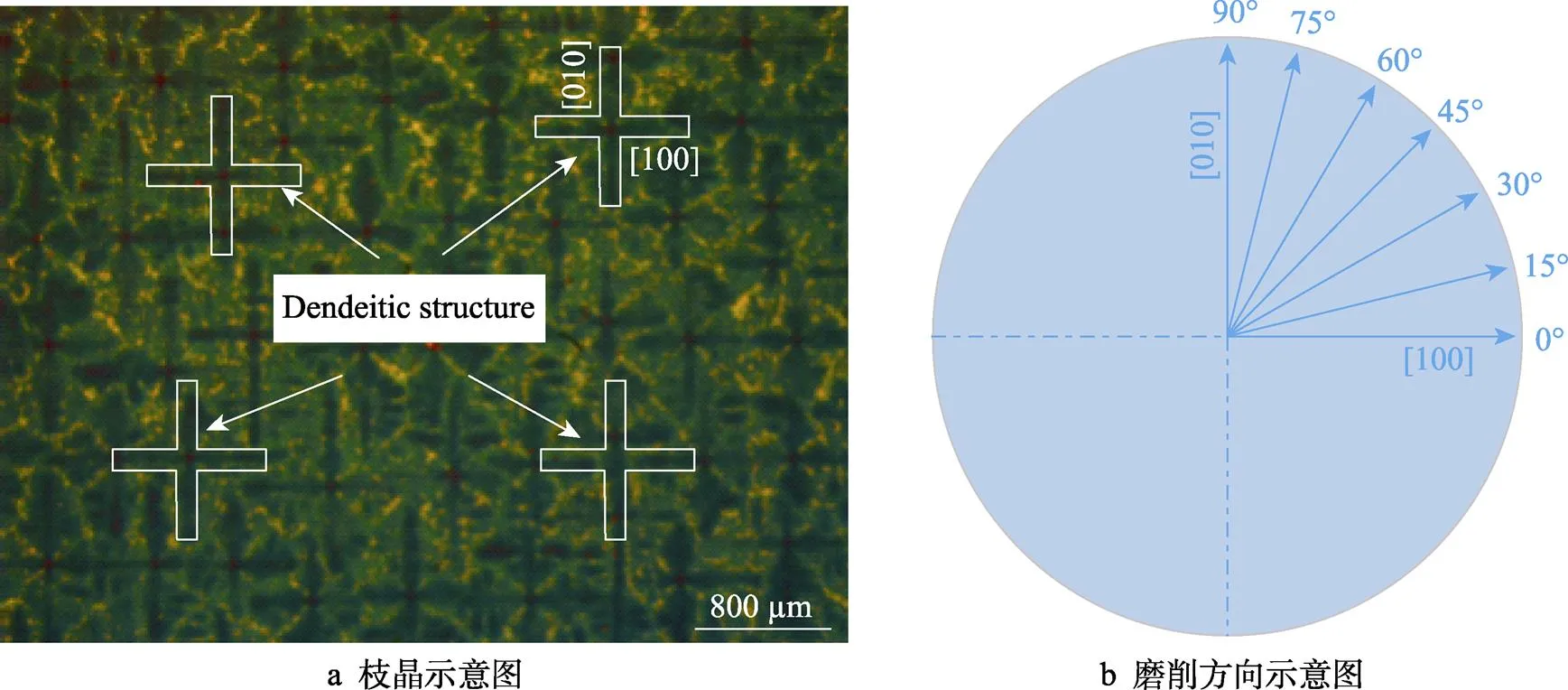

采用的加工设备为Chevalier FSG–B818CNC缓进三轴磨床,切削液为巴索乳化液(质量分数为3%)。砂轮为圣戈班公司诺顿系列、牌号为WA/PA80– F25VCF2的白刚玉、铬刚玉混合磨料砂轮。实验装置如图1所示。首先使用线切割分别将试棒切出(001)、(011)和(111)等3个典型晶面的方形试块,获得不同晶面工件。然后选取(001)晶面制备金相样件,选择冰醋酸作为腐蚀液,腐蚀时间为10 s,使用光学显微镜观察枝晶的生长方向,确定[100]和[010]晶向后沿与[100]方向成不同角度()切割,制作不同晶向的试块,沿不同晶向磨削示意图如图2所示。为了方便表征,(001)晶面不同晶向采用与[100]方向的夹角表示。所有工件均制成20 mm×10 mm×15 mm(长×宽×高)的长方体,采用粗磨、精磨去除线切割的重熔层,以保证工件的初始表面状态一致。

不同晶面、(001)晶面不同晶向的削实验工艺参数均为砂轮线速度20 m/s、工件进给速度150 mm/min、磨削深度0.2 mm,选用逆磨的加工方式。为了避免砂轮磨损对实验结果造成影响,每加工1个工件后均修整1次砂轮。

图1 实验装置

图2 不同晶向磨削示意图

表面粗糙度采用表面轮廓仪(Talysurf CLI2000)测量,分辨率为0.8 nm,测量方向垂直于磨削纹理,在每个工件表面随机选取5个测量位置。表面形貌采用激光共聚焦显微镜(OLYMPUS OLS5000)和扫描电镜(ZEISS Sigma 300)进行观察。沿垂直于磨削表面剖切制作金相试样,并观察其显微硬度和塑性变形层,分别采用显微维氏硬度计(Qness)和扫描电镜进行检测。在测量前,使用酒精擦拭所有加工后的工件,并用热风枪干燥,以保证工件表面无油污、碎屑等,确保测量的准确性。

2 结果及分析

2.1 不同晶面磨削后表面完整性

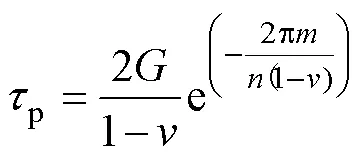

IC10单晶高温合金属于航空领域典型的难加工延塑性合金[27],晶体结构为典型的面心立方晶体。单晶高温合金无晶界,材料去除方式主要通过外力使晶格内部产生位错,发生滑移,直至累积到一定程度后发生断裂,在晶格内部遇到的主要位错阻力为派纳力,见式(1)[28]。

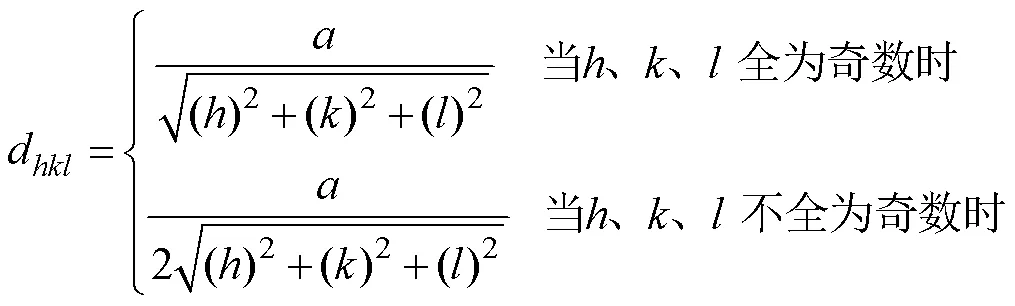

式中:为切变模量;为泊松比;为晶面间距;为滑移方向上的原子间距。

由式(1)可知,派纳力主要由晶面间距和滑移方向上的原子间距决定,晶面间距越大,滑移方向上原子间距越小,派纳力越小,越容易发生剪切滑移,从而导致塑性变形。由于面心立方晶体结构中棱长相等,==,晶面间距的计算见式(2)[29]。

图3 (111)晶面滑移系示意图

Fig.3 Schematic diagram of slip system of (111) crystal plane

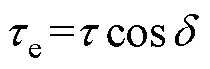

当外部剪切应力与(111)晶面存在夹角时,在滑移面上的有效分切应力如式(3)。

因为(001)与(111)晶面之间的夹角大于(011)与(111)晶面之间夹角,因此以此反推可知,在同样的加工条件下,加工(111)晶面最容易发生塑性变形,(011)晶面次之,(001)晶面最难发生塑性变形。

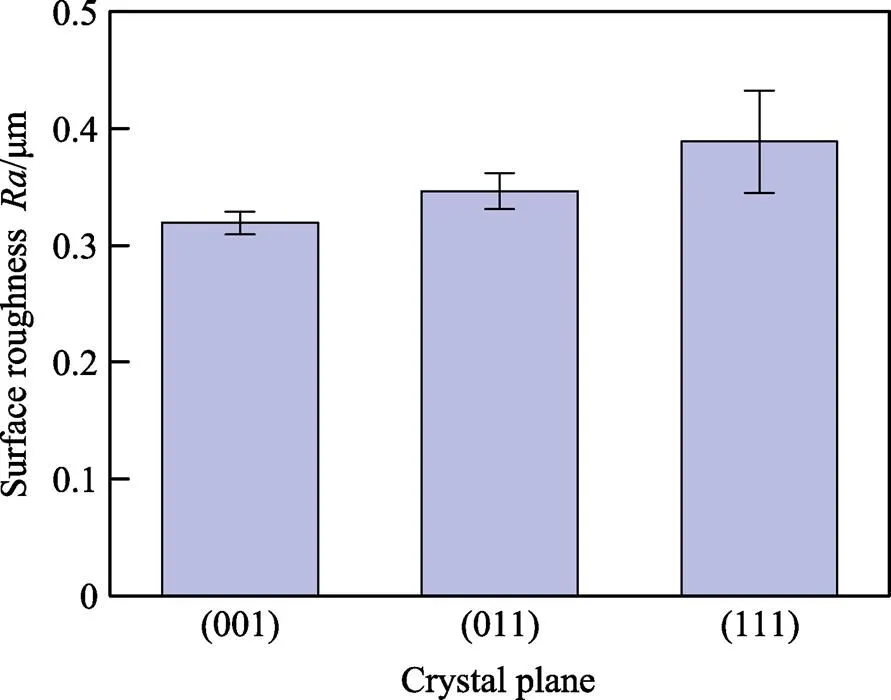

如图4所示,不同晶面加工后的平均表面粗糙度为0.3~0.4 μm,(111)晶面加工后平均表面粗糙度约为0.39 μm,(011)和(001)晶面的平均表面粗糙度依次约为0.35 μm和0.32 μm。表面粗糙度用于反映工件表面较小间距的微观凹凸不平程度,其值与被加工表面微观形貌的几何高度变化和均匀程度有很大联系。由于磨削表面微观形貌由砂轮表面随机分布的大量磨粒经过多次滑擦、耕犁、切削所形成,其中滑擦仅会发生弹性变形,材料并未发生永久变形或被去除,在切削阶段将工件材料进行剥离,以形成切屑,耕犁阶段在工件表面发生了永久塑性变形,材料未被去除,也不会发生弹性回复,因此可以认为常规检测到的工件表面微观形貌主要为材料加工后引起的永久塑性变形,即加工完成后耕犁造成工件微观表面凹凸不平。IC10单晶高温合金的剪切滑移面为{111}晶面族,在相同加工工艺参数下,(111)晶面最容易发生塑性变形,从而使得表面的耕犁程度最大,形成的加工纹理峰谷差异最大,加工后表面粗糙度最高。同理,(011)晶面磨削后的表面粗糙度次之,(001)晶面的最小。

图4 不同晶面加工后表面粗糙度

如图5所示,从表面形貌来看,(001)晶面在磨削后工件表面加工纹理最均匀,存在部分由磨粒耕犁引起的材料隆起现象;(011)晶面较(001)晶面磨削后形成的峰谷变化更大,出现了较深的沟壑;(111)晶面则出现了不规则的塑性流动、隆起及较深的犁沟,表面加工纹理更加不规则。如图6所示,对垂直加工纹理进行轮廓分析发现,不同晶面磨削后表面波峰波谷起伏程度并不相同,沿(001)晶面加工后其表面轮廓分布最均匀,(011)晶面次之,(111)晶面加工后的形貌峰谷变化幅度最大。假设同一砂轮的磨粒分布情况在磨削前后并未发生明显的变化,由于砂轮表面的磨粒分布不均匀,大小、形状呈现随机分布状态,这会导致在磨削过程中部分磨粒仅发生了滑擦,另一部分磨粒发生了滑擦、耕犁,而只有发生了滑擦、耕犁、切削整个阶段的磨粒才是有效的切削磨粒,因此导致表面轮廓出现了不规则的高低变化差异。(111)晶面最容易发生剪切滑移,在相同的工艺参数下发生的塑性变形最剧烈,导致表面塑性流动及隆起沟壑等现象最严重,且部分区域纹理错乱。同理,(011)晶面加工后表面形貌次之,(001)晶面加工后表面纹理一致性最好。

图5 不同晶面加工后表面SEM形貌

图6 不同晶面加工后表面三维形貌分布

如图7所示,不同晶面加工后表层均产生硬化,(001)晶面硬化程度最强,(011)晶面次之,(111)晶面硬化程度最弱。在IC10高温合金缓进磨削过程中磨削温度可达到1 000 ℃以上[18],磨削后的工件表面仍然具有很高的温度。采用强力的切削液高速冷却,使得工件表面发生了磨削淬硬现象。由于在磨削过程中克服材料的弹塑性变形所做的功大部分转换为磨削热,在同一工艺参数下材料的去除量基本一致,(111)晶面最容易塑性变形,在材料去除过程中遇到的阻力最小,去除同样体积的材料做的功最小,释放出的磨削热最小,在切削液的冷却下磨削淬硬效果最差,因此(111)晶面显微硬度最小,而(001)晶面最难发生塑性变形,所以去除同等体积材料做功最大,释放的磨削热量最大,淬硬效果更严重,显微硬度最大。(011)晶面显微硬度则介于两者之间。

图7 不同晶面加工后显微硬度

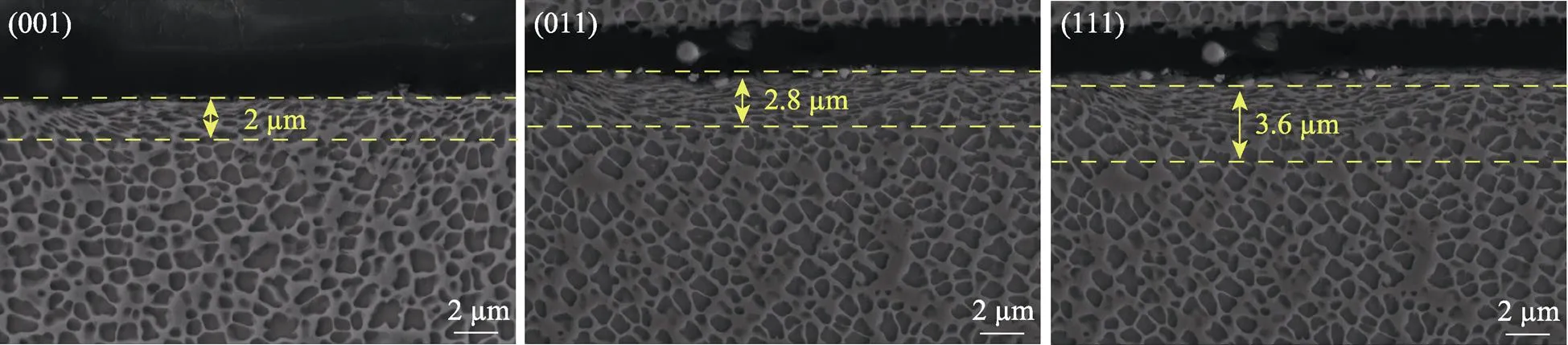

如图8所示,磨削表面下存在微米级厚度的塑性变形层,显微组织扭曲拉长,较基体变化明显。这是因为在缓进磨削过程中磨粒与材料的相互作用会产生很大的磨削力,在磨削表面下出现高应力和高应变率梯度,致使靠近磨削表面处发生了大量位错,导致材料出现严重塑性变形,随着深度的增加,显微组织逐渐与基体保持一致。其中,(001)晶面塑性变形层的厚度为2 μm,(011)晶面的厚度为2.8 μm,(111)晶面塑性变形层的厚度为3.6 μm。这是由于(111)晶面为IC10单晶高温合金的剪切滑移面,在相同工艺参数下,(111)晶面更容易发生剪切滑移,塑性变形最剧烈,变形能以位错的形式储存于材料内部,导致塑性变形层厚度最大。(011)晶面发生塑性变形的难度(001)晶面更大,因此(011)晶面塑性变形层厚度次之,(001)晶面塑性变形层厚度最小。

图8 不同晶面塑性变形层厚度SEM形貌

2.2 不同晶向磨削后表面完整性

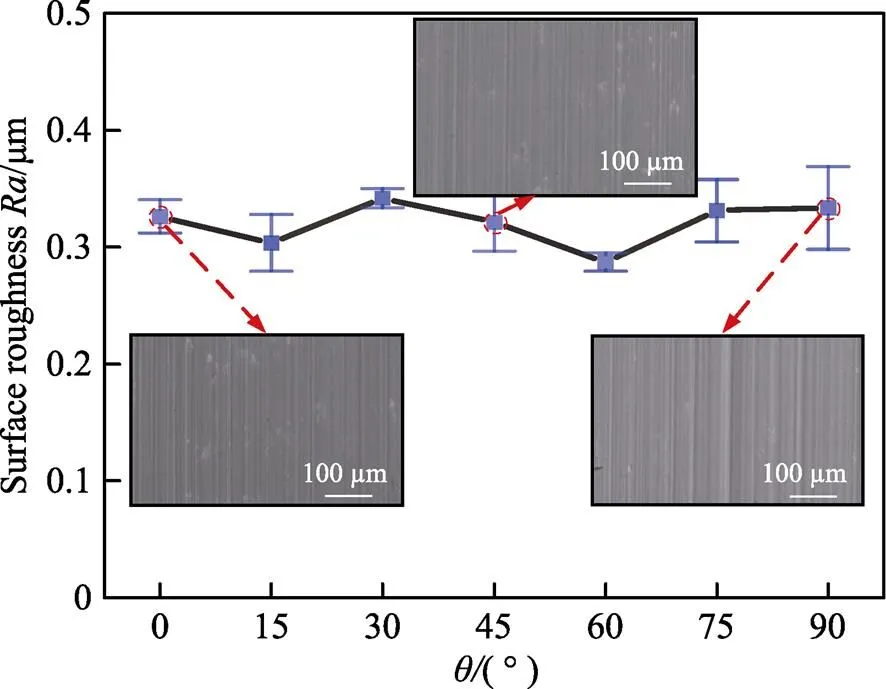

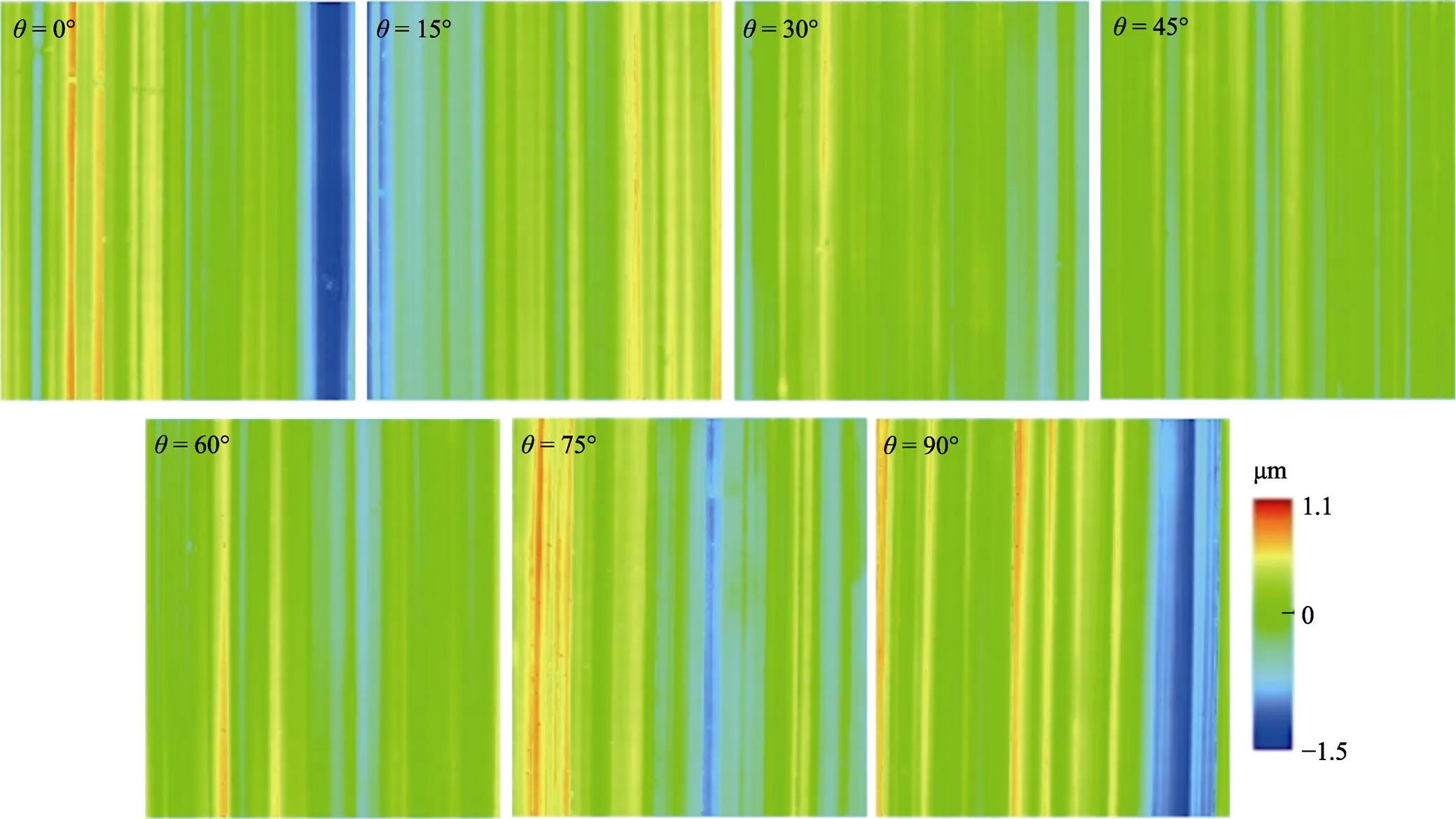

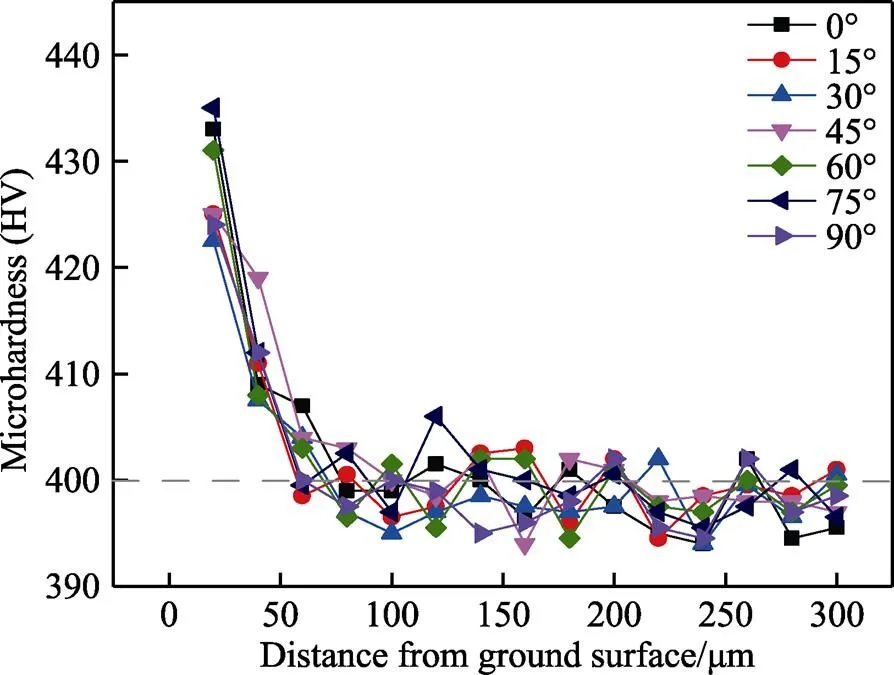

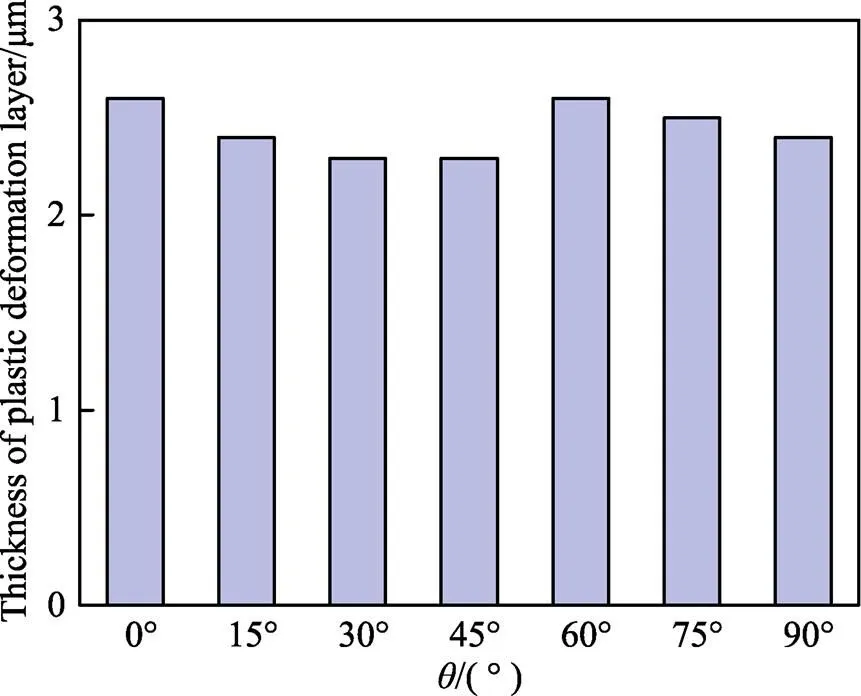

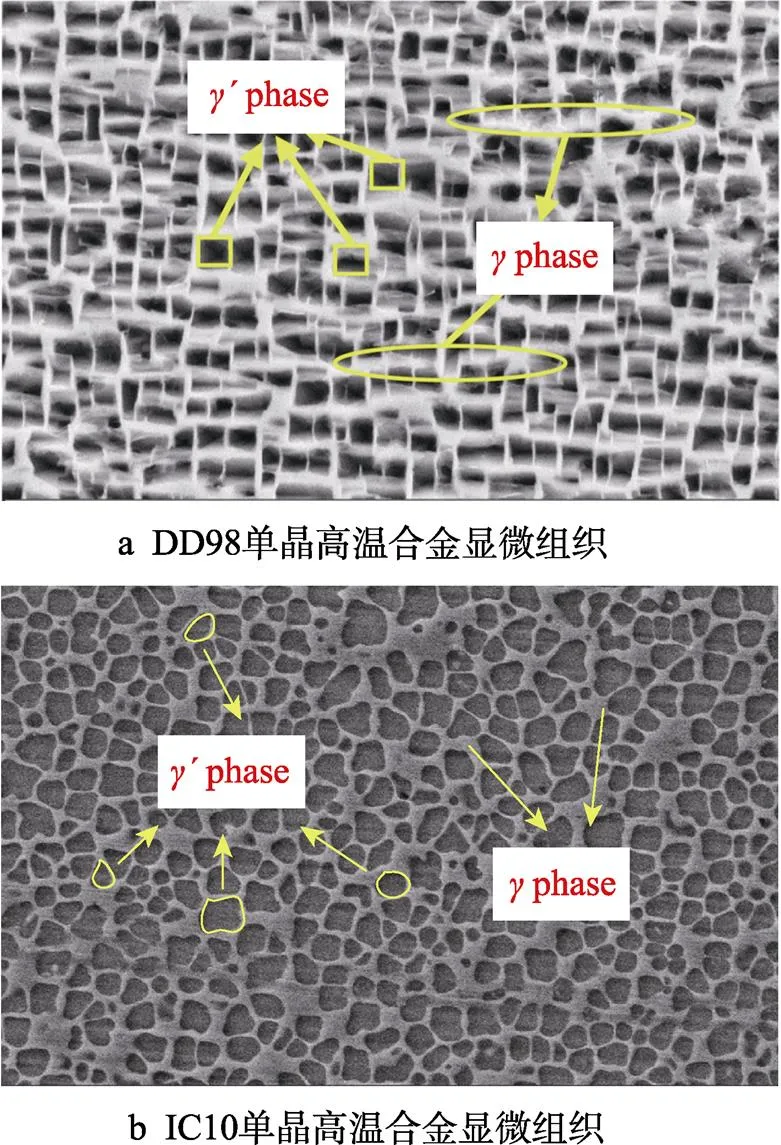

在同一工艺参数下,沿(001)晶面不同晶向加工后工件的表面粗糙度、表面形貌、显微硬度和塑性变形层厚度如图9—12所示。当在0°~90°间变化时,表面粗糙度在0.3~0.4 μm间波动,表面加工轮廓的起伏程度在2.7 μm内,基体硬度基本维持在400HV左右,沿=75°磨削加工后,工件的显微硬度最大。沿=0°和=60°加工后,塑性变形层最厚,同一晶面不同晶向缓进磨削后表面完整性并未呈现明显的规律性变化。针对上述结果,对比了不同单晶高温合金磨削后的实验现象。DD98单晶高温合金平面磨削后在同一晶面的不同晶向的表面粗糙度呈现对称趋势,在沿(001)晶面与[100]成45°晶向磨削时表面粗糙度最小,且表面加工纹理最平整[21]。为了进一步探索实验现象的形成机制,分别制作金相样件对比DD98和IC10单晶热处理后的组织,发现其显微组织形态并不相同,如图13所示。DD98热处理后,ʹ相呈现较规则的方形,而IC10热处理后其ʹ相呈现随机分布的圆形、方形、三角形等形态。由于单晶高温合金热处理后,ʹ相作为加强相其体积分数会占60%以上,其组织形态严重影响了力学性能。由此,当沿IC10同一晶面不同晶向进行缓进磨削时,加强相ʹ形态随机分布导致沿不同方向加工时在显微组织的角度来观察并无明显差异,因此同一晶面不同晶向加工后表面完整性并未呈现明显的周期性变化。实验结果表明,镍基单晶高温合金力学性能各向异性,在一定程度上会受到显微组织形态的影响。

图9 不同晶向加工后表面粗糙度

图10 不同晶向加工后表面形貌

图11 不同晶向加工后显微硬度

图12 不同晶向加工后塑性变形层厚度

图13 不同单晶高温合金显微组织形态SEM形貌

3 结论

通过对IC10单晶高温合金不同晶面和(001)晶面不同晶向的缓进磨削实验,探究了上述因素对表面完整性的影响规律,并对其出现的现象进行了讨论,得到如下结论。

1)IC10单晶高温合金晶格为典型的面心立方结构,材料去除以晶格剪切滑移的形式进行,其中{111}晶面族为滑移面。由于相同工艺参数下沿不同晶面磨削时发生塑性变形的难易程度不同,进而对加工后工件表面完整性会产生一定影响。实验结果表明,(001)晶面加工后具有最优的表面质量,且显微硬度最大,塑性变形层厚度最小。

2)IC10单晶高温合金显微组织呈现随机分布的圆形、方形、三角形等多种状态,导致同一晶面不同晶向磨削后工件表面完整性未呈现周期性变化。

单晶涡轮叶片的服役环境通常在1 000 ℃以上,且伴随着复杂的应力环境,其高温下的疲劳寿命与表面完整性有着重要联系。磨削是涡轮叶片机加工的最后一道工序,文中探究了缓进给磨削中各向异性对IC10单晶高温合金表面完整性的影响,(001)晶面磨削后有较好的表面质量及较薄的塑性变形层,有利于零件获得更高的疲劳寿命,对涡轮叶片机械加工前工序铸造的定向生长方向可以提供一定参考,以实现零件更优异的服役性能。后期的研究方向将聚焦于建立工件表面完整性与零件服役过程中的断裂或疲劳破坏的系统性联系。

[1] 刘大响, 金捷, 彭友梅, 等. 大型飞机发动机的发展现状和关键技术分析[J]. 航空动力学报, 2008, 23(6): 976-980.

LIU Da-xiang, JIN Jie, PENG You-mei, et al. Summarization of Development Status and Key Technologies for Large Airplane Engines[J]. Journal of Aerospace Power, 2008, 23(6): 976-980.

[2] GOHARDANI A S, DOULGERIS G, SINGH R. Challenges of Future Aircraft Propulsion: A Review of Distributed Propulsion Technology and Its Potential Application for the All Electric Commercial Aircraft[J]. Progress in Aerospace Sciences, 2011, 47(5): 369-391.

[3] 丁文锋, 苗情, 李本凯, 等. 面向航空发动机的镍基合金磨削技术研究进展[J]. 机械工程学报, 2019, 55(1): 189-215.

DING Wen-feng, MIAO Qing, LI Ben-kai, et al. Review on Grinding Technology of Nickel-Based Superalloys Used for Aero-Engine[J]. Journal of Mechanical Engineering, 2019, 55(1): 189-215.

[4] 赵希宏, 黄朝晖, 谭永宁, 等. 新型Ni3Al基定向高温合金IC10[J]. 航空材料学报, 2006, 26(3): 20-24.

ZHAO Xi-hong, HUANG Zhao-hui, TAN Yong-ning, et al. New Ni3Al-Based Directionally-Solidified Superalloy IC10[J]. Journal of Aeronautical Materials, 2006, 26(3): 20-24.

[5] 张宏建, 温卫东, 崔海涛, 等. IC10合金的高温拉伸性能[J]. 机械工程材料, 2008, 32(3): 52-56.

ZHANG Hong-jian, WEN Wei-dong, CUI Hai-tao, et al. Tensile Behaviors of IC10 Alloy at High Temperatures[J]. Materials for Mechanical Engineering, 2008, 32(3): 52-56.

[6] 周静怡, 赵文侠, 郑真, 等. 硼含量对IC10高温合金凝固行为的影响[J]. 材料工程, 2014, 42(8): 90-96.

ZHOU Jing-yi, ZHAO Wen-xia, ZHENG Zhen, et al. Effect of Boron Content on Solidification Behavior of IC10 Superalloy[J]. Journal of Materials Engineering, 2014, 42(8): 90-96.

[7] 柴禄, 侯金保, 张胜. 工艺参数对IC10单晶TLP接头组织和性能的影响[J]. 焊接学报, 2018, 39(8): 114-118.

CHAI Lu, HOU Jin-bao, ZHANG Sheng. Influence of Process Parameters on Microstructure and Properties of IC10 Single Crystal TLP Joints[J]. Transactions of the China Welding Institution, 2018, 39(8): 114-118.

[8] 王树志, 刘广华, 王本志, 等. IC10单晶高温合金叶片荧光渗透检测的缺陷显示[J]. 无损检测, 2017, 39(1): 35-37.

WANG Shu-zhi, LIU Guang-hua, WANG Ben-zhi, et al. The Defect Indication of Fluorescent Penetrating Inspection for IC10 Single Crystal Super Alloy Blade[J]. Nondestructive Testing Technologying, 2017, 39(1): 35-37.

[9] 杨硕, 常保华, 邢彬, 等. 强制冷却对IC10合金激光熔覆组织与硬度的影响[J]. 焊接学报, 2018, 39(3): 31-35.

YANG Shuo, CHANG Bao-hua, XING Bin, et al. Influences of Forced Cooling on the Microstructure and Microhardness in Laser Metal Deposition of IC10 Super Alloy[J]. Transactions of the China Welding Institution, 2018, 39(3): 31-35.

[10] YUE Xiong, LIU Feng-mei, CHEN He-xing, et al. Effect of Bonding Temperature on Microstructure Evolution during TLP Bonding of a Ni3Al Based Superalloy IC10[J]. MATEC Web of Conferences, 2018, 206: 03004.

[11] YANG Shuo, DU Dong, CHANG Bao-hua. Studies of the Influence of Beam Profile and Cooling Conditions on the Laser Deposition of a Directionally-Solidified Superalloy[J]. Materials (Basel, Switzerland), 2018, 11(2): 240.

[12] 高奇, 巩亚东, 周云光. 单晶Ni3Al基高温合金微铣削表面粗糙度试验研究[J]. 中国机械工程, 2016, 27(6): 801-804.

GAO Qi, GONG Ya-dong, ZHOU Yun-guang. Experimental Study on Surface Roughness in Micro-Milling of Single Crystal Ni3Al-Based Superalloy[J]. China Mechanical Engineering, 2016, 27(6): 801-804.

[13] GAO Qi, GONG ya dong, ZHOU yun guang. Experimental Study on Surface Quality in Micro-Milling of Single Crystal Superalloy[J]. Advanced Materials Research, 2016, 1136: 196-202.

[14] 冯克明, 赵金坠. 先进磨削技术应用现状与展望[J]. 轴承, 2020(4): 60-67.

FENG Ke-ming, ZHAO Jin-zhui. Present Situation and Prospect of Advanced Grinding Technology Application[J]. Bearing, 2020(4): 60-67.

[15] 徐九华, 张志伟, 傅玉灿. 镍基高温合金高效成型磨削的研究进展与展望[J]. 航空学报, 2014, 35(2): 351-360.

XU Jiu-hua, ZHANG Zhi-wei, FU Yu-can. Review and Prospect on High Efficiency Profile Grinding of Nickel- Based Superalloys[J]. Acta Aeronautica et Astronautica Sinica, 2014, 35(2): 351-360.

[16] 张浩, 刘吉川. 涡轮叶片榫齿加工方法分析[J]. 内燃机, 2019(4): 31-33.

ZHANG Hao, LIU Ji-chuan. Analysis of Machining Method of Turbine Blade Tenon Tooth[J]. Internal Combustion Engines, 2019(4): 31-33.

[17] 杨忠学, 张帅奇, 张强. IC10定向凝固高温合金缓进给磨削表面完整性研究[J]. 航空制造技术, 2019, 62(6): 62-70.

YANG Zhong-xue, ZHANG Shuai-qi, ZHANG Qiang. Surface Integrity of IClO Directionally Solidified Superalloy in Creep Feed Grinding[J]. Aeronautical Manufacturing Technology, 2019, 62(6): 62-70.

[18] ZHANG Shuai-qi, YANG Zhong-xue, JIANG Rui-song, et al. Effect of Creep Feed Grinding on Surface Integrity and Fatigue Life of Ni3Al Based Superalloy IC10[J]. Chinese Journal of Aeronautics, 2021, 34(1): 438-448.

[19] ZHU Xiao-xiang, WANG Wen-hu, JIANG Rui-song, et al. Performances of Ni3Al-Based Intermetallic IC10 in Creep-Feed Grinding[J]. The International Journal of Advanced Manufacturing Technology, 2020, 108(3): 809- 820.

[20] 张健, 王莉, 王栋, 等. 镍基单晶高温合金的研发进展[J]. 金属学报, 2019, 55(9): 1077-1094.

ZHANG Jian, WANG Li, WANG Dong, et al. Recent Progress in Research and Development of Nickel-Based Single Crystal Superalloys[J]. Acta Metallurgica Sinica, 2019, 55(9): 1077-1094.

[21] CAI Ming, GONG Ya-dong, SUN Yao, et al. Experimental Study on Grinding Surface Properties of Nickel- Based Single Crystal Superalloy DD5[J]. The International Journal of Advanced Manufacturing Technology, 2019, 101(1): 71-85.

[22] ZHOU Yun-guang, GONG Ya-dong, CAI Ming, et al. Study on Surface Quality and Subsurface Recrystallization of Nickel-Based Single-Crystal Superalloy in Micro- Grinding[J]. The International Journal of Advanced Manufacturing Technology, 2017, 90(5): 1749-1768.

[23] 丁文锋, 李敏, 李本凯, 等. 难加工金属材料磨削加工表面完整性研究进展[J]. 航空材料学报, 2021, 41(4): 36-56.

DING Wen-feng, LI Min, LI Ben-kai, et al. Recent Progress on Surface Integrity of Grinding Difficult-to-Cut Metal Materials[J]. Journal of Aeronautical Materials, 2021, 41(4): 36-56.

[24] QUAN Fang, CHEN Zhi-tong, LI Qian-tong, et al. Effects of Process Combinations of Milling, Grinding, and Polishing on the Surface Integrity and Fatigue Life of GH4169 Components[J]. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 2020, 234(3): 538-548.

[25] 罗学昆, 吴小燕, 王科昌, 等. 表面完整性对FGH95合金高温疲劳性能的影响[J]. 航空材料学报, 2020, 40(2): 53-60.

LUO Xue-kun, WU Xiao-yan, WANG Ke-chang, et al. Effect of Surface Integrity Evolution on High-Temperature Fatigue Property of FGH95 Alloy[J]. Journal of Aeronautical Materials, 2020, 40(2): 53-60.

[26] GUO Jiang, GOH M H, WANG Pan, et al. Investigation on Surface Integrity of Electron Beam Melted Ti-6Al-4 V by Precision Grinding and Electropolishing[J]. Chinese Journal of Aeronautics, 2021, 34(12): 28-38.

[27] 高宾华, 保文成, 陈超群, 等. 延塑性航空合金磨削砂轮粘附及粘附抑制技术的研究现状与展望[J]. 航空制造技术, 2021, 64(7): 53-71.

GAO Bin-hua, BAO Wen-cheng, CHEN Chao-qun, et al. Research Status and Future Development of Wheel Loading and Suppressed in Grinding of Ductility Aeronautical Alloys[J]. Aeronautical Manufacturing Technology, 2021, 64(7): 53-71.

[28] 陈日曜. 金属切削原理[M]. 2版. 北京:机械工业出版社, 2012: 196-203.

CHEN Ri-yao. The Theory of Metal Cut[M]. 2nded. Beijing: China Machine Press, 2012: 196-203.

[29] 周云光. 镍基单晶高温合金微磨削工艺理论与关键技术研究[D]. 沈阳: 东北大学, 2017: 21-25.

ZHOU Yun-guang. Study on the Technological Theory and Key Technology in Micro Grinding Nickel-based Single Crystal Superalloy[D]. Shenyang: Northeastern University, 2017: 21-25.

Effect of Anisotropy on Surface Integrity of IC10 Superalloy after Grinding

1,2,1,3a,3a,3a,3b,1

(1. State Key Laboratory of High-Performance Precision Manufacturing, Department of Mechanical Engineering, Dalian University of Technology, Liaoning Dalian 116024, China; 2. Military Representative Office of Army Equipment Department in Beijing, Beijing 100037, China; 3. Beijing Institute of Aeronautical Materials, a. Key Laboratory of Advanced High Temperature Structural Materials, b. Institute of High Temperature Materials, Beijing 100095, China)

IC10 superalloy has been used to manufacture turbine blades of high thrust-to-weight ratio aero-engine due to its excellent properties such as small specific gravity, high strength and creep resistance under high-temperature environment. Creep feed grinding which has the characteristics of high efficiency and high precision is applied for precision machining after blade casting. Surface integrity after processing has an important impact on the fatigue life and service performance of the parts. Owing to the difficult-to-machine characteristics of superalloy, it is difficult to ensure the surface integrity of the workpiece after grinding. Specifically, surface integrity of single crystal superalloy is affected not only by the grinding process parameters, but also by anisotropy. Therefore, the work aims to systematically study the effect of the anisotropy of IC10 single crystal superalloy on the surface roughness, surface morphology, microhardness and plastic deformation layer after grinding and explore its engineering application.The sticks of IC10 single crystal superalloy were poured by the spiral crystal selection method and the directional solidification process. The stick of which growth direction from the [001] crystal orientation was 4.9° was selected (generally considered to be qualified within 8°), and then subject to solid solution process and the aging treatment. The workpieces with three typical crystal planes (001), (011) and (111) were cut by wire cutting, and the (001) crystal plane was selected to make metallographic samples to determine [100] and [010] crystal orientation according to dendrite direction. The workpieces with different crystal orientations were cut along the [100] crystal orientation every 15°. All workpieces were cut into 20 mm×10 mm×15 mm cuboid. Before the experiment, the surface of the workpieces was finely ground to remove the remelted layer caused by the wire cutting to ensure that workpieces were consistent. Creep feed grinding experiments were carried out along different crystal planes and different crystal directions under the same process parameter (grinding wheel linear speed of 20 m/s, workpiece feed speed of 150 mm/min, and grinding depth of 0.2 mm). The experimental equipment was a three-axis creep feed grinder (Chevalier FSG-B818CNC), the coolant was an emulsion (Basso) with a concentration of 3wt.%, and the grinding wheel was mixed abrasive grinding wheel with white corundum and chromium corundum (Norton WA/PA80-F25VCF2). The surface profiler (Talysurf CLI2000) was used to measure the surface roughness of the workpiece after grinding and the laser confocal microscope (OLYMPUS OLS5000) and the scanning electron microscope (ZEISS Sigma 300) were used to observe the surface morphology. The micro Vickers hardness tester (Qness) was used to test the microhardness, and the scanning electron microscope was used to observe the plastic deformation layer. The surface roughnessof different crystal planes after grinding was between 0.3-0.4 μm. The surface roughnessof (001) crystal plane after processing was 0.32 μm. The surface processing texture was uniform and the degree of contour fluctuation was minimal. The surface roughnessof (011) crystal surface after processing was 0.35 μm. The surface roughnessof (111) crystal plane after grinding was 0.39 μm, and deep furrows and pits appeared on the surface of the workpiece. The surface of different crystal planes hardened after processing, and the degree of hardening was (001), (011) and (111) from strong to weak. There was plastic deformation layer with micron-sized thickness under the grinding surface. The (111) crystal plane had the thickest plastic deformation layer at 3.6 μm, and the thickness of (011) and (001) crystal planes were respectively 2.8 μm and 2 μm. The surface roughness, surface morphology, microhardness and plastic deformation layer of (001) crystal plane with different crystal orientations after grinding did not show obvious regular changes. The anisotropy of IC10 single crystal superalloy has a certain effect on the surface integrity of workpiece after grinding. The surface integrity of different crystal planes after grinding changes regularly due to difference in plastic deformation of different crystal planes. The surface roughness of (001) crystal plane is the lowest after processing, the surface processing texture is the smoothest, the microhardness is the largest, and the thickness of plastic deformation layer is the smallest. However, the status of microstructure is randomly distributed such as circles, squares, triangles, etc., which results in no obvious regularity for the surface integrity of workpiece with different crystal orientations on the same crystal plane.

IC10 single crystal superalloy; creep feed grinding; anisotropy; surface roughness; surface morphology; microhardness; plastic deformation layer

V261.2+5

A

1001-3660(2023)01-0222-10

10.16490/j.cnki.issn.1001-3660.2023.01.023

2021–12–28;

2022–04–25

2021-12-28;

2022-04-25

国家自然科学基金(51975096)

National Natural Science Foundation of China (51975096)

朱志成(1997—),男,硕士,主要研究方向为超精密加工。

ZHU Zhi-cheng (1997-), Male, Master, Research focus: ultra-precision machining.

郭江(1982—),男,博士,教授,主要研究方向为超精密加工。

GUO Jiang (1982-), Male, Doctor, Professor, Research focus: ultra-precision machining.

朱志成, 杨昭, 潘博, 等.各向异性对IC10高温合金磨削表面完整性的影响[J]. 表面技术, 2023, 52(1): 222-231.

ZHU Zhi-cheng, YANG Zhao, PAN Bo, et al. Effect of Anisotropy on Surface Integrity of IC10 Superalloy after Grinding[J]. Surface Technology, 2023, 52(1): 222-231.

责任编辑:彭颋